MERCEDES-BENZ METRIS 2020 MY20 Operator’s Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2020, Model line: METRIS, Model: MERCEDES-BENZ METRIS 2020Pages: 320, PDF Size: 26.38 MB

Page 301 of 320

G

WARNING

On uphill and downhill slopes, the jack could

tip over with the vehicle raised. There is a

risk of injury.

Do not change wheels on uphill or downhill

gradients. Notify a qualified specialist work-

shop.

! Only position the jack on the jacking

points intended for this purpose. You could

otherwise damage the vehicle.

Observe the following when raising the vehi-

cle:

R To raise the vehicle, only use the vehicle-

specific jack that has been tested and

approved by Mercedes-Benz. If the jack is

used incorrectly, it could tip over while the

vehicle is raised.

R The vehicle's jack is intended only to raise

the vehicle for a short time when changing a

wheel. It is not suited for performing mainte-

nance work under the vehicle.

R Avoid changing the wheel on uphill and

downhill slopes.

R Before raising the vehicle, secure it from

rolling away by applying the parking brake

and inserting wheel chocks. Never disen-

gage the parking brake while the vehicle is

raised.

R The jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a large,

load-bearing underlay must be used. On a

slippery surface, a non-slip underlay must

be used, e.g. rubber mats.

R Make sure that the distance between the

underside of the tires and the ground does

not exceed

1.2 in(3 cm).

R Never place your hands or feet under the

raised vehicle.

R Never lie under the raised vehicle.

R Never start the engine when the vehicle is

raised.

R Never open or close a door or the tailgate/

door when the vehicle is raised.

R Make sure that no persons are present in

the vehicle when the vehicle is raised. Jacking points : (rubber stoppers) are loca-

ted just behind the front wheel arches and just

in front of the rear wheel arches.

X Place jack ; beneath corresponding jack-

ing points :.

X Turn handwheel = until jack plate ; sits

securely on jacking point :.

X Make sure the base of jack ; is positioned

vertically beneath jacking point :.

X Assemble adapter ? and ratchet A from

the vehicle tool kit.

X Place adapter ? and ratchet A on the hex-

agon nut of jack ; so that the lettering

AB/DOWN is visible.

X Turn ratchet A in the AUF/UP direction

until the tire is a maximum of 3 cm off the

ground.

When doing so, jack ; may move to one of

the side support surfaces.

Removing a wheel !

Do not place wheel bolts in sand or on a

dirty surface. The bolt and wheel hub

threads could otherwise be damaged when

you screw them in.

X Unscrew the wheel bolts.

X Remove the wheel. Changing wheels

299

Wheels and tires Z

Page 302 of 320

Mounting a new wheel

G

WARNING

Oiled or greased wheel bolts or damaged

wheel bolts/hub threads can cause the

wheel bolts to come loose. As a result, you

could lose a wheel while driving. There is a

risk of accident.

Never oil or grease wheel bolts. In the event

of damage to the threads, contact a quali-

fied specialist workshop immediately. Have

the damaged wheel bolts or hub threads

replaced/renewed. Do not continue driving. G

WARNING

If you tighten the wheel bolts or wheel nuts

when the vehicle is raised, the jack could tip

over. There is a risk of injury.

Only tighten the wheel bolts or wheel nuts

when the vehicle is on the ground.

Always observe the instructions and safety

notes on "Changing a wheel"

(Y page 297).

Only use wheel bolts that have been designed

for the wheel and the vehicle. For safety rea-

sons, Mercedes-Benz recommends that you

only use wheel bolts which have been

approved for Mercedes-Benz vehicles and the

respective wheel.

! On vehicles equipped with a tire pressure

monitor, electronic components are located

in the wheel.

Tire-mounting tools should not be used near

the valve. This could damage the electronic

components.

