ignition MAZDA PROTEGE 1992 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 967 of 1164

TROUBLESHOOTING GUIDE U

I 23UOUX-01

03UOUX-02

Step 5 Measure voltage at refrigerant pressure switch

No.1

Measure the voltage at the following terminal wires of the

refrigerant pressure switch No. 1 connector.

VB: Battery voltage

Wire

WV

W-) Voltage Action

V0 Repair wire (B/R)

ov Next check wire (B/L)

VB Go to Step 6

ov Repair wire (B/L)

Step 6 Measure refrigerant pressure

1. Turn the ignition switch OFF.

2. Connect the high-pressure hose of the manifold gauge to

the high-pressure gauge fitting.

3. Measure the refrigerant pressure at the high-pressure side.

High-pressure side:

Above 451 kPa (4.6 kg/cm2, 65 psi)

4. If not as specified, check the refrigerant system by refer-

ring to the troubleshooting information on page U-14.

5. If correct, replace refrigerant pressure switch No.2 with cool-

er pipe No.2. (Refer to page U-54.)

23UOUX-014

U-l 1

Page 1011 of 1164

AIR CONDITIONER U

REFRIGERANT PRESSURE

2.0 f 0.2 kg/cm* 27 f 2 kg/cm’

4.1 f 0.5 kg/cm* 21 * 4 kg/cm*

03uoux-09

9

23UOUX-050

REFRIGERANT PRESSURE SWITCH No.1

Inspection

1. Turn the ignition switch OFF.

2. Connect the manifold gauge set and measure the high-

pressure side refrigerant pressure.

High-pressure side:

Above 451 kPa (4.6 kg/cm2, 65 psi)

3. If not as specified, check the refrigerant system, referring

to the troubleshooting information on page U-14.

4. If correct, go to the next step.

5. Disconnect the refrigerant pressure switch No.1 connector.

6. Check for continuity of the switch.

Terminals

1 Continuity

a-b

Yes I

7. If not as specified, replace the switch together with cooler

pipe No.2. (Refer to page U-54.)

Note

l If problems occur in the refrigeration system, caus-

ing abnormally high (above 2,649 SL: 196 kPa [27 f

2 kg/cm2, 384 f 28 PSI]) or low (below 196 f 20

kPa [2.0 f 0.2 kg/cm2, 28 & 2.8 psi]) pressures,

refrigerant pressure switch No.1 cuts power to the

magnetic clutch to protect the mechanical compo-

nents. If the pressure recovers to within normal

operating range (below 2,080 f 392 kPa [21 f 4

kg/cm2, 299 f 57 psi] or above 402 f. 49 kPa t4.1

f 0.5 kg/cm2, 58 f 7 psi]), the power is again re-

stored.

REFRIGERANT PRESSURE SWITCH No.2

(BP ENGINE WITH ATX)

Inspection

1. Turn the ignition switch OFF.

2. Connect the manifold gauge set and measure the high-

pressure side refrigerant pressure.

High-pressure side:

below 1,177 kPa (12 kg/cm2, 171 psi)

3. Disconnect the refrigerant pressure switch No.2 connector.

4. Check continuity of the switch.

Terminals

a-b I Continuity

No

5. If not as specified, replace the switch together with cooler

pipe No.2. (Refer to page U-54.)

