center console MERCEDES-BENZ SPRINTER 2013 MY13 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2013, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2013Pages: 334, PDF Size: 3.88 MB

Page 230 of 334

X

To use the cigarette lighter: turn the key

to position 1in the ignition lock.

X Press in cigarette lighter 0005.

The cigarette lighte rwill pop out

automatically when the heatin gelemen tis

red-hot.

X Pull the cigarette lighter out of the socket

by its handle. 12

Vsocket

! Only use the 12 V socket (25 A) on the

center console for connecting the tire

inflatio ncompressor (Premium tire

sealant). You may otherwise damage the

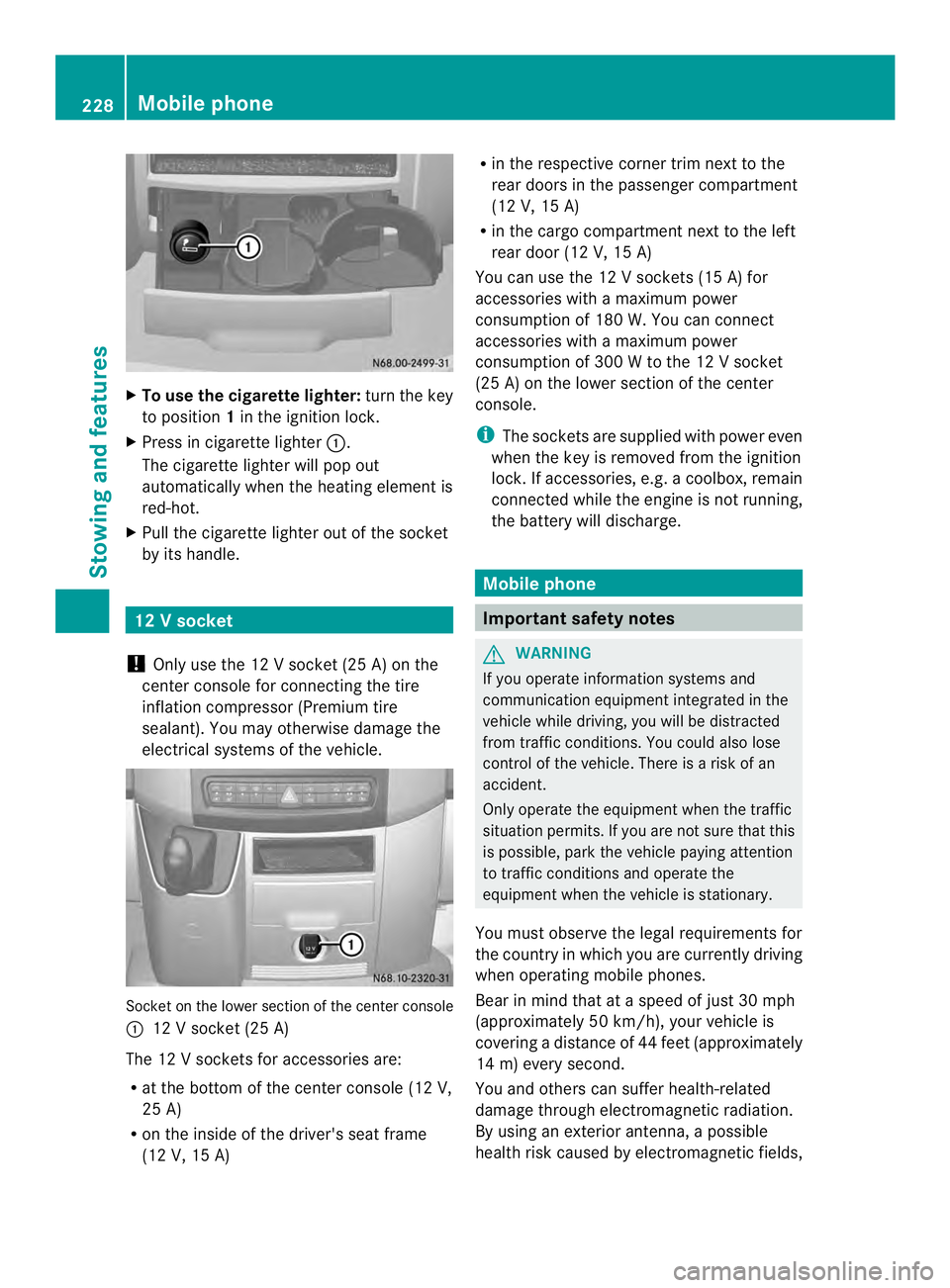

electrical systems of the vehicle. Socket on the lower section of the center console

