boot MITSUBISHI 3000GT 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 5 of 1146

,

b

00-I

GENERALCONTENTS

MOOOA- .

GENERAL DATA AND SPECIFICATIONS . . . . . .21

HOW TO USE THIS MANUAL. . . . . . . . . . . . . . . . . . . . . . . . . . . .3Definition of Terms

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3Explanation of Circuit Diagrams

. . . . . .._...........7Explanation of Manual Contents

. . . . . . . . . . . . . . . . . . . .4

Explanation of the Troubleshooting Guide . .

6ModelIndications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3Scope of Maintenance, Repair and

ServicingExplanations

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3Troubleshooting

. . . . . . .._.......................................3

LUBRICATION AND MAINTENANCE. . . . . .._....31SCHEDULED MAINTENANCE TABLE. . . . . . .._.

MAIN SEALANT AND ADHESIVE TABLE. . .44

MAINTENANCE SERVICE

. . . . . . . . . . . . . . . .._......_.....__Air Cleaner Element

. . . . . . .._......._......_................Automatic Transaxle

. . . . . . . . . . . . . . . . . . . . . . . . .._......._.....Ball Joint and Steering Linkage Seals

. . . . . . . . . . . .

BrakeHoses. . . . . . . . . . . . . . . . . . . . . . . . . . . .._......._.._...._......._..

Disc Brake Pads. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Drive Belt (For Alternator)

. . . . . . . . .._.........._..........Drive Shaft Boots

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Engine Coolant

. . . . . . . . . . . . ..__.._.............................Engine Oil

.._....__._.................................................Engine Oil Filter

. . . . .._._.......__.................. . . . . . . . . . . .Exhaust System

_....._......._.....__._............,...........Fuel Hoses

..__......__............................................36

3740

42

42

42

38

43

41

38

39

43

36

FuelSystem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Manual Transaxle

. . . . . . . . . .._........................_.......Rear Axle

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .._..._.._..____.._.......

SparkPlugs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .._...............TimingBelt

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MASTER TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . .

PRECAUTIONS BEFORE SERVICE. . . . . . . . . . . . . . . .

RECOMMENDED LUBRICANTS AND

LUBRICANT CAPACITIES TABLE. . . . . . .._........

SPECIAL HANDLING INSTRUCTIONS

FOR AWD MODELS. . . . . . . . . . . . .._...._........................

TIGHTENING TORQUE. . . . . . . . . . . . . . . ..__.....................

TOWING AND HOISTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VEHICLE IDENTIFICATION. . . . . . . . . . . . . . . . . . . . . . . . .._.....Chassis Number .

.._............................................Engine Model Stamping

.._..........................._...._Theft Protection

. . . . .._.........................................Vehicle Identification Code Chart Plate

.._.....Vehicle Identification Number List

.._._....._..._.Vehicle Identification Number Location

. . . .._

Vehicle Information Code Plate . . . . .._._......_.......Vehicle Safety Certification Label

. . . ..I . . . . .._..._...

