MERCEDES-BENZ SPRINTER 2005 Service Repair Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2005, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2005Pages: 1232, PDF Size: 39.23 MB

Page 821 of 1232

REAR BUMPER - STEP

REMOVAL

(1) Remove rear fascia. (Refer to 13 - FRAME &

BUMPERS/BUMPERS/REAR FASCIA - REMOVAL)

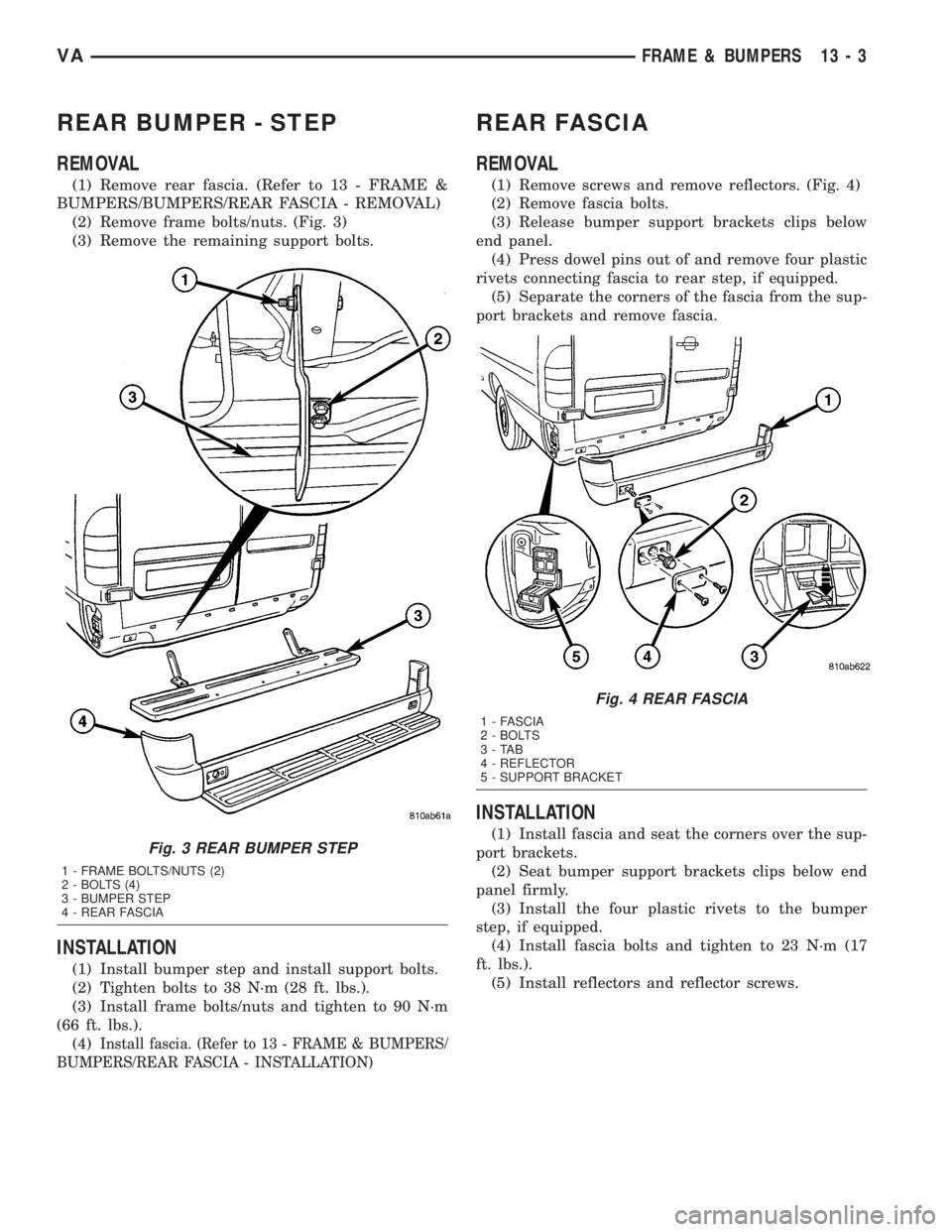

(2) Remove frame bolts/nuts. (Fig. 3)

(3) Remove the remaining support bolts.

INSTALLATION

(1) Install bumper step and install support bolts.

(2) Tighten bolts to 38 N´m (28 ft. lbs.).

(3) Install frame bolts/nuts and tighten to 90 N´m

(66 ft. lbs.).

(4)

Install fascia. (Refer to 13 - FRAME & BUMPERS/

BUMPERS/REAR FASCIA - INSTALLATION)

