check engine MITSUBISHI 3000GT 1991 Manual Online

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 210 of 1146

13-104FUEL SYSTEM - On-vehicle Inspection of MPI Components

-l4Harness side

connector

L----.[ Q1J

7FUO971

‘Y-4 ’onnector for

7FUO78C

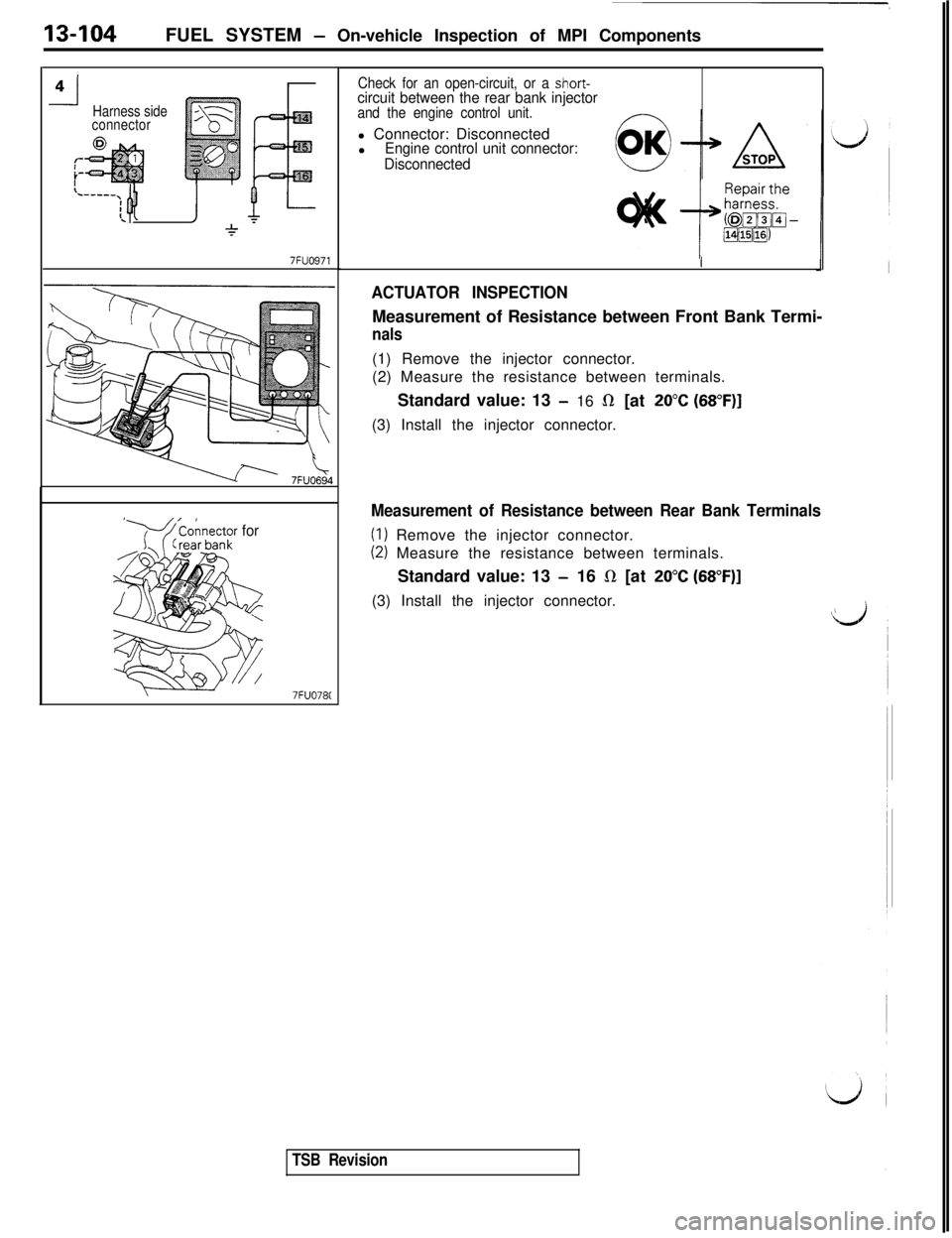

Check for an open-circuit, or a short-circuit between the rear bank injectorand the engine control unit.l Connector: Disconnected

l

Engine control unit connector:

Disconnected

I

ACTUATOR INSPECTIONMeasurement of Resistance between Front Bank Termi-

nals(1) Remove the injector connector.

(2) Measure the resistance between terminals.

Standard value: 13

- 16 il [at 20°C (68”F)](3) Install the injector connector.

Measurement of Resistance between Rear Bank Terminals

(I) Remove the injector connector.

(2) Measure the resistance between terminals.

Standard value: 13

- 16 Q [at 20°C (68”F)](3) Install the injector connector.

