engine MAZDA PROTEGE 1992 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 386 of 1164

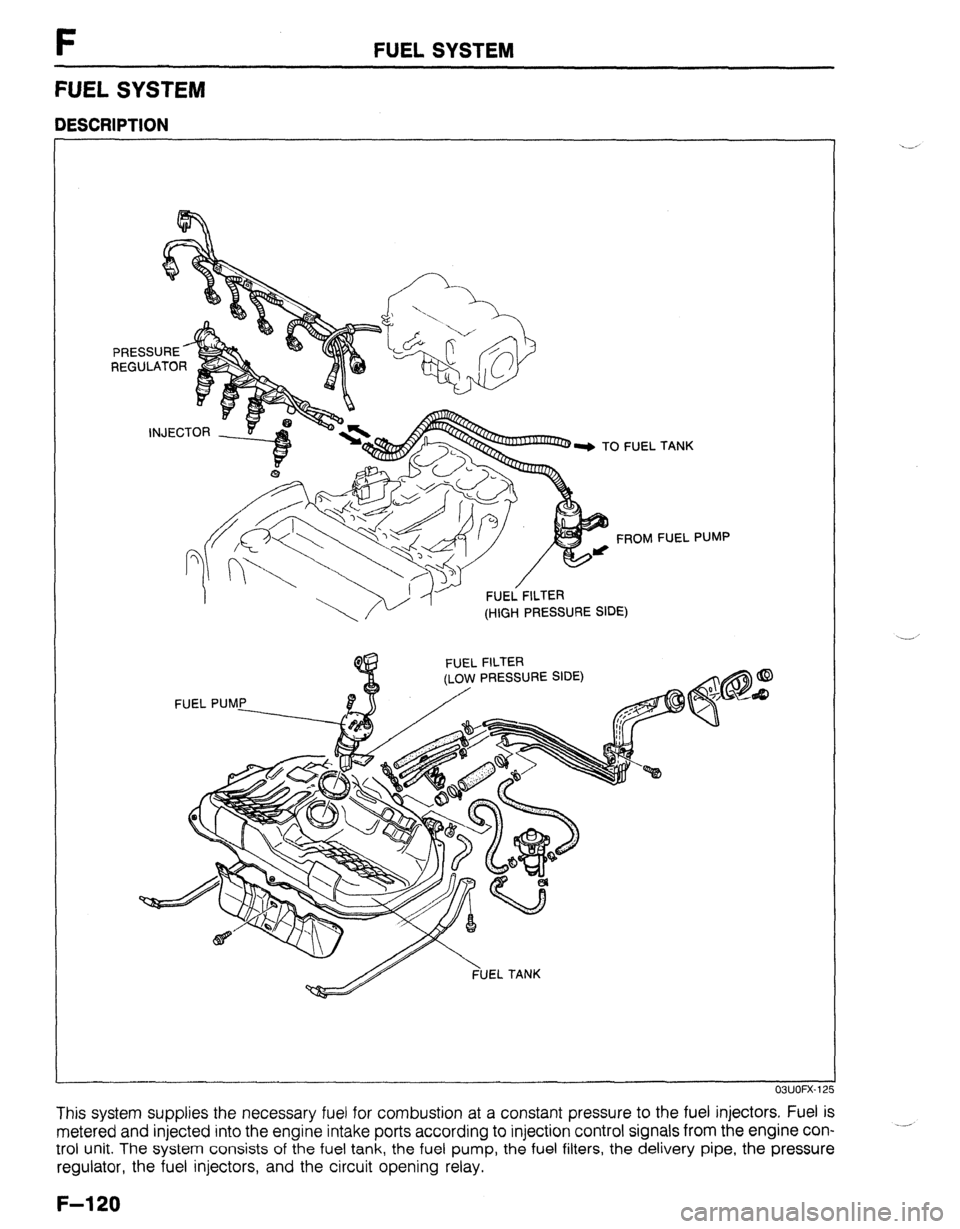

F FUEL SYSTEM

FUEL SYSTEM

DESCRIPTION

FUEL FILTER

(HIGH PRESSURE SIDE) . TANK

FUEL PUMP

PRESSURE SIDE)

OWOFX-12

This system supplies the necessary fuel for combustion at a constant pressure to the fuel injectors. Fuel is

metered and injected into the engine intake ports according to injection control signals from the engine con-

trol unit. The system consists of the fuel tank, the fuel pump, the fuel filters, the delivery pipe, the pressure

