torque MAZDA PROTEGE 1992 User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 54 of 1164

Bl ON-VEHICLE MAINTENANCE

01 EOBX-056

23UOBi -0:

Steps After Installation

1. Lower the vehicle.

2. Connect the negative battery cable.

3. Start the engine and check the ignition timing.

(Refer to page 61-8)

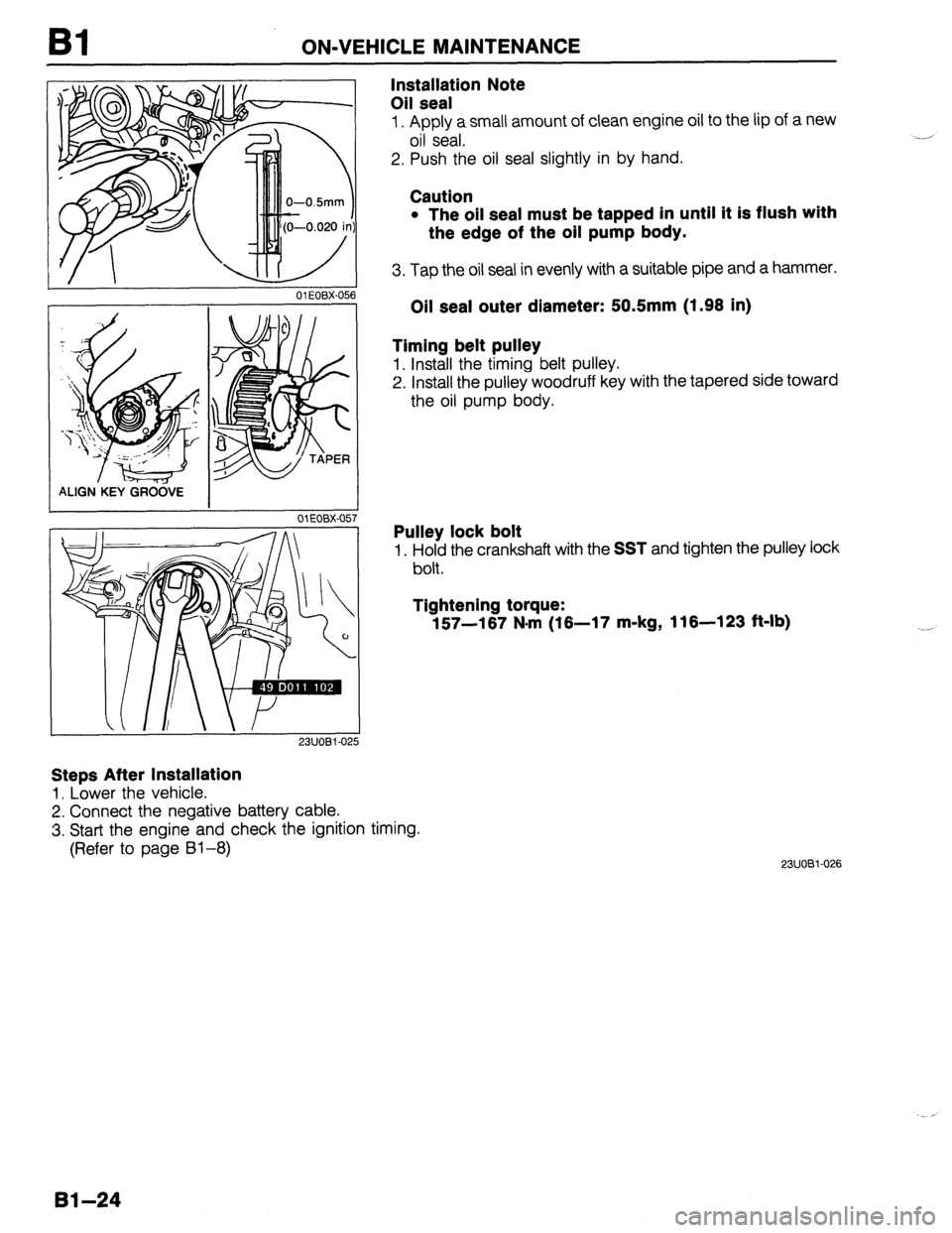

Installation Note

Oil seal

1. Apply a small amount of clean engine oil to the lip of a new

oil seal.

