check engine MITSUBISHI 3000GT 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 332 of 1146

INTAKE AND EXHAUST - Turbocharger (Rear)

0

Comrxessorwheel \u ~i, rOlR0182

I05FOO19

SERVICE POINT OF REMOVALM15LBAF

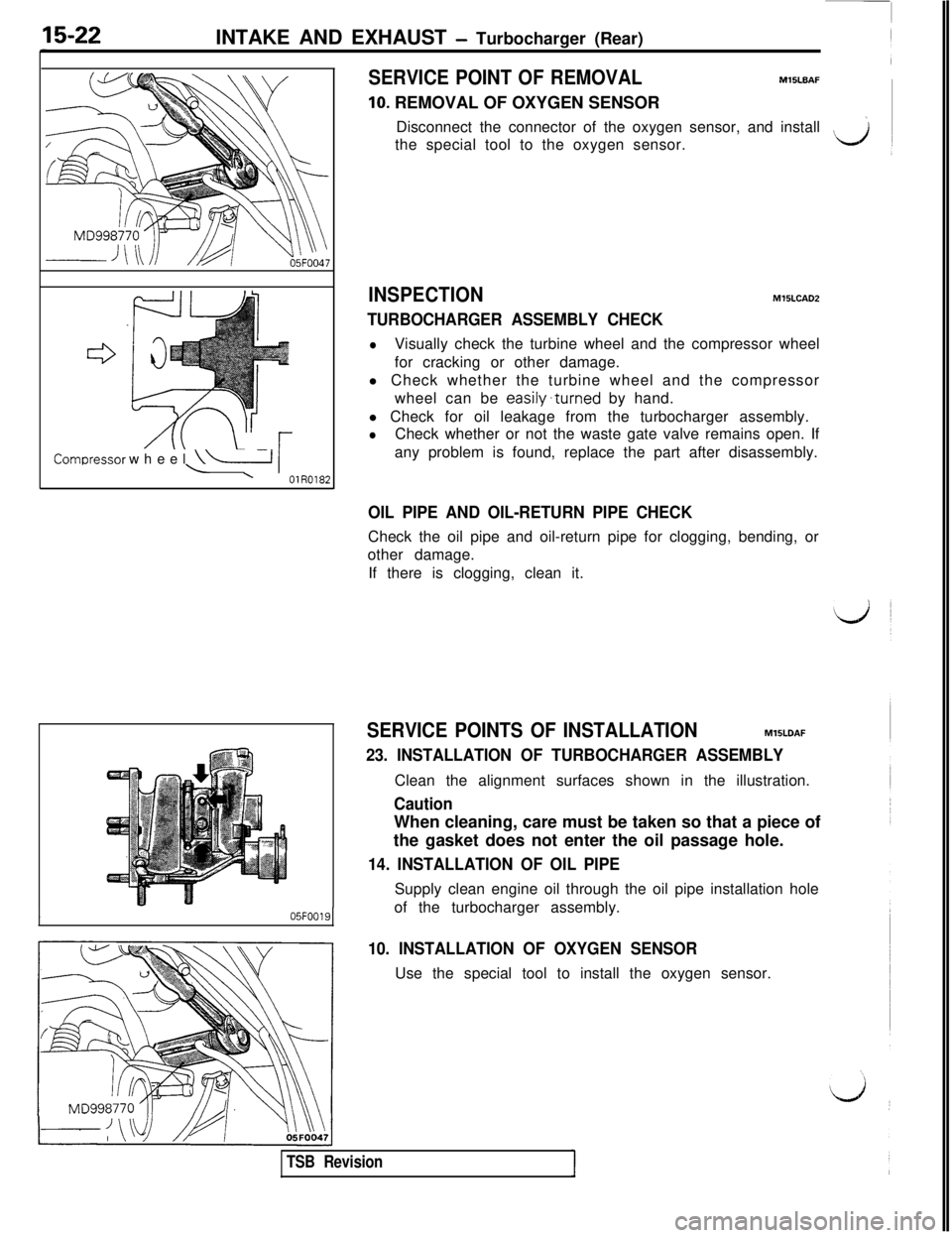

10. REMOVAL OF OXYGEN SENSOR

Disconnect the connector of the oxygen sensor, and install

’the special tool to the oxygen sensor.

