sensor MITSUBISHI 3000GT 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 1108 of 1146

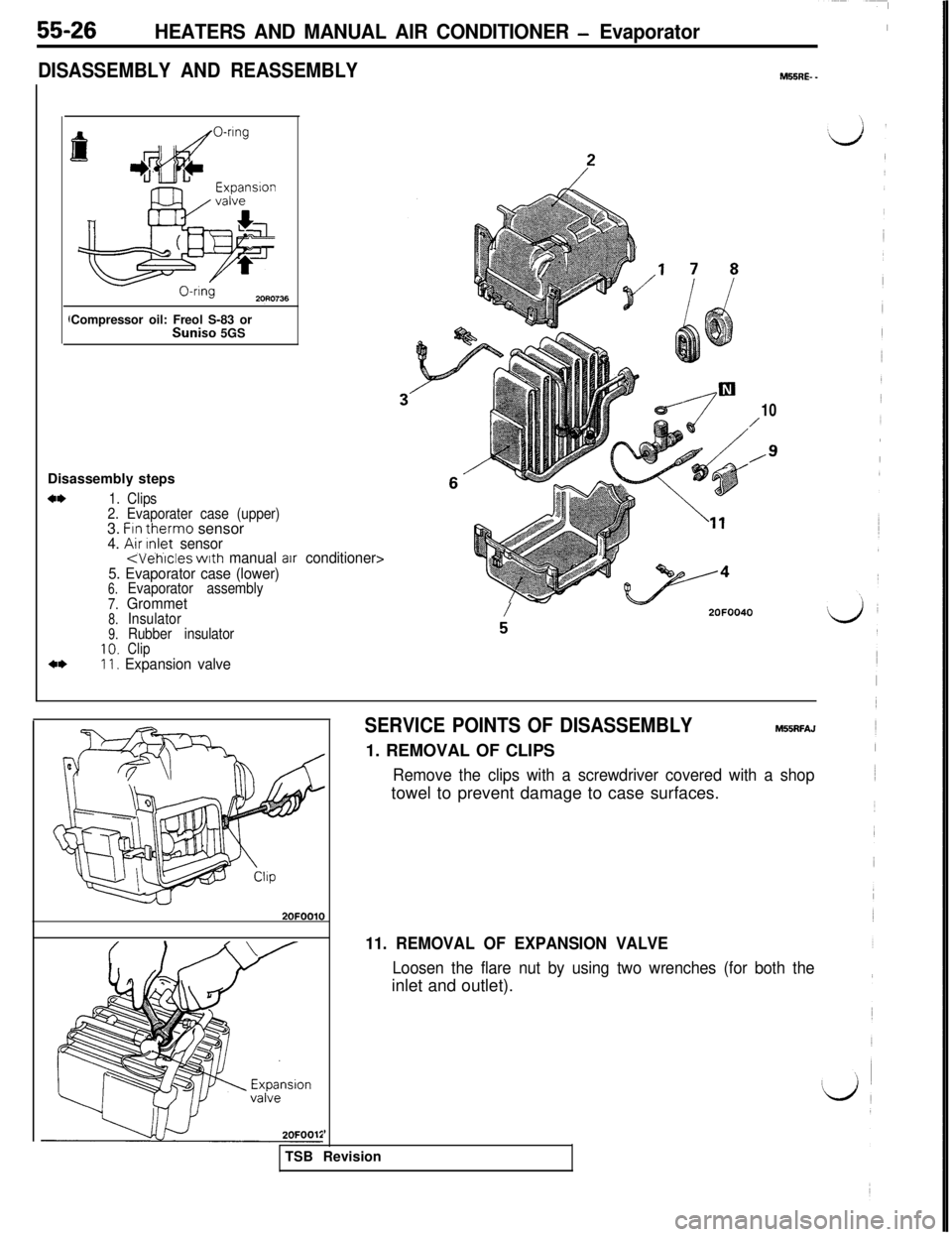

55-26HEATERS AND MANUAL AIR CONDITIONER - Evaporator

DISASSEMBLY AND REASSEMBLYM55RE- -Compressor oil: Freol S-83 or

Suniso 5GS

Disassembly steps

4*1. Clips

2. Evaporater case (upper)3.

Fin therm0 sensor4. AirInlet sensor

4*

5. Evaporator case (lower)

6.Evaporator assembly

7.Grommet8.Insulator9.Rubber insulator10.Clip11. Expansion valve

10/

9

/2OFOO40

1TSB Revision

SERVICE POINTS OF DISASSEMBLYM55RFAJ1. REMOVAL OF CLIPS

Remove the clips with a screwdriver covered with a shoptowel to prevent damage to case surfaces.

11. REMOVAL OF EXPANSION VALVE

Loosen the flare nut by using two wrenches (for both theinlet and outlet).