REAR FASCIA

REMOVAL

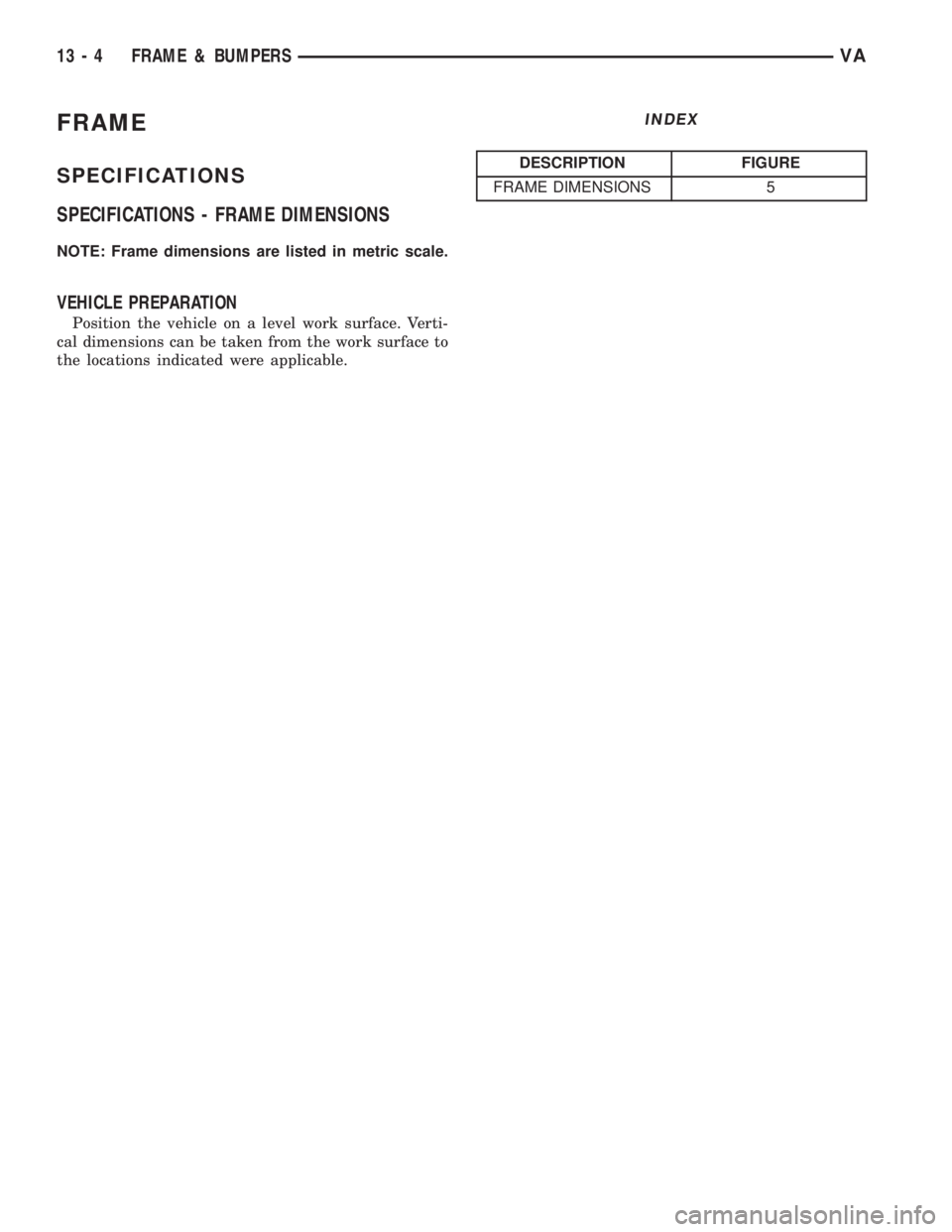

(1) Remove screws and remove reflectors. (Fig. 4)

(2) Remove fascia bolts.

(3) Release bumper support brackets clips below

end panel.

(4) Press dowel pins out of and remove four plastic

rivets connecting fascia to rear step, if equipped.

(5) Separate the corners of the fascia from the sup-

port brackets and remove fascia.

INSTALLATION

(1) Install fascia and seat the corners over the sup-

port brackets.

(2) Seat bumper support brackets clips below end

panel firmly.

(3) Install the four plastic rivets to the bumper

step, if equipped.

(4) Install fascia bolts and tighten to 23 N´m (17

ft. lbs.).

(5) Install reflectors and reflector screws.Fig. 3 REAR BUMPER STEP

1 - FRAME BOLTS/NUTS (2)

2 - BOLTS (4)

3 - BUMPER STEP

4 - REAR FASCIA

Fig. 4 REAR FASCIA

1 - FASCIA

2 - BOLTS

3-TAB

4 - REFLECTOR

5 - SUPPORT BRACKET

VAFRAME & BUMPERS 13 - 3

Page 822 of 1232

FRAME

SPECIFICATIONS

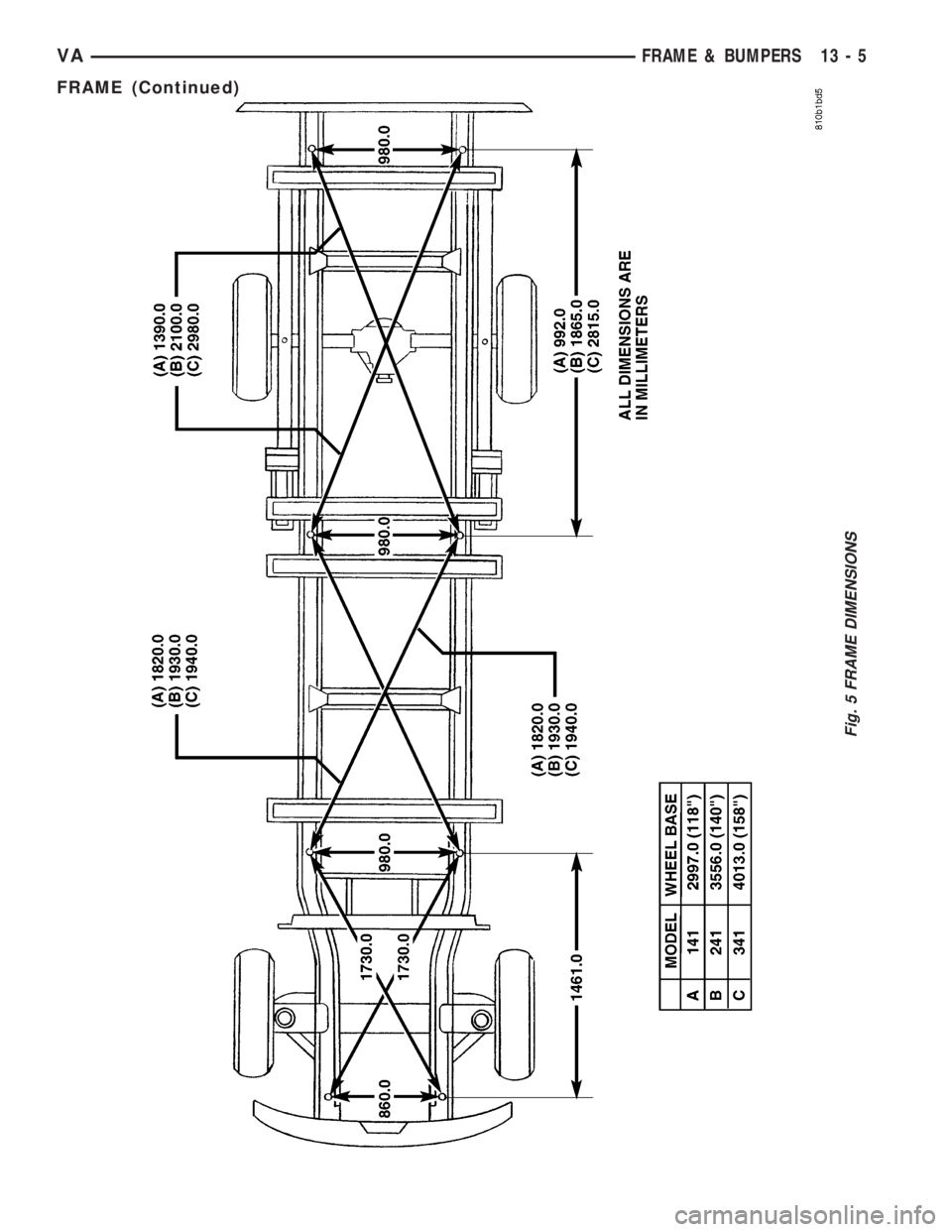

SPECIFICATIONS - FRAME DIMENSIONS

NOTE: Frame dimensions are listed in metric scale.

VEHICLE PREPARATION

Position the vehicle on a level work surface. Verti-

cal dimensions can be taken from the work surface to

the locations indicated were applicable.