Only have tires changed at a qualified spe-

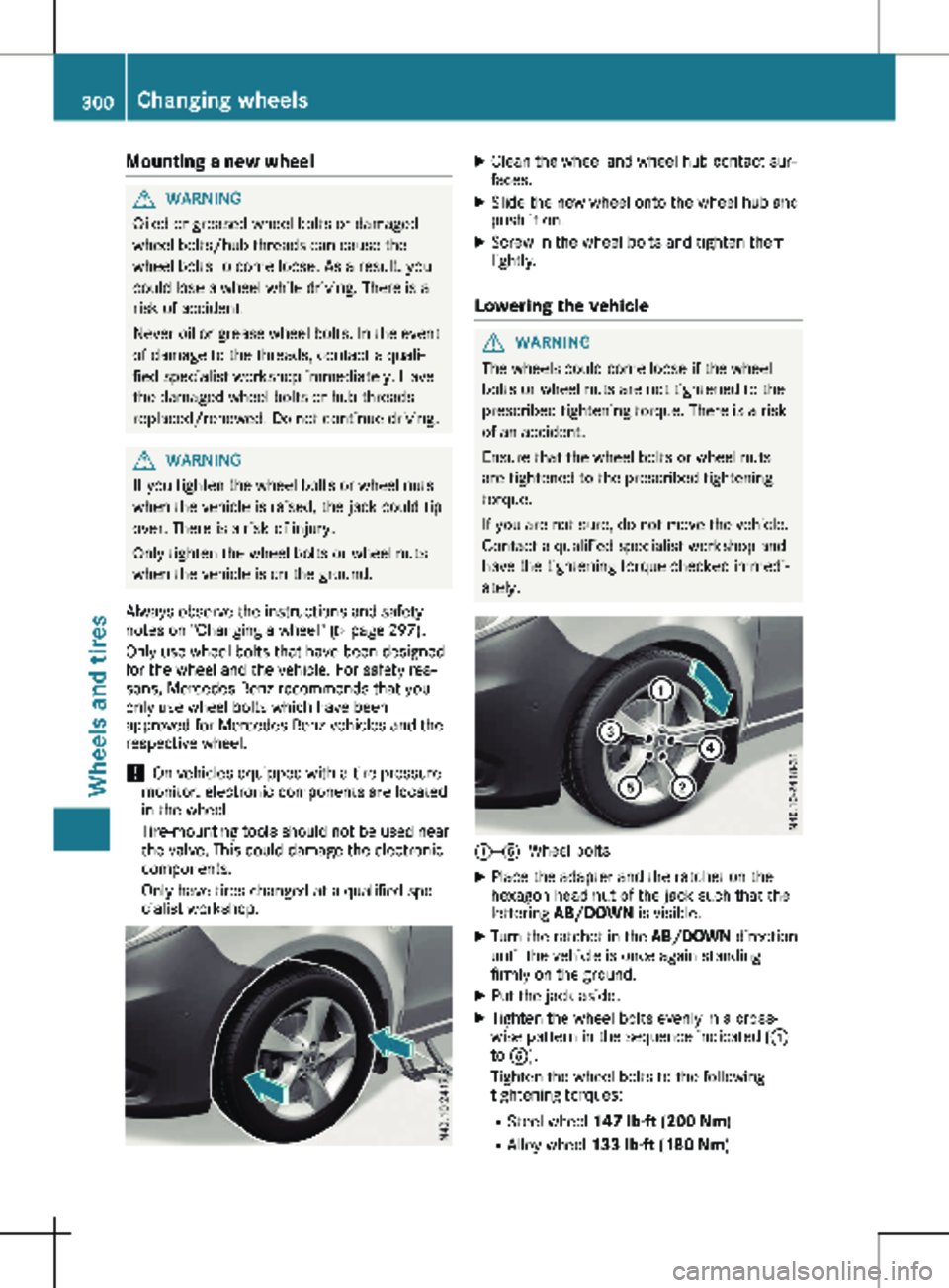

cialist workshop. X

Clean the wheel and wheel hub contact sur-

faces.

X Slide the new wheel onto the wheel hub and

push it on.

X Screw in the wheel bolts and tighten them

lightly.

Lowering the vehicle G

WARNING

The wheels could come loose if the wheel

bolts or wheel nuts are not tightened to the

prescribed tightening torque. There is a risk

of an accident.

Ensure that the wheel bolts or wheel nuts

are tightened to the prescribed tightening

torque.

If you are not sure, do not move the vehicle.

Contact a qualified specialist workshop and

have the tightening torque checked immedi-

ately. :—A

Wheel bolts

X Place the adapter and the ratchet on the

hexagon head nut of the jack such that the

lettering AB/DOWN is visible.

X Turn the ratchet in the AB/DOWN direction

until the vehicle is once again standing

firmly on the ground.

X Put the jack aside.

X Tighten the wheel bolts evenly in a cross-

wise pattern in the sequence indicated (:

to A).

Tighten the wheel bolts to the following

tightening torques:

R Steel wheel 147 lb-ft (200 Nm)

R Alloy wheel 133 lb-ft (180 Nm)300

Changing wheels

Wheels and tires

Page 303 of 320

X

Turn the jack back to its out-of-use position.

X Stow the jack and the rest of the tire-

change tool kit in the vehicle again.

X Wheel with hub cap: position the opening

for the tire valve in the hub cap over the tire

valve.

X Push the edge of the hub cap with both

hands against the wheel until it clicks into

place. Make sure the hub cap retaining

catches engage on the steel wheel.

X If included in the vehicle equipment, secure

the faulty wheel in the spare wheel bracket

(Y page

303). Otherwise, transport the

faulty wheel in the cargo compartment.

X Check the tire pressure of the newly moun-

ted wheel and adjust it if necessary.

Observe the recommended tire pressure

( Y page

282).

Vehicles with the tire pressure monitor sys-

tem: all mounted wheels must be equipped

with functioning sensors.

X Retighten the wheel bolts or wheel nuts to

the specified tightening torque after the

vehicle has been driven for

30 miles

(50 km).

When using a wheel/spare wheel with a new

or newly painted wheel rim, have the wheel

bolts/nuts retightened again after approx-

imately

600 to 3,000 miles (1,000 to

5,000 km). Observe the specified tightening

torque. Wheel and tire combinations

General notes

! Retreaded tires are neither tested nor rec-

ommended by Mercedes-Benz, since previ-

ous damage cannot always be detected on

retreaded tires. As a result, Mercedes-Benz

cannot guarantee vehicle safety if retreaded

tires are mounted. Do not mount used tires

if you have no information about their previ-

ous usage.

! For safety reasons, Mercedes-Benz recom-

mends that you only use tires, wheels and accessories which have been approved by

Mercedes-Benz specifically for your vehicle.

These tires have been specially adapted for

use with the driving safety systems, such as

ABS or ESP

®

.

Only use tires, wheels or accessories tested

and approved by Mercedes-Benz. Certain

characteristics, e.g. handling, vehicle noise

emissions or fuel consumption, may other-

wise be adversely affected. In addition,

when driving with a load, tire dimension var-

iations could cause the tires to come into

contact with the bodywork and axle compo-

nents. This could result in damage to the

tires or the vehicle.

Mercedes-Benz accepts no liability for dam-

age resulting from the use of tires, wheels

or accessories other than those tested and

approved.

Further information on wheels, tires and

approved combinations can be obtained

from a qualified specialist workshop.

! Large wheels: the lower the section width

for a certain wheel size, the lower the ride

comfort is on poor road surfaces. Roll com-

fort and suspension comfort are reduced

and the risk of damage to the wheels and

tires as a result of driving over obstacles

increases.

You will find a table with the recommended

tire pressures for various vehicle loads on the

inside of your vehicle's fuel filler flap or under

"Tire pressure tables"

(Y page 289). You can

find further information under "Tire pressure"

( Y page 282).

Check tire pressures regularly and only when

the tires are cold.

Notes on the vehicle equipment – always

equip the vehicle:

R with tires of the same size across an axle

(left/right)

R with the same type of tires on all wheels at

a given time (summer tires, winter tires)

