ECU MERCEDES-BENZ SPRINTER 2013 MY13 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2013, Model line: SPRINTER, Model: MERCEDES-BENZ SPRINTER 2013Pages: 334, PDF Size: 3.88 MB

Page 237 of 334

!

Observe the information on the maximum

loading capacity of the individual cargo tie-

down points.

If you use several cargo tie-down points to

secure a load, you must always take the

maximum loading capacity of the weakest

cargo tie-down point into account.

If you brake hard, for example, the forces

acting could be up to several times the

weight force of the load. Always use

multiple cargo tie-down points in order to

distribute the force absorption. Load the

anchorages evenly.

Spread the load evenly between the cargo tie-

down points or tie-down rings.

Please also refer to the notes aboutq ualified

specialist workshops (Y page 26).

Always observe the operating instructions or

the notes of the lashing strap manufacturer

for the operation of th elashing strap.

Information about the maximum loading

capacity of the cargo tie-down points can be

found in the "Technical data" section

(Y page 327).

As the driver, you are responsible for ensuring

that:

R The applicable requirements and

guidelines relating to load-securing

practices must be met.

If this is no tthe case, this may constitute a

punishable offense, depending on local

legislation and any ensuing consequences.

You should therefore observe the

respective legal requirements for the

relevant country.

Make sure that the load is secure before every

journey and at regular intervals during a long

journey. Correct an incorrectly or

inadequately secured load if necessary.

You can obtain information about securing

the load correctly from the manufacturer of

the load securing aids or tie down for securing

the load.

X Fill spaces between the load and the cargo

compartmentw alls or wheel housings (form-locking). Use rigid load securing aids,

such as wedges, woode

nfixings or

padding.

X Attach secured and stabilized loads in all

directions. Use the carg otie-down points

or cargo tie-down rings and the loading rails

in the cargo compartmen toronthe loading

area.

Only use tie downs, such as lashing rods or

lashing nets and lashing straps, that have

been tested in accordance with current

standards (e.g. DIN EN).

Always use the cargo tie-down rings closest

to the load to secure it and pad sharp edges

for protection.

Loads, and heavy loads in particular, should

preferably be secured using the cargo tie-

down rings.

i Tie downs tested in accordance with

current standards (e.g. DIN EN) are

available at any qualified specialist

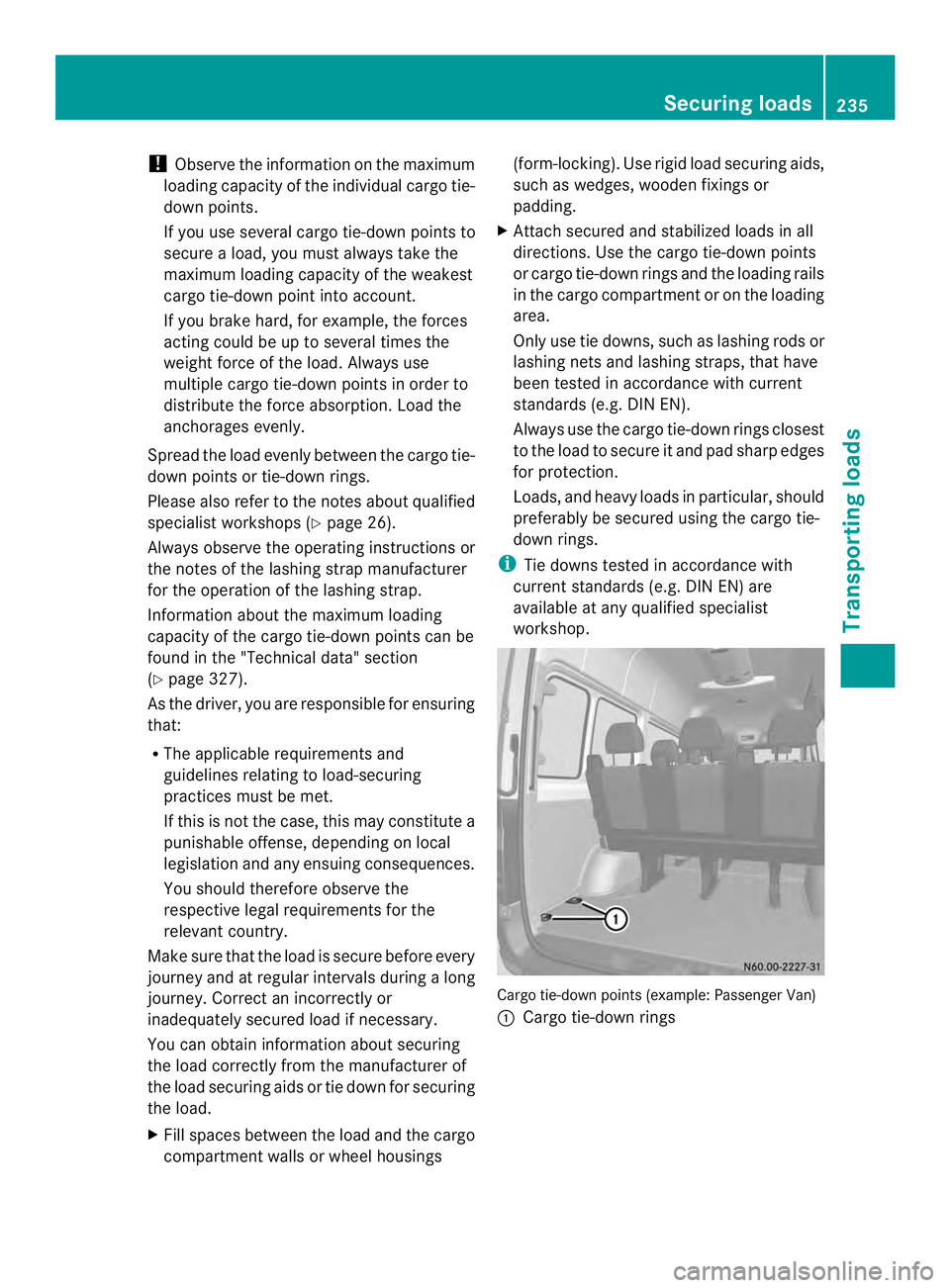

workshop. Cargo tie-down points (example: Passenger Van)