regulator, the fuel injectors, and the circuit opening relay. ._*

F-l 20

Page 387 of 1164

FUEL PUMP CONNECTOR

/

REAR SEAT C

FUEL SYSTEM F

PRECAUTION

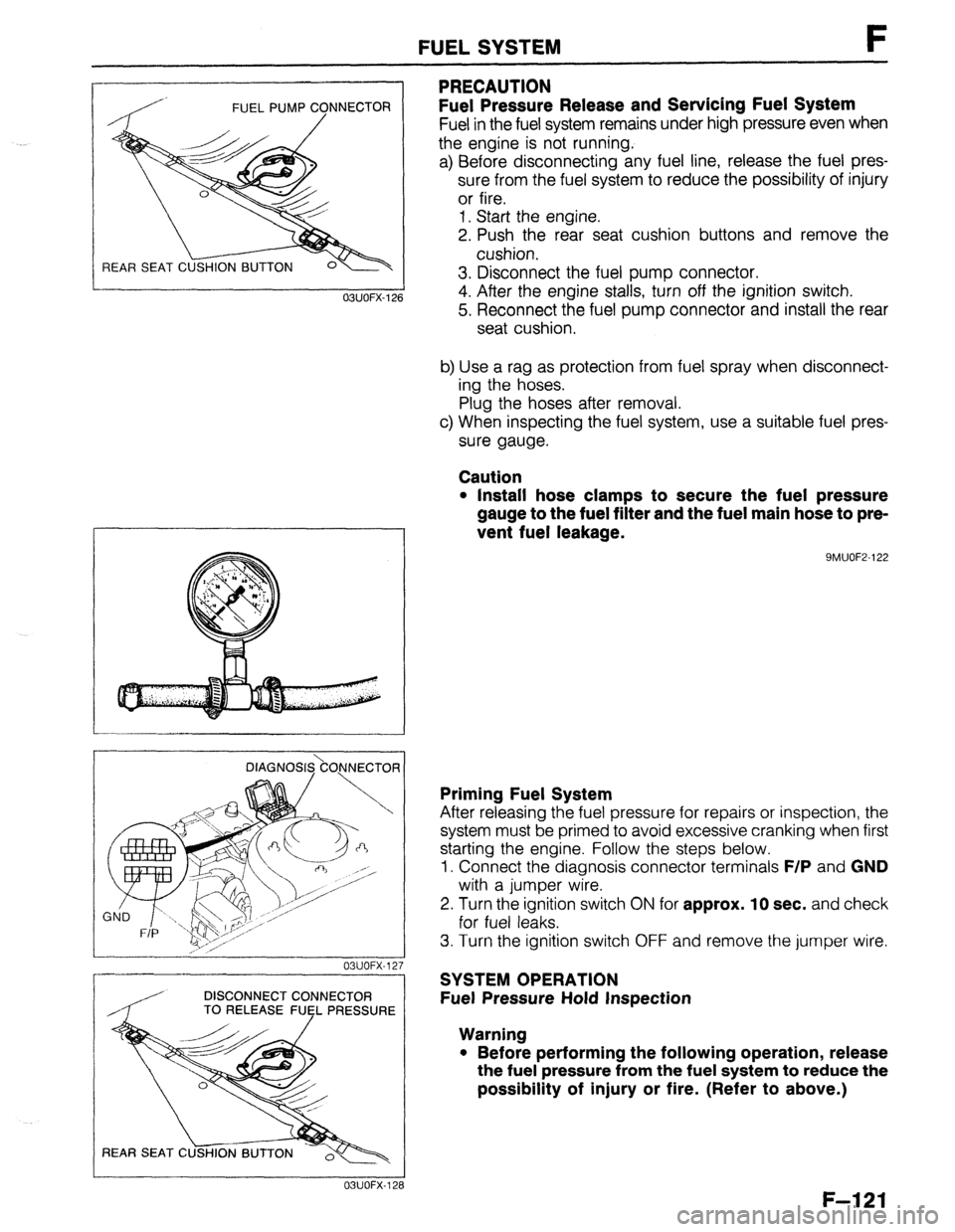

Fuel Pressure Release and Servicing Fuel System

Fuel in the fuel system remains under high pressure even when

the engine is not running.

a) Before disconnecting any fuel line, release the fuel pres-

sure from the fuel system to reduce the possibility of injury

or fire.

1. Start the engine.

2. Push the rear seat cushion buttons and remove the

cushion.

3. Disconnect the fuel pump connector.

4. After the engine stalls, turn off the ignition switch.

5. Reconnect the fuel pump connector and install the rear

seat cushion.

b) Use a rag as protection from fuel spray when disconnect-

ing the hoses.

Plug the hoses after removal.

c) When inspecting the fuel system, use a suitable fuel pres-

sure gauge.

Caution

l Install hose clamps to secure the fuel pressure

gauge to the fuel filter and the fuel main hose to pre-

vent fuel leakage.

9MUOF2-122 OBUOFX-126

DlAGNOS&O,NNECTOR

03UOFX-12.

-

DISCONNECT CONNECTOR

/ TO RELEASE FUEL PRESSURE

03UOFX-12;

Priming Fuel System

After releasing the fuel pressure for repairs or inspection, the

system must be primed to avoid excessive cranking when first

starting the engine. Follow the steps below.

1. Connect the diagnosis connector terminals

F/P and GND

with a jumper wire.

2. Turn the ignition switch

ON for approx. 10 sec. and check

for fuel leaks.

3. Turn the ignition switch OFF and remove the jumper wire.

SYSTEM OPERATION

Fuel Pressure Hold Inspection

Warning

l Before performing the following operation, release

the fuel pressure from the fuel system to reduce the

possibility of injury or fire. (Refer to above.)