i Not all wheel/tire combinations can be

installed at the factory in all countries. Wheel and tire combinations

301

Wheels and tires Z

Page 304 of 320

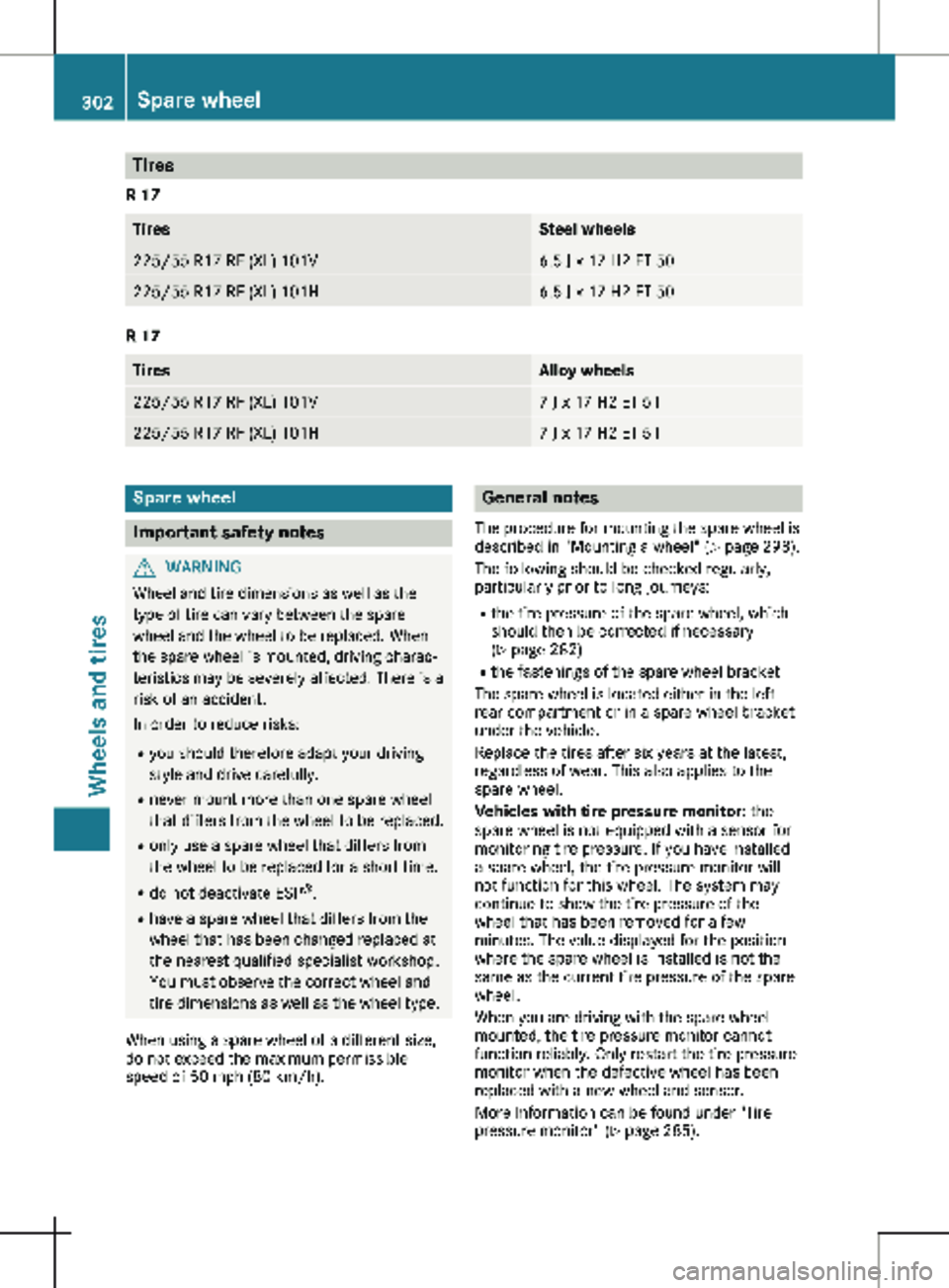

Tires

R 17 Tires Steel wheels

225/55 R17 RF (XL) 101V 6.5 J x 17 H2 ET 50

225/55 R17 RF (XL) 101H 6.5 J x 17 H2 ET 50

R 17

Tires Alloy wheels

225/55 R17 RF (XL) 101V 7 J x 17 H2 ET 51

225/55 R17 RF (XL) 101H 7 J x 17 H2 ET 51

Spare wheel

Important safety notes

G

WARNING

Wheel and tire dimensions as well as the

type of tire can vary between the spare

wheel and the wheel to be replaced. When

the spare wheel is mounted, driving charac-

teristics may be severely affected. There is a

risk of an accident.

In order to reduce risks:

R you should therefore adapt your driving

style and drive carefully.

R never mount more than one spare wheel

that differs from the wheel to be replaced.

R only use a spare wheel that differs from

the wheel to be replaced for a short time.

R do not deactivate ESP ®

.

R have a spare wheel that differs from the

wheel that has been changed replaced at

the nearest qualified specialist workshop.

You must observe the correct wheel and

tire dimensions as well as the wheel type.

When using a spare wheel of a different size,

do not exceed the maximum permissible

speed of

50 mph (80 km/h). General notes

The procedure for mounting the spare wheel is

described in "Mounting a wheel"

(Y page 298).

The following should be checked regularly,

particularly prior to long journeys:

R the tire pressure of the spare wheel, which

should then be corrected if necessary

(Y page 282)

R the fastenings of the spare wheel bracket

The spare wheel is located either in the left

rear compartment or in a spare wheel bracket

under the vehicle.

Replace the tires after six years at the latest,

regardless of wear. This also applies to the

spare wheel.

Vehicles with tire pressure monitor: the

spare wheel is not equipped with a sensor for

monitoring tire pressure. If you have installed

a spare wheel, the tire pressure monitor will

not function for this wheel. The system may

continue to show the tire pressure of the

wheel that has been removed for a few

minutes. The value displayed for the position

where the spare wheel is installed is not the

same as the current tire pressure of the spare

wheel.

When you are driving with the spare wheel

mounted, the tire pressure monitor cannot

function reliably. Only restart the tire pressure

monitor when the defective wheel has been

replaced with a new wheel and sensor.

