MERCEDES-BENZ ML430 1997 Complete Repair Manual

Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML430, Model: MERCEDES-BENZ ML430 1997Pages: 4133, PDF Size: 88.89 MB

Page 1861 of 4133

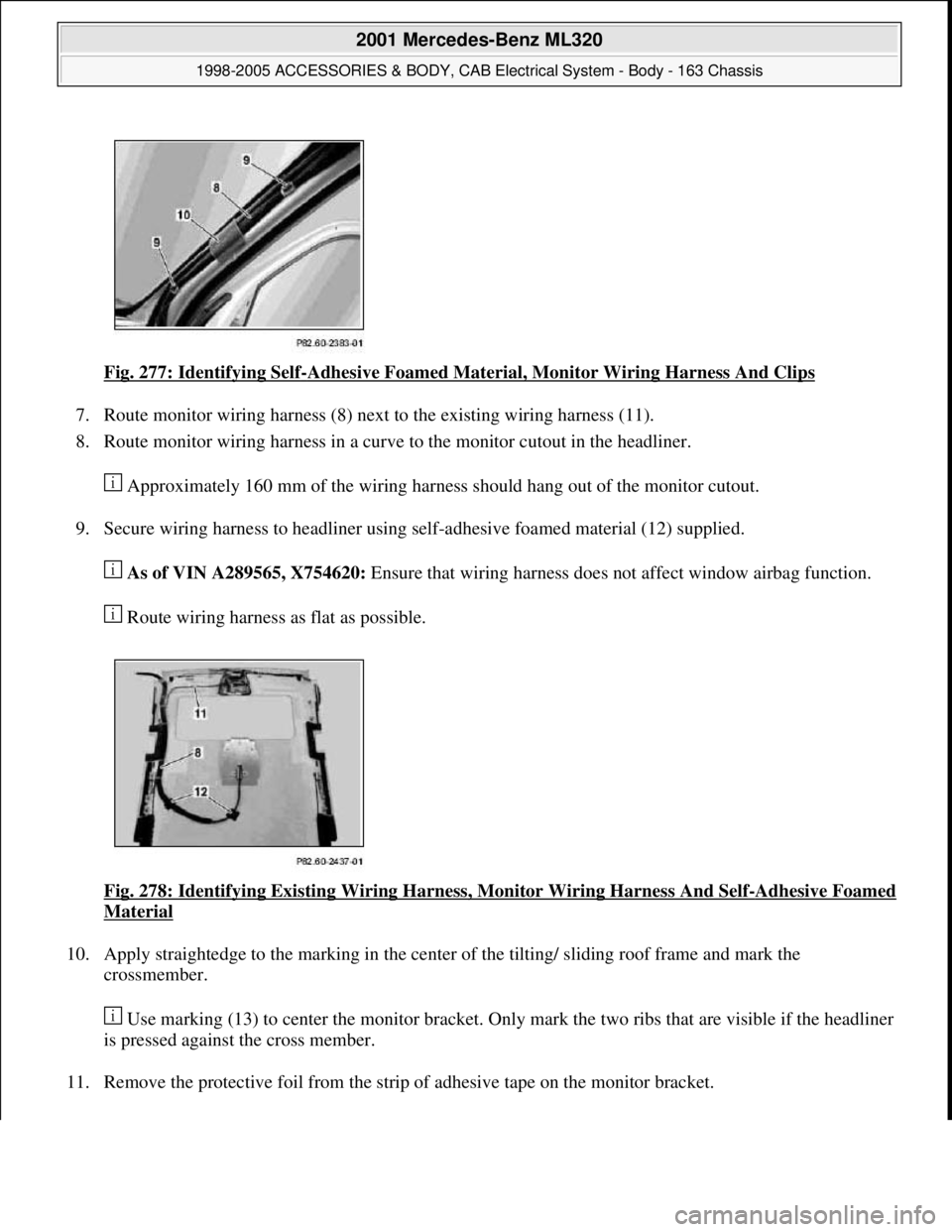

Fig. 277: Identifying Self-Adhesive Foamed Material, Monitor Wiring Harness And Clips

7. Route monitor wiring harness (8) next to the existing wiring harness (11).

8. Route monitor wiring harness in a curve to the monitor cutout in the headliner.

Approximately 160 mm of the wiring harness should hang out of the monitor cutout.

9. Secure wiring harness to headliner using self-adhesive foamed material (12) supplied.

As of VIN A289565, X754620: Ensure that wiring harness does not affect window airbag function.

Route wiring harness as flat as possible.

Fig. 278: Identifying Existing Wiring Harness, Monitor Wiring Harness And Self

-Adhesive Foamed

Material

10. Apply straightedge to the marking in the center of the tilting/ sliding roof frame and mark the

crossmember.

Use marking (13) to center the monitor bracket. Only mark the two ribs that are visible if the headliner

is pressed against the cross member.

11. Remove the protective foil from the strip of adhesive tape on the monitor bracket.

2001 Mercedes-Benz ML320

1998-2005 ACCESSORIES & BODY, CAB Electrical System - Body - 163 Chassis

me

Saturday, October 02, 2010 3:30:11 PMPage 366 © 2006 Mitchell Repair Information Company, LLC.