d,

INSPECTION

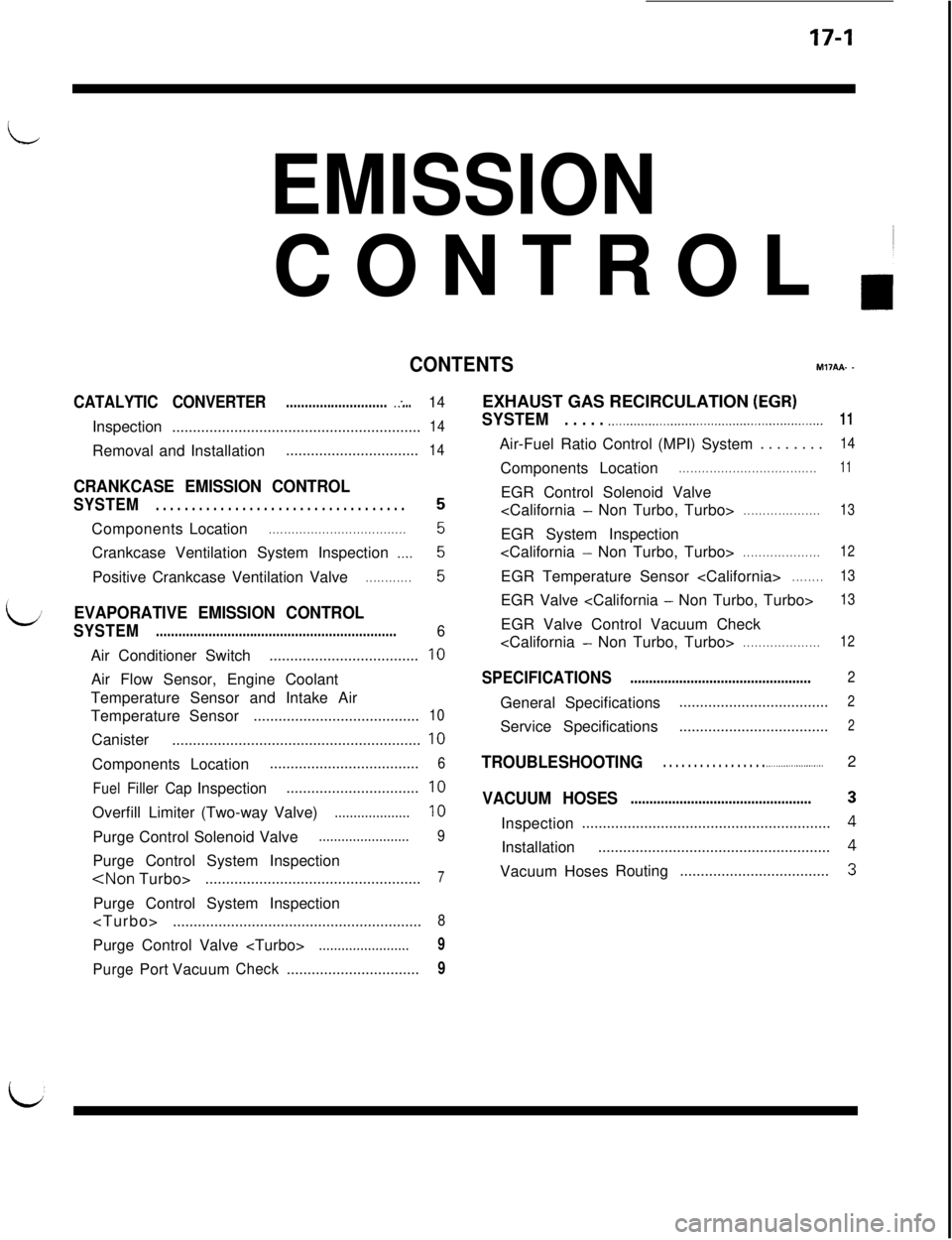

TURBOCHARGER ASSEMBLY CHECK

M15LCADZ

lVisually check the turbine wheel and the compressor wheel

for cracking or other damage.

l Check whether the turbine wheel and the compressor

wheel can be

easily.turned by hand.

l Check for oil leakage from the turbocharger assembly.

lCheck whether or not the waste gate valve remains open. If

any problem is found, replace the part after disassembly.

OIL PIPE AND OIL-RETURN PIPE CHECKCheck the oil pipe and oil-return pipe for clogging, bending, or

other damage.

If there is clogging, clean it.

SERVICE POINTS OF INSTALLATIONMlBLDAF

23. INSTALLATION OF TURBOCHARGER ASSEMBLYClean the alignment surfaces shown in the illustration.

CautionWhen cleaning, care must be taken so that a piece of

the gasket does not enter the oil passage hole.

14. INSTALLATION OF OIL PIPESupply clean engine oil through the oil pipe installation hole

of the turbocharger assembly.

10. INSTALLATION OF OXYGEN SENSORUse the special tool to install the oxygen sensor.

TSB Revision

Page 345 of 1146

17-1

EMISSIONCONTROL

.~

CATALYTIC CONVERTER............................:...Inspection

............................................................Removal and Installation

................................

CONTENTSM17.U. -

CRANKCASE EMISSION CONTROL

SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ComponentsLocation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Crankcase Ventilation System Inspection

._..Positive Crankcase Ventilation Valve

. . . . . . . . . . . .

EVAPORATIVE EMISSION CONTROL

SYSTEM................................................................Air Conditioner Switch

....................................Air Flow Sensor, Engine Coolant

Temperature Sensor and Intake Air

Temperature Sensor

........................................Canister

............................................................Components Location

....................................

FuelFiller CapInspection................................OverfillLimiter (Two-way Valve)

....................Purge Control Solenoid Valve

........................Purge Control System Inspection

............................................................Purge Control Valve

........................

PurgePort VacuumCheck................................14

14

14

6

10

10

10

6

10

10

9

7

8

9

9EXHAUST GAS RECIRCULATION

(EGR)

SYSTEM. . . . . ..____._.._........__........_____.........................Air-FuelRatio Control (MPI) System. . . . . . . .

Components Location

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .EGR Control Solenoid Valve

. . . . . . . .EGR Valve

EGR Valve Control Vacuum Check

SPECIFICATIONS................................................General Specifications

....................................Service Specifications

....................................

TROUBLESHOOTING. . . . . . . . . . . . . . . . . ..______...............

VACUUM HOSES................................................Inspection

............................................................Installation

........................................................VacuumHosesRouting

....................................

11

14

11

13

12

13

13

12

2

2

22

Page 346 of 1146

17-2EMISSION CONTROL - Specifications / Troubleshooting

SPECIFICATIONS

GENERAL SPECIFICATIONSMl’ICA- -\

Items

Crankcase emission control systemSpecifications

Closed type with positive crankcase ventilationvalve

Evaporative emission control systemCanister storage type

Canister

Charcoal type

Purge control solenoid valve

ON/OFF solenoid valve

Exhaust emission control system

Exhaust gas recirculation system

EGR valveVacuum-activated diaphragm type

EGR temperature sensor

EGR control solenoid valve

Catalytic converter

Monolith type

Location

Under floor

Turbocharger outlet (front bank and rear bank,)

and under floor

SERVICE SPECIFICATIONSMl7CB-.

ItemsSpecifications

Purge control solenoid valve coil resistance

036 - 44 [at 20°C (68”F)I\

EGR temperature sensor resistancekfl60 - 83 [at 50°C (I 22”F)]

