ECU MERCEDES-BENZ SPRINTER 2013 MY13 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2013, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2013Pages: 334, PDF Size: 3.88 MB

Page 257 of 334

X

Recharge the removed battery. Observe

the notes in the operating instructions for

your battery charger.

X Install the battery. Observe the notes on

reconnecting the battery.

i If batteries are no tbeing used, you should

charge them once a month.

It is also possible to charge the starter

battery using the jump-starting connection

point in the engine compartment

(Y page 267). Care

! Dirty battery clamps and battery surfaces

cause leak currents which lead to the

batteries discharging.

! Do not use cleaning agents containing

fuel. Cleaning agents containing fuel

corrode the battery housing.

! If dirt gets into the battery cell, battery

self-discharge will increase and the battery

may be damaged.

The following points on battery care must be

observed:

X Regularly chec kthe battery terminals and

the fastening of the negative cable to the

chassis to ensure that they are firmly

seated.

X Always keep the battery terminals and

battery surfaces clean and dry.

X Lightly grease the undersides of the battery

terminals with acid-resistant grease.

X Only clean the batteries when the caps are

screwed on.

Otherwise, dirt could get into the battery

cells.

X Unscrew the caps and clean blocked

breathers with a suitable tool such as a

piece of wire.

If you do not unscrew the caps for cleaning,

there is a risk of short circuit. The breathers in the caps and the cell

ventilation tubes must be open. Otherwise,

gas cannot escape.

X Only clean the battery casing with a

commercially available cleaning product. Care

Notes on care

G

WARNING

If you use openings in the bodywork or

detachable parts as steps, you could:

R slip and/or fall

R damage the vehicle and cause yourself to

fall.

There is a risk of injury.

Always use secure climbing aids, e.g. a

suitable ladder.

! For cleaning your vehicle, do not use any

of the following:

R dry, rough or hard cloths

R abrasive cleaning agents

R solvents

R cleaning agents containing solvents

Do not scrub.

Do not touch the surfaces or protective

films with hard objects, e.g. a ring or ice

scraper. You could otherwise scratch or

damage the surfaces and protective film.

! Do not park the vehicle for an extended

period straight after cleaning it, particularly

after having cleaned the wheels with wheel

cleaner. Wheel cleaners could cause

increased corrosion of the brake discs and

brake pads/linings. For this reason, you

should drive for a few minutes after

cleaning. Braking heats the brake discs and

the brake pads/linings, thus drying them.

The vehicle can then be parked. Care

255Maintenance and care Z

Page 260 of 334

!

Do not fold the windshield wipers away

from the windshield unless the hood is

closed. Otherwise, you could damage the

hood.

! Hold the wiper arm securely when folding

back. The windshield could be damaged if

the wiper arm smacks against it suddenly.

! Do not use dry cloths, abrasive products,

solvents or cleaning agents containing

solvents to clean the inside of the windows.

Do not touch the insides of the windows

with hard objects, e.g. an ice scraper or

ring. There is otherwise a risk of damaging

the windows.

Before cleaning the windshield

X Turn the key to position 0in the ignition

lock or remove it.

X Fold the windshield wiper arms away from

the windshield until you feel them engage.

Before switching the ignition on again, fold

the windshield wipers back into position.

Cleaning the windows

X Cleant he inside and outside of the

windows with a damp cloth and a cleaning

agent that is recommended and approved

for Sprinter vehicles. Exterior

Cleaning the wheels !

Do not use any acidic or alkaline cleaning

agents. They can cause corrosion on the

wheel bolts (wheel nuts) or the retainer

springs for the wheel-balancing weights.

! Do not park the vehicle for an extended

period straight after cleaning it, particularly

after having cleaned the wheels with wheel

cleaner. Wheel cleaners could cause

increased corrosion of the brake discs and

brake pads/linings. For this reason, you

should drive for a few minutes after

cleaning. Braking heats the brake discs and the brake pads/linings, thus drying them.

The vehicle can then be parked.

If you clean the wheels with a power washer,

observe the safety notes for the power

washer (Y page 257). You could otherwise

damage the tires.

Cleaning the wiper blades G

WARNING

You could become trapped by the windshield

wipers if they start moving while cleaning the

windshield or wiper blades. There is a risk of

injury.

Always switch off the windshield wipers and

the ignition before cleaning the windshield or

wiper blades.

! Do not fold the windshield wipers away

from the windshield unless the hood is

closed. Otherwise, you could damage the

hood.

! Do not pull the wiper blade. Otherwise,

the wiper blade could be damaged.

! Do not clean wiper blades too often and

do not rub them too hard. Otherwise, the

graphite coating could be damaged. This

could cause wiper noise.

! Hold the wiper arm securely when folding

back. The windshield could be damaged if

the wiper arm smacks against it suddenly.

X Turn the key to position 0in the ignition

lock or remove it.

X Fold the windshield wiper arms away from

the windshield until you feel them engage.

X Carefully clean the wiper blades with a

damp cloth.

X Fold back the wiper arms before switching

on the ignition.

Cleaning the exterior lighting !

Only use cleaning agents or cleaning

cloths which are suitable for plastic light

lenses. Unsuitable cleaning agents or 258

CareMaintenance and care

Page 270 of 334

Tow-starting and towing away

Important safety notes

G

WARNING

Functions relevant to safety are restricted or

no longe ravailable if:

R the engine is not running.

R the brake system or the powe rsteering is

malfunctioning.

R there is a malfunctio ninthe voltage supply

or the vehicle's electrical system.

If your vehicle is being towed, much more

force may be necessary to steer or brake.

There is a risk of an accident.

In such cases, use a tow bar. Before towing,

make sure that the steering moves freely. G

WARNING

You can no longer steer the vehicle if the

steering wheel lock has been engaged. There

is a risk of an accident.