Page 1862 of 4133

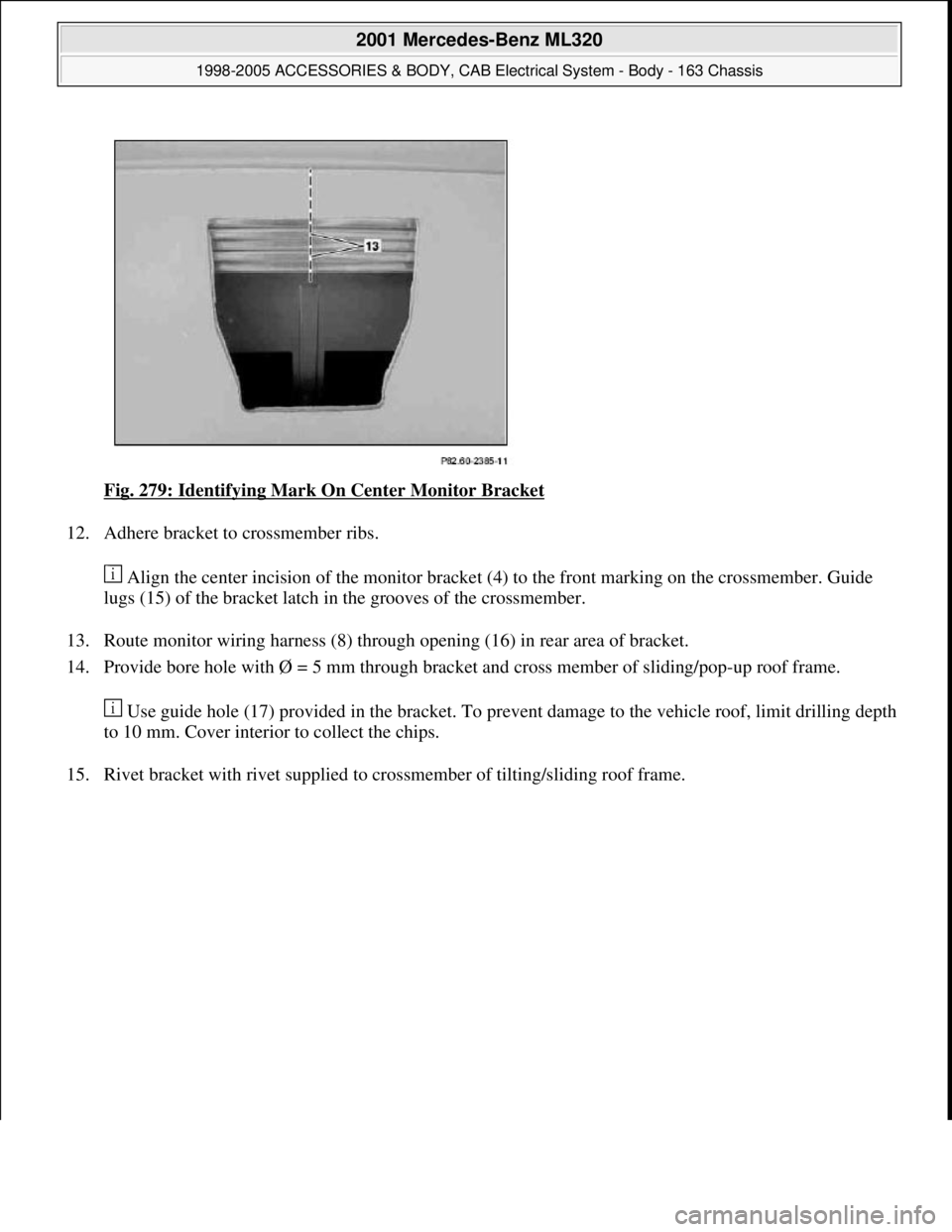

Fig. 279: Identifying Mark On Center Monitor Bracket

12. Adhere bracket to crossmember ribs.

Align the center incision of the monitor bracket (4) to the front marking on the crossmember. Guide

lugs (15) of the bracket latch in the grooves of the crossmember.

13. Route monitor wiring harness (8) through opening (16) in rear area of bracket.

14. Provide bore hole with Ø = 5 mm through bracket and cross member of sliding/pop-up roof frame.

Use guide hole (17) provided in the bracket. To prevent damage to the vehicle roof, limit drilling depth

to 10 mm. Cover interior to collect the chips.

15. Rivet bracket with rivet supplied to crossmember of tiltin

g/sliding roof frame.

2001 Mercedes-Benz ML320

1998-2005 ACCESSORIES & BODY, CAB Electrical System - Body - 163 Chassis

me

Saturday, October 02, 2010 3:30:11 PMPage 367 © 2006 Mitchell Repair Information Company, LLC.

