no spark MAZDA PROTEGE 1992 Owner's Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 390 of 1164

F FUEL SYSTEM

MIN. 35mm (1..4 in) -/

23UOFX-10

NJ

23UOFX-l(

OBUOFX-1:

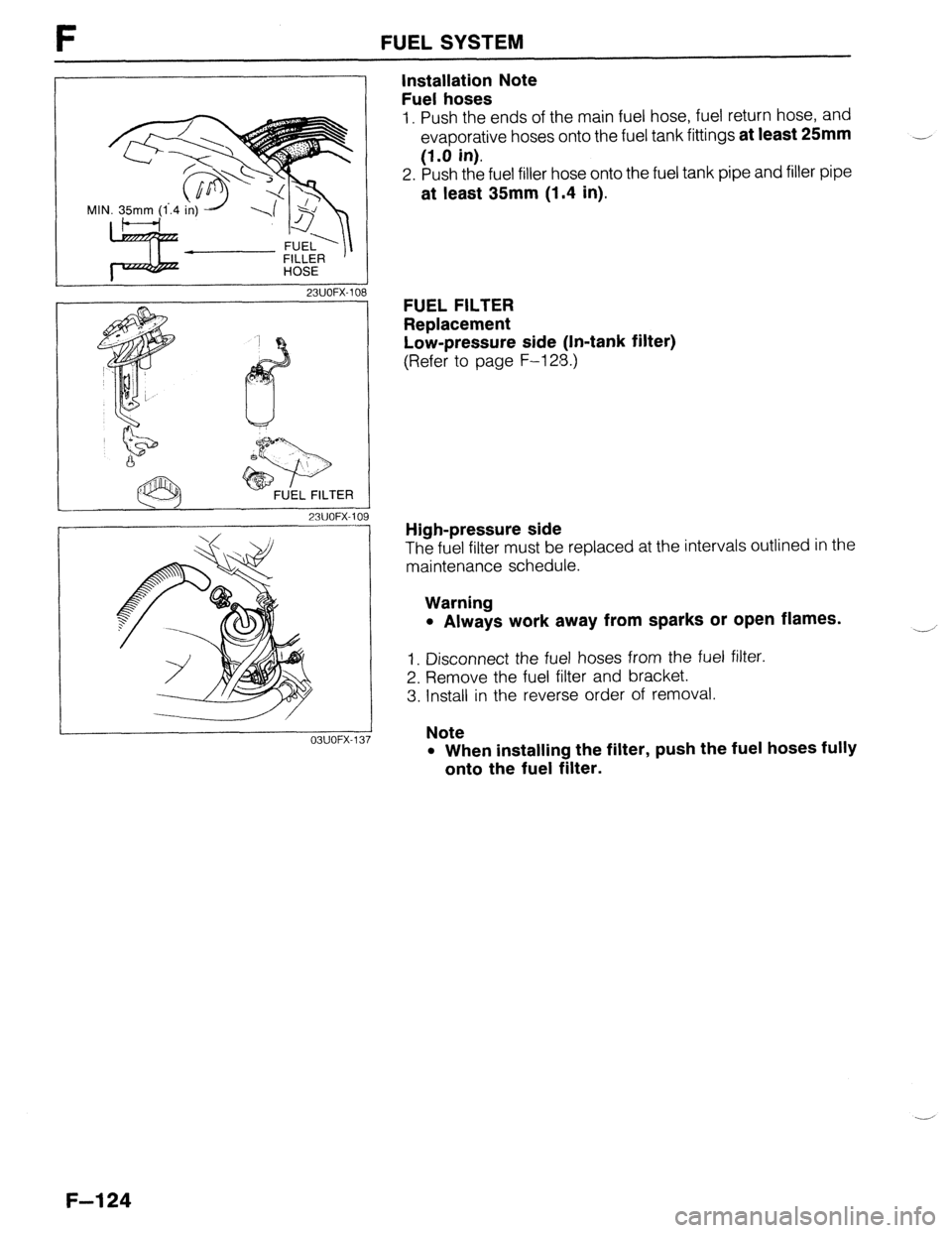

Installation Note

Fuel hoses

1. Push the ends of the main fuel hose, fuel return hose, and

evaporative hoses onto the fuel tank fittings at least 25mm

(1.0 in).