0005 12 V socket (25 A)

The 12 Vsockets for accessories are:

R at the bottom of the center console (12 V,

25 A)

R on the inside of the driver's seat frame

(12 V, 15 A) R

in the respective corner trim next to the

rear doors in the passenger compartment

(12 V, 15 A)

R in the cargo compartment next to the left

rear door (12 V, 15 A)

You can use the 12 V sockets (15 A) for

accessories with a maximu mpower

consumption of 180 W. You can connect

accessories with a maximum power

consumption of 300 W to the 12 V socket

(25 A) on the lower section of the center

console.

i The sockets are supplied with power even

when the key is removed from the ignition

lock. If accessories, e.g. a coolbox, remain

connected while the engine is not running,

the battery will discharge. Mobile phone

Important safety notes

G

WARNING

If you operate information systems and

communication equipment integrated in the

vehicle while driving, you will be distracted

from traffic conditions. You could also lose

control of the vehicle. There is a risk of an

accident.

Only operate the equipment when the traffic

situation permits. If you are not sure that this

is possible, park the vehicle paying attention

to traffic conditions and operate the

equipment when the vehicle is stationary.

You must observe the legal requirements for

the country in which you are currently driving

when operating mobile phones.

Bear in mind that at a speed of just 30 mph

(approximately 50 km/h), your vehicle is

covering a distance of 44 feet (approximately

14 m) every second.

You and others can suffer health-related

damage through electromagnetic radiation.

By using an exterior antenna, a possible

health risk caused by electromagnetic fields, 228

Mobile phoneStowing and features

Page 298 of 334

Do not drive any further. Contact a qualified

specialis tworkshop. G

WARNING

The tire sealant is harmful and causes

irritation. It must not come into contact with

your skin, eyes or clothing or be swallowed.

Do not inhale TIREFIT fumes. Keep tire sealant

away from children. There is a risk of injury.

If you come into contact with the tire sealant,

observe the following:

R Rinse off the tire sealant from your skin

immediately with water.

R If the tire sealant comes into contact with

your eyes, immediately rinse them

thoroughly with clean water.

R If tire sealant is swallowed, immediately

rinse your mouth out thoroughly and drink

plenty of water. Do not induce vomiting,

and seek medical attention immediately.

R Immediately change out of clothing which

has come into contact with tire sealant.

R If an allergic reaction occurs, seek medical

attention immediately.

In addition, observe the manufacturer's

safety instructions on the sticker on the tire

inflation compressor and on the sticker on the

tire sealant bottle.

The tire sealant is water-soluble. If tire sealant

escapes, you can wash it off with water.

i Have the tire sealant replaced every

8y ears at a qualified specialist workshop.

! The tire inflation compressor should only

be connected to the 12 V socket in the

center console. You may otherwise

damage the vehicle's electrics.

! Do not operate the tire inflation

compressor for longer than 20 minutes at

a time without a break. The tire inflation

compressor may otherwise overheat.

The tire inflation compressor can be

operated again once it has cooled down. H

Environmental note

Have the used tire sealant bottle disposed of

professionally, e.g. at aqualified specialist

workshop.

X Prepare the vehicle as described

(Y page 295).

X If possible, remove the foreign object that

has pierced the tire, e.g .the screw or the

nail.

It is beneficial to the sealing process if the

foreign body that has pierced the tire is

removed.

X Remove the Premium tire sealant, the

accompanying

"max 50 mph"("max80 km/h") sticker and

the tire inflation compressor from the

stowage compartmentint he right-hand

doorway (Y page 264).

