lock MAZDA MX-5 1994 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 434 of 1708

ROAD TEST L-range (Hold) shift diagram LOCKUP AVAILABLE WHEN COASTING 0 20 (1 2) 40 (25) 60 {37) 80 {50) 100 {63) 120 {75) 1 40 (87) 1 60 (99) VEHICLE SPEED kmh {mph) Noise and Vibration Drive the vehicle in 1 st (Hold) and listen closely for any out of the ordinary noise or vibration. The torque converter, propeller shift, and differential can be sources of abnormal noise and vibration if they are not functioning properly. Check these when searching for sources of noise and vibration. P-RANGE TEST 1. Shift into P range on a gentle slope, release the brake, and verify that the vehicle does not roll. 2. Shift into P range while driving the vehicle at 4 kmlh (2.5 mph) maximum on a level surface, and verify that the vehicle stops. Gartner Banana

Page 435 of 1708

K ROAD TEST Vehicle Speed at Shiftpoint Table Note Because of mechanical time lag, vehicle speed at shift during full-throttle is 5--6 kmlh (34 mph} higher than the specified vehicle speed. Mode POWER HOLD POWER HOLD -- POWER HOLD Wide open throttle Throttle condition Shift I Vehicle speed kmlh {rnph} - - D3 lockup ON DR-DA Wide open throttle I D*+Do 98-1 06 (61 -65) 152-1 62 {95--100) 58-64 436-39) J 33--46 {21-28) 5&76 {36--47) 82-1 1 0 {5 1 -68) 74-1 00 (46-62) 28--34 {I 7-21) 11-17 {7-10) 14-1 50 (87-93) 92-1 00 {57--62) 4248 (26-29) Half throttle Closed throttle position Kickdown (Wide open throttle) ,- . Dl-02 D2+D3 D344 D4 lockup ON D44'3 D3-+D1 D4-+D3 D3+D2 Ds-cDi Half throttle Closed throttle position Kickdown (Wide open throttle) All positions Wide open throttle Half throttle Closed throttle position Kickdown (Wide open throttle) All positions " 03-04 Dl432 D2-+D3 D3 lockup ON D3-04 D4+D3 D3+D1 D4+03 D3+D2 D2-4 D1-+D2 D2+D3 D4-rD3 D3+D1 D3 lockup ON %--cS:! s2-*s3 S3 lockup ON - - s142 s2+s3 Sg lockup ON Wide open throttle Half throttle Closed throttle position Kickdown (Wide open throttle) All positions s3-ts1 s3-*s2 s241 s3+s2 Sg lockup ON 152-1 62 {94-100) 44--55 (2&34) 99-1 08 {56-66) 98-1 06 {61-65) 140-164 (87-1 01) 28-34 {I 7-2 1 ) 11-1 7 {7-10) 14G150 {87-93) 92-1 00 (5742) 4248 {26--29) 27-33 {I 7-20) 35--45 (22-27) 152-1 58 {94-97) 12-18 {Gll} 95-1 05 (59-45) 58-64 (36-39) 1 00-1 08 {62--66) 98-1 05 (61 -65) 44-55 {28-34) 90--108 {56--67) 94-1 06 (58-66) 11-1 7 (7-1 0) 92-1 00 {57-42) 4248 (2629) 99-1 05 I61-65) 95--105 {59--65) L1-4-2 L142 . L3+L2 L24-1 L3-+L2 L2-h L241 L3 lockup ON d 5662 (35-38) 44--55 (27-34) 96-1 04 {60-64} 11-17 (7-lo} 99-105 {61--65) 4248 (26-29) 3-1 (21-25) 95-1 05 {59-65) i Gartner Banana

Page 443 of 1708

K ELECTRICAL SYSTEM COMPONENTS Replacement 1. Disconnect the negative battery cable. 2. On level ground, jack up the vehicle and support it evenly on safety stands. 4 3. Disconnect the vehicle speed pulse generator connec- tor. 4. Remove the vehicle speed pulse generator. 5. Install the new vehicle speed pulse generator. Tightening torque: 7.9--10.7 N-m (80-110 kgfecm, 70-95.4 in-lbf) 6. Connect the vehicle speed pulse generator connector. 7. Connect the negative battery cable. 1-2 SHIFT, 2-3 SHIFT, 3-4 SHIFT, 3-2 CONTROL SOLENOID VALVE Inspection 1. On level ground, jack up the vehicle and support it evenly on safety stands. 2. Disconnect the solenoid valve connector. d 3. Measure resistance between each terminal and ground. Resistance: l3-27a 4. If not correct, check the wiring harness for an open or short circuit. Replace the solenoid valve. Solenoid valve 1-2 shift 2-3 shift 3-4 shift 3-2 control LOCKUP CONTROL SOLENOID VALVE lnspection 1. Disconnect the solenoid valve connector. 2. Measure the resistance between the terminals. Terminal C D - A B Resistance: l3-2Sil 3. If not correct, replace the solenoid valve. Gartner Banana