2. Push the fuel filler hose onto the fuel tank pipe and filler pipe

at least 35mm (1.4 in).

FUEL FILTER

Replacement

Low-pressure side (In-tank filter)

(Refer to page F-128.)

High-pressure side

The fuel filter must be replaced at the intervals outlined in the

maintenance schedule.

Warning

l Always work away from sparks or open flames.

1. Disconnect the fuel hoses from the fuel filter.

2. Remove the fuel filter and bracket.

3. Install in the reverse order of removal.

Note

l When installing the filter, push the fuel hoses fully

onto the fuel filter.

F-l 24

Page 393 of 1164

FUEL SYSTEM F

DISCONNECT CONNECTOR

TO RELEASE FU5L PRESSURE

REAR SEAT C

23UOFX-11:

REPLACE

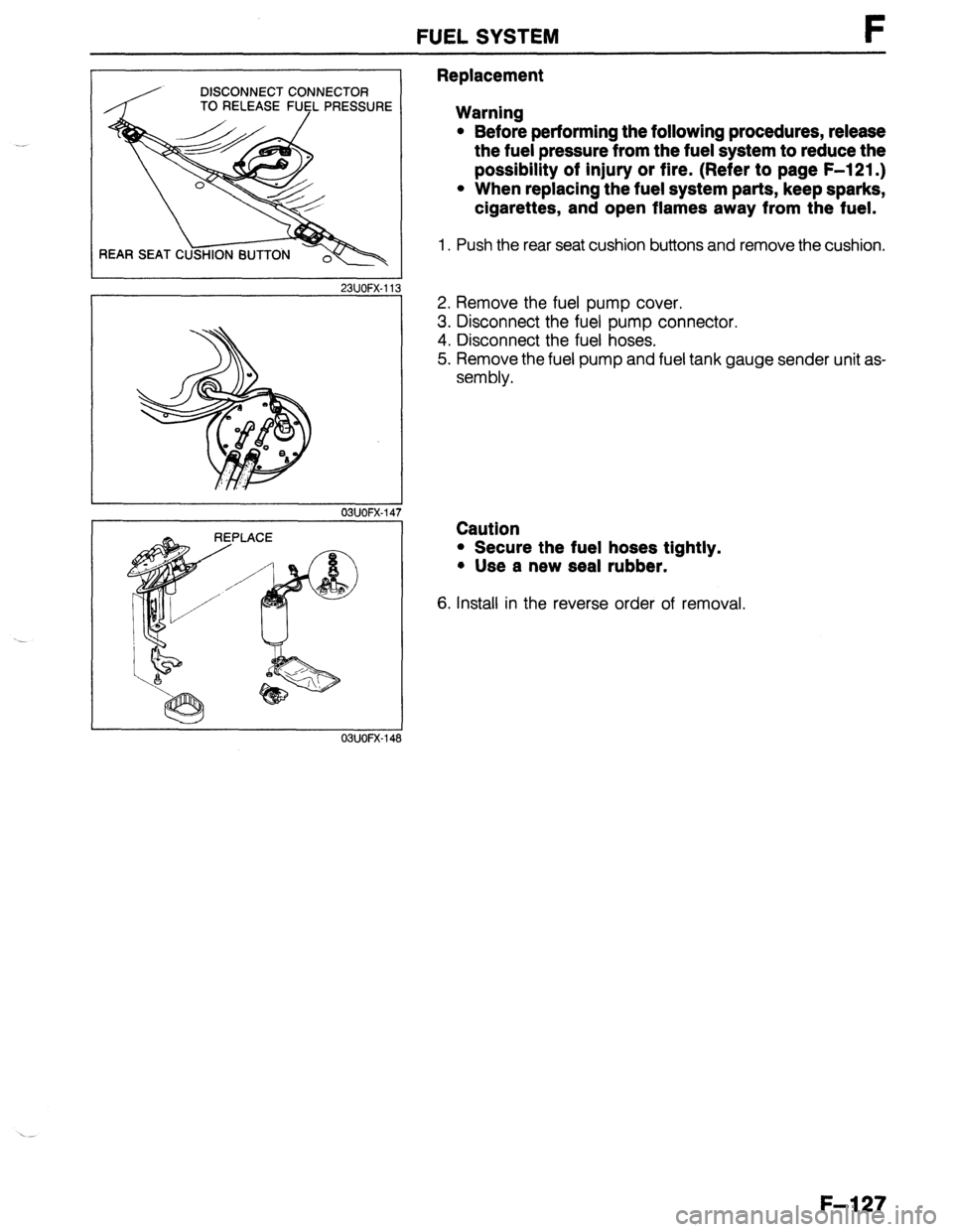

03UOFX-14s Replacement

Warning

l Before performing the following procedures, release

the fuel pressure from the fuel system to reduce the

possibility of injury or fire. (Refer to page F-121 .)

l When replacing the fuel system parts, keep sparks,

cigarettes, and open flames away from the fuel.

1. Push the rear seat cushion buttons and remove the cushion.

2. Remove the fuel pump cover.

3. Disconnect the fuel pump connector.

4. Disconnect the fuel hoses.

5. Remove the fuel pump and fuel tank gauge sender unit as-

sembly.

Caution

l Secure the fuel hoses tightly.

+ Use a new seal rubber.

