oil MAZDA PROTEGE 1992 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 920 of 1164

2L BUZZER 2A 28 2C 2D 1A 3K l--r nnmn

I I‘ I

1C 3L 2E 2G IL iG 1F 1D tB

3F 38 3G 1E 3D

l-l rt

II l-l

l-l It II l-l 1J 11 1H

1G IF 1E 1D 1C 1B 1A 2L 2K 2J 21 2H 2G 2F 2E 2D 2C 28 2A

r-l It ,I 3L 3K 3J 31 3H 3G 3F 3E 3D 3C 3B 3A

Ter- I I minal Connected to 1 1A Combination switch

1B Ground

IC Fuel tank unit

1 ID 1 EGI control unit

I

II L 1J 1

L Ter-

minal Connected to

2A Speed sensor output

28 Light switch (high beam)

2C Turn switch (L)

20 Turn switch (R)

2E Ground

2F Ground

2L 1 IGI battery Ter-

minal Connected to

3A

38 Alternator

3c

30 Oil pressure switch

3E

3F Parking brake switch, Brake fluid switch

3G Passive shoulder belt control unit

3H h

I 31

3J

3K

IG2 battery

3L Water temperature gauge unit

Page 972 of 1164

U TROUBLESHOOTING GUIDE

Case 1: Insufficient refrigerant

Measured pressure

Low-pressure side: Less than 78.5 kPa (0.8 kg/cm2, 11.4 psi)

High-pressure side: 785-883 kPa (8-9 kg/cm2, 114-128 psi)

Condition

l Outlet air from vents not cold.

l Bubbles seen in sight glass.