2. Push the oil seal slightly in by hand.

Caution

l The oil seal must be tapped in until it is flush with

the edge of the oil pump body.

3. Tap the oil seal in evenly with a suitable pipe and a hammer.

Oil seal outer diameter: 50.5mm (1.98 in)

Timing belt pulley

1. Install the timing belt pulley.

2. Install the pulley woodruff key with the tapered side toward

the oil pump body.

Pulley lock bolt

1. Hold the crankshaft with the SST and tighten the pulley lock

bolt.

Tightening torque:

157-167 N*rn (16-17 m-kg, 116-123 ft-lb)

23UOBi-026

Bl-24

Page 56 of 1164

Bl ON-VEHICLE MAINTENANCE

OIL SEAL LIP

L I I

OWOBX-063

05UOBX-069

Drive plate (ATX)

1. Hold the drive plate with the SST or equivalent.

2. Remove the drive plate lock bolts.

3. Remove the backing plate, drive plate, and adapter.

Oil seal

1. Cut the oil seal lip with a razor knife.

2. Remove the oil seal with a screwdriver protected with a rag.

Installation note

Oil seal

1. Apply a small amount of clean engine oil to the lip of a new

oil seal.

2. Push the oil seal slightly in by hand.

Caution

l The oil seal must be tapped in until it is flush with

the edge of the rear cover.

3. Tap the oil seal in evenly with a suitable pipe and a hammer.

Oil seal outer diameter: 1OOmm (3.94 in)

Flywheel (MTX)

1. Remove the sealant from the flywheel bolt holes in the crank-

shaft and from the flywheel bolts.

Caution

l If all the previous sealant cannot be removed from

a bolt, replace the bolt.

l Do not apply sealant if a new bolt is used.

2. Set the flywheel onto the crankshaft.

3. Apply sealant to the flywheel bolts and install them.

4. Hold the flywheel with the SST or equivalent.

5. Tighten the bolts in two or three steps in the order shown

in the figure.

Tightening torque:

96-103 N-m (9.6-10.5 m-kg, 71-76 ft-lb)

Page 57 of 1164

Bl

03UOBl-01 15

23UOBl-066

Drive plate (ATX)

1. Remove the sealant from the drive plate bolt holes in the

crankshaft and from the drive plate bolts.

Caution

l If all the previous sealant cannot be removed from

a bolt, replace the bolt.

l Do not apply new sealant if a new bolt is used.

2. Install the adapter, drive plate, and backing plate onto the

crankshaft.

3. Apply sealant to the drive plate bolts and install them.

4. Hold the drive plate with the

SST or equivalent.

5. Tighten the bolts in two or three steps in the order shown

in the figure.

Tightening torque:

96-103 N-m (9.8-10.5 m-kg, 71-76 ft-lb)

Steps After Installation

1. Connect the negative battery cable.

2. Start the engine and perform engine adjustments as necessary.

-.

05UOBX-072

81-27

Page 64 of 1164

REMOVAL

Step 6

Separate the engine and transaxle in the order shown in the figure.

