MERCEDES-BENZ SPRINTER 2005 Service Repair Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2005, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2005Pages: 1232, PDF Size: 39.23 MB

Page 851 of 1232

NOTE: Always replace the seals that seal off the

injectors at the cylinder head to the combustion

chamber and replace the retaining screws.

REMOVAL

WARNING: HIGH-PRESSURE FUEL LINES DELIVER

DIESEL FUEL UNDER EXTREME PRESSURE FROM

THE INJECTION PUMP TO THE FUEL INJECTORS.

THIS MAY BE AS HIGH AS 1600BAR (23,200 PSI).

USE EXTREME CAUTION WHEN INSPECTING FOR

HIGH-PRESSURE FUEL LEAKS. FUEL UNDER THIS

AMOUNT OF PRESSURE CAN PENETRATE SKIN

CAUSING PERSONAL INJURY OR DEATH. INSPECT

FOR HIGH-PRESSURE LEAKS WITH A SHEET OF

CARD BOARD. WEAR SAFETY GOGGLES AND

ADEQUATE PROTECTIVE CLOTHING WHEN SER-

VICING FUEL SYSTEM.

WARNING: NO SPARKS, OPEN FLAMES OR SMOK-

ING. RISK OF POISONING FROM INHALING AND

SWALLOWING FUEL. RISK OF INJURY TO EYES

AND SKIN FROM CONTACT WITH FUEL. POUR

FUELS ONLY INTO SUITABLE AND APPROPRI-

ATELY MARKED CONTAINERS. WEAR PROTECTIVE

CLOTHING.

NOTE: The engine must be lowered in the vehicle to

remove the fourth and fifth cylinders fuel injectors.

(1) Disconnect negative battery cable.

(2) Remove engine cover (Refer to 9 - ENGINE -

REMOVAL).

(3) Raise and suitably support the vehicle.

(4) Remove lower radiator deflector plate.

(5) Drain cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(6) Remove turbocharger down pipe assembly.

(7) Remove oil dipstick tube retaining bolt and pull

tube from oil pan.

(8) Lower vehicle.

(9) Remove upper radiator hose.

(10) Remove air cleaner box assembly and hoses.

(11) Remove charge air cooler inlet hose.

(12) Remove charge air cooler to turbocharger inlet

adaptor.

(13) Remove turbocharger to right engine mount

bracket.

(14) Disconnect steering coupler at gear box (RHD

Only).

(15) Remove battery (Refer to 8 - ELECTRICAL/

BATTERY SYSTEM/BATTERY - REMOVAL).

(16) Unclip PDC from battery tray and set aside.(17) Remove battery tray (Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/TRAY - REMOVAL).

(18) Remove power steering reservoir (Refer to 19 -

STEERING/PUMP/RESERVOIR - REMOVAL).

(19) Remove charger air cooler outlet hose.

(20) Remove intake manifold to left engine mount

bracket.

(21) Evacuate air conditioning system (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE).

(22) Disconnect air conditioning suction / discharge

lines at A/C compressor.

(23) Disconnect pedal position sensor electrical

connector.

(24) Unplug injector electrical connectors.

(25) Remove fuel / water separator to intake man-

ifold retaining bolts.

(26) Support engine with hoist.

(27) Remove engine mount through bolts.

(28) Remove right engine mount sill plate.

NOTE: Counterhold injection lines with wrench

socket at threaded connections of injectors.

(29) Disconnect fuel injector high pressure line.

(30) Remove fuel injector retaining bolt and ten-

sion claw.

(31) Suitably lower engine to gain fuel injector

access and remove injector.

NOTE: If injectors are tight, remove with extraction

claw in place of tensioning claw. If extraction claw

contacts cylinder head cover, remove cylinder head

cover. If necessary, remove injectors with threaded

adaptor and discard injector.

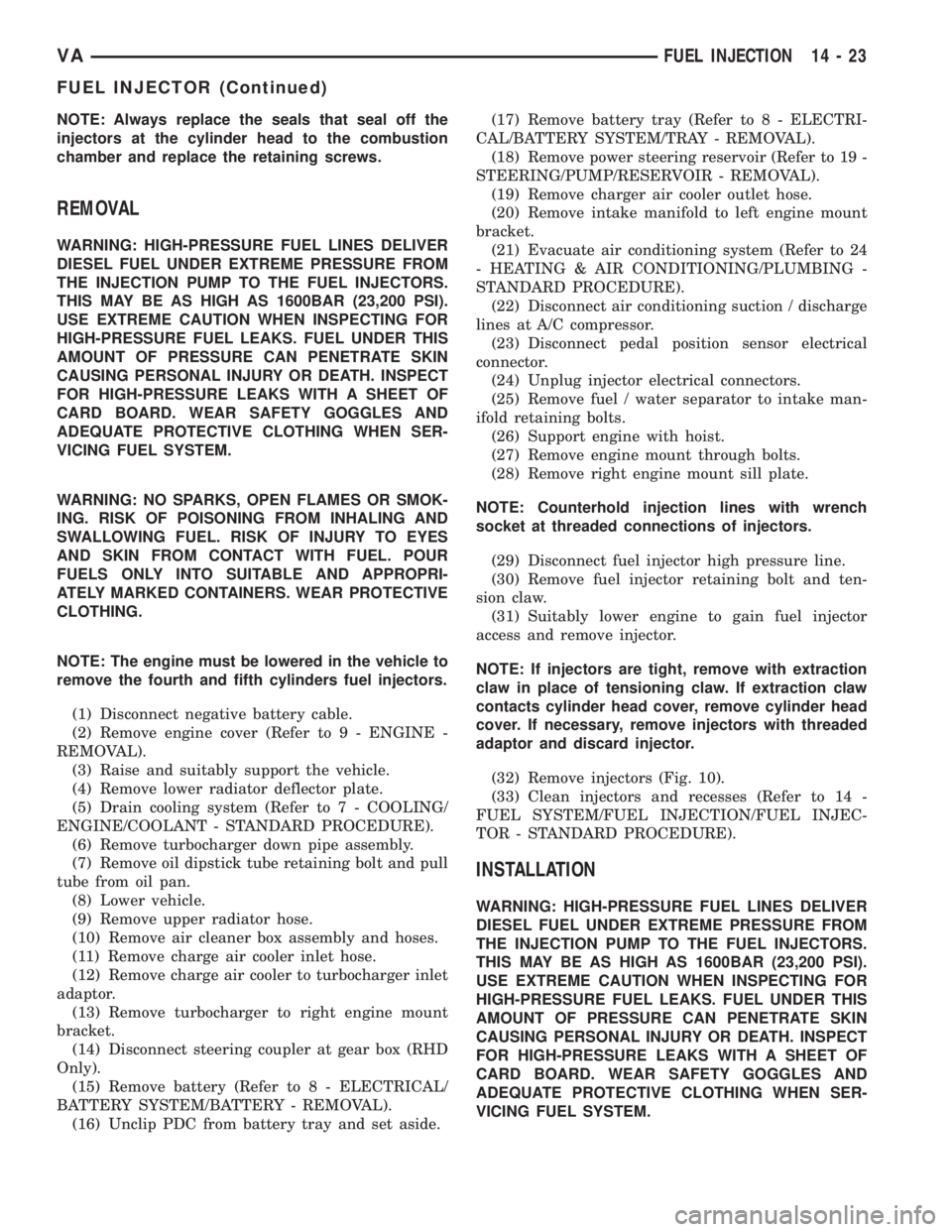

(32) Remove injectors (Fig. 10).