36

3943

37

3724

1532

35

20

23

16

8

10

11

11

8

9

8

10

10

Page 46 of 1146

00-42GENERAL - Maintenance Service

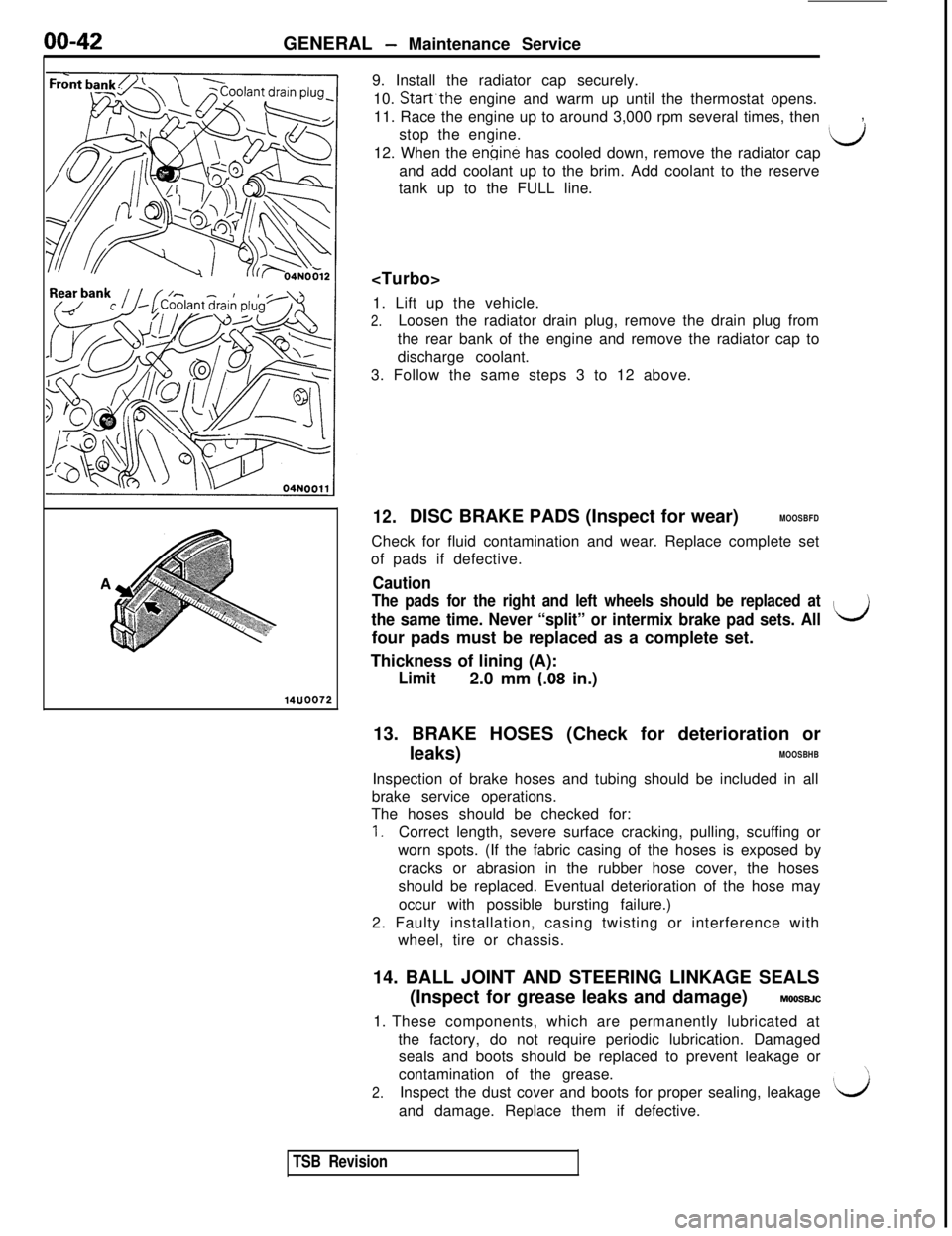

14UOO729. Install the radiator cap securely.

10.

Start’the engine and warm up until the thermostat opens.

11. Race the engine up to around 3,000 rpm several times, then

stop the engine.,12. When the enkine has cooled down, remove the radiator cap

L/and add coolant up to the brim. Add coolant to the reserve

tank up to the FULL line.

1. Lift up the vehicle.

2.Loosen the radiator drain plug, remove the drain plug from

the rear bank of the engine and remove the radiator cap to

discharge coolant.

3. Follow the same steps 3 to 12 above.

12.DISC BRAKE PADS (Inspect for wear)MOOSBFDCheck for fluid contamination and wear. Replace complete set

of pads if defective.

Caution

The pads for the right and left wheels should be replaced atIIthe same time. Never “split” or intermix brake pad sets. AllUfour pads must be replaced as a complete set.

Thickness of lining (A):

Limit2.0 mm (.08 in.)

13. BRAKE HOSES (Check for deterioration or

leaks)

MOOSBHBInspection of brake hoses and tubing should be included in all

brake service operations.

The hoses should be checked for:

1.Correct length, severe surface cracking, pulling, scuffing or

worn spots. (If the fabric casing of the hoses is exposed by

cracks or abrasion in the rubber hose cover, the hoses

should be replaced. Eventual deterioration of the hose may

occur with possible bursting failure.)

2. Faulty installation, casing twisting or interference with

wheel, tire or chassis.

14. BALL JOINT AND STEERING LINKAGE SEALS

(Inspect for grease leaks and damage)

MOOSglC1. These components, which are permanently lubricated at

the factory, do not require periodic lubrication. Damaged

seals and boots should be replaced to prevent leakage or

contamination of the grease.

2.Inspect the dust cover and boots for proper sealing, leakageIdand damage. Replace them if defective.

TSB Revision

Page 47 of 1146

GENERAL - Maintenance Service00-43

15. DRIVE SHAFT BOOTS (Inspect for grease

leaks and damage)

MOOSBJD1. These components, which are permanently lubricated at

the factory, do not require periodic lubrication. Damaged

boots should be replaced to prevent leakage or contamina-

tion of the, grease.

2.Inspect the boots for proper sealing, leakage and damage.

Replace it if defective.