6. Install in the reverse order of removal.

F-l 27

Page 396 of 1164

F FUELSYSTEM

DISCONNECT CONNECTOR

TO RELEASE FlJ$L PRESSURE

REAR SEAT C

23UOFX-11

INSTALL CLAMPS 7

03UOFX.I 59

F-l 30

DIAGNOSl&OJNECTOR

/ K

1 SUOFX-10

DISCONNECT CONNECTOR

TO RELEASE

FlJl$L PRESSURE

23UOFX-11

I

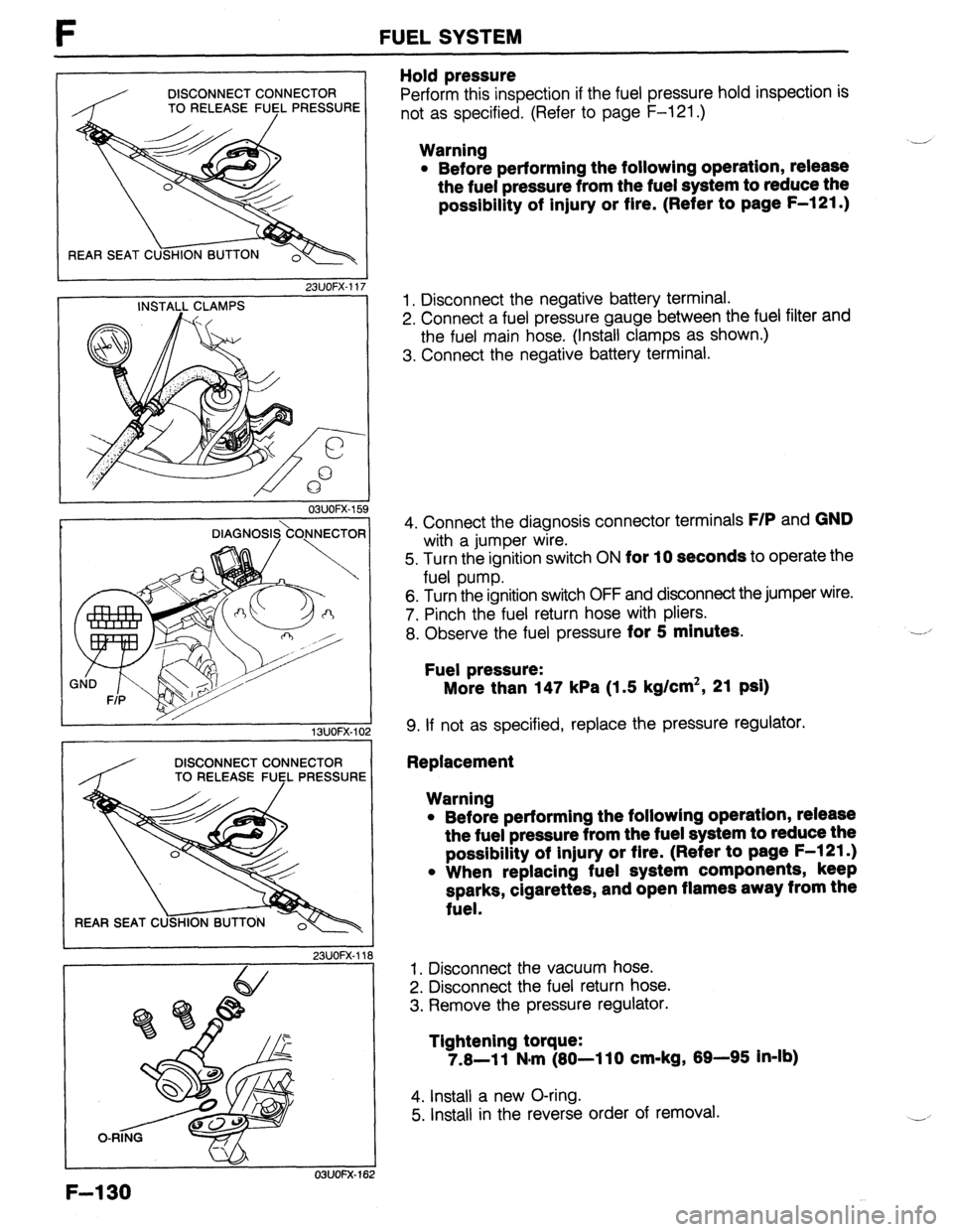

Hold pressure

Perform this inspection if the fuel pressure hold inspection is

not as specified. (Refer to page F-121 .)

Warning

l Before performing the following operation, release

the fuel pressure from the fuel system to reduce the

possibility of injury or fire. (Refer to page F-121 .) ,-

1. Disconnect the negative battery terminal.

2. Connect a fuel pressure gauge between the fuel filter and

the fuel main hose. (Install clamps as shown.)

3. Connect the negative battery terminal.

4. Connect the diagnosis connector terminals

F/P and GND

with a jumper wire.

5. Turn the ignition switch ON

for 10 seconds to operate the

fuel pump.

6. Turn the ignition switch OFF and disconnect the jumper wire.

7. Pinch the fuel return hose with pliers.

8. Observe the fuel pressure

for 5 minutes.

Fuel pressure:

More than 147 kPa (1.5 kg/cm2, 21 psi)

9. If not as specified, replace the pressure regulator.

Replacement

Warning

l Before performing the followlng operation, release

the fuel pressure from the fuel system to reduce the

possibility of injury or flre. (Refer to page F-l 21.)

l When replacing fuel system components, keep

sparks, cigarettes, and open flames away from the

fuel.

1. Disconnect the vacuum hose.

2. Disconnect the fuel return hose.

3. Remove the pressure regulator.

Tightening torque:

7.8-11 N#m (80-110 cm-kg, 89-95 In-lb)