Step 1

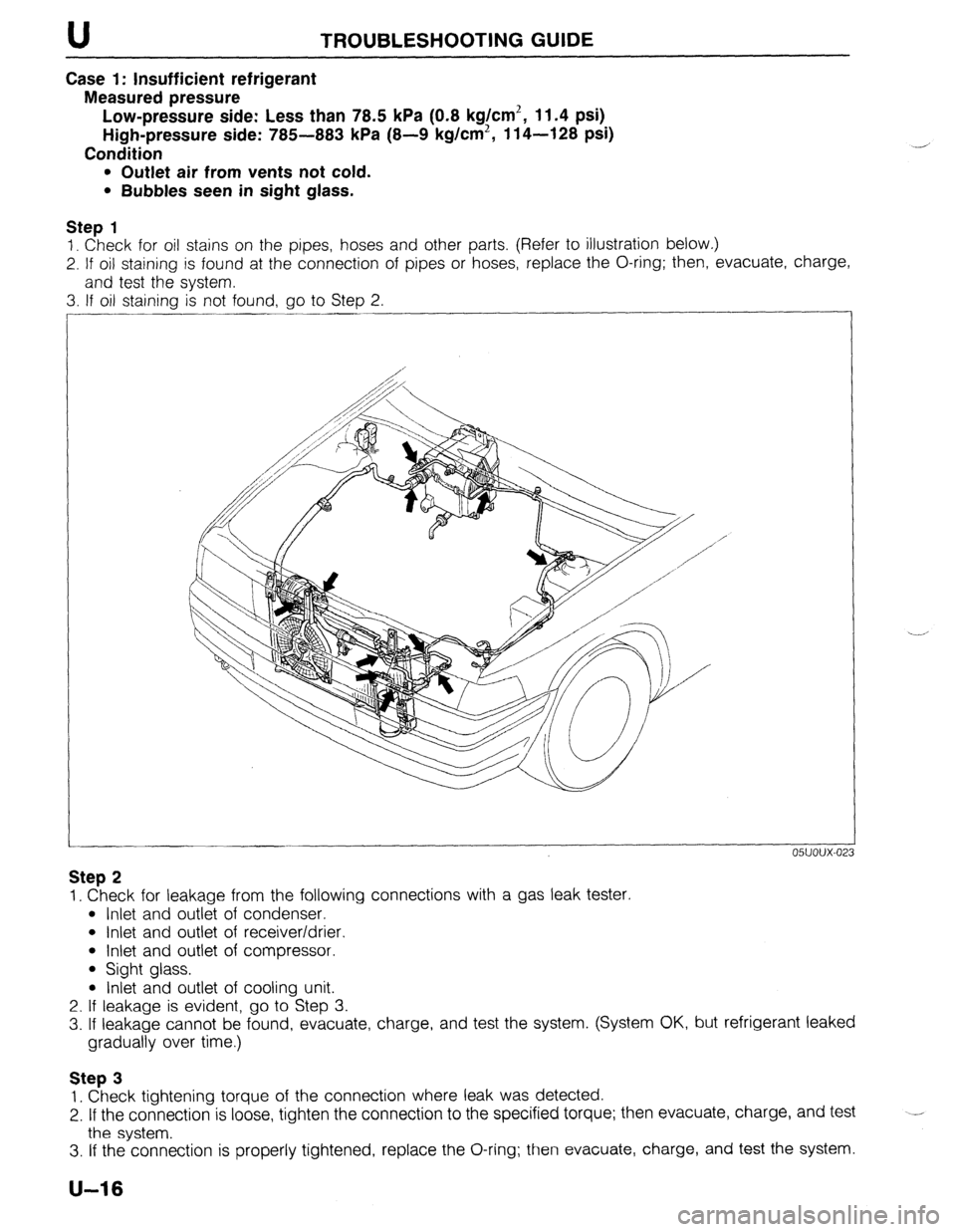

1. Check for oil stains on the pipes, hoses and other parts, (Refer to illustration below.)

2. If oil staining is found at the connection of pipes or hoses, replace the O-ring; then, evacuate, charge,

and test the system.

3. If oil staining is not found, go to Step 2.

05UOUX-02

Step 2

1. Check for leakage from the following connections with a gas leak tester.

l Inlet and outlet of condenser.

l Inlet and outlet of receiver/drier.

l Inlet and outlet of compressor.

l Sight glass.

l Inlet and outlet of cooling unit.

2. If leakage is evident, go to Step 3.

3. If leakage cannot be found, evacuate, charge, and test the system. (System OK, but refrigerant leaked

gradually over time.)

Step 3

1. Check tightening torque of the connection where leak was detected.

2. If the connection is loose, tighten the connection to the specified torque; then evacuate, charge, and test

the system. --

3. If the connection is properly tightened, replace the O-ring; then evacuate, charge, and test the system.

U-16

Page 994 of 1164

U

COOLING UNIT

Removal / Installation AIR CONDITIONER

1. Discharge the refrigeration system. (Refer to page U-32.)

2. Remove the glove box, glove box cover, undercover, and instrument panel stay. (Refer to Section S.)

3. Remove the cooling unit as shown in the figure. -

Note

l Immediately plug all open fittings to keep moisture out of system.

4. Install the cooling unit in the reverse order of removal.

Note

l Position the cooling unit so that its connections match those of the heater unit and blower unit.

l Apply clean compressor oil to the O-rings before connecting the fittings.

l Do not apply compressor oil to the fitting nuts.

l When installing a new cooling unit, add compressor oil through the high-pressure pipe port

of the compressor.

Compressor oil: 50 cc (3.05 cu in)

Tightening torque

Outlet pipe: 20-29 N*m (2.0-3.0 m-kg, 14-22 ft-lb)

lnla+ nina. Q n,7n N.m (I -0-2.0 m&a. 7,7-IA ftJh IIllcvb yap”. “.” -1 . . . . . \..’ -_- __- ..~, JII .- .I .-,

23UOUX-0: -.,

1. Cooling unit

Disassembly / Assembly.. . . . . . . . . . . . page U-39

U-38

Page 995 of 1164

AIR CONDITIONER U

Dlsassembly / Assembly

Disassemble and assemble as shown in the figure.

1. Evaporator 2. Expansion valve 3. Thermoswitch

Replacement

Expansion valve

Note

l Before replacement of the expansion valve, care-

fully check the refrigeration system, referring to the

troubleshooting information on page U-14.

1. Remove the cooling unit. (Refer to page U-38.)

2. Disassemble the cooling unit. Remove the evaporator and

expansion valve as an assembly.

3. Disconnect the inlet and outlet pipes.

I 4. Remove the capillary tube from the outlet pipe and remove

23UOUX-024 the expansion valve.

5. Install in the reverse order of removal, noting the following.

Note

l Apply clean compressor oil to the O-rings before

connecting the fittings.

Tightening torque

Inlet pipe:

12-15 N-m (1.2-l .5 m-kg, 8.7-l 1 ft-lb)

Outlet pipe:

29-34 Nmrn (3.0-3.5 m-kg, 22-25 ft-lb)

u-39

Page 997 of 1164

AIR CONDITIONER U

COMPRESSOR

Removal / Installation

1. Discharge the refrigeration system. (Refer to page U-32.)

2. Remove the undercover.

3. Remove the compressor as shown in the figure, referring to

Removal Note.