(33) Clean injectors and recesses (Refer to 14 -

FUEL SYSTEM/FUEL INJECTION/FUEL INJEC-

TOR - STANDARD PROCEDURE).

INSTALLATION

WARNING: HIGH-PRESSURE FUEL LINES DELIVER

DIESEL FUEL UNDER EXTREME PRESSURE FROM

THE INJECTION PUMP TO THE FUEL INJECTORS.

THIS MAY BE AS HIGH AS 1600BAR (23,200 PSI).

USE EXTREME CAUTION WHEN INSPECTING FOR

HIGH-PRESSURE FUEL LEAKS. FUEL UNDER THIS

AMOUNT OF PRESSURE CAN PENETRATE SKIN

CAUSING PERSONAL INJURY OR DEATH. INSPECT

FOR HIGH-PRESSURE LEAKS WITH A SHEET OF

CARD BOARD. WEAR SAFETY GOGGLES AND

ADEQUATE PROTECTIVE CLOTHING WHEN SER-

VICING FUEL SYSTEM.

VAFUEL INJECTION 14 - 23

FUEL INJECTOR (Continued)

Page 852 of 1232

WARNING: NO SPARKS, OPEN FLAMES OR SMOK-

ING. RISK OF POISONING FROM INHALING AND

SWALLOWING FUEL. RISK OF INJURY TO EYES

AND SKIN FROM CONTACT WITH FUEL. POUR

FUELS ONLY INTO SUITABLE AND APPROPRI-

ATELY MARKED CONTAINERS. WEAR PROTECTIVE

CLOTHING.

(1) Clean injectors and recesses (Refer to 14 -

FUEL SYSTEM/FUEL INJECTION/FUEL INJEC-

TOR - STANDARD PROCEDURE).

(2) Coat injector body with anti seize lubricant

then install injectors with new seals.

(3) Install tensioning claws with new screws at

injectors. Tighten screws in two stages, 7 N´m (62

lbs. in.) then 90É.

NOTE: If locking clamp has been pulled off at injec-

tor, the locking clamp must be replaced.

(4) Position fuel return line at injectors and secure

locking clamps.NOTE: Counterhold injection lines with wrench

socket at threaded connections of injectors.

(5) Install high pressure injection lines (Refer to

14 - FUEL SYSTEM/FUEL DELIVERY/FUEL LINES

- INSTALLATION).

(6) Reconnect injector electrical connectors.

(7) Raise engine and install right sill plate.

(8) Install engine mount through bolts and tighten

to 40N´m (30 lbs. ft.).

(9) Install fuel / water separator to intake mani-

fold retaining bolts.

(10) Connect pedal position sensor electrical con-

nector.

(11) Connect air conditioning lines to A/C compres-

sor.

(12) Install intake manifold to left engine mount

bracket.

(13) Install charge air cooler outlet hose.

(14) Install power steering reservoir(Refer to 19 -

STEERING/PUMP/RESERVOIR - INSTALLATION).

Fig. 10 FUEL INJECTOR REMOVAL / INSTALLATION

1 - FUEL INJECTOR RETURN LINE

2 - RETAINING CLIP

3 - INJECTOR HIGH PRESSURE LINE

4 - INJECTOR SEAL5 - FUEL INJECTOR

6 - TENSIONING CLAW

7 - SPECIAL TOOLS #8938 AND # 8937

14 - 24 FUEL INJECTIONVA

FUEL INJECTOR (Continued)

Page 853 of 1232

(15) Install battery tray(Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/TRAY - INSTALLATION).

(16) Connect PDC to battery tray.

(17) Install battery (Refer to 8 - ELECTRICAL/

BATTERY SYSTEM/BATTERY - INSTALLATION).

(18) Connect steering coupler at gear box (RHD

Only).

(19) Install turbocharger to right engine mount

bracket (Refer to 11 - EXHAUST SYSTEM/TURBO-

CHARGER SYSTEM - INSTALLATION).

(20) Install charge air cooler to turbocharger inlet

adaptor (Refer to 11 - EXHAUST SYSTEM/CHARGE

AIR COOLER AND PLUMBING - INSTALLATION) .

(21) Install charger air cooler inlet hose (Refer to

11 - EXHAUST SYSTEM/CHARGE AIR COOLER

AND PLUMBING - INSTALLATION).

(22) Install air cleaner box assembly and hoses.

(23) Install upper radiator hose.

(24) Raise vehicle.

(25) Install dipstick tube into oil pan and tighten

retaining bolt.

(26) Install turbocharger down pipe assembly.

(27) Close cooling system drain.

(28) Install lower radiator deflector plate.

(29) Lower vehicle.

(30) Connect negative battery cable.

(31) Install engine cover (Refer to 9 - ENGINE -

INSTALLATION)..

(32) Fill cooling system with the correct mixture to

the proper level (Refer to 7 - COOLING/ENGINE/

COOLANT - STANDARD PROCEDURE).

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT PUT YOUR

HANDS NEAR PULLEYS, BELTS OR FAN. DO NOT

WEAR LOOSE CLOTHING.

(33) Start engine and inspect for leaks.

(34) Recharge air conditioning system.