11 - 14 [at 100°C (212”F)l

EGR control solenoid valve coil resistance1236 - 44 [at 20°C (68”F)lI

TROUBLESHOOTING

Symptom

Engine will not start

or hard to start

Rough idle or engine

stalls

Probable cause

Vacuum hose disconnected or damaged

The EGR valve is not closed

Malfunction of the purge control solenoid valve

The EGR valve is not closed

Vacuum hose disconnected or damaged

Malfunction of the positive crankcase ventilationvalveRemedy

Repair or replace

Repair or replace

Repair or replace

Repair or replace

Repair or replace

Replace

Malfunction of the purge control systemCheck the system; if there is a

problem, check its component parts

Engine hesitates or3oor acceleration

Zxcessive oil:onsumptron

Malfunction of the exhaust gas recirculation

system

Positive crankcase ventilation line cloggedCheck the system; if there is a

problem, check its component parts

Check positive crankcase

ventila-tion system

Ioor fuel mileageMalfunction of the exhaust gas recirculation

systemTSB RevisionCheck the system; if there is a

problem, check its component parts

d

Page 349 of 1146

EMISSION CONTROL - Crankcase Emission Control System17-5

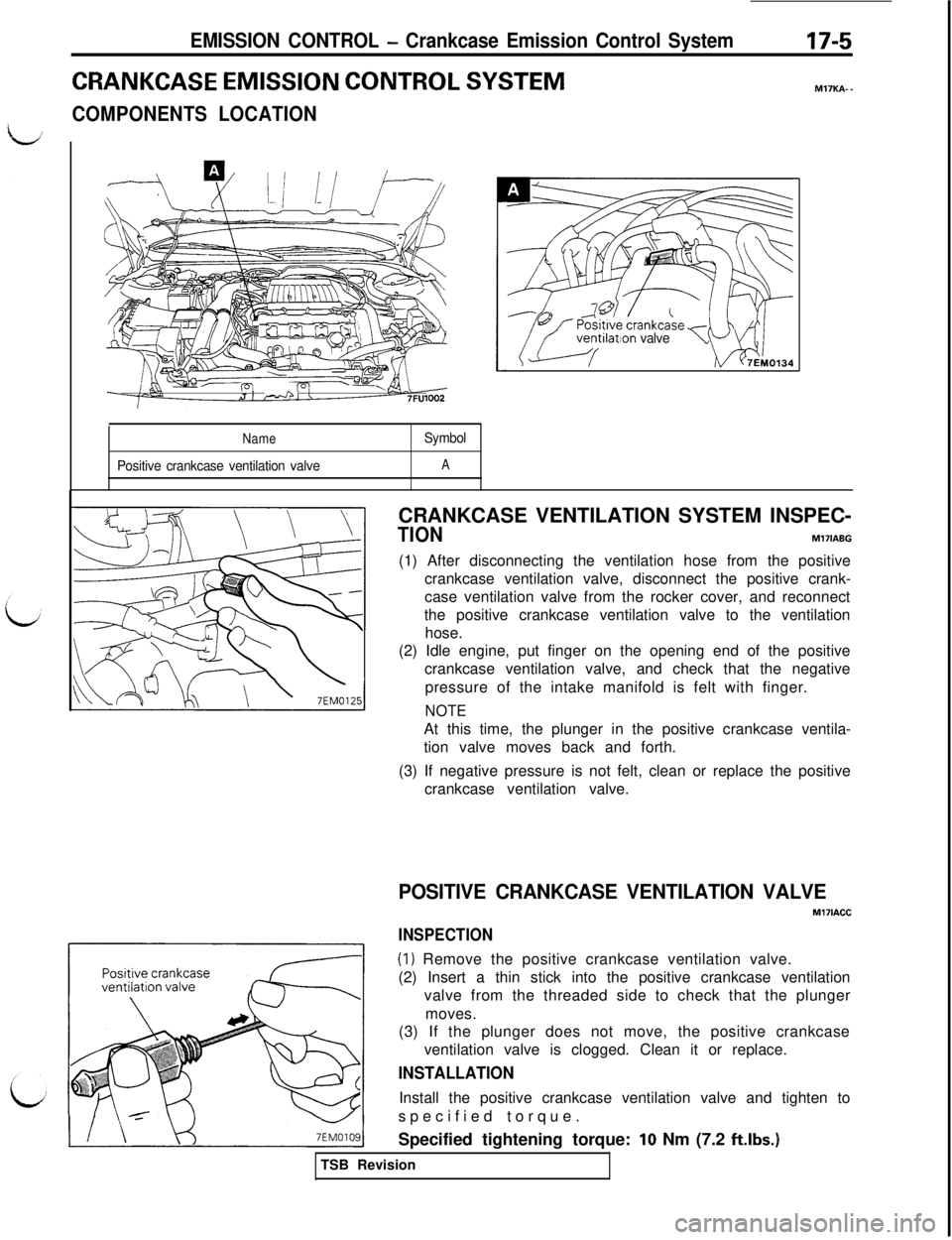

CRANKCASE EMISSION CONTROL SYSTEM

COMPONENTS LOCATIONJ

Ir--‘-l7FU1002

Name

Positive crankcase ventilation valveSymbolA

i{

ventilation valve\”

------rLYJ7EM0134M17KA--

CRANKCASE VENTILATION SYSTEM INSPEC-

TIONM171ABG(1) After disconnecting the ventilation hose from the positive

crankcase ventilation valve, disconnect the positive crank-

case ventilation valve from the rocker cover, and reconnect

the positive crankcase ventilation valve to the ventilation

hose.

(2) Idle engine, put finger on the opening end of the positive

crankcase ventilation valve, and check that the negative

pressure of the intake manifold is felt with finger.

NOTEAt this time, the plunger in the positive crankcase ventila-

tion valve moves back and forth.

(3) If negative pressure is not felt, clean or replace the positive

crankcase ventilation valve.

POSITIVE CRANKCASE VENTILATION VALVEMl7lACC

INSPECTION

(1) Remove the positive crankcase ventilation valve.

(2) Insert a thin stick into the positive crankcase ventilation

valve from the threaded side to check that the plunger

moves.

(3) If the plunger does not move, the positive crankcase

ventilation valve is clogged. Clean it or replace.

INSTALLATIONInstall the positive crankcase ventilation valve and tighten to

specified torque.

