engine coolant MITSUBISHI 3000GT 1991 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 65 of 1146

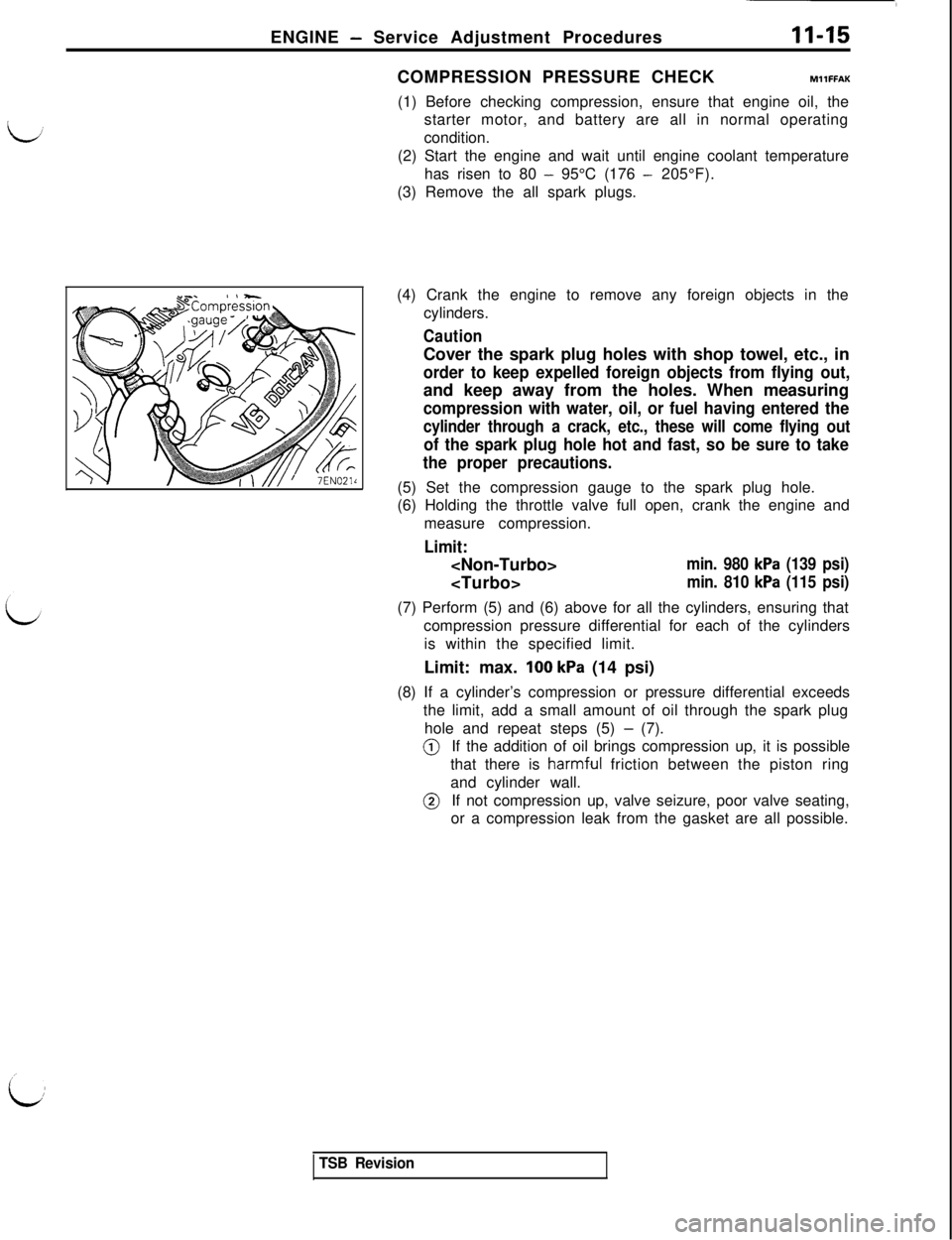

ENGINE - Service Adjustment Procedures11-15COMPRESSION PRESSURE CHECKMllFFAK

(1) Before checking compression, ensure that engine oil, the

starter motor, and battery are all in normal operating

condition.

(2) Start the engine and wait until engine coolant temperature

has risen to 80

- 95°C (176 - 205°F).

(3) Remove the all spark plugs.

(4) Crank the engine to remove any foreign objects in the

cylinders.

CautionCover the spark plug holes with shop towel, etc., in

order to keep expelled foreign objects from flying out,and keep away from the holes. When measuring

compression with water, oil, or fuel having entered the

cylinder through a crack, etc., these will come flying out

of the spark plug hole hot and fast, so be sure to take

the proper precautions.(5) Set the compression gauge to the spark plug hole.

(6) Holding the throttle valve full open, crank the engine and

measure compression.

Limit:

min. 980 kPa (139 psi)

min. 810 kPa (115 psi)(7) Perform (5) and (6) above for all the cylinders, ensuring that

compression pressure differential for each of the cylinders

is within the specified limit.

Limit: max.

100 kPa (14 psi)

(8) If a cylinder’s compression or pressure differential exceeds

the limit, add a small amount of oil through the spark plug

hole and repeat steps (5)

- (7).@If the addition of oil brings compression up, it is possible

that there is

harmf,uI friction between the piston ring

and cylinder wall.@If not compression up, valve seizure, poor valve seating,

or a compression leak from the gasket are all possible.