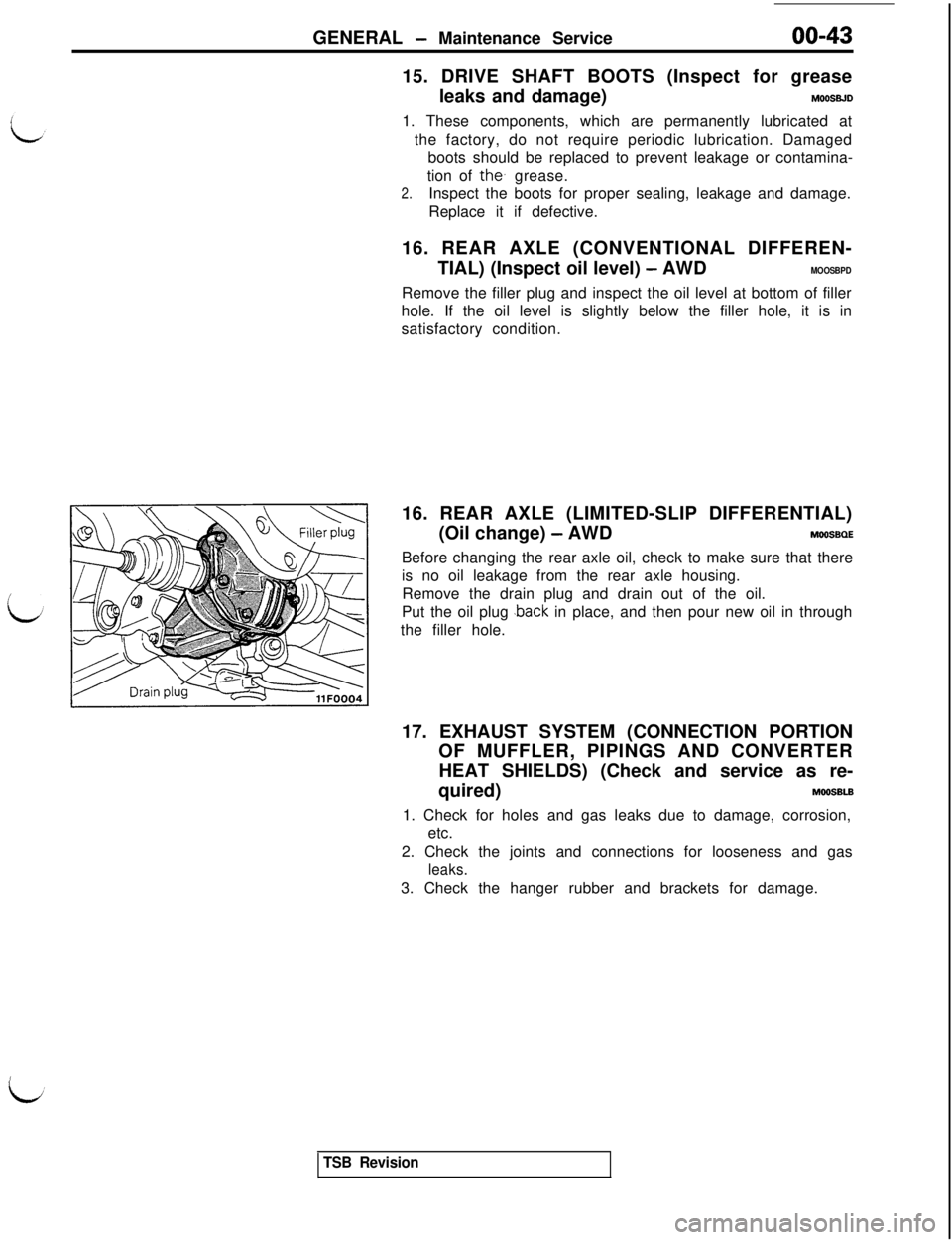

16. REAR AXLE (CONVENTIONAL DIFFEREN-

TIAL) (Inspect oil level)

- AWDMOOSBPDRemove the filler plug and inspect the oil level at bottom of filler

hole. If the oil level is slightly below the filler hole, it is in

satisfactory condition.

16. REAR AXLE (LIMITED-SLIP DIFFERENTIAL)

(Oil change)

- AWDMOOSBQEBefore changing the rear axle oil, check to make sure that there

is no oil leakage from the rear axle housing.

Remove the drain plug and drain out of the oil.

Put the oil plug

,back in place, and then pour new oil in through

the filler hole.

17. EXHAUST SYSTEM (CONNECTION PORTION

OF MUFFLER, PIPINGS AND CONVERTER

HEAT SHIELDS) (Check and service as re-

quired)

MOOSBLB1. Check for holes and gas leaks due to damage, corrosion,

etc.

2. Check the joints and connections for looseness and gas

leaks.3. Check the hanger rubber and brackets for damage.

TSB Revision

Page 372 of 1146

21-14CLUTCH i Clutch Master Cylinder

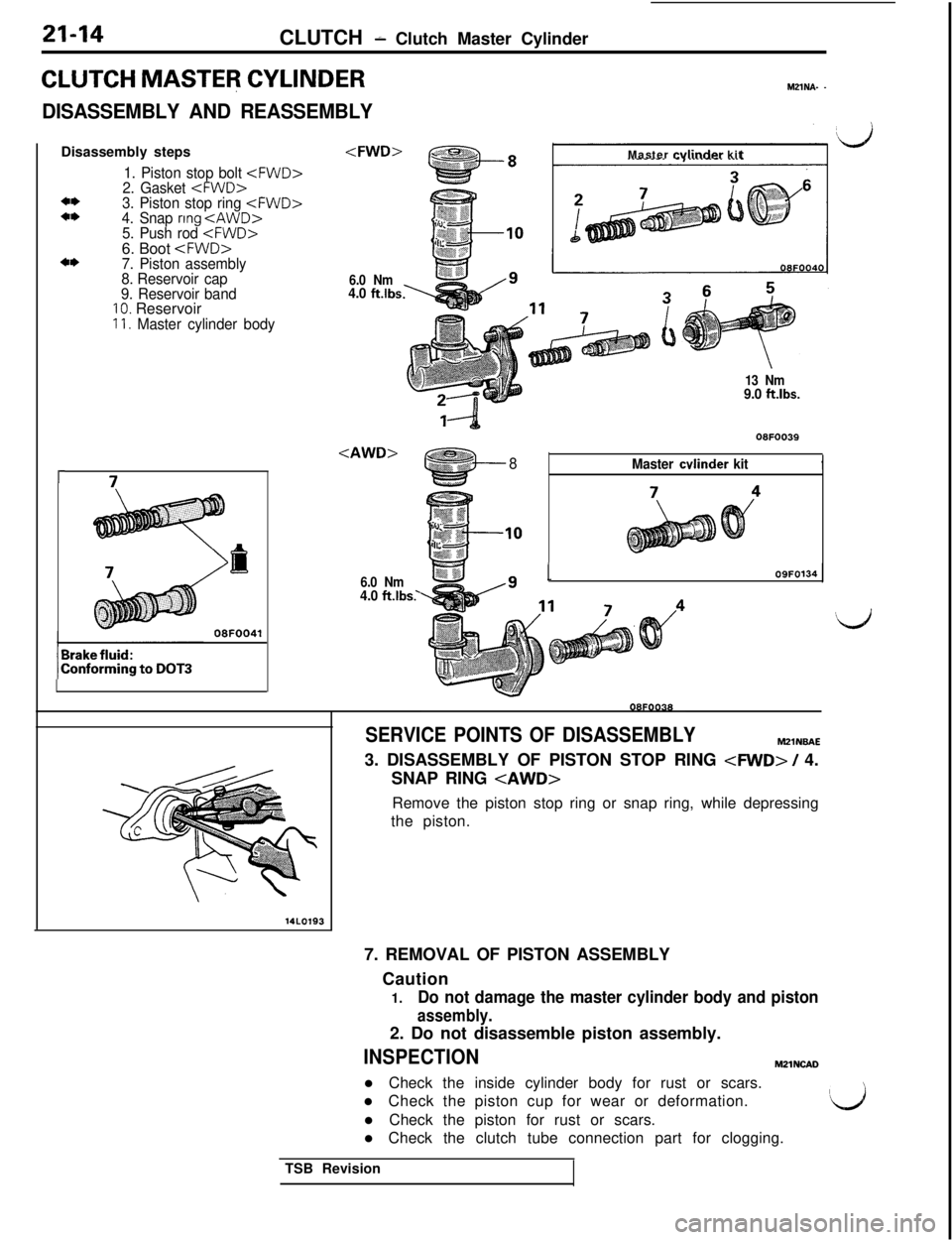

CLUTCH MASTER CYLINDER

DISASSEMBLY AND REASSEMBLY

M21NA. -Disassembly steps

1. Piston stop bolt

6. Boot

c*7. Piston assembly

8. Reservoir cap

9. Reservoir band

10. Reservoir11. Master cylinder body

6.0 Nm4.0 ft.lbs

08FOO40

13 Nm9.0 ftlbs.

---&08FOO39

r

08FOO41

6.0 Nm4.0 ft.lbs:Master

cvlinder kit1

109FOl3414LO193

SERVICE POINTS OF DISASSEMBLYM21NSAE3. DISASSEMBLY OF PISTON STOP RING

SNAP RING

the piston.