MTX BP SOHC

ATX

BP SOHC

--

03UOB1-060

1. Intake manifold bracket 5. Integrated stiffener (B6 engine)

2. Starter and bracket 6. Torque converter nuts (ATX)

3. Throttle cable (ATX) 7. Transaxle mounting bolts

4. No.2 engine mount rubber and bracket 8. Transaxle

01-34

Page 81 of 1164

DISASSEMBLY Bl

23UOBl-03

05UOBX-1’ 9

23UOBl-040

03UOBl-08 5

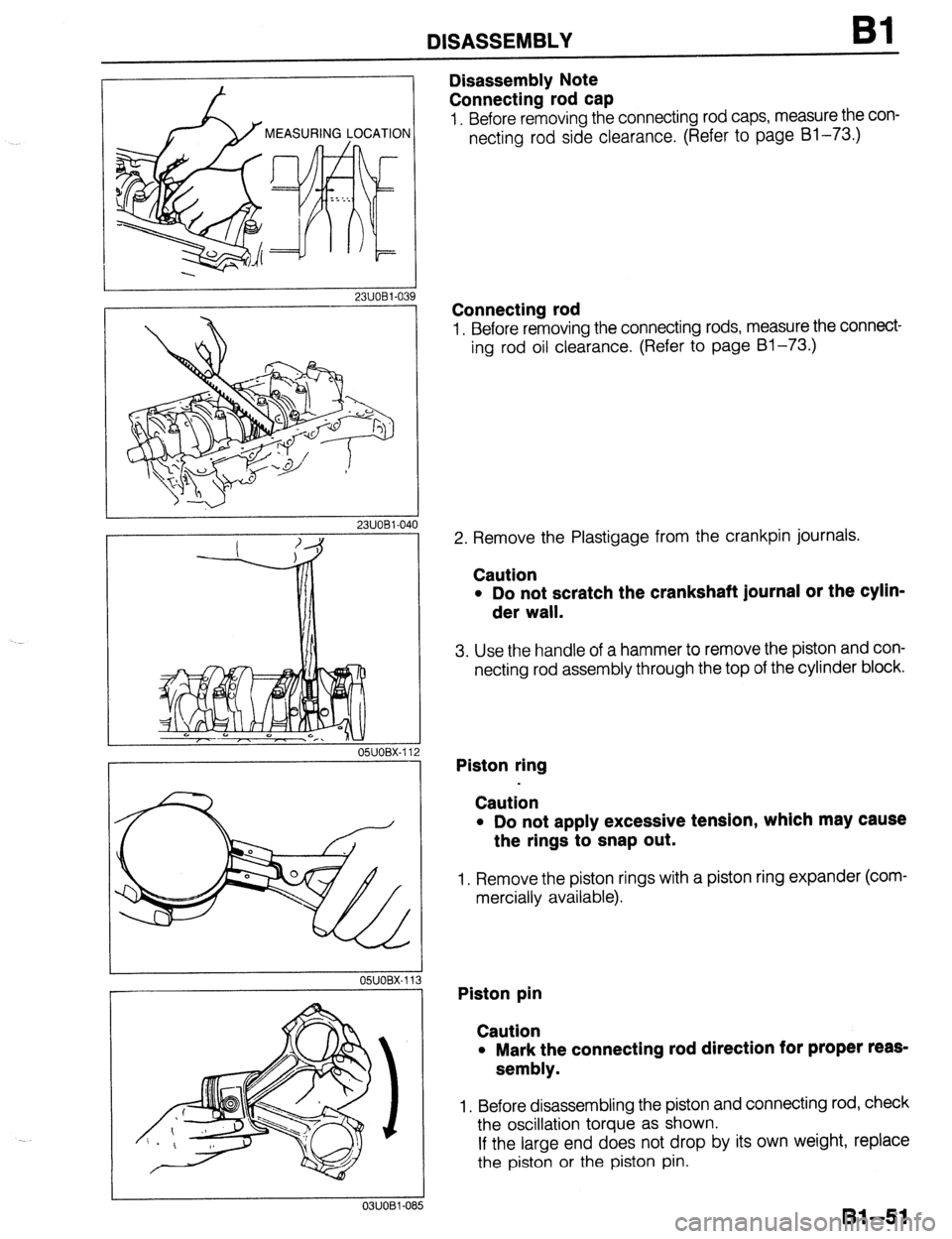

Disassembly Note

Connecting rod cap

1. Before removing the connecting rod caps, measure the con-

necting rod side clearance. (Refer to page Bl-73.)

Connecting rod

1. Before removing the connecting rods, measure the connect-

ing rod oil clearance. (Refer to page Bl-73.)

2. Remove the Plastigage from the crankpin journals.

Caution

l Do not scratch the crankshaft journal or the cylin-

der wall.

3. Use the handle of a hammer to remove the piston and con-

necting rod assembly through the top of the cylinder block.

Piston ring

Caution

l Do not apply excessive tension, which may cause

the rings to snap out.

1. Remove the piston rings with a piston ring expander (com-

mercially available).

Piston pin

Caution

l Mark the connecting rod direction for proper reas-

sembly.

1. Before disassembling the piston and connecting rod, check

the oscillation torque as shown.

If the large end does not drop by its own weight, replace

the piston or the piston pin.