\

TSB Revision

Page 212 of 1146

13-106FUEL SYSTEM - On-vehicle Inspection of MPI Components

INSPECTION

Using Multi-use Tester

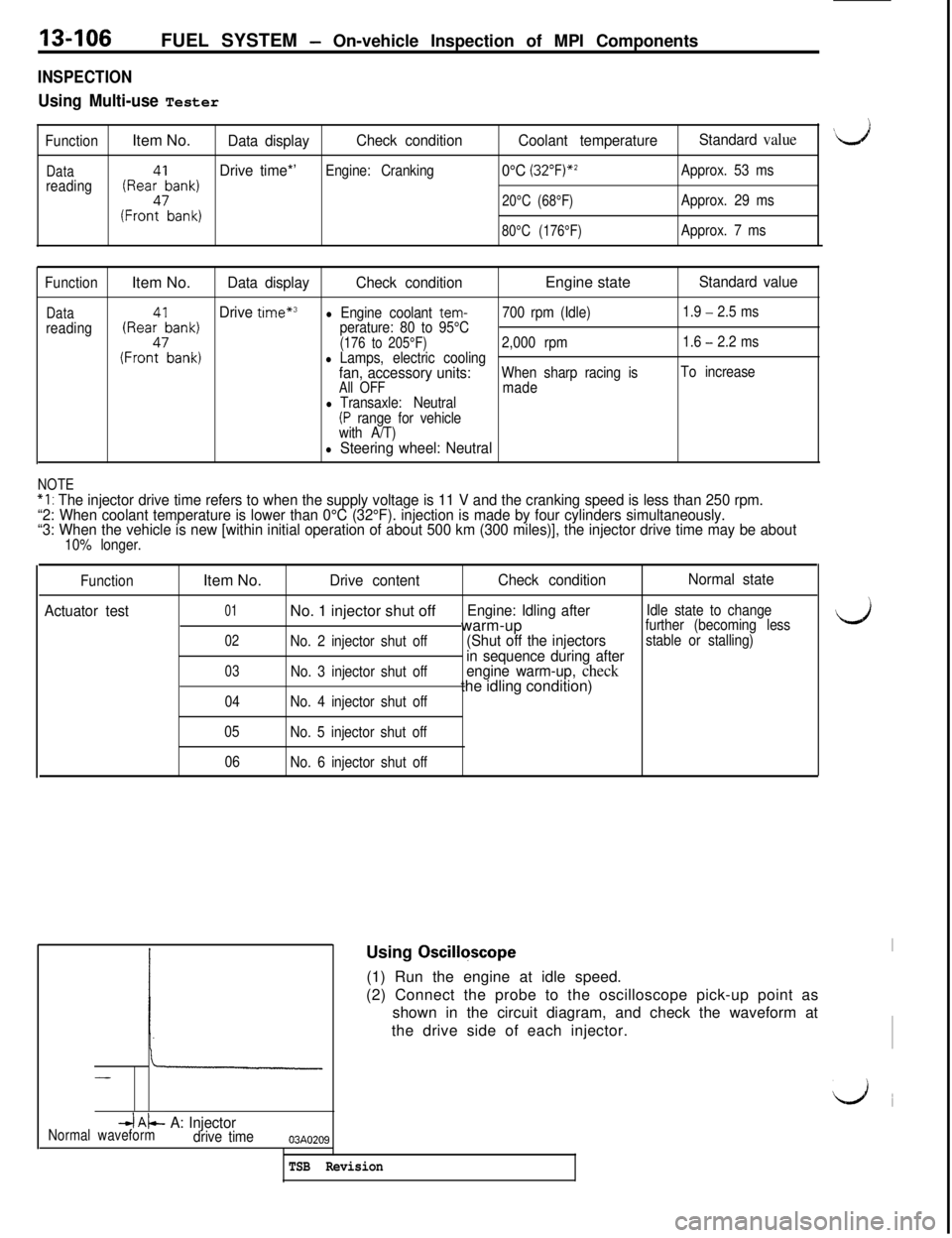

FunctionItem No.Data displayCheck conditionCoolant temperatureStandard value‘L,,,J

DataDrive time*’0°C (32’F)*’readingiRea:bankiEngine: CrankingApprox. 53 ms

(FronT7bank)20°C (68°F)

Approx. 29 ms

80°C (176°F)Approx. 7 ms

FunctionItem No.

Data displayCheck conditionEngine stateStandard value

Datareading(Reaebank)Drive time*3l Engine coolant tem-700 rpm (Idle)1.9 - 2.5 ms

perature: 80 to 95°C

(Front7banki(176 to 205°F)2,000 rpm1.6 - 2.2 ms

l Lamps, electric coolingfan, accessory units:To increase

All OFFWhen sharp racing is

made

l Transaxle: Neutral(P range for vehicle

with A/T)

l Steering wheel: Neutral

NOTE“I : The injector drive time refers to when the supply voltage is 11 V and the cranking speed is less than 250 rpm.

“2: When coolant temperature is lower than 0°C (32°F). injection is made by four cylinders simultaneously.

“3: When the vehicle is new [within initial operation of about 500 km (300 miles)], the injector drive time may be about

10% longer.

Function

Actuator testItem No.

Drive contentCheck conditionNormal state

01No. 1 injector shut offEngine: Idling afterIdle state to changewarm-upfurther (becoming less

02No. 2 injector shut off(Shut off the injectorsstable or stalling)

03in sequence during afterNo. 3 injector shut offengine warm-up, checkthe idling condition)

04No. 4 injector shut off

05

No. 5 injector shut off

06

No. 6 injector shut off

\,iUsing

OscillqscopeI(1) Run the engine at idle speed.