7. REMOVAL OF PISTON ASSEMBLY

Caution

1.Do not damage the master cylinder body and piston

assembly.2. Do not disassemble piston assembly.

INSPECTIONMZlNCAD

l Check the inside cylinder body for rust or scars.

l Check the piston cup for wear or deformation.

Idl Check the piston for rust or scars.

l Check the clutch tube connection part for clogging.

TSB Revision

Page 373 of 1146

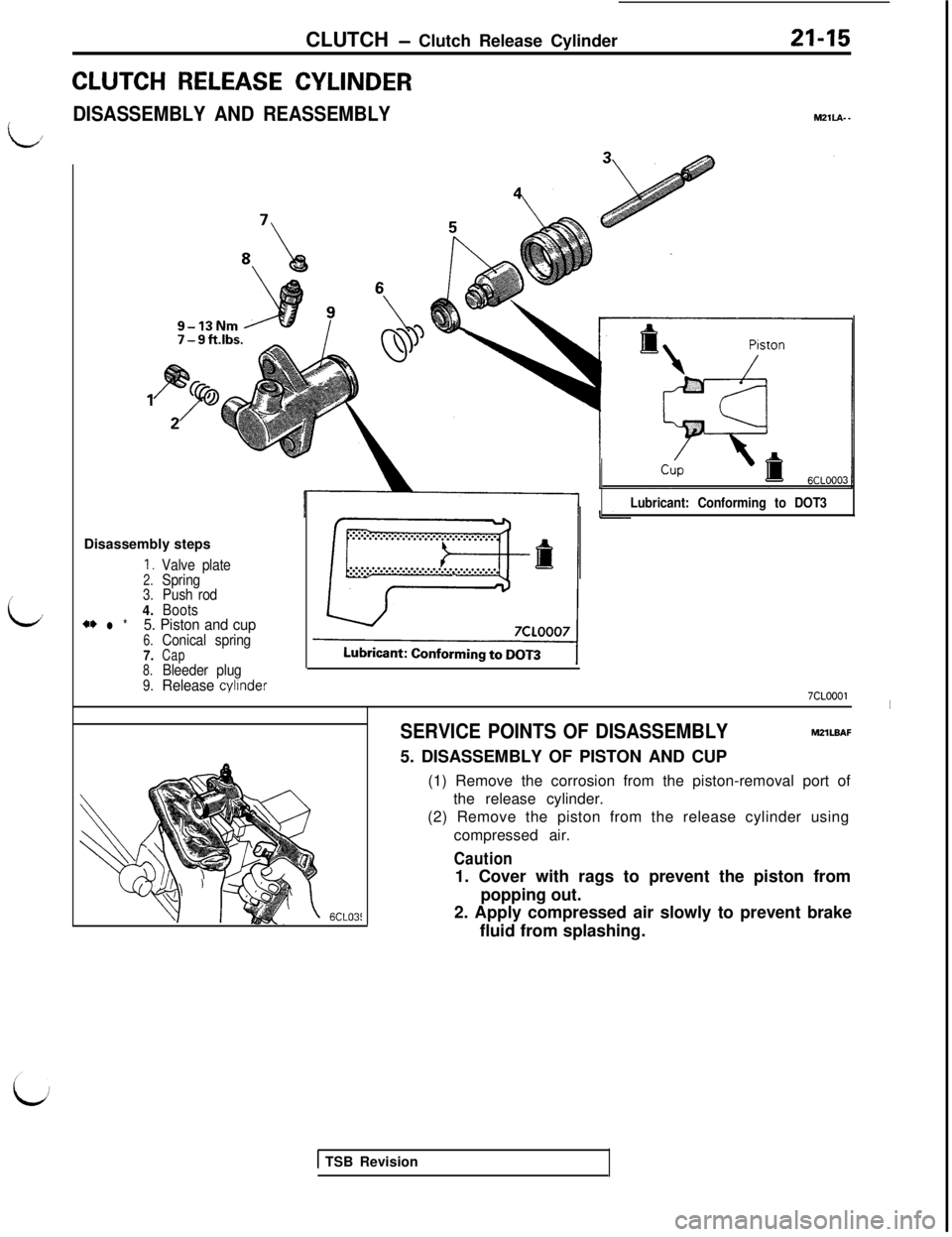

CLUTCH - Clutch Release Cylinder21-15

CLUTCH RELEASE CYLINDER

DISASSEMBLY AND REASSEMBLY

L.4/

/

iJ

Lubricant: Conforming to DOT3Disassembly steps

1.Valve plate2.Spring3.Push rod4.Boots*I) l *5. Piston and cup6.Conical spring

7.Cap

8.Bleeder plug9.Release cylinder7CLOOOl

6CLO3!

SERVICE POINTS OF DISASSEMBLYM2lLBAF5. DISASSEMBLY OF PISTON AND CUP

(1) Remove the corrosion from the piston-removal port of

the release cylinder.

(2) Remove the piston from the release cylinder using

compressed air.

Caution1. Cover with rags to prevent the piston from

popping out.

2. Apply compressed air slowly to prevent brake

fluid from splashing.