FUEL PRESSURE SENSOR

DESCRIPTION

DESCRIPTION

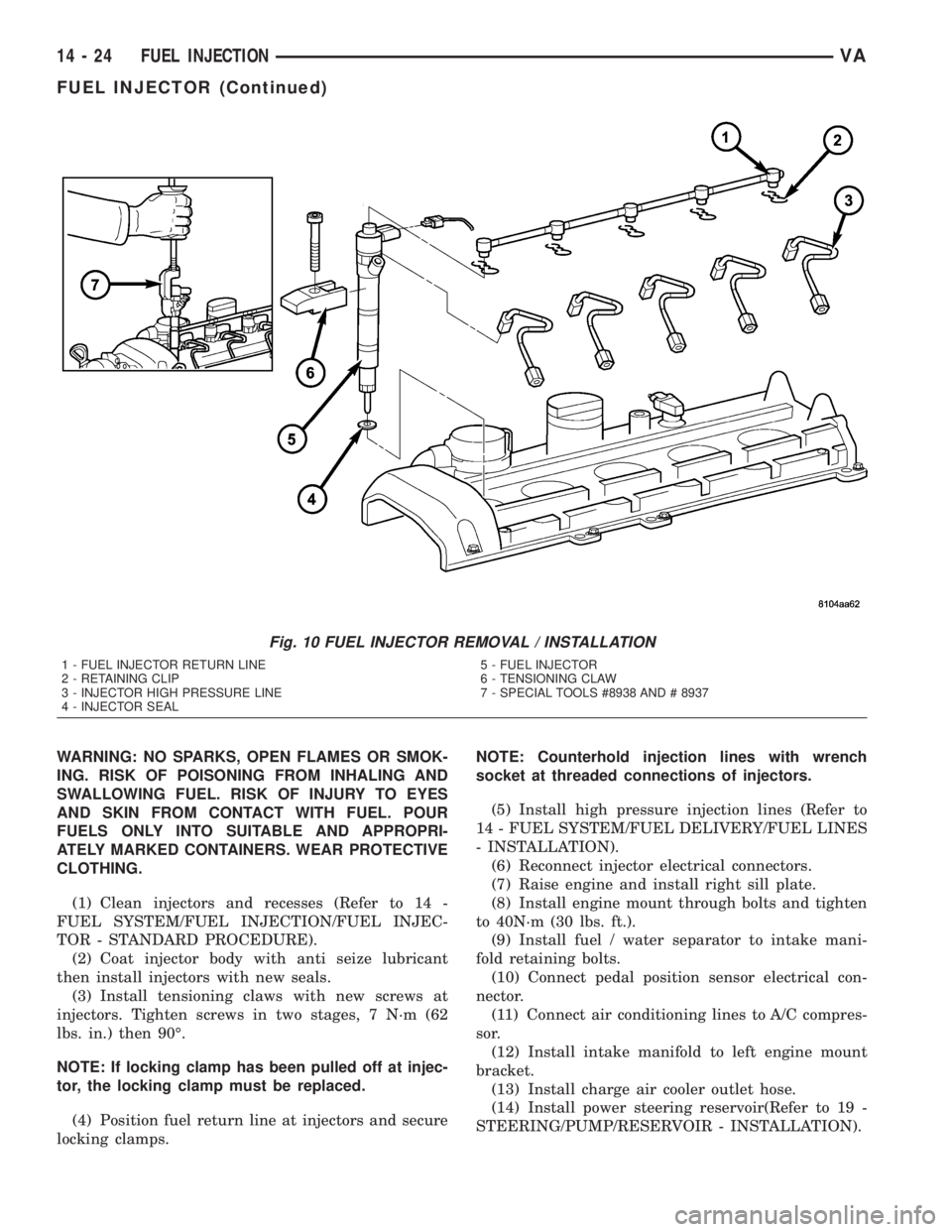

The fuel pressure sensor provides the current low

pressure (the pressure that exist at the inlet of the

high pressure injection pump) fuel pressure to the

ECM (Fig. 11).

The fuel pressure when the engine is idling is

approximately 36 psi (2.5 Bar). The fuel pressure

while driving is 50±58 psi (3.5 - 4.0Bar).

DESCRIPTION

The fuel rail pressure sensor provides the current

fuel rail pressure to the ECM.

OPERATION

OPERATION

A diaphragm and an electric resistance meter are

integrated in the fuel pressure sensor. The non-con-

stant fuel system pressure from the low pressure fuel

pump influences the position of the diaphragm which

in turn alters it's electrical resistance. This resis-

tance is analyzed by the ECM. The ECM then actu-

ates the fuel rail pressure control valve until the

desired rail pressure value is obtained (Fig. 11).

OPERATION

The fuel rail pressure sensor measures the current

fuel rail pressure and sends a voltage signal to the

ECM. The ECM then actuates the fuel rail pressure

control valve solenoid until the desired rail pressure

is achieved.

Fig. 11 FUEL PRESSURE SENSOR

VAFUEL INJECTION 14 - 25

FUEL INJECTOR (Continued)

Page 854 of 1232

REMOVAL

REMOVAL

WARNING: HIGH PRESSURE FUEL LINES DELIVER

DIESEL FUEL UNDER EXTREME PRESSURE FROM

THE INJECTION PUMP TO THE FUEL INJECTORS.

THIS MAY BE AS HIGH AS 23,000PSI (1600)BAR.

USE EXTREME CAUTION WHEN INSPECTING FOR

HIGH PRESSURE FUEL LEAKS. FUEL UNDER THIS

AMOUNT OF PRESSURE CAN PENETRATE SKIN

CAUSING PERSONAL INJURY OR DEATH. INSPECT

FOR HIGH PRESSURE LEAKS WITH A SHEET OF

CARD BOARD. WEAR SAFETY GOGGLES AND

ADEQUATE PROTECTIVE CLOTHING WHEN SER-

VICING THE FUEL SYSTEM.