X Affix the sticker within the driver's field of

vision. Tire inflation compressor

0005

Switch

0006 Angled connecting piece

0026 Tire inflation compressor hose

0025 Flap

0023 Pressure gauge with pressure release

screw

0024 Connector with cable

X Open flap 0025on the tire inflation

compressor.

X Pull connector 0024and hose 0026with

pressure gauge 0023from the housing. 296

Flat tireWheels and tires

Page 299 of 334

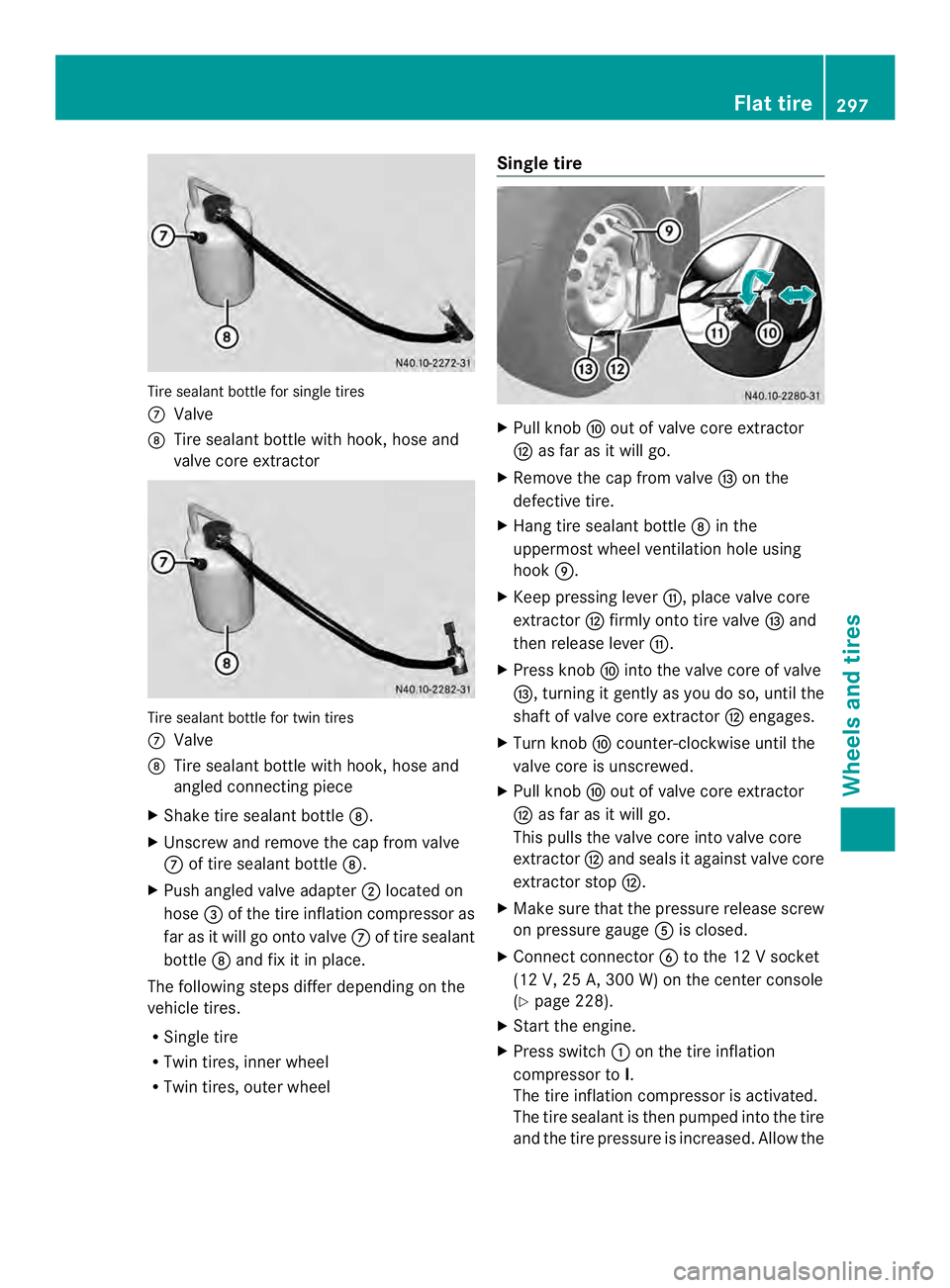

Tire sealant bottle for single tires

0018

Valve

0019 Tire sealant bottle with hook, hose and

valve core extractor Tire sealant bottle for twin tires

0018

Valve

0019 Tire sealant bottle with hook, hose and

angled connecting piece

X Shake tire sealant bottle 0019.