INDEX

DESCRIPTION FIGURE

FRAME DIMENSIONS 5

13 - 4 FRAME & BUMPERSVA

Page 823 of 1232

Fig. 5 FRAME DIMENSIONS

VAFRAME & BUMPERS 13 - 5

FRAME (Continued)

Page 824 of 1232

SPECIFICATIONS - TORQUE

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Brake line nuts 14 10 Ð

Brake pads wear

indicator caliper bolt10 7 89

Engine cradle bolts 125 92 Ð

Engine mount bolt

to engine bracket83 61 Ð

Engine mount nuts

to engine cradle45 33 Ð

Power steering line

nuts37 27 Ð

Steering gear

mounting bolts - 1st

stage25 18 Ð

Steering Gear

mounting bolts -

2nd stage45 33 Ð

Steering Gear

mounting bolts - 3rd

stage90ÉÐÐ

Steering gear

u-joint bolt24 18 Ð

Sway bar bushing

bolts30 22 Ð

Trailer hitch angle

bracket bolts/nuts50*

See

Warning37*

See

WarningÐ

Trailer hitch frame

bolts11 0 8 1 Ð

Transmission

crossmember nuts45 33 Ð

Transmission mount

bolts/nuts45 33 Ð

WARNING: Microencapsulated bolts and self-lock-

ing nuts may only be used once. If you use

microencapsulated bolt or self-locking nuts more

than once, the self-locking function is rendered

useless. The trailer hitch may become detached

from the vehicle, possibly resulting in a serious risk

of injury and/or damage to property, including dam-

age to the vehicle.

ENGINE CRADLE

CROSSMEMBER

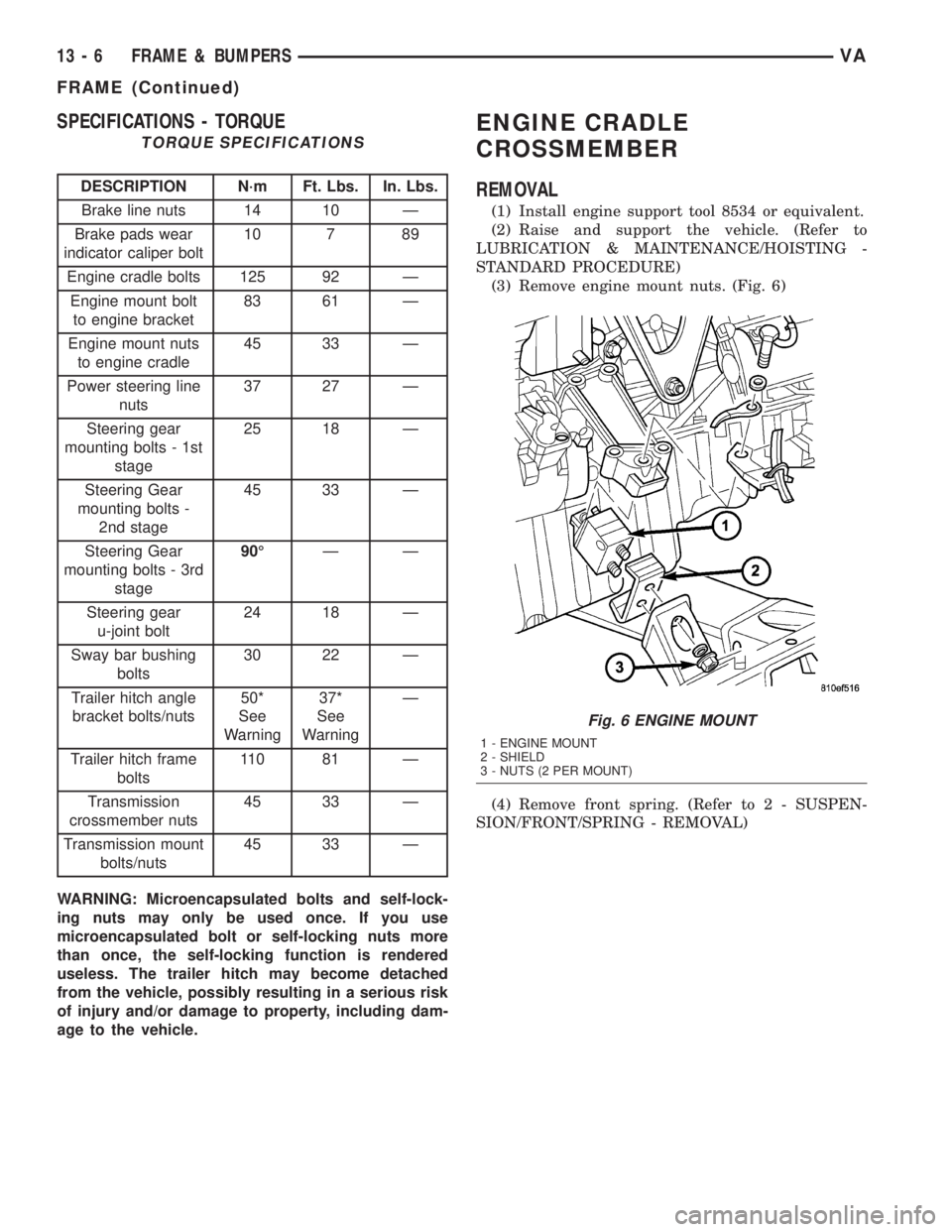

REMOVAL

(1) Install engine support tool 8534 or equivalent.

(2) Raise and support the vehicle. (Refer to

LUBRICATION & MAINTENANCE/HOISTING -

STANDARD PROCEDURE)

(3) Remove engine mount nuts. (Fig. 6)

(4) Remove front spring. (Refer to 2 - SUSPEN-

SION/FRONT/SPRING - REMOVAL)

Fig. 6 ENGINE MOUNT

1 - ENGINE MOUNT

2 - SHIELD

3 - NUTS (2 PER MOUNT)

13 - 6 FRAME & BUMPERSVA

FRAME (Continued)