6. If correct, go to next stop.

u-55

Page 1023 of 1164

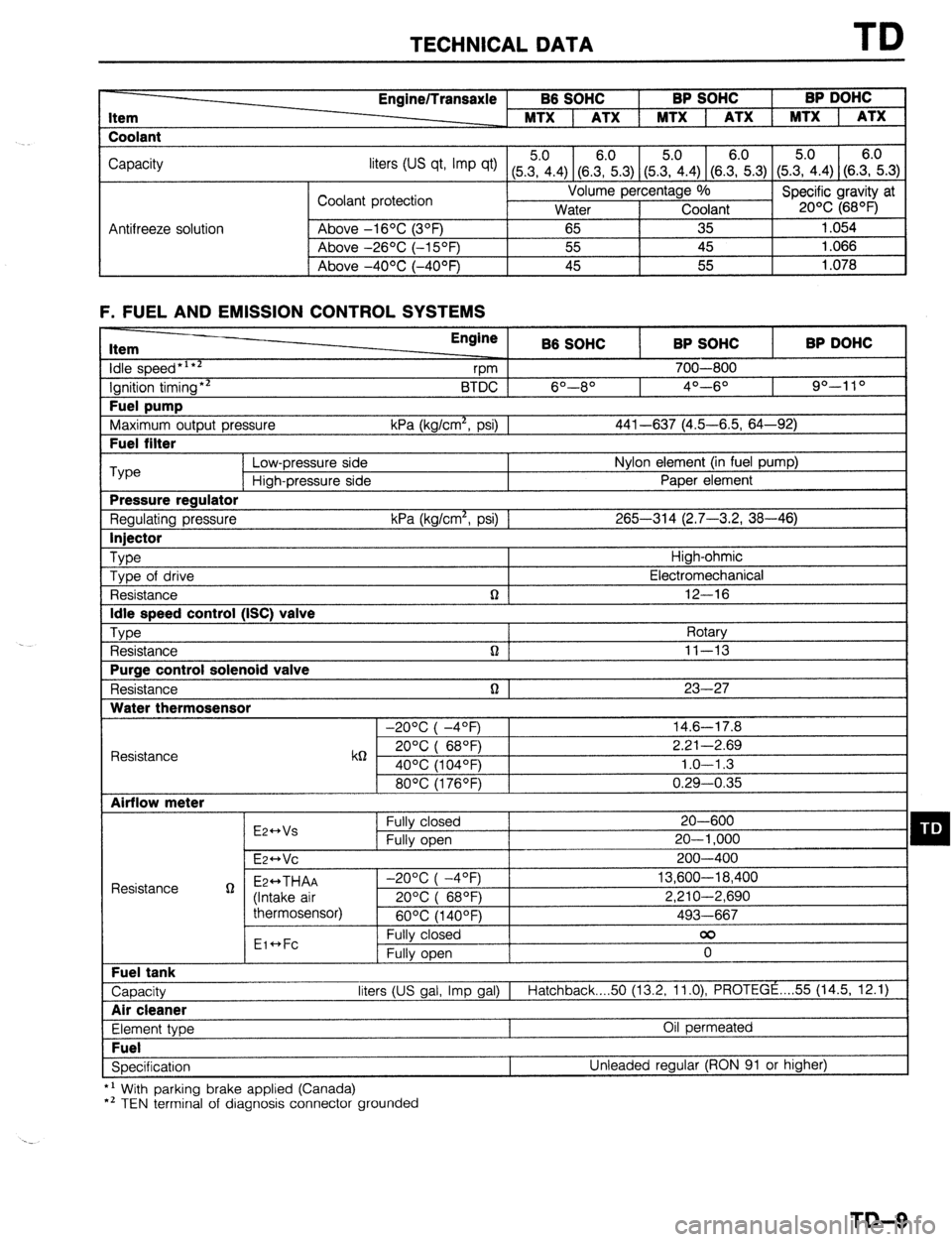

TECHNICAL DATA TD

Item

Coolant Engine/Transaxle B6 SOHC BP SOHC BP DOHC

MTX 1 ATX 1 MTX 1 ATX 1 MTX 1 ATX

Capacity

liters tus qt, Imp qt) (5Z.4) (8.E.3) (5&4) (SE.3) (5.?i.4) (S.E.3)

Coolant protection Volume percentage %

Specific gravity at

Water Coolant 20% (68OF)

Antifreeze solution Above -16OC (3OF)