X Unscrew and remove the cap from valve

0018 of tire sealant bottle 0019.

X Push angled valve adapter 0006located on

hose 0026of the tire inflation compressor as

far as it will go ontov alve0018of tire sealant

bottle 0019and fix it in place.

The following steps differ depending on the

vehicle tires.

R Single tire

R Twin tires, inner wheel

R Twin tires, outer wheel Single tire

X

Pull knob 001Bout of valve core extractor

001D as far as it will go.

X Remove the cap from valve 001Eon the

defective tire.

X Hang tire sealan tbottle 0019in the

uppermost wheel ventilation hole using

hook 001A.

X Keep pressing lever 001C, place valve core

extractor 001Dfirmly onto tire valve 001Eand

then release lever 001C.

X Press knob 001Binto the valve core of valve

001E, turning it gently as you do so, until the

shaft of valve core extractor 001Dengages.

X Turn knob 001Bcounter-clockwise until the

valve core is unscrewed.

X Pull knob 001Bout of valve core extractor

001D as far as it will go.

This pulls the valve core into valve core

extractor 001Dand seals it against valve core

extractor stop 001D.

X Make sure that the pressure release screw

on pressure gauge 0023is closed.

X Connect connector 0024to the 12 V socket

(12 V, 25 A, 300 W) on the center console

(Y page 228).

X Start the engine.

X Press switch 0005on the tire inflation

compressor to I.

The tire inflation compressor is activated.