TSB Revision

Page 66 of 1146

11-16ENGINE - Service Adjustment Procedures

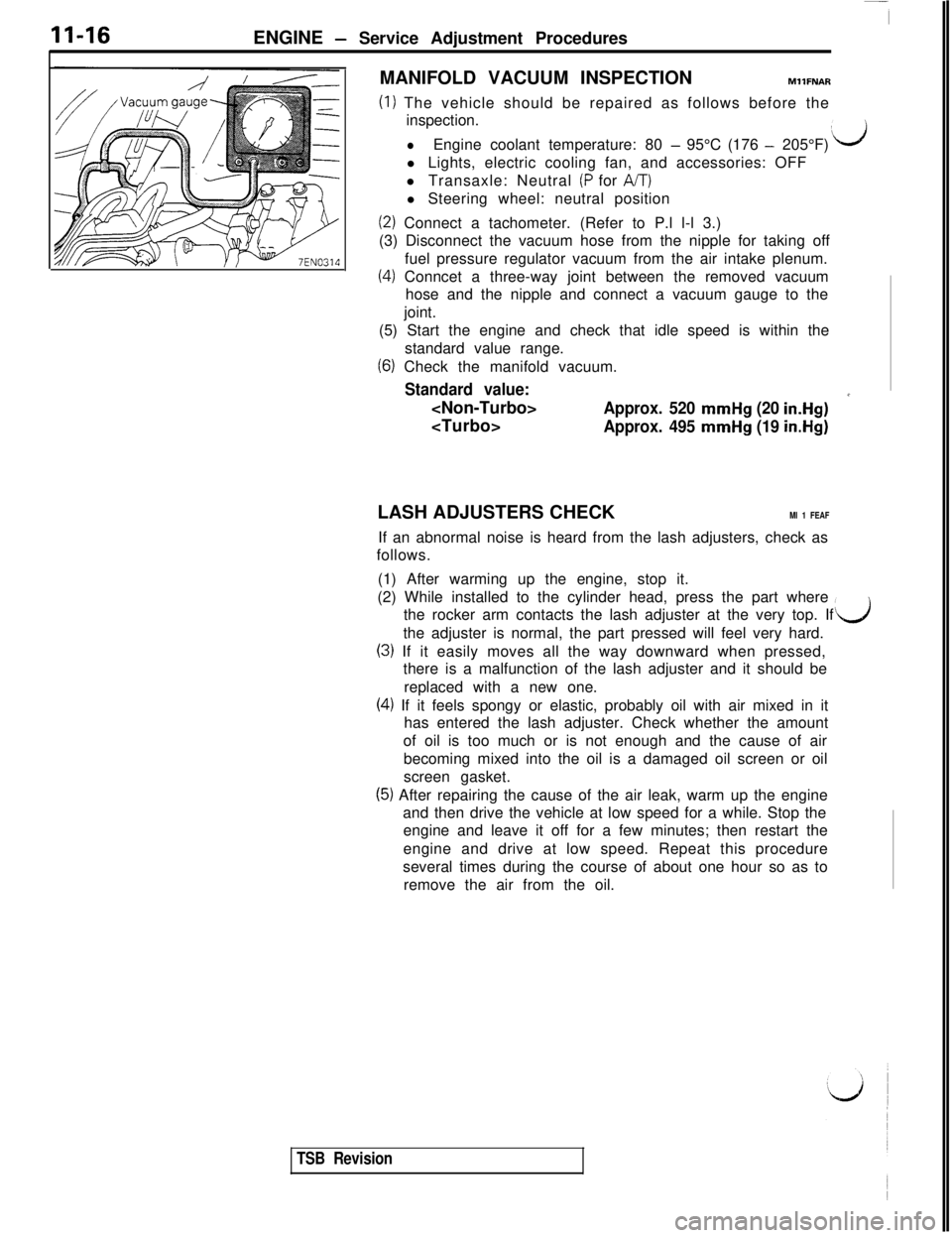

MANIFOLD VACUUM INSPECTION

MllFNAR

(1) The vehicle should be repaired as follows before the

inspection.

lEngine coolant temperature: 80 - 95°C (176 - 205°F)‘dl Lights, electric cooling fan, and accessories: OFF

l Transaxle: Neutral

(P for A/T)l Steering wheel: neutral position

(2) Connect a tachometer. (Refer to P.l l-l 3.)

(3) Disconnect the vacuum hose from the nipple for taking off

fuel pressure regulator vacuum from the air intake plenum.

(4) Conncet a three-way joint between the removed vacuum

hose and the nipple and connect a vacuum gauge to the

joint.

(5) Start the engine and check that idle speed is within the

standard value range.

(6) Check the manifold vacuum.

Standard value:

*

Approx. 495 mmHg (19 in.Hg)LASH ADJUSTERS CHECK

Ml 1 FEAFIf an abnormal noise is heard from the lash adjusters, check as

follows.

(1) After warming up the engine, stop it.

(2) While installed to the cylinder head, press the part where

the rocker arm contacts the lash adjuster at the very top. If

the adjuster is normal, the part pressed will feel very hard.

d

(3) If it easily moves all the way downward when pressed,

there is a malfunction of the lash adjuster and it should be

replaced with a new one.

(4) If it feels spongy or elastic, probably oil with air mixed in it

has entered the lash adjuster. Check whether the amount

of oil is too much or is not enough and the cause of air

becoming mixed into the oil is a damaged oil screen or oil

screen gasket.

(5) After repairing the cause of the air leak, warm up the engine

and then drive the vehicle at low speed for a while. Stop the

engine and leave it off for a few minutes; then restart the

engine and drive at low speed. Repeat this procedure

several times during the course of about one hour so as to

remove the air from the oil.