Always switch off the ignition when towing the

vehicle with a tow cable or a tow bar. G

WARNING

If the weight of the vehicle to be towed or tow-

started is greater than the permissible gross

weight of your vehicle:

R the towing eye could detach itself

R the vehicle/trailer combination could

rollover.

There is a risk of an accident.

When towing or tow-starting another vehicle,

its weight should not be greater than the

permissible gross weight of your vehicle.

Information on your vehicle's gross vehicle

weight rating can be found on the vehicle

identification plate (Y page 315).

! Only secure the tow rope or tow bar at the

towing eyes. Otherwise, the vehicle could

be damaged. !

Observe the following points when towing

with a tow rope:

R Secure the tow rope on the same side on

both vehicles.

R Ensure that the tow cable is not longer

than legally permitted. Mark the tow

cable in the middle, e.g. with a white

cloth (30 x 30 cm). This will make other

road users aware that the vehicle is being

towed.

R Only secure the tow cable to the towing

eye.

R Observe the brake lamps of the towing

vehicle while driving. Always maintain a

distance so that the tow rope does not

sag.

R Do not use steel cables or chains to tow

your vehicle. You could otherwise

damage the vehicle.

! Do not use the towing eye for recovery,

this could damage the vehicle. If in doubt,

recover the vehicle with acrane.

! When towing, pull away slowly and

smoothly .Ifthe tractive power is too high,

the vehicles could be damaged.

Observe the legal requirements for the

relevant country when towing.

It is preferable to have the vehicle

transported on a transporter or trailer instead

of towing it.

The automatic transmission selector lever

must be in the Nposition when towing the

vehicle.

The battery must be connected and charged.

Otherwise, you:

R cannot turn the key in the ignition lock to

position 2

R cannot move the selector lever to position

Non vehicles with automatic transmission.

i Switch off the automatic locking feature

before the vehicle is towed (Y page 69). You

could otherwise lock yourself out of the

vehicle when pushing or towing away the

vehicle. 268

Tow-starting and towing awayBreakdown assistance

Page 282 of 334

the braking properties and the driving

characteristics .There is a risk of an accident.

Avoid tire pressures that are too low in all the

tires, including the spare wheel.

Underinflated tires can:

R fail from being overheated

R adversely affect handling

R wear excessively and/or unevenly

R have an adverse effect on fuel consumption

Overinflated tires G

WARNING

Tires with excessively high pressure can burst

because they are damaged more easily by

road debris, potholes etc. In addition, they

also suffer from irregular wear, which can

severely impair the braking properties and the

driving characteristics. There is a risk of an

accident.

Avoid tire pressures that are too high in all the

tires, including the spare wheel.

Overinflated tires can:

R increase the braking distance

R adversely affect handling

R wear excessively and/or unevenly

R adversely affect ride comfort

R be more susceptible to damage

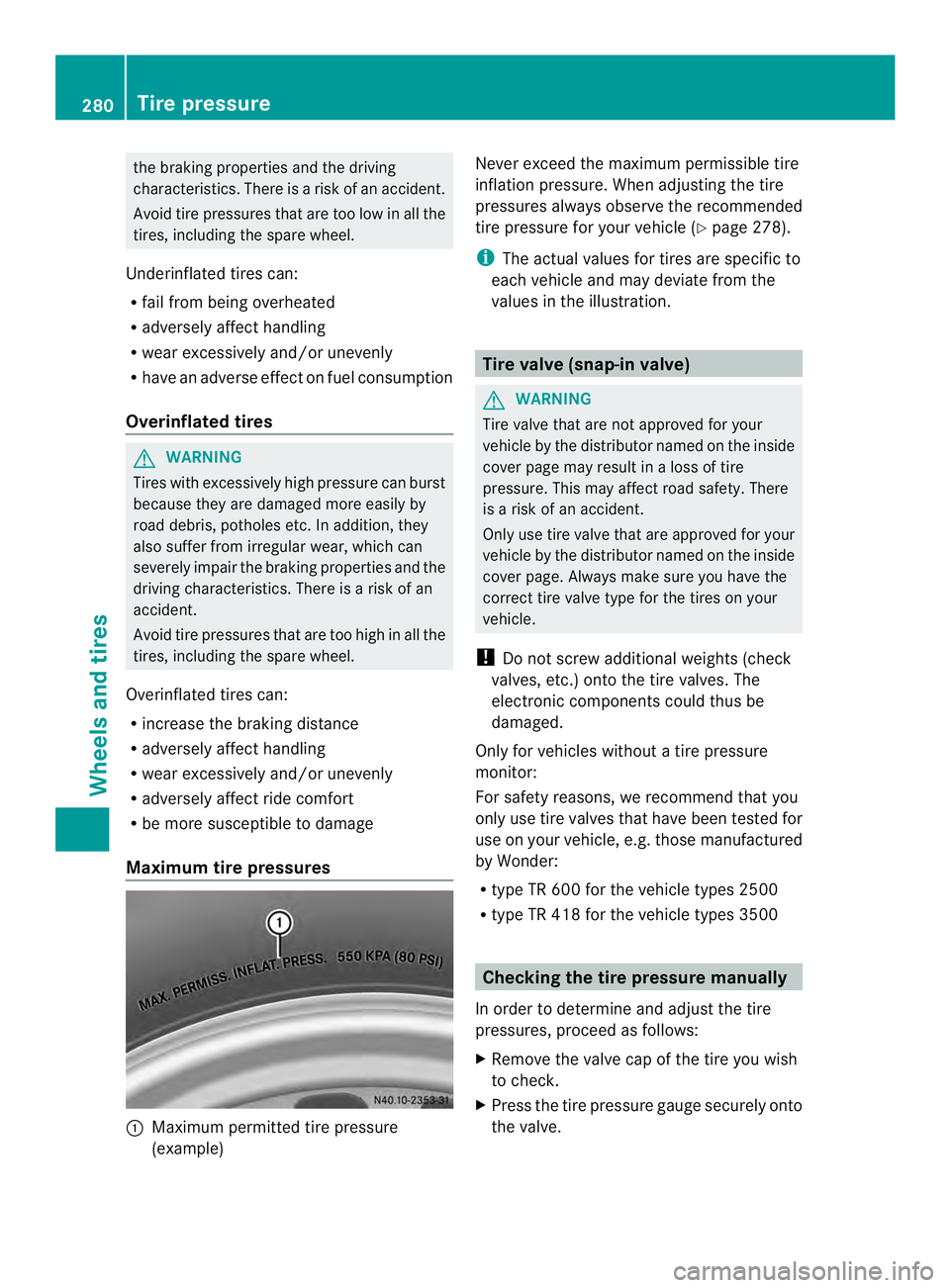

Maximum tire pressures 0005

Maximum permitted tire pressure

(example) Never exceed the maximum permissible tire

inflation pressure. When adjusting the tire

pressures always observe the recommended

tire pressure for your vehicle (Y

page 278).

i The actual values for tires are specific to

each vehicle and may deviate from the

values in the illustration. Tire valve (snap-in valve)

G

WARNING

Tire valve that are not approved for your

vehicle by the distributor named on the inside

cover page may result in a loss of tire

pressure. This may affect road safety. There

is a risk of an accident.

Only use tire valve that are approved for your

vehicle by the distributor named on the inside

cover page. Always make sure you have the

correct tire valve type for the tires on your

vehicle.

! Do not screw additional weights (check

valves, etc.) onto the tire valves. The

electronic components could thus be

damaged.

Only for vehicles without atire pressure

monitor:

For safety reasons, we recommend that you

only use tire valves that have been tested for

use on your vehicle, e.g. those manufactured

by Wonder:

R type TR 600 for the vehicle types 2500

R type TR 418 for the vehicle types 3500 Checking the tire pressure manually

In order to determine and adjust the tire

pressures, proceed as follows:

X Remove the valve cap of the tire you wish

to check.

X Press the tire pressure gauge securely onto

the valve. 280

Tire pressureWheels and tires

Page 296 of 334

is bar. 100 kilopascals (kPa) are the

equivalen tof1bar.

Load index

In addition to the load bearing index, a load

index can be stamped onto the sidewall of the

tire. It specifies the load-bearing capacity of

the tire more precisely.

Curb weight

The weigh tofavehicle with standard

equipment including the maximu mfilling

capacity of fuel, oil, and coolant. It also

includes the air-conditionin gsystem and

optional equipmen tifthese are installed on

the vehicle, but does not include passengers

or luggage.

Maximum tire load

The maximum tire load in kilograms or

pounds is the maximum weight for which a

tire is approved.

Maximum permissible tire pressure

Maximum permissible tire pressure for one

tire.

Maximum load on one tire

Maximum load on one tire. This is calculated

by dividing the maximum axle load of one axle

by two.

PSI (Pounds per square inch)

Standard unit of measurement for tire

pressure.

Aspect ratio

Relationship between tire height and width in

percent.

Tire pressure

Pressure inside the tire applying an outward

force to every square inch of the tire's

surface. Tire pressure is specified in pounds

per square inch (psi), in kilopascal (kPa) or in

bar. Tire pressure should only be corrected

when the tires are cold. Cold tire pressure

The tires are cold:

R if the vehicle has been parked for at least

three hours without direct sunlight on the

tires, and

R if the vehicle has not been driven further

than 1 mile (1.6 km)

Tire tread

The part of the tire that comes into contact

with the road.

Tire bead

The tire bead ensures that the tire sits

securely on the wheel. There are several steel

wires in the bead to prevent the tire from

coming loose from the wheel rim.

Sidewall

The part of the tire between the tread and the

tire bead.

Weight of optional extras

The combined weight of those optional extras

that weigh more than the replaced standard

parts and more than 2.3 kg (5 lbs). These

optional extras, such as high-performance

brakes, level control, a roof rack or a high-

performance battery, are not included in the

curb weight and the weight of the

accessories.

TIN (Tire Identification Number)

Au nique identificatio nnumbe rwhich can be

used by a tire manufacturer to identify tires,

for example for a product recall, and thus

identify the purchasers. The TIN is composed

of the manufacturer identification code, tire

size, tire model code and manufacturing date.