0005

Cargo tie-down rings Securing loads

235Transporting loads Z

Page 238 of 334

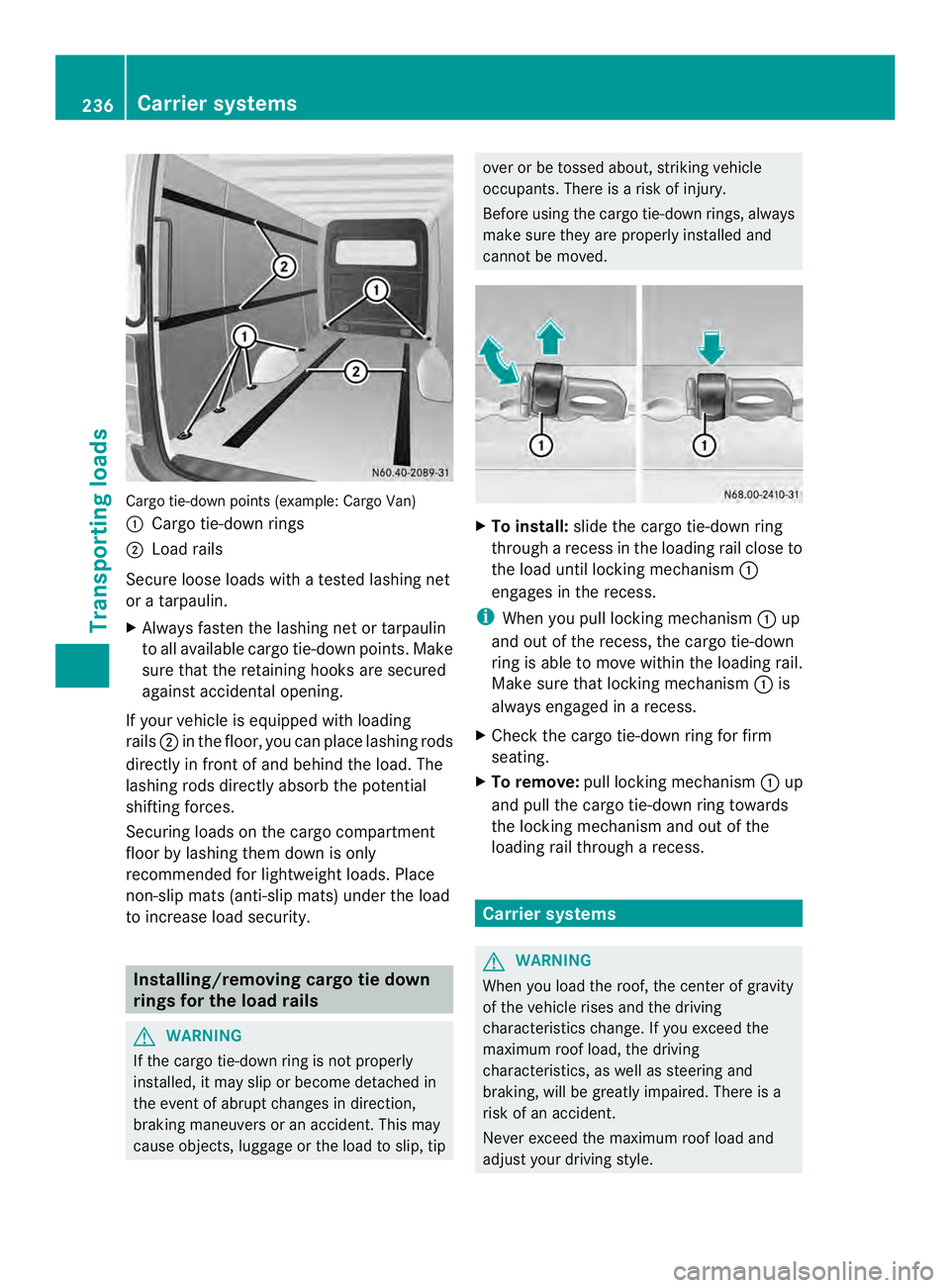

Cargo tie-down points (example

:Cargo Van)

0005 Cargo tie-down rings

0006 Load rails

Secure loose loads with a tested lashing net

or a tarpaulin.

X Always fasten the lashing net or tarpaulin

to all available cargo tie-down points .Make

sure that the retaining hooks are secured

against accidental opening.

If your vehicle is equipped with loading

rails 0006in the floor, you can place lashing rods

directly in fron tofand behind the load .The

lashing rods directly absorb the potential

shifting forces.

Securing loads on the cargo compartment

floor by lashing them down is only

recommended for lightweight loads. Place

non-slip mats (anti-slip mats) under the load

to increase load security. Installing/removing cargo tie down

rings for the load rails

G

WARNING

If the cargo tie-down ring is not properly

installed, it may slip or become detached in

the event of abrupt changes in direction,

braking maneuvers or an accident. This may

cause objects, luggage or the load to slip, tip over or be tossed about, striking vehicle

occupants. There is a risk of injury.

Before using the cargo tie-down rings, always

make sure they are properly installed and

cannot be moved.

X

To install: slide the cargo tie-down ring

through a recess in the loading rail close to

the load until locking mechanism 0005

engages in the recess.

i When you pull locking mechanism 0005up

and out of the recess, the cargo tie-down

ring is able to move within the loading rail.

Make sure that locking mechanism 0005is

always engaged in a recess.

X Check the cargo tie-down ring for firm

seating.

X To remove: pull locking mechanism 0005up

and pull the cargo tie-down ring towards

the locking mechanism and out of the

loading rail through a recess. Carrier systems

G

WARNING

When you load the roof, the center of gravity

of the vehicle rises and the driving

characteristics change. If you exceed the

maximum roof load, the driving

characteristics, as well as steering and

braking, will be greatly impaired. There is a

risk of an accident.

Never exceed the maximum roof load and

adjust your driving style. 236

Carrier systemsTransporting loads

Page 239 of 334

You can find information about the maximum

roof load in the "Technical data" section

(Y page 327).

! Make sure that:

R the screws for the roof carrier are

tightened in the sliding blocks to a torque

of 6.0 – 7.4 lb-f t(8 – 10 Nm)

R the bolts, whe ntightened, do not touch

the rails.

R the slot nuts are not located in the area

of the plastic caps.

R the slot nuts have the right cross-section.

R the mounting rails in the interior are free

of dirt.

R the screws are retightened evenly after

approximately 300 miles (500 km).

We recommend that you only use roof

racks tested and approved by Sprinter.

These help avoid vehicle damage.

! If you want to retrofit securing rails, have

it done at a qualified specialist workshop.