More Information can be found under "Tire

pressure monitor" (Y page 285). 302

Spare wheel

Wheels and tires

Page 305 of 320

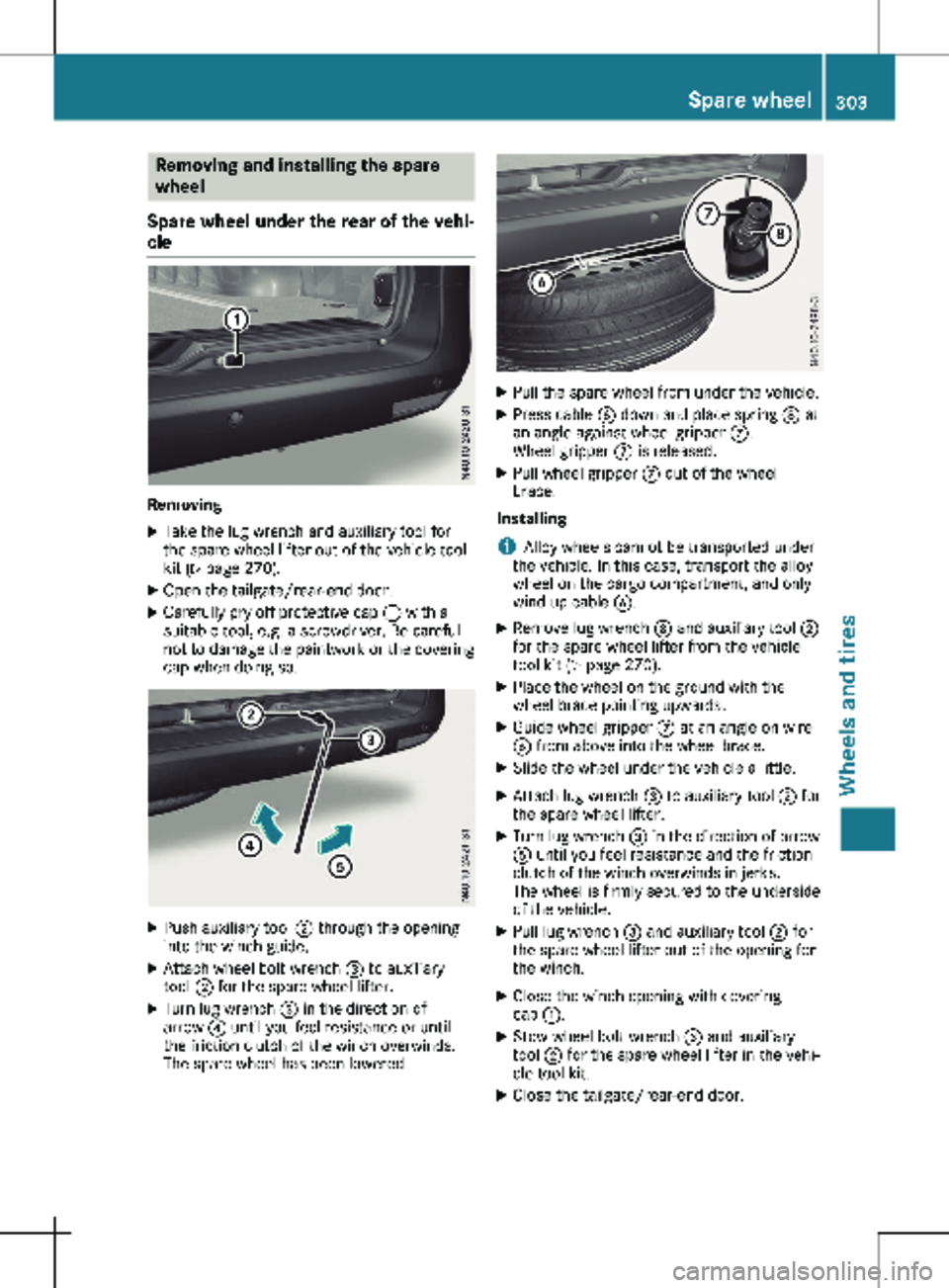

Removing and installing the spare

wheel

Spare wheel under the rear of the vehi-

cle Removing

X Take the lug wrench and auxiliary tool for

the spare wheel lifter out of the vehicle tool

kit

(Y page 270).

X Open the tailgate/rear-end door.

X Carefully pry off protective cap : with a

suitable tool, e.g. a screwdriver. Be careful

not to damage the paintwork or the covering

cap when doing so. X

Push auxiliary tool ; through the opening

into the winch guide.

X Attach wheel bolt wrench = to auxiliary

tool ; for the spare wheel lifter.

X Turn lug wrench = in the direction of

arrow ? until you feel resistance or until

the friction clutch of the winch overwinds.

The spare wheel has been lowered. X

Pull the spare wheel from under the vehicle.

X Press cable B down and place spring D at

an angle against wheel gripper C.

Wheel gripper C is released.

X Pull wheel gripper C out of the wheel

brace.

Installing

i Alloy wheels cannot be transported under

the vehicle. In this case, transport the alloy

wheel on the cargo compartment, and only

wind up cable B.

X Remove lug wrench = and auxiliary tool ;

for the spare wheel lifter from the vehicle

tool kit

(Y page 270).

X Place the wheel on the ground with the

wheel brace pointing upwards.

X Guide wheel gripper C at an angle on wire

B from above into the wheel brace.

X Slide the wheel under the vehicle a little.

X Attach lug wrench = to auxiliary tool ; for

the spare wheel lifter.

X Turn lug wrench = in the direction of arrow

A until you feel resistance and the friction

clutch of the winch overwinds in jerks.

The wheel is firmly secured to the underside

of the vehicle.

X Pull lug wrench = and auxiliary tool ; for

the spare wheel lifter out of the opening for

the winch.

X Close the winch opening with covering

cap :.

X Stow wheel bolt wrench = and auxiliary

tool ; for the spare wheel lifter in the vehi-

cle tool kit.

X Close the tailgate/rear-end door. Spare wheel

303

Wheels and tires Z

Page 306 of 320

Useful information

This Operator's Manual describes all models

as well as standard and optional equipment of

your vehicle that were available at the time of

going to print. Country-specific variations are

possible. Note that your vehicle may not be

equipped with all of the described functions.

This also applies to systems and functions rel-

evant to safety.

Read the information on qualified specialist

workshops (Y page

32).Vehicle electronics

Tampering with the engine electron-

ics

! Have work carried out on the engine elec-

tronics and its associated parts, such as

control units, sensors, actuating compo-

nents and fuel lines, only at a qualified spe-

cialist workshop. Vehicle components may

otherwise wear more quickly. This can lead

to the loss of the New Vehicle Limited War-

ranty. Installing electrical or electronic

equipment

You and others can suffer health-related dam-

age through electromagnetic radiation. By

using an exterior antenna, a possible health

risk caused by electromagnetic fields, as dis-

cussed in scientific circles, is taken into

account. Only have the exterior antenna instal-

led by a qualified specialist workshop.

Electrical and electronic devices may have a

detrimental effect on both the comfort and the

operating safety of the vehicle. If equipment of

this kind is installed, its electromagnetic com-

patibility must be checked and verified.

If these devices are linked to functions associ-

ated with resistance to interference, they must

have type approval. This applies to the device

or its interfaces to the vehicle electronics, e.g.

charging brackets.

A telephone or two-way radio to be installed in

the vehicle must be approved. You can obtain

further information from any Mercedes-Benz

Commercial Van Center. For operation of mobile phones and two-way

radios, Mercedes-Benz recommends connec-

tion to an approved exterior antenna. This is

the only way to ensure optimum reception

quality inside the vehicle and to minimize

mutual interference between the vehicle elec-

tronics, mobile phones and two-way radios.