4. Install the compressor in the reverse order of removal, referring to Installation Note.

5. Install the undercover.

6. Charge the refrigeration system. (Refer to page U-33.)

u

24-35 (2.4-3.6, 17-26)

N.m (m-kg, ft-it

23UOUX-0

1. Suction hose

2. Discharge hose 3. Compressor

Note

l Immediately plug any open fittings to keep moisture out of the system.

l Apply new compressor oil to the O-rings before connecting the fittings.

l Do not apply compressor oil to the fittings.

l Tightening torque Compressor inlet and outlet: 9.8-l 8 N.m (1.0-l .8 m-kg, 8-l 2 ft-lb)

l Adjust the belt tension to specification.

lb-41

Page 1000 of 1164

U AIR CONDITIONER

23UOUX-02

Thermal Protector Replacement

1. Removal of discharge valve body

Remove the bolts and carefully remove the discharge valve

body. .-

2. Removal of snap ring and thermal protector

Note

l When removing the thermal protector, do not pull

the harness wires but push the protector out from

its back side.

23UOUX-028 3. Installation of thermal protector

1) Check that the O-ring groove is free from foreign matter.

Apply compressor oil to the O-ring and properly fit it in

the groove.

2) Before installing the thermal protector, check it for con-

tinuity.

23uoux-029 _/”

THERMAL PROTECTOR

23UOUX-03

TH

PR

3) Install the snap ring so that its chamfered edge side faces

the thermal protector (the non-chamfered side faces out-

ward) as shown left.

Make sure the snap ring is seated securely in its groove.

Note

l Install the thermal protector so that its two lead wire

outlet sections are horizontal as shown left.

Page 1001 of 1164

AIR CONDITIONER U

23UOUX-031 DISCHARGE

VALVE BODY

CYLINDER

1

23UOUX-03

4. Installation of discharge valve body

1) Replace the O-ring and gasket with new ones.

Apply compressor oil to the new O-ring and gasket and

properly assemble them.

Note

l Fit the gasket as shown left while checking that its

top side faces upward.

2) Carefully install the discharge valve body on the com-

pressor and finger tighten the six M6 bolts.

Note

Bolt torquing sequence

l Torque the two socket head bolts (A) to the specifi-

cation.

l Torque the four bolts (B) in a diagonal manner to

the specification.

Tightening torgue: 9.8 N,rn (100 cm-kg, 87 in-lb)

u-45

Page 1003 of 1164

AIR CONDITIONER U

r 23UOUX-036

L 23UOUX.03

I

L

23UOUX-03 7

Shaft Seal Replacement

1. Remove the armature plate.

Note

l Removal of the clutch pulley and coil is not

necessary.

2. Remove the felt seal and snap ring.

3. Remove the shim(s).

4. Insert the

SST into the compressor aligning the cutout of

the

SST with the groove of the seal plate.

5. Rotate the

SST counterclockwise to make sure that the

cutout is engaged with the seal plate.

6. Pull out the seal plate.

7. Insert the

SST into the compressor aligning the cutout of

the

SST with the metal pawl of the shaft seal.

8. Rotate the

SST counterclockwise to make sure that the cut-

off is engaged with the metal pawl.

9. Pull out the shaft seal.

u-47

Page 1004 of 1164

U AIR CONDITIONER

23UOUX.04

IO. Lay down the compressor and clean the shaft seal contact-

ing face of the compressor with cleaning solvent.

Caution

l Keep the cleaning solvent and dirt out of the com-

pressor.

l Do not use any cloth for cleaning.

Clean only by rinsing with the solvent.

l Do not spill the refrigerant oil from the compressor.

Refill the same amount of the oil if the oil is spilled

out.

23uoux-039

11. Clean the new shaft seal throughly with cleaning solvent.

12. Lubricate the shaft seal with refrigerant oil (SUNISO 5GS

or equivalent) and install it on the

SST.

Note

l Use only clean refrigerant oil.

l Do not touch the sealing surfaces of the shaft seal

after lubricated.

23UOUX-040

13. Liberally lubricate the compressor shaft with refrigerant oil.

14. Install the shaft seal onto the compressor shaft aligning the

seal case flats with the shaft flats.

U-48

Page 1005 of 1164

AIR CONDITIONER U

15. Clean the seal plate with cleaning solvent.

Lubricate the seal plate with refrigerant oil (SUNISO 5GS

or equivalent).

Note

l Use only clean refrigerant oil.

l Do not touch the sealing surface of the seal plate

after lubricated.

23lJoux-042

SHAFT SEAL PLATE

14

16. First, slide the seal plate into the compressor by hand as

far as possible.

17. Press the seal plate with grip side of the

SST.

18. Install the snap ring with its chamfered edge inside.

19. Press the snap ring with the grip side of the

SST, then in-

stall the felt seal.

20. Make sure the snap ring is seated correctly in its groove.

21. Install the shim(s).

22. Install the armature plate.

Measure the clearance between the pulley and armature

plate all the way around.

If the clearance is not as specified, add or remove the shim

as required.

Clearance: 0.4-0.5mm (0.016-0.020 in)

Shim

Part number Thickness mm (in)

B455 61 L15 0.2 (0.008)

8456 61 L15 0.5 (0.020)

u-49