The tire sealant is then pumped into the tire

and the tire pressure is increased. Allow the Flat tire

297Wheels and tires Z

Page 301 of 334

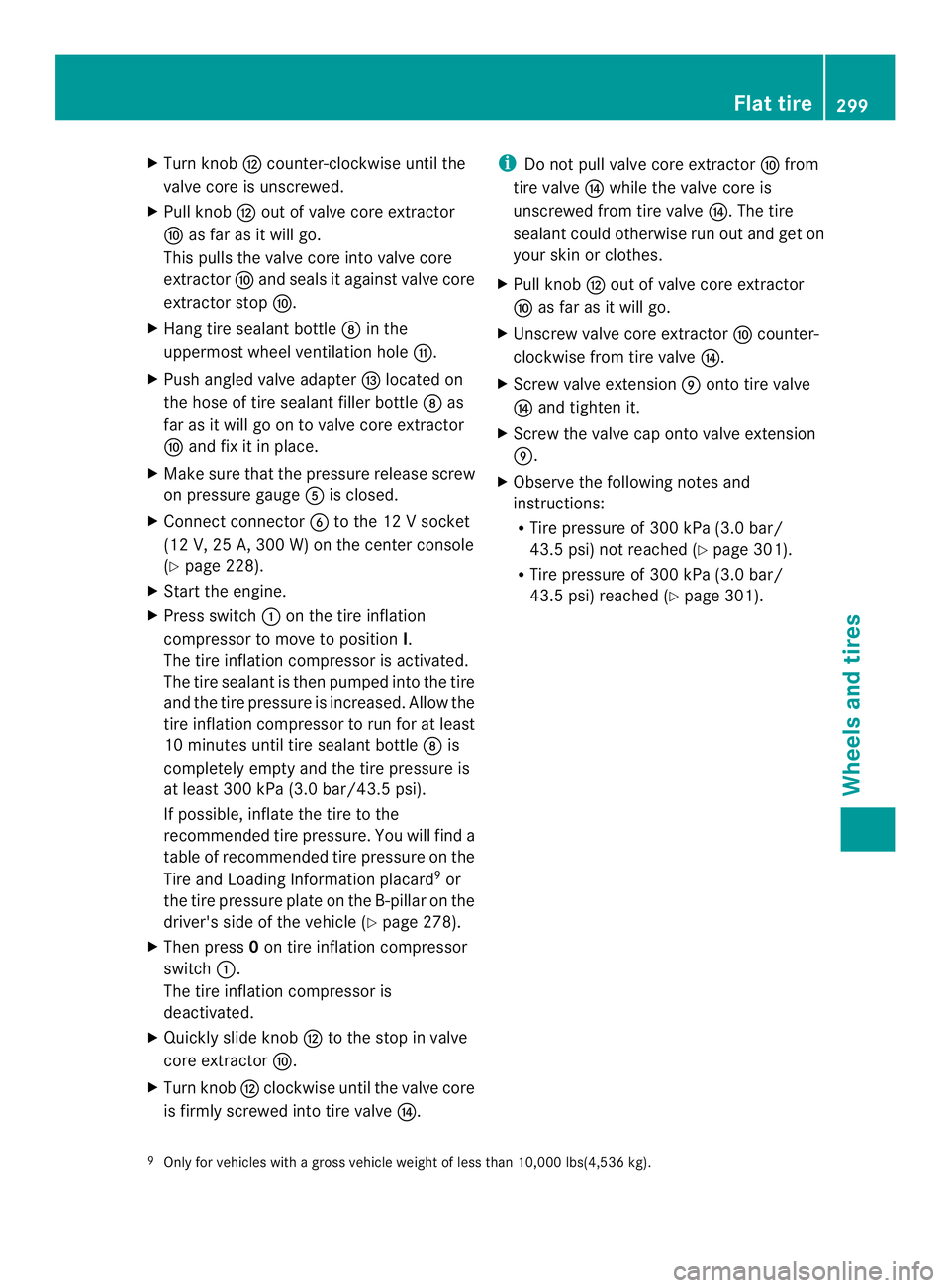

X

Turn knob 001Dcounter-clockwise until the

valve core is unscrewed.

X Pull knob 001Dout of valve core extractor

001B as far as it will go.

This pulls the valve core into valve core

extractor 001Band seals it against valve core

extractor stop 001B.

X Hang tire sealant bottle 0019in the

uppermost wheel ventilation hole 001C.

X Push angled valve adapter 001Elocated on

the hose of tire sealant filler bottle 0019as

far as it will go on to valve core extractor

001B and fix it in place.

X Make sure that the pressure release screw

on pressure gauge 0023is closed.

X Connect connector 0024to the 12 V socket

(12 V, 25 A, 300 W) on the center console

(Y page 228).

X Start the engine.

X Press switch 0005on the tire inflation

compressor to move to position I.

The tire inflation compressor is activated.

The tire sealant is then pumped into the tire

and the tire pressure is increased. Allow the

tire inflation compressor to run for at least

10 minutes until tire sealant bottle 0019is

completely empty and the tire pressure is

at least 300 kPa (3.0 bar/43.5 psi).

If possible, inflate the tire to the

recommended tire pressure. You will find a

table of recommended tire pressure on the

Tire and Loading Information placard 9

or

the tire pressure plate on the B-pillar on the

driver's side of the vehicle ( Ypage 278).

X Then press 0on tire inflation compressor

switch 0005.

The tire inflation compressor is

deactivated.

X Quickly slide knob 001Dto the stop in valve

core extractor 001B.

X Turn knob 001Dclockwise until the valve core

is firmly screwed into tire valve 001F.i

Do not pull valve core extractor 001Bfrom

tire valve 001Fwhile the valve core is

unscrewed from tire valve 001F. The tire

sealant could otherwise run out and get on

your skin or clothes.

X Pull knob 001Dout of valve core extractor

001B as far as it will go.

X Unscrew valve core extractor 001Bcounter-

clockwise from tire valve 001F.

X Screw valve extension 001Aonto tire valve

001F and tighten it.

X Screw the valve cap onto valve extension

001A.