The transmission output of the mobile phone

or two-way radio may not exceed the following

maximum transmission output (PEAK): Frequency range Maximum trans-

mission output

(PEAK)

Shortwave

(f < 50 MHz

) 100 W

4 m waveband 30 W

2 m waveband 50 W

Trunked radio/Tetra 35 W

70 cm waveband 35 W

GSM/UMTS/LTE 10 W

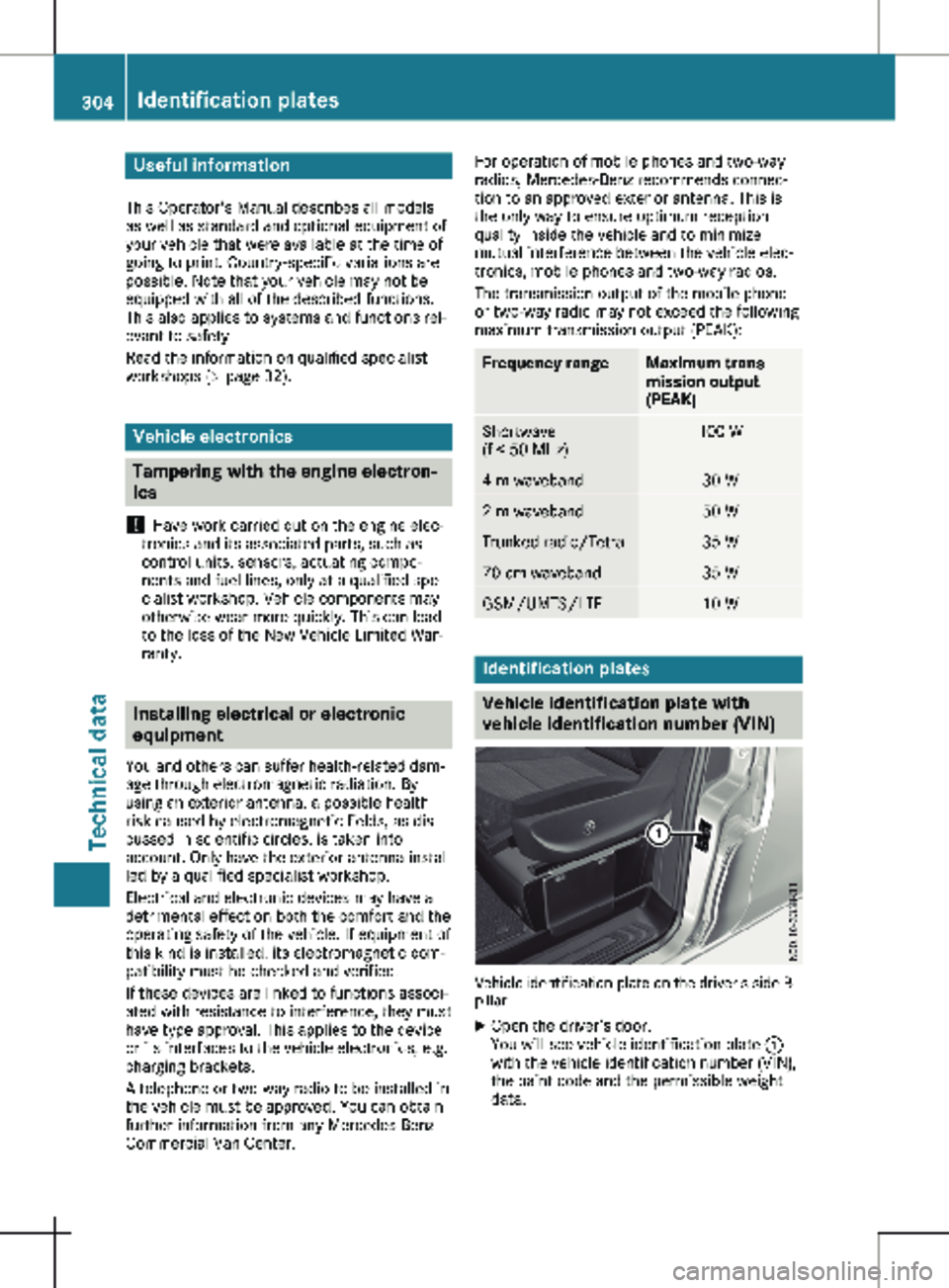

Identification plates

Vehicle identification plate with

vehicle identification number (VIN)

Vehicle identification plate on the driver's side B-

pillar

X Open the driver’s door.

You will see vehicle identification plate :