F-121

Page 395 of 1164

FUEL SYSTEM F

STA

OBUOFX- 15

03UOFX-15

DISCONNECT CONNECTOR

TO RELEASE FUfL PRESSURE

REAR SEAT C

23UOFX-11

INSTALL CLAMPS

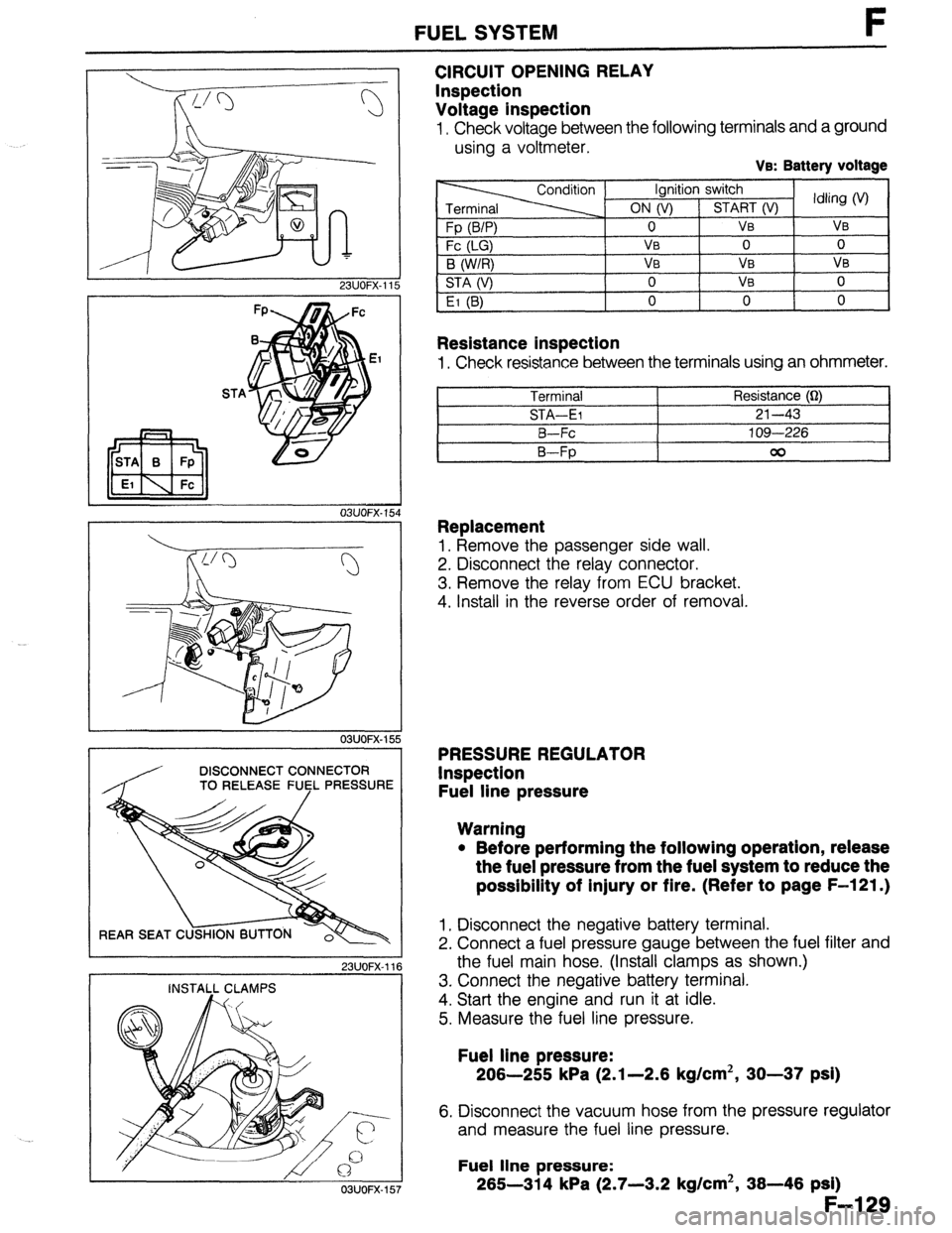

CIRCUIT OPENING RELAY

Inspection

Voltage inspection

I, Check voltage between the following terminals and a ground

using a voltmeter.

Ve: Battery voltage

Resistance inspection

1, Check resistance between the terminals using an ohmmeter.

Terminal Resistance (Q)

STA-El 21-43

B-Fc 109-226

B-Fp 00

Replacement

1, Remove the passenger side wall.

2. Disconnect the relay connector.

3. Remove the relay from ECU bracket.

4. Install in the reverse order of removal.

PRESSURE REGULATOR

Inspection

Fuel line pressure

Warning

l Before performing the following operation, release

the fuel pressure from the fuel system to reduce the

possibility of injury or fire. (Refer to page F-121.)

1, Disconnect the negative battery terminal.

2. Connect a fuel pressure gauge between the fuel filter and

the fuel main hose. (Install clamps as shown.)

3. Connect the negative battery terminal.

4. Start the engine and run it at idle.

5. Measure the fuel line pressure.

Fuel line pressure:

206-255 kPa (2.1-2.6 kg/cm2, 30-37 psi)

6. Disconnect the vacuum hose from the pressure regulator

and measure the fuel line pressure.