TSB Revision

Page 68 of 1146

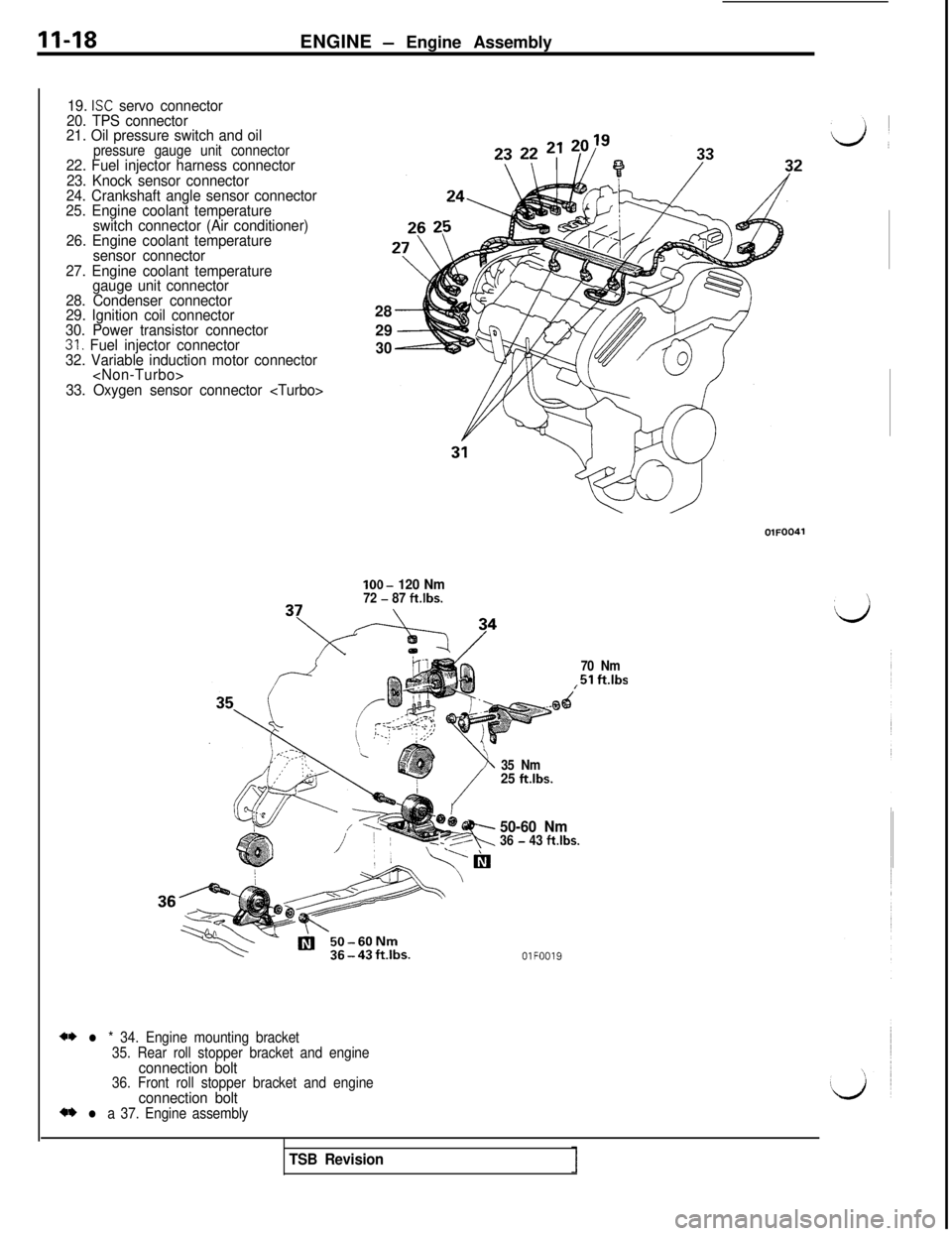

II-18ENGINE - Engine Assembly

19. ISC servo connector

20. TPS connector

21. Oil pressure switch and oil

pressure gauge unit connector22. Fuel injector harness connector

23. Knock sensor connector

24. Crankshaft angle sensor connector

25. Engine coolant temperature

switch connector (Air conditioner)

26. Engine coolant temperature

sensor connector

27. Engine coolant temperature

gauge unit connector

28. Condenser connector

29. Ignition coil connector

30. Power transistor connector

31. Fuel injector connector

32. Variable induction motor connector

33. Oxygen sensor connector

2930lOO-

120 Nm72 - 87 ft.lbs.

70 Nm

,51 ftlbs

** l * 34. Engine mounting bracket

35. Rear roll stopper bracket and engine

connection bolt36. Front roll stopper bracket and engineconnection bolt** l a 37. Engine assembly35 Nm

25 ft.lbs.

?I,---R

50-60 Nm36 - 43 ftlbs.

