check engine MITSUBISHI 3000GT 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 243 of 1146

FUEL SYSTEM - Orwehicle lnwection of MPI Components.13-137Fuel gauge cover

03FOOO4

j check terminal ----T( 04~oo1,/RELEASE OF RESIDUAL PRESSURE FROM HIGH

PRESSURE FUEL HOSEM13FGAIMake the following operations to release the pressure remain-

ing in fuel pipe line so that fuel will not flow out.

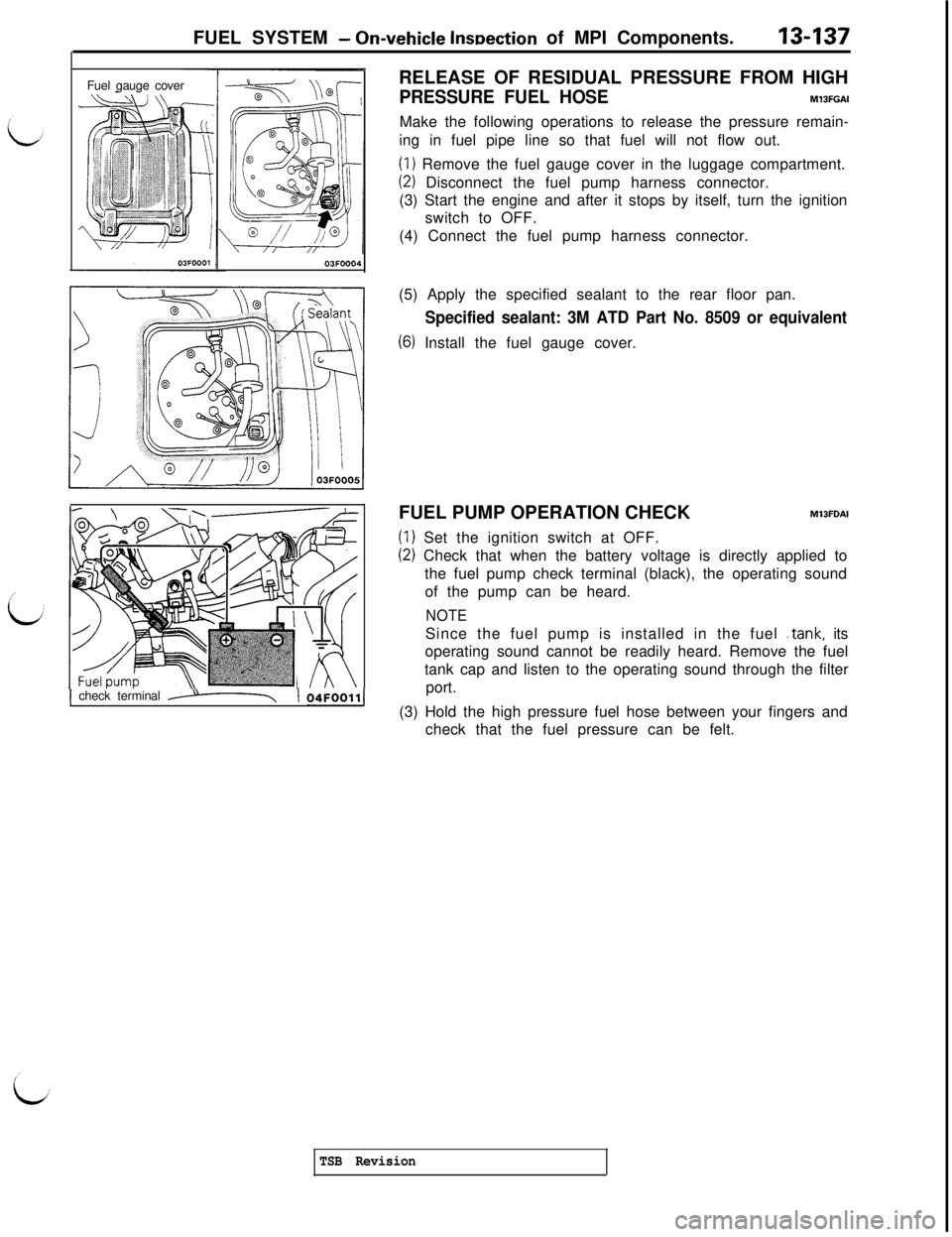

(I) Remove the fuel gauge cover in the luggage compartment.

(2) Disconnect the fuel pump harness connector.

(3) Start the engine and after it stops by itself, turn the ignition

switch to OFF.

(4) Connect the fuel pump harness connector.

(5) Apply the specified sealant to the rear floor pan.

Specified sealant: 3M ATD Part No. 8509 or equivalent

(6) Install the fuel gauge cover.

FUEL PUMP OPERATION CHECK

M13FDAI

(1) Set the ignition switch at OFF.

(2) Check that when the battery voltage is directly applied to

the fuel pump check terminal (black), the operating sound

of the pump can be heard.

NOTESince the fuel pump is installed in the fuel

.tank, its

operating sound cannot be readily heard. Remove the fuel

tank cap and listen to the operating sound through the filter

port.

(3) Hold the high pressure fuel hose between your fingers and

check that the fuel pressure can be felt.