Fuel line pressure:

265-314 kPa (2.7-3.2 kg/cm2, 36-46 psi)

F-l 29

03UOFX-157

Page 397 of 1164

231JOFX-1

FUEL SYSTEM F

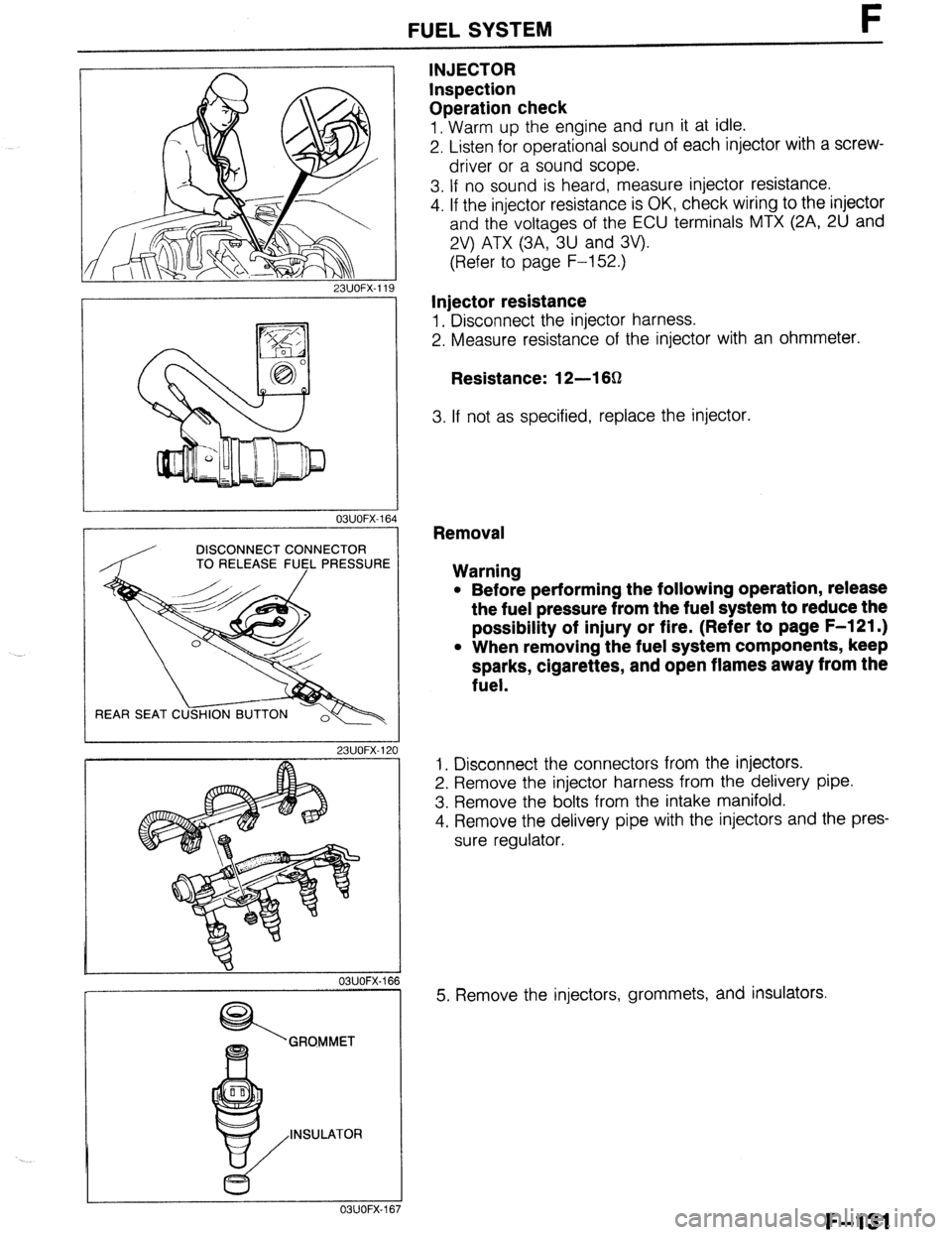

INJECTOR

Inspection

Operation check

1. Warm up the engine and run it at idle.

2. Listen for operational sound of each injector with a screw-

driver or a sound scope.

3. If no sound is heard, measure injector resistance.

4. If the injector resistance is OK, check wiring to the injector

and the voltages of the ECU terminals MTX (2A, 2U and

2V) ATX (3A, 3U and 3V).

(Refer to page F-152.)

Injector resistance

1. Disconnect the injector harness.

2. Measure resistance of the injector with an ohmmeter.

Resistance: 12-l 6Q

3. If not as specified, replace the injector.

03UOFX-1

DISCONNECT CONNECTOR

TO RELEASE FU5L PRESSUR

REAR SEAT C

23UOFX-1

OBUOFX-

GRQMMET

INSULATOR

c5

OSUOFX-

Removal

Warning

l Before performing the following operation, release

the fuel pressure from the fuel system to reduce the

possibility of injury or fire. (Refer to page F-121 .)

l When removing the fuel system components, keep

sparks, cigarettes, and open flames away from the

fuel.

1. Disconnect the connectors from the injectors.

2. Remove the injector harness from the delivery pipe.

3. Remove the bolts from the intake manifold.

4. Remove the delivery pipe with the injectors and the pres-

sure regulator.

5. Remove the injectors, grommets, and insulators.

F-131

Page 399 of 1164

FUEL SYSTEM I-

9MUOF2-17

INJEC

GRO

,:.: ‘.L.. :

,;:y :.*‘.

+:: ..y&

..: .:: ,: ,:y>

‘$pID~~ :i

..,..:,:,

,.,i. :)I,

./[::/: :

. ...:;.

/jj,.‘, ;.::,::

.’ .::: ij!/ji..