Page 1111 of 1146

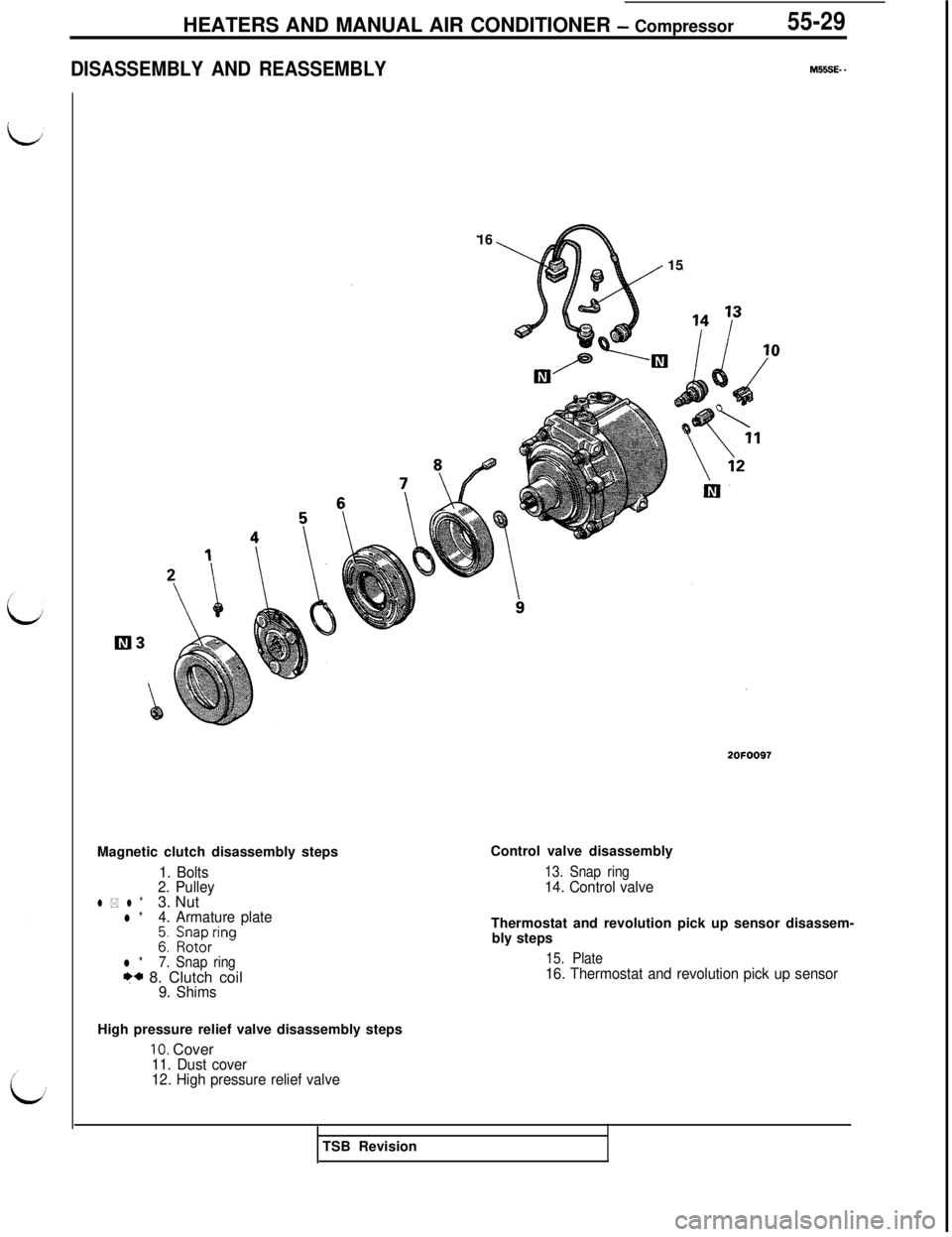

HEATERS AND MANUAL AIR CONDITIONER - Compressor

DISASSEMBLY AND REASSEMBLY

55-29

M55SE- -16

152OFOO97

Magnetic clutch disassembly steps

1. Bolts

2. Pulley

l * l *3. Nutl *4. Armature plate

gI i;yirring

l *7. Snap ringF* 8. Clutch coil9. ShimsControl valve disassembly

13. Snap ring14. Control valveThermostat and revolution pick up sensor disassem-

bly steps

15. Plate16. Thermostat and revolution pick up sensorHigh pressure relief valve disassembly steps

10. Cover11. Dust cover

12. High pressure relief valveTSB Revision

Page 1113 of 1146

HEATERS AND MANUAL AIR CONDITIONER - Compressor55-3120N003d

2OFOO96

I

Ec-3

3180?+I! (25)zz

h34\

*

Engine speed rpm2OPO2S

\CrankshaftTapered part

20A0157