Page 1863 of 4133

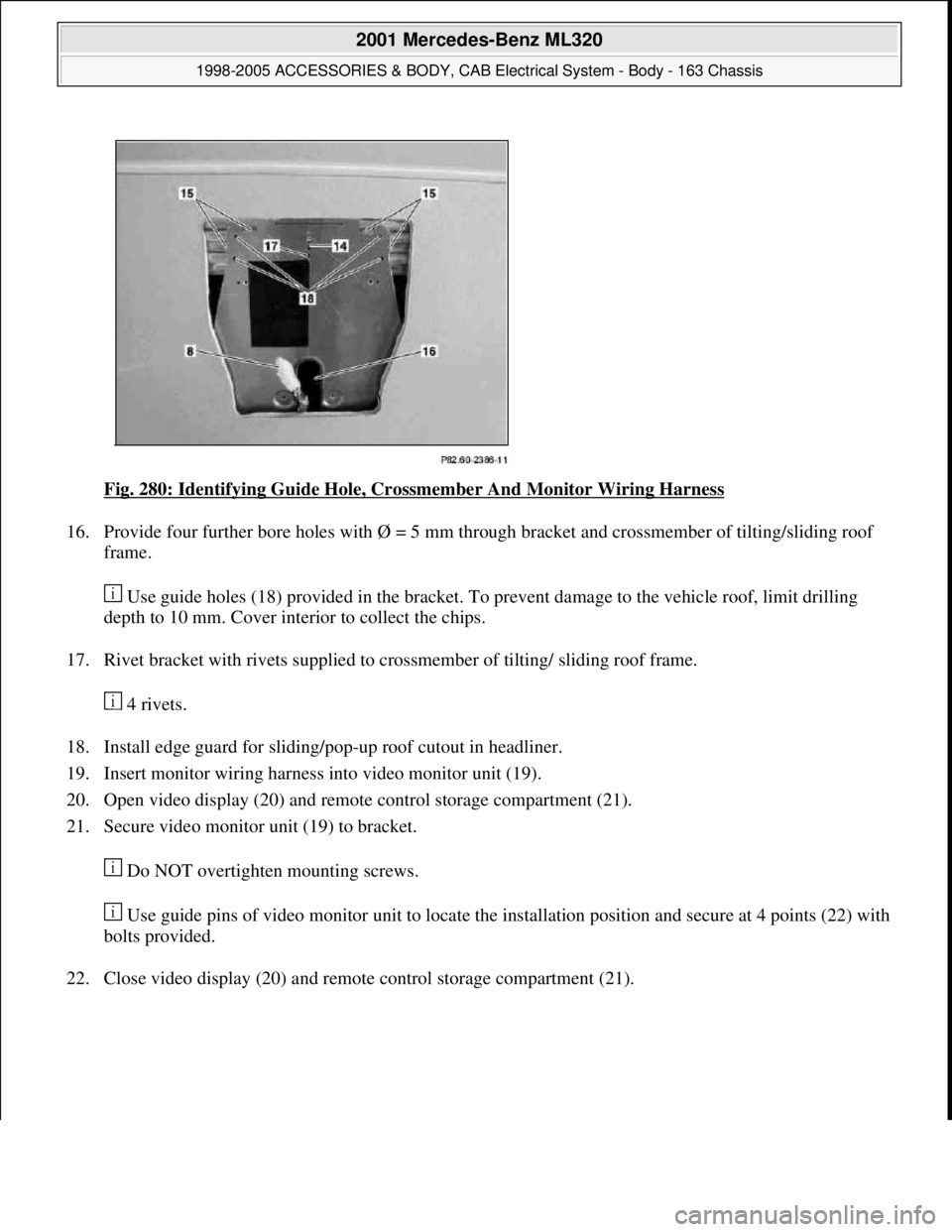

Fig. 280: Identifying Guide Hole, Crossmember And Monitor Wiring Harness

16. Provide four further bore holes with Ø = 5 mm through bracket and crossmember of tilting/sliding roof

frame.

Use guide holes (18) provided in the bracket. To prevent damage to the vehicle roof, limit drilling

depth to 10 mm. Cover interior to collect the chips.

17. Rivet bracket with rivets supplied to crossmember of tilting/ sliding roof frame.

4 rivets.

18. Install edge guard for sliding/pop-up roof cutout in headliner.

19. Insert monitor wiring harness into video monitor unit (19).

20. Open video display (20) and remote control storage compartment (21).

21. Secure video monitor unit (19) to bracket.

Do NOT overtighten mounting screws.

Use guide pins of video monitor unit to locate the installation position and secure at 4 points (22) with

bolts provided.

22. Close video display (20) and remote control storage compartment (21).

2001 Mercedes-Benz ML320

1998-2005 ACCESSORIES & BODY, CAB Electrical System - Body - 163 Chassis

me

Saturday, October 02, 2010 3:30:11 PMPage 368 © 2006 Mitchell Repair Information Company, LLC.

Page 1864 of 4133

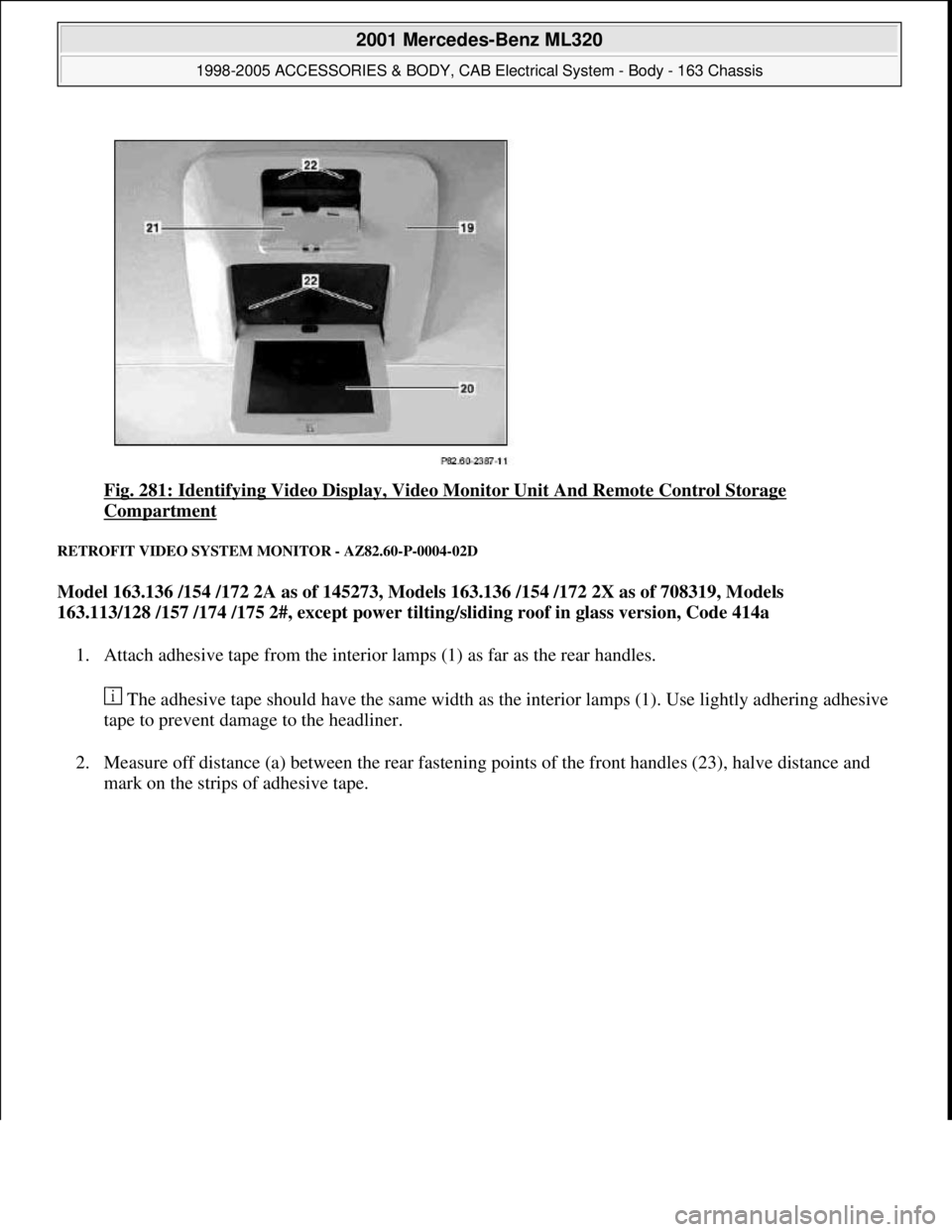

Fig. 281: Identifying Video Display, Video Monitor Unit And Remote Control Storage