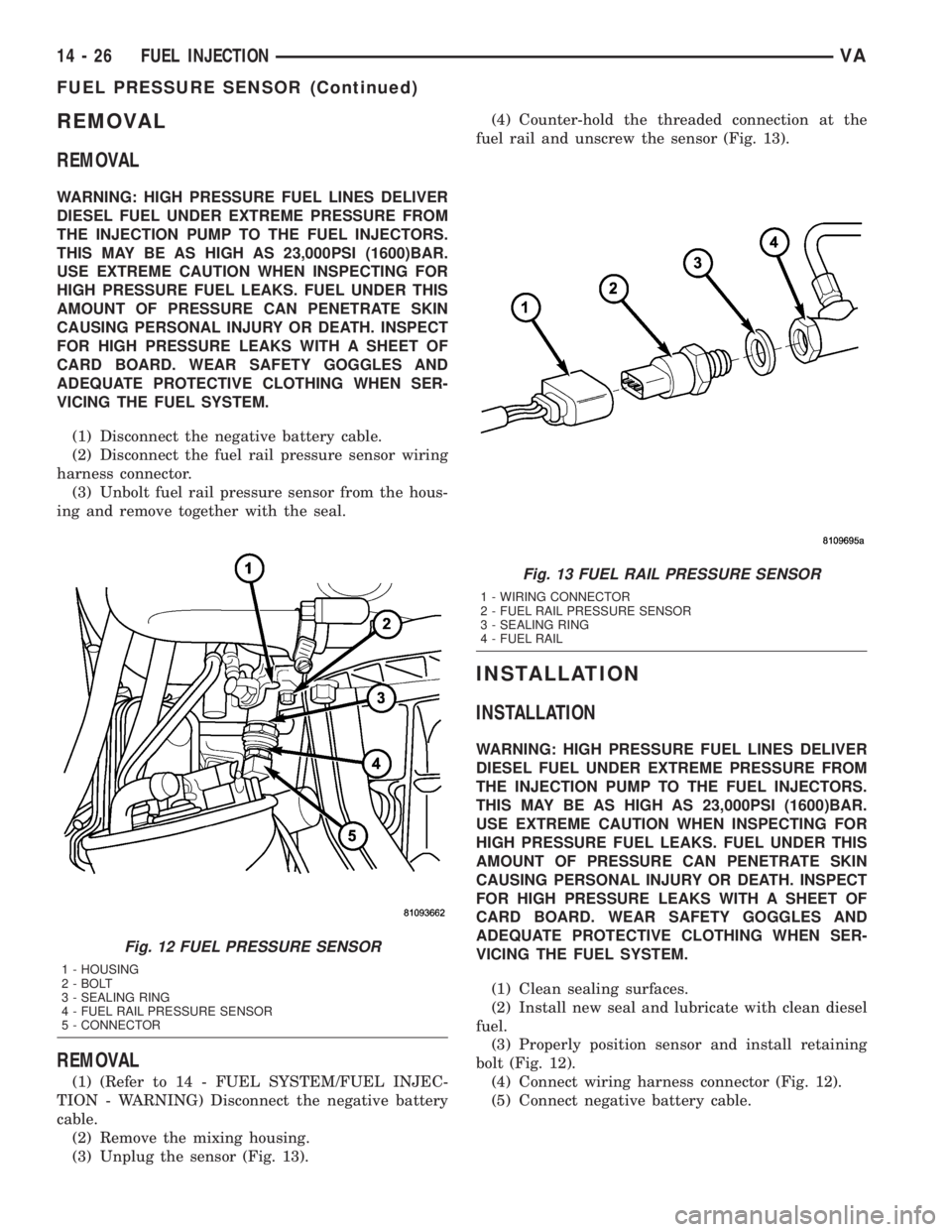

(1) Disconnect the negative battery cable.

(2) Disconnect the fuel rail pressure sensor wiring

harness connector.

(3) Unbolt fuel rail pressure sensor from the hous-

ing and remove together with the seal.

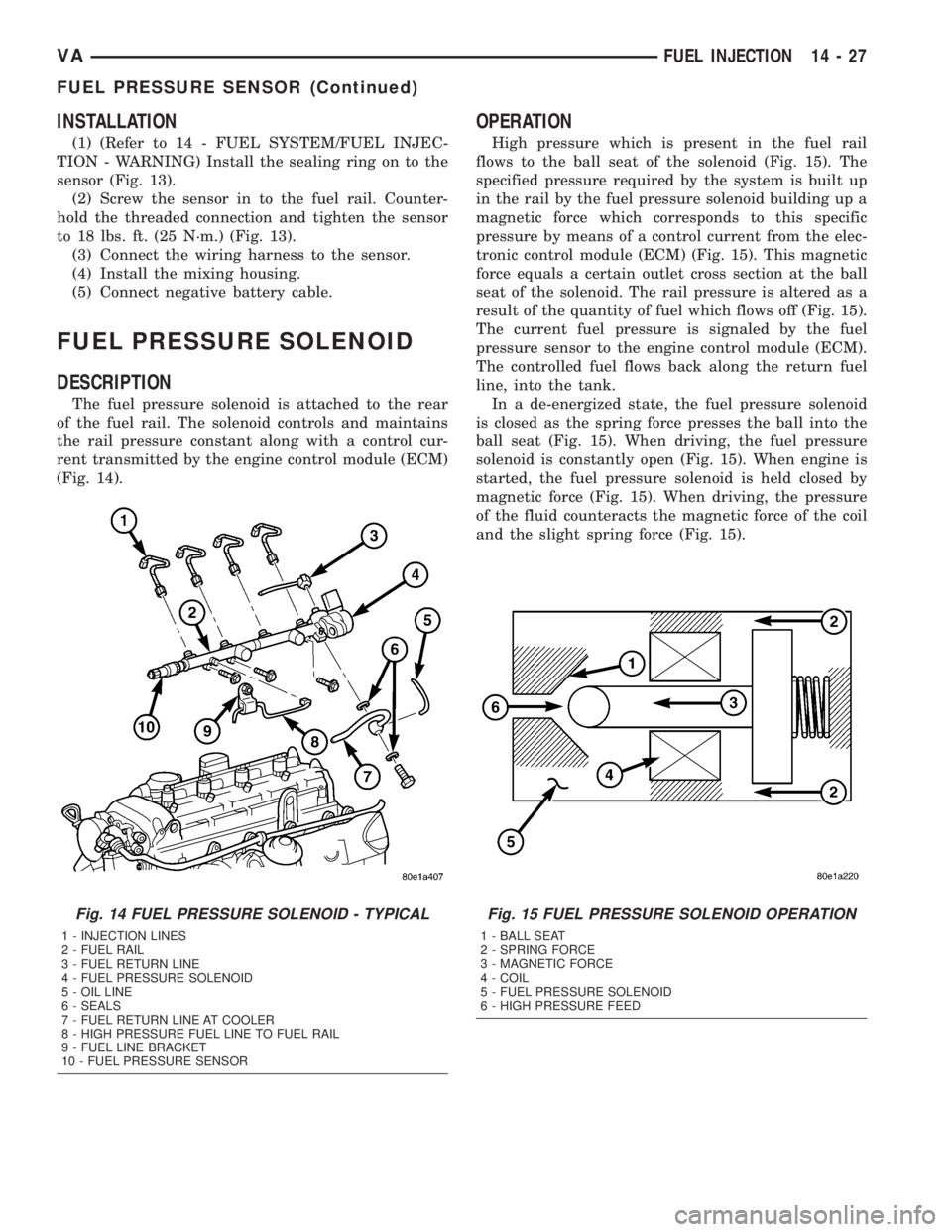

REMOVAL

(1) (Refer to 14 - FUEL SYSTEM/FUEL INJEC-

TION - WARNING) Disconnect the negative battery

cable.

(2) Remove the mixing housing.

(3) Unplug the sensor (Fig. 13).(4) Counter-hold the threaded connection at the

fuel rail and unscrew the sensor (Fig. 13).

INSTALLATION

INSTALLATION

WARNING: HIGH PRESSURE FUEL LINES DELIVER

DIESEL FUEL UNDER EXTREME PRESSURE FROM

THE INJECTION PUMP TO THE FUEL INJECTORS.

THIS MAY BE AS HIGH AS 23,000PSI (1600)BAR.

USE EXTREME CAUTION WHEN INSPECTING FOR

HIGH PRESSURE FUEL LEAKS. FUEL UNDER THIS

AMOUNT OF PRESSURE CAN PENETRATE SKIN

CAUSING PERSONAL INJURY OR DEATH. INSPECT

FOR HIGH PRESSURE LEAKS WITH A SHEET OF

CARD BOARD. WEAR SAFETY GOGGLES AND

ADEQUATE PROTECTIVE CLOTHING WHEN SER-

VICING THE FUEL SYSTEM.

(1) Clean sealing surfaces.

(2) Install new seal and lubricate with clean diesel

fuel.

(3) Properly position sensor and install retaining

bolt (Fig. 12).

(4) Connect wiring harness connector (Fig. 12).

(5) Connect negative battery cable.