1 TSB Revision

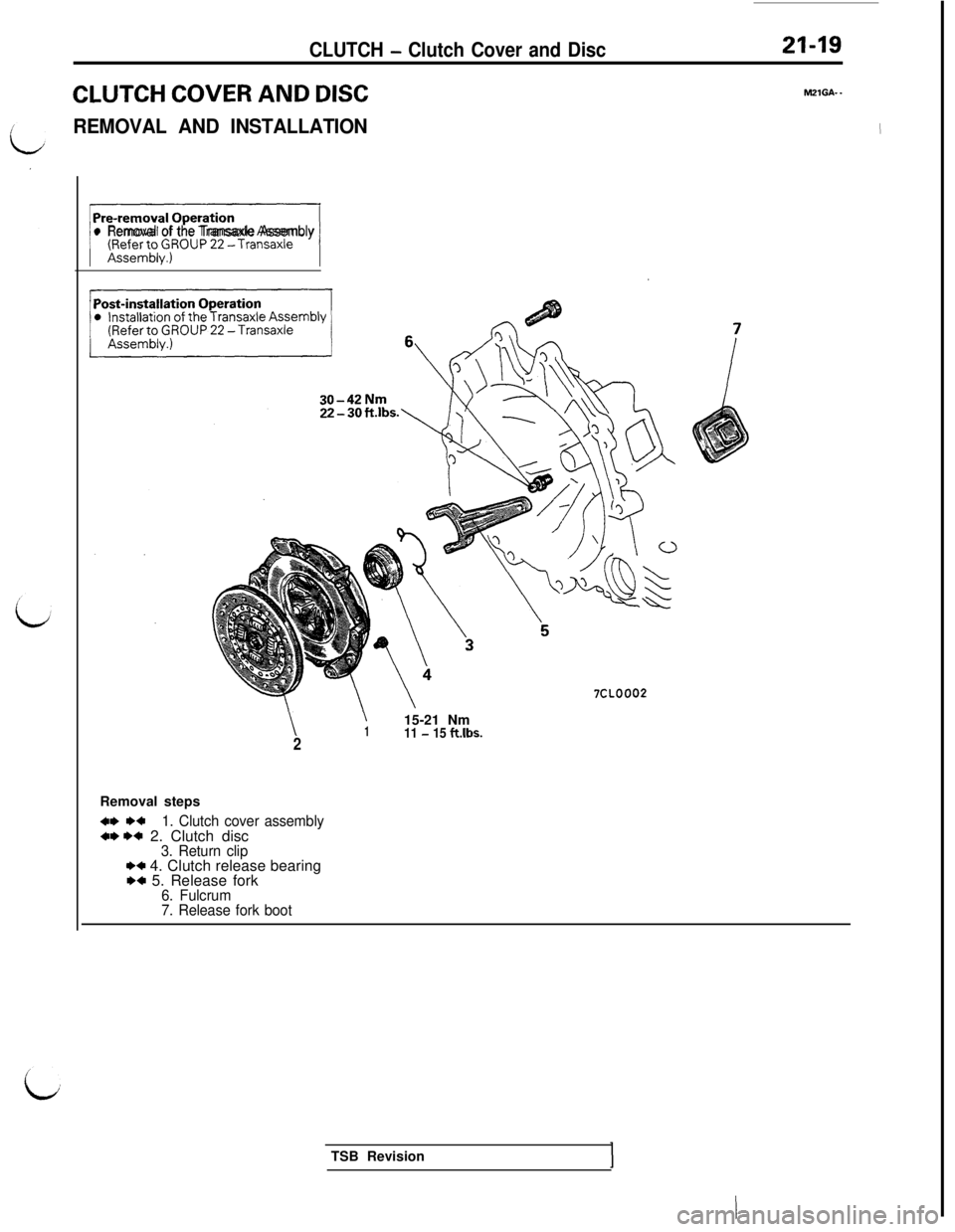

Page 377 of 1146

CLUTCH - Clutch Cover and Disc

CLUTCH COVER AND DISC

REMOVAL AND INSTALLATION

21-19

M21GA-.

I

)Il Removal of the Transaxle Assembly

30-42Nm

\\115-21 Nm11 - 15 klbs.2Removal steps

M w1. Clutch cover assembly+e W+ 2. Clutch disc3. Return clipI)* 4. Clutch release bearingW+ 5. Release fork6. Fulcrum