65 35 1.054

Above -26OC (-15OF) 55 45 1.066

I Above -4OOC (-40°F) 45 55

1.078

F. FUEL AND EMISSION CONTROL SYSTEMS Item

idle speed*‘**

Ignition timing** Fuel pump

Maximum output pressure Fuel filter Engine

B6 SOHC BP SOHC BP DOHC

vm 700-800

BTDC 6O--8O 4O---6O 90-l 10

kPa (kg/cm*, psi) 1 441-637 (4.5-6.5, 64-92) ‘Type

Low-pressure side Nylon element (in fuel pump)

High-pressure side Paper element Pressure regulator

Regulating pressure kPa (kg/cm*, psi) 1 265-314 (2.7-3.2, 38-46) Injector

Type

High-ohmic

Type of drive Electromechanical

Resistance n 12-16 Idle speed control (ISC) valve

Type

Rotary

Resistance n ] 11-13 Purge control solenoid valve

Resistance n 1 23-27 Water thermosensor

-20°C( -4OF) 14.6-17.8

Resistance k6 20°C( 68QF) 2.21-2.69

40% (104OF) 1.0-l .3

80°C(1760F) 0.29-0.35 Airflow meter

E2++Vs Fully closed 20-600 q D Fully open 20-l ,000

E~HVC 200-400

Resistance g Ez++THAA -2O%(-4OF) 13,600-18,400

(Intake air 20%( 68OF) 2,210-2,690

thermosensor)

60°C(1400F) 493-667

Eic*Fc Fully closed 00

Fully open 0 Fuel tank

Capacity liters (US gal, Imp gal) I

Hatchback 50 (13.2, 11.0) PROTEGE . . . . 55 (14.5, 12.1) Air cleaner

Element type Oil permeated Fuel

Specification Unleaded regular (RON 91 or higher)

*’ With parking brake applied (Canada)

*’ TEN terminal of diagnosis connector grounded

TD-9

Page 1024 of 1164

TD TECHNICAL DATA

G. ENGINE ELECTRICAL SYSTEM

3attery Dark

current*’

Alternator 86 SOHC BP SOHC

I BP DOHC

MTX 1 ATX 1 MTX 1 ATX

Voltage V 12

Type and capacity (20-hour rate) 55D23L (60AH) 1 55D23L (60AH)

mA Max. 20.0

Type A.C

output V-A 12-65

Regulator type Transistorized (built-in IC regulator)

Regulated voltage V 14.1-14.7

Brush length Standard 21.5 (0.846)

mm (in) Minimum 8.0 (0.315)

Drive belt deflection

New 8-Q (0.31-0.35)

;riL’F,i Used Q-10 (0.35-0.39)

Coaxial

Type Direct Direct Coaxial

reduction Direct

reductior

Starter output V-kW 12-0.85 12-0.95 12-1.4 12-0.95 12-1.4

Brush length Standard 17 (0.67) 17 (0.67) 17.5 (0.69) 17 (0.67) 17.5 (0.69

mm (in) Minimum 11.5 (0.453) 11.5 (0.453) 10.0 (0.39) 11.5 (0.453) 10.0 (0.39

Distributor Electronic spark advance (photo diode)

Ignition timing BTDC

(TEN terminal of diagnosis connector grounded) 6O-8O 4O-6O 9”-11 O

Ignition coil Resistance Primary coil winding 0.81 -O.QQg

(at 20% [68OF]) Secondary coil winding lo-16 kg

SK&E-1 1 BKR5E-11

NGK

BKRGE-11 BKRGE-11

BKR7E-11

Spark plug Type

NIPPONDENSO KlGPR-Ull

K20PRUll KlGPR-Ull

K20PRUll

K22PRUll *:

. Plug gap

Firing order mm (in) 1.0-l .l (0.039-0.043)

l-3-4-2

---

’ Dark current is the constant flow of current while the ignition switch IS UFF.

(i.e engine control unit, audio, etc.) ..-

._*

T&l 0

Page 1050 of 1164

PARTS INDEX

I

CRANKSHAFT.. ....................................

I31 -64

CYLINDER BLOCK .............................. 61-60

CYLINDER HEAD..

............................... 81-54

CYLINDER HEAD GASKET .................