(2) Connect the probe to the oscilloscope pick-up point as

shown in the circuit diagram, and check the waveform at

the drive side of each injector.~

-

LJ

4 AL A: InjectorNormal waveformdrive time03A0209

TSB Revision

Page 213 of 1146

FUEL SYSTEM - On-vehicle Inspection of MPI Components13-107

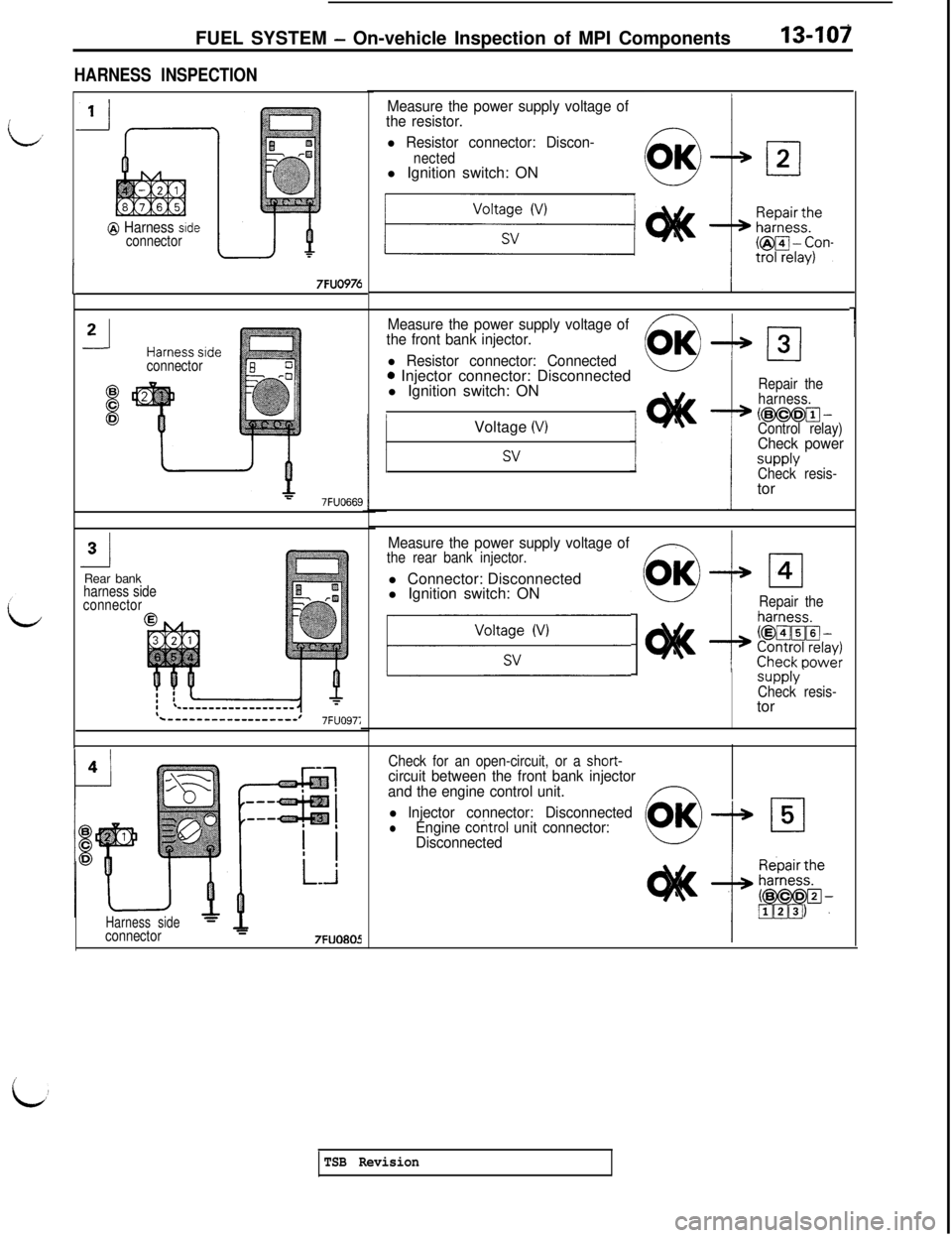

HARNESS INSPECTION

@ Harness sideconnector

I

I

7FUO976

Measure the power supply voltage of

the resistor.

l Resistor connector: Discon-

nectedl Ignition switch: ON

connector

7FUO669-I

3Rear bank

harness side

connector

.------------------’7FUO97;

Harness sideconnectorz7FUO805

Measure the power supply voltage of

the front bank injector.

l Resistor connector: Connected0 Injector connector: Disconnected

l Ignition switch: ON

Voltage

(V)

0

OK03

Repair the

harness.

(@g@pJ-Control relay)Check power

supplyCheck resis-tor

Measure the power supply voltage ofthe rear bank injector.l Connector: Disconnected

l Ignition switch: ON

*

04

Repair the

supply’Check resis-tor

Check for an open-circuit, or a short-circuit between the front bank injector

and the engine control unit.

f---l -

l Injector connector: DisconnectedlEngine control unit connector:

Disconnected

1

TSB Revision

Page 214 of 1146

13-108

IFUEL SYSTEM

- 0n-vehicle Inspection of MPI Components

------+ Rear bankconnector 1

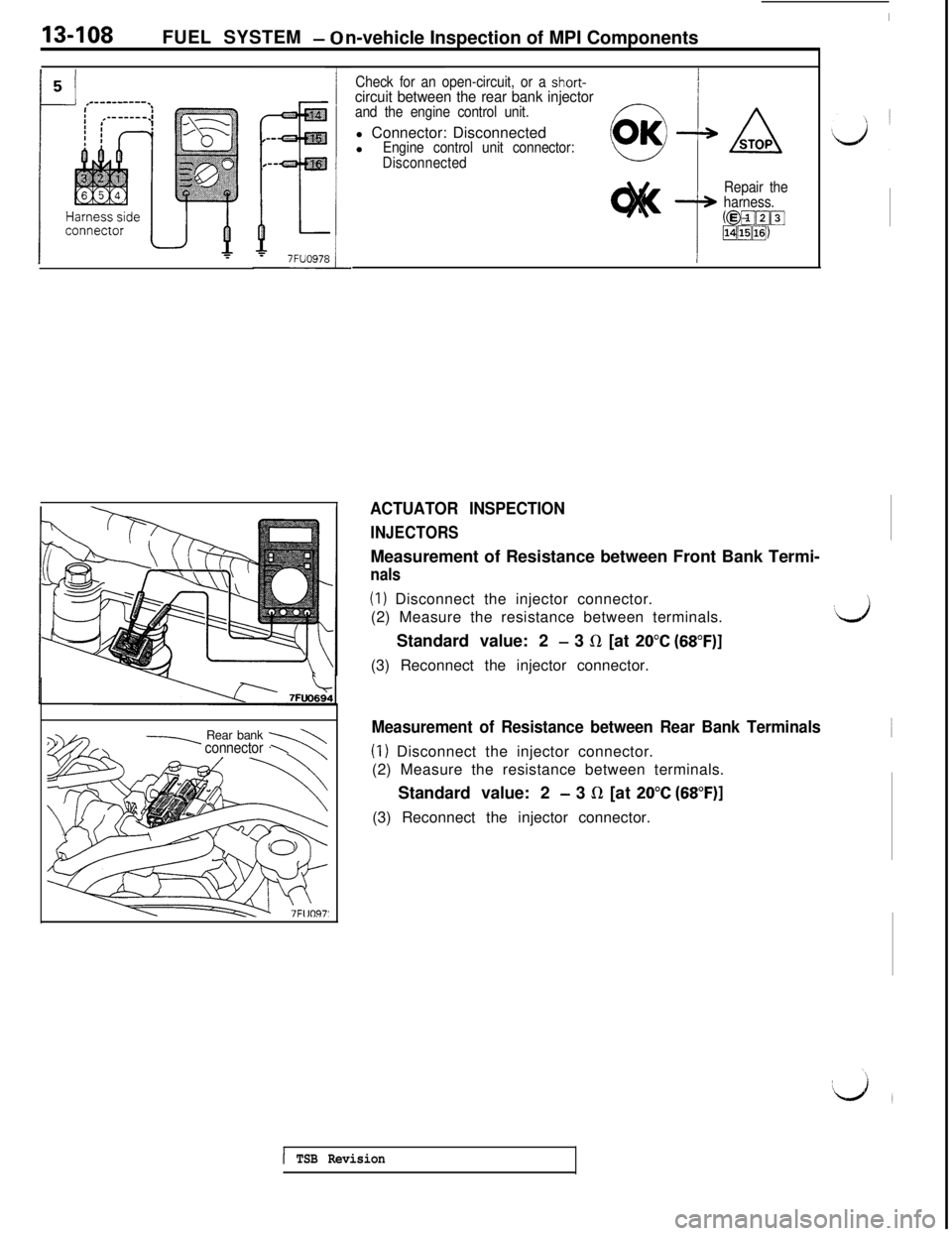

Check for an open-circuit, or a short-circuit between the rear bank injectorand the engine control unit.l Connector: Disconnected

l

Engine control unit connector:

Disconnected0

OKASTOP

Repair the

harness.