7. Release fork bootTSB Revision

Page 392 of 1146

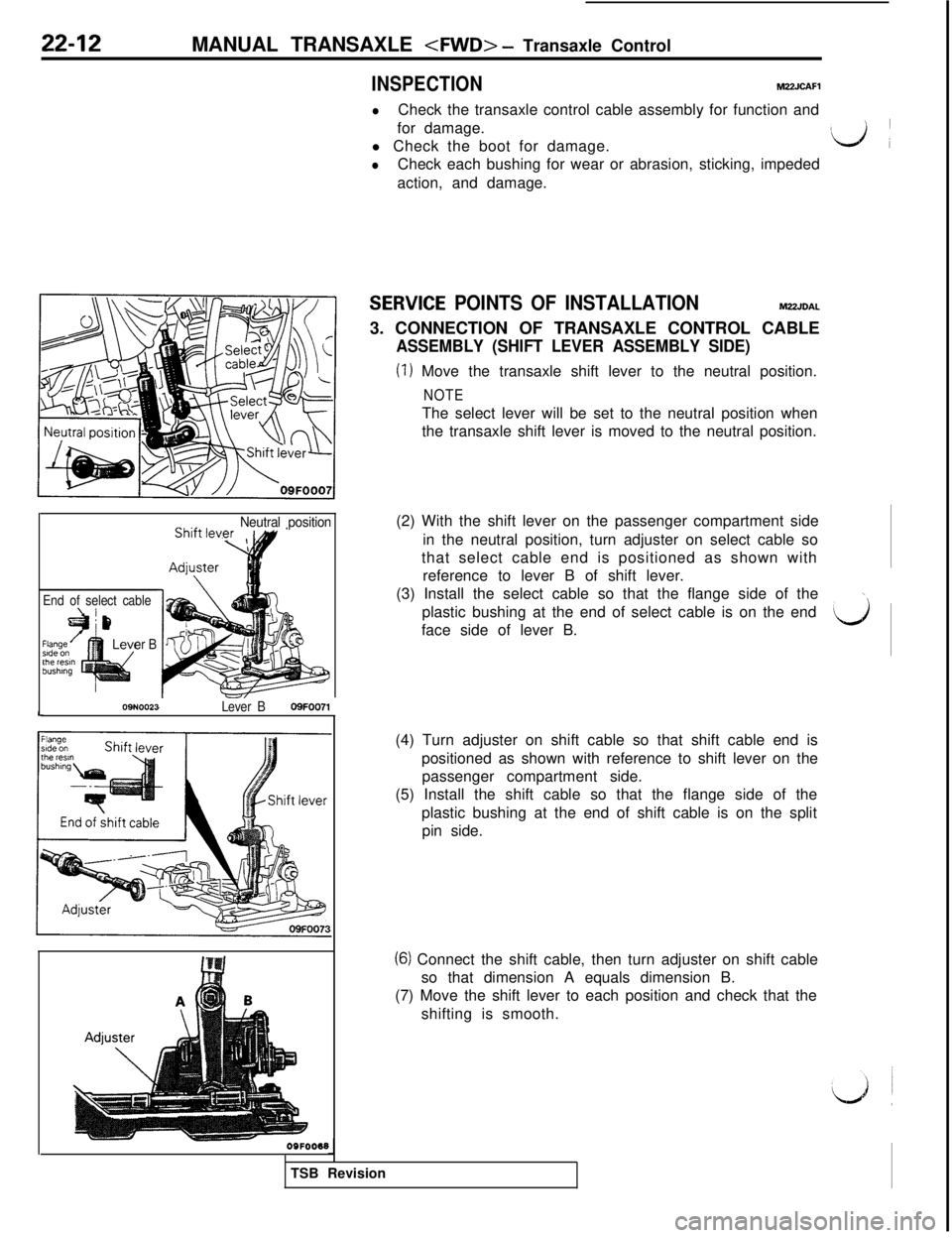

22-12MANUAL TRANSAXLE

INSPECTIONM22JCAFl

lCheck the transaxle control cable assembly for function and

for damage.

l Check the boot for damage.

IlJ 1

lCheck each bushing for wear or abrasion, sticking, impeded

action, and damage.

0910023Lever B09FOO71

End of select cable

er B

Neutral position

OSFOOo8

SERVlCE POINTS OF INSTALLATIONMUJDAL

3. CONNECTION OF TRANSAXLE CONTROL CABLE

ASSEMBLY (SHIFT LEVER ASSEMBLY SIDE)

(I) Move the transaxle shift lever to the neutral position.

NOTEThe select lever will be set to the neutral position when

the transaxle shift lever is moved to the neutral position.

(2) With the shift lever on the passenger compartment side

in the neutral position, turn adjuster on select cable so

that select cable end is positioned as shown with

reference to lever B of shift lever.

(3) Install the select cable so that the flange side of the

\plastic bushing at the end of select cable is on the end

face side of lever B.

d(4) Turn adjuster on shift cable so that shift cable end is

positioned as shown with reference to shift lever on the

passenger compartment side.

(5) Install the shift cable so that the flange side of the

plastic bushing at the end of shift cable is on the split

pin side.

(6) Connect the shift cable, then turn adjuster on shift cable

so that dimension A equals dimension B.

(7) Move the shift lever to each position and check that the

shifting is smooth.