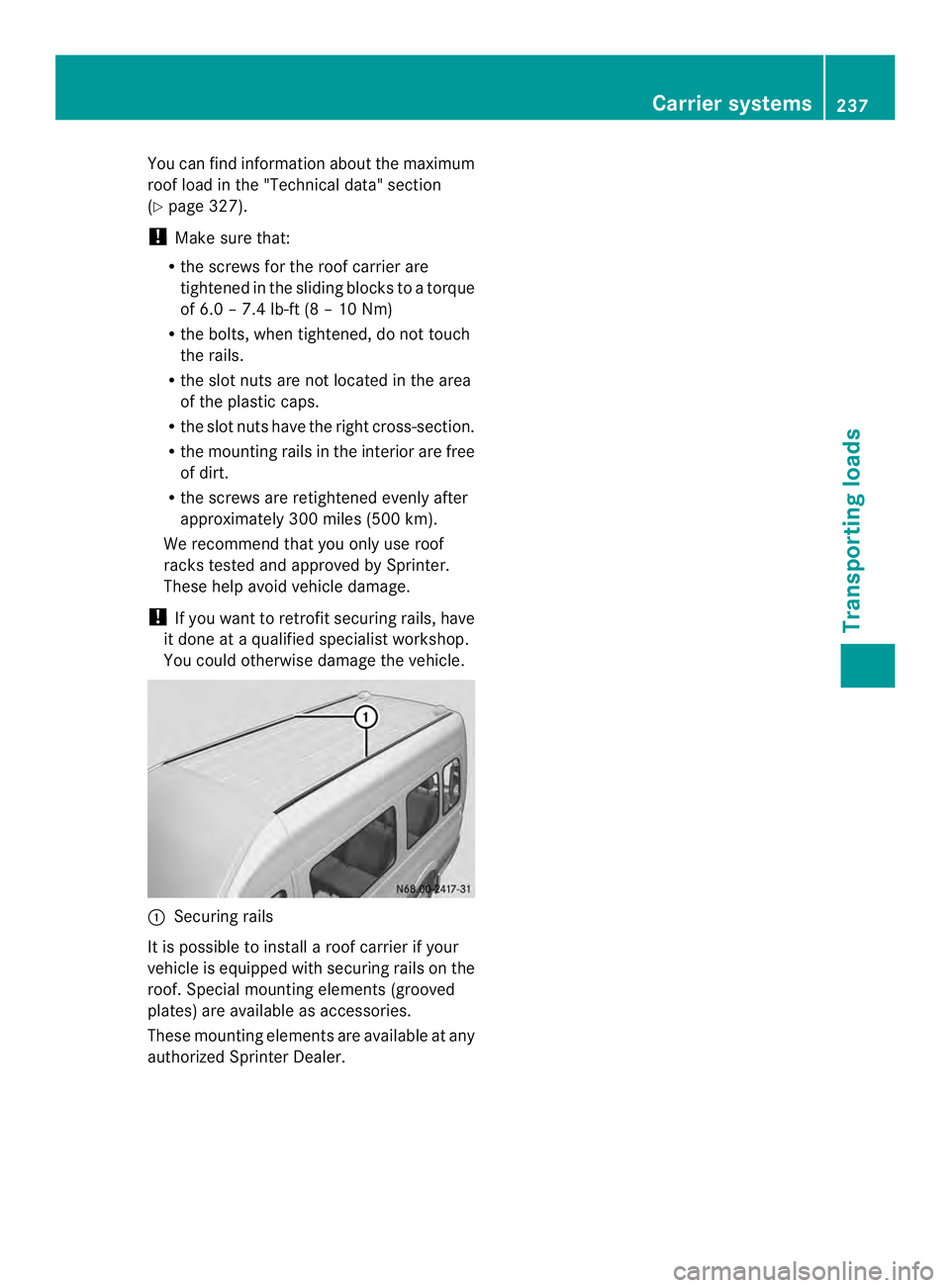

You could otherwise damage the vehicle. 0005

Securing rails

It is possible to install aroof carrier if your

vehicle is equipped with securing rails on the

roof. Special mounting elements (grooved

plates) are available as accessories.

These mounting elements are available at any

authorized Sprinter Dealer. Carrier systems

237Transporting loads Z

Page 243 of 334

X

Secure the vehicle to prevent it from rolling

away.

X Pull release handle 0005on the hood.

The hood is released. X

Reach into the gap and push grip 0006on the

hood catch upwards. X

Swing the hood upwards unti lsuppor tstrut

0026 engages and the hood is supported.

Closing the hood G

WARNING

If the hood is unlatched, it could tip forward

during rapid deceleratio nofthe vehicle and

hit persons or objects within its path. There is

a risk of an accident and injury.

Therefore, always make sure that the hood is

closed and locked completely before driving

off. If the hood is not locked and you are already

driving at walking pace:

R

the yellow 0004indicator lamp in the

instrumentc luster goes on for vehicles

without steering-wheel buttons.

R the 0004 Hood open display appears for

vehicles with steering-wheel buttons.

! When you press the support strut back,

make sure that you do not press it against

the detent position and cause it to bend.

! Do not use your hands to push the hood

down. You could damage it otherwise.

X Lift the hood slightly.

X Press support strut 0026towards the back.

X Lower the hood and allow it to fall with

momentum fro maheight of approximately

1 ft (30 cm).

The hood locks audibly.

X Check that the hood is correctly locked.

If the hood can be raised slightly, it is not

properly engaged.

i If the hood is not correctly engaged, open

the hood again. Let the hood fall with a little

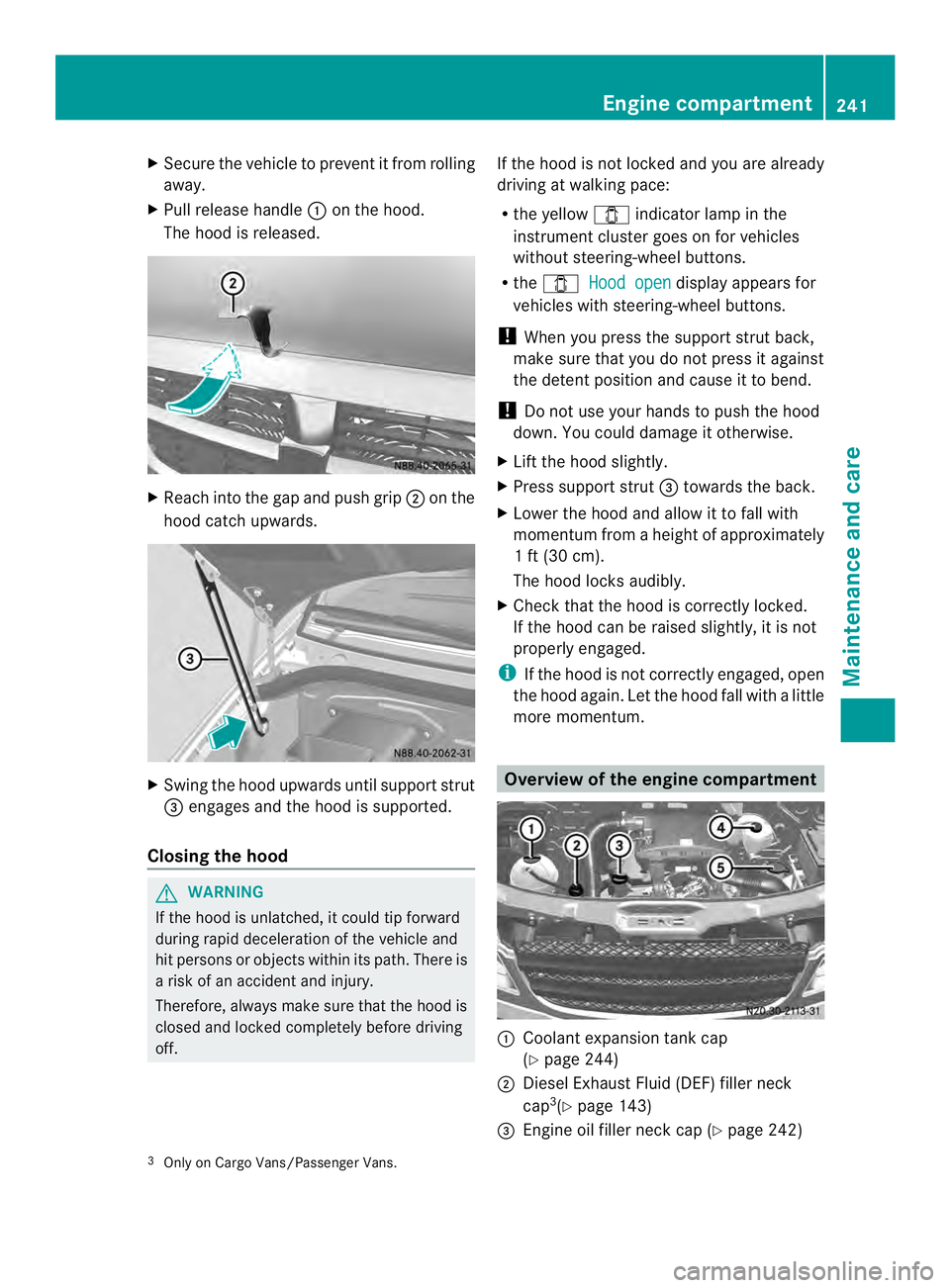

more momentum. Overview of the engine compartment

0005

Coolant expansion tank cap

(Ypage 244)

0006 Diesel Exhaust Fluid (DEF) filler neck

cap 3

(Y page 143)

0026 Engine oil filler neck cap (Y page 242)

3 Only on Cargo Vans/Passenger Vans. Engine compartment

241Maintenance and care Z

Page 245 of 334

Engine

oil Add

1.0quart X

Add the amount of oil

shown (Y page 244).