@ilT’ilpt-

iiWF4)

ACTUATOR INSPECTION

INJECTORSMeasurement of Resistance between Front Bank Termi-

nals

(1) Disconnect the injector connector.

(2) Measure the resistance between terminals.

Standard value: 2

- 3 R [at 20°C (68”F)](3) Reconnect the injector connector.

‘iJ

Measurement of Resistance between Rear Bank Terminals

(‘I ) Disconnect the injector connector.

(2) Measure the resistance between terminals.

Standard value: 2

- 3 R [at 20°C (68”F)](3) Reconnect the injector connector.

1 TSB Revision

Page 216 of 1146

13-110FUEL SYSTEM - On-vehicle Inspection of MPI Components

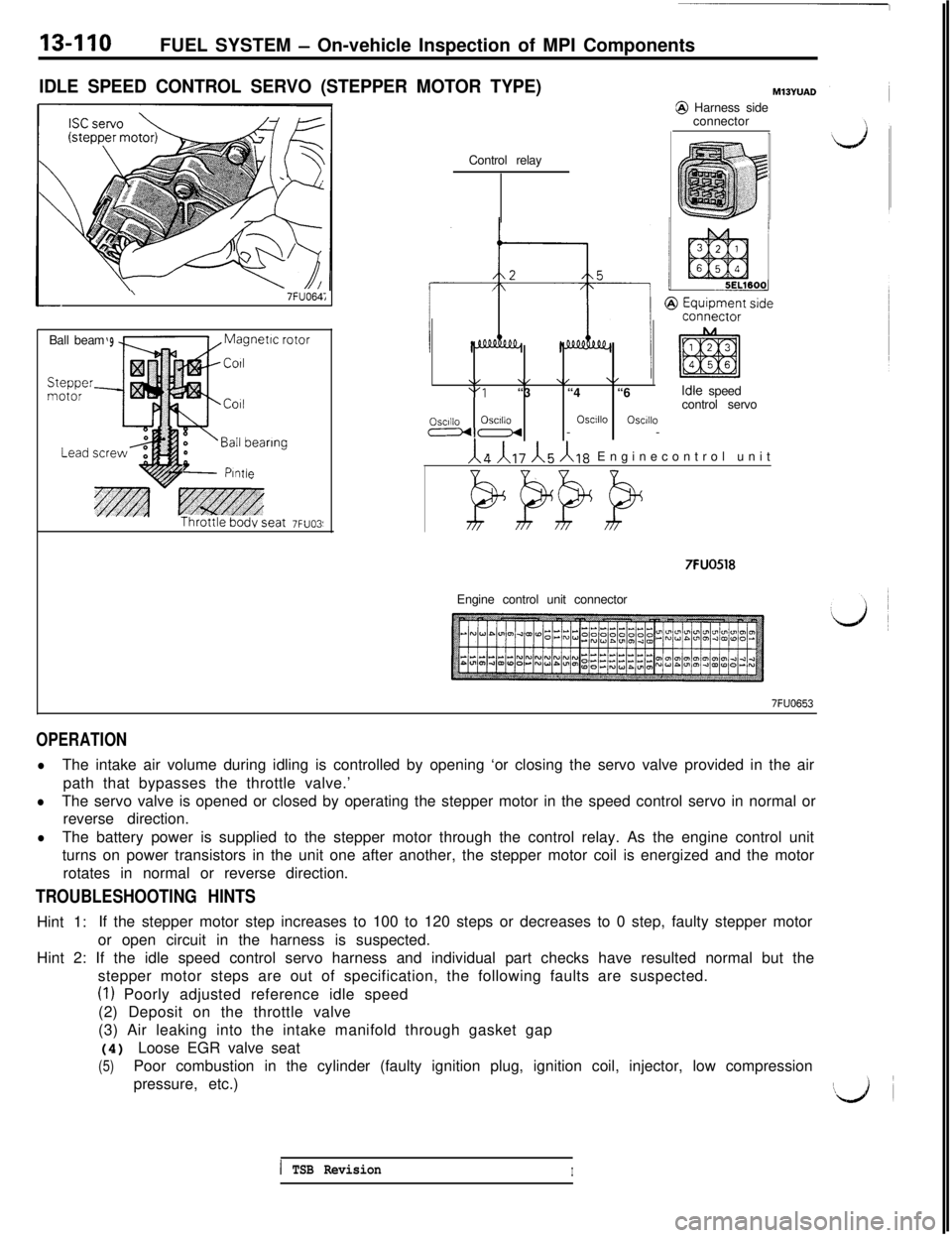

IDLE SPEED CONTROL SERVO (STEPPER MOTOR TYPE)\

7FUO64;Ball beam

‘9

L PlntleControl relay

@ Harness side

connector

\/1, \,\/“1“3 “4 “6Idle speed

control servo

OSCIIIOOSCIIIOOSClllOosclllomu--

/(a /(IT ),!j /I,, Enginecontrol unit

BPPP

7FUO518Engine control unit connector

7FUO653

OPERATION

lThe intake air volume during idling is controlled by opening ‘or closing the servo valve provided in the air

path that bypasses the throttle valve.’

lThe servo valve is opened or closed by operating the stepper motor in the speed control servo in normal or

reverse direction.

lThe battery power is supplied to the stepper motor through the control relay. As the engine control unit

turns on power transistors in the unit one after another, the stepper motor coil is energized and the motor

rotates in normal or reverse direction.