OSUOFX-17

T MANIFOLD DELIVERY’ PIPE

MUOFX-17

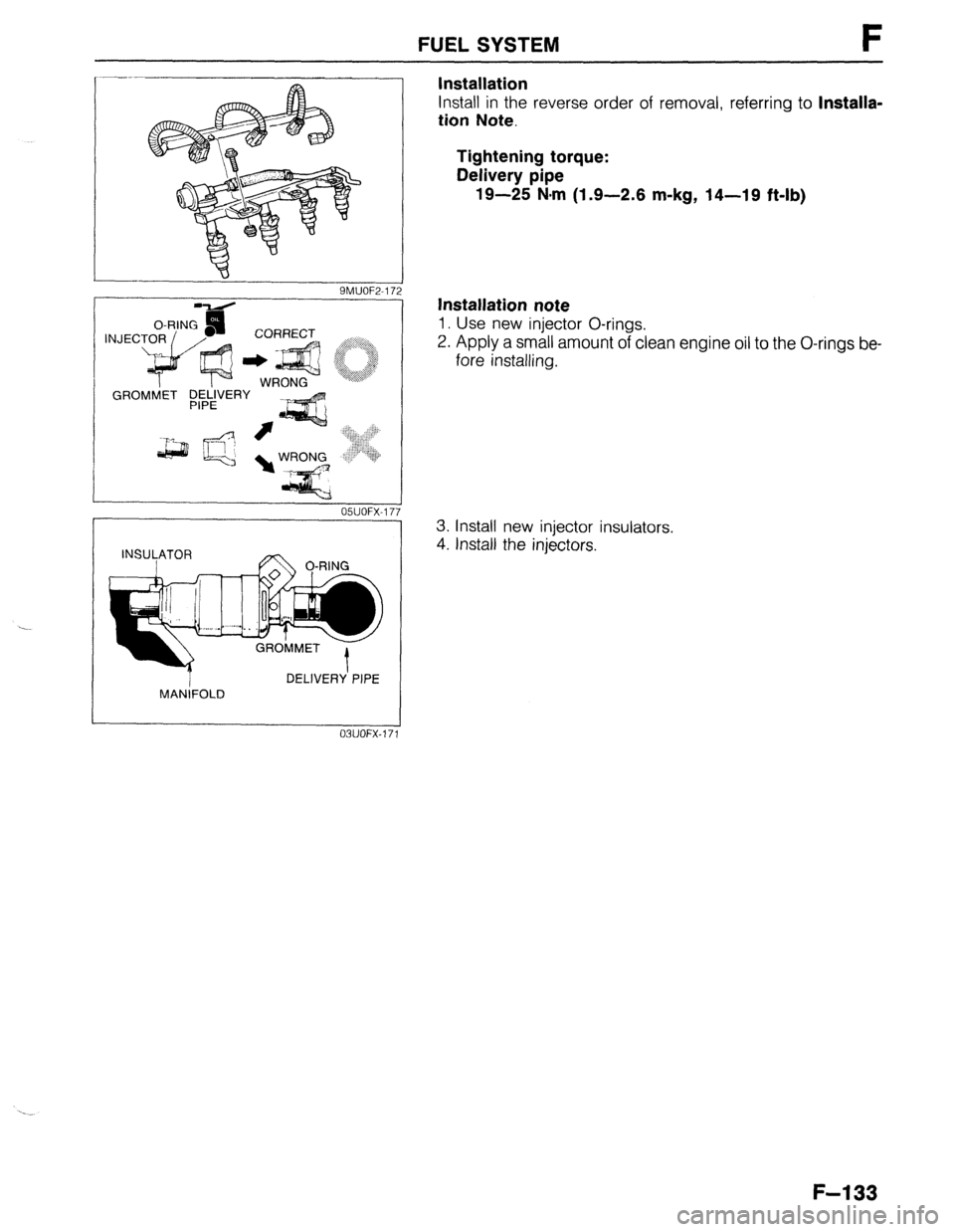

Installation

Install in the reverse order of removal, referring to Installa-

tion Note.

Tightening torque:

Delivery pipe

19-25 N.m (1.9-2.6 m-kg, 14-19 ft-lb)

Installation note

1. Use new injector O-rings.

2. Apply a small amount of clean engine oil to the O-rings be-

fore installing.

