torque MAZDA PROTEGE 1992 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 485 of 1164

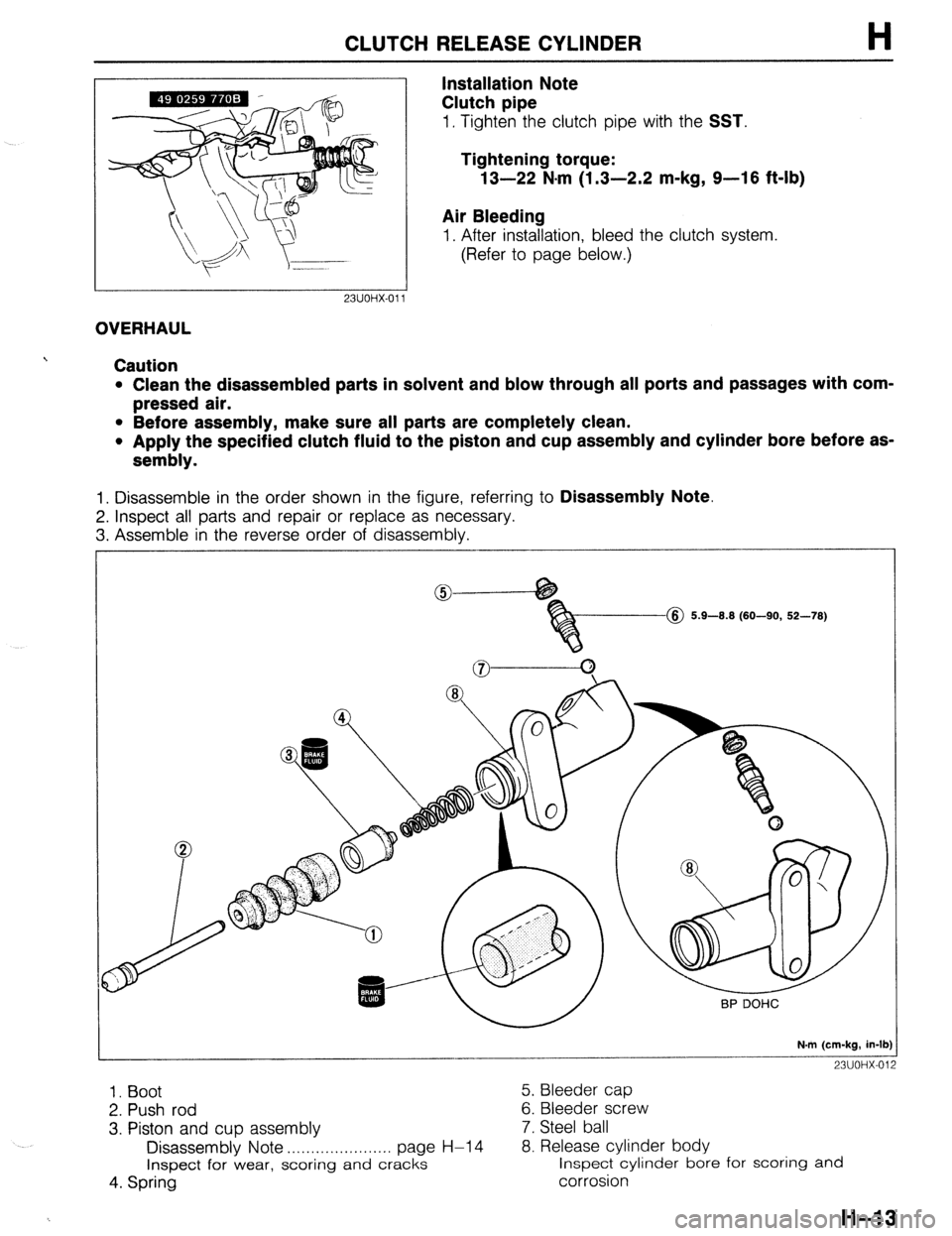

CLUTCH RELEASE CYLINDER

Installation Note

Clutch pipe

H

1. Tighten the clutch pipe with the SST.

Tightening torque:

13-22 N-m (1.3-2.2 m-kg, 9-16 ft-lb)

Air Bleeding

1. After installation, bleed the clutch system.

(Refer to page below.)