81-51

Page 97 of 1164

ASSEMBLY Bl

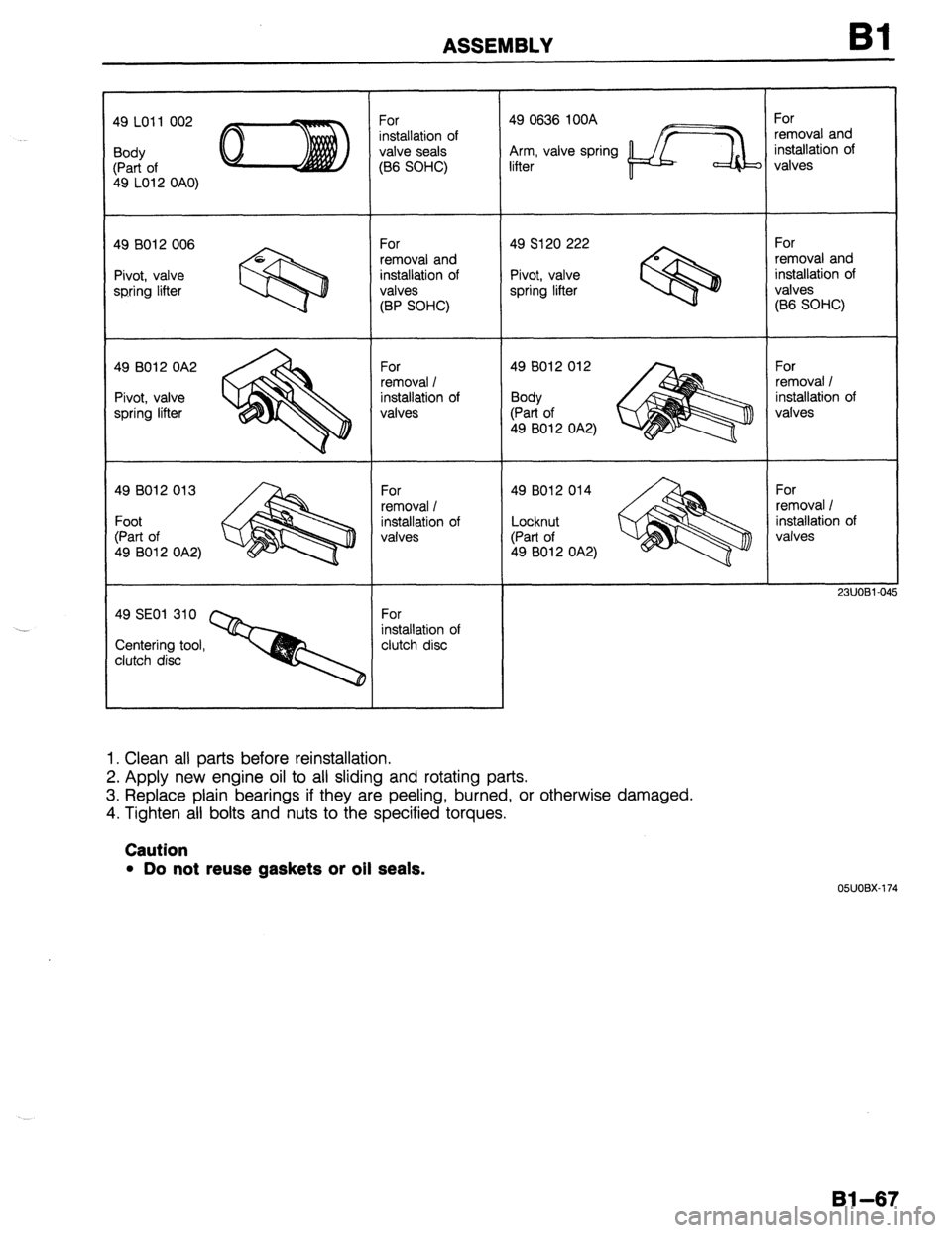

19 LO11 002

Body

:Part of

49 LO12 OAO)

49 8012 006

Pivot, valve

spring lifter

49 8012 OA2

Pivot, valve

spring lifter

49 8012 013

Foot

(Part of

49 B012 OA2)

49 SE01 310

Centering tool,

clutch disc For

installation of

valve seals

(B6 SOHC)

For

removal and

installation of

valves

(BP SOHC)

For

removal I

installation of

valves

For

removal I

installation of

valves

For

installation of

clutch disc 49 0636 1OOA

Arm, valve spring

lifter

49 s120 222

0

Pivot, valve

spring lifter

%

49 8012 012

Body

(Part of

49 8012 OA2)

49 B012 014

Locknut

(Part of

49 8012 OA2)

1. Clean all parts before reinstallation.

2. Apply new engine oil to all sliding and rotating parts.

3. Replace plain bearings if they are peeling, burned, or otherwise damaged.

4. Tighten all bolts and nuts to the specified torques.

Caution

l Do not reuse gaskets or oil seals.