Page 825 of 1232

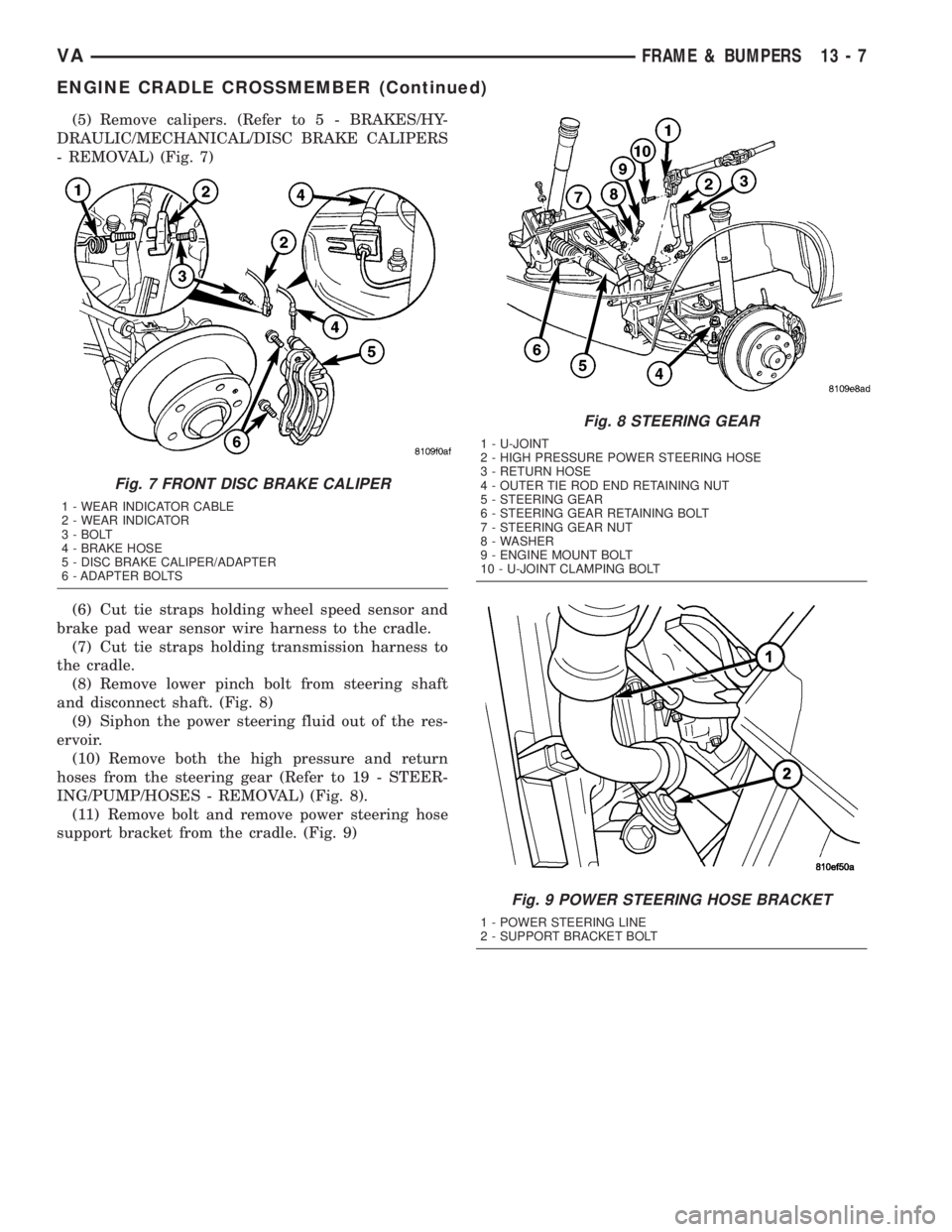

(5) Remove calipers. (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/DISC BRAKE CALIPERS

- REMOVAL) (Fig. 7)

(6) Cut tie straps holding wheel speed sensor and

brake pad wear sensor wire harness to the cradle.

(7) Cut tie straps holding transmission harness to

the cradle.

(8) Remove lower pinch bolt from steering shaft

and disconnect shaft. (Fig. 8)

(9) Siphon the power steering fluid out of the res-

ervoir.

(10) Remove both the high pressure and return

hoses from the steering gear (Refer to 19 - STEER-

ING/PUMP/HOSES - REMOVAL) (Fig. 8).

(11) Remove bolt and remove power steering hose

support bracket from the cradle. (Fig. 9)

Fig. 7 FRONT DISC BRAKE CALIPER

1 - WEAR INDICATOR CABLE

2 - WEAR INDICATOR

3 - BOLT

4 - BRAKE HOSE

5 - DISC BRAKE CALIPER/ADAPTER

6 - ADAPTER BOLTS

Fig. 8 STEERING GEAR

1 - U-JOINT

2 - HIGH PRESSURE POWER STEERING HOSE

3 - RETURN HOSE

4 - OUTER TIE ROD END RETAINING NUT

5 - STEERING GEAR

6 - STEERING GEAR RETAINING BOLT

7 - STEERING GEAR NUT

8 - WASHER

9 - ENGINE MOUNT BOLT

10 - U-JOINT CLAMPING BOLT

Fig. 9 POWER STEERING HOSE BRACKET

1 - POWER STEERING LINE

2 - SUPPORT BRACKET BOLT

VAFRAME & BUMPERS 13 - 7

ENGINE CRADLE CROSSMEMBER (Continued)

