engine MAZDA PROTEGE 1992 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 475 of 1164

OUTLINE, TROUBLESHOOTING GUIDE

OUTLINE

SPECIFICATIONS

-

-

Item

Clutch control Engine/Transaxle B6 SOHC BP SOHC BP DOHC

F!Wl-R GBM-R Hvdraulic

Clutch cover

Clutch disc Type

Set load Diaphragm spring

N

(kg, lb) 1 3,630 (370, 814) 1 3,826 (390, 858) 1 3,846 (392, 862)

30 17.48)

200 (7.87) 215 (8.46) Outer diameter mm (in)

Inner diameter mm (in)

Pressure plate

side mm (in)

Thickness

Flywheel side

mm lit-d

1! , I

130 (5.12) ’ ’

150 i5.91 j

3.5 (0.138) 3.8 (0.150)

3.5 (0.138)

Type Suspended

Clutch pedal

Master cylinder

Release cylinder

Clutch fluid Pedal ratio 6.55

Full stroke mm (in) 135 (5.32)

Height (With carpet)

mm (in) 196-204 (7.72-8.03)

Inner diameter mm (in) 15.87 (0.625)

Inner diameter

mm (in) 19.05 (0.750)

SAE J1703 or FMVSS116 DOT-3

23UOHX-003

TROUBLESHOOTING GUIDE Problem Possible Cause Remedy Page

Slipping

Clutch disc facing worn excessively Replace H-15, 17

Clutch disc facing surface hardened or oil on surface Repair or replace H-15

Pressure plate damaged Repair or replace H-15

Diaphragm spring damaged or weakened Replace H-15

Insufficient clutch pedal play Adjust H- 5

Clutch pedal sticking Repair or replace H- 6

Flywheel damaged Repair or replace H-15, 17 Faulty disen-

Excessive runout or damaged clutch disc Replace H-15, 17 gagement Clutch disc splines rusted or worn Remove rust or replace H-15

Oil on facing Repair or replace H-15

Diaphragm spring weakened Replace H-15

Excessive clutch pedal play Adjust H- 5

Insufficient clutch fluid

Add fluid H- 3

Leakage of clutch fluid Locate and repair or -

replace Clutch vibrates

Oil on facing Repair or replace H-15 when accelerating Torsion rubbers weakened Replace H-15

Clutch disc facing hardened or damaged Repair or replace H-15

Clutch disc facing rivets loose Replace H-15

Pressure plate damaged or excessive runout Replace H-15

Flywheel surface hardened or damaged Repair or replace H-15

Loose or worn engine mount Tighten or replace - Clutch pedal

Pedal shaft not properly lubricated Lubricate or replace H- 6 sticking

Abnormal noise

Clutch release bearing damaged Replace H-15, 17

Poor lubrication of release bearing sleeve Lubricate or replace H-15

Torsion rubbers weakened Replace H-15

Excessive crankshaft end play Repair Refer to Section E

Pilot bearing worn or damaged Replace H-15, 18

Worn pivot points of release fork Repair or replace H-15

^^. .^. I~, ^r

H-3

Page 486 of 1164

H CLUTCH RELEASE CYLINDER, CLUTCH UNIT

Disassembly Note

Piston and cup assembly

Caution

l Hold a rag over the release cylinder to prevent the

piston and cup assembly from suddenly popping

out.

1. Remove the piston and cup assembly by applying com-

pressed air through the clutch pipe installation hole.

I

I

13UOHX-017

CLUTCH UNIT

PREPARATION

SST

49 EOll IA0

Brake set,

ring gear

49 EOll 104

Collor

(Part of

49 EOl 1 1 AO)

49 SE01 310A

Clutch disc

centering tool

49 1285 073

Chuck

IPart of

b9 1285 071) For

prevention of

engine rotation 49 EOll 103

Shaft

(Part of

49 EOl 1 1 AO)

For 49

EOI 1 105 prevention of

engine rotation Stopper 453

(Part of

49 EOl 1 IA0

4

For

installation of

clutch disc 49 1285 071

Puller, bearing

For

removal of pilot

bearing For

prevention of

engine rotation

For

prevention of

engine rotation

23UOHX-013

For

removal of pilot

H-14

Page 493 of 1164

OUTLINE Jl

OUTLINE

SPECIFICATIONS

c EnginelTransaxle

B6 SOHC BP SOHC

Item FSM-R

I

Transaxle control

I Floor shift

Synchromesh system Forward: Synchromesh

Reverse: Selective sliding

1 1st

I 3.416

2nd 1.842

I

Gear ratio

4th

Final aear ratio 5th

Reverse I

0.918

0.731

3.214

4.105 3.619

Grade

I API service GL-4

Oil Viscosity

I SAE 75W-90

Capacity liters (US qt, Imp qt) 2.68 (2.83, 2.36)