TSB Revision

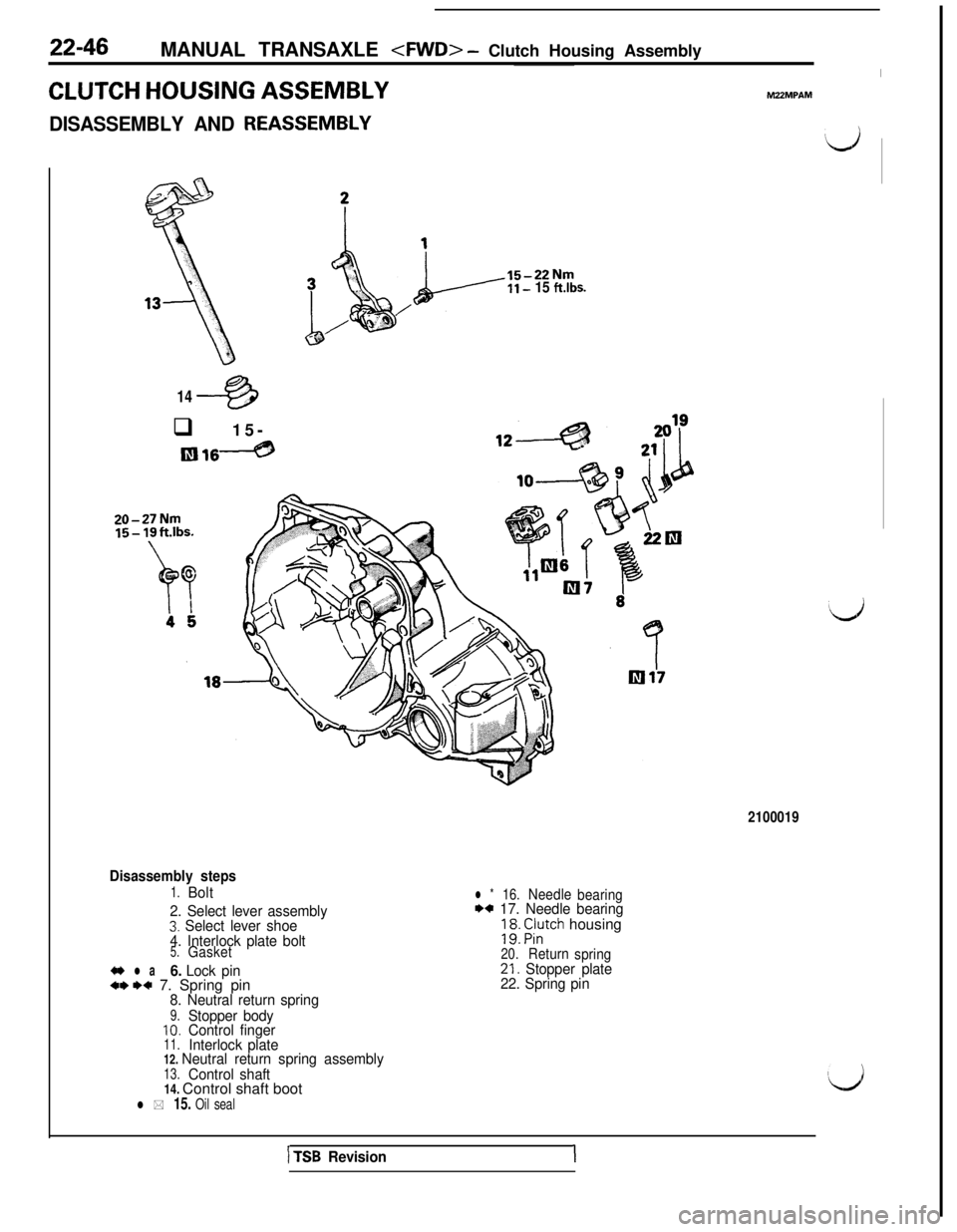

Page 426 of 1146

22-46MANUAL TRANSAXLE

CLUTCH HOUSING ASSEMBLYM22MPAM

DISASSEMBLY AND REASSEMELY

iJ15-22Nm

II- 15 ft.lbs.

/

1443q 15-

m16----@20-27Nm

15- 19ft.lbs.

2100019

Disassembly steps

1.Bolt

2. Select lever assembly

3. Select lever shoe

4. Interlock plate bolt

5.Gasket

4~ l a6. Lock pin+* I)* 7. Spring pin8. Neutral return spring

9.Stopper body10.Control finger11.Interlock plate12. Neutral return spring assembly13.Control shaft14. Control shaft boot

l * 15. Oil seal

l *16.Needle

bearingI)+ 17. Needle bearing

; 98: F:;tch housing

20.Return

spring21. Stopper plate

22. Spring pin

1 TSB Revision1

Page 435 of 1146

MANUAL TRANSAXLE

03FOO

Air‘mtakehose A Air intake

hose C

Air intake hose B05FOO2:

Air hose A

05FOOZE

8

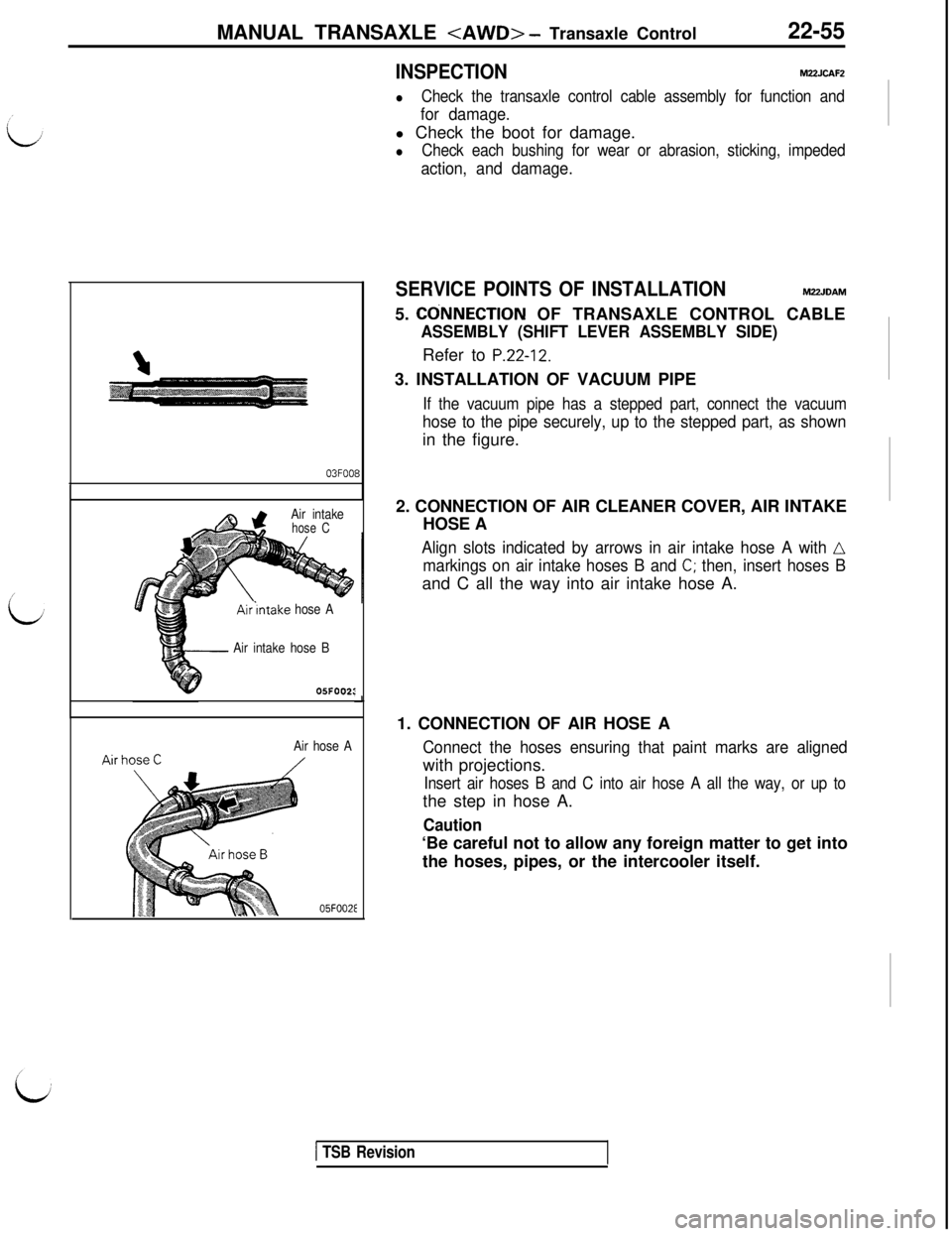

INSPECTIONM22JCAFZ

lCheck the transaxle control cable assembly for function and

for damage.l Check the boot for damage.

lCheck each bushing for wear or abrasion, sticking, impeded

action, and damage.

SERVICE POINTS OF INSTALLATIONM22JDAM5.