with the vehicle identification number (VIN),

the paint code and the permissible weight

data. 304

Identification plates

Technical data

Page 307 of 320

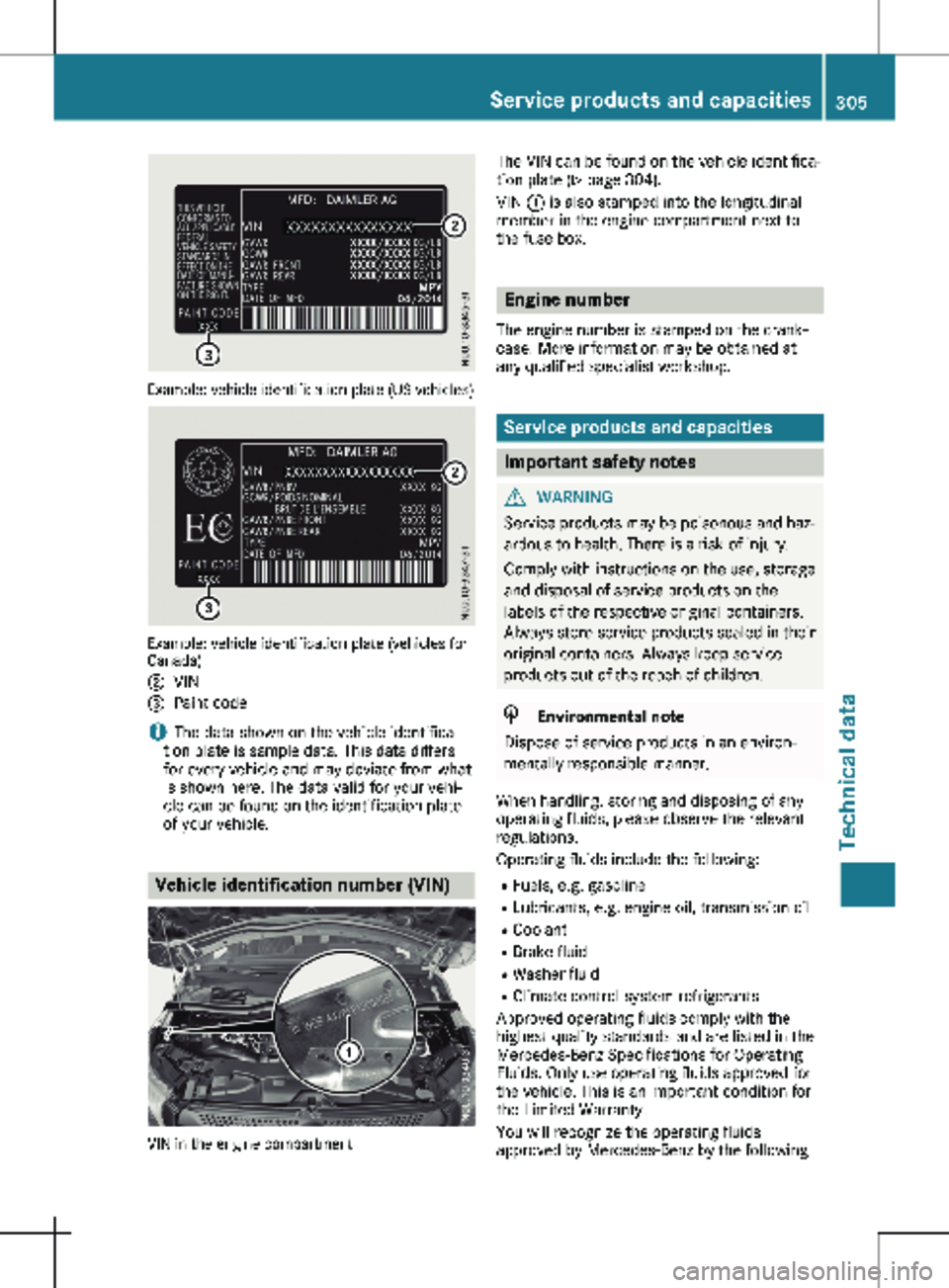

Example: vehicle identification plate (US vehicles)

Example: vehicle identification plate (vehicles for

Canada)

; VIN

= Paint code

i The data shown on the vehicle identifica-

tion plate is sample data. This data differs

for every vehicle and may deviate from what

is shown here. The data valid for your vehi-

cle can be found on the identification plate

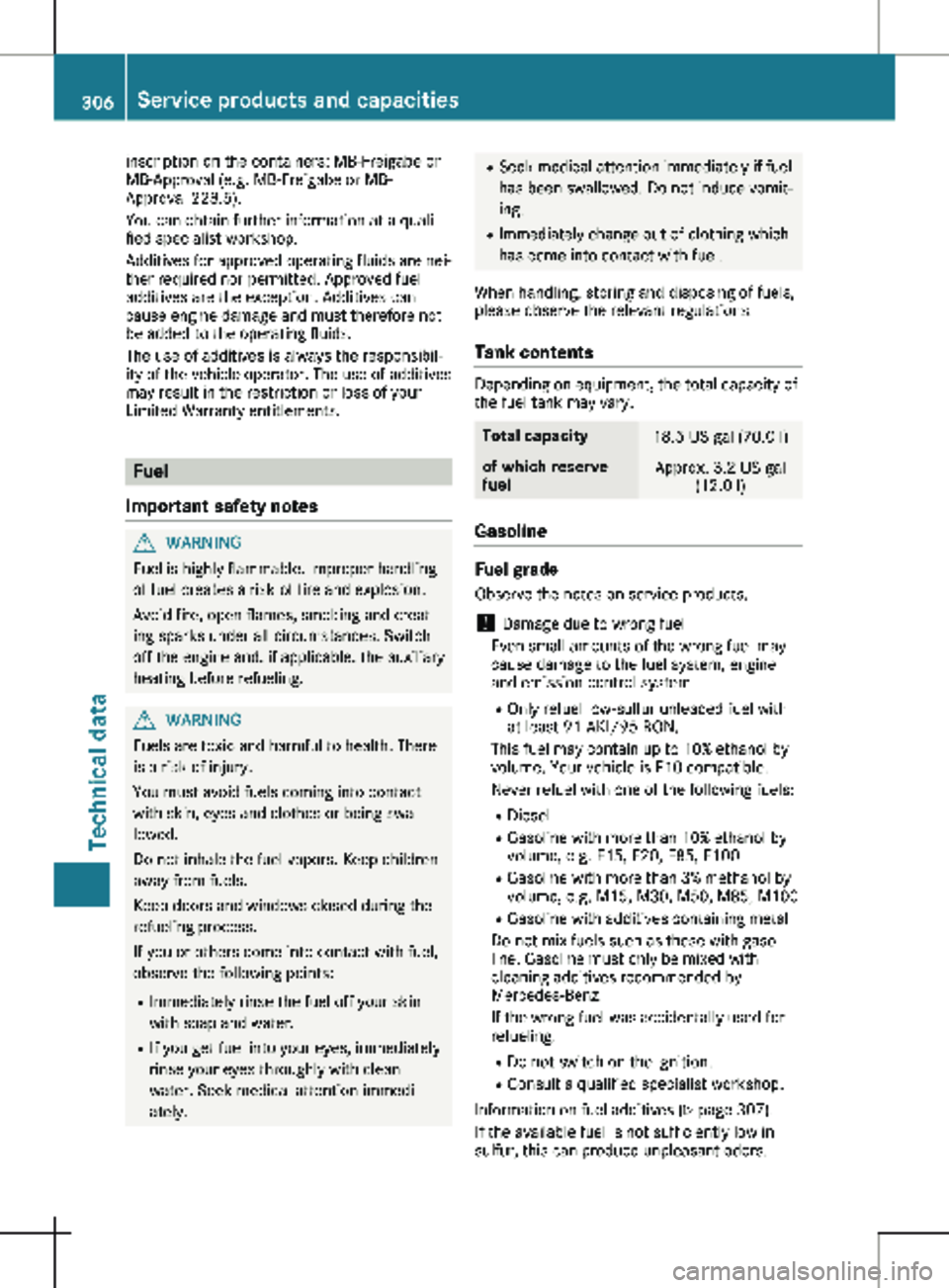

of your vehicle. Vehicle identification number (VIN)

VIN in the engine compartment The VIN can be found on the vehicle identifica-

tion plate (Y page

304).

VIN : is also stamped into the longitudinal

member in the engine compartment next to

the fuse box. Engine number

The engine number is stamped on the crank-

case. More information may be obtained at

any qualified specialist workshop. Service products and capacities

Important safety notes

G

WARNING

Service products may be poisonous and haz-

ardous to health. There is a risk of injury.

Comply with instructions on the use, storage

and disposal of service products on the

labels of the respective original containers.

Always store service products sealed in their

original containers. Always keep service

products out of the reach of children. H

Environmental note

Dispose of service products in an environ-

mentally responsible manner.