I

3 For

removal and

installation of

valves

For

removal and

installation of

valves

(B6 SOHC)

For

removal I

installation of

valves

For

removal I

installation of

valves

23UOBl-0,

05UOBX-174

Bl-67

Page 98 of 1164

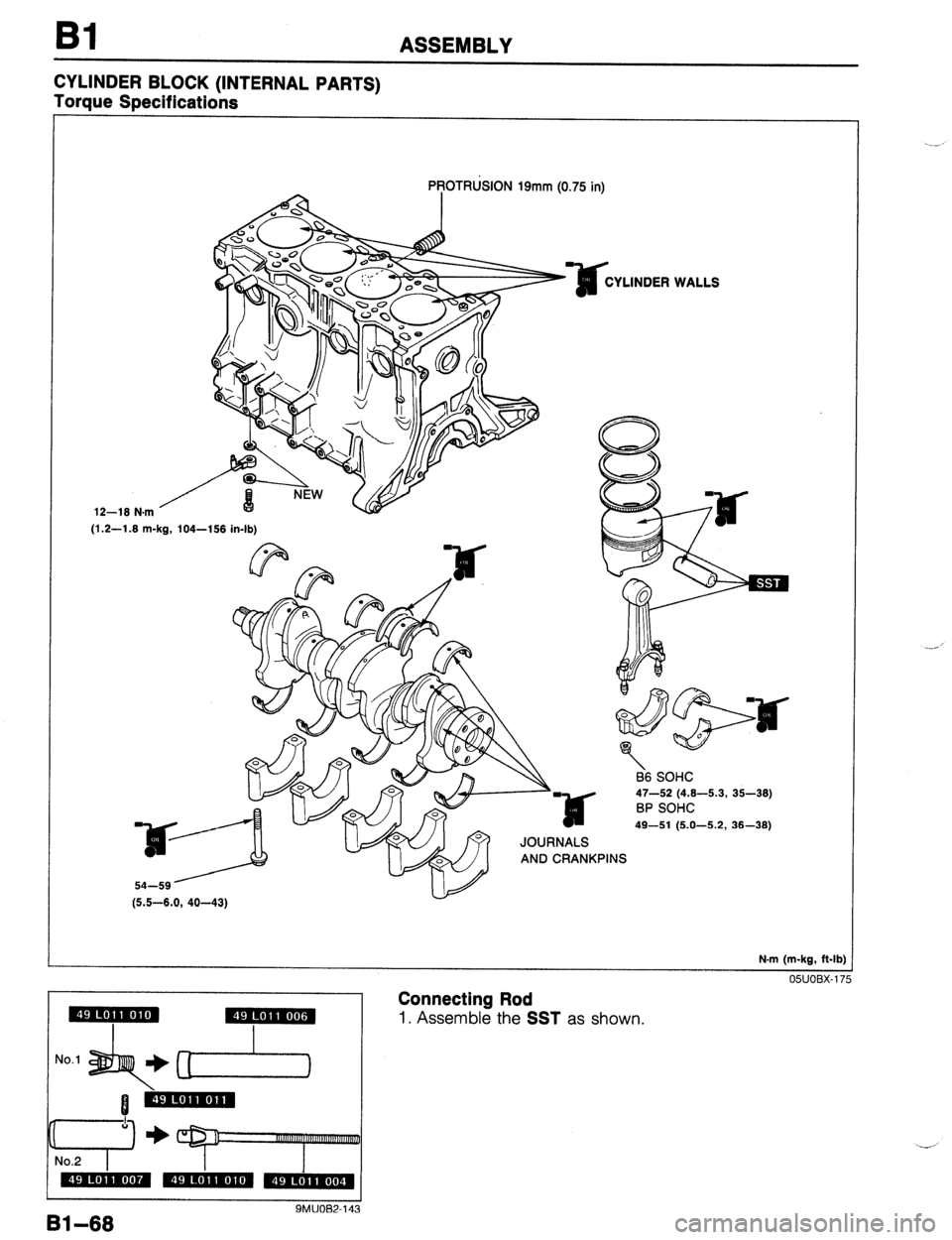

Bl ASSEMBLY

CYLINDER BLOCK (INTERNAL PARTS)