Compartment

RETROFIT VIDEO SYSTEM MONITOR - AZ82.60-P-0004-02D

Model 163.136 /154 /172 2A as of 145273, Models 163.136 /154 /172 2X as of 708319, Models

163.113/128 /157 /174 /175 2#, except power tilting/sliding roof in glass version, Code 414a

1. Attach adhesive tape from the interior lamps (1) as far as the rear handles.

The adhesive tape should have the same width as the interior lamps (1). Use lightly adhering adhesive

tape to prevent damage to the headliner.

2. Measure off distance (a) between the rear fastening points of the front handles (23), halve distance and

mark on the strips of adhesive tape.

2001 Mercedes-Benz ML320

1998-2005 ACCESSORIES & BODY, CAB Electrical System - Body - 163 Chassis

me

Saturday, October 02, 2010 3:30:11 PMPage 369 © 2006 Mitchell Repair Information Company, LLC.

Page 1865 of 4133

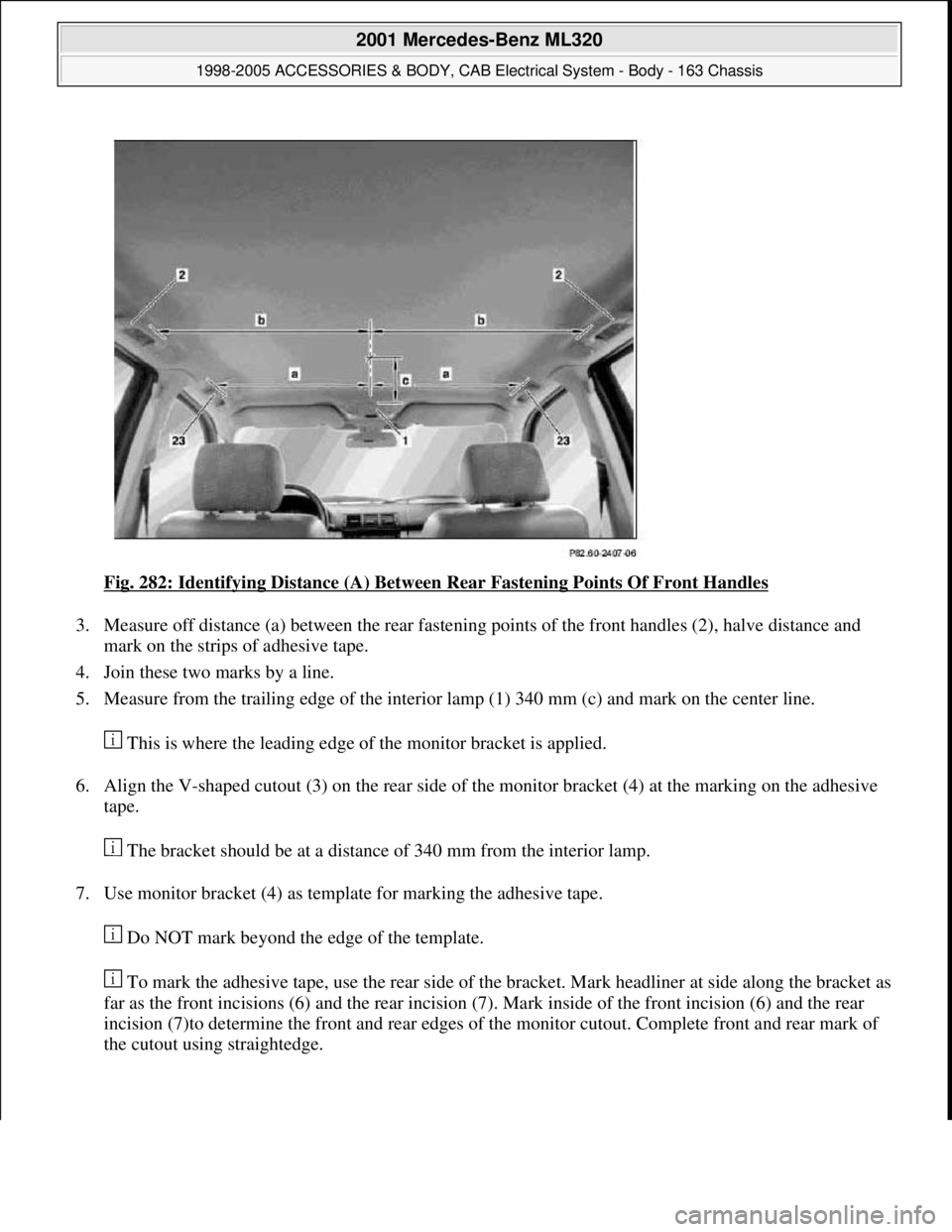

Fig. 282: Identifying Distance (A) Between Rear Fastening Points Of Front Handles

3. Measure off distance (a) between the rear fastening points of the front handles (2), halve distance and

mark on the strips of adhesive tape.

4. Join these two marks by a line.

5. Measure from the trailing edge of the interior lamp (1) 340 mm (c) and mark on the center line.

This is where the leading edge of the monitor bracket is applied.

6. Align the V-shaped cutout (3) on the rear side of the monitor bracket (4) at the marking on the adhesive

tape.

The bracket should be at a distance of 340 mm from the interior lamp.

7. Use monitor bracket (4) as template for marking the adhesive tape.

Do NOT mark beyond the edge of the template.

To mark the adhesive tape, use the rear side of the bracket. Mark headliner at side along the bracket as

far as the front incisions (6) and the rear incision (7). Mark inside of the front incision (6) and the rear

incision (7)to determine the front and rear edges of the monitor cutout. Complete front and rear mark of

the cutout usin

g straightedge.