OlFOO19

TSB Revision

Page 73 of 1146

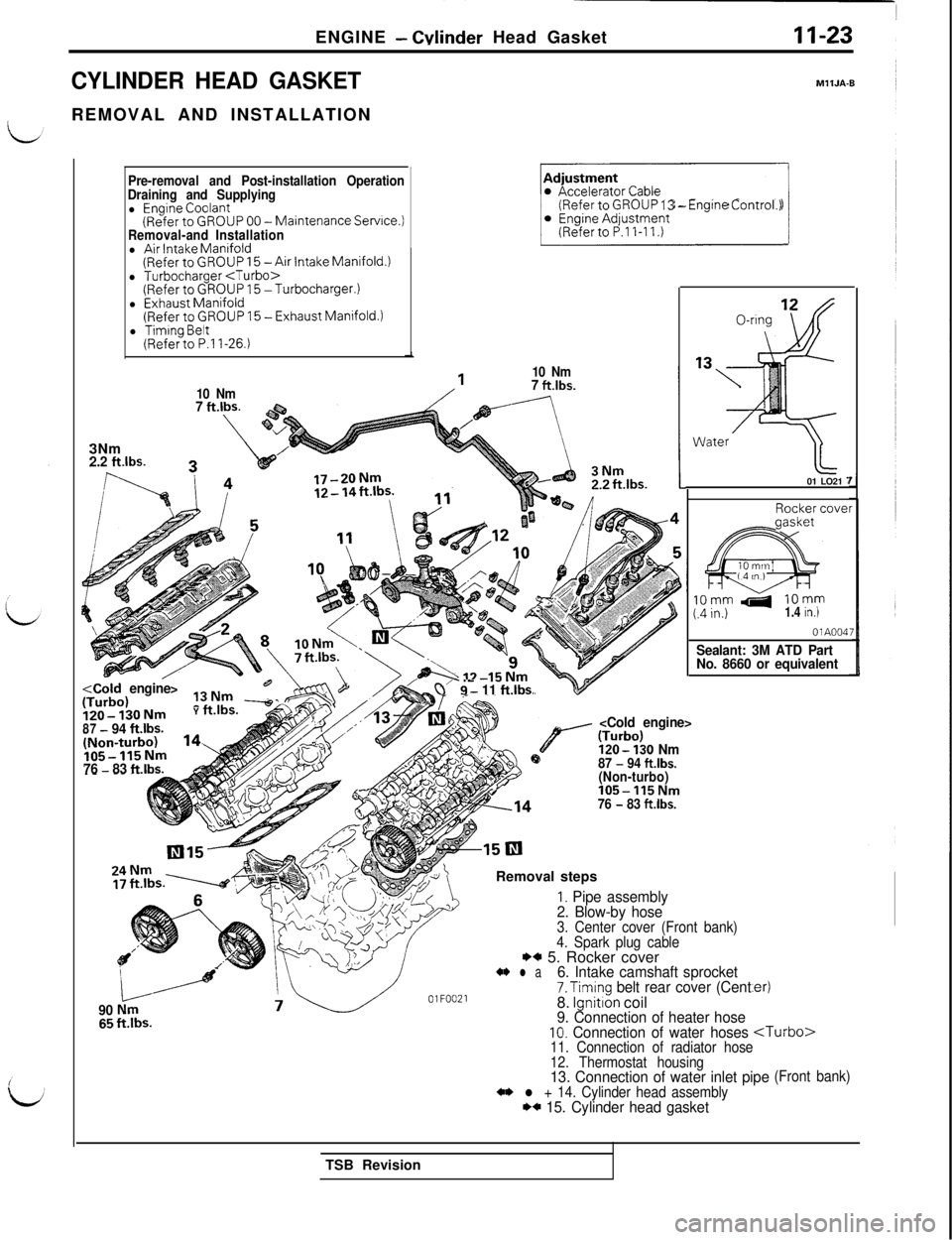

ENGINE - Winder Head Gasket11-23

CYLINDER HEAD GASKETREMOVAL AND INSTALLATION

MllJA-6

Pre-removal and Post-installation Operation

Draining and Supplying

l Engine Coolant(Refer to GROUP 00 -Maintenance Service.)Removal-and Installationl Air Intake Manifold(Refer to GROUP 15 -Air intake Manifold.)l Turbocharger

10 Nm3Nm

2.2 klbs.P

~~(Refer to GROUP 13 - Engrne Control.)

10 Nm7 ft.lbs.

7 ft.lbs.\

120-nng

‘3, ;

%

;;

Water01 LO21

7

i2o-IjONmY rt.lDS.

87

- 94 ft.lbs.

76 - 83 ft.lbs.d

I. Pipe assembly

2. Blow-by hose

90

Nm3. Center cover (Front bank)

4. Spark plug cable

HI 5. Rocker cover4* l a

I

6. Intake camshaft sprocket7. Timing belt rear cover (Cent

7.----A//OlFOO218. Ignition coil9. Connection of heater hose10. Connection of water hoses

Rocker coverIOmm

410mm(.4 in.)1.4 in.)

OlA004;

Sealant: 3M ATD Part

No. 8660 or equivalent

.er)

tl-urbo>11. Connection of radiator hose

12. Thermostat housing

13. Connection of water inlet pipe** l + 14. Cylinder head assembly** 15. Cylinder head gasket

(Front bank)TSB Revision

Page 74 of 1146

11-24ENGINE - Cylinder Head Gasket

ldentlfrcatlonmark

01 N009iOlL0472

0111044

JI

j:: 1: :: ::p:i

c1

Q80401Q5 c

Frontbank074930296

- OlL105j8

TSB Revision

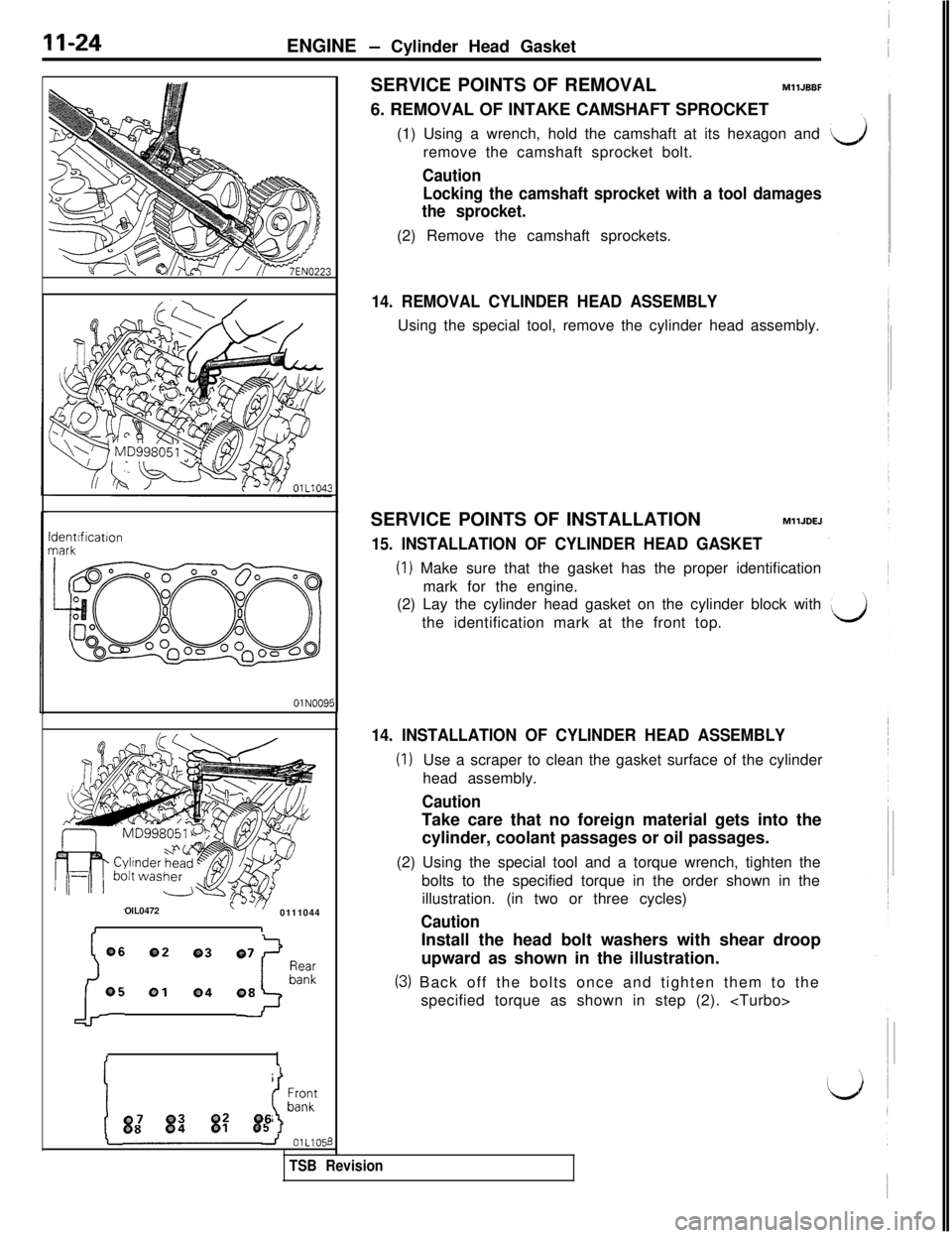

5SERVICE POINTS OF REMOVALMllJBBF

6. REMOVAL OF INTAKE CAMSHAFT SPROCKET

(1) Using a wrench, hold the camshaft at its hexagon and

remove the camshaft sprocket bolt.