Specified tightening torque:

10 Nm (7.2 ft.lbs.1TSB Revision

Page 351 of 1146

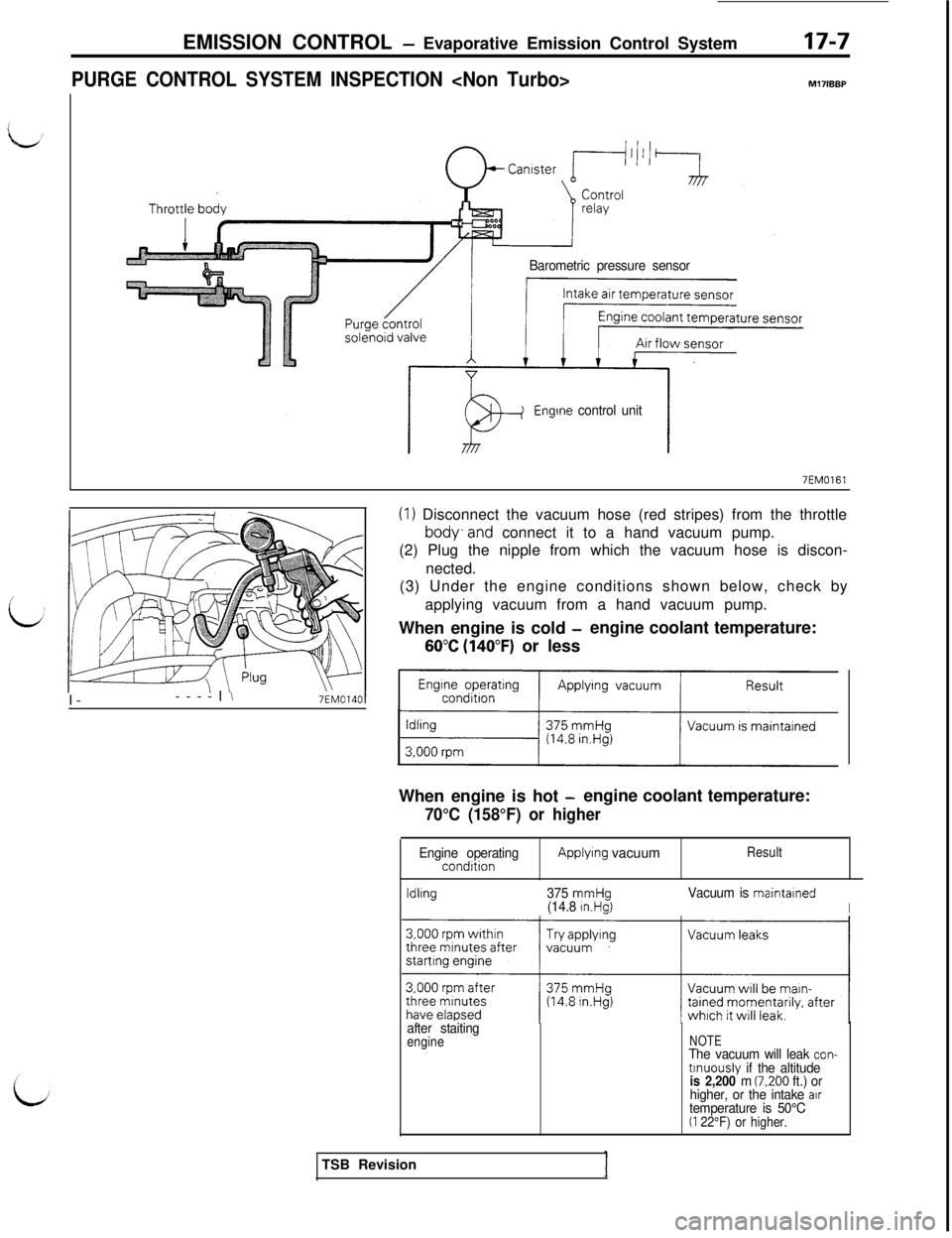

EMISSION CONTROL - Evaporative Emission Control System17-7

PURGE CONTROL SYSTEM INSPECTION

Barometric pressure sensor

Engine control unit

7EM0161I-----I

\7EM0140t

(1) Disconnect the vacuum hose (red stripes) from the throttle

body,and connect it to a hand vacuum pump.

(2) Plug the nipple from which the vacuum hose is discon-

nected.

(3) Under the engine conditions shown below, check by

applying vacuum from a hand vacuum pump.

When engine is cold

-engine coolant temperature:

60°C (140°F) or less

When engine is hot

-engine coolant temperature:

70°C (158°F) or higher

Engine operatingcondttionApplying vacuumResult

ldllng375 mmHg(14.8 In.Hg)Vacuum is maintalned

I

after staitingengineNOTEThe vacuum will leak con-tenuously if the altitudeis 2,200 m (7.200 ft.) or