Page 826 of 1232

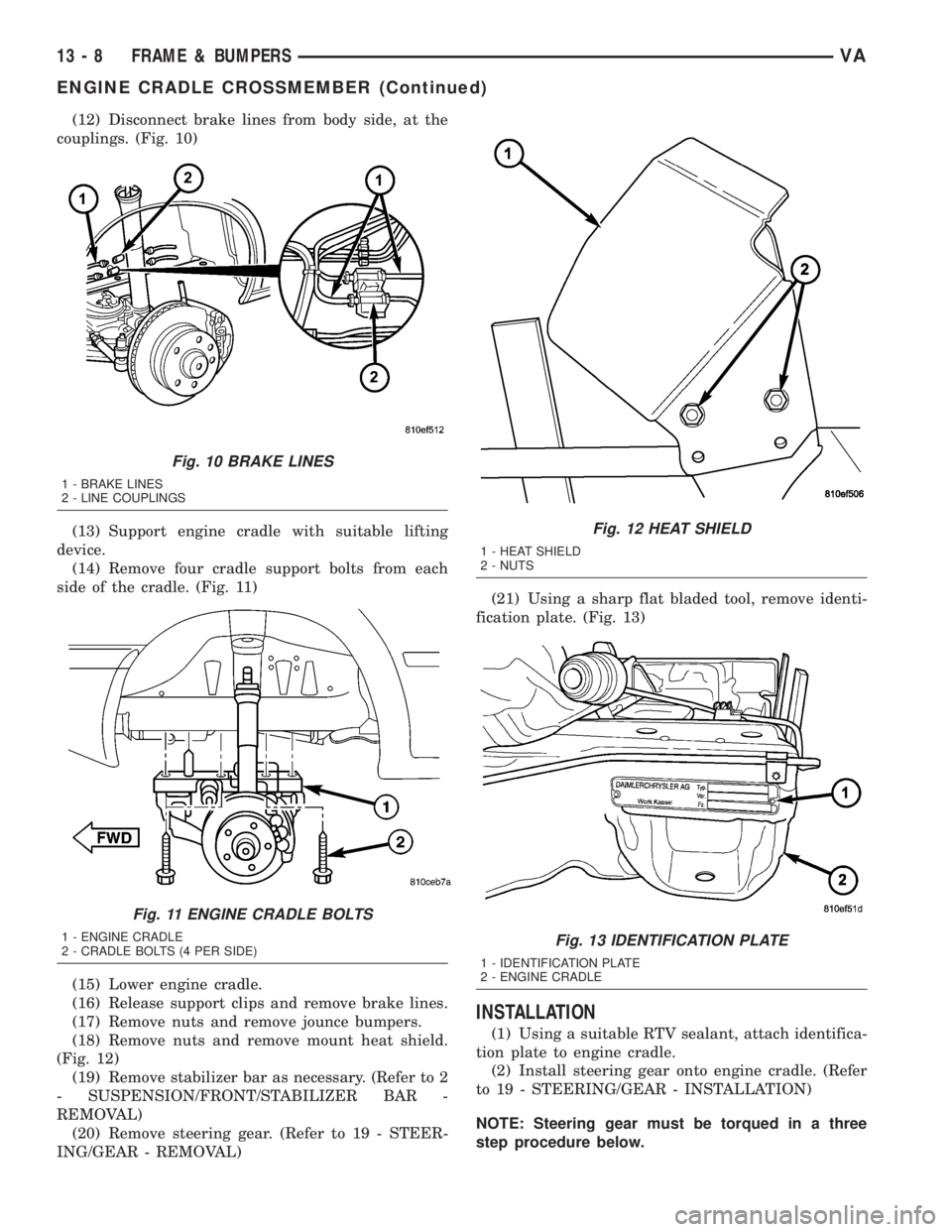

(12) Disconnect brake lines from body side, at the

couplings. (Fig. 10)

(13) Support engine cradle with suitable lifting

device.

(14) Remove four cradle support bolts from each

side of the cradle. (Fig. 11)

(15) Lower engine cradle.

(16) Release support clips and remove brake lines.

(17) Remove nuts and remove jounce bumpers.

(18) Remove nuts and remove mount heat shield.

(Fig. 12)

(19) Remove stabilizer bar as necessary. (Refer to 2

- SUSPENSION/FRONT/STABILIZER BAR -

REMOVAL)

(20) Remove steering gear. (Refer to 19 - STEER-

ING/GEAR - REMOVAL)(21) Using a sharp flat bladed tool, remove identi-

fication plate. (Fig. 13)

INSTALLATION

(1) Using a suitable RTV sealant, attach identifica-

tion plate to engine cradle.

(2) Install steering gear onto engine cradle. (Refer

to 19 - STEERING/GEAR - INSTALLATION)

NOTE: Steering gear must be torqued in a three

step procedure below.

Fig. 10 BRAKE LINES

1 - BRAKE LINES

2 - LINE COUPLINGS

Fig. 11 ENGINE CRADLE BOLTS

1 - ENGINE CRADLE

2 - CRADLE BOLTS (4 PER SIDE)

Fig. 12 HEAT SHIELD

1 - HEAT SHIELD

2 - NUTS

Fig. 13 IDENTIFICATION PLATE

1 - IDENTIFICATION PLATE

2 - ENGINE CRADLE

13 - 8 FRAME & BUMPERSVA

ENGINE CRADLE CROSSMEMBER (Continued)

Page 827 of 1232

(3) Tighten steering gear bolts in three stages as

follows.

1. Tighten to 25 N´m (18 ft. lbs.)

2. Then tighten to 45 N´m (33 ft. lbs.)

3. Then tighten bolts an additional 90É.

(4) Install stabilizer bar. (Refer to 2 - SUSPEN-

SION/FRONT/STABILIZER BAR - INSTALLATION)

(5) Install heat shield and nuts.

(6) Install jounce bumpers and install nuts.

(7) Install support clips and brake lines.

(8) Raise engine cradle into place and install bolts.

(9) Tighten bolts to 125 N´m (92 ft. lbs.).

(10) Connect brake lines at couplings and tighten

to 14 N´m (10 ft. lbs.).

(11) Position power steering hose and install sup-

port bracket bolt.

(12) Install both power steering hoses at steering

gear. (Refer to 19 - STEERING/PUMP/HOSES -

INSTALLATION)

(13) Connect steering shaft to gear and install the

lower pinch bolt.

(14) Tighten lower pinch bolt to 24 N´m (18 ft.

lbs.).

(15) Install new tie straps holding transmission

harness to cradle.

(16) Install front spring. (Refer to 2 - SUSPEN-

SION/FRONT/SPRING - INSTALLATION)

(17) Install engine mount nuts and tighten to 45

N´m (33 ft. lbs.).

(18) Install calipers. (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/DISC BRAKE CALIPERS

- INSTALLATION)

(19) Install new tie straps holding wheel speed

sensors and brake pad wear sensors wire harness to

cradle.

(20) Check and align vehicle to specifications.

(Refer to 2 - SUSPENSION/WHEEL ALIGNMENT -

STANDARD PROCEDURE)