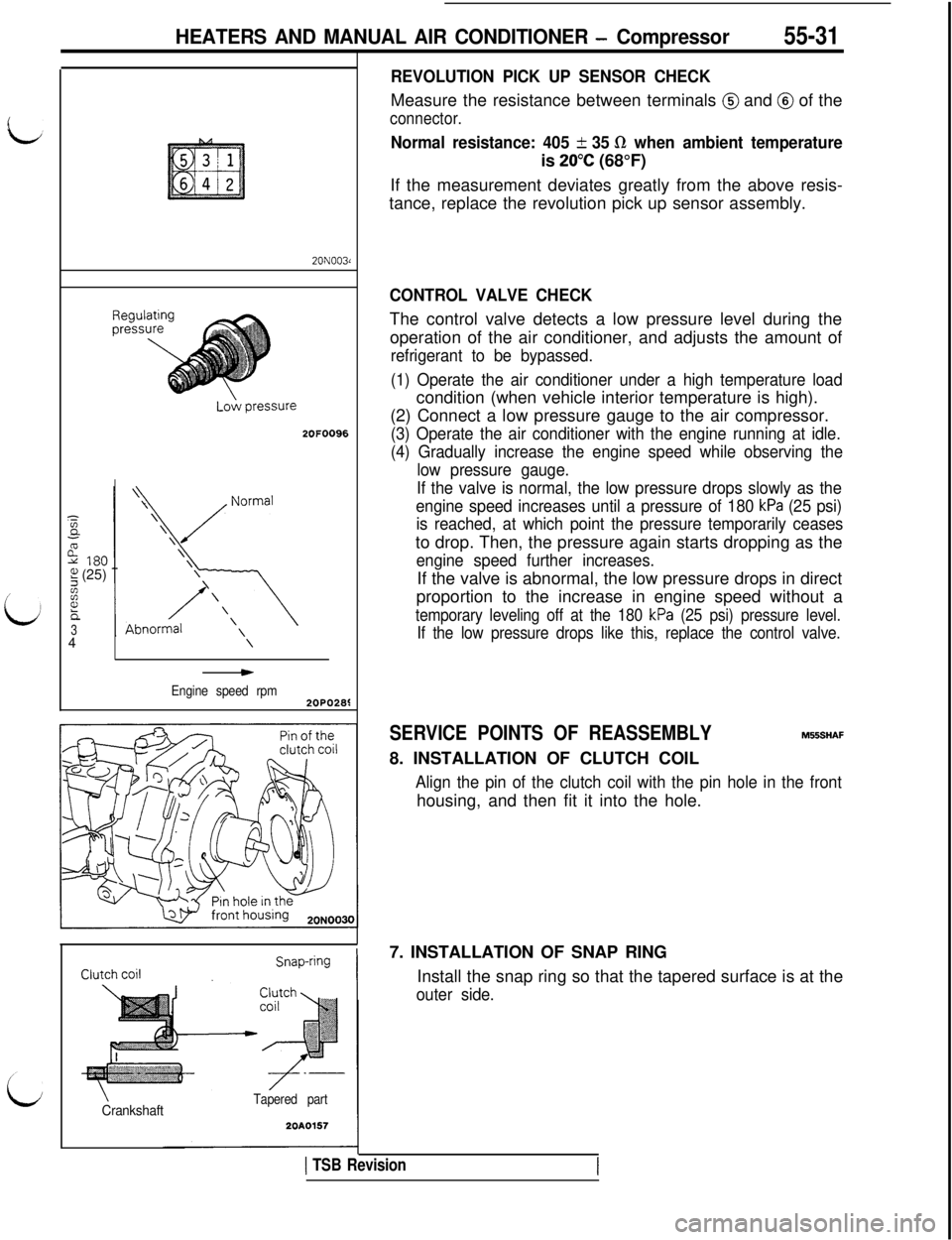

REVOLUTION PICK UP SENSOR CHECKMeasure the resistance between terminals

@ and @ of the

connector.

Normal resistance: 405 + 35 R when ambient temperatureis

20°C (68°F)

If the measurement deviates greatly from the above resis-

tance, replace the revolution pick up sensor assembly.

CONTROL VALVE CHECKThe control valve detects a low pressure level during the

operation of the air conditioner, and adjusts the amount of

refrigerant to be bypassed.

(1) Operate the air conditioner under a high temperature loadcondition (when vehicle interior temperature is high).

(2) Connect a low pressure gauge to the air compressor.

(3) Operate the air conditioner with the engine running at idle.

(4) Gradually increase the engine speed while observing the

low pressure gauge.

If the valve is normal, the low pressure drops slowly as the

engine speed increases until a pressure of 180

kPa (25 psi)

is reached, at which point the pressure temporarily ceasesto drop. Then, the pressure again starts dropping as the

engine speed further increases.If the valve is abnormal, the low pressure drops in direct

proportion to the increase in engine speed without a

temporary leveling off at the 180 kPa (25 psi) pressure level.

If the low pressure drops like this, replace the control valve.

SERVICE POINTS OF REASSEMBLYM556HAF

8. INSTALLATION OF CLUTCH COIL

Align the pin of the clutch coil with the pin hole in the fronthousing, and then fit it into the hole.

7. INSTALLATION OF SNAP RING

Install the snap ring so that the tapered surface is at the

outer side.