TROUBLESHOOTING HINTSHint 1:If the stepper motor step increases to 100 to 120 steps or decreases to 0 step, faulty stepper motor

or open circuit in the harness is suspected.

Hint 2: If the idle speed control servo harness and individual part checks have resulted normal but the

stepper motor steps are out of specification, the following faults are suspected.

(I) Poorly adjusted reference idle speed

(2) Deposit on the throttle valve

(3) Air leaking into the intake manifold through gasket gap

(4) Loose EGR valve seat

(5)Poor combustion in the cylinder (faulty ignition plug, ignition coil, injector, low compression

pressure, etc.)

\L.J

1 TSB RevisionI

Page 217 of 1146

FUEL SYSTEM - On-vehicle .lnspection of MPI Components13-111

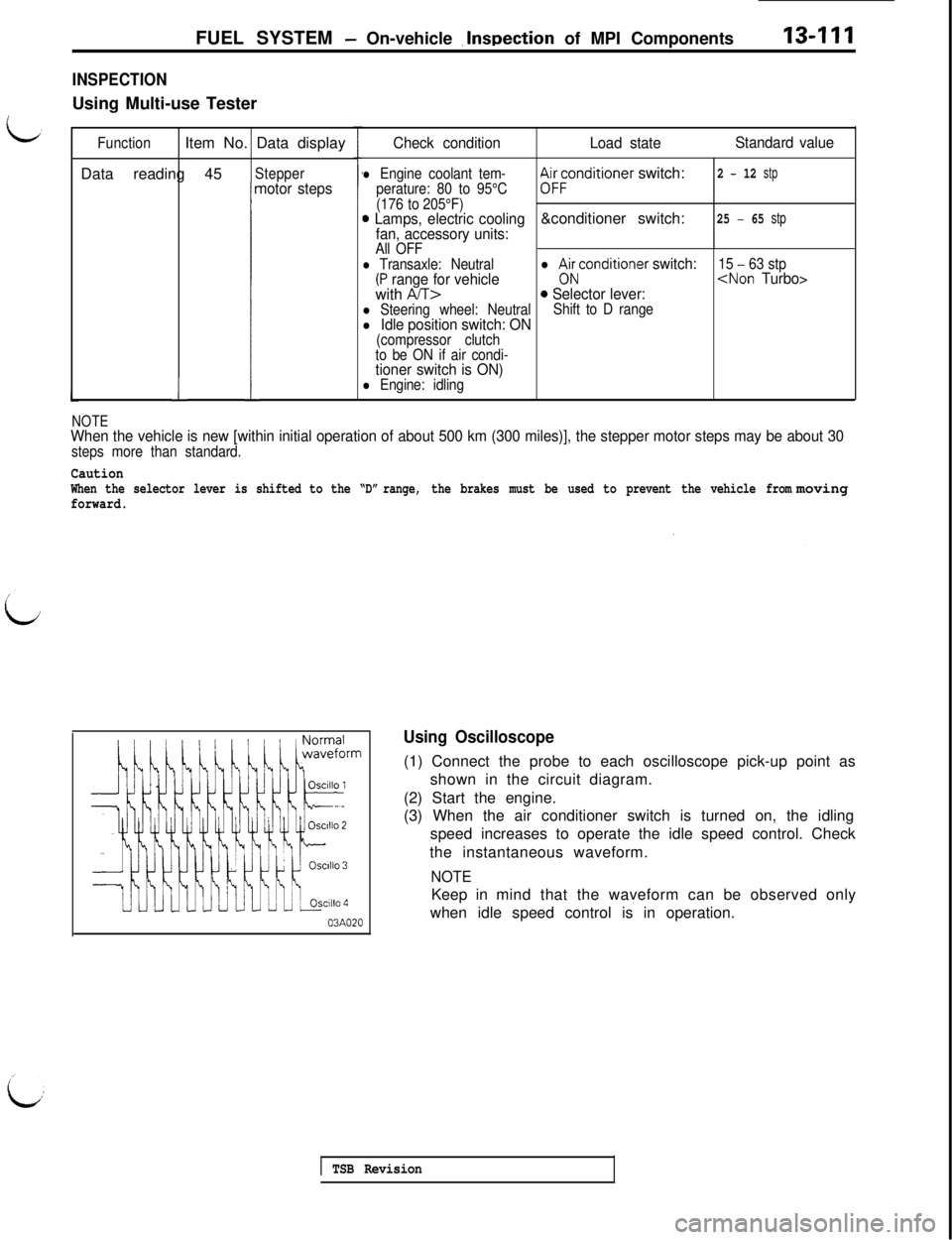

INSPECTIONUsing Multi-use Tester

FunctionItem No. Data display

Data reading 45

Stepper

1

motor steps

~

Check condition

l Engine coolant tem-

perature: 80 to 95°C

(176 to 205°F)

0 Lamps, electric cooling

fan, accessory units:

All OFFl Transaxle: Neutral(P range for vehiclewith AA>l Steering wheel: Neutrall Idle position switch: ON(compressor clutch

to be ON if air condi-

tioner switch is ON)l Engine: idling

Load stateStandard value

;;rnditioner switch:2 - 12 stp&conditioner switch:

25 - 65 stp

l $irNconditioner switch:15 - 63 stp

NOTEWhen the vehicle is new [within initial operation of about 500 km (300 miles)], the stepper motor steps may be about 30steps more than standard.

CautionWhen the selector lever is shifted to the “D”range, the brakes must be used to prevent the vehicle frommovingforward.

03A020

Using Oscilloscope(1) Connect the probe to each oscilloscope pick-up point as

shown in the circuit diagram.

(2) Start the engine.

(3) When the air conditioner switch is turned on, the idling

speed increases to operate the idle speed control. Check

the instantaneous waveform.

NOTEKeep in mind that the waveform can be observed only

when idle speed control is in operation.