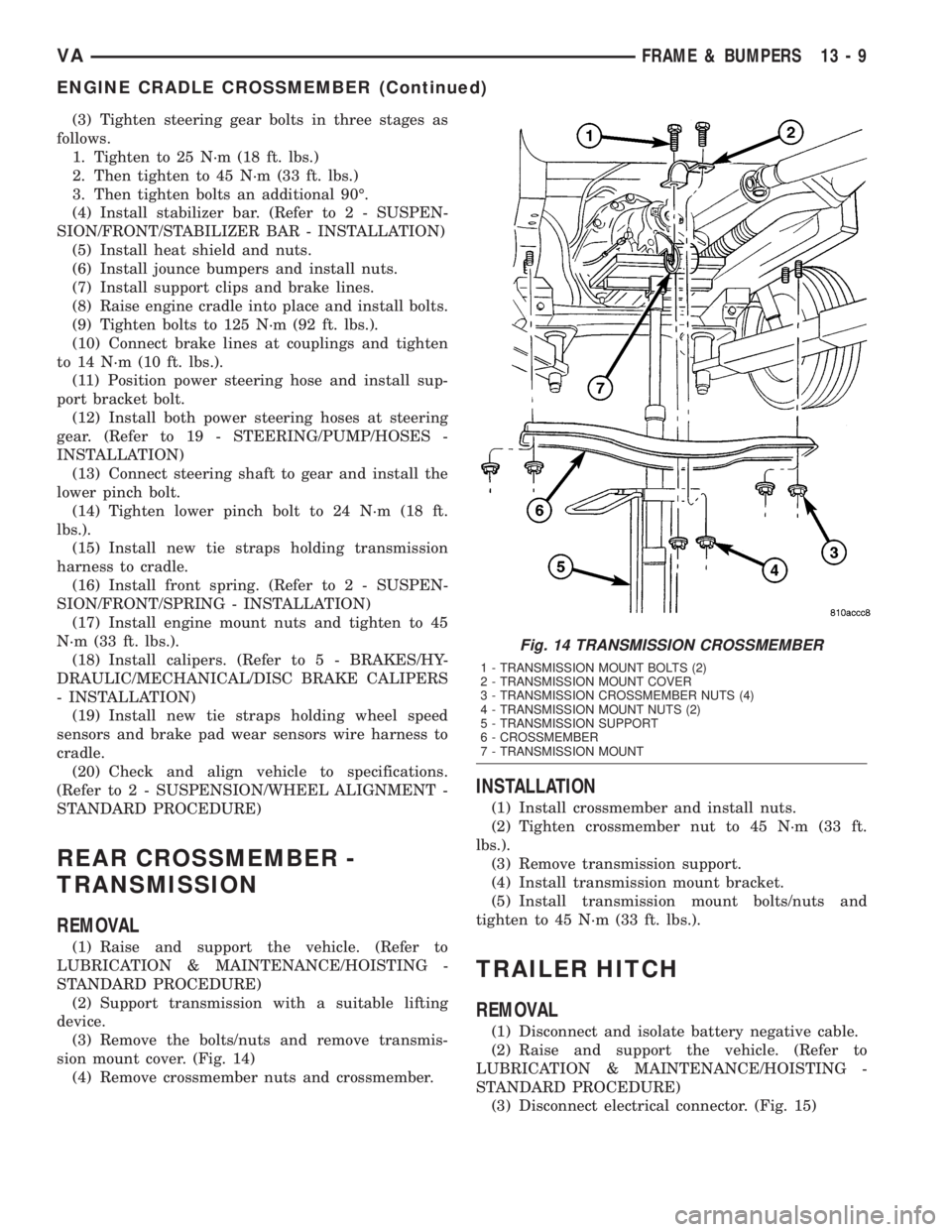

REAR CROSSMEMBER -

TRANSMISSION

REMOVAL

(1) Raise and support the vehicle. (Refer to

LUBRICATION & MAINTENANCE/HOISTING -

STANDARD PROCEDURE)

(2) Support transmission with a suitable lifting

device.

(3) Remove the bolts/nuts and remove transmis-

sion mount cover. (Fig. 14)

(4) Remove crossmember nuts and crossmember.

INSTALLATION

(1) Install crossmember and install nuts.

(2) Tighten crossmember nut to 45 N´m (33 ft.

lbs.).

(3) Remove transmission support.

(4) Install transmission mount bracket.

(5) Install transmission mount bolts/nuts and

tighten to 45 N´m (33 ft. lbs.).

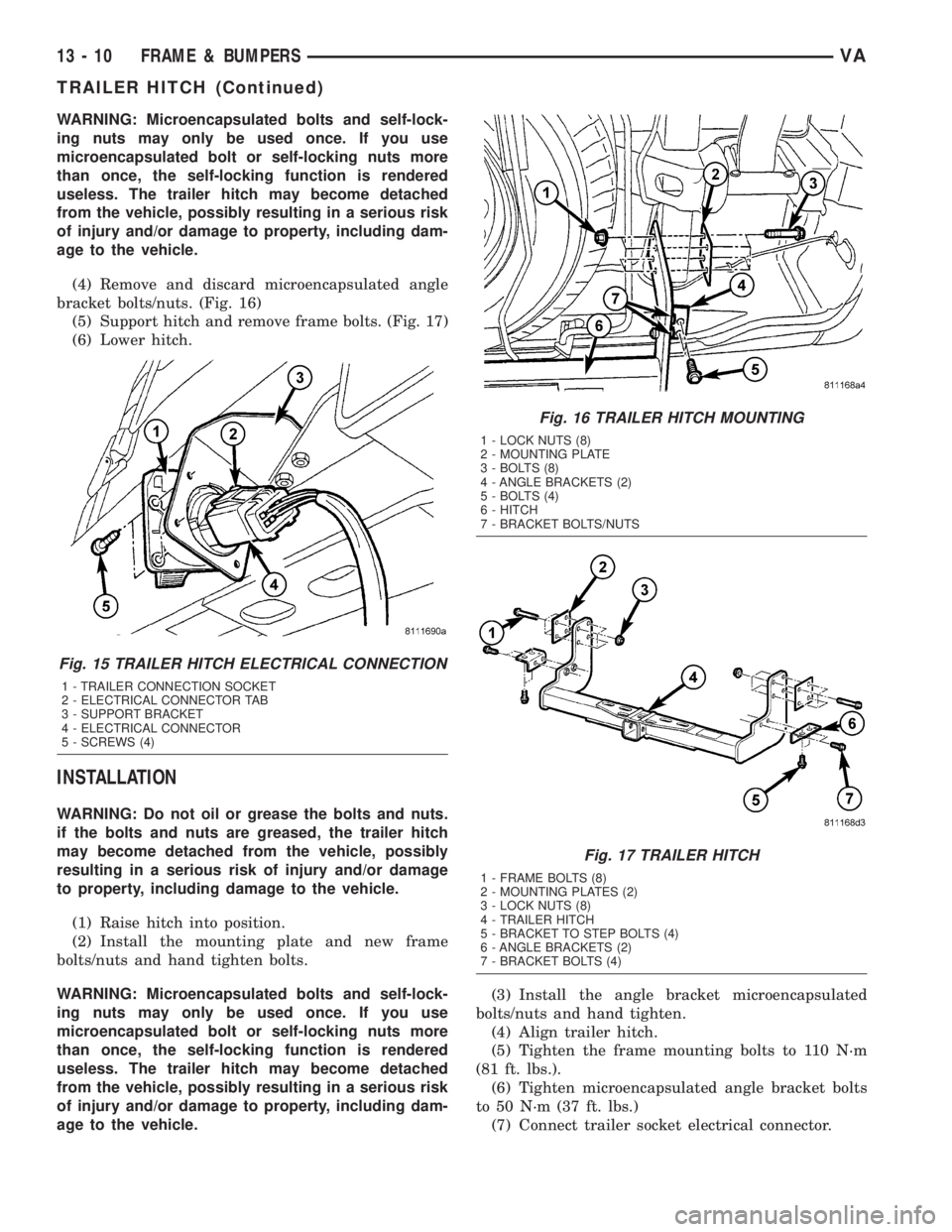

TRAILER HITCH

REMOVAL

(1) Disconnect and isolate battery negative cable.

(2) Raise and support the vehicle. (Refer to

LUBRICATION & MAINTENANCE/HOISTING -

STANDARD PROCEDURE)

(3) Disconnect electrical connector. (Fig. 15)

Fig. 14 TRANSMISSION CROSSMEMBER

1 - TRANSMISSION MOUNT BOLTS (2)

2 - TRANSMISSION MOUNT COVER

3 - TRANSMISSION CROSSMEMBER NUTS (4)

4 - TRANSMISSION MOUNT NUTS (2)

5 - TRANSMISSION SUPPORT

6 - CROSSMEMBER

7 - TRANSMISSION MOUNT

VAFRAME & BUMPERS 13 - 9

ENGINE CRADLE CROSSMEMBER (Continued)

Page 828 of 1232

WARNING: Microencapsulated bolts and self-lock-

ing nuts may only be used once. If you use

microencapsulated bolt or self-locking nuts more

than once, the self-locking function is rendered

useless. The trailer hitch may become detached

from the vehicle, possibly resulting in a serious risk

of injury and/or damage to property, including dam-

age to the vehicle.