Load bearing index

The load bearing index (also load index) is a

code that contains the maximum load bearing

capacity of a tire. 294

What you should know about wheels and tiresWheels and tires

Page 305 of 334

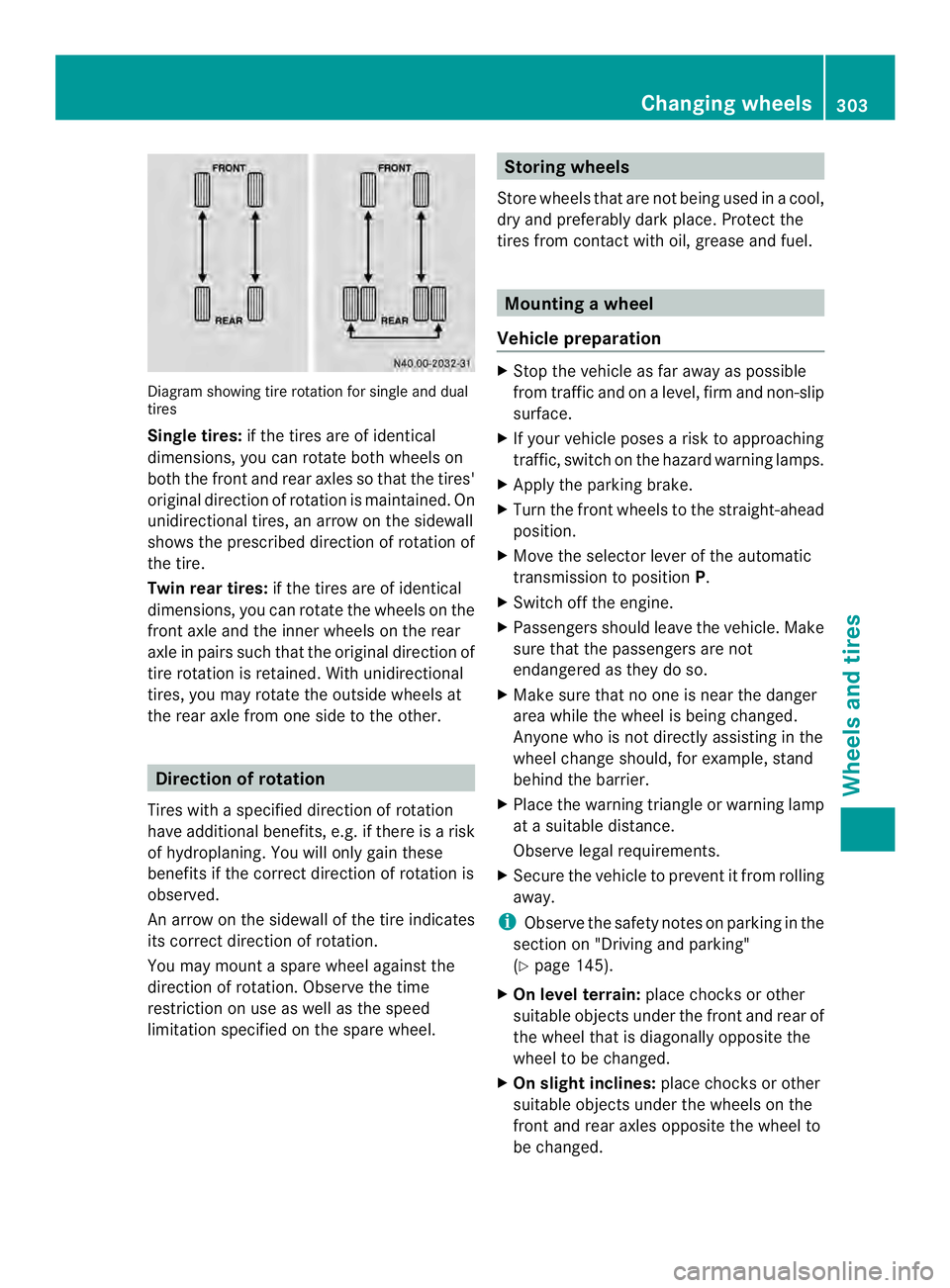

Diagra

mshowing tire rotation for single and dual

tires

Single tires: if the tires are of identical

dimensions, you can rotate both wheels on

both the front and rear axles so that the tires'

original direction of rotation is maintained. On

unidirectional tires, an arrow on the sidewall

shows the prescribed direction of rotation of

the tire.

Twin rear tires: if the tires are of identical

dimensions, you can rotate the wheels on the

front axle and the inner wheels on the rear

axle in pairs such that the original direction of

tire rotation is retained. With unidirectional

tires, you may rotate the outside wheels at

the rear axle from one side to the other. Direction of rotation

Tires with a specified direction of rotation

have additional benefits, e.g. if there is a risk

of hydroplaning. You will only gain these

benefits if the correct direction of rotation is

observed.

An arrow on the sidewall of the tire indicates

its correct direction of rotation.

You may mount a spare wheel against the

direction of rotation. Observe the time

restriction on use as well as the speed

limitation specified on the spare wheel. Storing wheels

Store wheels that are not being used in a cool,

dry and preferably dark place. Protect the

tires from contact with oil, grease and fuel. Mounting

awheel

Vehicle preparation X

Stop the vehicle as far away as possible

from traffic and on a level, firm and non-slip

surface.

X If you rvehicle poses a risk to approaching

traffic, switch on the hazard warning lamps.

X Apply the parking brake.

X Turn the fron twheels to the straight-ahead

position.

X Move the selector lever of the automatic

transmission to position P.

X Switch off the engine.

X Passengers should leave the vehicle. Make

sure that the passengers are not

endangered as they do so.

X Make sure that no one is near the danger

area while the wheel is being changed.

Anyone who is not directly assisting in the

wheel change should, for example, stand

behind the barrier.

X Place the warning triangle or warning lamp

at a suitable distance.

Observe legal requirements.

X Secure the vehicle to prevent it from rolling

away.

i Observe the safety notes on parking in the

section on "Driving and parking"

(Y page 145).

X On level terrain: place chocks or other

suitable objects under the front and rear of

the wheel that is diagonally opposite the

wheel to be changed.