Bl-16

DRIVE BELT(S). ...................................... 81-5

FRONT OIL SEAL ................................ 81-23

HLA .............................................. Bl-7,20,60

OIL JET ................................................ 81-61

PISTON.. ...............................................

Bl-62

PISTON PIN..

........................................ 81-62

PISTON RING

....................................... 81-62

REAR

OIL SEAL..

................................. 81-25

TENSIONER, IDLER ............................. Bl-65

TENSIONER

SPRING ...........................

Bl-65

TIMING BELT ..................................

Bl-12,65

TIMING BELT PULLEY ........................

Bl-65

VALVE MECHANISM ........................... Bl-55

ENGINE

(BP DOHC) .................................... B2-2

CAMSHAFT ..........................................

82-58

CAMSHAFT PULLEY ...........................

B2-65

CONNECTING ROD..

........................... 82-63

CRANKSHAFT ......................................

B2-64

CYLINDER BLOCK ..............................

82-60

CYLINDER

HEAD.. ............................... B2-54

CYLINDER HEAD GASKET .................

82-16

DRIVE

BELTS.. .......................................

B2-5

FRONT

OIL SEAL ................................

82-26

H LA ..............................................

OIL JET .......................... B2-7iyL;;

......................

PISTON .................................................

B2-62

PISTON PIN ..........................................

82-62

PISTON RING..

..................................... 82-62

REAR OIL SEAL ................................... B2-28

TENSIONER, IDLER ............................. B2-65

TENSIONER SPRING ........................... B2-65

TIMING

BELT.. ................................

B2-12,65

TIMING BELT PULLEY ........................ 82-65

VALVE MECHANISM ........................... 82-55

ENGINE CONTROL UNIT (ECU) ............... F-149

ENGINE COOLANT

........................................ E-5

ENGINE OIL.. .................................................

D-7

ENGINE OIL FILTER.. .................................... D-8

’ EXHAUST SYSTEM. ...................................

F-136

EXTRACTOR CHAMBER .............................. S-53

F

FAN MOTOR (COOLING FAN). ................... E-14

FAN RELAY (COOLING FAN). ..................... E-18

FLASHER UNIT ............................................

T-17

FLOORMAT ..................................................

S-99

FLYWHEEL ..................................................

H-18

FRONT AXLE .................................................

M-4

FRONT BRAKE ............................................

P-l 8

FRONT BUMPER ......................................... S-39

FRONT DOOR ................................................

S-8

FRONT DOOR LOCK AND OPENER ..........

S-13

PI-2

FRONT FENDER PANEL ............................... S-7

FRONT LOWER ARM .................................. R-16

FRONT SHOCK ABSORBER AND SPRING R-11

FRONT SIDE WINDOW REGULATOR AND

GLASS ........................................................ S-10

FRONT STABILIZER..

................................... R-l 8

FRONT SUSPENSION .................................. R-l 0

FUEL FILLER LID AND OPENER..

.............. S-37

FUEL FILTER .............................................. F-l 24

FUEL GAUGE SENDER UNIT ..................... T-73

FUEL PUMP ............................................... F-125

FUEL TANK

................................................ F-123

FUSE AND JOINT BOX.. .............................. T-12

H

HEADLIGHT AND

FRONT COMBINATION LIGHT..

................ T-41

HEADLIGHT RELAY ..................................... T-l 8

HEADLINER ................................................. S-89

HEATER CONTROL UNIT.. ......................... U-26

HEATER UNIT

.............................................. U-21

HIGH-MOUNT STOPLIGHT

.......................... T-45

HIGH-TENSION LEAD ................................. G-l 7

HOOD ............................................................. S-5

HORN T-88

...........................................................

HORN RELAY

.......................................... T-18,88

.__. ’

I I

IGNITER .......................................................