13UOJl-00

Jl-3

Page 496 of 1164

Jl TROUBLESHOOTING GUIDE

TROUBLESHOOTING GUIDE

Problem

Shift lever won’t shift

smoothly or is hard

to shift

Too much play in

shift lever

I------

Difficult to shift

Won’t stay in gear

Abnormal noise

I

Possible cause

Seized shift lever ball

Seized change control rod joint

Bent change control rod

Worn change control rod bushing

Weak shift lever ball spring

Worn shift lever ball bushing

Bent change rod

No grease in transaxle control

Insufficient oil

Deterioration of oil quality

Wear or play of shift fork or shift rod

Worn synchronizer ring

Worn synchronizer cone of gear

Bad contact of synchronizer ring and cone of gear

Excessive longitudinal play of gears

Worn bearing

Worn synchronizer key spring

Excessive primary shaft gear bearing preload

improperly adjusted change guide plate

Bent change control rod

Worn change control rod bushing

Weak shift lever ball spring

improperly installed extension bar

Worn shift fork

Worn clutch hub

Worn clutch hub sleeve

Worn gear sliding part of both shaft gears

Worn gear sliding part of each gear

Worn steel sliding groove of control end

Weak spring pressing against steel ball

Excessive thrust clearance

Worn bearing

Improperly installed engine mount

Insufficient oil

Deterioration of oil quality

Worn bearing

Worn sliding surfaces of gears or shafts

Excessive gear backlash

Damaged gear teeth

Foreign material in gears

Damaged differential gear or excessive backlash Remedy Replace

Replace

Replace

Replace

Replace

Replace

Replace

Lubricate with grease

Add oil

Replace with oil of

specified quality

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Adjust

Adjust

Replace

Replace

Replace

Tighten

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Replace

Tighten

Add oil

Replace

Adjust or replace

Replace

Replace

Replace with oil of

specified quality

Replace

Adjust or replace Page Jl-56

Jl-56

Jl-56

Jl-56

Jl-56

Jl-56

Jl-56

Jl-56

Jl- 7

Jl- 7

Jl-14

Jl-22, 24

Jl-22, 24

Jl-22, 24

Jl-22, 24

Jl-22, 24

Jl-22, 24

Jl-36

Jl-17

Jl-56

Jl-56

Jl-56

Jl-56

Jl-14

Jl-22, 24

Jl-22, 24

Jl-22, 24

Jl-22, 24

Jl-14

Jl-14

Jl-22, 24

Jl-22, 24

Jl-48

Jl- 7

Jl- 7

Jl-22, 24

Jl-22, 24

Jl-22, 24

Jl-22, 24

Jl-22, 24

Jl-53

03UOJl-OC --

-../

51-6

Page 498 of 1164

Jl TRANSAXLE

TRANSAXLE

PREPARATION

SST

19 GO17 5A0

support of engine removal of tie-rod

19 0107 680A

Hanger, transaxle

49 F401 440

49 BOO1 795

49 0839 42%

removal of gears

49 GO30 370

49 F401 366A

49 F401 3308

49 F401 335A -.,

.J

Page 501 of 1164

TRANSAXLE Jl

1. Wheel and tire

2. Splash shield

3. Air hose and resonance chamber

4. Battery

5. Battery carrier

6. Speedometer cable

7. Back-up light switch connector

8. Neutral switch connector

9. Ground

10. Starter

11. Extension bar

12. Control rod

13. Engine mount member

Removal Note . . . . . . . . . . . . . . . . . . . . . . 14. Exhaust pipe

15. Engine mount No.2

16. Clutch release cvlinder

Removal Note . . . . . . . . . . . . . . . . . . . . . . . . . . . page Jl-1 1

17. Tie-rod end

Removal Note . . . . . . . . . . . . . . . . . . . . . . . . page Jl-12

18. Stabilizer (BP SOHC)

19. Driveshaft

Removal Note . . . . . . . . . . . . . . . . . . . . . . . . . . . page Jl-12

20. Engine mount No.4

21. Transaxle

Removal Note . . . . . . . . . . . . . . . . . . . . . . . . . . . page Jl-12

page Jl-11

03UOJl-012

Removal Note

Engine mount member

1. Suspend the engine with the SST and remove the engine

mount member.