3. Install new injector insulators.

4. Install the injectors.

F-l 33

Page 400 of 1164

F PRESSURE REGULATOR CONTROL SYSTEM

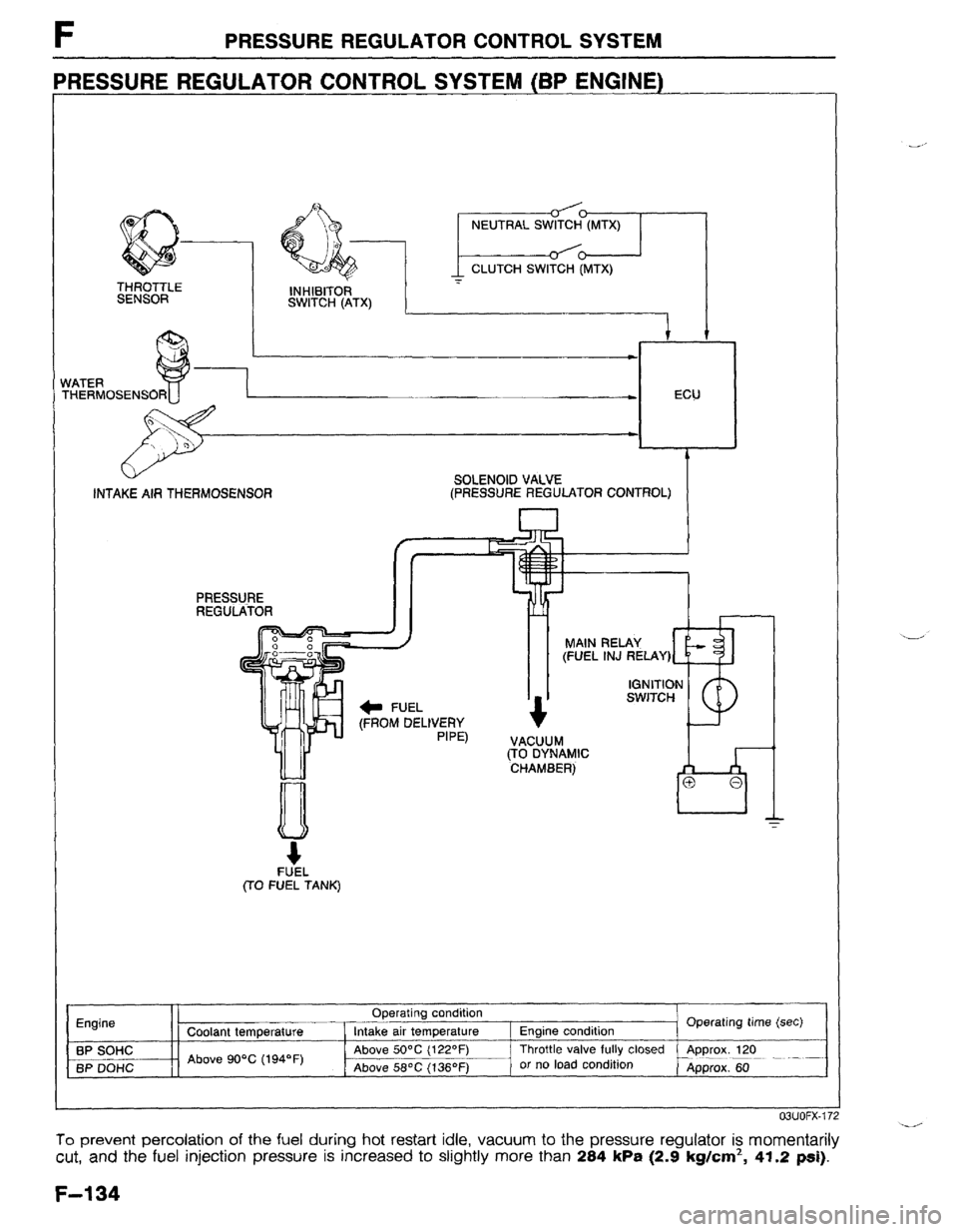

PRESSURE REGULATOR CONTROL SYSTEM (BP ENGINE)

THERMOSEN

SOLENOID VALVE

(PRESSURE REGULATOR CONTROL)

(FROM DELIVERY

FUEL

(TO FUEL TANK)

Engine

BP SOHC

BP DOHC Coolant temperature

Above 90% (194*F) Operating condition

Intake air temperature

Above 50°C (122OF)

Above 58OC (136OF) Engine condition . Operating time (set)

Throttle valve fully closed

Approx. 120

or no load condition

Approx. 60

#.nr IAt-%/ 4 7

To prevent percolation of the fuel during hot restart idle, vacuum to the pressure regulator is momentarily

cut, and the fuel injection pressure is increased to slightly more than 284 kPa (2.9 kg/cm2, 41.2 psi).

F-l 34

Page 401 of 1164

PRESSUREREGULATORCONTROLSYSTEM F

03UOFX-17

*

03UOFX-14!