G-23

IGNITION COIL.. .......................................... G-19

INJECTOR .................................................. F-l 31

INSTRUMENT CLUSTER

AND SPEEDOMETER CABLE

.................... T-69

INTAKE MANIFOLD ................................... F-113

INTERIOR LAMP ..................................... T-52,53

ISC VALVE.. ................................................ F-l 16

J

JOINT SHAFT (FRONT AXLE) .................... M-18

L

LATERAL LINK AND TRAILING LINK.. ....... R-26

LICENSE PLATE LIGHT.. ............................. T-47

i

M

I

---

MAIN RELAY (FUEL INJ. RELAY). ............ F-172

MANUAL STEERING ..................................... N-4

MANUAL TRANSAXLE (F5M-R). .................. Jl-2

Page 1055 of 1164

Z

SYSTEM INDEX

System Section System Section

AUDIO SYSTEM ......................................................... J

BACK-UP LIGHTS ...................................................

F-3

CHARGING SYSTEM ............................................... A-2

CIGARETTE LIGHTER ............................................... I-1

COMMON CONNECTOR LIST ..................................... X

COOLING FAN SYSTEM ....................................... B-3.4

COURTESY LAMPS .................................................. l-3

CRUISE CONTROL SYSTEM ...................................... Q

DAYTIME RUNNING UGHTS .................................... E-3

DIAGNOSIS CONNECTOR .......................................... U

DIGITAL CLOCK ....................................................... l-l

ELECTRICAL WIRING SCHEMATIC ............................. W

ENGINE CONTROL SYSTEM (MT) ................. B-l a, 1 b, 1 c

ENGINE 8 EC-AT CONTROL

SYSTEM (EC-AT) ...................................... B-2a,2b,2c

GENERAL INFORMATION .......................................... GI

GROUND POINT ........................................................ Y

HEADLIGHTS ....................................................... E-l ,2

HEATER 8 AIR CONDITIONER .................................... G

HORN .................................................................... F-3

IGNITION KEY CYLINDER LAMP ............................... l-2

ILLUMINATION LAMPS .............................................

l-4

INSTRUMENT CLUSTER . WARNING LAMPS .............. C INTER CONNECTING OF JOINT BOX ......................... JB

INTERIOR LAMP ...................................................... l-2

JOINT BOX .............................................................. JB

LICENSE PLATE UGHTS ......................................... E-4

PARTS INDEX ........................................................... PI

PARTS LOCATION ................................................... PL

PASSIVE SHOULDER BELT CONTROL SYSTEM .......... S

POSITION LIGHTS ................................................... E-4

POWER DOOR LOCK ............................................. K-2

POWER OUTSIDE MIRROR ......................................... L

POWER WINDOW ................................................... K-l

REAR SIDE MARKER LIGHTS.. ................................. E-4

REAR WINDOW DEFROSTER .................................... I-1

REAR WIPER 8 WASHER ........................................ D-3

SHIFT-LOCK SYSTEM ................................................ H

SLIDING SUNROOF ................................................... M

SOUND WARNING SYSTEM ...................................... l-2

STARTING SYSTEM ................................................ A-l

STOPLIGHTS .......................................................... F-2

TAILLIGHTS ............................................................ E-4

TRUNK COMPARTMENT LAMP ................................. l-3

TURN 8 HAZARD FLASHER UGHTS ......................... F-l

WINDSHIELD WIPER 8 WASHER .......................... D-l ,2

Page 1060 of 1164

Z-Gl-4 Reading Wiring Diagrams

System circuit diagram/connector diagram

l These show the circuits for each system, from the power supply to the ground. The power supply side

is on the upper part of the page, the ground side on the lower part. The diagrams describe circuits with

the ignition switch off.

Below is an explanation of the various points in the diagram.

) Indicates operating conditions for switches.

The prefix letter indicates the system in which

:he connector is used.