X Check the engine oil level

againa fter a few minutes. Engine

oil Add

1.5quart

Engine

oil Add

2.0quart

Engine

oil level

Reduce

oil level The oil level is too high.

X

Have excess oil removed. Eng. oil

lev. Turn

ignition

on for

level X

Turn the key to

position 2in the ignition

lock. Observe

wait.

period X

Repeat the engine oil

measurement after about

5 minutes if the engine is

at normal operating

temperature.

X Repeat the engine oil

measurement after about

30 minutes if the engine

is not at normal operating

temperature. Engine

oil level

Not when

eng.

running X

Switch off the engine and

wait for approximately

5 minutes if the engine is

at normal operating

temperature. Then,

perform the engine oil

measurement. Measurement units in the display:

R

qts USA only

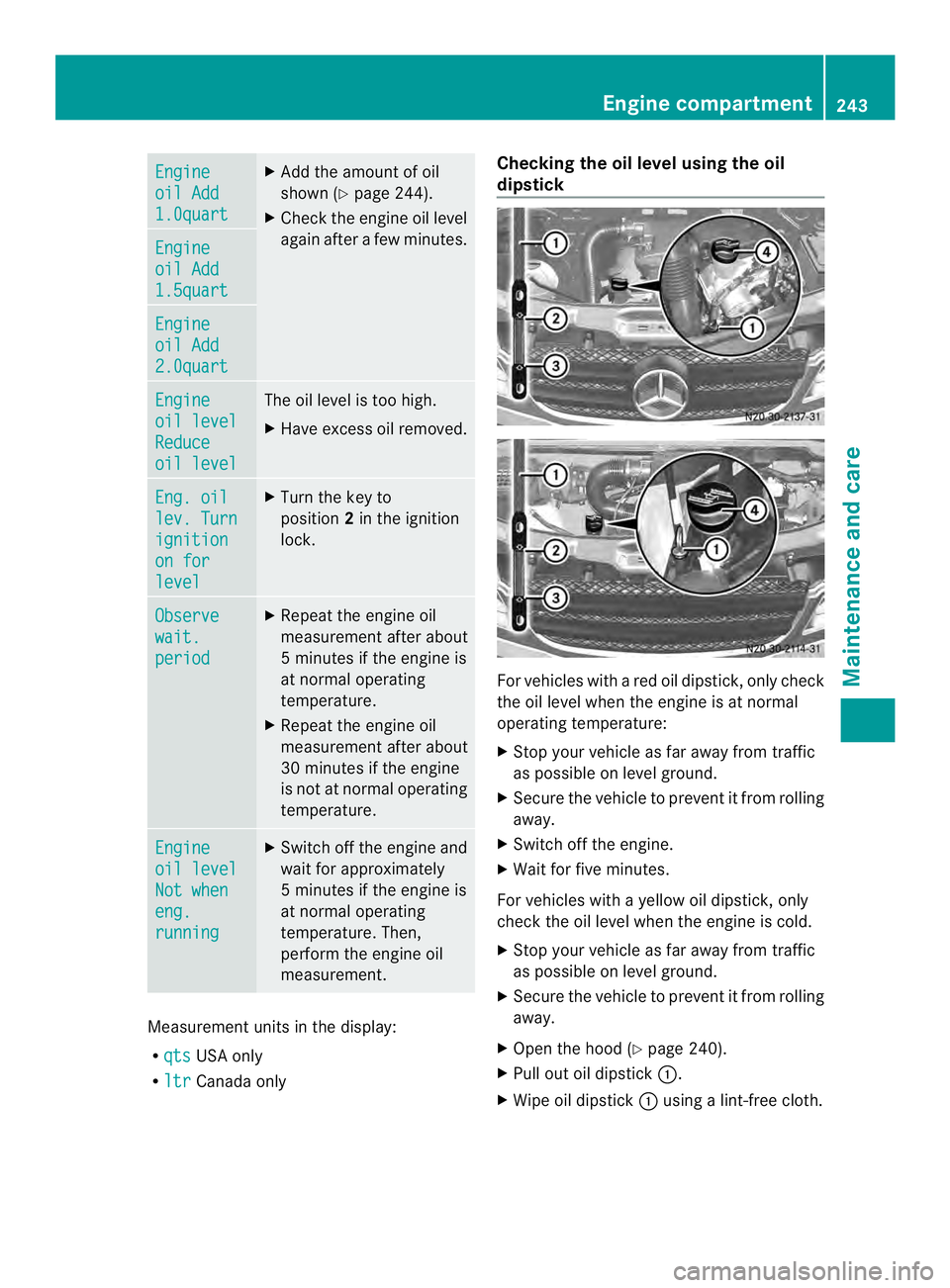

R ltr Canada only Checking the oil level using the oil

dipstick

For vehicles with a red oil dipstick, only check

the oil level whe

nthe engine is at normal

operating temperature:

X Stop your vehicle as far away from traffic

as possible on level ground.

X Secure the vehicle to prevent it from rolling

away.

X Switch off the engine.

X Wait for five minutes.

For vehicles with a yellow oil dipstick, only

check the oil level when the engine is cold.

X Stop your vehicle as far away from traffic

as possible on level ground.

X Secure the vehicle to prevent it from rolling

away.

X Open the hood (Y page 240).

X Pull out oil dipstick 0005.

X Wipe oil dipstick 0005using a lint-free cloth. Engine compartment

243Maintenance and care Z

Page 247 of 334

G

WARNING

Coolant contains glycol and is therefore toxic.

Do not swallow the coolant. See a doctor

immediately if you swallow coolant.

Make sure that coolant does not come into

contact with skin, eyesorc lothing. In case of

contac twith eyes, rinse immediately with

plenty of clean water .Clean affected areas of

skin and clothing with soap and water

immediately. Change any affected clothing

immediately. G

WARNING

If antifreeze comes into contact with hot

components in the engine compartment, it

may ignite. There is a risk of fire and injury.

Let the engine cool down before you add

antifreeze. Make sure that antifreeze is not

spilled nex tto the filler neck.T horoughly

clean the antifreeze from components before

starting the engine.