Fig. 12 FUEL PRESSURE SENSOR

1 - HOUSING

2 - BOLT

3 - SEALING RING

4 - FUEL RAIL PRESSURE SENSOR

5 - CONNECTOR

Fig. 13 FUEL RAIL PRESSURE SENSOR

1 - WIRING CONNECTOR

2 - FUEL RAIL PRESSURE SENSOR

3 - SEALING RING

4 - FUEL RAIL

14 - 26 FUEL INJECTIONVA

FUEL PRESSURE SENSOR (Continued)

Page 855 of 1232

INSTALLATION

(1) (Refer to 14 - FUEL SYSTEM/FUEL INJEC-

TION - WARNING) Install the sealing ring on to the

sensor (Fig. 13).

(2) Screw the sensor in to the fuel rail. Counter-

hold the threaded connection and tighten the sensor

to 18 lbs. ft. (25 N´m.) (Fig. 13).

(3) Connect the wiring harness to the sensor.

(4) Install the mixing housing.

(5) Connect negative battery cable.

FUEL PRESSURE SOLENOID

DESCRIPTION

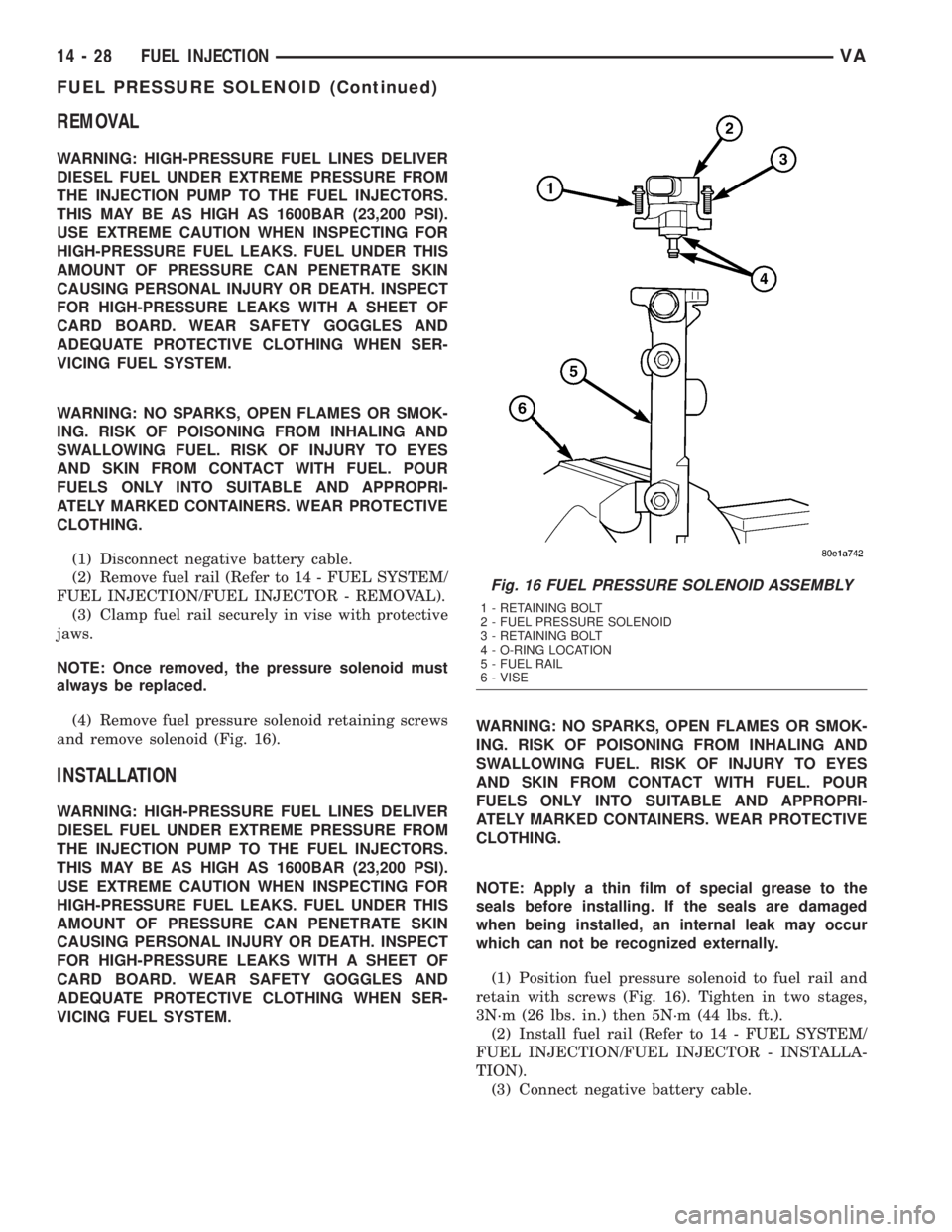

The fuel pressure solenoid is attached to the rear

of the fuel rail. The solenoid controls and maintains

the rail pressure constant along with a control cur-

rent transmitted by the engine control module (ECM)

(Fig. 14).

OPERATION

High pressure which is present in the fuel rail

flows to the ball seat of the solenoid (Fig. 15). The

specified pressure required by the system is built up

in the rail by the fuel pressure solenoid building up a

magnetic force which corresponds to this specific

pressure by means of a control current from the elec-

tronic control module (ECM) (Fig. 15). This magnetic

force equals a certain outlet cross section at the ball

seat of the solenoid. The rail pressure is altered as a

result of the quantity of fuel which flows off (Fig. 15).

The current fuel pressure is signaled by the fuel

pressure sensor to the engine control module (ECM).

The controlled fuel flows back along the return fuel

line, into the tank.

In a de-energized state, the fuel pressure solenoid

is closed as the spring force presses the ball into the

ball seat (Fig. 15). When driving, the fuel pressure

solenoid is constantly open (Fig. 15). When engine is

started, the fuel pressure solenoid is held closed by

magnetic force (Fig. 15). When driving, the pressure

of the fluid counteracts the magnetic force of the coil

and the slight spring force (Fig. 15).

Fig. 14 FUEL PRESSURE SOLENOID - TYPICAL

1 - INJECTION LINES

2 - FUEL RAIL

3 - FUEL RETURN LINE

4 - FUEL PRESSURE SOLENOID

5 - OIL LINE

6 - SEALS

7 - FUEL RETURN LINE AT COOLER

8 - HIGH PRESSURE FUEL LINE TO FUEL RAIL

9 - FUEL LINE BRACKET

10 - FUEL PRESSURE SENSOR

Fig. 15 FUEL PRESSURE SOLENOID OPERATION

1 - BALL SEAT

2 - SPRING FORCE

3 - MAGNETIC FORCE

4 - COIL

5 - FUEL PRESSURE SOLENOID

6 - HIGH PRESSURE FEED

VAFUEL INJECTION 14 - 27

FUEL PRESSURE SENSOR (Continued)

Page 856 of 1232

REMOVAL

WARNING: HIGH-PRESSURE FUEL LINES DELIVER

DIESEL FUEL UNDER EXTREME PRESSURE FROM

THE INJECTION PUMP TO THE FUEL INJECTORS.

THIS MAY BE AS HIGH AS 1600BAR (23,200 PSI).