JB: Joint box connections

X : Common connectors

A : Charging system/starting system

connectors

B : Engine control system connectors

C : Gauge control system connectors

D : Wiper system connectors

E : Lighting system connectors

F : Signal system connectors

G : Air-conditioning system connectors

H : Transmission control system

connectors

I : Interior lamp system connectors

J : Audio/radio connectors

K : Power window/power door lock system

connectors

L : Remote control mirror system

connectors

M : Sliding sunroof system connectors

N : Power steering/4-wheel steering

system connectors

0 : Anti-lock brake system connectors

P : Power seat/seat heater system

connectors

Cl : Auto cruise control system connectors

R : Auto adjusting suspension system

connectors

S : Passive shoulder belt control/air bag

system connectors

T : Others

Y : Ground connector

- .

1

\\‘

IGNITION SYSTEM l ENGINE CONTROL 9 harness ground is represented differently

:han a unit ground.

Types of grounds Symbol

Harness

I

-

-

-

-

‘“G:

si-

P

7:’

.I

I

I

.i

-

-

-

f

9

Tiii

zs

LL

a

EE

-

Page 1065 of 1164

Reading Wiring Diagrams Z-GI-9

Symbol ‘ Meaning Symbol Meaning

Horn l Generates sound when current flows. Switch (1) l Allows or breaks current flow by

opening and closing circuits.

Speaker

w

Heater l Generates heat when current flows. Normally open (NO)

Switch (2)

Normally closed (NC)

Harness l Unconnected intersecting harness.

Speed sensor l Movement of magnet in speedometer

set turns contact within sensor on and

Off. (Not connected)

l Connected intersecting harness.

Ignition switch @Turning ignition key operates switch

contacts to complete various circuits.

(Connected)

rlormally open (NO)

Relay (1) l Current flowing through coil produces electromagnetic force causing contact to open or close.

____- .~.~~

Open Closed

--.--.-m.---------,

Relay (2) Normally open relay (NO)

- Ri i No flow ’ ni 1 Closed

Normally closed relay (NC) Flow

ormally closed (NC)

Sensor (variable) l Resistor whose resistance changes Diode

l Known as a semiconductor rectifier.

--3p6G- with operation of other components. diode allows current flow in one

direction only

--T- IA

IY Calhode(K)+- Anode(A)

* Flow of electric current

K-1 KD, he>:

-

ensor (thermistor)

l Resistor whose resistance changes Light emitting diode 0 Diode that lights when current flows

with temperature.

(LED)

l Unlike ordinary light bulbs, diode does

not generate heat when lit

Capacitor

l Component that temporarily stores “2, Cathode(K) --&---Anode(A)

I7

Cathode(K)

electrical charge.

c Anode(A)

----il---- .

Flow of electric current

Solenoid

l Current flowing through co11 generates Reference(zener) l Allows current to flow In one dlrectlon

electromagnetic force to operate diode up to a certain voltage. allows current

plungers, etc. cd to flow In other dIrectron once that

J-

voltage IS exceeded.