(4) Remove and discard microencapsulated angle

bracket bolts/nuts. (Fig. 16)

(5) Support hitch and remove frame bolts. (Fig. 17)

(6) Lower hitch.

INSTALLATION

WARNING: Do not oil or grease the bolts and nuts.

if the bolts and nuts are greased, the trailer hitch

may become detached from the vehicle, possibly

resulting in a serious risk of injury and/or damage

to property, including damage to the vehicle.

(1) Raise hitch into position.

(2) Install the mounting plate and new frame

bolts/nuts and hand tighten bolts.

WARNING: Microencapsulated bolts and self-lock-

ing nuts may only be used once. If you use

microencapsulated bolt or self-locking nuts more

than once, the self-locking function is rendered

useless. The trailer hitch may become detached

from the vehicle, possibly resulting in a serious risk

of injury and/or damage to property, including dam-

age to the vehicle.(3) Install the angle bracket microencapsulated

bolts/nuts and hand tighten.

(4) Align trailer hitch.

(5) Tighten the frame mounting bolts to 110 N´m

(81 ft. lbs.).

(6) Tighten microencapsulated angle bracket bolts

to 50 N´m (37 ft. lbs.)

(7) Connect trailer socket electrical connector.

Fig. 15 TRAILER HITCH ELECTRICAL CONNECTION

1 - TRAILER CONNECTION SOCKET

2 - ELECTRICAL CONNECTOR TAB

3 - SUPPORT BRACKET

4 - ELECTRICAL CONNECTOR

5 - SCREWS (4)

Fig. 16 TRAILER HITCH MOUNTING

1 - LOCK NUTS (8)

2 - MOUNTING PLATE

3 - BOLTS (8)

4 - ANGLE BRACKETS (2)

5 - BOLTS (4)

6 - HITCH

7 - BRACKET BOLTS/NUTS

Fig. 17 TRAILER HITCH

1 - FRAME BOLTS (8)

2 - MOUNTING PLATES (2)

3 - LOCK NUTS (8)

4 - TRAILER HITCH

5 - BRACKET TO STEP BOLTS (4)

6 - ANGLE BRACKETS (2)

7 - BRACKET BOLTS (4)

13 - 10 FRAME & BUMPERSVA

TRAILER HITCH (Continued)

Page 829 of 1232

FUEL SYSTEM

TABLE OF CONTENTS

page page

FUEL SYSTEM

WARNING

WARNING - HIGH FUEL SYSTEM

PRESSURE...........................1

WARNING............................1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - HIGH

PRESSURE FUEL LINES.................1

DIAGNOSIS AND TESTING - AIR IN FUEL

SYSTEM.............................2

STANDARD PROCEDURE

STANDARD PROCEDURES - CLEANING

FUEL SYSTEM COMPONENTS............2STANDARD PROCEDURE -

DISCONNECTING AND CONNECTING

FUEL LINES..........................2

STANDARD PROCEDURES - DRAINING

WATER FROM FUEL FILTER..............2

STANDARD PROCEDURE - LOW

PRESSURE FUEL PUMP TEST............3

FUEL DELIVERY..........................4

FUEL INJECTION........................17

FUEL SYSTEM

WARNING

WARNING - HIGH FUEL SYSTEM PRESSURE

WARNING: HIGH-PRESSURE FUEL LINES DELIVER

FUEL UNDER EXTREME PRESSURE FROM THE

INJECTION PUMP TO THE INJECTORS. THIS

MAYBE AS HIGH AS 1600BAR (23,200PSI). USE

EXTREME CAUTION WHEN INSPECTING FOR HIGH-

PRESSURE FUEL LEAKS. FUEL UNDER THIS

AMOUNT OF PRESSURE CAN PENETRATE SKIN

CAUSING PERSONAL INJURY OR DEATH. INSPECT

HIGH-PRESSURE FUEL LEAKS WITH A SHEET OF

CARDBOARD. WEAR SAFETY GOGGLES AND ADE-

QUATE PROTECTIVE CLOTHING WHEN SERVICING

FUEL SYSTEM.