OSUOFX-17

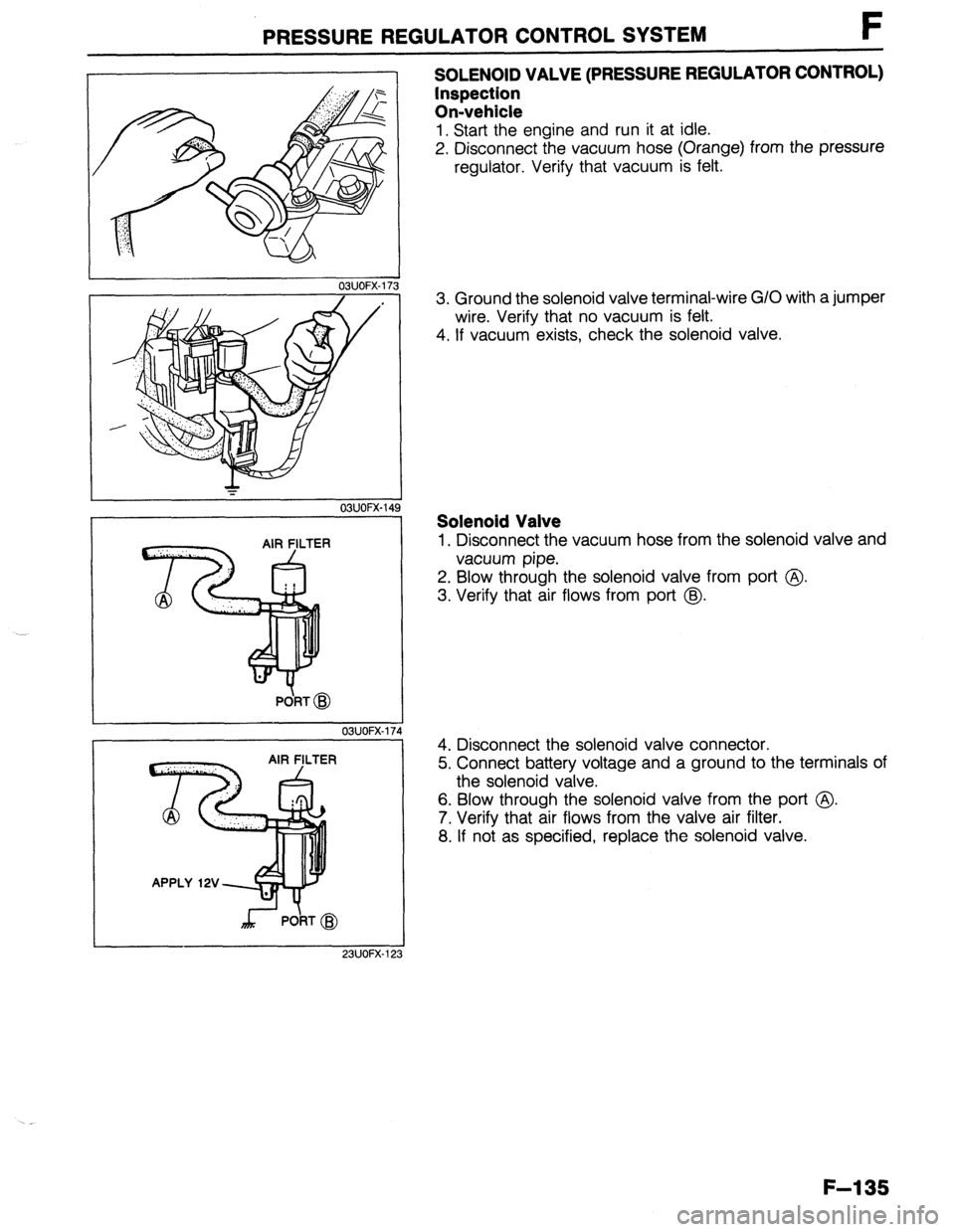

SOLENOID VALVE (PRESSURE REGULATOR CONTROL)

Inspection

On-vehicle

1. Start the engine and run it at idle.

2. Disconnect the vacuum hose (Orange) from the pressure

regulator. Verify that vacuum is felt.

3. Ground the solenoid valve terminal-wire G/O with a jumper

wire. Verify that no vacuum is felt.

4. If vacuum exists, check the solenoid valve.

Solenoid Valve

1. Disconnect the vacuum hose from the solenoid valve and

vacuum pipe.

2. Blow through the solenoid valve from port @

3. Verify that air flows from port @.

4. Disconnect the solenoid valve connector.

5. Connect battery voltage and a ground to the terminals of

the solenoid valve.