z-9

Page 1066 of 1164

Z-GI-10 Reading Wiring Diagrams

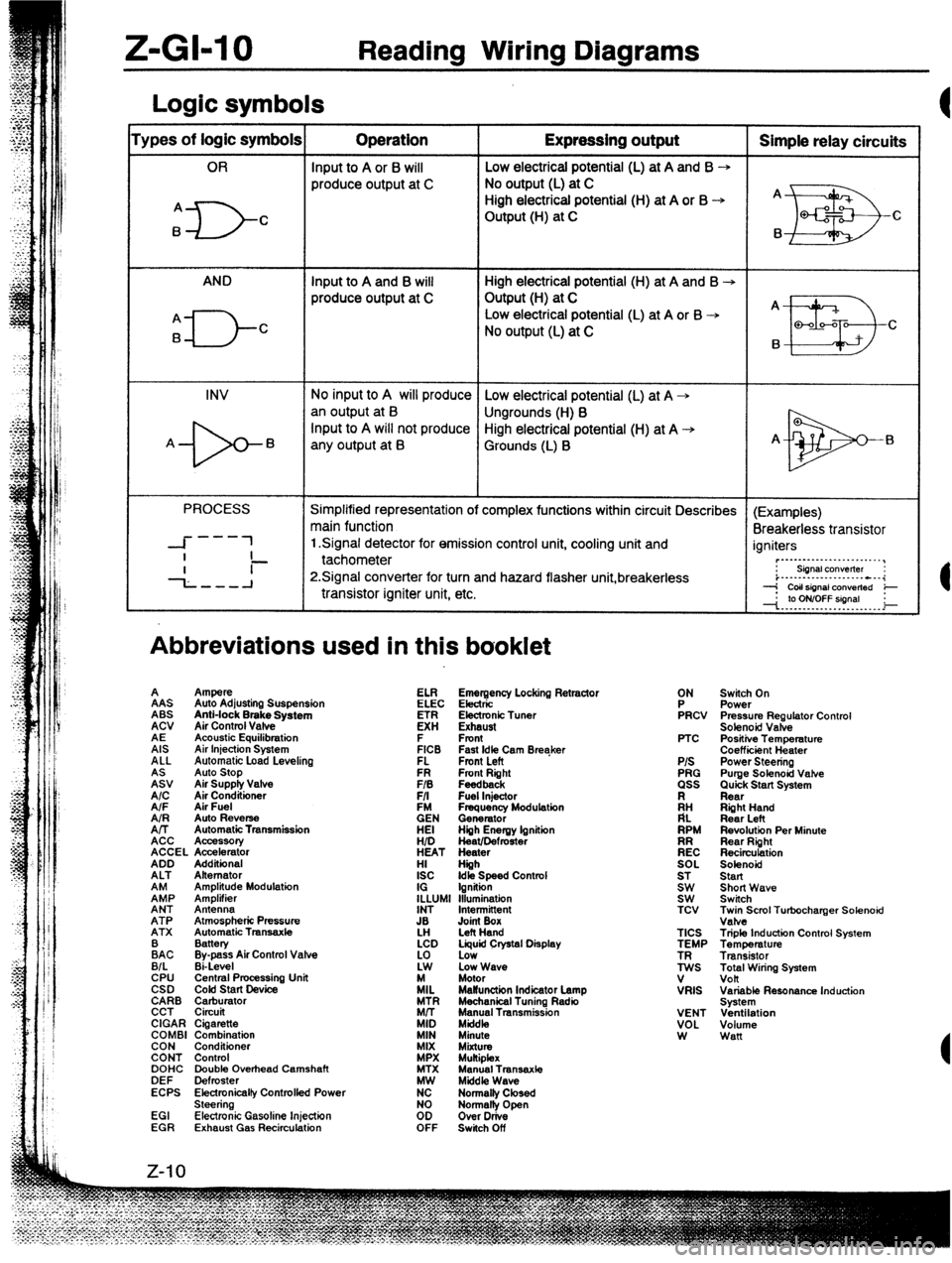

Logic symbols

‘ypes of logic symbols Operation Expressing output Simple relay circuits

OR Input to A or 6 will Low electrical potential (L) at A and B --,

produce output at C No output (L) at C

High electrical potential (H) at A or B -+ A

A

ID- C Output (H) at C

EB Q-f2 c

B B

AND Input to A and B will High electrical potential (H) at A and B -+

produce output at C Output (H) at C

A _

A

El-- Low electrical potential (L) at A or B -+

B C

No output (L) at C

B

II!I3 Q-00-Q

C

INV No input to A will produce Low electrical potential (L) at A +

an output at B

Ungrounds (H) B

-b- Input to A will not produce High electrical potential (H) at A +

A B

any output at B Grounds (L) B A-

El

PROCESS Simplified representation of complex functions within circuit Describes (Examples)

main function

Breakerless transistor

---

-I- 1 1 Signal detector for emission control unit, cooling unit and

I igniters

- ~._..._...._._..._._..__,

--L--A tachometer

P.Signal converter for turn and hazard flasher unit,breakerless : siinalcon”elter :

i..-.--...-.........---i

transistor igniter unit, etc. --j CoIlsignal ConVerted e

--I. .‘p. Y?YT?!!9’. . _ i

Abbreviations used in this booklet

A

%J Ampere

Auto Stop

Air Supply Valve

A/C AAS

Air Conditioner Auto Adjusting Suspension

A/F Air Fuel ABS

AIR Anti-lock Brake System

Auto Reverse

A/T ACV

Automatic Transmission

ACC Air Control Vafve

Acc%K4tIory

ACCEL Accelerator

ADD AE

Additional Acoustic Equilibration

ALT Alternator

EP AIS

Amplitude Modulation Air Injection System

Amplifier ALL

ANT Antenna Automatic Load Levelino

ATP Atmospheric Pressure

ATX Automatic Tmnsaxle FR Fmnt Right ELI?