1 TSB Revision

Page 218 of 1146

13-112FUEL SYSTEM - 0

n-vehicleInspection of MPI Components

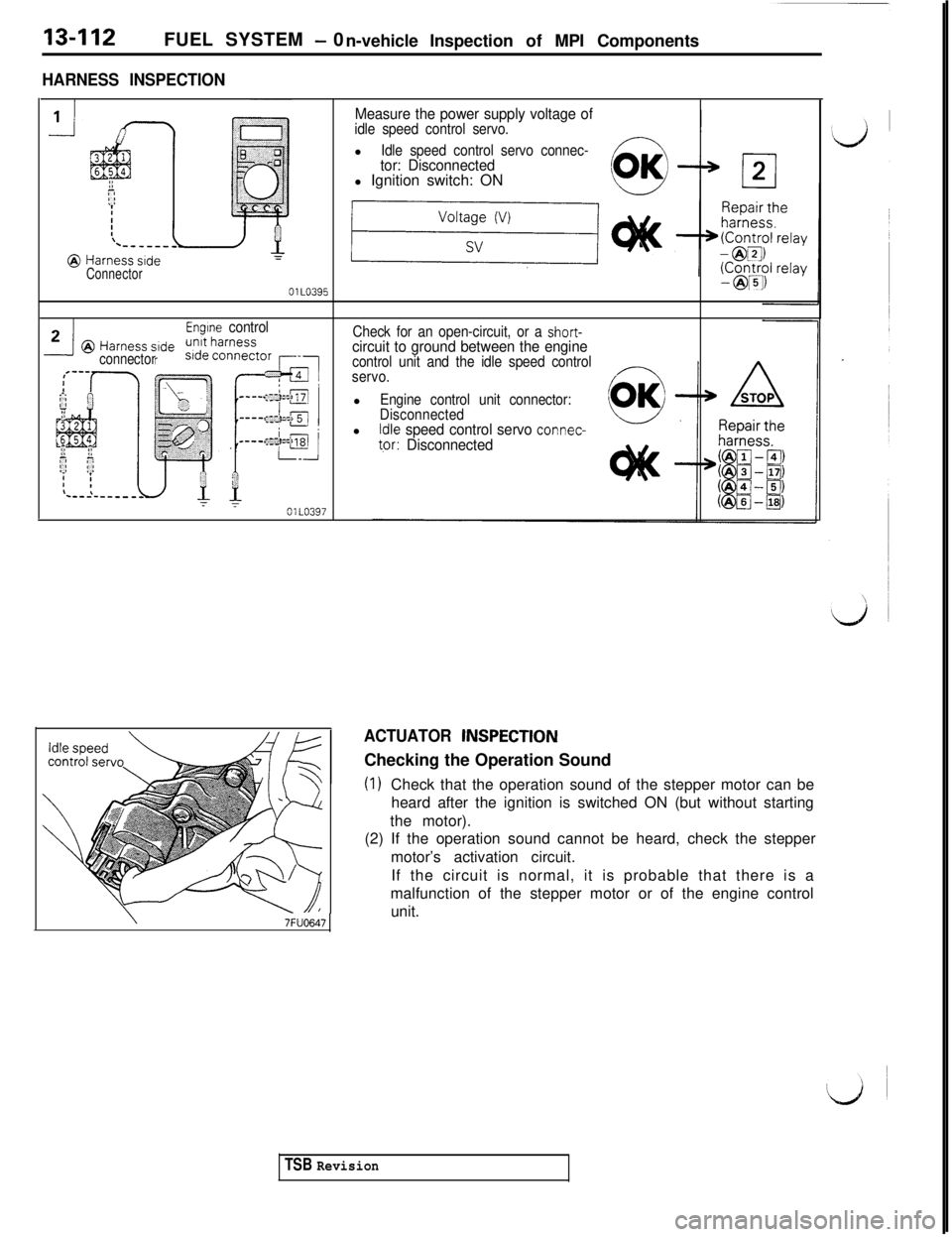

HARNESS INSPECTION

Measure the power supply voltage ofidle speed control servo.l

Idle speed control servo connec-tor: Disconnectedl Ignition switch: ON

Connector

connector

OlLO395- WI)

Engine control

Check for an open-circuit, or a short-circuit to ground between the enginecontrol unit and the idle speed control

servo.l

Engine control unit connector:

Disconnectedl

Idle speed control servo connec-tar: Disconnected

ACTUATOR I’NSPECTIONChecking the Operation Sound

(1)Check that the operation sound of the stepper motor can be

heard after the ignition is switched ON (but without starting

the motor).

(2) If the operation sound cannot be heard, check the stepper

motor’s activation circuit.

If the circuit is normal, it is probable that there is a

malfunction of the stepper motor or of the engine control

unit.