Caution

Locking the camshaft sprocket with a tool damages

the sprocket.(2) Remove the camshaft sprockets.

14. REMOVAL CYLINDER HEAD ASSEMBLYUsing the special tool, remove the cylinder head assembly.

SERVICE POINTS OF INSTALLATION

MllJDEJ

15. INSTALLATION OF CYLINDER HEAD GASKET

(1) Make sure that the gasket has the proper identification

mark for the engine.

(2) Lay the cylinder head gasket on the cylinder block with

the identification mark at the front top.

14. INSTALLATION OF CYLINDER HEAD ASSEMBLY

(1)Use a scraper to clean the gasket surface of the cylinder

head assembly.

CautionTake care that no foreign material gets into the

cylinder, coolant passages or oil passages.

(2) Using the special tool and a torque wrench, tighten the

bolts to the specified torque in the order shown in the

illustration. (in two or three cycles)

CautionInstall the head bolt washers with shear droop

upward as shown in the illustration.

(3) Back off the bolts once and tighten them to the

specified torque as shown in step (2).

Page 108 of 1146

13-2

Boost Meter

Components Location........................................................36

Crank Angle Sensor

............................................................72Detonation Sensor................................................................84EGR Control Solenoid Valve

EGR Temperature Sensor

Fuel Pump Operation Check................................................137Fuel Pump Relay No. 2........................................................53Fuel Pump Resistor............................................................53

Idle Position Switch............................................................68Idle Speed Control Servo (Stepper Motor Type)............1 IOIgnition Coil and Power Transistor....................................115Ignition Switch-ST and Inhibitor Switch ................76Ignition Switch-ST

Injectors

94

Oxygen Sensor

Power Steering Oil Pressure Switch................................80Power Supply and Ignition Switch-IG................................41

Purge Control Solenord Valve............................................1 19Release of Residual Pressure from High

Pressure Fuel Hose............................................................137Throttle Position Sensor....................................................65Top Dead Center Sensor....................................................70Variable Induction Control Servo (DC Motor)

SERVICE ADJUSTMENT PROCEDURES............................31

Adjustment of Fixed SAS....................................................35Adjustment of Idle Position Switch and

Throttle Position Sensor (TPS)............................................33Basic Idle Speed Adjustment............................................31Throttle Body (Throttle Valve Area) Cleaning....................33

SPECIAL TOOLS........................................................................8

SPECIFICATIONS

....................................................................6

General Specifications........................................................6Sealant....................................................................................7Service Specifications........................................................7

THROlTLE BODY....................................................................143

TROUBLESHOOTING............................................................9

Check Chart Classified by Problem Symptoms................16Circuit Diagram....................................................................18Engine Warning Light (Malfunction Indicator Light)........11Explanation and Cautions about Harness Check............10Explanation of Troubleshooting Procedures....................9Fuel Tank and Fuel Line........................................................30

Problem Symptoms Table (For Your Information)............17Self-diagnosis........................................................................12)