TSB Revision

Page 244 of 1146

13438FUEL SYSTEM - On-vehicle Inspection of MPI ComponentsI/

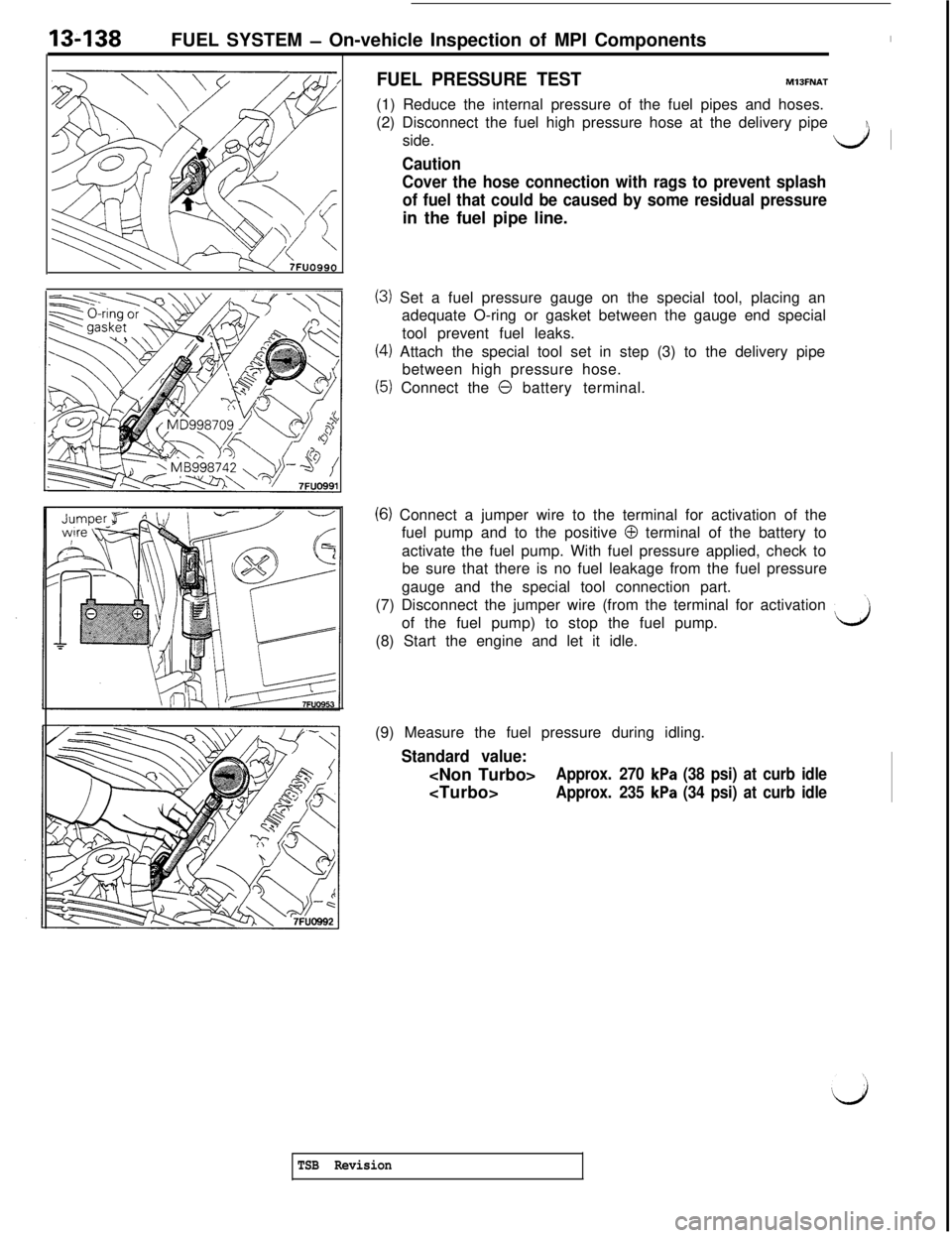

FUEL PRESSURE TESTMlJFNAT(1) Reduce the internal pressure of the fuel pipes and hoses.

(2) Disconnect the fuel high pressure hose at the delivery pipe

side.

dl

Caution

Cover the hose connection with rags to prevent splash

of fuel that could be caused by some residual pressurein the fuel pipe line.

(3) Set a fuel pressure gauge on the special tool, placing an

adequate O-ring or gasket between the gauge end special

tool prevent fuel leaks.

(4) Attach the special tool set in step (3) to the delivery pipe

between high pressure hose.

(5) Connect the 0 battery terminal.

(6) Connect a jumper wire to the terminal for activation of the

fuel pump and to the positive

0 terminal of the battery to

activate the fuel pump. With fuel pressure applied, check to

be sure that there is no fuel leakage from the fuel pressure

gauge and the special tool connection part.

(7) Disconnect the jumper wire (from the terminal for activation

’of the fuel pump) to stop the fuel pump.

(8) Start the engine and let it idle.

d(9) Measure the fuel pressure during idling.

Standard value:

Approx. 270 kPa (38 psi) at curb idle

Approx. 235 kPa (34 psi) at curb idle

TSB Revision

Page 245 of 1146

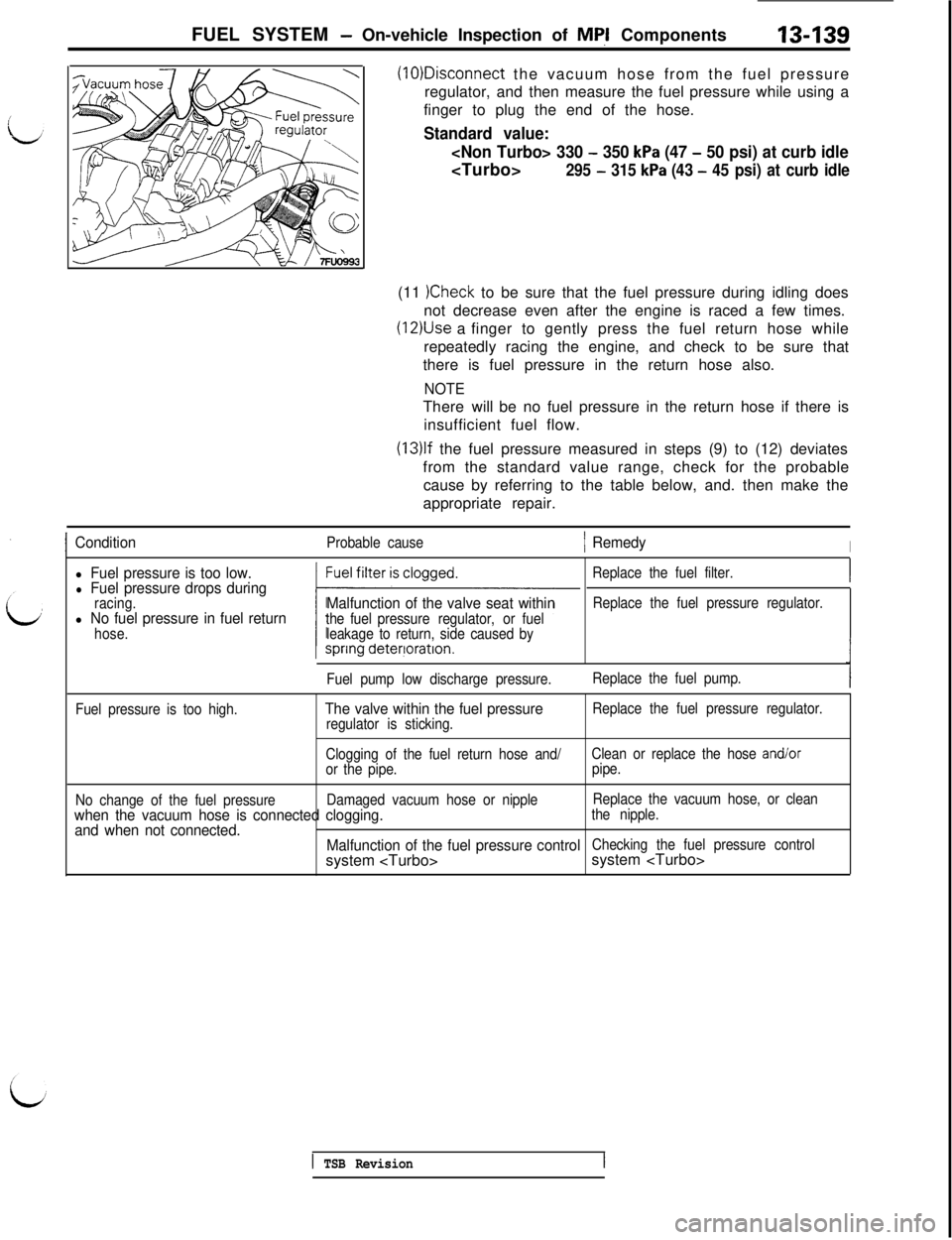

FUEL SYSTEM - On-vehicle Inspection of Mql Components13439(10)Disconnect the vacuum hose from the fuel pressure

regulator, and then measure the fuel pressure while using a

finger to plug the end of the hose.

Standard value:

- 350 kPa (47 - 50 psi) at curb idle

295 - 315 kPa (43 - 45 psi) at curb idle(11

)Check to be sure that the fuel pressure during idling does

not decrease even after the engine is raced a few times.

(12)Use a finger to gently press the fuel return hose while

repeatedly racing the engine, and check to be sure that

there is fuel pressure in the return hose also.

NOTEThere will be no fuel pressure in the return hose if there is

insufficient fuel flow.

(13)lf the fuel pressure measured in steps (9) to (12) deviates

from the standard value range, check for the probable

cause by referring to the table below, and. then make the

appropriate repair.

IConditionProbable cause1 RemedyI

l Fuel pressure is too low.l Fuel pressure drops duringracing.l No fuel pressure in fuel returnhose.

Malfunction of the valve seat withinthe fuel pressure regulator, or fuel

leakage to return, side caused byReplace the fuel filter.

Replace the fuel pressure regulator.

Fuel pump low discharge pressure.Replace the fuel pump.

Fuel pressure is too high.

The valve within the fuel pressureregulator is sticking.Replace the fuel pressure regulator.

Clogging of the fuel return hose and/Clean or replace the hose

and/oror the pipe.pipe.

No change of the fuel pressureDamaged vacuum hose or nippleReplace the vacuum hose, or clean

when the vacuum hose is connected clogging.the nipple.

and when not connected.