TSB Revision

Page 222 of 1146

13-116FUEL SYSTEM - 0

n-vehicle Inspection of MPI Components

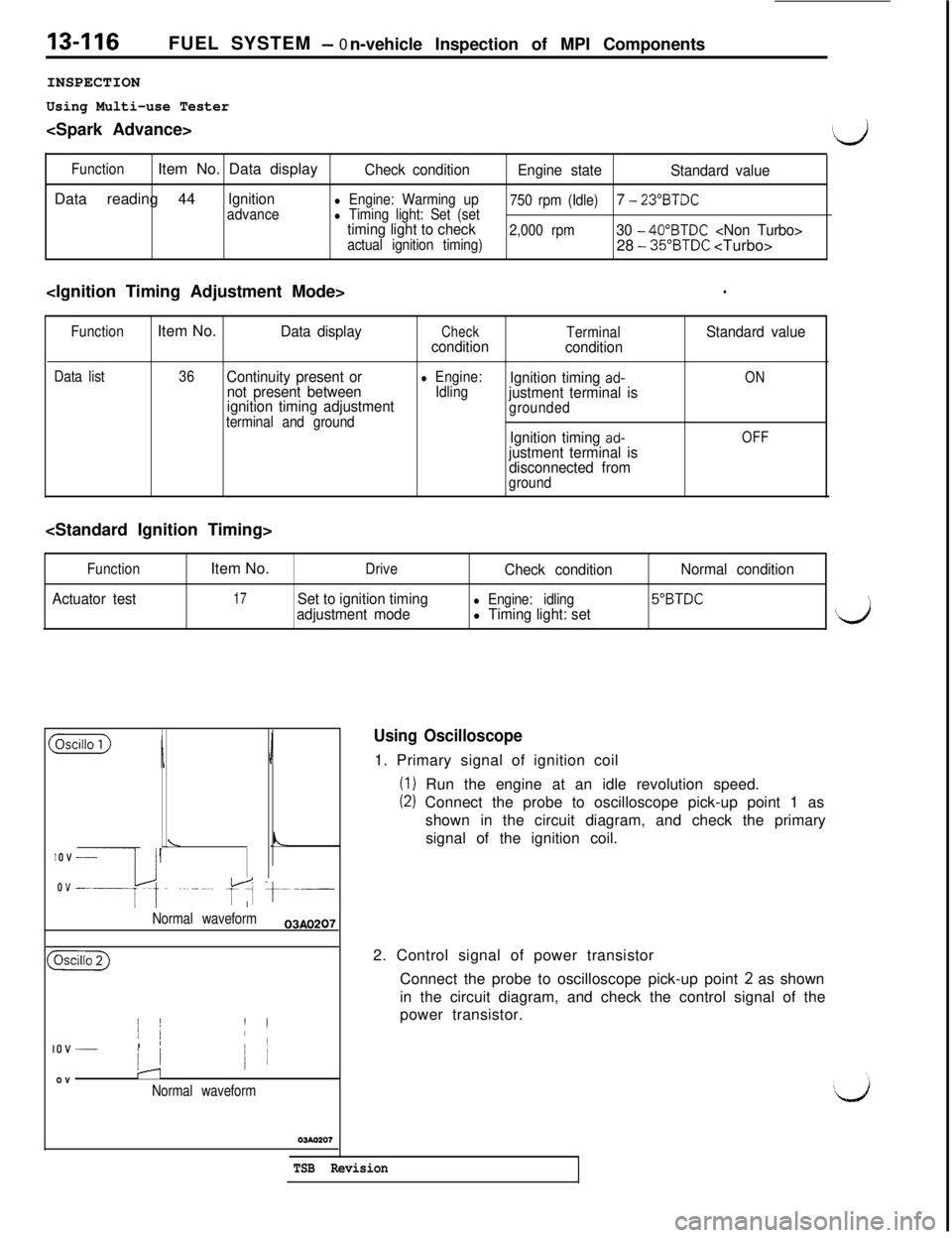

INSPECTION

Using Multi-use Tester

(d

FunctionItem No. Data displayCheck condition

Engine state

Standard valueData reading 44

Ignitionadvancel Engine: Warming up

750 rpm (Idle)7 - 23”BTDCl Timing light: Set (settiming light to check2,000 rpm30 - 40”BTDC

‘

Function

Data listItem No.Data displayCheckTerminalStandard value

condition

condition

36Continuity present or

not present betweenl Engine:

IdlingIgnition timing ad-ON

ignition timing adjustmentjustment terminal isterminal and groundgrounded

Ignition timing ad-OFFjustment terminal is

disconnected from

ground

Function

Actuator testItem No.

DriveCheck conditionNormal condition

17Set to ignition timingl Engine: idling5”BTDCadjustment model Timing light: set\

($Gizi)

IJ

\LIOV _

ovep~,. ..~_~.~ fA t---.-

I

Normal waveform03AO207

(

j /’ II

IOV _I ’/

/ 1ovIJ

Normal waveform

Using Oscilloscope1. Primary signal of ignition coil

(I) Run the engine at an idle revolution speed.

(2) Connect the probe to oscilloscope pick-up point 1 as

shown in the circuit diagram, and check the primary

signal of the ignition coil.

2. Control signal of power transistor

Connect the probe to oscilloscope pick-up point

2 as shown

in the circuit diagram, and check the control signal of the

power transistor.