23UOHX-011

OVERHAUL

Caution

l Clean the disassembled parts in solvent and blow through all ports and passages with com-

pressed air.

l Before assembly, make sure all parts are completely clean.

l Apply the specified clutch fluid to the piston and cup assembly and cylinder bore before as-

sembly.

1. Disassemble in the order shown in the figure, referring to Disassembly Note.

2. Inspect all parts and repair or replace as necessary.

3. Assemble in the reverse order of disassembly.

@ 5.9-8.8 (60-90, 52-78)

N.m (cm-kg, in-lb)

23UOHX-012

1. Boot 5. Bleeder cap

2. Push rod 6. Bleeder screw

3. Piston and cup assembly 7. Steel ball

Disassembly Note . . . . . . . . . . . . . . . . . . . . . . page H-l 4 8. Release cylinder body

Inspect for wear, scoring

and cracks inspect cylinder bore for scoring and

4. Spring corrosion

H-13

Page 488 of 1164

H CLUTCH UNIT

/ 6fs 23UOHX-015

Removal Note

Clutch cover and disc

1. Install the SST or equivalent.

2. Loosen each bolt one turn at a time in a crisscross pattern

until spring tension is released. Then remove the clutch COV-

er and disc.

‘6

I

23UOHX-016

23UOHX-01

Pilot bearing

1. Remove the pilot bearing with the SST if necessary.

Flywheel

Note

l After removing the flywheel, inspect for oil leakage

past the crankshaft rear oil seal.

If necessary, replace the oil seal.

(Refer to Section B.) -J

1. Hold the flywheel with the SST or equivalent.

2. Remove the flywheel.

Installation Note

Flywheel

1. Wipe the bolts clean and apply sealant to the bolt threads.

2. Install the flywheel and the

SST or equivalent.

3. Tighten the bolts in the pattern shown.

Tightening torque:

96-103 N,m (9.6-10.5 m-kg, 71-76 ft-lb)

Pilot bearing

Note

l Install the pilot bearing flush with the flywheel.

1. Install the new bearing with a suitable pipe.

Bearing outer diameter: 35mm (1.376 in) .-’

Page 489 of 1164

CLUTCH UNIT, RELEASE BEARING, CLUTCH COVER, CLUTCH DISC H

L

13UOHX-01;

03UOHX-03 8

23UOHX-018

5

03UOHX-032

03UOHX-03

Clutch disc

1. Clean the clutch disc splines and main drive gear splines;

then apply organic molybdenum sulfide grease.

2. Hold the clutch disc in position with the

SST.

Clutch cover

1. Install the SST or equivalent.

2. Align the dowel holes with the flywheel dowels.

3. Tighten the bolts evenly and gradually in the pattern shown.

Tightening torque:

18-26 Nom (1.8-2.7 m-kg, 13-20 ft-lb)

RELEASE BEARING

INSPECTION

Note

l The clutch release bearing Is a sealed bearlng and

must not be washed in solvent.

1. Turn the bearing while applying force in the axial direction.

If the bearing sticks or has excessive resistance, replace it.

CLUTCH COVER

INSPECTION

Note

l Minor scoring or burning should be removed with

emery paper.

1. Inspect the contact surface of the clutch disc for scoring,

cracks, and burning. Repair or replace as necessary.

2. Inspect the contact surface of the clutch release bearing

for wear and cracks.

If there is wear or cracks, replace the clutch cover.

CLUTCH DISC

INSPECTION

Note

l Use sandpaper if the trouble is minor.

1. Inspect the lining surface for burning and oil contamination.

Replace the clutch disc if it is badly burned or oil soaked.

2. Inspect for loose facing rivets and rubbers.

Replace the clutch disc if either is loose.

H-17

Page 497 of 1164

TRANSAXLE OIL Jl

/

03UOJl-00

03UOJl-O(

TRANSAXLE OIL

INSPECTION

Note

l Park the vehicle on level ground.

1. Disconnect the speedometer cable and remove the speedo-

meter driven gear.

2. Verify that the oil level is between the F and L.

3. Install the speedometer driven gear.

Tightening torque:

7.8-12 N,m (80-120 cm-kg, 89-l 04 in-lb)

4. Connect the speedometer cable.

REPLACEMENT

1. Disconnect the speedometer cable and remove the speedo-

meter driven gear.