Torque SPecifications

12-18 N.m PROTRLklON 19mm (0.75 in)

YLINDER

(1.2-1.8 m-kg, 104-158 in-lb)

JOURNALS

AND CRANKPINS

(5.5-8.0, 40-43) WALLS

66 SOHC

47-52 (4.8-5.3, 35-38)

BP SOHC

49-51 (5.0-5.2, 36-38)

N.m (m-kg, ft-lb)

05UOBX-171

Connecting Rod

1. Assemble the SST as shown.

9MUOW143

Page 99 of 1164

ASSEMBLY Bl

I-

r

I 03UOBl-12

A NO.1

M

9MUOB2-14 I ‘NDENTIFICATION MARK

03UOBl-02

I

23UOBl-04

05UOBX.179

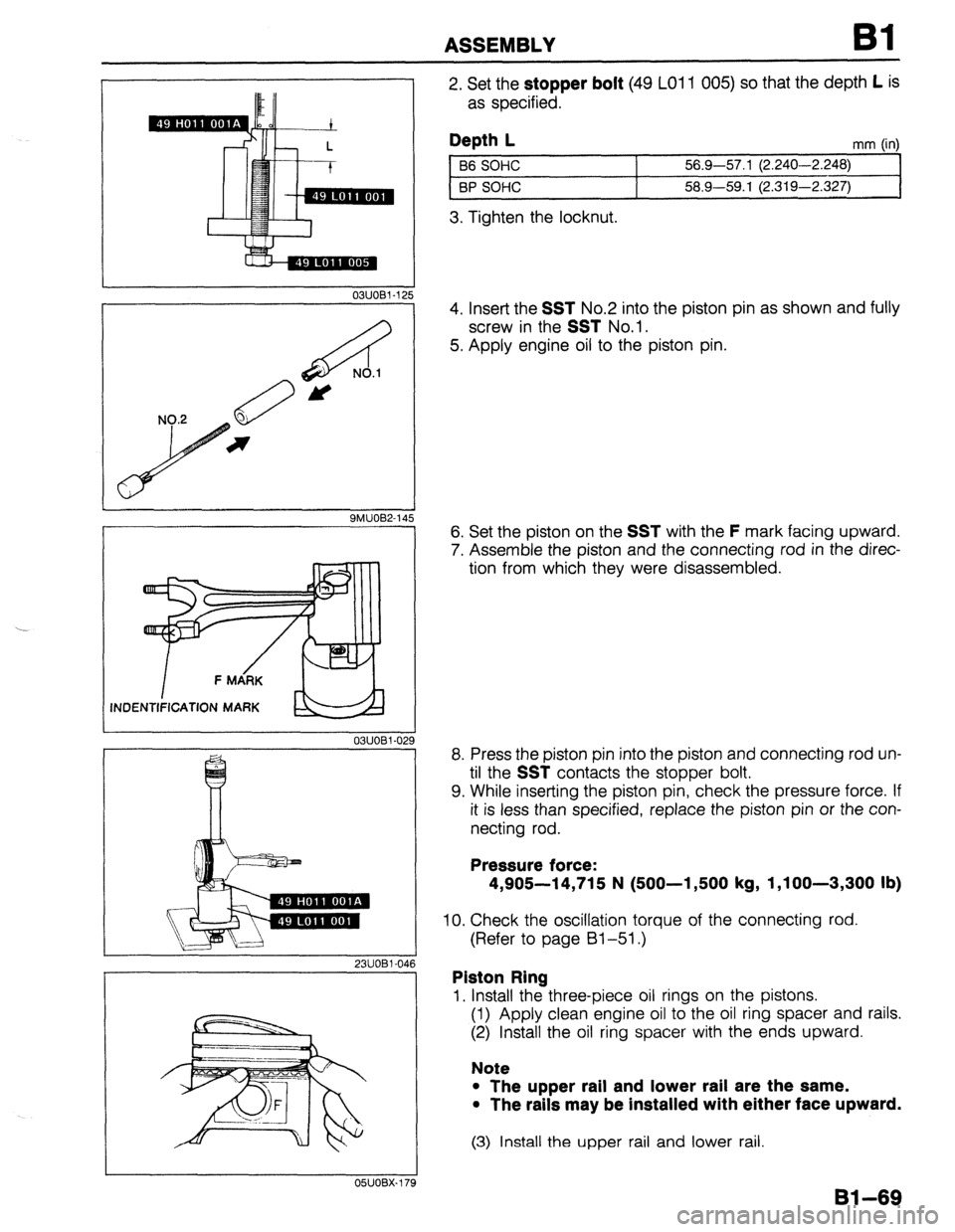

2. Set the stopper bolt (49 LO1 1 005) so that the depth L is

as specified.

Depth L

B6 SOHC

BP SOHC mm (in)

I 56.9-57.1 (2.240-2.248)

58.9-59.1 (2.319-2.327)

3. Tighten the locknut.

4. Insert the

SST No.2 into the piston pin as shown and fully

screw in the

SST No.1.

5. Apply engine oil to the piston pin.

6. Set the piston on the

SST with the F mark facing upward.

7. Assemble the piston and the connecting rod in the direc-

tion from which they were disassembled.

8. Press the piston pin into the piston and connecting rod un-

til the SST contacts the stopper bolt.

9. While inserting the piston pin, check the pressure force. If

it is less than specified, replace the piston pin or the con-

necting rod.

Pressure force:

4,905-14,715 N (500-l ,500 kg, 1 ,lOO-3,300 lb)

10. Check the oscillation torque of the connecting rod.

(Refer to page Bl-51.)

Piston Ring 1,

Install the three-piece oil rings on the pistons.

(1) Apply clean engine oil to the oil ring spacer and rails.

(2) Install the oil ring spacer with the ends upward.

Note

l The upper rail and lower rail are the same.

l The rails may be installed with either face upward. (3) Install the upper rail and lower rail

Bl-69

Page 100 of 1164

Bl ASSEMBLY

SPACER TANG

OIL RING

SPACER ENDS

PISTON

I

05u0Bx-180

R I

OWOBX-18.