4. Install a new O-ring.

5. Install in the reverse order of removal.

Page 397 of 1164

231JOFX-1

FUEL SYSTEM F

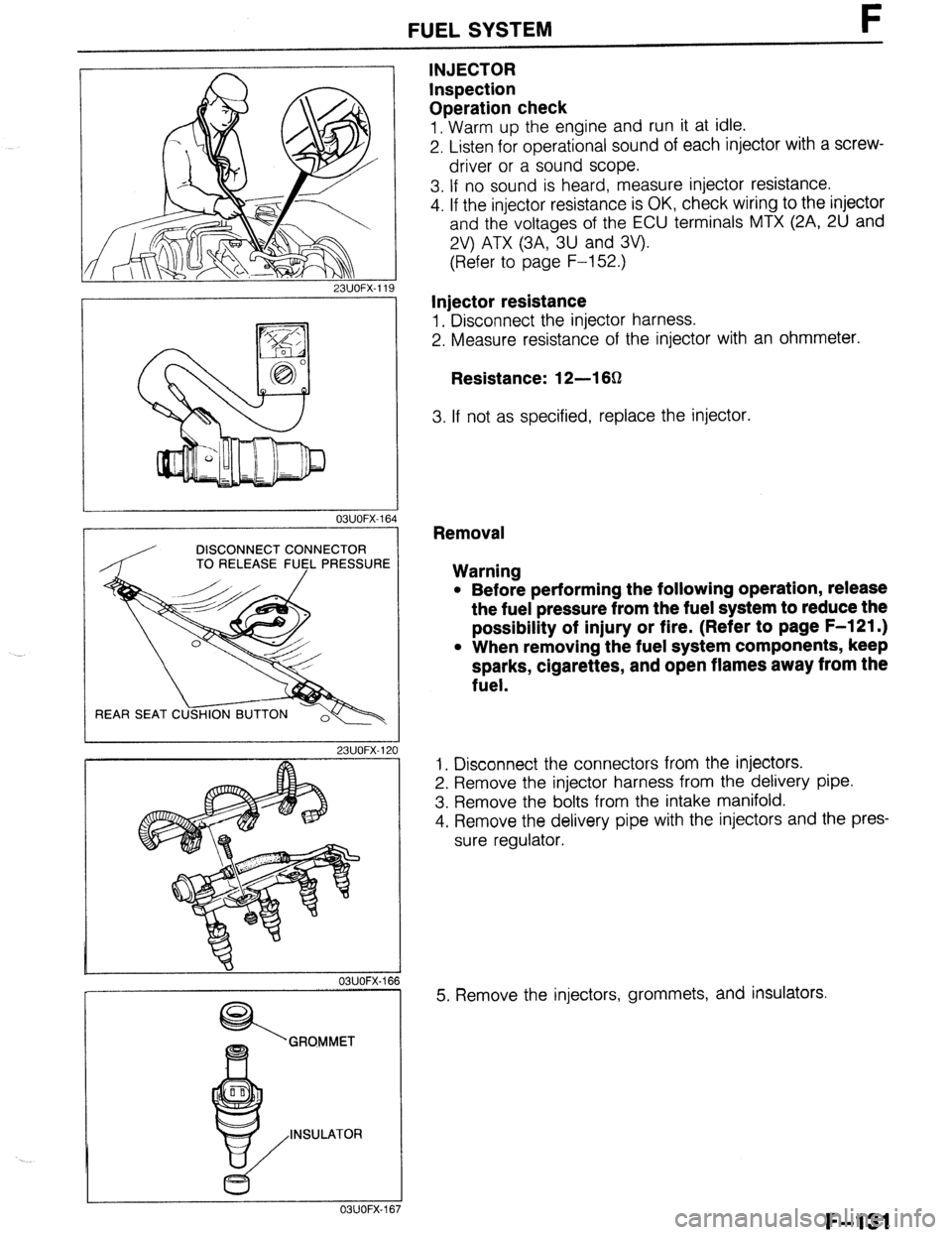

INJECTOR

Inspection

Operation check

1. Warm up the engine and run it at idle.

2. Listen for operational sound of each injector with a screw-

driver or a sound scope.

3. If no sound is heard, measure injector resistance.

4. If the injector resistance is OK, check wiring to the injector

and the voltages of the ECU terminals MTX (2A, 2U and

2V) ATX (3A, 3U and 3V).

(Refer to page F-152.)

Injector resistance

1. Disconnect the injector harness.

2. Measure resistance of the injector with an ohmmeter.

Resistance: 12-l 6Q

3. If not as specified, replace the injector.

03UOFX-1

DISCONNECT CONNECTOR

TO RELEASE FU5L PRESSUR

REAR SEAT C

23UOFX-1

OBUOFX-

GRQMMET

INSULATOR

c5

OSUOFX-

Removal

Warning

l Before performing the following operation, release

the fuel pressure from the fuel system to reduce the

possibility of injury or fire. (Refer to page F-121 .)

l When removing the fuel system components, keep

sparks, cigarettes, and open flames away from the

fuel.

1. Disconnect the connectors from the injectors.

2. Remove the injector harness from the delivery pipe.

3. Remove the bolts from the intake manifold.

4. Remove the delivery pipe with the injectors and the pres-

sure regulator.