2. Remove the drain plug and washer. Drain the oil into a suita-

ble container.

3. Install a new washer and the drain plug.

Tightening torque:

39-54 N#rn (4.0-5.5 m-kg, 29-40 ft-lb)

4. Add the necessary amount of the specified oil through the

speedometer driven gear mounting.

Specified oil

Grade: API service GL-4

Viscosity: SAE 75W-90

Capacity: 2.88 liters (2.83 US qt, 2.38 Imp qt)

5. Verify the oil level.

6. Install the speedometer driven gear and connect the

speedometer cable.

Jl-7

Page 527 of 1164

TRANSAXLE Jl

Shim selection

Adjust the bearing preload and select the shim(s) as follows.

Primary shaft assembly

1, Set the primary shaft assembly into the clutch housing.

2. Install the transaxle case to the clutch housing and tighten

the bolts to the specified torque.

Tightening torque:

19-26 N#m (1.9-2.6 m-kg, 14-19 ft-lb)

03UOJl-083 3. Mount a dial indicator to the transaxle hanger and meas-

ure the primary shaft thrust clearance.

03UOJl-064

03UOJl-Of%!

03UOJl-086

Clearance: 0.005-0.1 OOmm (0.0002-0.0039 in)

4. Select the closest shim on the thin side from the table.

Adjustment shim thickness: mm (in)

0.1 (0.004) 0.2 (0.008) 0.3 (0.012)

1 0.4 (0.016)

0.5 (0.020) 0.6 (0.024)

Secondary shaft bearing preload

1. Install the funnel and bearing outer race into the clutch

housing.

2. Set the secondary shaft into the clutch housing.

3. Install the secondary shaft bearing outer race into the trans-

axle case.

4. Install the transaxle case to the clutch housing and tighten

the bolts to the specified torque.

Tightening torque:

19-26 N-m (1.9-2.6 m-kg, 14-19 ft-lb)

5. Mount a dial indicator to the transaxle case and measure

the secondary shaft end play.

6. Select the shim as follows.

(a) Add 0.03mm (0.0012 in) to the thrust clearance.

(b) Add 0.08mm (0.0031 in) to the thrust clearance.

(c) Select the thickest shim in the range from (a) to (b) from

the table.

I

13UOJl.004

Jl-37

Page 528 of 1164

Jl TRANSAXLE

51-38

03UOJ l-08!

RACE

OWOJ i-09

ONJOJl-09 , _.

03UOJ I-09

Example: 0.22mm (0.009 in)

0.22mm (0.009 in) + 0.03mm (0.001 in)

= 0.25mm (0.010 in)

0.22mm (0.009 in) + 0.08mm (0.003 in)

= 0.30mm (0.012 in)

Range: 0.25mm (0.010 in)-0.30mm (0.012 in)

Select the 0.30mm (0.012 in).

Adjustment shim thickness:

mm (in)

0.15 (0.006) 0.20 (0.008) 0.25 (0.010) 0.30 (0.012)

0.35 (0.014) 0.40 (0.016) 0.45 (0.018) 0.50 (0.020)

93GOJ I-524

Differential

1. Install the bearing outer race into the clutch housing.

2. Set the differential assembly into the clutch housing.

Note

l Turn A and B until the gap shown in the figure is

eliminated.

3. Install the transaxle case side bearing outer race to the SST

(selector).

4. Set the

SST (collars) in the positions shown in the figure.

5. Tighten the

SST (bolts) to the specified torque.

Tightening torque:

19-26 N-m (1.9-2.6 m-kg, 14-19 ft-lb)

Page 529 of 1164

TRANSAXLE Jl

03UOJl-09:

03UOJi-09

03UOJl-09

03UOJl-09

03UOJl-0:

Note

l Turn the bars until the SST (selector) can no longer

be moved.

6. To seat the bearings, mount the bars on parts @ and @I

of the selector, and turn the selector so the gap is widened.

7. Turn in the reverse direction until the gap is eliminated.

8. Install the

SST to the differential pinion gear through the

transaxle case.

9. Turn the

SST with a torque wrench. Adjust the SST (selec-

tor) with the bars until the specified preload is obtained.