! Take care not to spill any coolant on

painted surfaces. You could otherwise

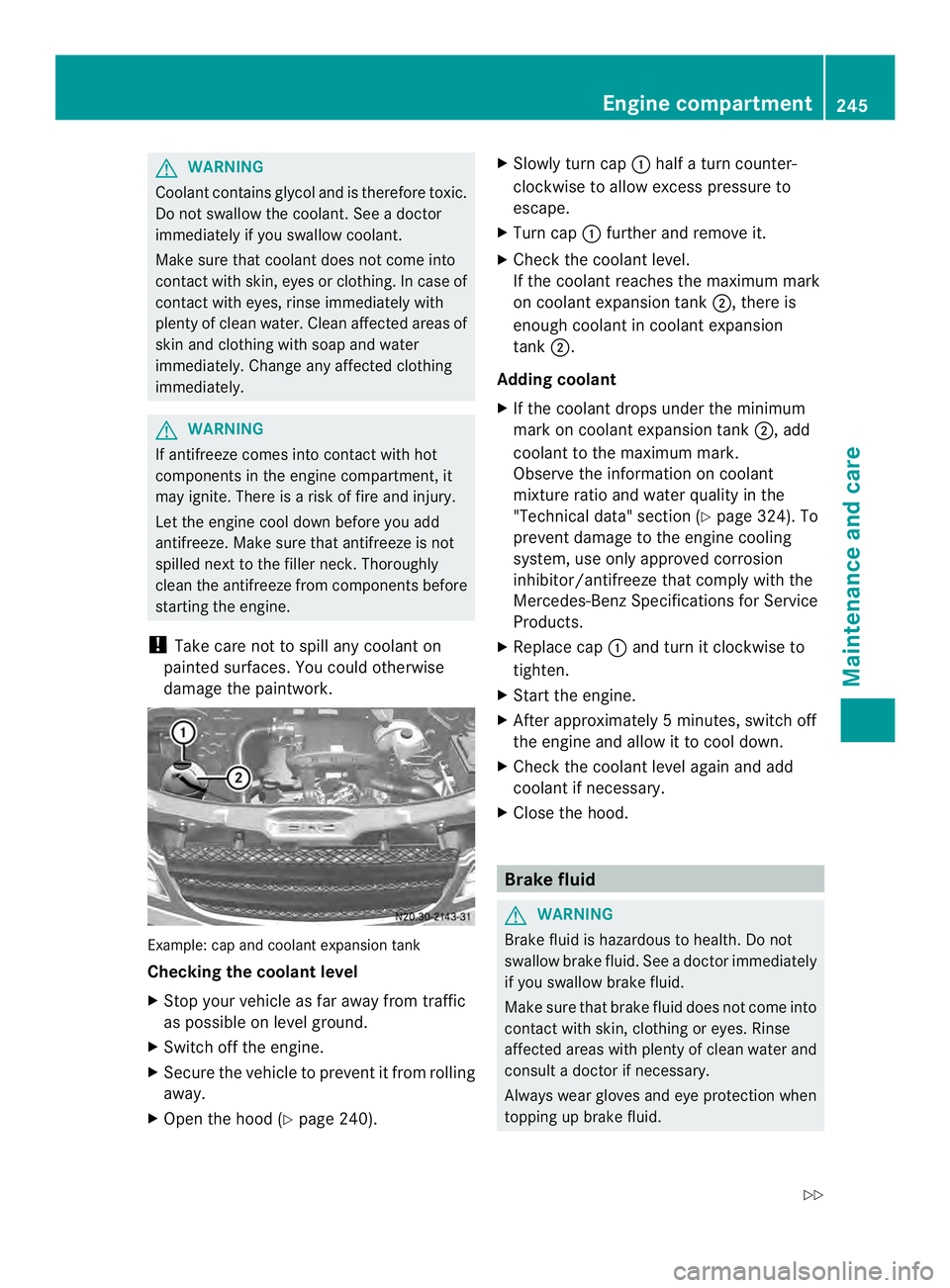

damage the paintwork. Example: cap and coolant expansion tank

Checking the coolant level

X

Stop your vehicle as far away from traffic

as possible on level ground.

X Switch off the engine.

X Secure the vehicle to prevent it from rolling

away.

X Open the hood (Y page 240). X

Slowly turn cap 0005half a turn counter-

clockwise to allow excess pressure to

escape.

X Turn cap 0005further and remove it.

X Check the coolant level.

If the coolant reaches the maximum mark

on coolant expansion tank 0006, there is

enough coolant in coolant expansion

tank 0006.

Adding coolant

X If the coolant drops under the minimum

mark on coolant expansion tank 0006, add

coolant to the maximum mark.

Observe the information on coolant

mixture ratio and water quality in the

"Technical data" section (Y page 324). To

prevent damage to the engine cooling

system, use only approved corrosion

inhibitor/antifreeze that comply with the

Mercedes-Benz Specifications for Service

Products.

X Replace cap 0005and turn it clockwise to

tighten.

X Start the engine.

X After approximately 5minutes, switch off

the engine and allow it to cool down.

X Check the coolan tlevel again and add

coolant if necessary.

X Close the hood. Brake fluid

G

WARNING

Brake fluid is hazardous to health. Do not

swallow brake fluid. See adoctor immediately

if you swallow brake fluid.

Make sure that brake fluid does not come into

contact with skin, clothing or eyes. Rinse

affected areas with plenty of clean water and

consult a doctor if necessary.

Always wear gloves and eye protection when

topping up brake fluid. Engine compartment

245Maintenance and care

Z

Page 248 of 334

Store brake fluid only in the original closed

container and keep it out of the reach of

children. Comply with safety regulations

when handling brake fluid.

! Brake fluid corrodes paint, plastic and

rubber .Ifpaint, plastic or rubbe rhas come

into contact with brake fluid, rinse with

wate rimmediately. G

WARNING

The brake fluid constantly absorbs moisture

from the air. This lowers the boiling point of

the brake fluid. If the boiling point of the brake

fluid is too low, vapo rpockets may form in the

brake system when the brakes are applied

hard. This would impair braking efficiency.

There is a risk of an accident.

You should have the brake fluid renewed at

the specified intervals.

! If the brake fluid level in the brake fluid

reservoir has fallen to the MIN mark or

below, check the brake system

immediately for leaks. Also check the

thickness of the brake linings. Visit a

qualified specialist workshop immediately.

Do not add brake fluid. This does not

correct the malfunction.

Have the brake fluid renewed every two

years.