WARNING

WARNING: UNDER NO CIRCUMSTANCES SHOULD

GASOLINE BE MIXED WITH DIESEL FUEL (NOT

EVEN DURING WINTER). THE HIGH PRESSURE

PUMP IS LUBRICATED BY DIESEL FUEL. IMMEDI-

ATE FUEL SYSTEM DAMAGE MAY OCCUR CAUS-

ING REPLACEMENT AND FLUSHING OF THE

COMPLETE DIESEL FUEL SYSTEM. HIGH PRES-

SURE PUMP SEIZURE WILL CAUSE METAL PARTI-

CLES TO SPREAD THROUGH OUT THE FUEL

CIRCUIT. ALL CDI FUEL SYSTEM COMPONENTS

CONNECTED TO THE FUEL CIRCUIT WILL HAVE TO

BE EXCHANGED AND THE LINES FLUSHED.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - HIGH PRESSURE

FUEL LINES

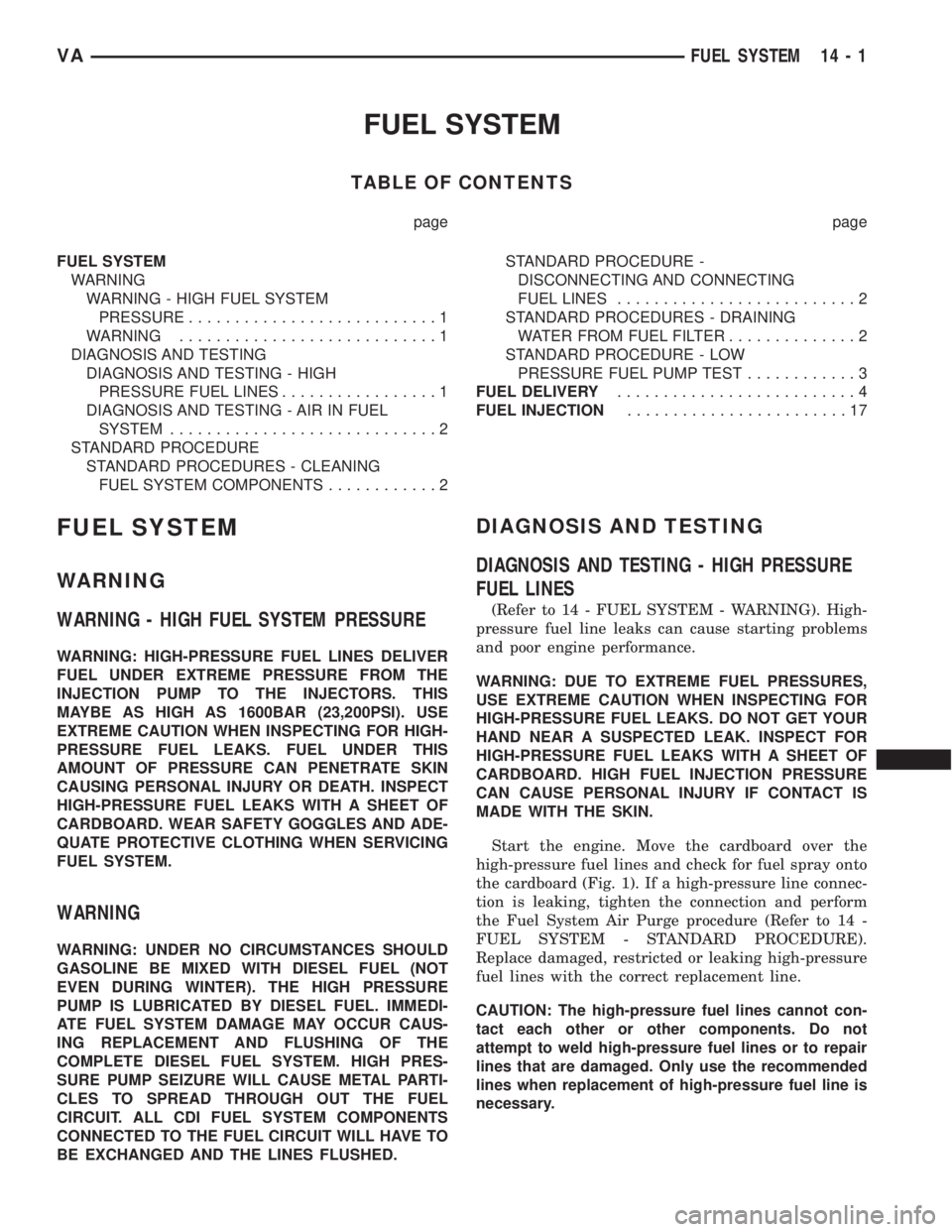

(Refer to 14 - FUEL SYSTEM - WARNING). High-

pressure fuel line leaks can cause starting problems

and poor engine performance.

WARNING: DUE TO EXTREME FUEL PRESSURES,

USE EXTREME CAUTION WHEN INSPECTING FOR

HIGH-PRESSURE FUEL LEAKS. DO NOT GET YOUR

HAND NEAR A SUSPECTED LEAK. INSPECT FOR

HIGH-PRESSURE FUEL LEAKS WITH A SHEET OF

CARDBOARD. HIGH FUEL INJECTION PRESSURE

CAN CAUSE PERSONAL INJURY IF CONTACT IS

MADE WITH THE SKIN.

Start the engine. Move the cardboard over the

high-pressure fuel lines and check for fuel spray onto

the cardboard (Fig. 1). If a high-pressure line connec-

tion is leaking, tighten the connection and perform

the Fuel System Air Purge procedure (Refer to 14 -

FUEL SYSTEM - STANDARD PROCEDURE).

Replace damaged, restricted or leaking high-pressure

fuel lines with the correct replacement line.

CAUTION: The high-pressure fuel lines cannot con-

tact each other or other components. Do not

attempt to weld high-pressure fuel lines or to repair

lines that are damaged. Only use the recommended

lines when replacement of high-pressure fuel line is

necessary.

VAFUEL SYSTEM 14 - 1

Page 830 of 1232

DIAGNOSIS AND TESTING - AIR IN FUEL

SYSTEM

Air will enter the fuel system whenever fuel supply

lines, separator filters, injection pump, high-pressure

lines or injectors are removed or disconnected. Air

trapped in the fuel system can result in hard start-

ing, a rough running engine, engine misfire, low

power, excessive smoke and fuel knock.

Inspect the fuel system from the fuel tank to the

injectors for loose connections (Refer to 14 - FUEL

SYSTEM - WARNING). Leaking fuel is an indicator

of loose connections or defective seals. Air can also

enter the fuel system between the fuel tank and the

fuel pump. Inspect the fuel tank and fuel lines for

damage that might allow air into the system.

With the DRBIIItconnected to the vehicle, select

Engine and the select Sensor Display. Page down to

view Fuel Pressure Set Point and Actual Fuel Pres-

sure. Start the engine and observe the Fuel Pressure

Set Point and the Actual Fuel Pressure. If the Actual

Fuel Pressure Oscillates above and below the Fuel

Pressure Set Point in a regular cycle, perform the

Fuel System Air Purge procedure (Refer to 14 -

FUEL SYSTEM - STANDARD PROCEDURE).

If the Actual Fuel Pressure gradually drops below

the Fuel Pressure Set Point then spikes well above

the Fuel Pressure Set Point, replace the fuel pres-

sure solenoid (Refer to 14 - FUEL SYSTEM/FUEL

INJECTION/FUEL PRESSURE SOLENOID -

REMOVAL), then perform the Fuel System Air Purgeprocedure (Refer to 14 - FUEL SYSTEM - STAN-

DARD PROCEDURE).

STANDARD PROCEDURE

STANDARD PROCEDURES - CLEANING FUEL

SYSTEM COMPONENTS

CAUTION: Cleanliness cannot be overemphasized

when handling or replacing diesel fuel system com-

ponents. This especially includes the fuel injectors,

high-pressure fuel lines, fuel rail, and fuel injection

pump. Very tight tolerances are used with these

parts. Dirt contamination could cause rapid part

wear and possible plugging of fuel injector nozzle

tip holes. This in turn could lead to possible engine

misfire. Always wash/clean any fuel system compo-

nent thoroughly before disassembly and then air

dry. DO NOT wire brush injector nozzles when

cleaning. Cap or cover any open part after disas-

sembly. Before assembly, examine each part for

dirt, grease or other contaminants and clean if nec-

essary. When installing new parts, lubricate them

with clean engine oil or clean diesel fuel only.

STANDARD PROCEDURE - DISCONNECTING

AND CONNECTING FUEL LINES

NOTE: Capture and store any fuel spillage in appro-

priately marked containers.

(1) Disconnect negative battery cable.

(2) Push release arm to release position A, as far

as the stop (arrow) (Fig. 2).

(3) Disconnect fuel line.

(4) Immediately return the release arm back to the

assembly position, as far as the stop (Fig. 2).

The release arm must not be left in the release

position for a long time. Connectors left in the

release position for lengthy periods may leak and

must be replaced.

(5) Insert connector into connection in assembly

position (B) (Fig. 2).

(6) Ensure that the connectors are firmly seated

and free of leaks (Fig. 2).

STANDARD PROCEDURES - DRAINING WATER

FROM FUEL FILTER

Refer to Fuel Filter/Water Separator removal/in-

stallation for procedures (Refer to 14 - FUEL SYS-

TEM/FUEL DELIVERY/FUEL FILTER / WATER

SEPARATOR - REMOVAL).

Fig. 1 Typical Test for Leaks with Cardboard

1 - HIGH-PRESSURE LINE

2 - CARDBOARD

3 - FITTING

14 - 2 FUEL SYSTEMVA

FUEL SYSTEM (Continued)