USE EXTREME CAUTION WHEN INSPECTING FOR

HIGH-PRESSURE FUEL LEAKS. FUEL UNDER THIS

AMOUNT OF PRESSURE CAN PENETRATE SKIN

CAUSING PERSONAL INJURY OR DEATH. INSPECT

FOR HIGH-PRESSURE LEAKS WITH A SHEET OF

CARD BOARD. WEAR SAFETY GOGGLES AND

ADEQUATE PROTECTIVE CLOTHING WHEN SER-

VICING FUEL SYSTEM.

WARNING: NO SPARKS, OPEN FLAMES OR SMOK-

ING. RISK OF POISONING FROM INHALING AND

SWALLOWING FUEL. RISK OF INJURY TO EYES

AND SKIN FROM CONTACT WITH FUEL. POUR

FUELS ONLY INTO SUITABLE AND APPROPRI-

ATELY MARKED CONTAINERS. WEAR PROTECTIVE

CLOTHING.

(1) Disconnect negative battery cable.

(2) Remove fuel rail (Refer to 14 - FUEL SYSTEM/

FUEL INJECTION/FUEL INJECTOR - REMOVAL).

(3) Clamp fuel rail securely in vise with protective

jaws.

NOTE: Once removed, the pressure solenoid must

always be replaced.

(4) Remove fuel pressure solenoid retaining screws

and remove solenoid (Fig. 16).

INSTALLATION

WARNING: HIGH-PRESSURE FUEL LINES DELIVER

DIESEL FUEL UNDER EXTREME PRESSURE FROM

THE INJECTION PUMP TO THE FUEL INJECTORS.

THIS MAY BE AS HIGH AS 1600BAR (23,200 PSI).

USE EXTREME CAUTION WHEN INSPECTING FOR

HIGH-PRESSURE FUEL LEAKS. FUEL UNDER THIS

AMOUNT OF PRESSURE CAN PENETRATE SKIN

CAUSING PERSONAL INJURY OR DEATH. INSPECT

FOR HIGH-PRESSURE LEAKS WITH A SHEET OF

CARD BOARD. WEAR SAFETY GOGGLES AND

ADEQUATE PROTECTIVE CLOTHING WHEN SER-

VICING FUEL SYSTEM.WARNING: NO SPARKS, OPEN FLAMES OR SMOK-

ING. RISK OF POISONING FROM INHALING AND

SWALLOWING FUEL. RISK OF INJURY TO EYES

AND SKIN FROM CONTACT WITH FUEL. POUR

FUELS ONLY INTO SUITABLE AND APPROPRI-

ATELY MARKED CONTAINERS. WEAR PROTECTIVE

CLOTHING.

NOTE: Apply a thin film of special grease to the

seals before installing. If the seals are damaged

when being installed, an internal leak may occur

which can not be recognized externally.

(1) Position fuel pressure solenoid to fuel rail and

retain with screws (Fig. 16). Tighten in two stages,

3N´m (26 lbs. in.) then 5N´m (44 lbs. ft.).

(2) Install fuel rail (Refer to 14 - FUEL SYSTEM/

FUEL INJECTION/FUEL INJECTOR - INSTALLA-

TION).

(3) Connect negative battery cable.

Fig. 16 FUEL PRESSURE SOLENOID ASSEMBLY

1 - RETAINING BOLT

2 - FUEL PRESSURE SOLENOID

3 - RETAINING BOLT

4 - O-RING LOCATION

5 - FUEL RAIL

6 - VISE

14 - 28 FUEL INJECTIONVA

FUEL PRESSURE SOLENOID (Continued)

Page 857 of 1232

WARNING: USE EXTREME CAUTION WHEN ENGINE

IS OPERATING. DO NOT PUT YOUR HANDS NEAR

PULLEYS, BELTS, OR FAN. DO NOT WEAR LOOSE

CLOTHES.

(4) Start engine and inspect for leaks (Refer to 14 -

FUEL SYSTEM - DIAGNOSIS AND TESTING).

FUEL TEMPERATURE SENSOR

DESCRIPTION

The fuel temperature sensor is located in the fuel

return line directly down stream of the fuel rail pres-

sure control valve. The sensor measures the temper-

ature of the fuel in the return pipe between the rail

and the pre-heating valve. The sensor ranges from -

40ÉF (- 40C) to 284ÉF (140ÉC). If the engine is cold,

the actual value sent will read ambient temperature.

The value rises after the engine has been started.

OPERATION

An negative temperature coefficient (NTC) resistor

integrated in the fuel temperature sensor alters it's

electrical resistance in line with the fuel temperature

(the resistance drops as the temperature rises). If

fuel temperature has reached 248ÉF and engine

speed is above 2000 rpm, a pumping element of the

high pressure fuel injection pump is switched off and

engine output is reduced.