6. Blow through the solenoid valve from the port @.

7. Verify that air flows from the valve air filter.

8. If not as specified, replace the solenoid valve.

F-l 35

Page 404 of 1164

F POSITIVE CRANKCASE VENTILATION (PCV) SYSTEM

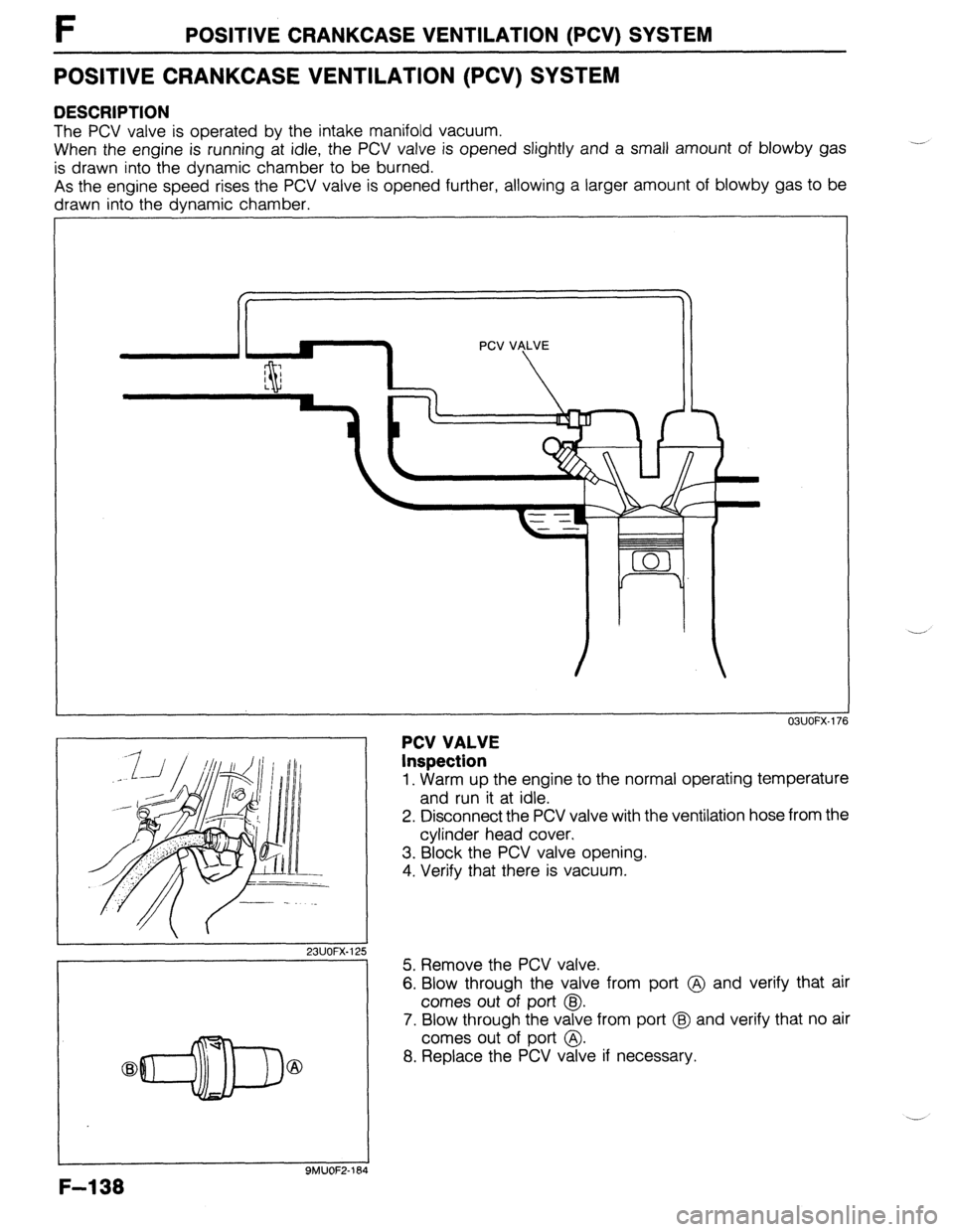

POSITIVE CRANKCASE VENTILATION (PCV) SYSTEM

DESCRIPTION

The PCV valve is operated by the intake manifold vacuum.

When the engine is running at idle, the PCV valve is opened slightly and a small amount of blowby gas

is drawn into the dynamic chamber to be burned.

As the engine speed rises the PCV valve is opened further, allowing a larger amount of blowby gas to be

drawn into the dynamic chamber.

23UOFX.1; !5

-7

F-l 38

9MUOF2-164

PCV VALVE

Inspection

OBUOFX-176

1. Warm up the engine to the normal operating temperature

and run it at idle.

2. Disconnect the PCV valve with the ventilation hose from the

cylinder head cover,

3. Block the PCV valve opening.

4. Verify that there is vacuum.

5. Remove the PCV valve.

6. Blow through the valve from port @ and verify that air

comes out of port @I.

7. Blow through the valve from port @ and verify that no air

comes out of port @.

8. Replace the PCV valve if necessary.

Page 405 of 1164

EVAPORATIVE EMISSION CONTROL SYSTEM t

EVAPORATIVE EMISSION CONTROL SYSTEM

DESCRIPTION

/ /

ENGINE ENGINE

CONTROL CONTROL - INPUT - INPUT

UNIT UNIT

- -

SOLENOID VALVE SOLENOID VALVE k k / /

CHECK VALVE CHECK VALVE

(TWO-WAY) (TWO-WAY)

CHARCOAL CHARCOAL

CANISTER CANISTER

CHECK-AND-CUTC CHECK-AND-CUTC

VALVE VALVE

SEPARATOR SEPARATOR TO ENGINE TO ENGINE SIGNALS

The evaporative emission control system consists of the separator, the check-and-cut valve, the two-way

check valve, the charcoal canister, the purge control solenoid valve, the engine control unit (ECU), and the

input devices. The amount of evaporative fumes introduced into the engine and burned is controlled by the

solenoid valve to correspond to the engine’s operating conditions. To maintain best engine performance,

the solenoid valve is controlled by the ECU.

Operation

.._ The solenoid valve (purge control) is controlled by duty signals from the ECU to perform purging of the char-

coal canister. Purging is done when these conditions are met:

(1) After warm-up

(2) Driving in gear

(3) Accelerator pedal depressed (idle switch OFF)

(4) Oxygen sensor functioning normally

F-l 39

Page 406 of 1164

F EVAPORATIVE EMISSION CONTROL SYSTEM

03UOFX-17! 3

03UOFX-180

INSTALLATION DIRECTION

F-l 40

I

23UOFX-126

03UOFX-18

OSUOFX-l&

SYSTEM OPERATION

1 Warm up the engine to normal operating temperature and

run it at idle.

2. Disconnect the vacuum hose from the solenoid valve as

shown in the figure, and verify that no vacuum is felt at the

solenoid valve. -.

3. If not as specified, check the solenoid valve.

SOLENOID VALVE (PURGE CONTROL)

Inspection

1. Disconnect the vacuum hoses from the solenoid valve.

2. Verify that no air flows through the valve.

3. Disconnect the solenoid valve connector and supply bat-

tery voltage as shown in the figure.

4. Verify that air flows through the valve.

5. If not as specified, replace the solenoid valve.

SEPARATOR

Inspection

1. Remove the left side trim.

2. Remove the separator.

3. Visually check the separator for damage. Replace it if

necessary.

CHECK VALVE (TWO-WAY)

Inspection

1. Remove the valve.

2. Check the operation of the valve with a vacuum pump.

Apply approx. 37 mmHg (1.46 inHg)

vacuum at port A Airflow

Apply approx. 44 mmHg (1.73 inHg)

vacuum at port B Airflow