X On slight inclines: place chocks or other

suitable objects under the wheels on the

front and rear axles opposite the wheel to

be changed. Changing wheels

303Wheels and tires Z

Page 306 of 334

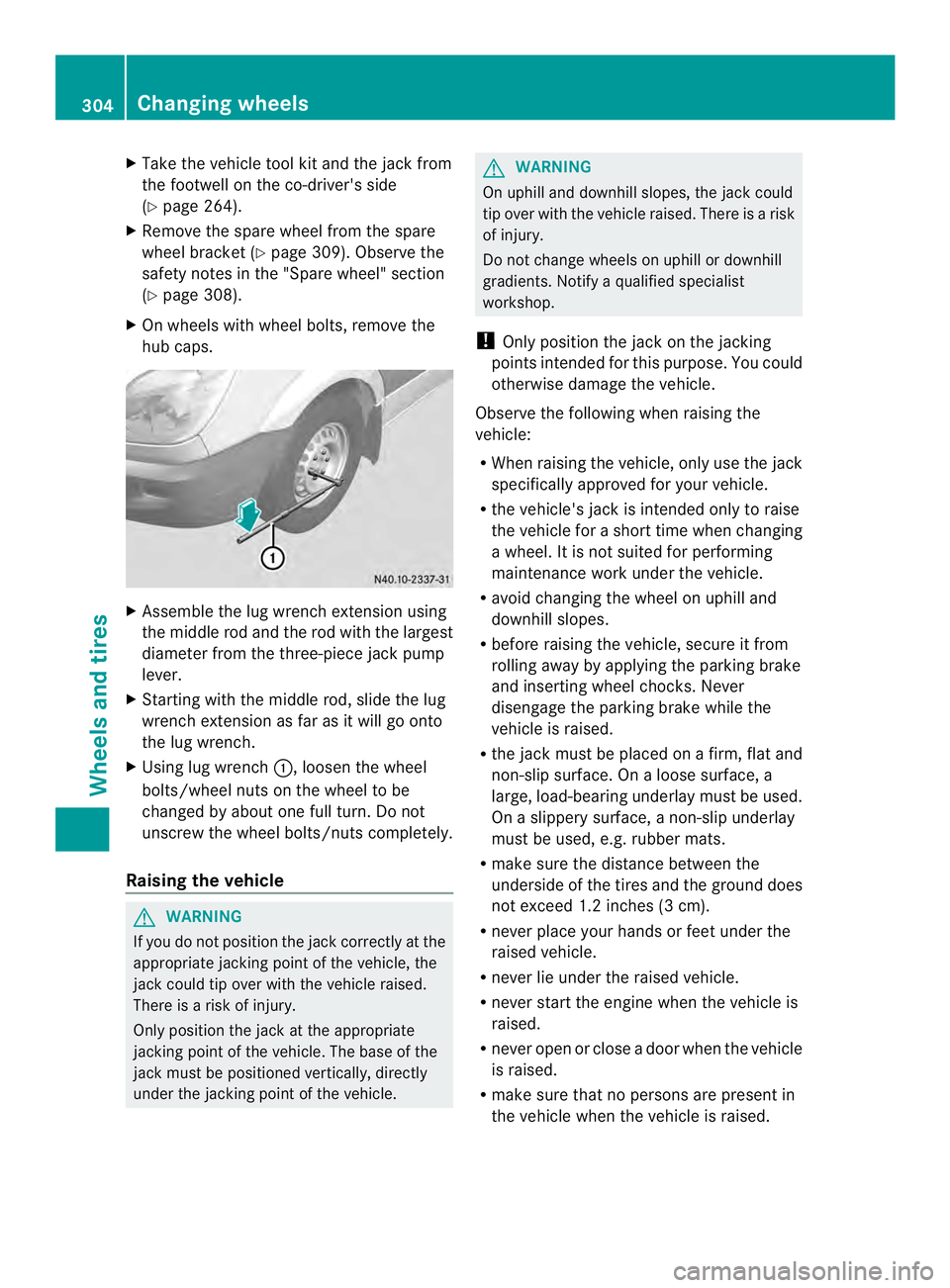

X

Take the vehicle tool kit and the jack from

the footwell on the co-driver's side

(Y page 264).

X Remove the spare wheel from the spare

wheel bracket (Y page 309). Observe the

safety notes in the "Spare wheel" section

(Y page 308).

X On wheels with wheel bolts, remove the

hub caps. X

Assemble the lug wrench extension using

the middle rod and the rod with the largest

diameter from the three-piece jack pump

lever.

X Starting with the middle rod, slide the lug

wrench extension as far as it will go onto

the lug wrench.

X Using lug wrench 0005, loosen the wheel

bolts/wheel nuts on the wheel to be

changed by about one full turn. Do not

unscrew the wheel bolts/nuts completely.

Raising the vehicle G

WARNING

If you do not position the jack correctly at the

appropriate jacking point of the vehicle, the

jack could tip over with the vehicle raised.

There is a risk of injury.

Only position the jack at the appropriate

jacking point of the vehicle. The base of the

jack must be positioned vertically, directly

under the jacking point of the vehicle. G

WARNING

On uphill and downhill slopes, the jack could

tip over with the vehicle raised. There is a risk

of injury.

Do not change wheels on uphill or downhill

gradients. Notify a qualified specialist

workshop.

! Only position the jack on the jacking

points intended for this purpose. You could

otherwise damage the vehicle.

Observe the following when raising the

vehicle:

R When raising the vehicle, only use the jack

specifically approved for your vehicle.

R the vehicle's jack is intended only to raise

the vehicle for a short time when changing

a wheel. It is not suited for performing

maintenance work under the vehicle.

R avoid changing the wheel on uphill and

downhill slopes.

R before raising the vehicle, secure it from

rolling away by applying the parking brake

and inserting wheel chocks. Never

disengage the parking brake while the

vehicle is raised.

R the jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a

large, load-bearing underlay must be used.

On a slippery surface, a non-slip underlay

must be used, e.g. rubber mats.

R make sure the distance between the

underside of the tires and the ground does

not exceed 1.2 inches (3 cm).

R never place your hands or feet under the

raised vehicle.

R never lie under the raised vehicle.

R never start the engine when the vehicle is

raised.

R never open or close a door when the vehicle

is raised.