Observe the information on brake fluid in the

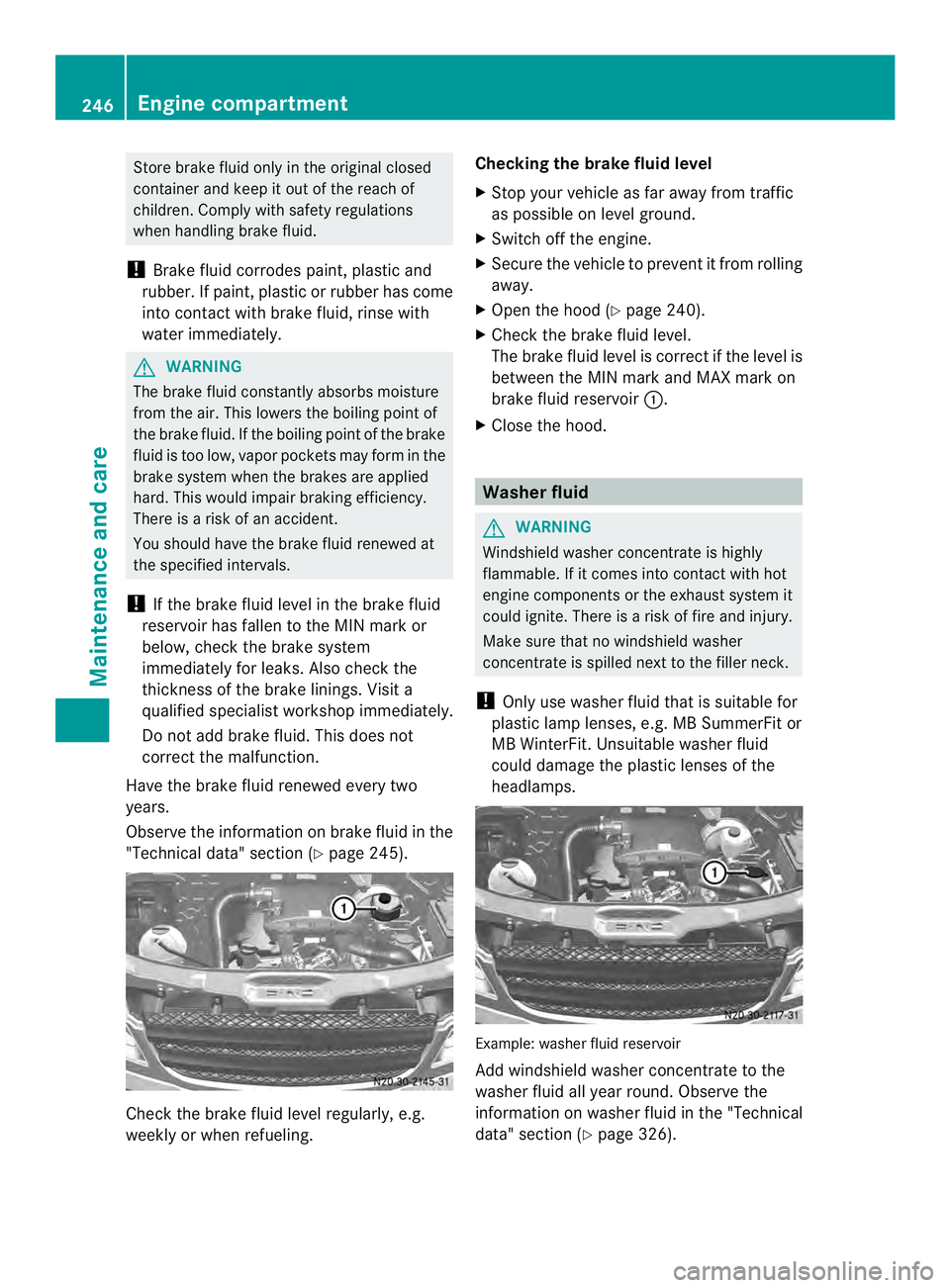

"Technical data" section ( Ypage 245). Check the brake fluid level regularly, e.g.

weekly or when refueling. Checking the brake fluid level

X

Stop your vehicle as far away from traffic

as possible on level ground.

X Switch off the engine.

X Secure the vehicle to prevent it from rolling

away.

X Open the hood (Y page 240).

X Check the brake fluid level.

The brake fluid level is correc tifthe level is

between the MIN mark and MAX mark on

brake fluid reservoir 0005.

X Close the hood. Washer fluid

G

WARNING

Windshield washer concentrate is highly

flammable. If it comes into contact with hot

engine components or the exhaust system it

could ignite. There is a risk of fire and injury.

Make sure that no windshield washer

concentrate is spilled next to the filler neck.

! Only use washer fluid that is suitable for

plastic lamp lenses, e.g. MB SummerFit or

MB WinterFit. Unsuitable washer fluid

could damage the plastic lenses of the

headlamps. Example: washer fluid reservoir

Add windshield washer concentrate to the

washer fluid all year round. Observe the

information on washer fluid in the "Technical

data" section (Y

page 326).246

Engine compartmentMaintenance and care

Page 249 of 334

Adding washer fluid

X

Mix the washe rfluid to the appropriate

mixing ratio in a container beforehand.

X Open the hood (Y page 240).

X Pull cap 0005on the washer fluid reservoir

upwards at the tab.

X Add the premixed washer fluid.

X Press cap 0005onto the filler neck until it

engages audibly.

X Close the hood. Fuel system

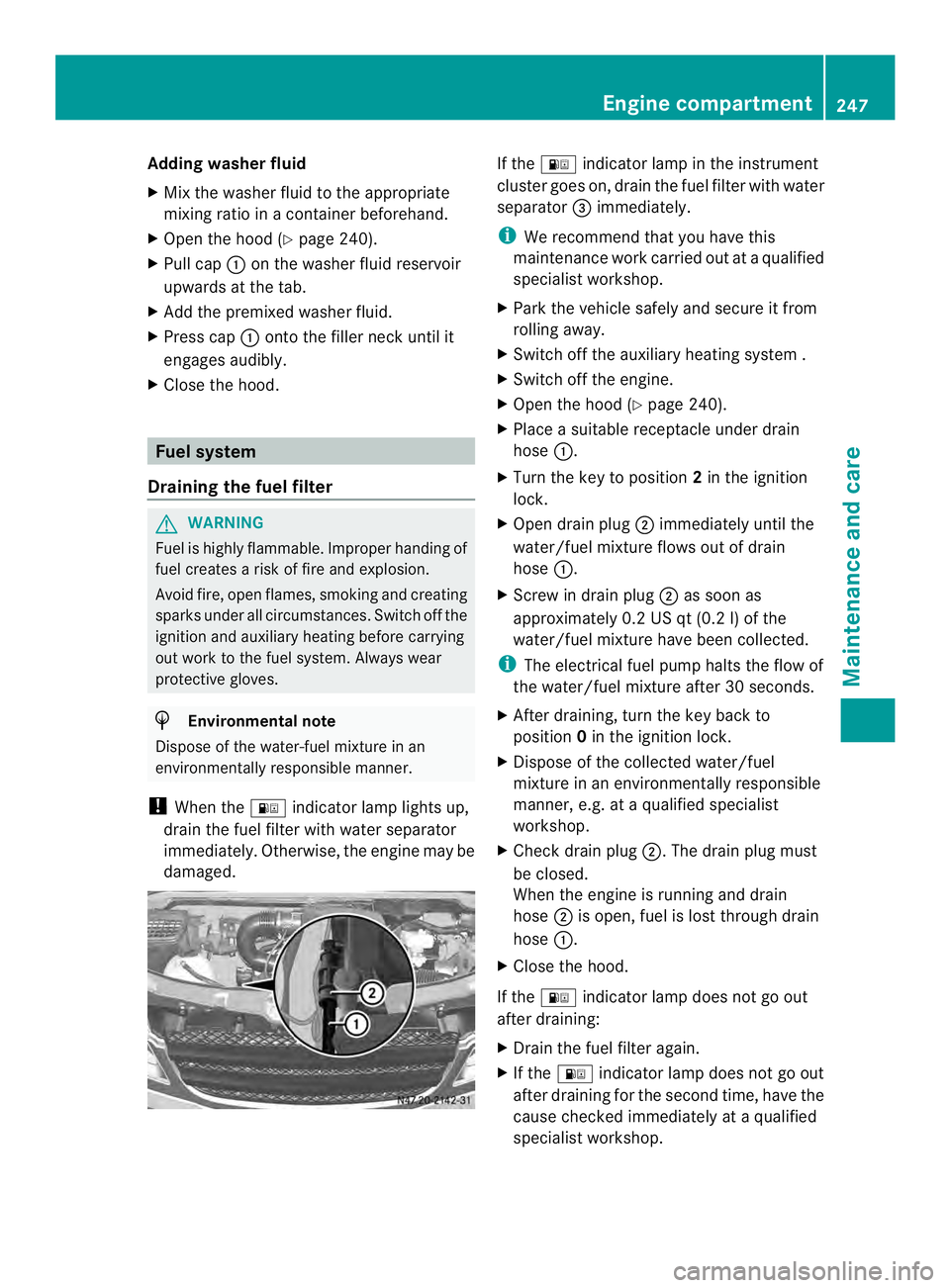

Draining the fuel filter G

WARNING

Fuel is highly flammable. Improper handing of

fuel creates a risk of fire and explosion.