03UOJ2-015 Clutch release cylinder

Caution

l Do not damage the clutch pipe.

1. Remove the bolts shown.

2. Lay aside the clutch release cylinder and the clutch pipe

when removing the transaxle.

03UOJl-013

,Jl-11

Page 502 of 1164

Jl TRANSAXLE

L

r

r

23UOJl-002

03lJOJl-016

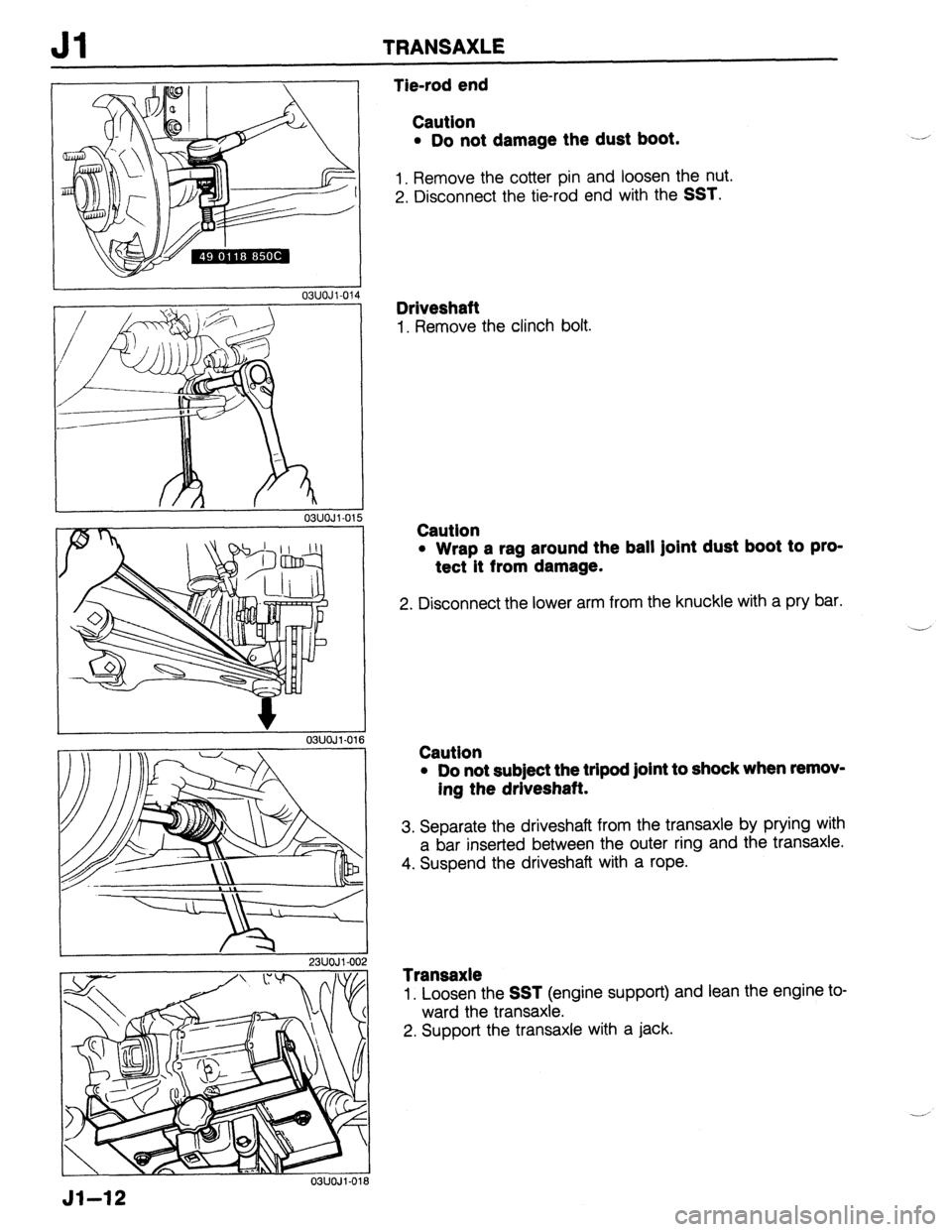

Tie-rod end

Caution

l Do not damage the dust boot.