higher, or the intake airtemperature is 50°C(I 22°F) or higher.TSB Revision

Page 352 of 1146

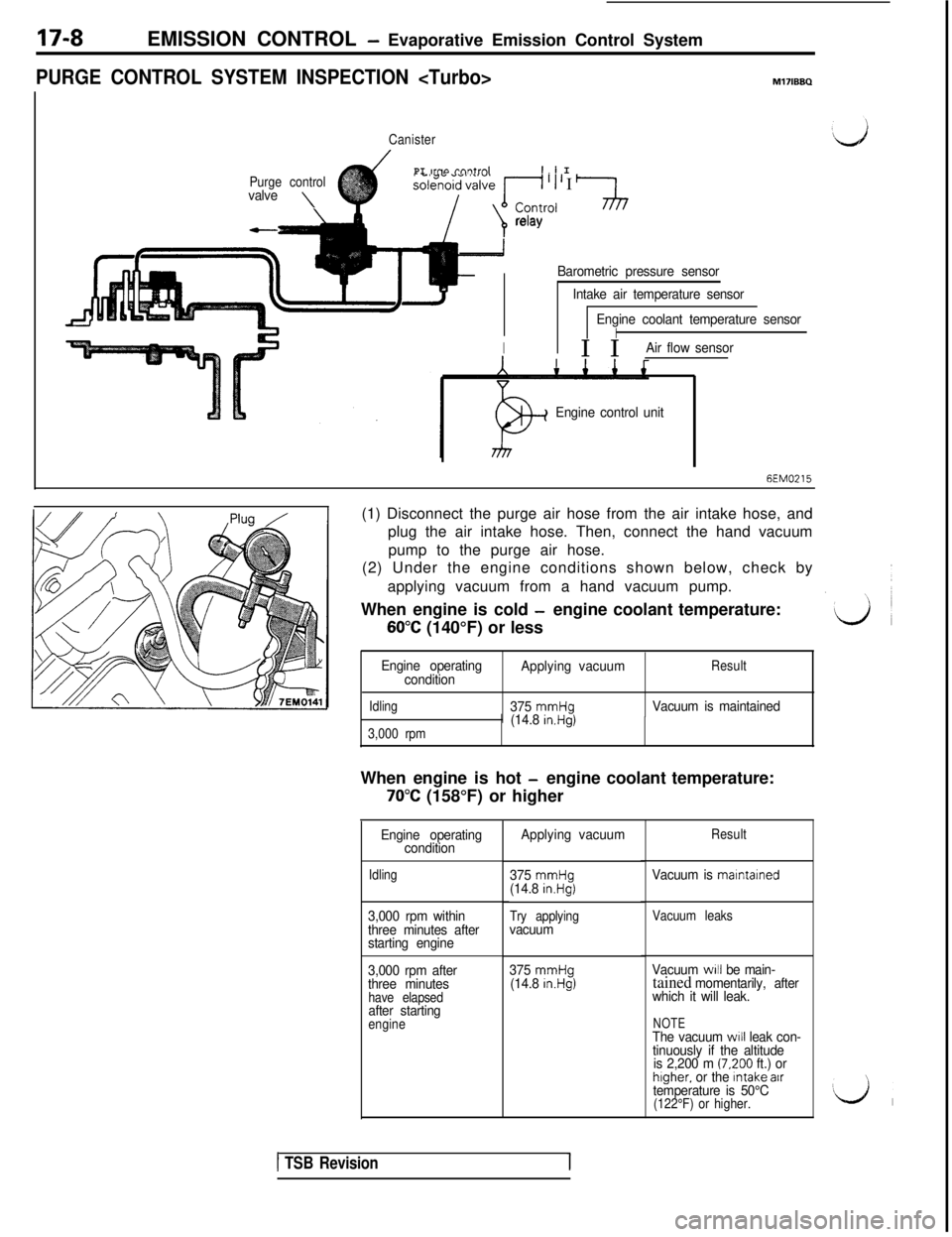

17-8EMISSION CONTROL - Evaporative Emission Control System

PURGE CONTROL SYSTEM INSPECTION

Canister

Purge control

valve\

PI IrnQ rnntrnlI.1 I

kXffo~~~~r~~ ’ I I-J

relay

Barometric pressure sensor

Intake air temperature sensor

Engine coolant temperature sensor

II1 I IAir flow sensor

Engine control unit

6EM0215(1) Disconnect the purge air hose from the air intake hose, and

plug the air intake hose. Then, connect the hand vacuum

pump to the purge air hose.

(2) Under the engine conditions shown below, check by

applying vacuum from a hand vacuum pump.

When engine is cold

-engine coolant temperature:

60°C (140°F) or less

Engine operating

conditionApplying vacuumResult

Idling

375 mmHgVacuum is maintained

3,000 rpm(14.8 in.Hg)When engine is hot

-engine coolant temperature:

70°C (158°F) or higher

Engine operating

condition

Idling

3,000 rpm within

three minutes after

starting engine

3,000 rpm after

three minutes

have elapsedafter startingengine

Applying vacuum

375

mmHg(14.8 in.Hg)

Try applyingvacuum

375

mmHg(14.8 in.Hg)

Result

Vacuum is marntained

Vacuum leaks

Vacuum WIII be main-tained momentarily, after

which it will leak.

NOTEThe vacuum WIII leak con-

tinuously if the altitude

is 2,200 m

(7,200 ft.) orhrgher. or the Intake arrtemperature is 50°C(122°F) or higher.