Preload:

0.03-0.74 N#m (0.3-7.6 cm-kg, 0.26-6.60 in-lb)

10. Remove the SST.

11. Measure the clearance around the entire circumference of

the

SST (selector).

12. Select the proper adjust shim(s) to be used for the differen-

tial by referring to the table and selecting the shim which

is nearest (on the thick side) to the largest measured clear-

ance in the selector.

Adjust shim thickness:

0.20 (0.008)

0.25 (0.010)

0.40 (0.016)

0.45 (0.018) mm (in)

0.30 (0.012) 0.35 (0.014)

0.50 (0.020) 0.55 (0.022)

13. Remove the SST (bolts).

14. Remove the transaxle case and the

SST (collars).

Jl-39

Page 530 of 1164

Jl TRANSAXLE

,

,,

03UOJi-09

03UOJl-10

Jl-40

OSUOJl-1C

15. Remove the bearing outer race from the SST (selector).

16. install the selected shim(s) and bearing outer race to the

transaxle case.

-’

Bearing preload (Differential)

Measure the preload as follows.

1. Set the differential assembly into the clutch housing.

2. Install the transaxle case onto the clutch housing.

Tightening torque:

19-26 N-m (1.9-2.6 m-kg, 14-19 ft-lb)

3. Install the SST to the differential side gear through the trans-

axle case.

4. Measure the bearing preload.

Preload:

0.03-0.74 N,m (0.3-7.6 cm-kg, 0.26-6.60 in-lb)

5. If not as specified, readjust the bearing preload.

6. Remove the SST.

7. Remove the transaxle case and differential assembly.

Page 537 of 1164

TRANSAXLE Jl

- 23UOJl-01

03UOJl-11

03UOJl-14

I 03UOJl-11

Transaxle case assembly

1, Apply a thin coat of sealant to the contact surfaces of the

clutch housing and transaxle case, tighten the transaxle case

installation bolts to the specified torque.

Tightening torque:

19-26 Nom (1.9-2.6 m-kg, 14-19 ft-lb)

Clutch hub assembly (6th) and 6th shlft fork

1. Install the clutch hub assembly (5th) and the 5th shift fork

together.

Locknut

1. Shift to 1 st gear.

2. Lock the primary shaft with the

SST.

3. Tighten new locknuts on the primary and secondary shafts.

Tightening torque:

126-206 N*m (13.0-21 m-kg, 94-152 ft-lb)

4. Stake the locknuts.

5. Measure the 5th gear thrust clearance with a dial indicator.

Clearance: 0.06-0.26mm (0.0024-0.0102 in)

Maximum : 0.31 mm (0.0122 in)

6. If not as specified, reassemble the transaxle.

Jl-47

Page 539 of 1164

TRANSAXLE Jl

1. Transaxle

Installation Note ..,......,.............. page Jl-49

2. Engine mount No.4

3. Driveshaft

Installation Note . . . . . . . . . . . . . . . . . . . . . . . . page Jl-50

4. Stabilizer (BP SOHC)

Installation Note . . . . . . . . . . . . . . . . . . . . . . . . page Jl-50

5. Tie-rod end

Installation Note ,........,..,........... page Jl-50

6. Clutch release cylinder

7. Engine mount No.2

8. Exhaust pipe

9. Engine mounting member

Installation Note . . . . . . . . . . . . . . . . . . . . . . . .

page Jl-50

10. Control rod

Installation Note . . . . . . . . . . . . . . . . . . . . . . . . page Jl-51 11. Extension bar

Installation Note . . . . . . . . . . . . . . . . . . . . . . . . page Jl-51

1 12. Starter

13. Ground

Installation Note .,..,...,......,........ page Jl-5

14. Neutral switch connector

15. Back-up light switch connector

16. Speedometer cable

Installation Note . . . . . . . . . . . . . . . . . . . . . . . .

page Jl-5

17. Battery carrier

18. Battery

19. Air hose and resonance chamber

20. Splash shield

21. Wheel and tire 1

Installation Note

Transaxle

1. Set the transaxle on a jack and lift it into place.

Install tne transaxle oorts.

Tightening torque:

64-69 N*rn (6.5-9.1 m-kg, 47-66 ft-lb)

Loosely tighten engine mount No.4 bolts.

Jl-49