R make sure that no persons are present in

the vehicle when the vehicle is raised. 304

Changing wheelsWheels and tires

Page 307 of 334

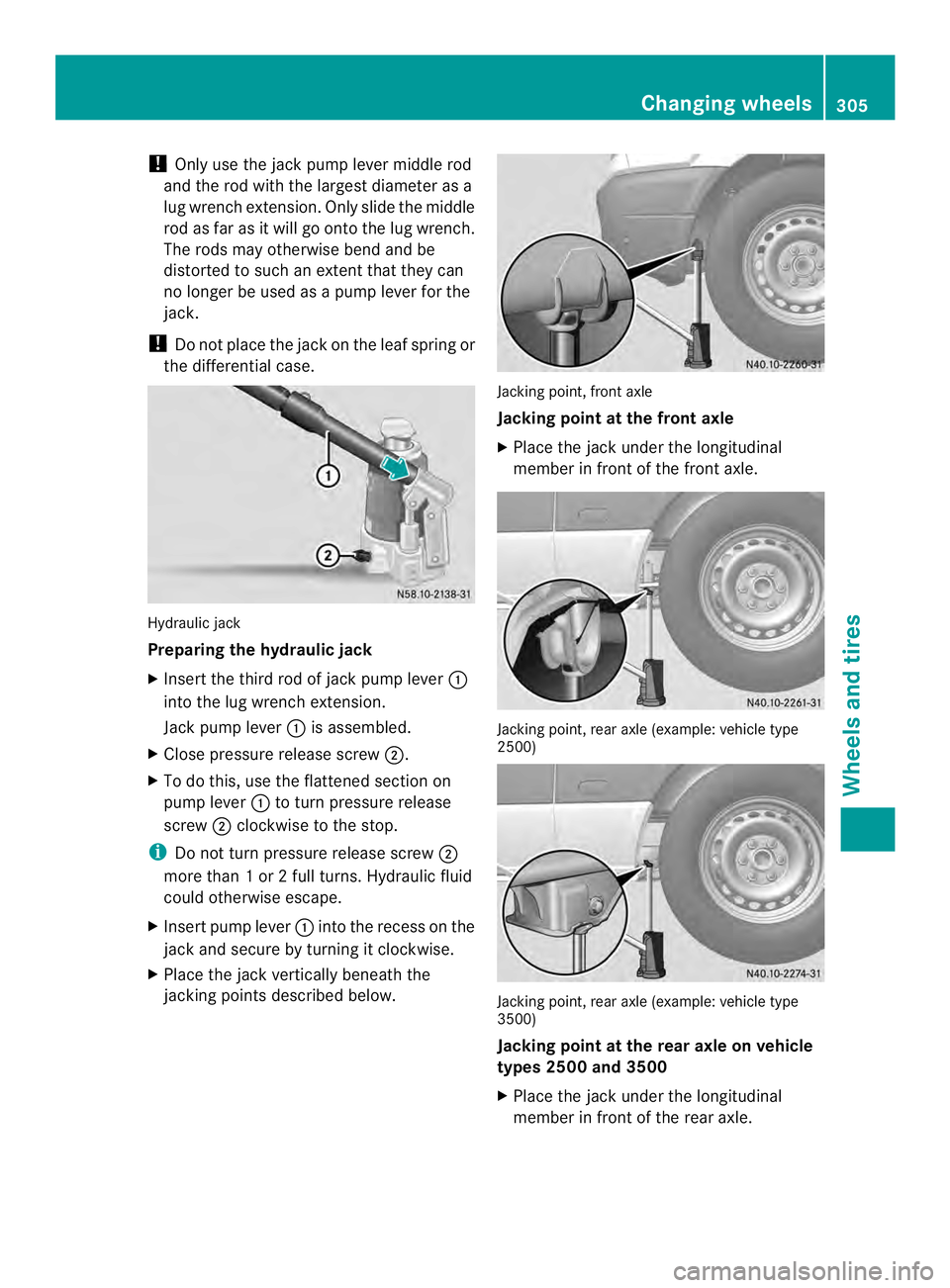

!

Only use the jack pump lever middle rod

and the rod with the largest diameter as a

lug wrench extension. Only slide the middle

rod as far as it will go onto the lug wrench.

The rods may otherwise bend and be

distorted to such an extent that they can

no longer be used as a pump lever for the

jack.

! Do not place the jack on the leaf spring or

the differential case. Hydraulic jack

Preparing the hydraulic jack

X

Insert the third rod of jack pump lever 0005

into the lug wrench extension.

Jack pump lever 0005is assembled.

X Close pressure release screw 0006.

X To do this, use the flattened section on

pump lever 0005to turn pressure release

screw 0006clockwise to the stop.

i Do not turn pressure release screw 0006

more than 1 or 2 full turns. Hydraulic fluid

could otherwise escape.

X Insert pump lever 0005into the recess on the

jack and secure by turning it clockwise.

X Place the jack vertically beneath the

jacking points described below. Jacking point, front axle

Jacking point at the front axle

X

Place the jack under the longitudinal

member in front of the front axle. Jacking point, rear axle (example: vehicle type

2500)

Jacking point, rear axle (example: vehicle type

3500)

Jacking point at the rear axle on vehicle

types 2500 and 3500

X

Place the jack under the longitudinal

member in front of the rear axle. Changing wheels

305Wheels and tires Z

Page 310 of 334

X

Wheel with hub cap: position the opening

for the tire valve in the hub cap over the tire

valve.

X Push the edge of the hub cap with both

hands against the wheel until it clicks into

place. Make sure the hub cap retaining

catches engage on the steel wheel.

X Wheel with central hub cap: position the

retaining lugs of the central hub cap over

the wheel bolts.

X Hit the middle of the hub cap to engage it

on the wheel.

X Secure the faulty wheel in the spare wheel

bracket (Y page 309).

X Check the tire pressure of the newly

mounted wheel and adjust it if necessary.

Observe the recommended tire pressure

(Y page 278).

X Retighten the wheel bolts or wheel nuts to

the specified tightening torque after the

vehicle has been driven for 30 miles

(50 km).