I

Page 112 of 1146

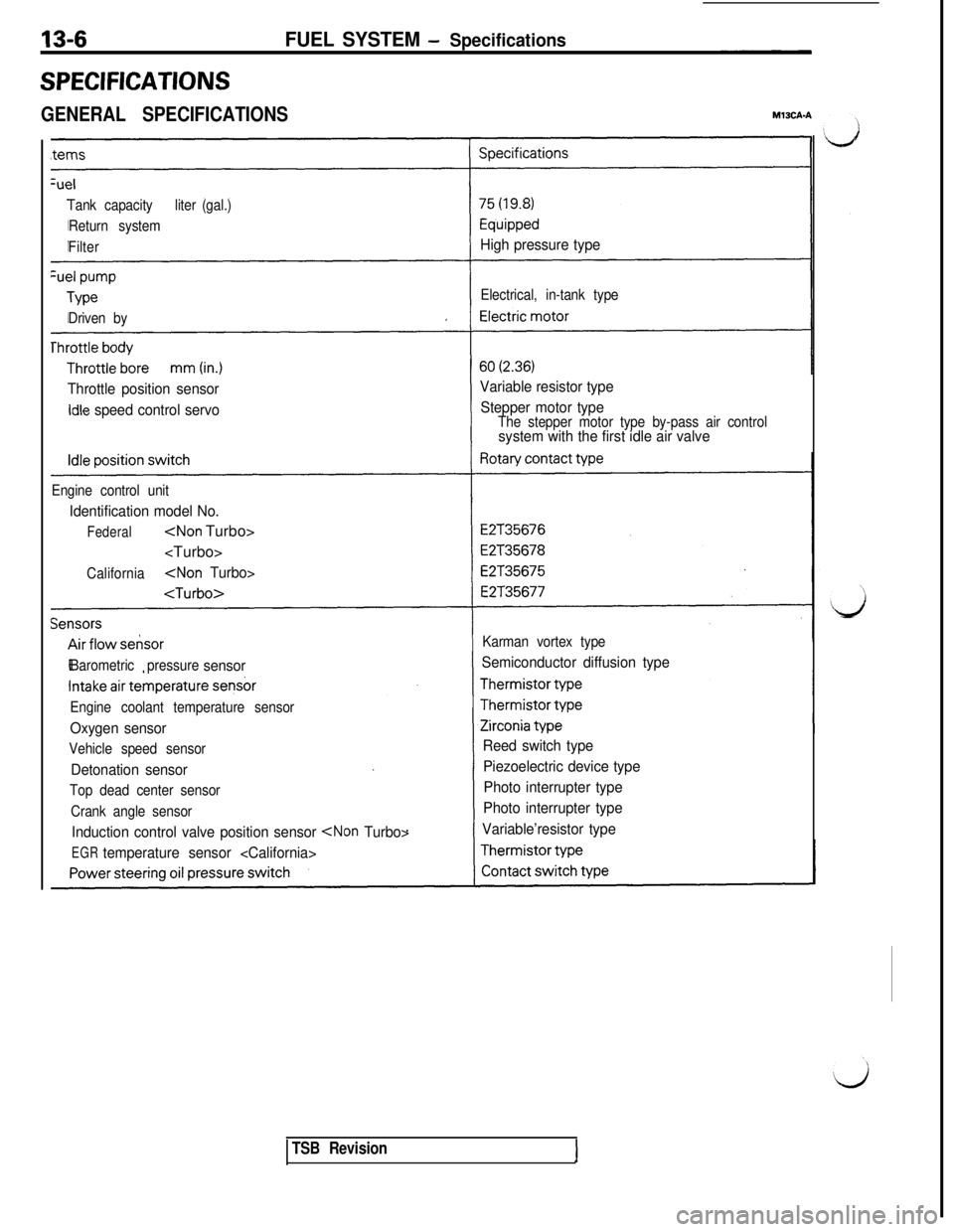

Tank capacityliter (gal.)

Return system

Filter

High pressure type

Electrical, in-tank type

Driven by

Throttle position sensor

idle speed control servoVariable resistor type

Stepper motor typeThe stepper motor type by-pass air controlsystem with the first idle air valve

Engine control unit

Identification model No.

Federal

California

Karman vortex type

Barometric pressure

sensorSemiconductor diffusion type

Engine coolant temperature sensor

Oxygen sensor

Vehicle speed sensor

Detonation sensor

Top dead center sensor

Crank angle sensor

Induction control valve position sensor

EGRtemperature sensor

Piezoelectric device type

Photo interrupter type

Photo interrupter type

Variable’resistor type

13-6FUEL SYSTEM - Specifications

SPECIFICATIONS

GENERAL SPECIFICATIONS

TSB Revision

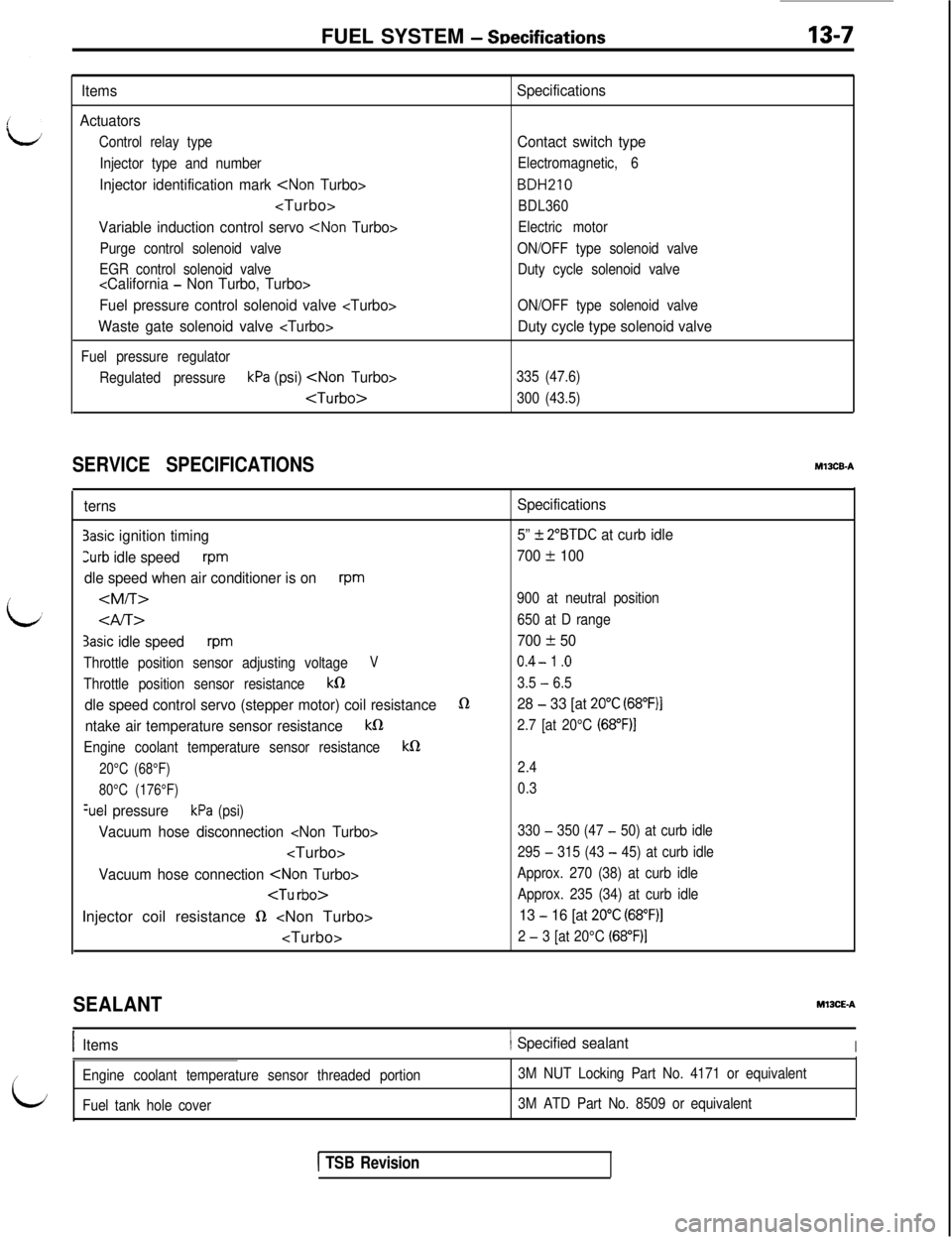

Page 113 of 1146

FUEL SYSTEM - SDecifications

L

Items

Actuators

Control relay type

Injector type and number

Injector identification mark

Variable induction control servo

Purge control solenoid valve

EGR control solenoid valve

Fuel pressure control solenoid valve

Waste gate solenoid valve

Fuel pressure regulator

Regulated pressure

kPa (psi)

Specifications

Contact switch type

Electromagnetic, 6

BDH210

BDL360

Electric motor

ON/OFF type solenoid valve

Duty cycle solenoid valve

ON/OFF type solenoid valve

Duty cycle type solenoid valve

335 (47.6)