When handling, storing and disposing of any

operating fluids, please observe the relevant

regulations.

Operating fluids include the following:

R Fuels, e.g. gasoline

R Lubricants, e.g. engine oil, transmission oil

R Coolant

R Brake fluid

R Washer fluid

R Climate control system refrigerants

Approved operating fluids comply with the

highest quality standards and are listed in the

Mercedes-Benz Specifications for Operating

Fluids. Only use operating fluids approved for

the vehicle. This is an important condition for

the Limited Warranty.

You will recognize the operating fluids

approved by Mercedes-Benz by the following Service products and capacities

305

Technical data Z

Page 308 of 320

inscription on the containers: MB-Freigabe or

MB-Approval (e.g. MB-Freigabe or MB-

Approval 228.5).

You can obtain further information at a quali-

fied specialist workshop.

Additives for approved operating fluids are nei-

ther required nor permitted. Approved fuel

additives are the exception. Additives can

cause engine damage and must therefore not

be added to the operating fluids.

The use of additives is always the responsibil-

ity of the vehicle operator. The use of additives

may result in the restriction or loss of your

Limited Warranty entitlements. Fuel

Important safety notes G

WARNING

Fuel is highly flammable. Improper handling

of fuel creates a risk of fire and explosion.

Avoid fire, open flames, smoking and creat-

ing sparks under all circumstances. Switch

off the engine and, if applicable, the auxiliary

heating before refueling. G

WARNING

Fuels are toxic and harmful to health. There

is a risk of injury.

You must avoid fuels coming into contact

with skin, eyes and clothes or being swal-

lowed.

Do not inhale the fuel vapors. Keep children

away from fuels.

Keep doors and windows closed during the

refueling process.

If you or others come into contact with fuel,

observe the following points:

R Immediately rinse the fuel off your skin

with soap and water.

R If you get fuel into your eyes, immediately

rinse your eyes throughly with clean

water. Seek medical attention immedi-

ately. R

Seek medical attention immediately if fuel

has been swallowed. Do not induce vomit-

ing.

R Immediately change out of clothing which

has come into contact with fuel.

When handling, storing and disposing of fuels,

please observe the relevant regulations.

Tank contents Depending on equipment, the total capacity of

the fuel tank may vary.

Total capacity

18.5 US gal (70.0 l)

of which reserve

fuel

Approx. 3.2 US gal

(12.0 l ) Gasoline

Fuel grade

Observe the notes on service products.

! Damage due to wrong fuel

Even small amounts of the wrong fuel may

cause damage to the fuel system, engine

and emission control system.

R Only refuel low-sulfur unleaded fuel with

at least

91 AKI/95 RON.

This fuel may contain up to 10% ethanol by

volume. Your vehicle is E10 compatible.

Never refuel with one of the following fuels:

R Diesel

R Gasoline with more than 10% ethanol by

volume, e.g. E15, E20, E85, E100

R Gasoline with more than 3% methanol by

volume, e.g. M15, M30, M50, M85, M100

R Gasoline with additives containing metal

Do not mix fuels such as these with gaso-

line. Gasoline must only be mixed with

cleaning additives recommended by

Mercedes-Benz.

If the wrong fuel was accidentally used for

refueling:

R Do not switch on the ignition.

R Consult a qualified specialist workshop.

Information on fuel additives (Y page 307). If the available fuel is not sufficiently low in

sulfur, this can produce unpleasant odors. 306

Service products and capacities

Technical data

Page 309 of 320

!

Filter the fuel before transferring it to the

vehicle if you are refueling the vehicle from

barrels or containers.

This will prevent malfunctions in the fuel

system due to contaminated fuel.

i E10 fuel contains an admixture of up to

10% bioethanol. Your vehicle is E10 compat-

ible. You can refuel your vehicle with E10

fuel.

i You can obtain information on fuel grades

at a qualified specialist workshop or at a gas

station. If there is no identification on the

filling pump, consult a gas station attendant.

For more information about refueling

(Y page

136).

Fuel additives

! Operating the engine with subsequently

added fuel additives can cause engine dam-

age. Do not mix fuel additives with fuel. This

does not include additives for the removal

and prevention of deposits. Gasoline can

only be mixed with additives recommended

by Mercedes-Benz. Follow the instructions

in the product description. You can find fur-

ther information on recommended additives

in any Mercedes-Benz Commercial Van Cen-

ter.

Mercedes-Benz recommends using brand-

name fuels with additives.

If you use fuels without these additives for a

long period of time, deposits can form. This

primarily forms on the inlet valve and in the

combustion chamber.

In some countries, the available fuel grade

may be inadequate. Residue could build up in

the fuel injection system as a result. In this

case, in consultation with a Mercedes-Benz

Commercial Van Center, the fuel should be

mixed with the cleaning additive recommen-

ded by Mercedes-Benz. You must observe the

notes and mixing ratios indicated on the con-

tainer.

Do not add other fuel additives to the fuel.

This results in unnecessary costs and can

damage the engine. Information on fuel consumption H

Environmental note

CO 2 (carbon dioxide) is the gas that accord-

ing to the current state of knowledge is

mainly responsible for the heating of the

earth's atmosphere (greenhouse effect). The

CO 2 emissions of your vehicle vary in direct

correspondence with the fuel consumption

and is therefore dependent on:

R the efficient utilization of the fuel by the

engine

R the respective style of driving

R other non-technical factors, such as envi-

ronmental influences, condition of the

road or traffic flow, for example

You can help to minimize CO 2 emissions

with a conservative driving style and regular

maintenance of your vehicle .

Only for certain countries: the respective cur-

rent consumption and emission values of your

vehicle can be found in the COC papers (EC

CERTIFICATE OF CONFORMITY). These docu-

ments are supplied when the vehicle is deliv-

ered.

Consumption figures were found in the cur-

rently valid respective version: R for vehicles with exhaust gas standard Euro

6 as per directive (EC) no. 715/2007

R for vehicles with exhaust gas standard

EURO VI as per directive (EC) no. 595/2009

Fuel consumption depends on:

R the vehicle version

R the style of driving

R the operating conditions

R the fuel type and fuel grade used

The vehicle will use more fuel than usual in the

following situations:

R at very low outside temperatures

R in city traffic

R during short journeys

R on mountainous terrain

R when towing a trailer

Observe the advice in the "Protection of the

environment" section to keep fuel consump-

tion low

(Y page 29). Service products and capacities

307

Technical data Z

Page 310 of 320

The following components of the different

vehicle versions influence fuel consumption:

R tire sizes, tire tread, tire pressure, tire condi-

tion

R transmission ratios for the drive assemblies

R additional equipment (e.g. air-conditioning

system, auxiliary heating system)

For these reasons, the actual consumption fig-

ures for your vehicle may deviate from the

consumption figures determined according to

EU Directive

80/1268/EEC.