5. Remove the injectors, grommets, and insulators.

F-131

Page 398 of 1164

l Be extremely careful when working with fuel. I

23UOFX.121 Always work away from sparks or open flames.

3. Connect the diagnosis connector terminals F/P and GND

with a jumper wire.

FUEL SYSTEM

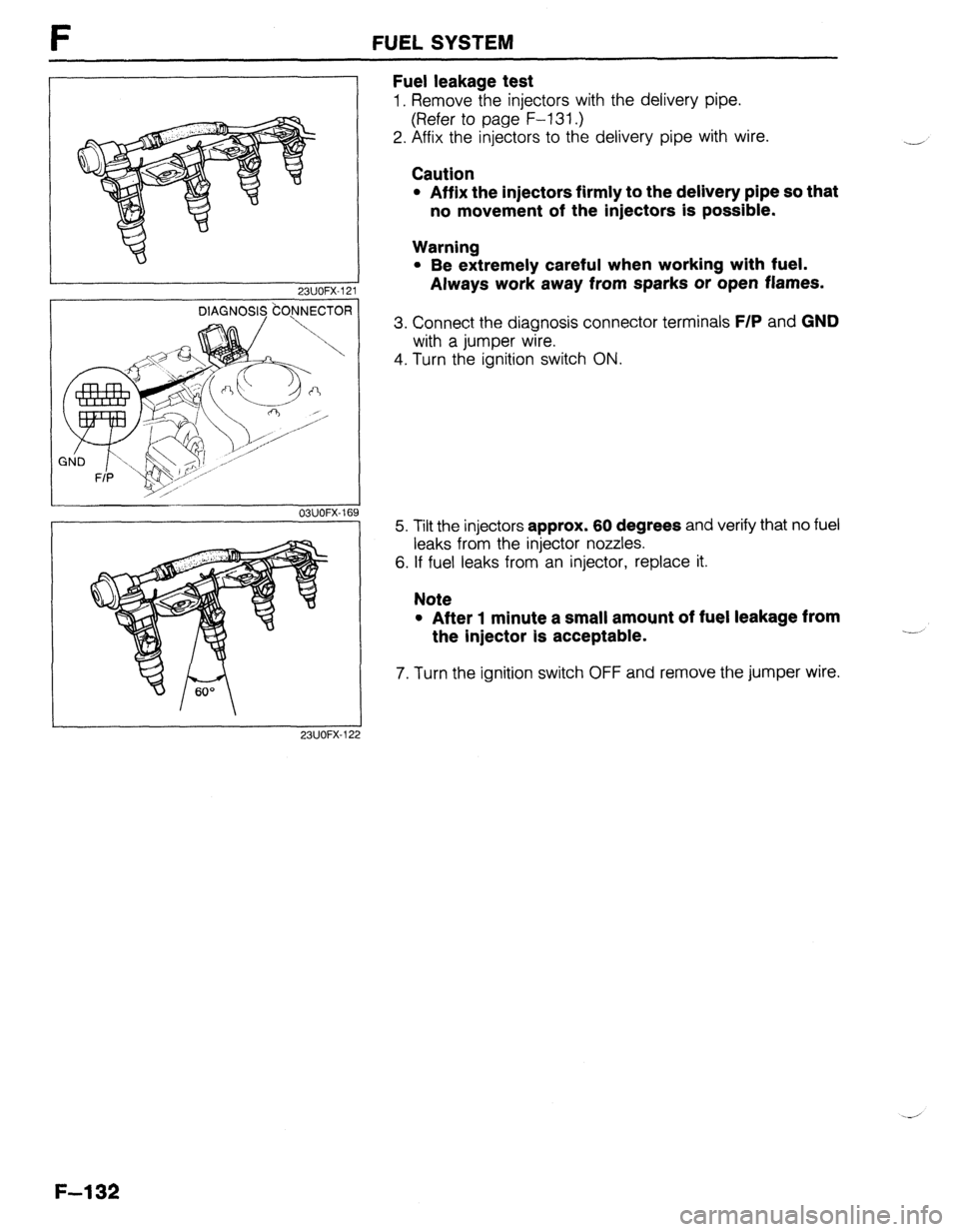

Fuel leakage test

1. Remove the injectors with the delivery pipe.

(Refer to page F-l 31.)