300 (43.5)

SERVICE SPECIFICATIONS

i

ternsSpecifications

3asic ignition timing5” -t 2”BTDC at curb idle

3urb idle speedrpm700 * 100

dle speed when air conditioner is on

rpm

3asic idle speedrpm700 + 50

Throttle position sensor adjusting voltageV0.4- 1 .o

Throttle position sensor resistancek03.5 - 6.5

dle speed control servo (stepper motor) coil resistance028 - 33 [at 20°C (68”F)I

ntake air temperature sensor resistancekfi2.7 [at 20°C (68”F)I

Engine coolant temperature sensor resistancekQ

20°C (68°F)

2.4

80°C (176°F)0.3

%el pressurekPa (psi)

Vacuum hose disconnection

295 - 315 (43 - 45) at curb idle

Vacuum hose connection

Sz

2 - 3 [at 20°C (68”F)I

SEALANTMlXE-A

IItems1 Specified sealantI

/

L

Engine coolant temperature sensor threaded portion3M NUT Locking Part No. 4171 or equivalent

Fuel tank hole cover3M ATD Part No. 8509 or equivalent

1 TSB Revision

Page 117 of 1146

FUEL SYSTEM - Troubleshooting13-11

L

L

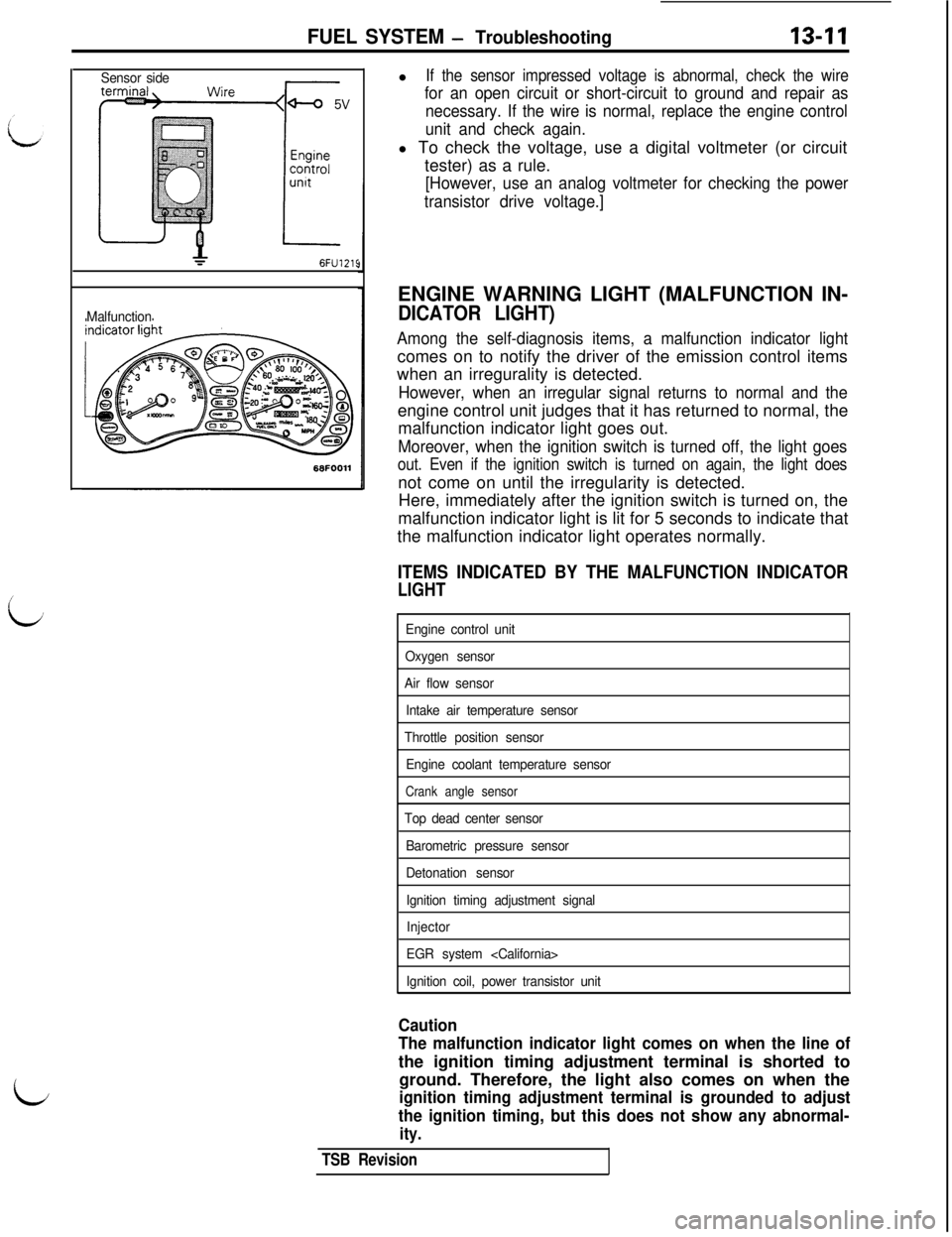

Sensor side6FU1215

Malfunctionl

If the sensor impressed voltage is abnormal, check the wire

for an open circuit or short-circuit to ground and repair as

necessary. If the wire is normal, replace the engine control

unit and check again.l To check the voltage, use a digital voltmeter (or circuit

tester) as a rule.

[However, use an analog voltmeter for checking the power

transistor drive voltage.]ENGINE WARNING LIGHT (MALFUNCTION IN-

DICATOR LIGHT)

Among the self-diagnosis items, a malfunction indicator lightcomes on to notify the driver of the emission control items

when an irregurality is detected.

However, when an irregular signal returns to normal and theengine control unit judges that it has returned to normal, the

malfunction indicator light goes out.

Moreover, when the ignition switch is turned off, the light goes

out. Even if the ignition switch is turned on again, the light doesnot come on until the irregularity is detected.

Here, immediately after the ignition switch is turned on, the

malfunction indicator light is lit for 5 seconds to indicate that

the malfunction indicator light operates normally.