Malfunction of the fuel pressure controlChecking the fuel pressure controlsystem

1 TSB Revision

Page 246 of 1146

13-140FUEL SYSTEM - On-vehicle Inspection of MPI Components

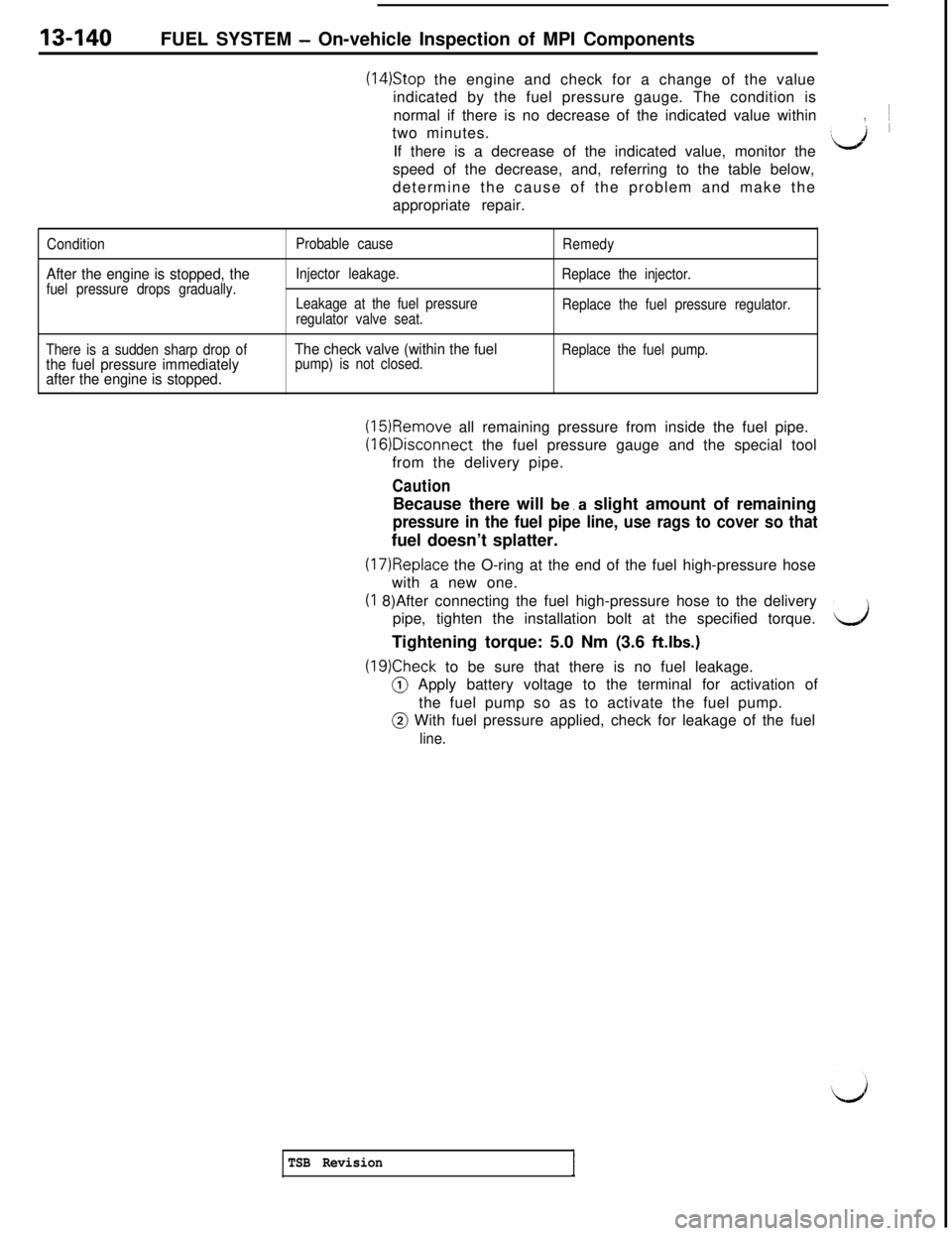

(14)Stop the engine and check for a change of the value

indicated by the fuel pressure gauge. The condition is

normal if there is no decrease of the indicated value within~

two minutes.

,If there is a decrease of the indicated value, monitor the

:d ’speed of the decrease, and, referring to the table below,

determine the cause of the problem and make the

appropriate repair.

Condition

After the engine is stopped, thefuel pressure drops gradually.Probable cause

Injector leakage.

Leakage at the fuel pressure

regulator valve seat.Remedy

Replace the injector.

Replace the fuel pressure regulator.

There is a sudden sharp drop of

the fuel pressure immediately

after the engine is stopped.The check valve (within the fuelpump) is not closed.Replace the fuel pump.

(15)Remove all remaining pressure from inside the fuel pipe.(16)Disconnect the fuel pressure gauge and the special tool

from the delivery pipe.

CautionBecause there will be.a slight amount of remaining

pressure in the fuel pipe line, use rags to cover so thatfuel doesn’t splatter.

(17)Replace the O-ring at the end of the fuel high-pressure hose

with a new one.(I 8)After connecting the fuel high-pressure hose to the delivery

pipe, tighten the installation bolt at the specified torque.

dTightening torque: 5.0 Nm (3.6 ftlbs.)

(19)Check to be sure that there is no fuel leakage.@ Apply battery voltage to the terminal for activation of

the fuel pump so as to activate the fuel pump.@ With fuel pressure applied, check for leakage of the fuel

line.

TSB Revision

Page 258 of 1146

13-152FUEL SYSTEM- Fuel Line and Vapor Line

03FOO3

05FOO735 Nm7r; ft

Ihr-k” ._..I_.

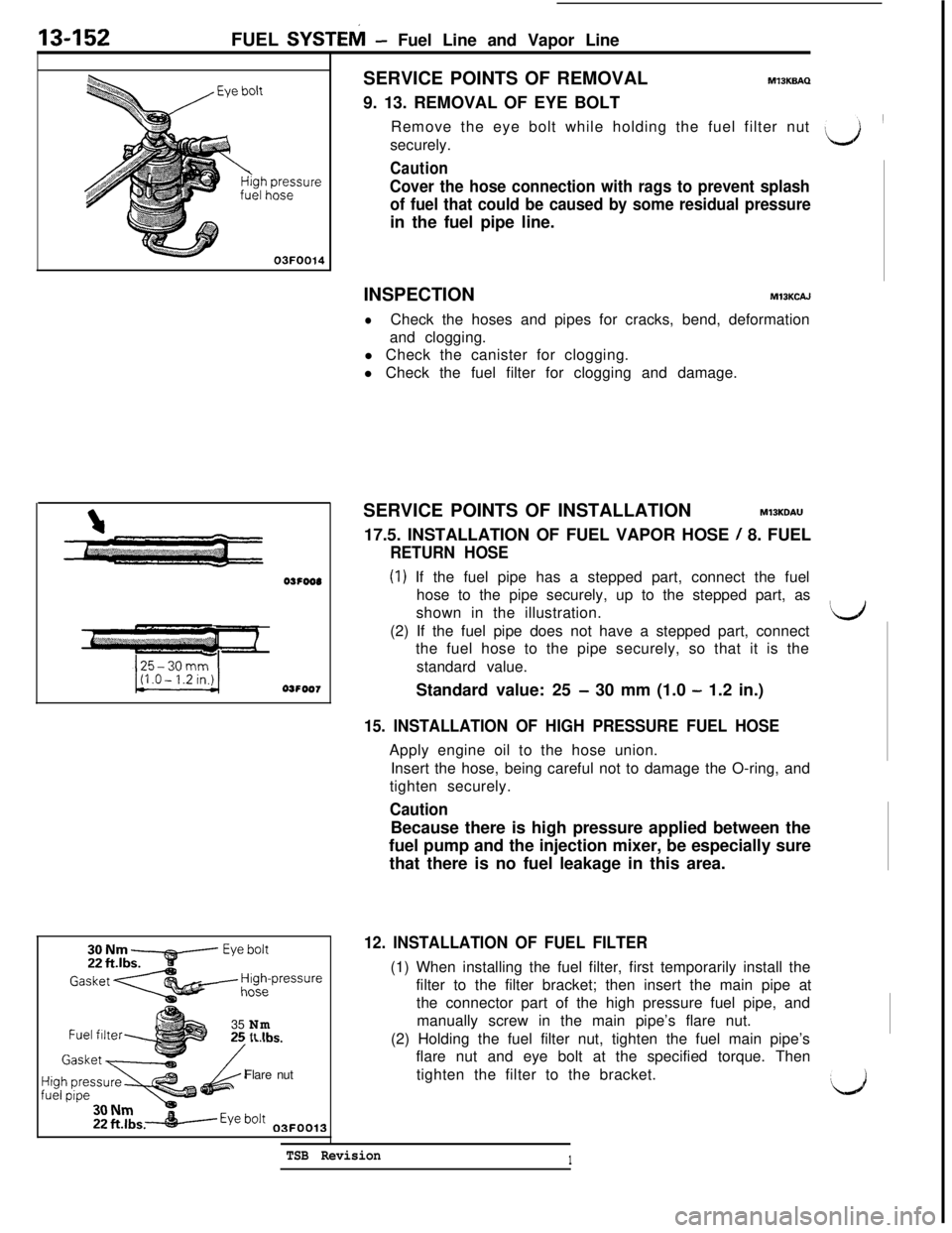

@dFlare nut,xSERVICE POINTS OF REMOVAL

MlBKBAQ9. 13. REMOVAL OF EYE BOLT

Remove the eye bolt while holding the fuel filter nut

\securely.