2. Affix the injectors to the delivery pipe with wire.

Caution

l Affix the injectors firmly to the delivery pipe so that

no movement of the injectors is possible.

-

Warning

4. Turn the ignition switch ON.

03UOFX-16’

23UOFX-12 9 5. Tilt the injectors approx. 60 degrees and verify that no fuel

leaks from the injector nozzles.

6. If fuel leaks from an injector, replace it.

Note

l After 1 minute a small amount of fuel leakage from

the injector Is acceptable.

7. Turn the ignition switch OFF and remove the jumper wire.

-i

F-l 32

Page 411 of 1164

DECHOKE CONTROL SYSTEM t-

DECHOKE CONTROL SYSTEM

DESCRIPTION

To facilitate starting the engine when the spark plugs become fouled, such as when the engine is flooded,

fuel injection is cut if the throttle valve is held wide open while cranking and the engine coolant temperature

is O°C (32OF) or below. This allows the spark oluas to drv and purges excess fuel from the cylinders.

f-- ECU _

. IGNITION SWITCH (START)

l ENGINE SPEED BELOW 500 rpm ’

l THROTTLE VALVE FULLY OPEN

l ENGINE COOLANT TEMPERATURE ;

BELOW

0% (32°F) I FUEL CUT

OBUOFX-19

I / / ‘ I

SYSTEM OPERATION

1.

2. Check if the engine coolant temperature is below O°C

(32OF).

If the engine coolant temperature is above O°C (32OF), dis-

connect the water thermosensor connector and connect an

approx. 10 kB resistor to the connector.

03UOFX.198 3. Turn the ignition switch to START and verify that the injec-

OBUOFX-19! 3

tor operating sound is heard.

4. Depress the accelerator pedal fully and turn the ignition

switch START. Verify that no injector operating sound is

heard.

F-l 45

Page 441 of 1164

G

ENGINE ELECTRICAL SYSTEM

INDEX ......................................................

OUTLINE ..................................................

SPECIFICATIONS .................................... G- 3

TROUBLESHOOTING

GUIDE.. .................... G-

4

DIAGNOSTIC INDEX ................................

SYMPTOM TROUBLESHOOTING..

............. :- t

-

CHARGING SYSTEM ................................. G- 6

PREPARATION .......................................

CIRCUIT DIAGRAM ................................. :I ;

TROUBLESHOOTING .............................. G- 7

BATTERY ............................................... G- 6

ALTERNATOR ........................................ G-10

DRIVE BELT ........................................... G-14

IGNITION SYSTEM .................................... G-15

PREPARATION ....................................... G-15

CIRCUIT DIAGRAM ................................. G-15

TROUBLESHOOTING .............................. G-16

IGNITION TIMING ................................... G-17

HIGH-TENSION LEAD .............................. G-17

SPARK PLUGS ....................................... G-16

IGNITION COIL ....................................... G-19

DISTRIBUTOR ........................................ G-20

IGNITER ................................................ G-23

STARTING SYSTEM .................................. G-24

PREPARATION ....................................... G-24

CIRCUIT DIAGRAM ................................. G-24

STARTER ...............................................

G-25

STARTER INTERLOCK SWITCH (MTX)

........ G-31

03UOGX-001

Page 442 of 1164

G INDEX

NDEX

- 03UOGX-00:

6. Ignition coil 1. Battery

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page G- 8

Recharging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..t page G- 9

2. Alternator

Removal / Installation . . . . . . . . . . . . . . . . . .

page G-l 0

Disassembly / Assembly . . . . . . . . . . . . . page G-l 1

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

page G-l 2

3. Drive belt

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

page G-l 4

Adjustment . . . . . . . . page G-l 4

Replacement . . . . . . . . . . . . . .

page G-l 4

4. High-tension lead

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page G-l 7

5. Spark plugs

Removal / Installation . . . . . . . . . . page G-1 0

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

page G-l 8

G-2

Inspection .,.. . . . . . . . . . . . . . . . . I . . . . . page

G-l 9

7. Distributor

Spark test ., . . . . . . . . . . ,... . . . . . . . .