Page 448 of 1708

TRANSMISSION K 1. Shift rod 12. Lockup solenoid connector 2. Undercover 13. Oil pipe 3. Performance rod 14. Harness 4. Exhaust pipe 15. Power plant frame (PPF) 5. Propeller shaft Removal Note ............. page K-48 Removal .................... section L 1 6. Undercover 6. Speedometer cable 17. Torque converter Nut - 7. Vacuum hose 18. Starter u 8. Parklneutral switch connector 19. Transmission mount bolt 9. Vehicle speed pulse generator connector 20. Transmission 10. Solenoid connector Removal Note ............. page K-49 11. ATF thermosensor connector Gartner Banana

Page 449 of 1708

K TRANSMISSION Removal note Power plant frame (PPF) 1. Disconnect the wire harness from the power plant frame. 2. Support the transmission with a jack. 3. Remove the front bolts. BOLT SLEEVE 0 BLOCK BOLT (MI 4 x 1.5 45UOKX-084 4. Remove the rear bolts, and pry out the bolt spacer. 5. Screw a long bolt (MI4 x 1.5) into the sleeve. 6. Twist and pull the bolt and sleeve downward. 7. Install a bolt (M6 x 1) into the hole in the block to kee sleeve from turning and unscrew the long (MI 4 x 1.5). 8. Remove the remaining bolt (M6 x 1). !p the bolt Caution Removing the PPF spacers will reduce the perfor- mance of the PPF. If the spacers are removed, re- place the PPF as an assembly. 9. Remove the power plant frame. Gartner Banana

Page 452 of 1708

TRANSMISSION K Components / @ O-RING. O-RING, REPLACE O-RING, REPLACE 1. Vacuum diaphragm 6. Oil pan On-vehicle Removal ....... page K-130 7. Magnet Inspection ................ page K-130 8. Control valve body On-vehicle Installation ..... page K-131 Disassembly I Inspection ... page K-112 On-vehicle Adjustment ..... page K-131 Assembly ................ page K-125 2. Lockup control solenoid valve On-vehicle Removal ....... page K-128 Inspection ................ page K- 42 On-vehicle Installation ..... page K-129 3. Vehicle speed pulse generator 9. Solenoid valve connector Inspection ................ page K- 41 10. Converter housing 4. ParWneutral switch 11. 2nd band servo w Inspection ................ page K- 39 Disassembly I Inspection I Adjustment ............... page K- 40 Assembly ............... page K- 83 5. Torque converter On-vehicle Adjustment ..... page K- 85 Inspection ................ page K- 61 Gartner Banana

Page 456 of 1708

TRANSMISSION K Procedure 1. Place wooden blocks under the transmission at the con- verter housing and the extension housing positions. 2. Remove the oil pan and gasket. Examine any material found in the pan or on the magnet to determine the condition of the transmission. Clutch facing material . . . . . Drive plate and brake band wear Steel (magnetic) . . . . . . . . . . Bearing, gear, and driven plate wear Aluminum (nonmagnetic) . . Bushings or cast alumi- num parts wear If large amounts of material are found, replace the torque converter and carefully check the transmission for the cause. 3. Install the oil pan and gasket with a few bolts to protect the valve body. 4. Remove the vacuum diaphragm, lockup control solenoid valve, vehicle speed pulse generator, and O-rings. 5. Remove the parwneutral switch. 6. Remove the speedometer driven gear from the exten- sion housing. 7. Remove the O-ring from the speedometer driven gear. Gartner Banana

Page 459 of 1708

K TRANSMISSION 21. Loosen the fourth gear band servo locknut and tighten the piston stem. 22. Mark the fourth gear case and oil pump for proper reas- sembly. 23. Install the SST to the oil pump assembly. 24. Slowly remove the oil pump from the transmission case by evenly sliding the weights of the SST. 25. Remove the SST from the oil pump. 26. Loosen the piston stem of the fourth gear band servo. Remove the fourth gear connecting shell and fourth gear planetary gear unit (fourth gear sun gear, fourth gear planetary pinion carrier, fourth gear clutch hub), and di- rect clutch. 27. Remove the fourth gear brake band, and hold it together with a piece of wire as shown in the figure. 28. Remove the band strut. Gartner Banana