2001 Mercedes-Benz ML320

1998-2005 ACCESSORIES & BODY, CAB Electrical System - Body - 163 Chassis

me

Saturday, October 02, 2010 3:30:11 PMPage 370 © 2006 Mitchell Repair Information Company, LLC.

Page 1866 of 4133

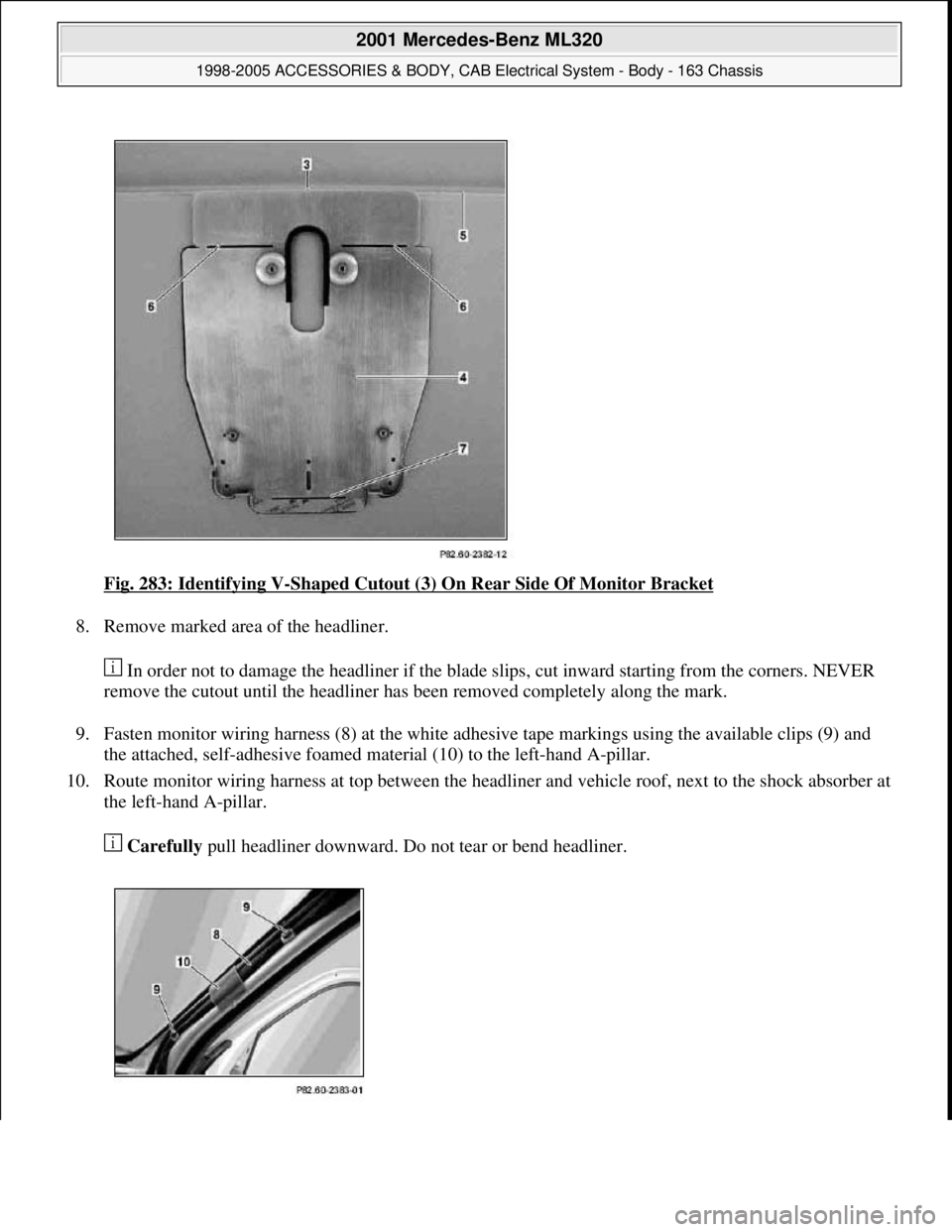

Fig. 283: Identifying V-Shaped Cutout (3) On Rear Side Of Monitor Bracket

8. Remove marked area of the headliner.

In order not to damage the headliner if the blade slips, cut inward starting from the corners. NEVER

remove the cutout until the headliner has been removed completely along the mark.

9. Fasten monitor wiring harness (8) at the white adhesive tape markings using the available clips (9) and

the attached, self-adhesive foamed material (10) to the left-hand A-pillar.

10. Route monitor wiring harness at top between the headliner and vehicle roof, next to the shock absorber at

the left-hand A-pillar.

Carefully pull headliner downward. Do not tear or bend headliner.

2001 Mercedes-Benz ML320

1998-2005 ACCESSORIES & BODY, CAB Electrical System - Body - 163 Chassis

me

Saturday, October 02, 2010 3:30:12 PMPage 371 © 2006 Mitchell Repair Information Company, LLC.