Caution

Cover the hose connection with rags to prevent splash

of fuel that could be caused by some residual pressurein the fuel pipe line.

INSPECTION

MIBKCAJ

lCheck the hoses and pipes for cracks, bend, deformation

and clogging.

l Check the canister for clogging.

l Check the fuel filter for clogging and damage.

SERVICE POINTS OF INSTALLATION

MlSKDAU17.5. INSTALLATION OF FUEL VAPOR HOSE

/ 8. FUEL

RETURN HOSE

(1) If the fuel pipe has a stepped part, connect the fuel

hose to the pipe securely, up to the stepped part, as

shown in the illustration.

Iti(2) If the fuel pipe does not have a stepped part, connect

the fuel hose to the pipe securely, so that it is the

standard value.

Standard value: 25

- 30 mm (1.0 - 1.2 in.)

15. INSTALLATION OF HIGH PRESSURE FUEL HOSEApply engine oil to the hose union.

Insert the hose, being careful not to damage the O-ring, and

tighten securely.

CautionBecause there is high pressure applied between the

fuel pump and the injection mixer, be especially sure

that there is no fuel leakage in this area.

12. INSTALLATION OF FUEL FILTER(1) When installing the fuel filter, first temporarily install the

filter to the filter bracket; then insert the main pipe at

the connector part of the high pressure fuel pipe, and

manually screw in the main pipe’s flare nut.

(2) Holding the fuel filter nut, tighten the fuel main pipe’s

flare nut and eye bolt at the specified torque. Then

tighten the filter to the bracket.

TSB Revision1

‘d

Page 262 of 1146

13-156ENGINE CONTROL - Service Adjustment Procedures

SERVICE ADJUSTMENT PROCEDURES

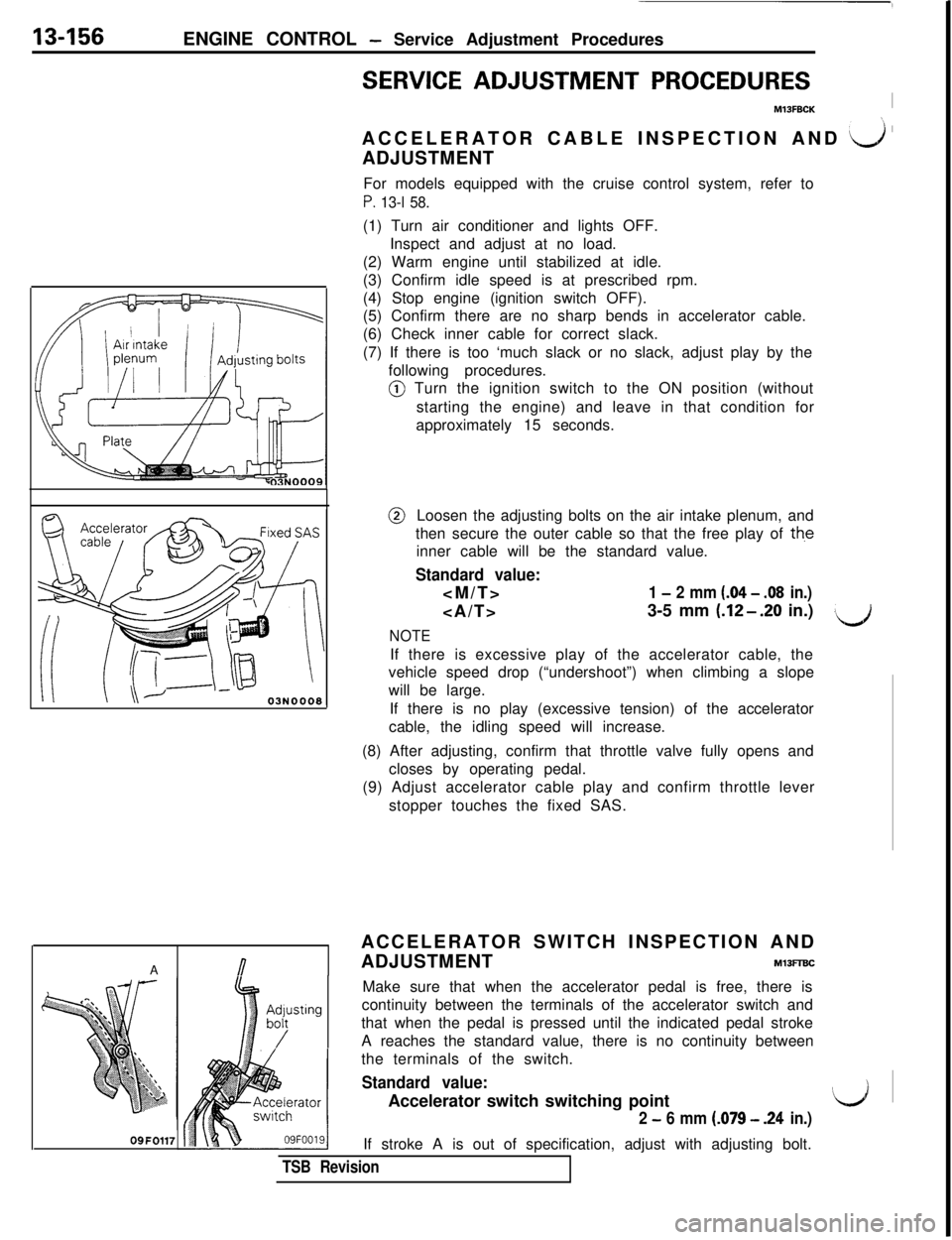

M13FBCKIACCELERATOR CABLE INSPECTION AND

a ’ADJUSTMENT

For models equipped with the cruise control system, refer to

P. 13-l 58.(1) Turn air conditioner and lights OFF.

Inspect and adjust at no load.

(2) Warm engine until stabilized at idle.

(3) Confirm idle speed is at prescribed rpm.