1 TSB Revision

Page 353 of 1146

EMISSION CONTROL - EvaporativeEmission Control System

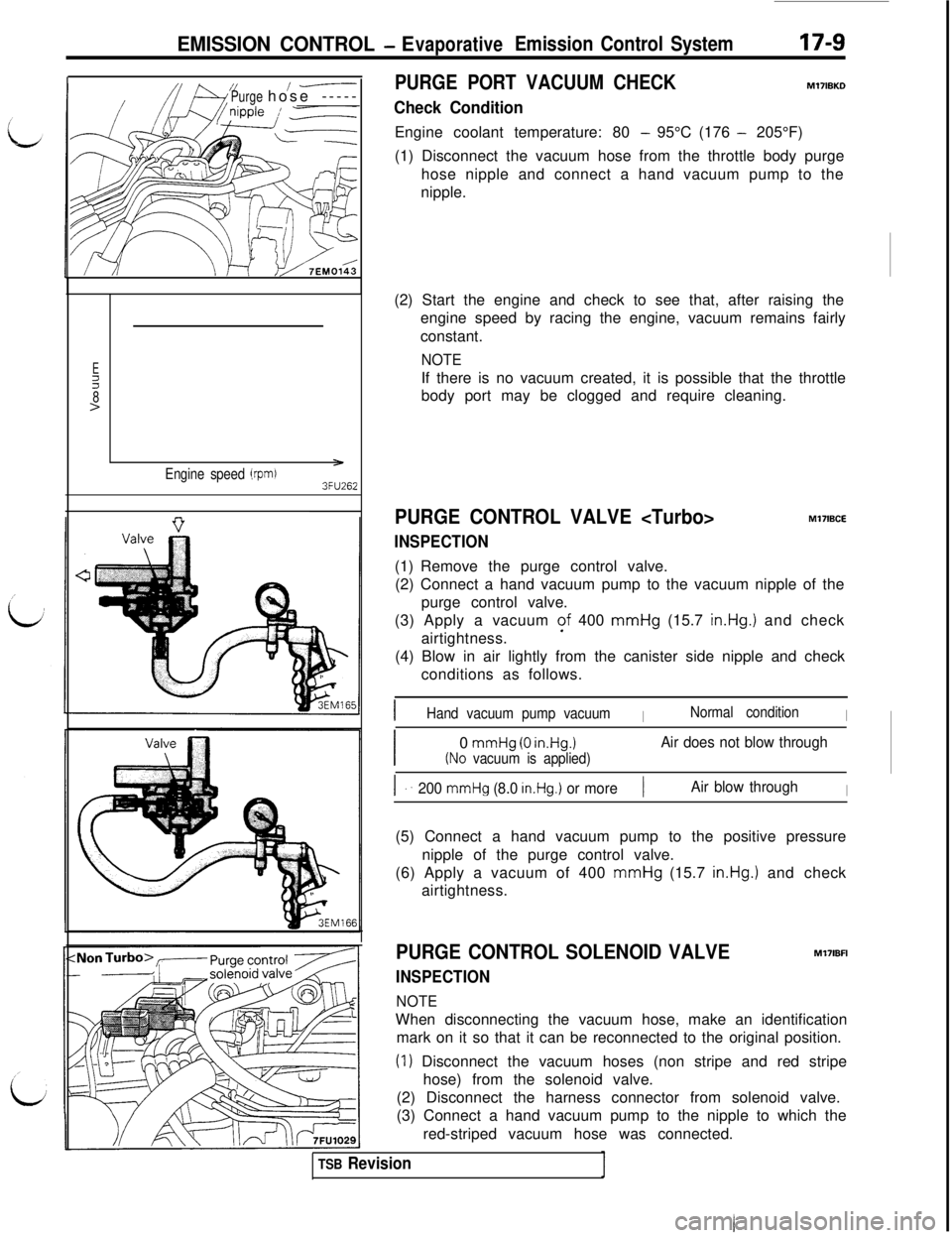

Purge/-----hose -----PURGE PORT VACUUM CHECK

Check Condition

17-9

M17lBKDEngine coolant temperature: 80

- 95°C (176 - 205°F)

(1) Disconnect the vacuum hose from the throttle body purge

hose nipple and connect a hand vacuum pump to the

nipple.

Ez8>

Engine speed (rprd3FU262(2) Start the engine and check to see that, after raising the

engine speed by racing the engine, vacuum remains fairly

constant.

NOTEIf there is no vacuum created, it is possible that the throttle

body port may be clogged and require cleaning.

PURGE CONTROL VALVE

INSPECTIONMl7IBCE

(1) Remove the purge control valve.

(2) Connect a hand vacuum pump to the vacuum nipple of the

purge control valve.

(3) Apply a vacuum of 400 mmHg (15.7

in.Hg.1 and check

airtightness.

(4) Blow in air lightly from the canister side nipple and check

conditions as follows.

IHand vacuum pump vacuumINormal conditionI

I0

mmHg (0 in.Hg.1Air does not blow through

(No vacuum is applied)

I ..200 mmHg (8.0 in.Hg.) or more1Air blow throughI(5) Connect a hand vacuum pump to the positive pressure

nipple of the purge control valve.

(6) Apply a vacuum of 400 mmHg (15.7

in.Hg.1 and check

airtightness.

PURGE CONTROL SOLENOID VALVE

INSPECTION

NOTEMl7lBFI

When disconnecting the vacuum hose, make an identification

mark on it so that it can be reconnected to the original position.

(I) Disconnect the vacuum hoses (non stripe and red stripe

hose) from the solenoid valve.

(2) Disconnect the harness connector from solenoid valve.

(3) Connect a hand vacuum pump to the nipple to which the

red-striped vacuum hose was connected.

TSB Revision

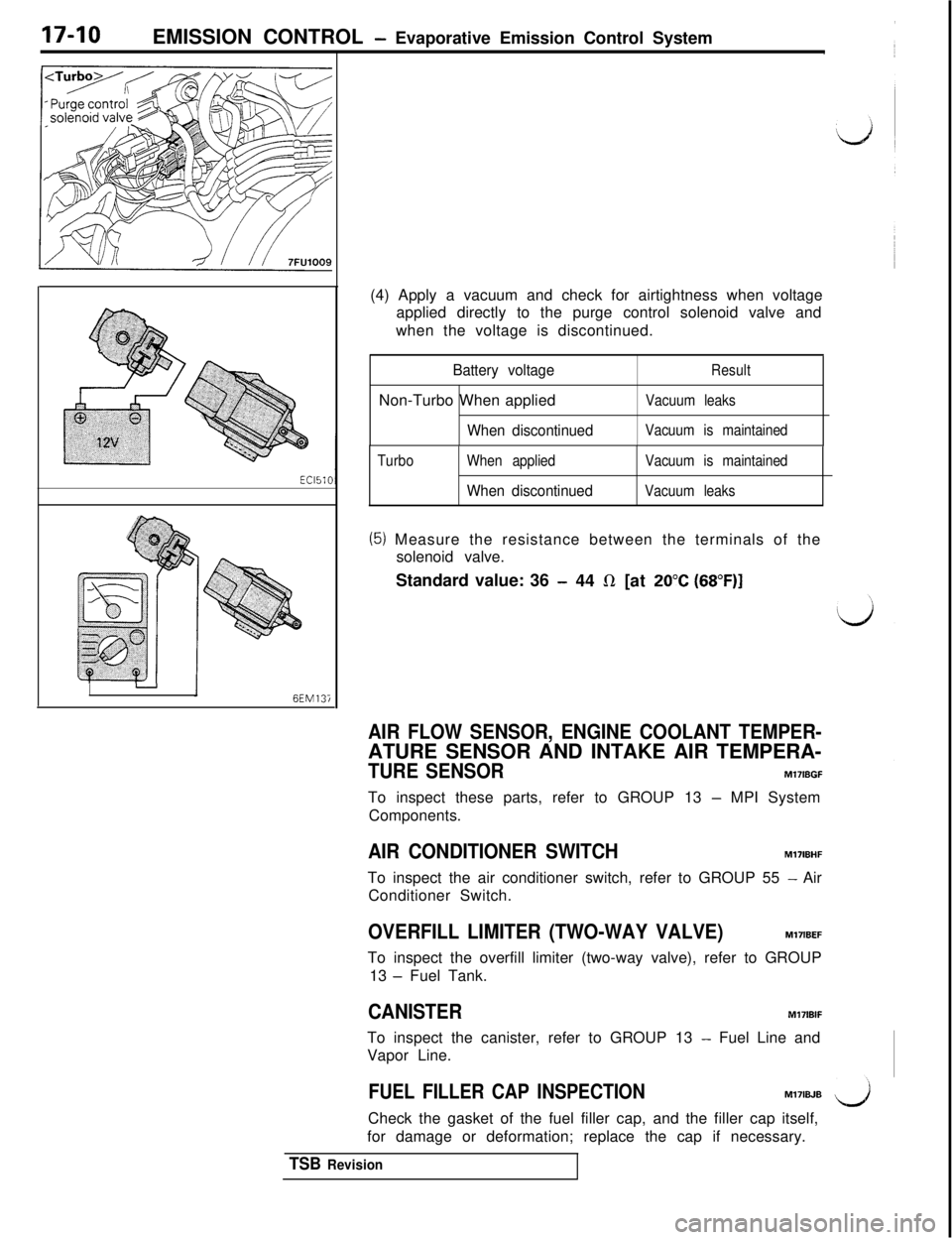

Page 354 of 1146

17-10EMISSION CONTROL - Evaporative Emission Control System

I-6EM13i(4) Apply a vacuum and check for airtightness when voltage

applied directly to the purge control solenoid valve and

when the voltage is discontinued.