Page 1867 of 4133

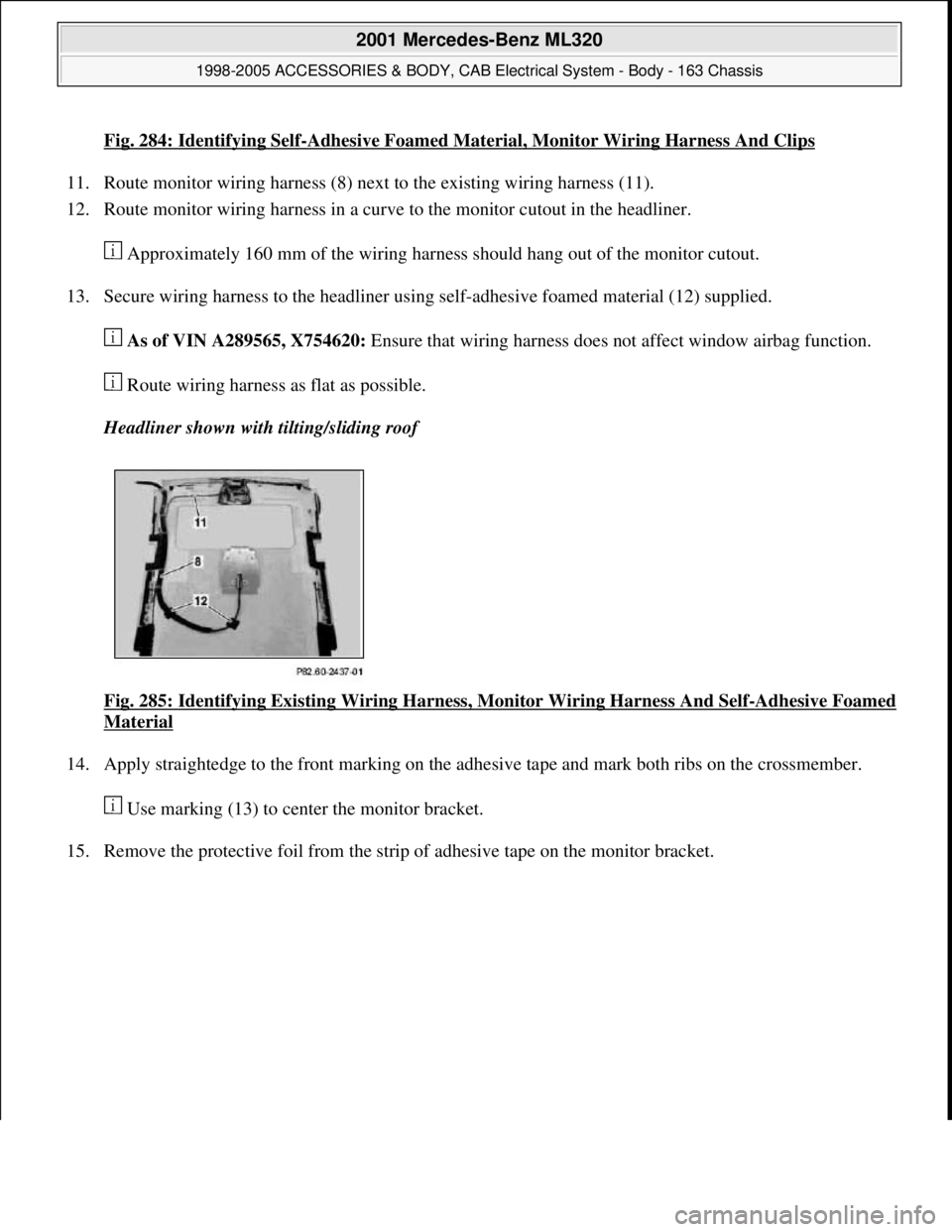

Fig. 284: Identifying Self-Adhesive Foamed Material, Monitor Wiring Harness And Clips

11. Route monitor wiring harness (8) next to the existing wiring harness (11).

12. Route monitor wiring harness in a curve to the monitor cutout in the headliner.

Approximately 160 mm of the wiring harness should hang out of the monitor cutout.

13. Secure wiring harness to the headliner using self-adhesive foamed material (12) supplied.

As of VIN A289565, X754620: Ensure that wiring harness does not affect window airbag function.

Route wiring harness as flat as possible.

Headliner shown with tilting/sliding roof

Fig. 285: Identifying Existing Wiring Harness, Monitor Wiring Harness And Self

-Adhesive Foamed

Material

14. Apply straightedge to the front marking on the adhesive tape and mark both ribs on the crossmember.

Use marking (13) to center the monitor bracket.

15. Remove the protective foil from the strip of adhesive tape on the monitor bracket.

2001 Mercedes-Benz ML320

1998-2005 ACCESSORIES & BODY, CAB Electrical System - Body - 163 Chassis

me

Saturday, October 02, 2010 3:30:12 PMPage 372 © 2006 Mitchell Repair Information Company, LLC.