1. Remove the cotter pin and loosen the nut.

2. Disconnect the tie-rod end with the

SST.

Driveshaft

1. Remove the clinch bolt.

Caution

l Wrap a rag around the ball Joint dust boot to pro-

tect it from damage.

2. Disconnect the lower arm from the knuckle with a pry bar.

.-’

Caution

l Do not sub]ect the tripod joint to shock when remov-

ing the driveshaft.

3. Separate the driveshaft from the transaxle by prying with

a bar inserted between the outer ring and the transaxle.

4. Suspend the driveshaft with a rope.

Transaxle

1. Loosen the SST (engine support) and lean the engine to-

ward the transaxle.

2. Support the transaxle with a jack.

Jl-12

Page 538 of 1164

/ cm-kg, -26-52 In-lb)

(3.8-5.3, 27-M)

Jl TRANSAXLE

INSTALLATION

1. Raise the vehicle and support it with safety stands.

2 Install in the order shown in the figure, referring to Installation Note.

3’ Add the specified amount of the specified transaxle oil. (Refer to page Jl-7.)

4: Warm up the engine and transaxle, and inspect for oil leakage and transaxle operation.

2.4-5.S N.m (30-60

9

1 8-11 N-m

o-110 cm-kg,

* h-95 In-lb)

.O,

cc.

ft-I

03UOJl-119

b)

51-48

Page 539 of 1164

TRANSAXLE Jl

1. Transaxle

Installation Note ..,......,.............. page Jl-49

2. Engine mount No.4

3. Driveshaft

Installation Note . . . . . . . . . . . . . . . . . . . . . . . . page Jl-50

4. Stabilizer (BP SOHC)

Installation Note . . . . . . . . . . . . . . . . . . . . . . . . page Jl-50

5. Tie-rod end

Installation Note ,........,..,........... page Jl-50

6. Clutch release cylinder

7. Engine mount No.2

8. Exhaust pipe

9. Engine mounting member

Installation Note . . . . . . . . . . . . . . . . . . . . . . . .

page Jl-50

10. Control rod

Installation Note . . . . . . . . . . . . . . . . . . . . . . . . page Jl-51 11. Extension bar

Installation Note . . . . . . . . . . . . . . . . . . . . . . . . page Jl-51

1 12. Starter

13. Ground

Installation Note .,..,...,......,........ page Jl-5

14. Neutral switch connector

15. Back-up light switch connector

16. Speedometer cable

Installation Note . . . . . . . . . . . . . . . . . . . . . . . .

page Jl-5

17. Battery carrier

18. Battery

19. Air hose and resonance chamber

20. Splash shield

21. Wheel and tire 1

Installation Note

Transaxle

1. Set the transaxle on a jack and lift it into place.

Install tne transaxle oorts.

Tightening torque:

64-69 N*rn (6.5-9.1 m-kg, 47-66 ft-lb)

Loosely tighten engine mount No.4 bolts.

Jl-49

Page 540 of 1164

03UOJi-12 3

03UOJl-124

L 03UOJl.126 I-

03UOJl-12

Jl TRANSAXLE

Driveshaft

Caution

l Verify that the oil seal is not damaged.

l Do not damage the oil seal

1. Insert the clip with the end-gap at the top of the groove.

2. Apply transaxle oil around the oil seal lip. Install the

driveshaft.

3. Verify that the driveshaft is correctly seated by pulling on

the shaft.

4. Connect the lower arm to the knuckle and tighten the clinch

bolt.

Tightening torque:

43-59 N-m (4.4-6.0 m-kg, 32-43 ft-lb)

Stabilizer (BP SOHC)

1. Tighten the nut until the specified amount of thread is ex-

posed at the end of the bolt.

Dimension A: 17-l 9mm (0.67-0.75 in)

Tie-rod end

1. Install the locknut.

Tightening torque:

42-57 N-m (4.3-5.6 m-kg, 31-42 ft-lb)

2. Secure the locknut with a new cotter pin.

Engine mounting member

1. Install the bolts and nuts as shown.

Tightening torque

@ : 37-52 N,m (3.6-5.3 m-kg, 27-36 ft-lb)

@I: 64-89 N-m (6.5-9.1 m-kg, 47-66 ft-lb)

51-50