Battery voltageResultNon-Turbo When applied

Vacuum leaks

When discontinuedVacuum is maintained

TurboWhen applied

When discontinued

Vacuum is maintained

Vacuum leaks

(5) Measure the resistance between the terminals of the

solenoid valve.

Standard value: 36

- 44 R [at 20°C (68”F)]

AIR FLOW SENSOR, ENGINE COOLANT TEMPER-ATURE SENSOR AND INTAKE AIR TEMPERA-

TURE SENSORM17lBGFTo inspect these parts, refer to GROUP 13

- MPI System

Components.

AIR CONDITIONER SWITCHMl7IBHF

To inspect the air conditioner switch, refer to GROUP 55

- Air

Conditioner Switch.

OVERFILL LIMITER (TWO-WAY VALVE)M17IBEFTo inspect the overfill limiter (two-way valve), refer to GROUP

13

- Fuel Tank.

CANISTERM17lBIFTo inspect the canister, refer to GROUP 13

- Fuel Line and

Vapor Line.

FUEL FILLER CAP INSPECTIONM17IBJBCheck the gasket of the fuel filler cap, and the filler cap itself,

for damage or deformation; replace the cap if necessary.

TSB Revision

Page 356 of 1146

17-12EMISSION CONTROL - Exhaust Gas Recirculation (EGR) System

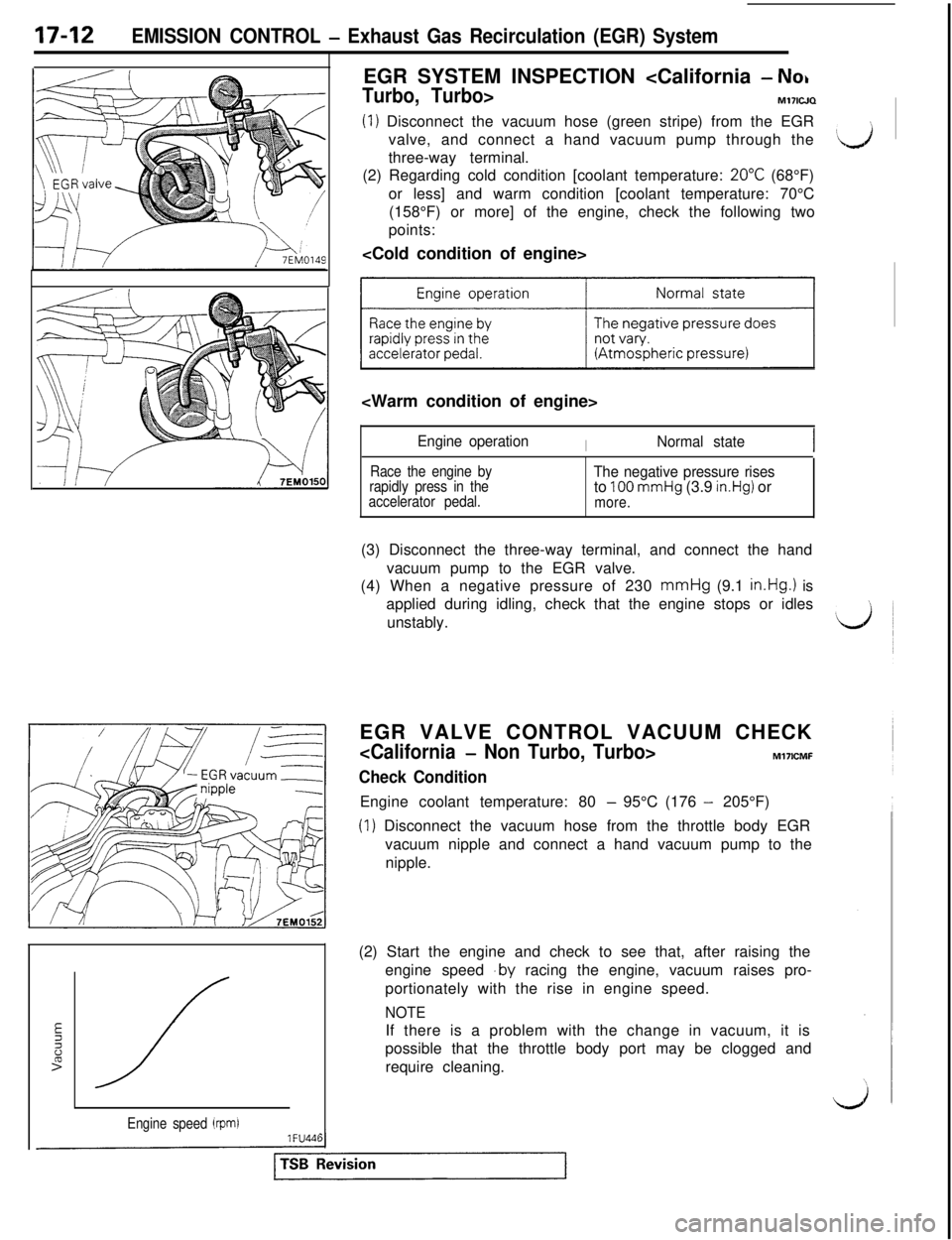

Engine speed (rpm)1 FU44lEGR SYSTEM INSPECTION

Turbo, Turbo>M171WQ

(1) Disconnect the vacuum hose (green stripe) from the EGR

valve, and connect a hand vacuum pump through the

three-way terminal.

(2) Regarding cold condition [coolant temperature:

20°C (68°F)

or less] and warm condition [coolant temperature: 70°C

(158°F) or more] of the engine, check the following two

points:

~1

Engine operationINormal state

Race the engine by

rapidly press in the

accelerator pedal.The negative pressure risesto 100 mmHg (3.9 in.Hg) ormore.(3) Disconnect the three-way terminal, and connect the hand

vacuum pump to the EGR valve.