Details on fuel consumption can be called up

in the on-board computer:

R on vehicles without steering wheel buttons

(Y page 177)

R on vehicles with steering wheel buttons

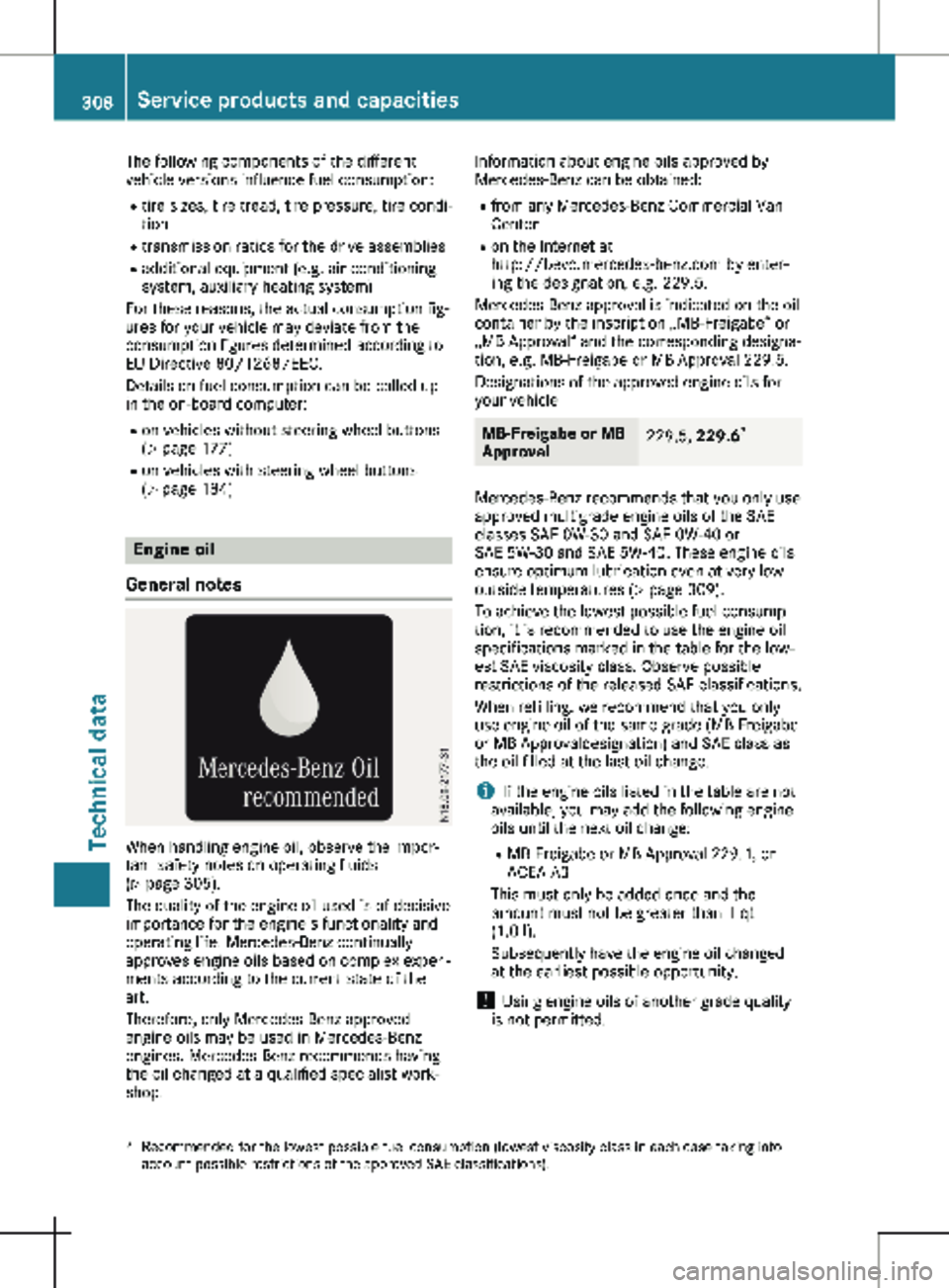

(Y page 184) Engine oil

General notes When handling engine oil, observe the impor-

tant safety notes on operating fluids

(Y page

305).

The quality of the engine oil used is of decisive

importance for the engine's functionality and

operating life. Mercedes-Benz continually

approves engine oils based on complex experi-

ments according to the current state of the

art.

Therefore, only Mercedes-Benz approved

engine oils may be used in Mercedes-Benz

engines. Mercedes-Benz recommends having

the oil changed at a qualified specialist work-

shop. Information about engine oils approved by

Mercedes-Benz can be obtained:

R from any Mercedes-Benz Commercial Van

Center

R on the Internet at

http://bevo.mercedes-benz.com

by enter-

ing the designation, e.g. 229.5.

Mercedes-Benz approval is indicated on the oil

container by the inscription „MB-Freigabe“ or

„MB Approval“ and the corresponding designa-

tion, e.g. MB-Freigabe or MB Approval 229.5.

Designations of the approved engine oils for

your vehicle MB-Freigabe or MB

Approval

229.5,

229.62 Mercedes-Benz recommends that you only use

approved multigrade engine oils of the SAE

classes

SAE 0W-30 and SAE 0W-40 or

SAE 5W-30 and SAE 5W-40. These engine oils

ensure optimum lubrication even at very low

outside temperatures (Y page 309).

To achieve the lowest possible fuel consump-

tion, it is recommended to use the engine oil

specifications marked in the table for the low-

est SAE viscosity class. Observe possible

restrictions of the released SAE classifications.

When refilling, we recommend that you only

use engine oil of the same grade (MB-Freigabe

or MB Approvaldesignation) and SAE class as

the oil filled at the last oil change.

i If the engine oils listed in the table are not

available, you may add the following engine

oils until the next oil change:

R MB-Freigabe or MB Approval 229.1, or

ACEA A3

This must only be added once and the

amount must not be greater than 1 qt

(1.0 l).

Subsequently have the engine oil changed

at the earliest possible opportunity.

! Using engine oils of another grade quality

is not permitted.

2 Recommended for the lowest possible fuel consumption (lowest viscosity class in each case taking into

account possible restrictions of the approved SAE classifications). 308

Service products and capacities

Technical data