Avoid fire, open flames ,smoking and creating

sparks under all circumstances. Switch off the

ignitio nand auxiliary heating before carrying

ou tw ork to the fuel system. Always wear

protective gloves. H

Environmental note

Dispose of the water-fuel mixture in an

environmentally responsible manner.

! When the 000Eindicator lamp lights up,

drain the fuel filter with water separator

immediately. Otherwise, the engine may be

damaged. If the

000E indicator lamp in the instrument

cluster goes on, drain the fuel filter with water

separator 0026immediately.

i We recommend that you have this

maintenance work carried out at a qualified

specialist workshop.

X Park the vehicle safely and secure it from

rolling away.

X Switch off the auxiliary heating system .

X Switch off the engine.

X Open the hood (Y page 240).

X Place a suitable receptacle under drain

hose 0005.

X Turn the key to position 2in the ignition

lock.

X Open drain plug 0006immediately until the

water/fuel mixture flows out of drain

hose 0005.

X Screw in drain plug 0006as soon as

approximately 0.2 US qt (0.2 l) of the

water/fuel mixture have been collected.

i The electrical fuel pump halts the flow of

the water/fuel mixture after 30 seconds.

X After draining, turn the key back to

position 0in the ignition lock.

X Dispose of the collected water/fuel

mixture in an environmentally responsible

manner, e.g. at a qualified specialist

workshop.

X Check drain plug 0006.The drain plug must

be closed.

When the engine is running and drain

hose 0006is open, fuel is lost through drain

hose 0005.

X Close the hood.

If the 000E indicator lamp does not go out

after draining:

X Drain the fuel filter again.

X If the 000E indicator lamp does not go out

after draining for the second time, have the

cause checked immediately at a qualified

specialist workshop. Engine compartment

247Maintenance and care Z

Page 250 of 334

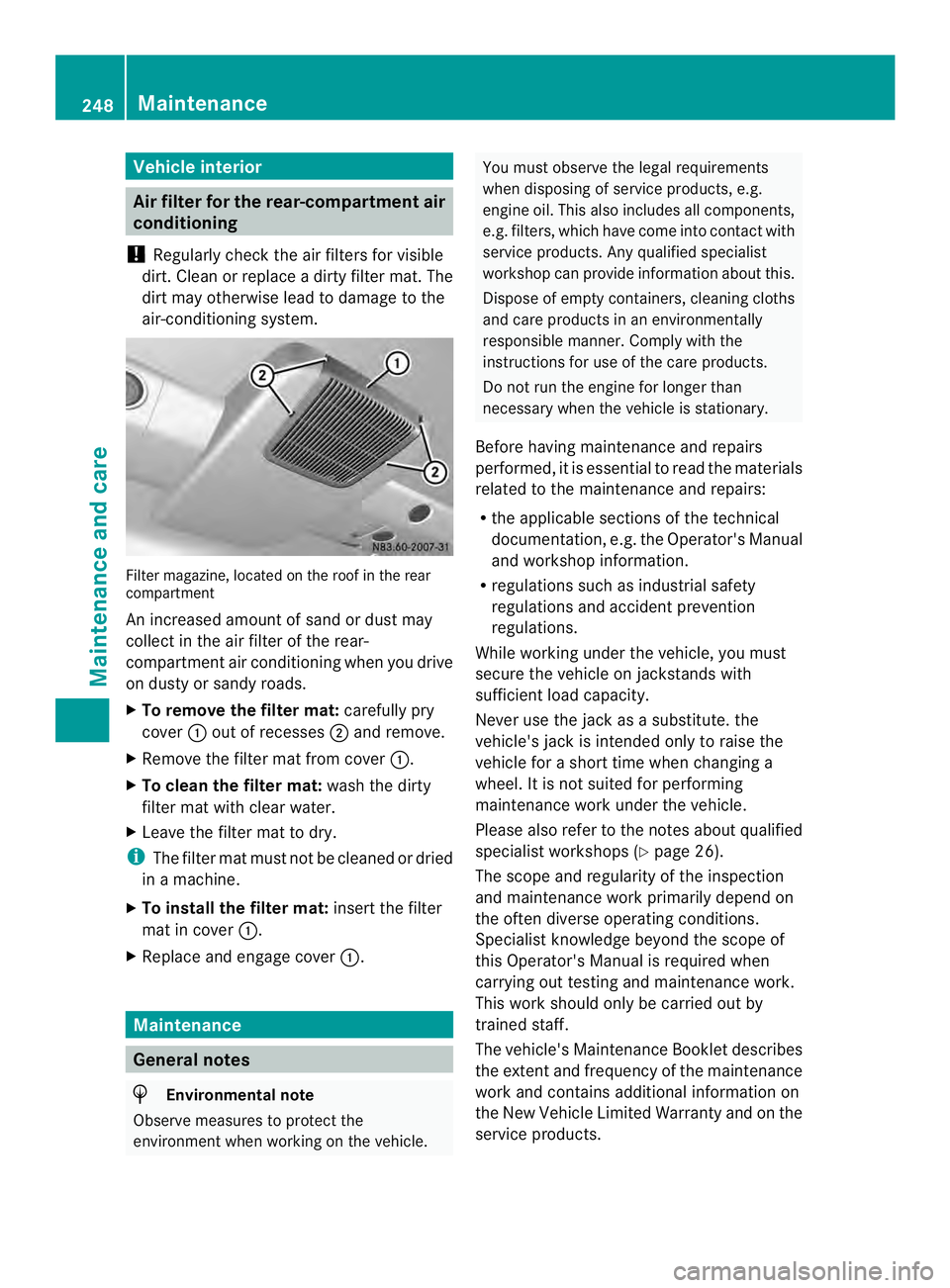

Vehicle interior

Air filter for the rear-compartment air

conditioning

! Regularly check the ai rfilters for visible

dirt .Clean or replace a dirty filter mat .The

dirt may otherwise lead to damage to the

air-conditioning system. Filter magazine, located on the roof in the rear

compartment

An increased amount of sand or dust may

collect in the air filter of the rear-

compartmenta

ir conditioning when you drive

on dusty or sandy roads.

X To remove the filter mat: carefully pry

cover 0005out of recesses 0006and remove.

X Remove the filter mat from cover 0005.

X To clean the filter mat: wash the dirty

filter mat with clear water.

X Leave the filter mat to dry.

i The filter mat must not be cleaned or dried

in a machine.

X To install the filter mat: insert the filter

mat in cover 0005.