When using a wheel/spare wheel with a new

or newly painted wheel rim, have the wheel

bolts/nuts retightened again after

approximately 600 to 3,000 miles (1,000 to

5,000 km). Observe the specified tightening

torque.

i Vehicles with the tire pressure monitor

system: all mounted wheels must be

equipped with functioning sensors. Wheel and tire combination

General notes

! Retreaded tires are neither tested nor

recommended for Sprinter vehicles, since

previous damage cannot always be

detected on retreaded tires. We can

therefore not guarantee driving safety. Do

not mount used tires if you have no

information about their previous usage. The recommended tire pressures can be

found:

R

on the Tire and Loading Information

placard 11

on the B-pillar on the driver's side

R on the tire pressure table on the B-pillar on

the driver's side

The recommended tire pressure can also be

found in the "Tire pressure table" section in

these Operating Instructions (Y page 285).

The wheel/tire combination for your vehicle

can be found on the tire pressure table.

Further information on wheel/tire

combination can be obtained at any qualified

specialist workshop.

Check tire pressures regularly and only when

the tires are cold. Observe the notes on the

recommended tire pressures (Y page 278).

Follow the maintenance recommendations in

the tire manufacturer's warranty book in your

vehicle documents.

Notes on the vehicle equipment –always

install the vehicle:

R with tires of the same size across an axle

(left/right)

R with the same type of tires on all wheels at

a given time (summer tires, winter tires) Spare wheel

Important safety notes

G

WARNING

Wheel and tire dimensions as well as the type

of tire can vary between the spare wheel and

the wheel to be replaced. When the spare

wheel is installed, driving characteristics may

be severely affected. There is a risk of an

accident.

In order to reduce risks:

R you should therefore adapt your driving

style and drive carefully.

R never install more than one spare wheel

that differs fro mthe wheel to be replaced.

11 Only for vehicles with a gross weight of less than 10,000 lbs(4,536 kg). 308

Spare wheelWheels and tires

Page 311 of 334

R

only use a spare wheel that differs from the

wheel to be replaced for a short time.

R do not deactivate ESP ®

.

R have a spare wheel that differs from the

wheel that has been changed replaced at

the nearest qualified specialist workshop.

You must observe the correc twheel and

tire dimensions as well as the wheel type.

When using a spare wheel of a different size,

do not exceed the maximum speed of

80 km/h. General notes

! Check the spare wheel regularly to see

that it is secure and has the prescribed tire

pressure.

The procedure for mounting the spare wheel

is described in "Mounting awheel"

(Y page 303).

The following should be checked regularly,

particularly prior to long journeys:

R the tire pressure of the spare wheel, which

should then be corrected if necessary

(Y page 278).

R the fastenings of the spare wheel bracket.

The spare wheel is located in a spare wheel

bracket under the rear of the vehicle.

Replace the tires after 6years at the latest,

regardless of wear. This also applies to the

spare wheel.