X Observe the following notes and

instructions:

R

Tire pressure of 300 kPa (3.0 bar/

43.5 psi) not reached (Y page 301).

R Tire pressure of 300 kPa (3.0 bar/

43.5p si) reached (Y page 301).

9 Only for vehicles with a gross vehicle weight of less than 10,000 lbs(4,536 kg). Flat tire

299Wheels and tires Z

Page 302 of 334

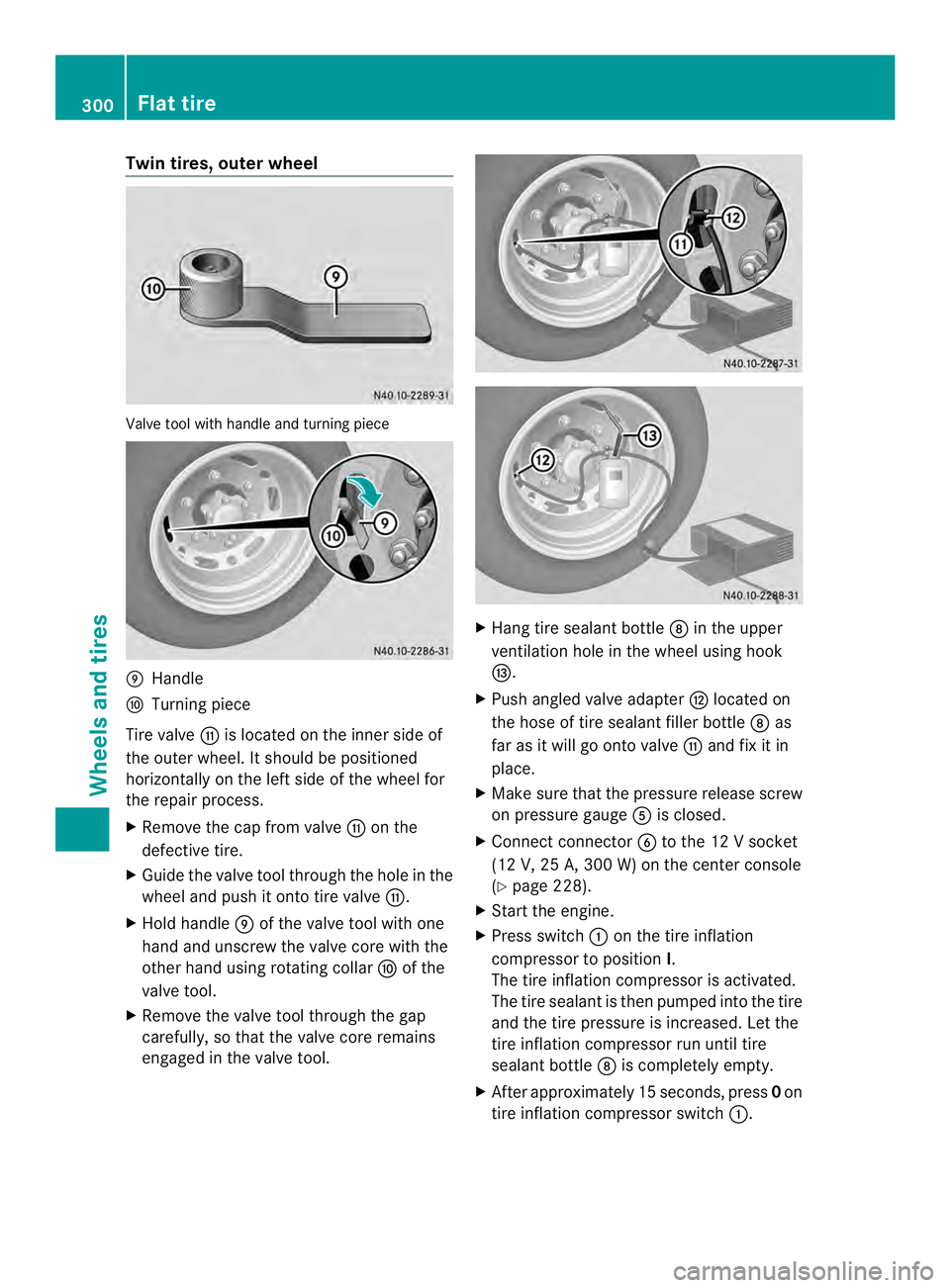

Twin tires, outer wheel

Valve tool with handle and turning piece

001A

Handle

001B Turning piece

Tire valve 001Cis located on the inne rside of

the outer wheel. It should be positioned

horizontally on the left side of the wheel for

the repair process.