FIB Feedback

F/I Fuel Injector Emergency Locking Retractor

EN ELEC Electric

Frequency Modulation

Generator

HEI Electronic Tuner

Hiih Energy lgnitiin

HID K!

Heat/Defmster

HEAT Heater Exhaust

HI Hiih F

ISC Front

Idk Speed Contml

IG Ignition

ILLUMI Illumination FICB

INT Intermittent FL Fast Idle Cam Breaker

Fmnt Left

JB

LH Joint Box

Left Hand

:AC Battery

Bypass Air Control Valve

B/L Ei-Level

CPU Central Pmcessing Unit

CSD COM start Device

CARB Carburator

CCT Circuit

CIGAR Cigarette

COMBI Combination

CON Conditioner

CONT Control

DOHC Double Overhead Camshaft

DEF Defroster

ECPS Electronicalfy Controlfed Power

Steering

EGI Electronic Gasoline Injection

EGR Exhaust Gas Recirculation LCD Liquid Crystal Display

:i Low

Low Wave

/IL Motor

MaWunction Indicator Lamp

MTR Mechanical Tuning Radio

Mrr Manual Transmission

MID Mkfdk,

MIN Minute

MIX

MiXtUt MPX Mukiplex

MTX Manual Transaxte

K Middle Wave

Normalty Closed

too Normally Open

Over Drive

OFF Switch Off ON

FRCV

PTC

P/S

PRG

ass

ii:

RPM

EC

SOL

ST

Et TCV

TICS

TEMP

ES

V

VRIS

VENT

VOL

W Switch On

Power

Pressure Regulator Control

Solenoid Valve

Positiie Temperature

Coefficiint Heater

Power Steering

Purge Solenoid Vahe

Quick Start System

Rear

Riiht Hand

Rear Left

Revolution Per Minute

Rear Right

Recirculation

Solenoid

Start

Short Wave

Switch

~;eScml Turbocharger Solenoid

Triple Induction Control System

Temperature

Transistor

Total Wiring System

volt

Variable Resonance Induction

System

Ventilation

Volume

Wan

Page 1067 of 1164

Troubleshootina Z-GM 1

Precautions when servicing electrical system

l Note the following items when servicing the electrical system.

l Do not alter the wiring or electrical equipment in any way as this may damage the vehicle or cause a fire

due to shorting or overcapacity of a circuit.

l Always disconnect the negative (- ) battery cable first and 0 Replace blown fuses with ones having the same designated

reconnect It last when disconnecting the battery. capacity.

1OA

15A

Zaution

l Be sure that the ignition and other switches are OFF

before disconnecting or connecting the battery

terminals.

Failure to do so may damage the semi-conductor

components. Caution l Replacing a fuse with one of a larger capacity than

designated may damage components or cause an electrical

fire.

l Secure harnesses with a clamp when provided to take Up l Tape areas of the

a Be sure that the harness

any slack. harness that may rub or

is not caught or damaged

bump against sharp

when mounting

edges to protect it from

components.

damage.

Caution

l Clamp all harnesses near vibrating components(e.g.

the engine) to remove any slack and prevent Contact

due to vibration.

l Do not handle roughly or drop electrical components.

l Disconnect heat sensitive

parts (e.g. relays, ECU)

when performing

maintenance where

temperatures may exceed l Make sure that the

connectors are securely

connected when

installed.

80°C (176°F) (i.e.welding).

oid