i If you have mounted a spare wheel, the

tire pressure monitor (Y page 281) will not

function for this wheel. The spare wheel is

not equipped with a sensor for monitoring

tire pressure. Removing and installing the spare

wheel

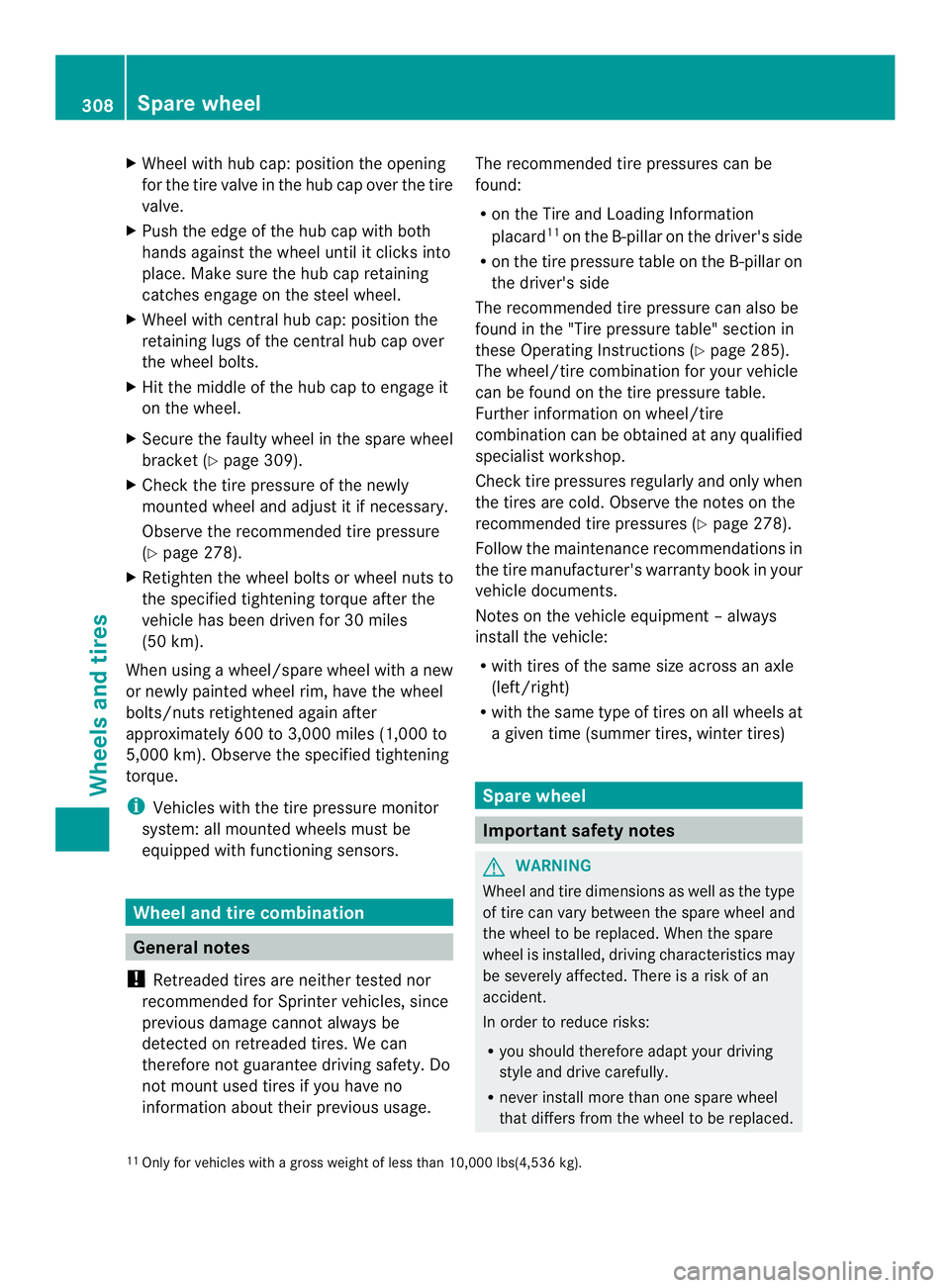

Cargo Van/Crew Van Bolt covers for the safety catches (example: Cargo

Van)

Removing

X

Open the rear doors.

X Position a screwdriver in recesses 0006and

pry off covers 0005.

X Using the lug wrench from the vehicle tool

kit (Y page 264), unscrew the now visible

bolts counter-clockwise by approximately

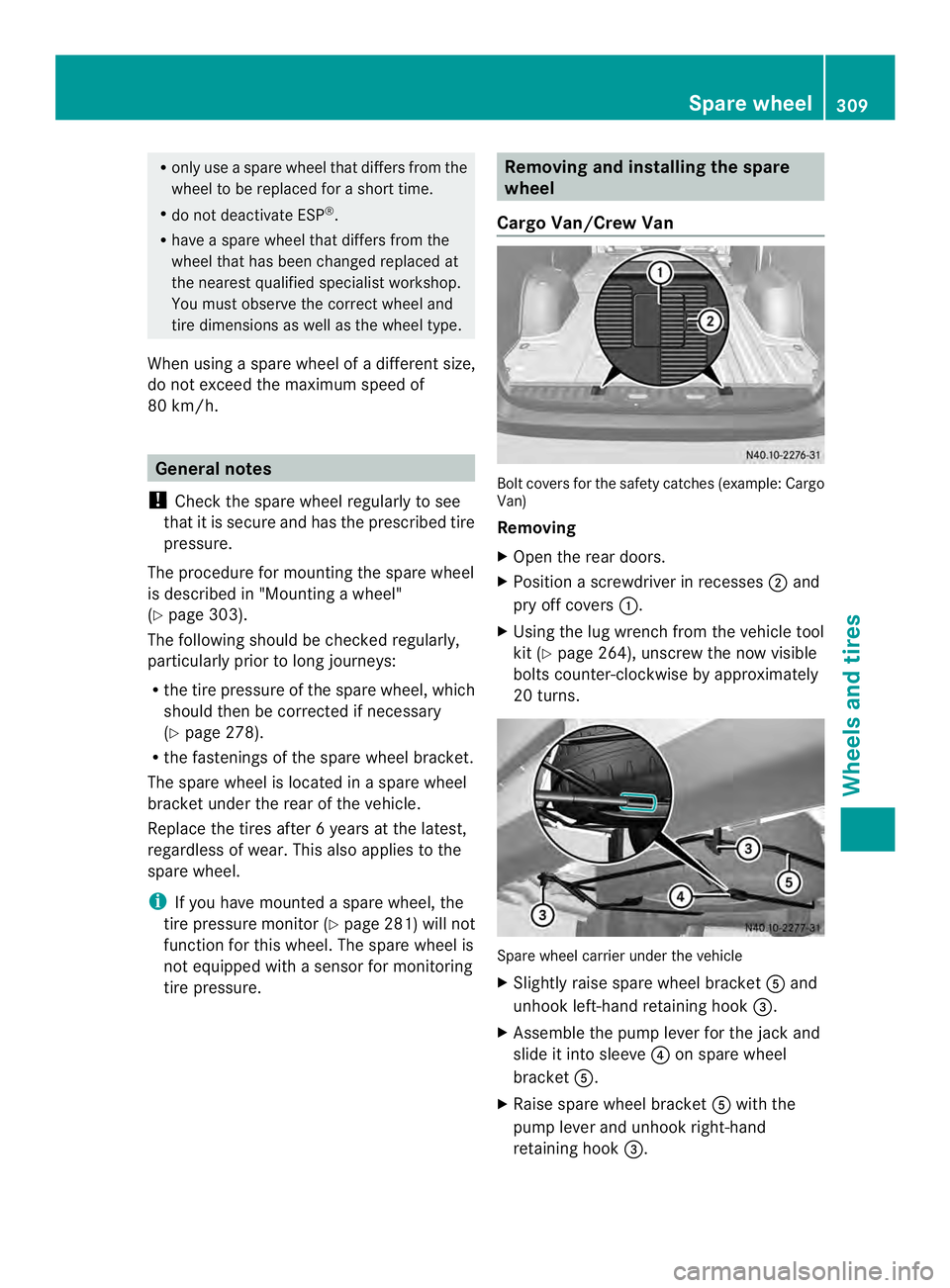

20 turns. Spare wheel carrier under the vehicle

X

Slightly raise spare wheel bracket 0023and

unhook left-hand retaining hook 0026.

X Assemble the pump lever for the jack and

slide it into sleeve 0025on spare wheel

bracket 0023.

X Raise spare wheel bracket 0023with the

pump lever and unhook right-hand

retaining hook 0026. Spare wheel

309Wheels and tires Z