CdNNECTlON OF TRANSAXLE CONTROL CABLE

ASSEMBLY (SHIFT LEVER ASSEMBLY SIDE)Refer to

P.22-12.3. INSTALLATION OF VACUUM PIPE

If the vacuum pipe has a stepped part, connect the vacuum

hose to the pipe securely, up to the stepped part, as shownin the figure.

2. CONNECTION OF AIR CLEANER COVER, AIR INTAKE

HOSE A

Align slots indicated by arrows in air intake hose A with n

markings on air intake hoses B and C; then, insert hoses Band C all the way into air intake hose A.

1. CONNECTION OF AIR HOSE A

Connect the hoses ensuring that paint marks are alignedwith projections.

Insert air hoses B and C into air hose A all the way, or up tothe step in hose A.

Caution‘Be careful not to allow any foreign matter to get into

the hoses, pipes, or the intercooler itself.

1 TSB Revision

Page 568 of 1146

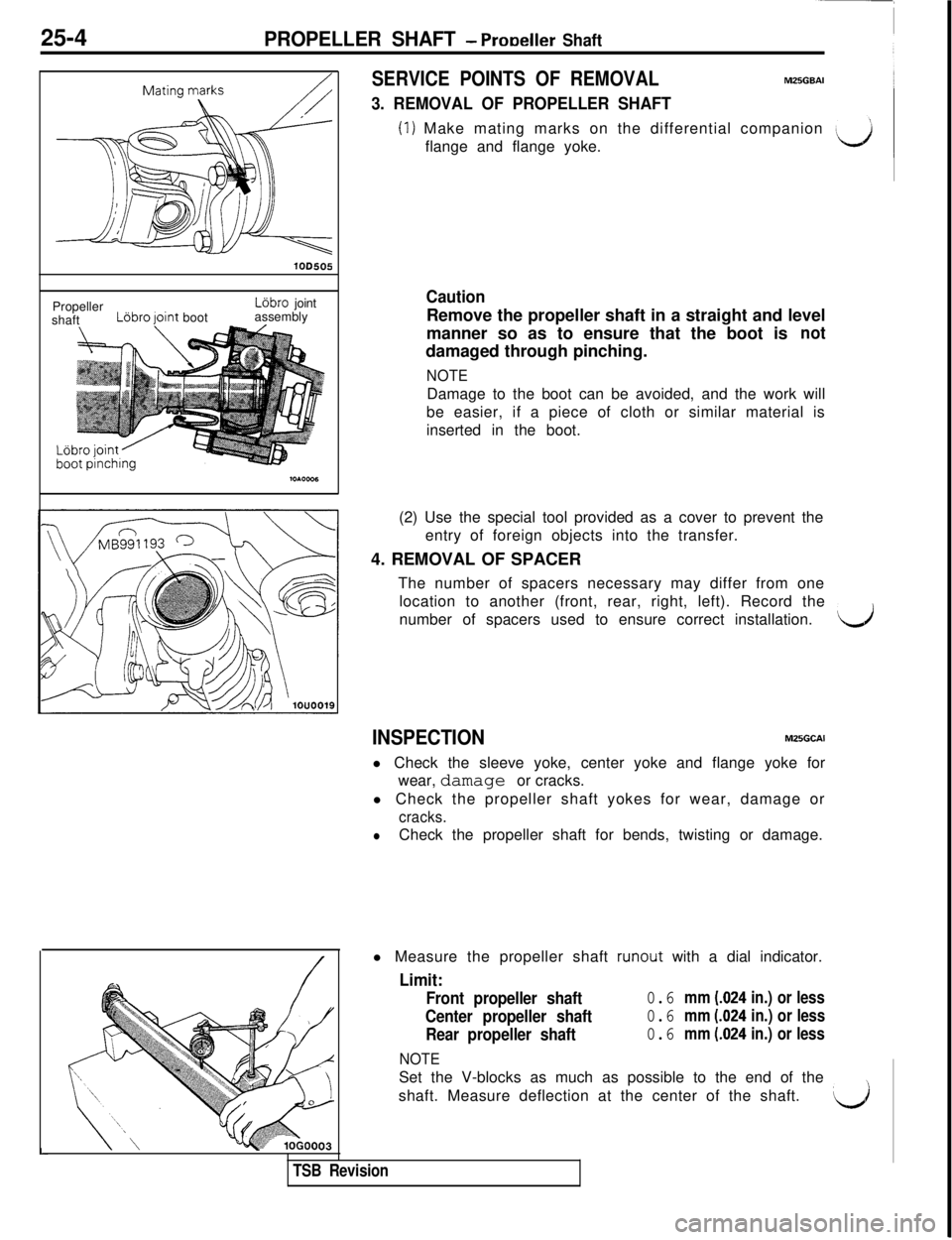

25-4PROPELLER SHAFT - ProDeller ShaftPropeller

LGbro joint

shaftL6bro Jointbootassembly

SERVICE POINTS OF REMOVALM25GEAI

3. REMOVAL OF PROPELLER SHAFT

(1) Make mating marks on the differential companion

flange and flange yoke.

CautionRemove the propeller shaft in a straight and level

manner so as to ensure that the boot is

notdamaged through pinching.

NOTEDamage to the boot can be avoided, and the work will

be easier, if a piece of cloth or similar material is

inserted in the boot.

(2) Use the special tool provided as a cover to prevent the

entry of foreign objects into the transfer.

4. REMOVAL OF SPACER

The number of spacers necessary may differ from one

location to another (front, rear, right, left). Record the

number of spacers used to ensure correct installation.

INSPECTIONM25GCAIl Check the sleeve yoke, center yoke and flange yoke for

wear, damage or cracks.

l Check the propeller shaft yokes for wear, damage or

cracks.

lCheck the propeller shaft for bends, twisting or damage.

l Measure the propeller shaft runout with a dial indicator.

Limit:

Front propeller shaft0.6 mm (.024 in.) or less

Center propeller shaft0.6 mm (.024 in.) or less

Rear propeller shaft0.6 mm (.024 in.) or less

NOTESet the V-blocks as much as possible to the end of the

shaft. Measure deflection at the center of the shaft.

d

Lj

TSB Revision