(4) Stop engine (ignition switch OFF).

(5) Confirm there are no sharp bends in accelerator cable.

(6) Check inner cable for correct slack.

(7) If there is too ‘much slack or no slack, adjust play by the

following procedures.@ Turn the ignition switch to the ON position (without

starting the engine) and leave in that condition for

approximately 15 seconds.@Loosen the adjusting bolts on the air intake plenum, and

then secure the outer cable so that the free play of

th,einner cable will be the standard value.

Standard value:

1 - 2 mm (.04 - .08 in.)3-5 mm

(.12-.20 in.)

NOTE

\JIf there is excessive play of the accelerator cable, the

vehicle speed drop (“undershoot”) when climbing a slope

will be large.

If there is no play (excessive tension) of the accelerator

cable, the idling speed will increase.

(8) After adjusting, confirm that throttle valve fully opens and

closes by operating pedal.

(9) Adjust accelerator cable play and confirm throttle lever

stopper touches the fixed SAS.

ACCELERATOR SWITCH INSPECTION AND

A

nADJUSTMENTMlBFlBC

09FO117Make sure that when the accelerator pedal is free, there is

;$ustingcontinuity between the terminals of the accelerator switch and

/that when the pedal is pressed until the indicated pedal stroke

A reaches the standard value, there is no continuity between

the terminals of the switch.

Standard value:Accelerator switch switching point

2 - 6 mm (.079 - .24 in.)If stroke A is out of specification, adjust with adjusting bolt.

TSB Revision

\

‘LJ ~

Page 263 of 1146

ENGINE CONTROL - Engine Control13-157

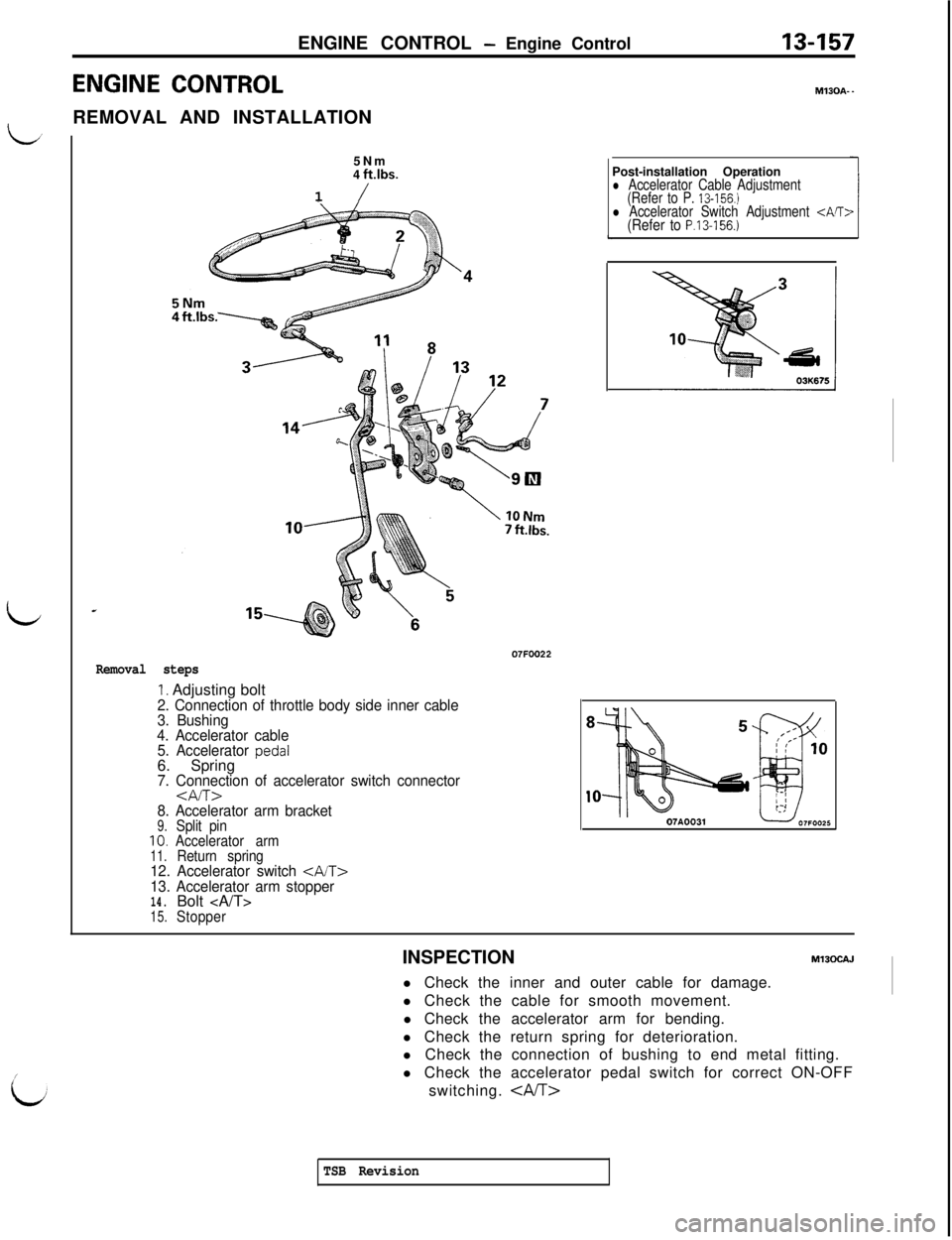

ENGINE CONTROLREMOVAL AND INSTALLATION

L’

/

ii5Nm

4

ftlbs.1

/

Removal steps

I. Adjusting bolt2. Connection of throttle body side inner cable

3. Bushing

4. Accelerator cable

5. Accelerator

oedal6. Spring ’7. Connection of accelerator switch connector8. Accelerator arm bracket9.Split pin10.Accelerator arm11.Return spring12. Accelerator switch 13. Accelerator arm stopper14.Bolt 15.StopperMl30A-

-Post-installation Operation

l Accelerator Cable Adjustment

(Refer to P. 13-156.)l Accelerator Switch Adjustment

07A0031INSPECTION

MlBOCAJl Check the inner and outer cable for damage.

l Check the cable for smooth movement.

l Check the accelerator arm for bending.

l Check the return spring for deterioration.

l Check the connection of bushing to end metal fitting.

l Check the accelerator pedal switch for correct ON-OFF

switching.