TSB Revision

Page 223 of 1146

FUEL SYSTEM - On-vehicle Inspection of MPI Components13-117

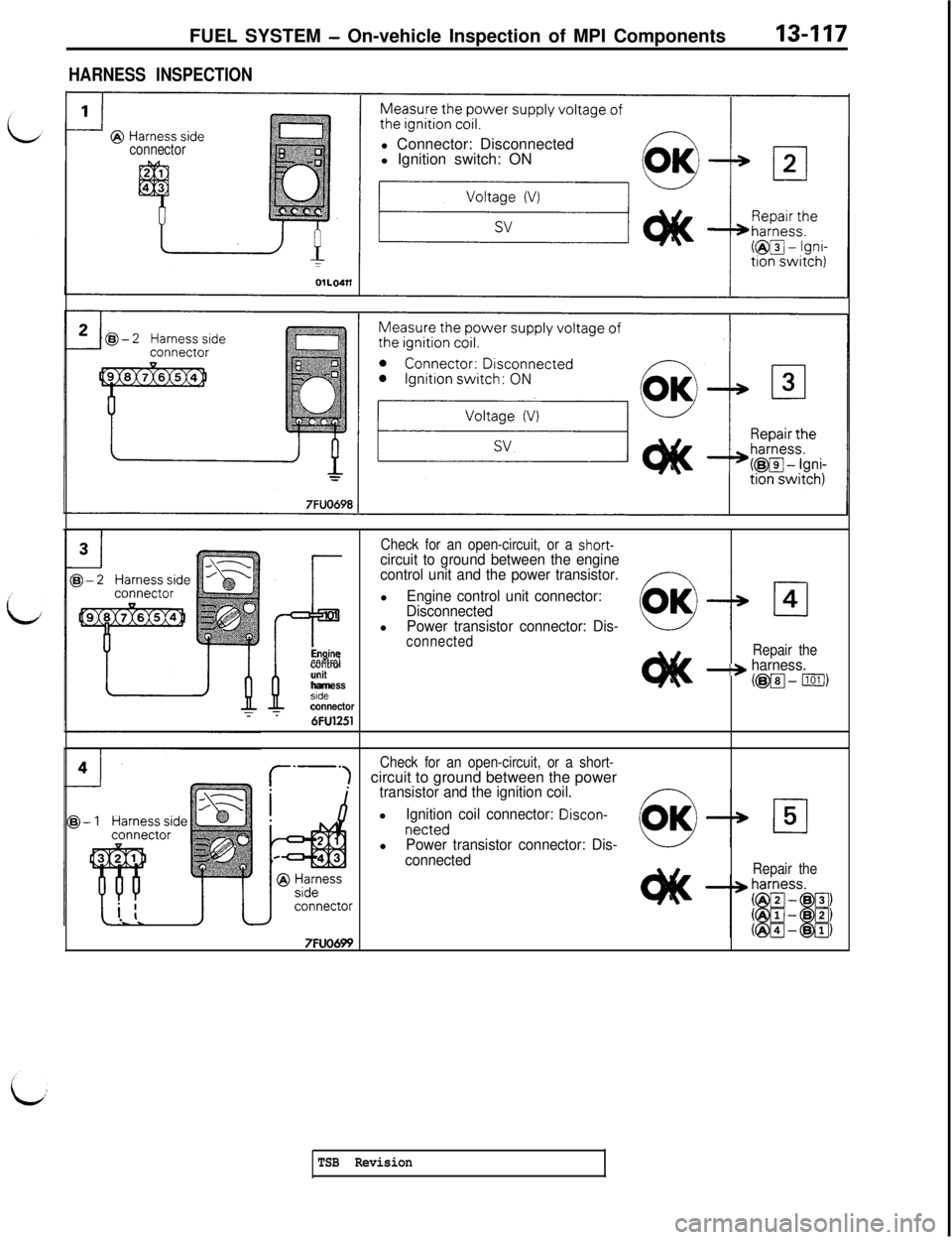

HARNESS INSPECTION

connectorl Connector: Disconnected

l Ignition switch: ON

Check for an open-circuit, or a short-

P

circuit to ground between the engine

control unit and the power transistor.l

Engine control unit connector:

Disconnectedl

Power transistor connector: Dis-connectedEngineRepair thecontrolunit-+ harness.harness(@@J-1101/)stdeconnector

T6FU1251

Check for an open-circuit, or a short-circuit to ground between the power

transistor and the ignition coil.l

Ignition coil connector: Discon-netted

l

Power transistor connector: Dis-

connected

Repair the

7FUO699

TSB Revision

Page 225 of 1146

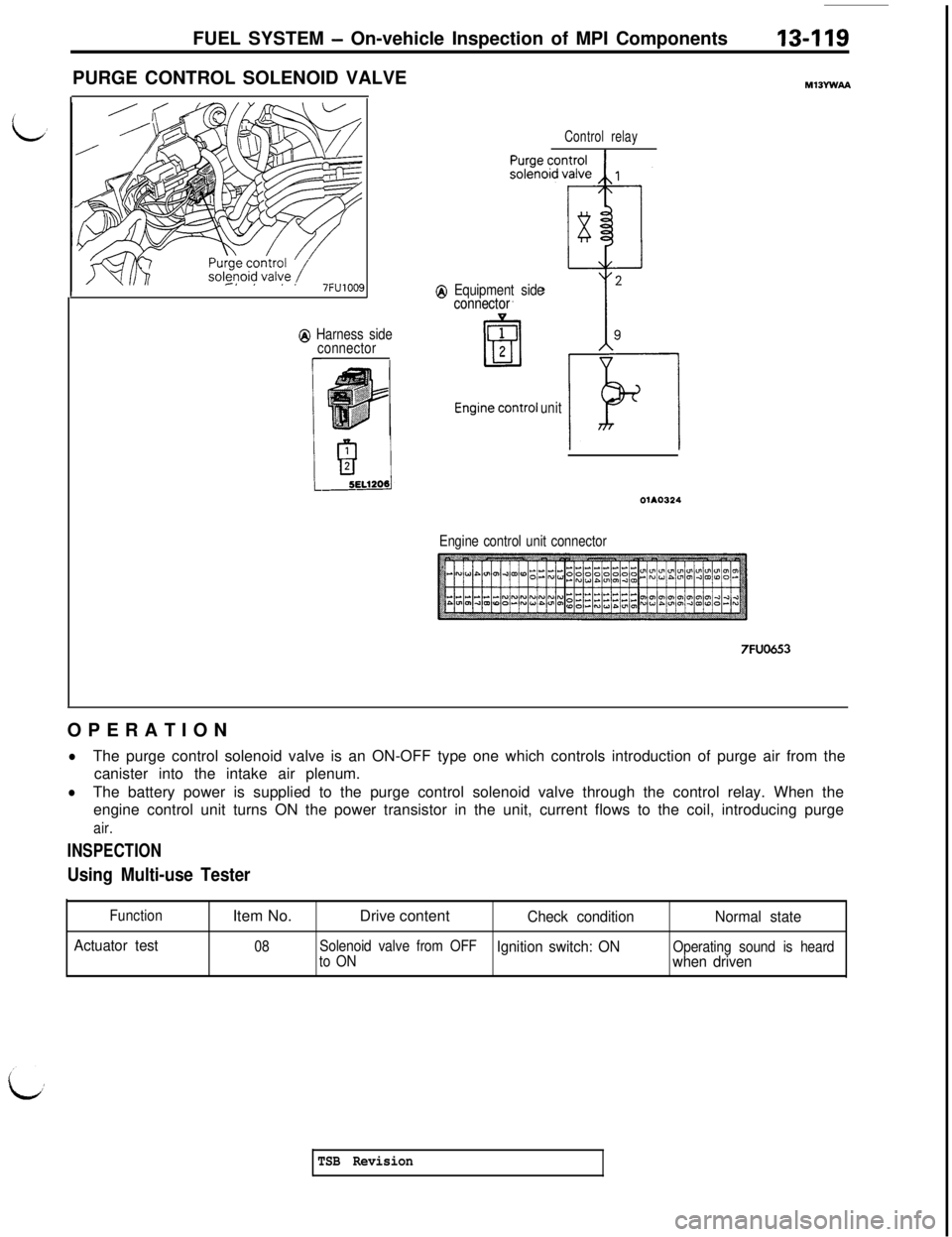

FUEL SYSTEM - On-vehicle Inspection of MPI Components13-119PURGE CONTROL SOLENOID VALVE

Q Harness side

connector

I

Control relay

@ Equipment side

connector connector

unit

OlAO324

Engine control unit connector

7FUO653OPERATION

lThe purge control solenoid valve is an ON-OFF type one which controls introduction of purge air from the

canister into the intake air plenum.

lThe battery power is supplied to the purge control solenoid valve through the control relay. When the

engine control unit turns ON the power transistor in the unit, current flows to the coil, introducing purge

air.

INSPECTION

Using Multi-use Tester

Function

Actuator testItem No.Drive content

Check conditionNormal state

08Solenoid valve from OFFIgnition switch: ONOperating sound is heard

to ONwhen driven

TSB Revision