Page 1868 of 4133

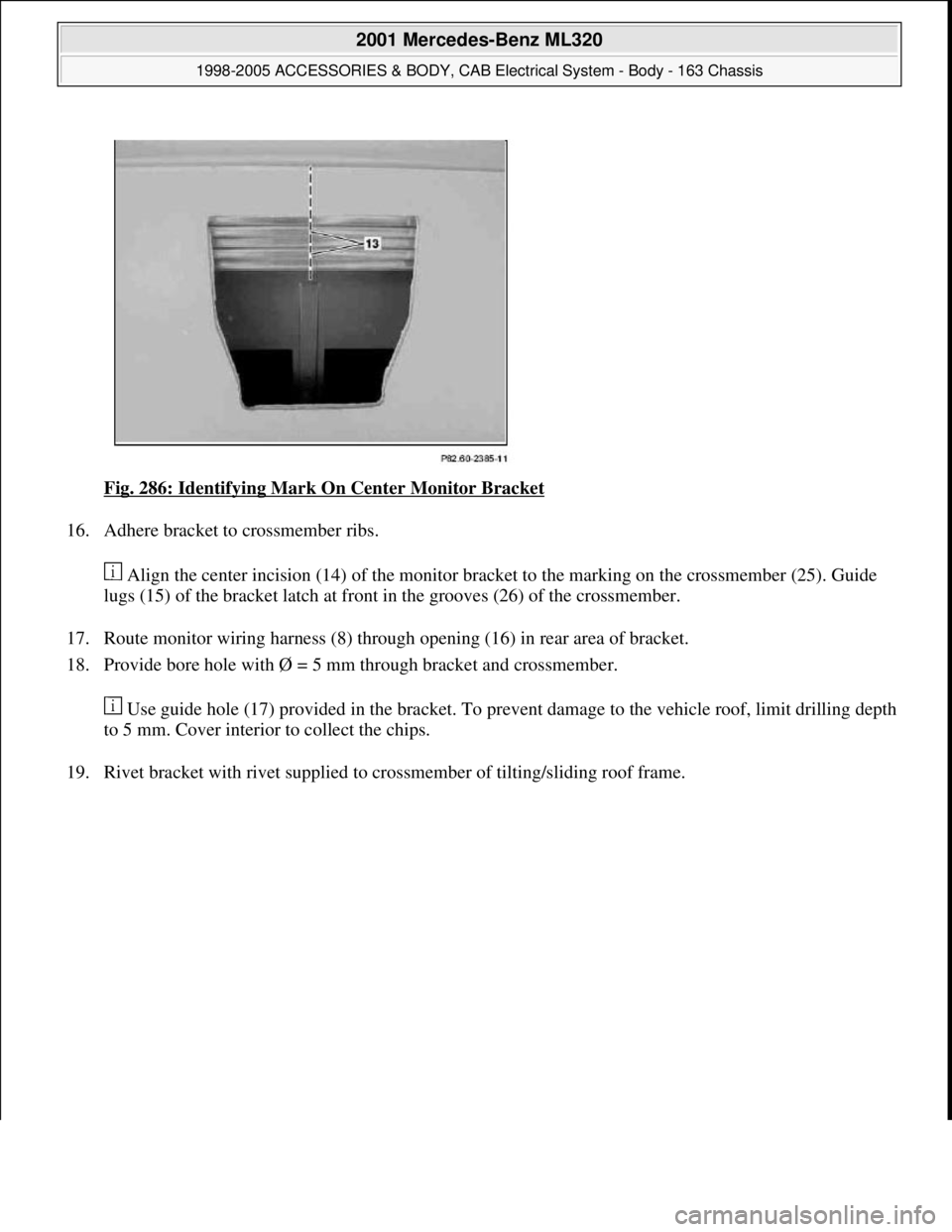

Fig. 286: Identifying Mark On Center Monitor Bracket

16. Adhere bracket to crossmember ribs.

Align the center incision (14) of the monitor bracket to the marking on the crossmember (25). Guide

lugs (15) of the bracket latch at front in the grooves (26) of the crossmember.

17. Route monitor wiring harness (8) through opening (16) in rear area of bracket.

18. Provide bore hole with Ø = 5 mm through bracket and crossmember.

Use guide hole (17) provided in the bracket. To prevent damage to the vehicle roof, limit drilling depth

to 5 mm. Cover interior to collect the chips.

19. Rivet bracket with rivet supplied to crossmember of tiltin

g/sliding roof frame.

2001 Mercedes-Benz ML320

1998-2005 ACCESSORIES & BODY, CAB Electrical System - Body - 163 Chassis

me

Saturday, October 02, 2010 3:30:12 PMPage 373 © 2006 Mitchell Repair Information Company, LLC.

Page 1869 of 4133

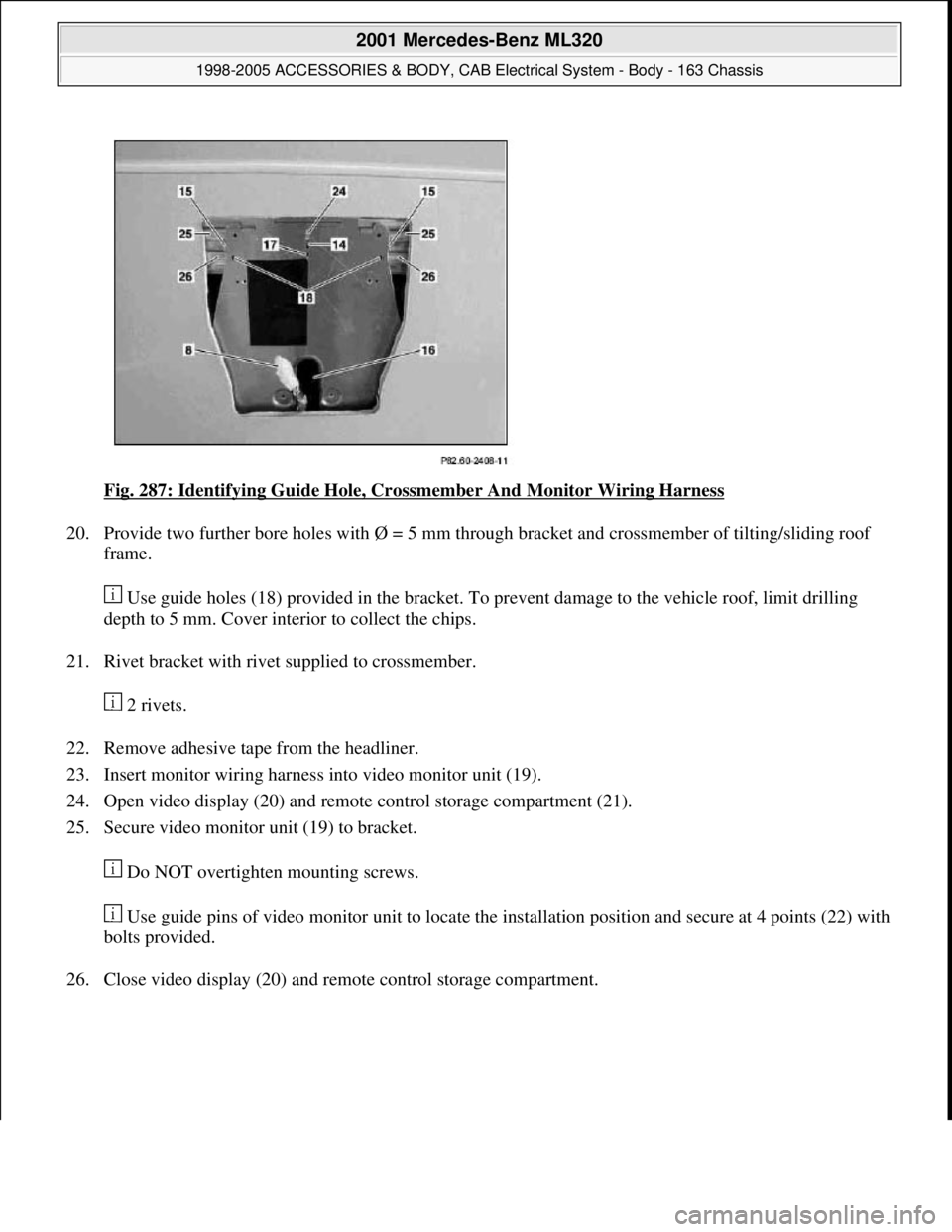

Fig. 287: Identifying Guide Hole, Crossmember And Monitor Wiring Harness

20. Provide two further bore holes with Ø = 5 mm through bracket and crossmember of tilting/sliding roof

frame.