TSB Revision

Page 284 of 1146

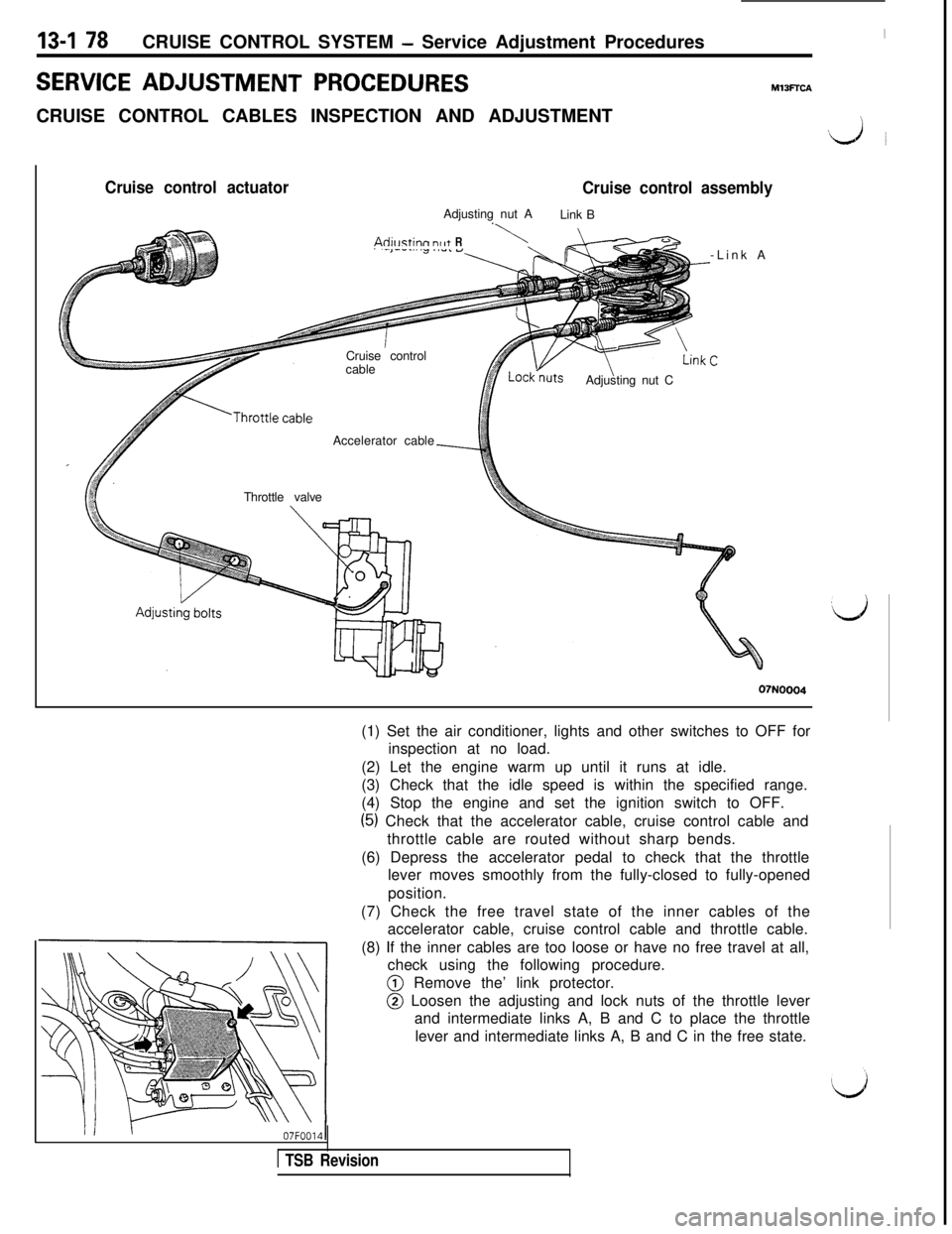

13-I 78CRUISE CONTROL SYSTEM - Service Adjustment ProceduresSERVICE

ADJUSTMENT PROCEDURESCRUISE CONTROL CABLES INSPECTION AND ADJUSTMENT

I

MlSFTCA

‘\J ~

Cruise control actuator

Cruise control assemblyAdjusting nut A

Link B

.

Adillstinn nr~+ R\Cruise control

cable

Adjusting nut C

Accelerator cable

Throttle valve-Link A

07N0004(1) Set the air conditioner, lights and other switches to OFF for

inspection at no load.

(2) Let the engine warm up until it runs at idle.

(3) Check that the idle speed is within the specified range.

(4) Stop the engine and set the ignition switch to OFF.

(5) Check that the accelerator cable, cruise control cable and

throttle cable are routed without sharp bends.

(6) Depress the accelerator pedal to check that the throttle

lever moves smoothly from the fully-closed to fully-opened

position.

(7) Check the free travel state of the inner cables of the

accelerator cable, cruise control cable and throttle cable.

(8) If the inner cables are too loose or have no free travel at all,

check using the following procedure.@ Remove the’ link protector.

@ Loosen the adjusting and lock nuts of the throttle lever

and intermediate links A, B and C to place the throttle

lever and intermediate links A, B and C in the free state.