(4) When a negative pressure of 230 mmHg (9.1

in.Hg.1 is

applied during idling, check that the engine stops or idles

unstably.

EGR VALVE CONTROL VACUUM CHECK

Check ConditionEngine coolant temperature: 80

- 95°C (176 - 205°F)

(1) Disconnect the vacuum hose from the throttle body EGR

vacuum nipple and connect a hand vacuum pump to the

nipple.

(2) Start the engine and check to see that, after raising the

engine speed

.by racing the engine, vacuum raises pro-

portionately with the rise in engine speed.

NOTEIf there is a problem with the change in vacuum, it is

possible that the throttle body port may be clogged and

require cleaning.

Page 358 of 1146

17-14 EMISSION CONTROL -Exhaust Gas Recirculation (EGR) System / Catalytic Converter

6EM01871

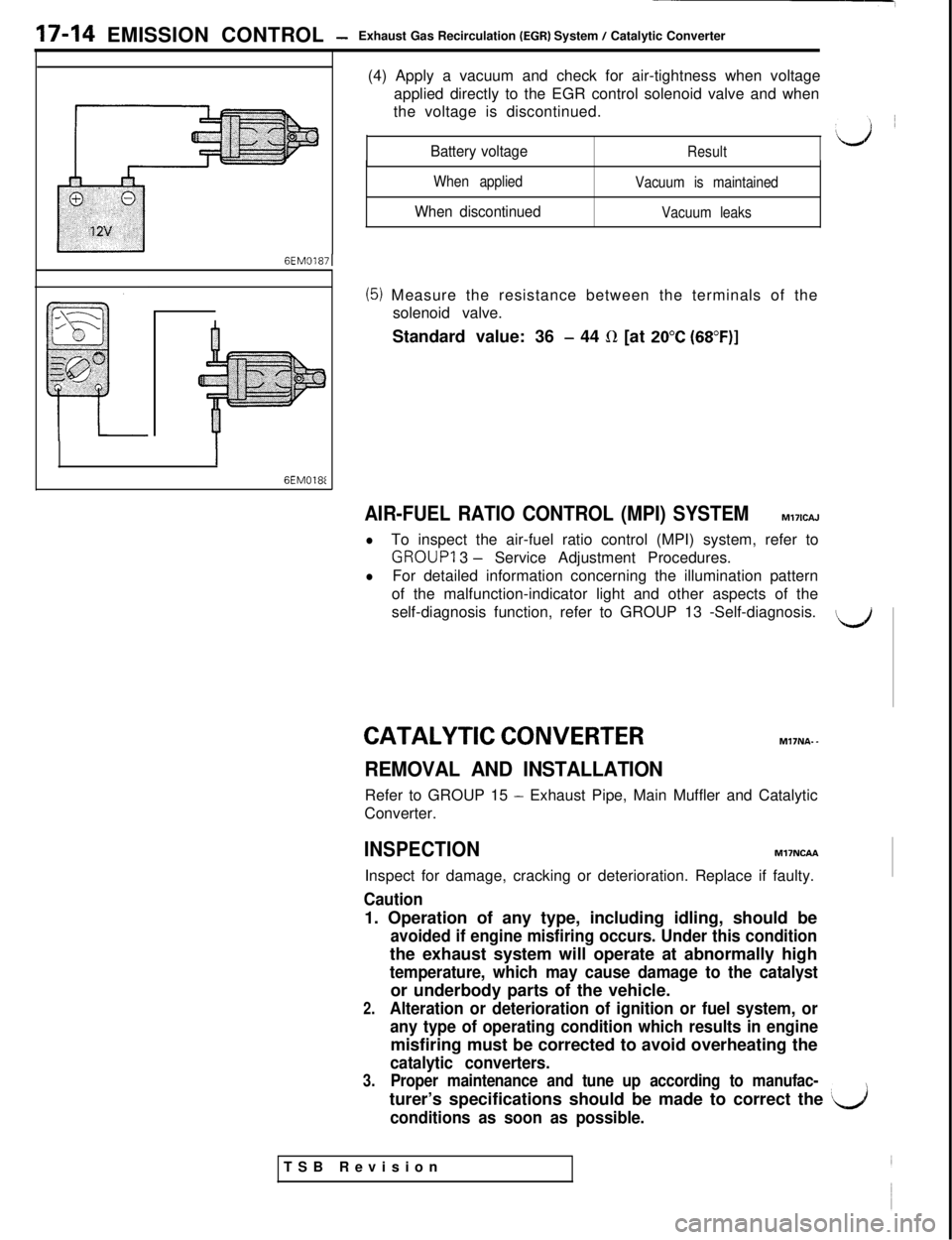

6EM0181(4) Apply a vacuum and check for air-tightness when voltage

applied directly to the EGR control solenoid valve and when

the voltage is discontinued.

Battery voltageResult

When applied

When discontinued

Vacuum is maintained

Vacuum leaks

(5) Measure the resistance between the terminals of the

solenoid valve.

Standard value: 36

- 44 R [at 20°C (68”F)]

AIR-FUEL RATIO CONTROL (MPI) SYSTEMM17ICAJ

lTo inspect the air-fuel ratio control (MPI) system, refer to

GROUP1 3 - Service Adjustment Procedures.

lFor detailed information concerning the illumination pattern

of the malfunction-indicator light and other aspects of the

self-diagnosis function, refer to GROUP 13 -Self-diagnosis.

\.J

CATALYTIC CONVERTERMl7N& -

REMOVAL AND INSTALLATIONRefer to GROUP 15

- Exhaust Pipe, Main Muffler and Catalytic

Converter.

INSPECTIONMl7NCAA

Inspect for damage, cracking or deterioration. Replace if faulty.

Caution1. Operation of any type, including idling, should be

avoided if engine misfiring occurs. Under this conditionthe exhaust system will operate at abnormally high

temperature, which may cause damage to the catalystor underbody parts of the vehicle.

2.Alteration or deterioration of ignition or fuel system, or

any type of operating condition which results in enginemisfiring must be corrected to avoid overheating the

catalytic converters.

3.Proper maintenance and tune up according to manufac-turer’s specifications should be made to correct the

‘bi

conditions as soon as possible.TSB Revision