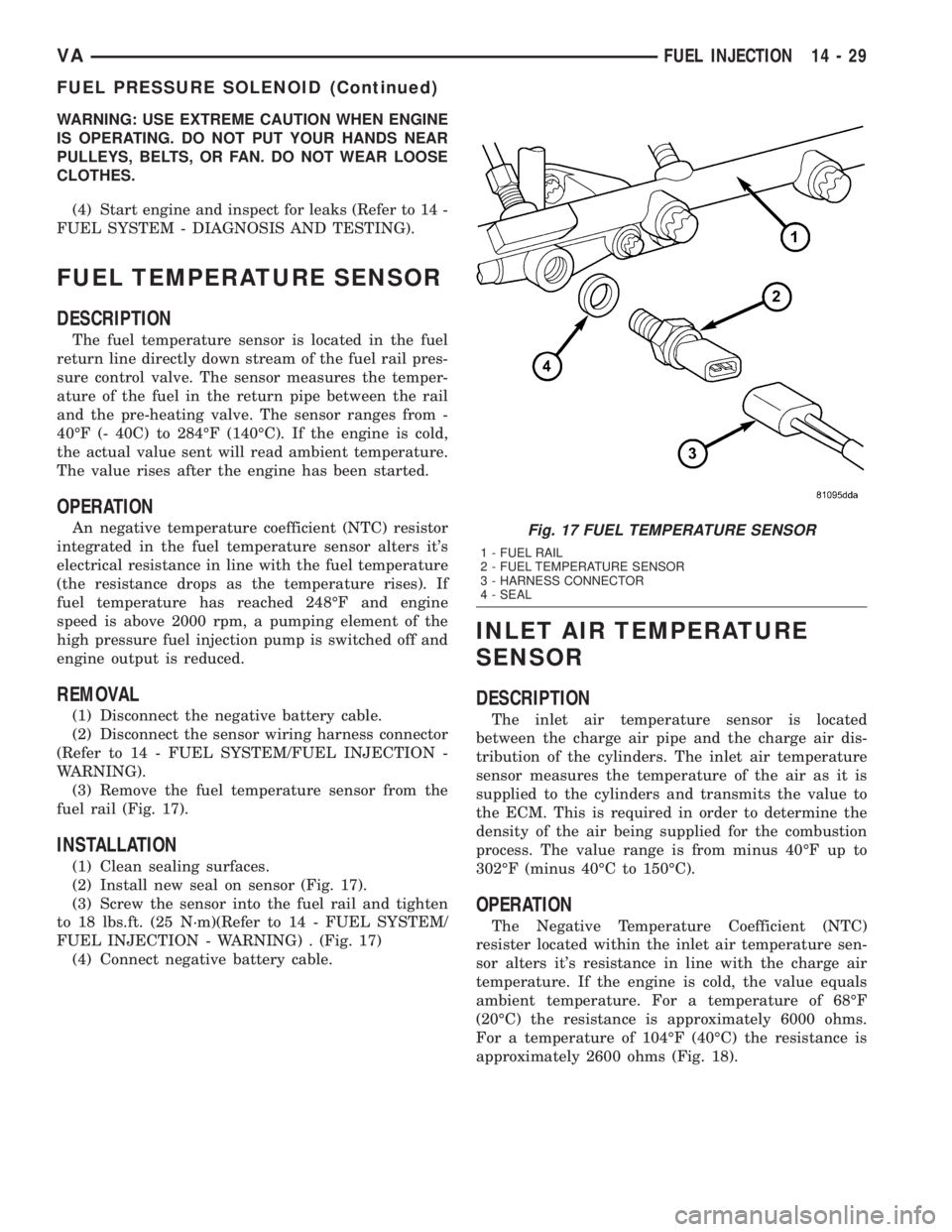

REMOVAL

(1) Disconnect the negative battery cable.

(2) Disconnect the sensor wiring harness connector

(Refer to 14 - FUEL SYSTEM/FUEL INJECTION -

WARNING).

(3) Remove the fuel temperature sensor from the

fuel rail (Fig. 17).

INSTALLATION

(1) Clean sealing surfaces.

(2) Install new seal on sensor (Fig. 17).

(3) Screw the sensor into the fuel rail and tighten

to 18 lbs.ft. (25 N´m)(Refer to 14 - FUEL SYSTEM/

FUEL INJECTION - WARNING) . (Fig. 17)

(4) Connect negative battery cable.

INLET AIR TEMPERATURE

SENSOR

DESCRIPTION

The inlet air temperature sensor is located

between the charge air pipe and the charge air dis-

tribution of the cylinders. The inlet air temperature

sensor measures the temperature of the air as it is

supplied to the cylinders and transmits the value to

the ECM. This is required in order to determine the

density of the air being supplied for the combustion

process. The value range is from minus 40ÉF up to

302ÉF (minus 40ÉC to 150ÉC).

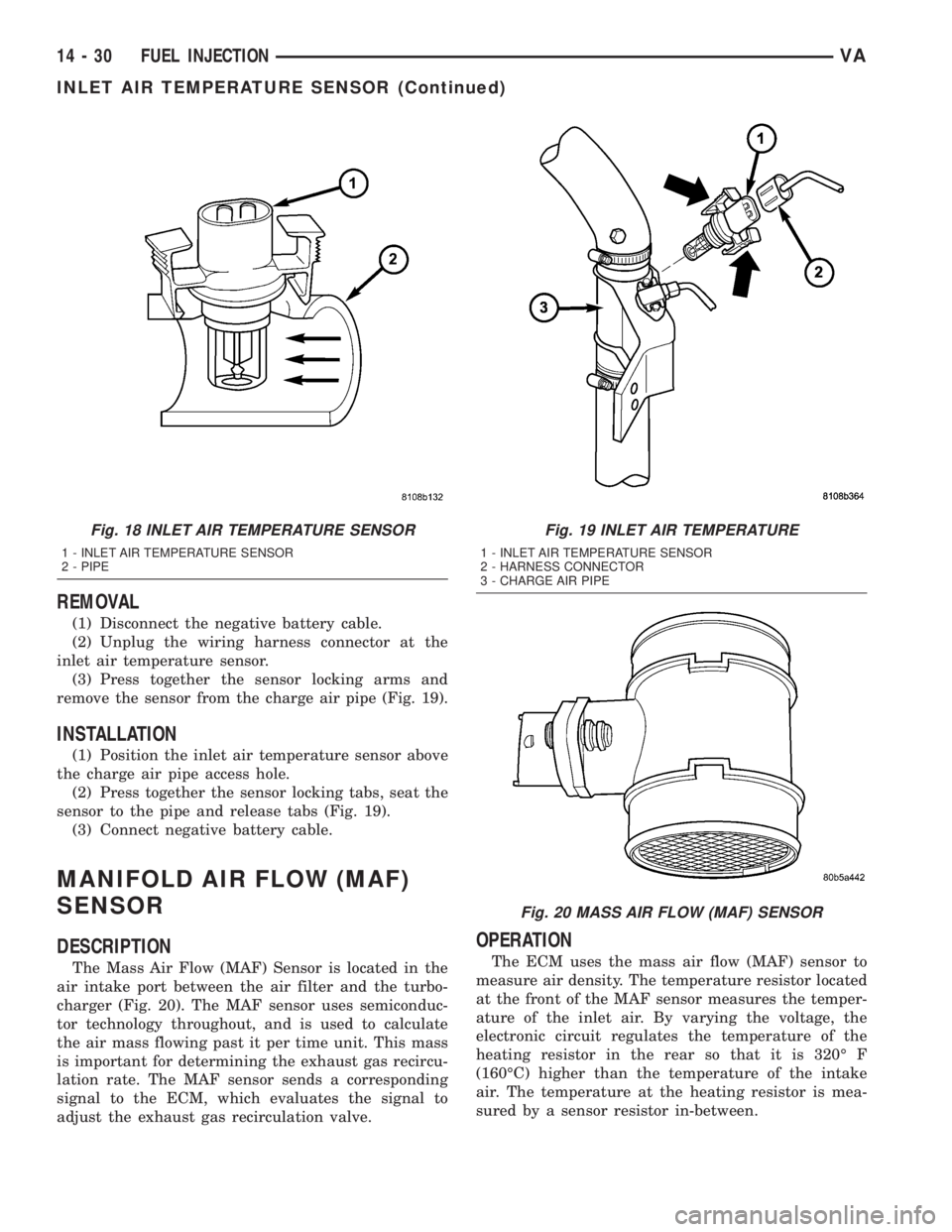

OPERATION

The Negative Temperature Coefficient (NTC)

resister located within the inlet air temperature sen-

sor alters it's resistance in line with the charge air

temperature. If the engine is cold, the value equals

ambient temperature. For a temperature of 68ÉF

(20ÉC) the resistance is approximately 6000 ohms.

For a temperature of 104ÉF (40ÉC) the resistance is

approximately 2600 ohms (Fig. 18).

Fig. 17 FUEL TEMPERATURE SENSOR

1 - FUEL RAIL

2 - FUEL TEMPERATURE SENSOR

3 - HARNESS CONNECTOR

4 - SEAL

VAFUEL INJECTION 14 - 29

FUEL PRESSURE SOLENOID (Continued)

Page 858 of 1232

REMOVAL

(1) Disconnect the negative battery cable.