1 TSB Revision

Page 285 of 1146

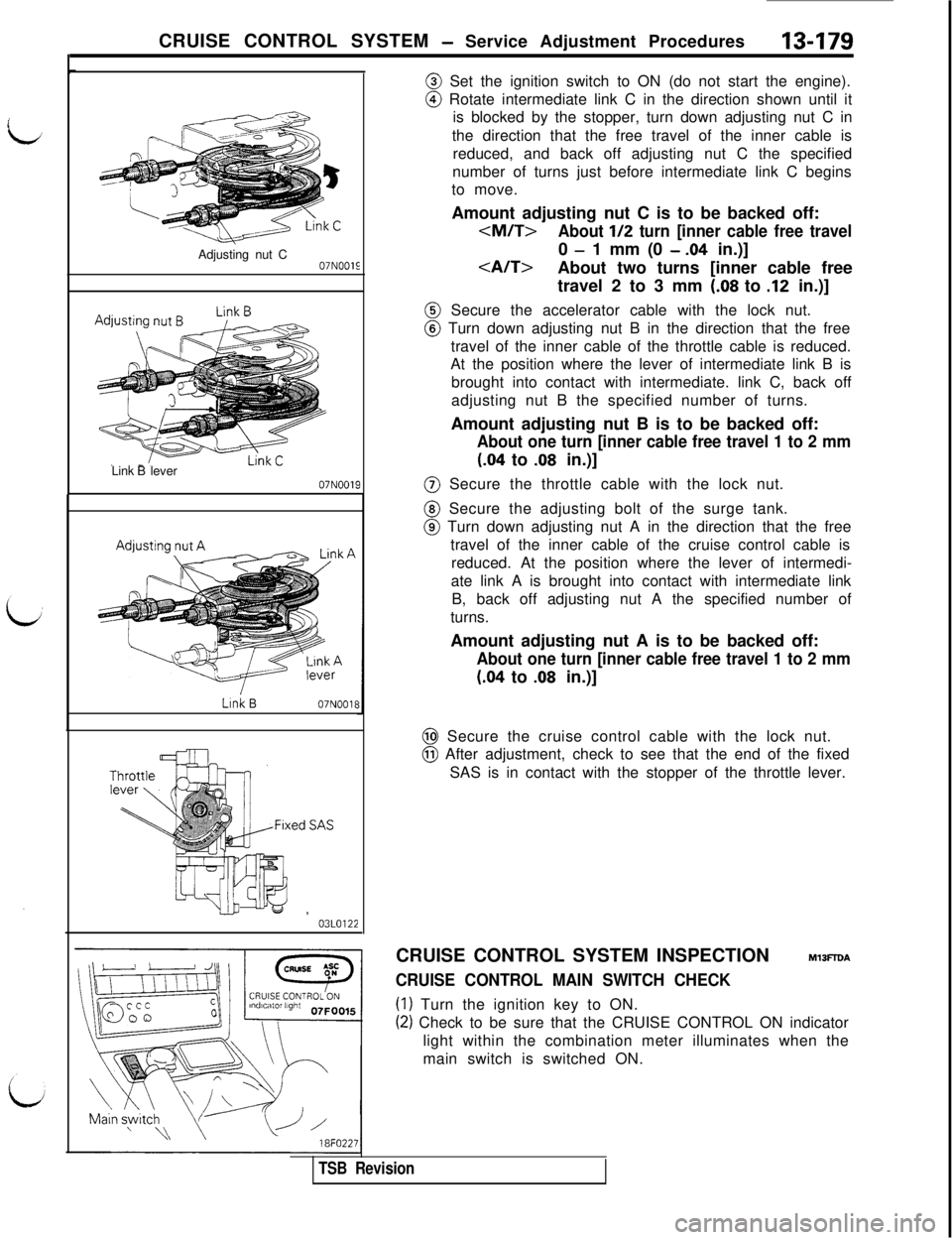

CRUISE CONTROL SYSTEM - Service Adjustment Procedures13-179Adjusting nut C

07NOOlELink Blever

07N0019Link

B07NOOlE

y,jj--ww ,03LO122

\\ \18FO2.2'@ Set the ignition switch to ON (do not start the engine).@ Rotate intermediate link C in the direction shown until it

is blocked by the stopper, turn down adjusting nut C in

the direction that the free travel of the inner cable is

reduced, and back off adjusting nut C the specified

number of turns just before intermediate link C begins

to move.

Amount adjusting nut C is to be backed off:

- 1 mm (0 - .04 in.)]

About two turns [inner cable free

travel 2 to 3 mm

(.08 to .12 in.)]@ Secure the accelerator cable with the lock nut.@ Turn down adjusting nut B in the direction that the free

travel of the inner cable of the throttle cable is reduced.

At the position where the lever of intermediate link B is

brought into contact with intermediate. link C, back off

adjusting nut B the specified number of turns.

Amount adjusting nut B is to be backed off:

About one turn [inner cable free travel 1 to 2 mm

(.04 to .08 in.)]@ Secure the throttle cable with the lock nut.@ Secure the adjusting bolt of the surge tank.@ Turn down adjusting nut A in the direction that the free

travel of the inner cable of the cruise control cable is

reduced. At the position where the lever of intermedi-

ate link A is brought into contact with intermediate link

B, back off adjusting nut A the specified number of

turns.

Amount adjusting nut A is to be backed off:

About one turn [inner cable free travel 1 to 2 mm

(.04 to .08 in.)]@ Secure the cruise control cable with the lock nut.@ After adjustment, check to see that the end of the fixed

SAS is in contact with the stopper of the throttle lever.

CRUISE CONTROL SYSTEM INSPECTION

MlBFlDA

CRUISE CONTROL MAIN SWITCH CHECK

(1) Turn the ignition key to ON.

(2) Check to be sure that the CRUISE CONTROL ON indicator

light within the combination meter illuminates when the

main switch is switched ON.

TSB Revision

Page 295 of 1146

COOLINGCONTENTS

M14AA..

ENGINE COOLANT TEMPERATURE GAUGE

UNIT, ENGINE COOLANT TEMPERATURESENSOR AND ENGINE COOLANT

TEMPERATURE SWITCH. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .._.__15

RADIATOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

SERVICE ADJUSTMENT PROCEDURES . . . . . . . .7Cap Pressure Test

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .._.......7Engine Coolant Concentration Test

. . . . . . . . . . . . . . . .‘7

L,Engine Coolant Leak Check

. . . . . . . . . . . . . . . . . . . . . . . . . . . .7Engine Coolant Replacement

. . . . . . . . . . . . . . . . . . . . . . . .7

SPECIFICATIONS. . . . . . . . . . . . .._.................................General Specifications

. ..___....___._...___.__............Lubricant

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .._.................._........Sealant and Adhesive

. . . . . . . . . . . . . . . . .._...........Service Specifications

. . . . . . . . . . . . . . . . . . . . . . . . . .

THERMOSTAT. . . ..__......................_.._...................

TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .._...No Rise in Temperature

Overheat

WATER PUMP, WATER PIPE AND WATER

HOSE. . . . _......_........_ _.._ .._..... . . . . . . . . . . . ._. . . . . . . . . . . . . . . . .

2

2

2

3

2

11

3

13