X Replace and engage cover 0005.Maintenance

General notes

H

Environmental note

Observe measures to protect the

environment when working on the vehicle. You must observe the legal requirements

when disposing of service products, e.g.

engine oil. This also includes all components,

e.g. filters, which have come into contac twith

service products. Any qualified specialist

workshop can provide information about this.

Dispose of empty containers, cleaning cloths

and care products in an environmentally

responsible manner. Comply with the

instructions for use of the care products.

Do not run the engine for longer than

necessary when the vehicle is stationary.

Before having maintenance and repairs

performed, it is essential to read the materials

related to the maintenance and repairs:

R the applicable sections of the technical

documentation, e.g. the Operator's Manual

and workshop information.

R regulations such as industrial safety

regulations and accident prevention

regulations.

While working under the vehicle, you must

secure the vehicle on jackstands with

sufficient load capacity.

Never use the jac kasas ubstitute .the

vehicle's jack is intended only to raise the

vehicle for a short time when changing a

wheel. It is not suited for performing

maintenance work under the vehicle.

Please also refer to the notes about qualified

specialist workshops (Y page 26).

The scope and regularity of the inspection

and maintenance work primarily depend on

the often diverse operating conditions.

Specialist knowledge beyond the scope of

this Operator's Manual is required when

carrying out testing and maintenance work.

This work should only be carried out by

trained staff.

The vehicle's Maintenance Booklet describes

the extenta nd frequency of the maintenance

work and contains additional informatio non

the New Vehicle Limited Warranty and on the

service products. 248

MaintenanceMaintenance and care

Page 253 of 334

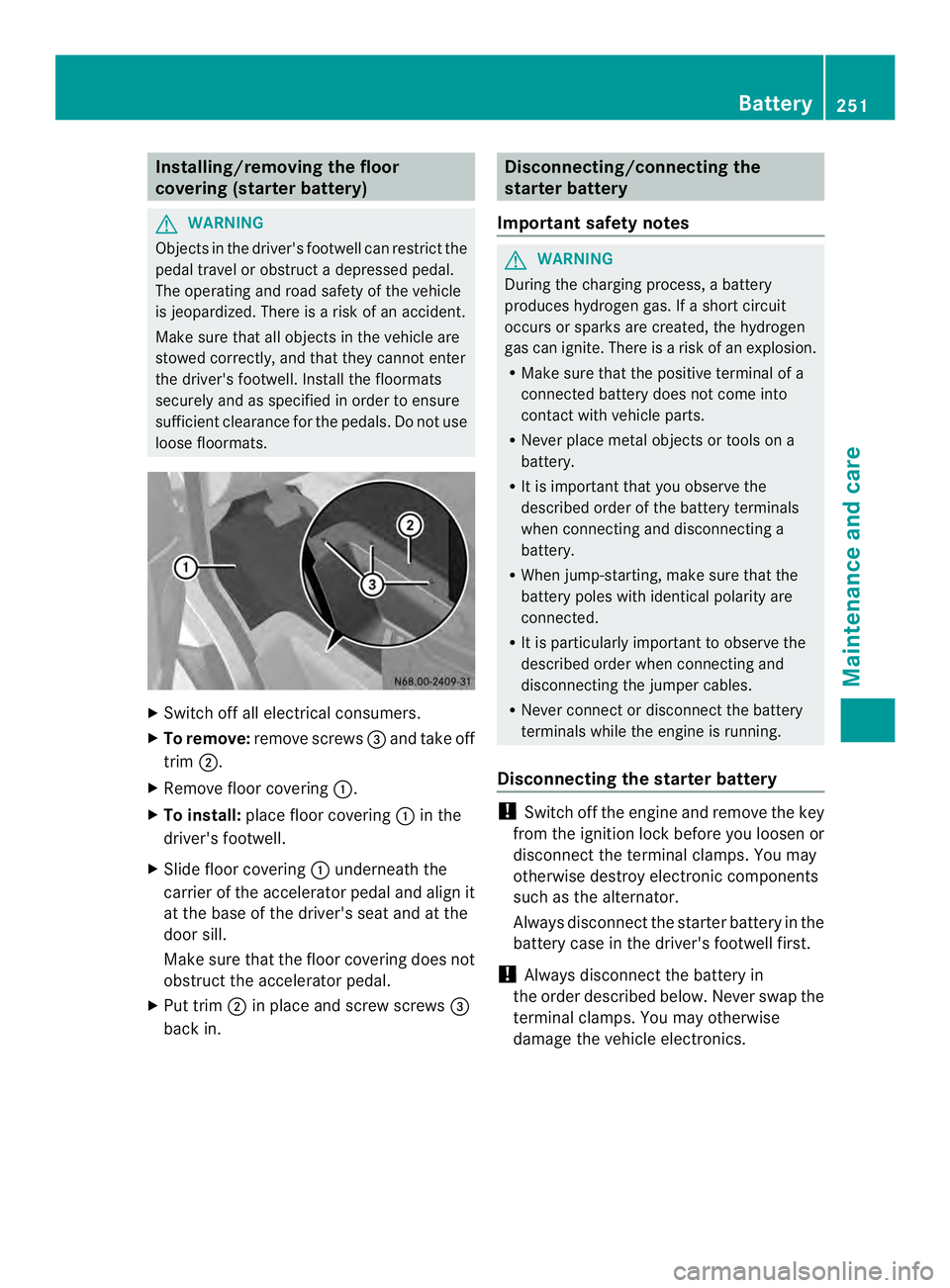

Installing/removing the floor

covering (starter battery)

G

WARNING

Objects in the driver' sfootwell can restric tthe

pedal travel or obstruct adepressed pedal.

The operating and road safety of the vehicle

is jeopardized. There is a risk of an accident.

Make sure that all objects in the vehicle are

stowed correctly, and that they cannot enter

the driver's footwell. Install the floormats

securely and as specified in order to ensure

sufficien tclearance for the pedals. Do not use

loose floormats. X

Switch off all electrical consumers.

X To remove: remove screws 0026and take off

trim 0006.

X Remove floor covering 0005.

X To install: place floor covering 0005in the

driver's footwell.

X Slide floor covering 0005underneath the

carrier of the accelerator pedal and align it

at the base of the driver's seat and at the

door sill.

Make sure that the floor covering does not

obstruct the accelerator pedal.

X Put trim 0006in place and screw screws 0026

back in. Disconnecting/connecting the

starter battery

Important safety notes G

WARNING

During the charging process, a battery

produces hydroge ngas. If a shor tcircuit

occurs or sparks are created, the hydrogen

gas can ignite. There is a risk of an explosion.

R Make sure that the positive terminal of a

connected battery does not come into

contact with vehicle parts.

R Never place metal objects or tools on a

battery.

R It is important that you observe the

described order of the battery terminals

when connecting and disconnecting a

battery.

R When jump-starting, make sure that the

battery poles with identical polarity are

connected.

R It is particularly important to observe the

described order when connecting and

disconnecting the jumper cables.

R Never connect or disconnect the battery

terminals while the engine is running.

Disconnecting the starter battery !

Switch off the engine and remove the key

fro mt he ignition lock before you loosen or

disconnectt he terminal clamps. You may

otherwise destroy electronic components

such as the alternator.

Always disconnectt he starter battery in the

battery case in the driver's footwell first.

! Always disconnectt he battery in

the order described below. Never swap the

terminal clamps. You may otherwise

damage the vehicle electronics. Battery

251Maintenance and care Z