81-70

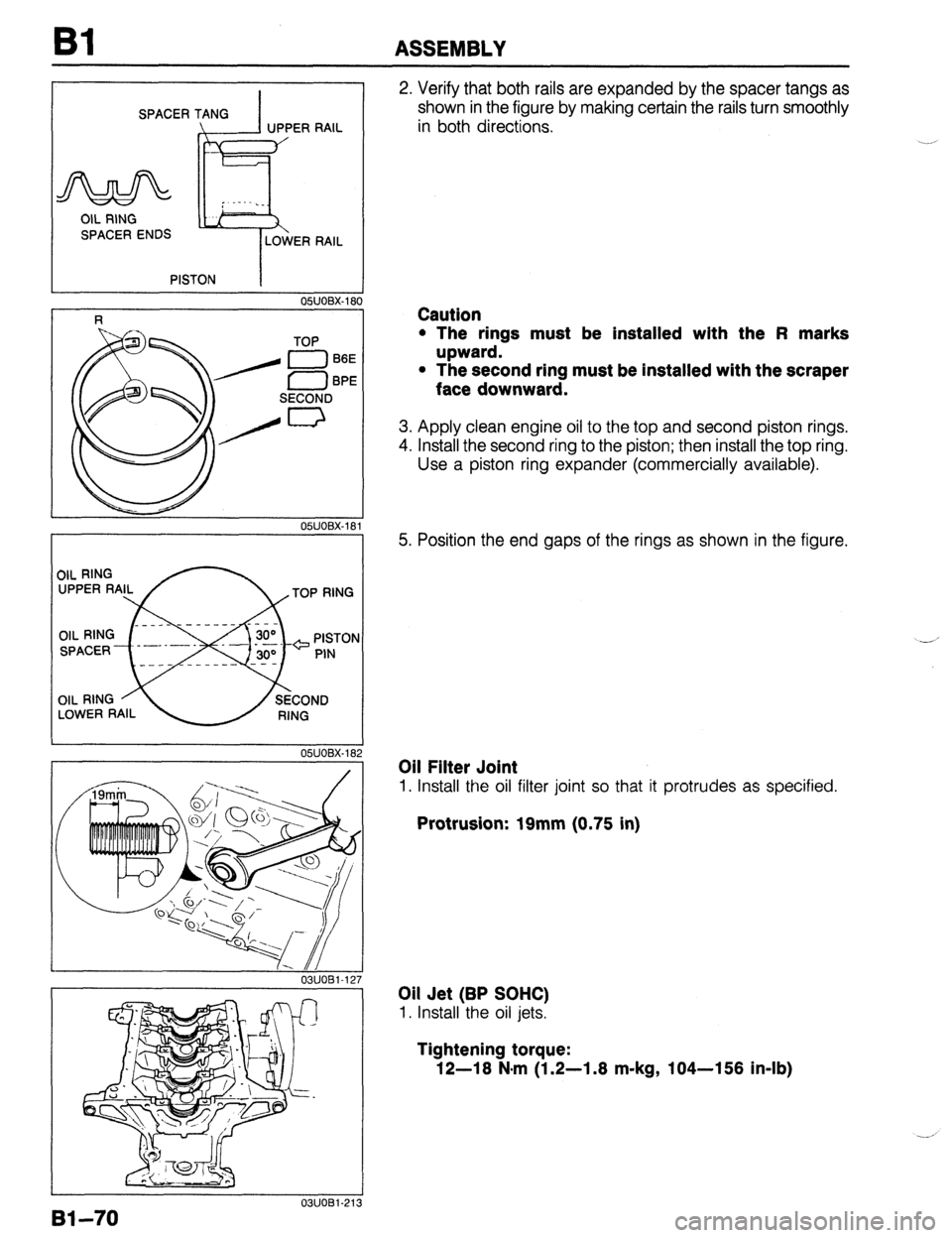

2. Verify that both rails are expanded by the spacer tangs as

shown in the figure by making certain the rails turn smoothly

in both directions.

Caution

l The rings must be installed with the R marks

upward.

l The second ring must be installed with the scraper

face downward.

3. Apply clean engine oil to the top and second piston rings.

4. Install the second ring to the piston; then install the top ring.

Use a piston ring expander (commercially available).

5. Position the end gaps of the rings as shown in the figure.

05UOBX-182 Oil Filter Joint

1. Install the oil filter joint so that it protrudes as specified

03UOBl-21:

Protrusion: 19mm (0.75 in)

Oil Jet (BP SOHC)

1. Install the oil jets.

Tightening torque:

12-18 N*m (1.2-1.8 m-kg, 104-158 in-lb)

Page 101 of 1164

ASSEMBLY

f

05UOW18

THRUST BEARING

OYJOBX-18

05UOBX-18

23UOBl-04

OWOBX-181

Crankshaft

1. Before installing the crankshaft, inspect the main bearing

oil clearances as follows.

Oil clearance inspection

(1) Remove all foreign material and oil from the journals and

bearings.

Caution

l Install the grooved upper main bearings in the cyl-

inder block.

l Install the thrust bearings with the oil groove fac-

ing the crankshaft.

(2) Install the upper main bearings and thrust bearings.

(3) Set the crankshaft in the cylinder block.

Caution

l Do not rotate the crankshaft when measurlng the

oil clearances.

(4) Position Plastigage atop the journals in the axial di-

rection.

(5) Install the lower main bearings and the main bearing

caps according to the cap number and + mark.

(6) Tighten the main bearing cap bolts in two or three steps

in the order shown in the figure.

Tightening torque:

54-59 N-m (5.5-6.0 m-kg, 40-43 ft-lb)

(7) Remove the main bearing caps, and measure the P lasti-

gage at each journal at the widest point for the smallest

clearance and at the narrowest point for the largest

clearance.

(8) If the oil clearance exceeds specification, grind the

crankshaft and use undersize main bearings.

(Refer to page Bl-64.)

Oil clearance: 0.016-0.036mm (0.0007-0.0014 in)

Maximum: O.lOmm (0.004 in)

2. Apply a liberal amount of clean engine oil to the main bear-

ings, thrust bearings and main journals.

3. Install the crankshaft and the main bearing caps accord-

ing to the cap number and + mark.

61-71