X Remove the cap from valve 001Con the

defective tire.

X Guide the valve tool through the hole in the

wheel and push it onto tir evalve 001C.

X Hold handle 001Aof the valve tool with one

hand and unscrew the valv ecore with the

other hand using rotating collar 001Bof the

valve tool.

X Remove the valve tool through the gap

carefully, so that the valve core remains

engaged in the valve tool. X

Hang tire sealant bottle 0019in the upper

ventilation hole in the wheel using hook

001E.

X Push angled valve adapter 001Dlocated on

the hose of tire sealant filler bottle 0019as

far as it will go onto valve 001Cand fix it in

place.

X Make sure that the pressure release screw

on pressure gauge 0023is closed.

X Connect connector 0024to the 12 V socket

(12 V, 25 A, 300 W) on the center console

(Y page 228).

X Start the engine.

X Press switch 0005on the tire inflation

compressor to position I.

The tire inflation compressor is activated.

The tire sealant is then pumped into the tire

and the tire pressure is increased. Let the

tire inflation compressor run until tire

sealant bottle 0019is completely empty.

X After approximately 15 seconds, press 0on

tire inflation compressor switch 0005.300

Flat tireWheels and tires

Page 316 of 334

Genuine Sprinter parts

! Air bags and Emergency Tensioning

Devices, as well as control units and

sensors for these restraint systems, may be

installed in the following areas of your

vehicle:

R doors

R door pillars

R door sills

R seats

R cockpit

R instrument cluster

R center console

Do not install accessories such as audio

systems in these areas. Do not carry out

repairs or welding. You could impair the

operating efficiency of the restraint

systems.

Have aftermarket accessories installed at

a qualified specialist workshop. H

Environmental note

We supply reconditioned assembliesa nd

parts which are of the same quality as new

parts. The same New Vehicl eLimited

Warranty applies as for new parts.

We tes tgenuine Sprinter parts, as well as

conversion parts and accessories that have

been specifically approved for the type of

vehicle, for:

R reliability

R safety

R suitability

Despite ongoing market research, we are

unable to assess other parts. If individual or

official approval is given, we assume no

responsibility for use in Sprinter vehicles.

In some countries, certain parts are only

officially approved for installation or

modification if they comply with legal

requirements. All genuine Sprinter parts

satisfy these requirements. Make sure that all

parts are suitable for your vehicle. All authorized Sprinter Dealers maintain a

supply of genuine Sprinter parts for required

service and repair work. Also, the

strategically distributed parts delivery

centers provide quick and reliable parts

service.

Always specify the vehicle identification

number (VIN) and engin

enumbe rwhen

ordering genuine Sprinter parts

(Y page 315). Vehicle electronics

Tampering with the engine

electronics

G

WARNING

Always have work on the engine electronics

and related components carried out at a

qualified specialist workshop. Otherwise, the

vehicle's operating safety could be affected.

! Only have engine electronics and the

corresponding parts, such as control units,

sensors or connector leads, serviced in a

qualified specialist workshop. Otherwise,

the vehicle parts may wear more quickly.

This can lead to loss of the New Vehicle

Limited Warranty. Installing electrical or electronic

equipment

G

WARNING

You and others may damage your health due

to excessive electromagnetic radiation. By

using an external antenna, the possible health

risks of electromagnetic fields, which are

under discussion among the scientific

community, should be largely prevented.

Therefore, only have the exterior antenna

installed at a qualified specialist workshop.

Electrical and electronic devices may have a

detrimental effect on both the comfort and

the operating safety of the vehicle. If 314

Vehicle electronicsTechnical data