page G,-20

Electronic advance inspection page G-20

Removal / Installation ,................. page G-21

Disassembly / Assembly.. , . . page

G-22

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

page G-22

8. Igniter

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

page G-23

9. Starter

Removal / Installation .;...........,.... page G-25

Disassembly ! Assembly . . . . . . . . . . . . . page G-26

Inspection . . . . ...‘........................,,,

page G-28 .--

10. Starter interluck switch

Inspection... . . . . . . . . . . . . . . . . . . . . ,.., ,...,

page G-31

Page 443 of 1164

OUTLINE G

OUTLINE

SPECIFICATIONS

Item EnginelTransaxle

‘-2, B6 SOHC BP SOHC BP DOHC

MTX 1 ATX MTX ( ATX

Voltage v 1 12

I

3attery

Dark current*’ Type and capacity

(20-hour rate)

mA 55D23L (60AH) 55D23L (60AH)

Max. 20.0

L\lternator

Starter

Type AC

output V-A 12-65

Regulator type Transistorized (built-in IC regulator)

Regulated voltage V 14.1-14.7

Brush length Standard 21.5 (0.846)

mm (in) Minimum 8.0 (0.315)

Drive belt deflection

New

98 N (10 kg, 22 lb)

mm (in) Used 8-Q (0.31-0.35)

Q-10 (0.35-0.39)

Type

I Direct Direct

I Coaxial

Direct Coaxial

reduction reduction I

output V-kW 12-0.95 12-0.95 12-1.4

12-0.95 12-1.4

Brush length Standard 17 (0.67) 17 (0.67) 17.5 (0.69) 17 (0.67)

17.5 (0.69)

mm (in) Minimum 11.5 (0.453) 11.5 (0.453) 10.0 (0.39) 11.5 (0.453) 10.0 (0.39)

Distributor

Ignition timing BTDC

(TEN terminal of diagnosis connector grounded) Electronic spark advance (photo diode)

6O--8O 4O-6O Q”-1 1 o

Ignition coil

Spark plug Resistance

(at 20% [68OF]) Primary

coil winding 0.81-O.QQg

Secondary

coil winding IO-16 kg

BKR5E-11 BKR5Ell BKR5Ell

NGK

BKR6E-11 BKRGEl 1 BKRGEli

BKR7Ell

Type NIPPON-

DENSON Kl GPR-Ul l

K20PRU 11 KIGPR-Ull

K20PR-Ul l KIGPR-Ull

K20PRUll

K22PR-Ul l

I Plua aao mm (in) I 1.0-l .l (0.039-0.043)

Firing order

’ Dark current is the constant flow of current while the ignition switch is OFF.

(i.e. engine control unit, audio, etc.) l-3-4-2

23lJOGX-00

G-3

Page 445 of 1164

TROUBLESHOOTING GUIDE G

3 Cranks slowly

STEP INSPECTION ACTION

1 Check if engine cranks normally with fully Yes Check charging system CT page G-7

charged battery

No Go to next step

2 Check starter cable connection for looseness Yes Repair or replace connection

and corrosion

OBUOGX-OC

I 1 4

.

Alternator warning lamp illuminates when engine running

STEP INSPECTION ACTION

1 Check for correct battery voltage at idle Yes Check wire harness between alternator L terminal and aI*

Specification: 14.1--14.7V ternator warning lamp

No Check charging system w page G-7

03UOGX-008

5 I Discharged battery I 1TEP INSPECTION

f Check charging system w page G-7 -

6

TEF

1

r

--

Yes

03UOGX-009

ACTION

Turn ignition switch ON and check dark current as shown

Dark current: Below 20mA

No Repair or replace parts as necessary 1

Misfire

INSPECTION

-

Disconnect high-tension lead from each spark

plug and check for strong blue spark while

cranking

, i

Yes

No T-

I

ACTION

- Check spark plug w page G-f8

~3 If OK, engine electrical system normal

~3 If not OK, clean or replace spark plug

Check ignition system ci’ page G-16

1 03UOGX-010

G-5