ITEMS INDICATED BY THE MALFUNCTION INDICATOR

LIGHT

Engine control unit

Oxygen sensor

Air flow sensor

Intake air temperature sensor

Throttle position sensor

Engine coolant temperature sensor

Crank angle sensor

Top dead center sensor

Barometric pressure sensor

Detonation sensor

Ignition timing adjustment signal

Injector

EGR system

Ignition coil, power transistor unit

Caution

The malfunction indicator light comes on when the line ofthe ignition timing adjustment terminal is shorted to

ground. Therefore, the light also comes on when the

ignition timing adjustment terminal is grounded to adjust

the ignition timing, but this does not show any abnormal-

ity.

TSB Revision

Page 119 of 1146

FUEL SYSTEM - Troubleshootinn

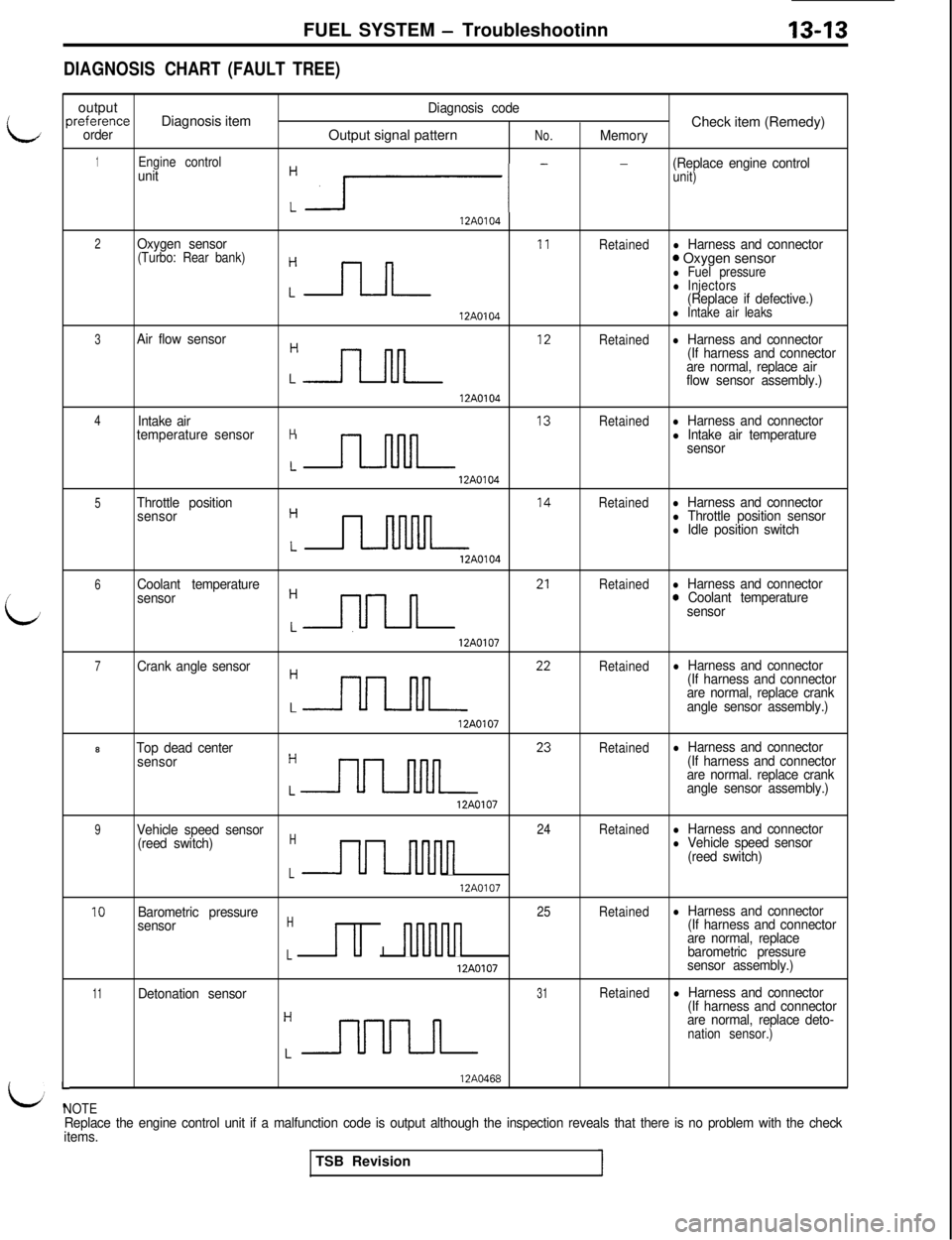

DIAGNOSISCHART (FAULT TREE)

i

L

Foutput

Diagnosis codeIreferenceDiagnosis item

Check item (Remedy)orderOutput signal patternNo.Memory

1Engine controlunit

:r- -

(Replace engine controlunit)

12A0104

2Oxygen sensorRetainedl Harness and connector(Turbo: Rear bank)

Cnn I’

0 Oxygen sensorl Fuel pressurel Injectors(Replace if defective.)

12A0104l Intake air leaks

3Air flow sensor

:n ‘*

Retainedl Harness and connector

(If harness and connector

are normal, replace air

flow sensor assembly.)

12A0104

4Intake airRetainedl Harness and connector

temperature sensorH

Ln I3

l Intake air temperature

sensor

12A0104

5Throttle position

sensor

:n I4

Retainedl Harness and connectorl Throttle position sensorl Idle position switch

12AO104

6Coolant temperature

:nn 21

Retainedl Harness and connector

sensor0 Coolant temperature

sensor12A0107

7Crank angle sensor

:nn 22

Retainedl Harness and connector

(If harness and connector

are normal, replace crank

angle sensor assembly.)

12A01078

Top dead centerRetainedl Harness and connector

sensor

:nn 23

(If harness and connector

are normal. replace crank

angle sensor assembly.)

12A0107

9Vehicle speed sensor24Retainedl Harness and connector

(reed switch)H

UInnnn

l Vehicle speed sensor

(reed switch)

L12A0107

10Barometric pressure25Retainedl Harness and connector

sensorHu I

nnluln

(If harness and connector

are normal, replace

Lbarometric pressure

12A0107sensor assembly.)

11Detonation sensor31Retainedl Harness and connector

:-r-uuuL

(If harness and connector

are normal, replace deto-

nation sensor.)

L-NOTE

12A0468

Replace the engine control unit if a malfunction code is output although the inspection reveals that there is no problem with the check

items.TSB Revision