(2) Unplug the wiring harness connector at the

inlet air temperature sensor.

(3) Press together the sensor locking arms and

remove the sensor from the charge air pipe (Fig. 19).

INSTALLATION

(1) Position the inlet air temperature sensor above

the charge air pipe access hole.

(2) Press together the sensor locking tabs, seat the

sensor to the pipe and release tabs (Fig. 19).

(3) Connect negative battery cable.

MANIFOLD AIR FLOW (MAF)

SENSOR

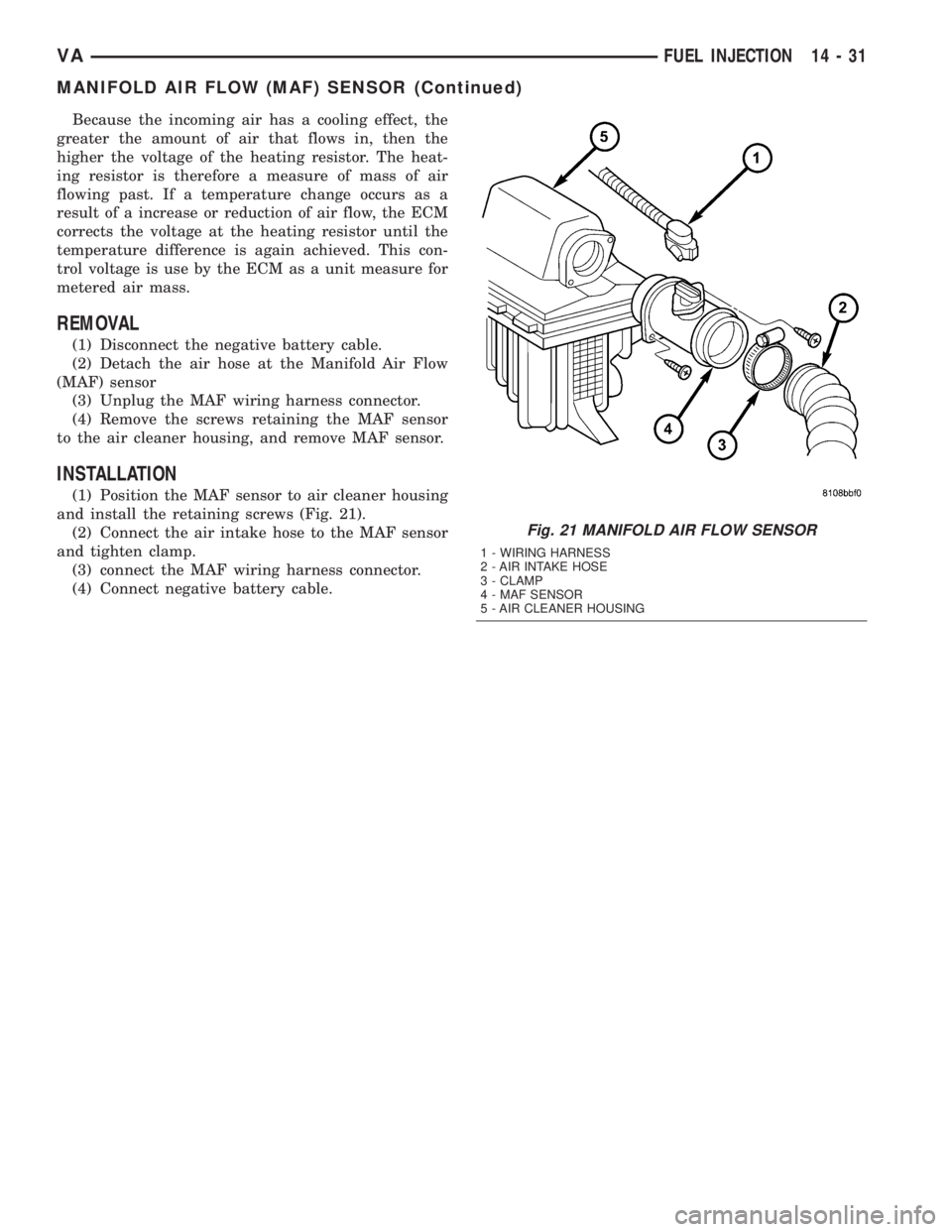

DESCRIPTION

The Mass Air Flow (MAF) Sensor is located in the

air intake port between the air filter and the turbo-

charger (Fig. 20). The MAF sensor uses semiconduc-

tor technology throughout, and is used to calculate

the air mass flowing past it per time unit. This mass

is important for determining the exhaust gas recircu-

lation rate. The MAF sensor sends a corresponding

signal to the ECM, which evaluates the signal to

adjust the exhaust gas recirculation valve.

OPERATION

The ECM uses the mass air flow (MAF) sensor to

measure air density. The temperature resistor located

at the front of the MAF sensor measures the temper-

ature of the inlet air. By varying the voltage, the

electronic circuit regulates the temperature of the

heating resistor in the rear so that it is 320É F

(160ÉC) higher than the temperature of the intake

air. The temperature at the heating resistor is mea-

sured by a sensor resistor in-between.

Fig. 18 INLET AIR TEMPERATURE SENSOR

1 - INLET AIR TEMPERATURE SENSOR

2 - PIPE

Fig. 19 INLET AIR TEMPERATURE

1 - INLET AIR TEMPERATURE SENSOR

2 - HARNESS CONNECTOR

3 - CHARGE AIR PIPE

Fig. 20 MASS AIR FLOW (MAF) SENSOR

14 - 30 FUEL INJECTIONVA

INLET AIR TEMPERATURE SENSOR (Continued)

Page 859 of 1232

Because the incoming air has a cooling effect, the

greater the amount of air that flows in, then the

higher the voltage of the heating resistor. The heat-

ing resistor is therefore a measure of mass of air

flowing past. If a temperature change occurs as a

result of a increase or reduction of air flow, the ECM

corrects the voltage at the heating resistor until the

temperature difference is again achieved. This con-

trol voltage is use by the ECM as a unit measure for

metered air mass.

REMOVAL

(1) Disconnect the negative battery cable.

(2) Detach the air hose at the Manifold Air Flow

(MAF) sensor

(3) Unplug the MAF wiring harness connector.

(4) Remove the screws retaining the MAF sensor

to the air cleaner housing, and remove MAF sensor.

INSTALLATION

(1) Position the MAF sensor to air cleaner housing

and install the retaining screws (Fig. 21).

(2) Connect the air intake hose to the MAF sensor

and tighten clamp.

(3) connect the MAF wiring harness connector.

(4) Connect negative battery cable.

Fig. 21 MANIFOLD AIR FLOW SENSOR

1 - WIRING HARNESS

2 - AIR INTAKE HOSE

3 - CLAMP

4 - MAF SENSOR

5 - AIR CLEANER HOUSING

VAFUEL INJECTION 14 - 31

MANIFOLD AIR FLOW (MAF) SENSOR (Continued)

Page 860 of 1232