Use guide holes (18) provided in the bracket. To prevent damage to the vehicle roof, limit drilling

depth to 5 mm. Cover interior to collect the chips.

21. Rivet bracket with rivet supplied to crossmember.

2 rivets.

22. Remove adhesive tape from the headliner.

23. Insert monitor wiring harness into video monitor unit (19).

24. Open video display (20) and remote control storage compartment (21).

25. Secure video monitor unit (19) to bracket.

Do NOT overtighten mounting screws.

Use guide pins of video monitor unit to locate the installation position and secure at 4 points (22) with

bolts provided.

26. Close video displa

y (20) and remote control storage compartment.

2001 Mercedes-Benz ML320

1998-2005 ACCESSORIES & BODY, CAB Electrical System - Body - 163 Chassis

me

Saturday, October 02, 2010 3:30:12 PMPage 374 © 2006 Mitchell Repair Information Company, LLC.

Page 1870 of 4133

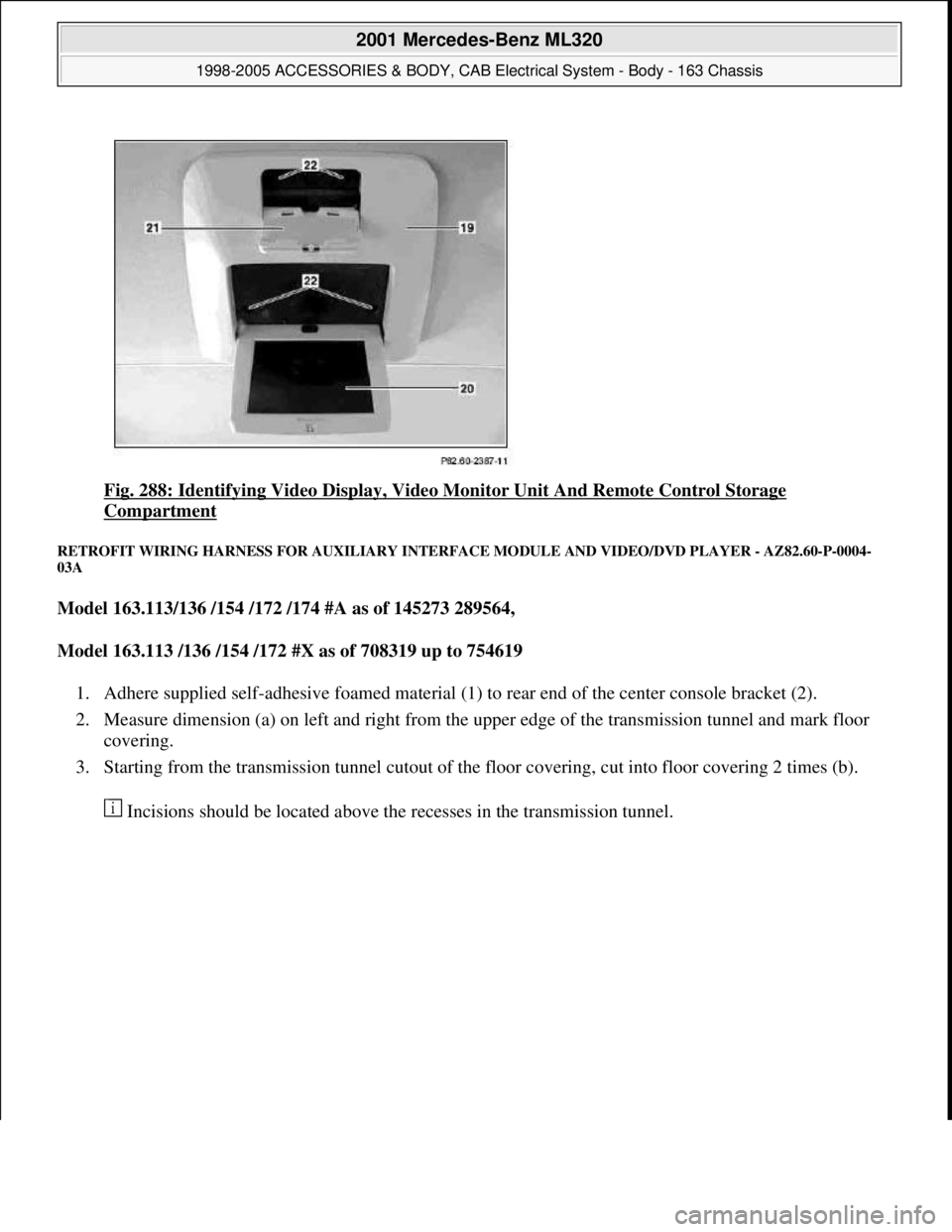

Fig. 288: Identifying Video Display, Video Monitor Unit And Remote Control Storage

Compartment

RETROFIT WIRING HARNESS FOR AUXILIARY INTERFACE MODULE AND VIDEO/DVD PLAYER - AZ82.60-P-0004-

03A

Model 163.113/136 /154 /172 /174 #A as of 145273 289564,

Model 163.113 /136 /154 /172 #X as of 708319 up to 754619

1. Adhere supplied self-adhesive foamed material (1) to rear end of the center console bracket (2).

2. Measure dimension (a) on left and right from the upper edge of the transmission tunnel and mark floor

covering.

3. Starting from the transmission tunnel cutout of the floor covering, cut into floor covering 2 times (b).

Incisions should be located above the recesses in the transmission tunnel.

2001 Mercedes-Benz ML320

1998-2005 ACCESSORIES & BODY, CAB Electrical System - Body - 163 Chassis

me

Saturday, October 02, 2010 3:30:12 PMPage 375 © 2006 Mitchell Repair Information Company, LLC.