Page 460 of 1708

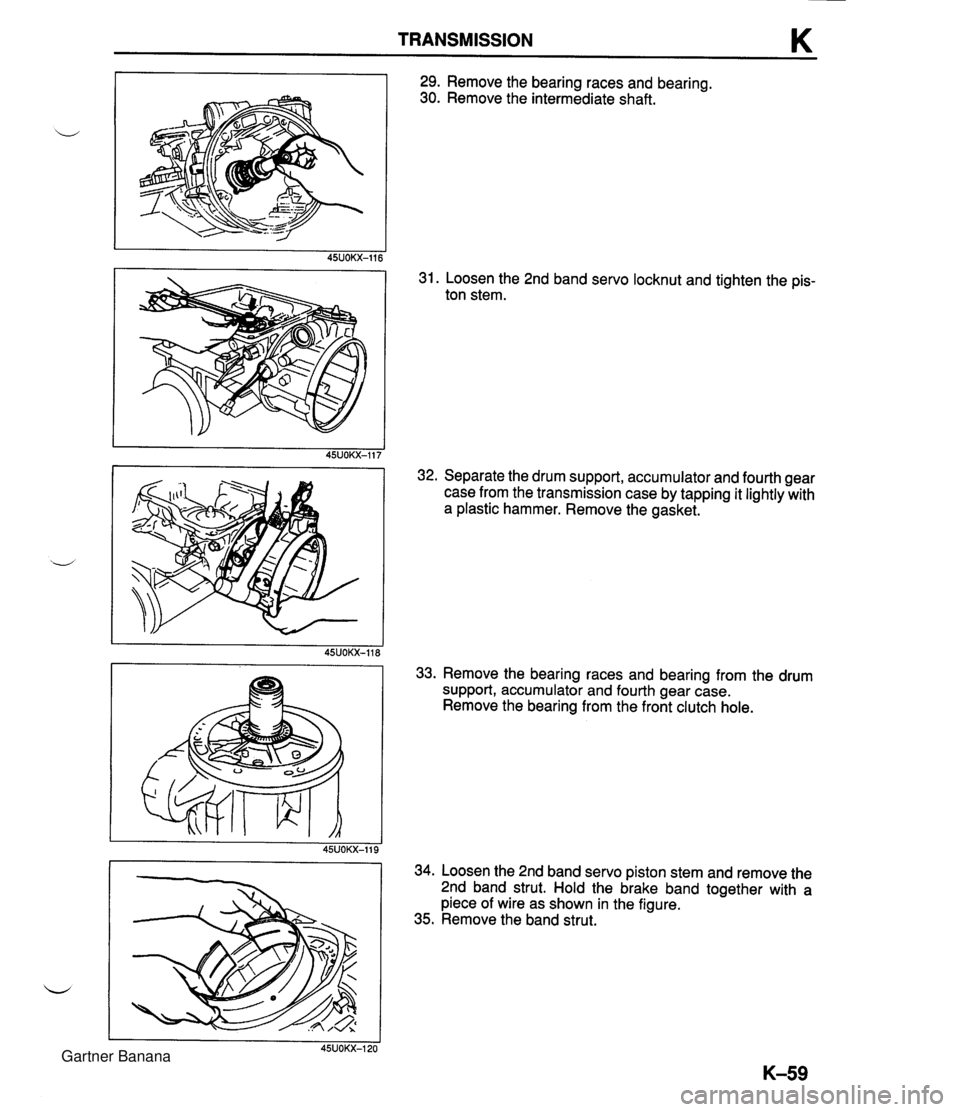

TRANSMISSION K 29. Remove the bearing races and bearing. 30. Remove the intermediate shaft. I 45UOKX-116 31. Loosen the 2nd band servo locknut and tighten the pis- ton stem. I 1 45UOKX-117 32. Separate the drum support, accumulator and fourth gear case from the transmission case by tapping it lightly with a plastic hammer. Remove the gasket. u 45UOKX-118 Remove the bearing races and bearing from the drum support, accumulator and fourth gear case. Remove the bearing from the front clutch hole. Loosen the 2nd band servo piston stem and remove the 2nd band strut. Hold the brake band together with a piece of wire as shown in the figure. Remove the band strut. Gartner Banana

Page 464 of 1708

TRANSMISSION K Disassembly I lnspection I Assembly 1. Disassemble in the order shown in the figure, referring to Disassembly Note. 2. Inspect all parts, and repair or replace as necessary. ,, 3. Assemble in the reverse order of disassembly, referring to Assembly procedure. 0 APPLY PETROLEUM JELLY 1. Snap ring 9. Inner gear 2. Sensing rotor Disassembly note .......... page K-64 3. Bearing Inspection ................. page K-64 4. Input shaft 10. Outer gear 5. O-ring Disassembly note .......... page K-64 6. Oil pump cover Inspection ................. page K-64 Disaseembly note .......... page K-64 11. Oil seal Inspection ................. page K-64 12. Roll pin 7. Oil pump housing 13. Plug Inspection ................. page K-64 14. Spring 8. O-ring Inspection ................. page K-65 15. Lockup control valve Gartner Banana