1 TSB Revision

Page 1118 of 1146

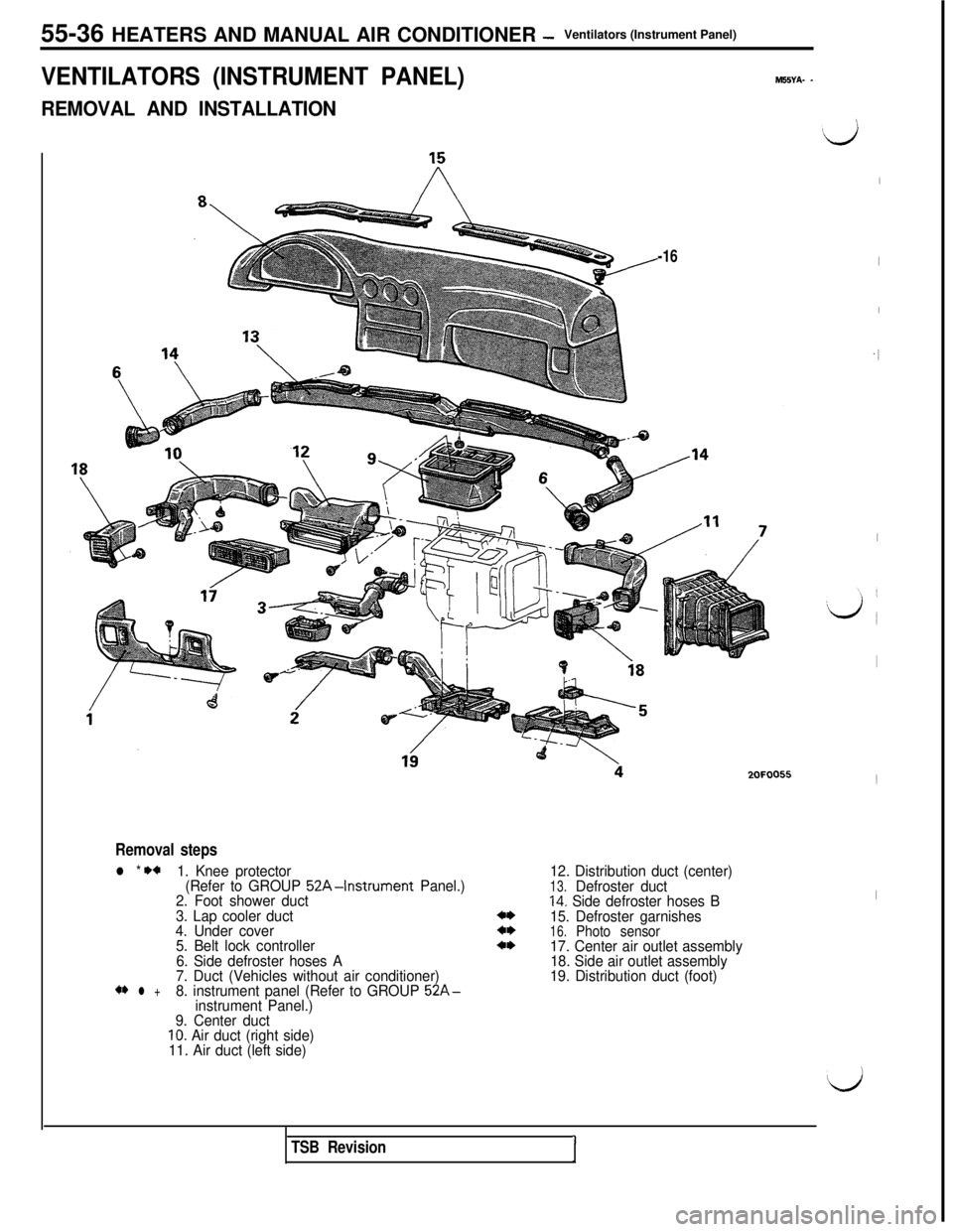

55-36 HEATERS AND MANUAL AIR CONDITIONER -Ventilators (Instrument Panel)

VENTILATORS (INSTRUMENT PANEL)M55YA- -

REMOVAL AND INSTALLATION

-16

/‘4

Removal steps

l * +a1. Knee protector

(Refer to GROUP 52A-Instrument Panel.)

2. Foot shower duct

3. Lap cooler duct

4. Under cover

5. Belt lock controller

6. Side defroster hoses A

7. Duct (Vehicles without air conditioner)

** l +8. instrument panel (Refer to GROUP 52A-instrument Panel.)

9. Center duct

10. Air duct (right side)

11. Air duct (left side)12. Distribution duct (center)

13.Defroster duct14. Side defroster hoses B

15. Defroster garnishes

16.Photo sensor17. Center air outlet assembly

18. Side air outlet assembly

19. Distribution duct (foot)2OFOO55

Ij

I

I

I

.I

I

I

!

I

‘d

TSB RevisionI

Page 1119 of 1146

HEATERS AND MANUAL AIR CONDITIONER -Ventilators (Instrument Panel) 55-37

/ 2OFOO321

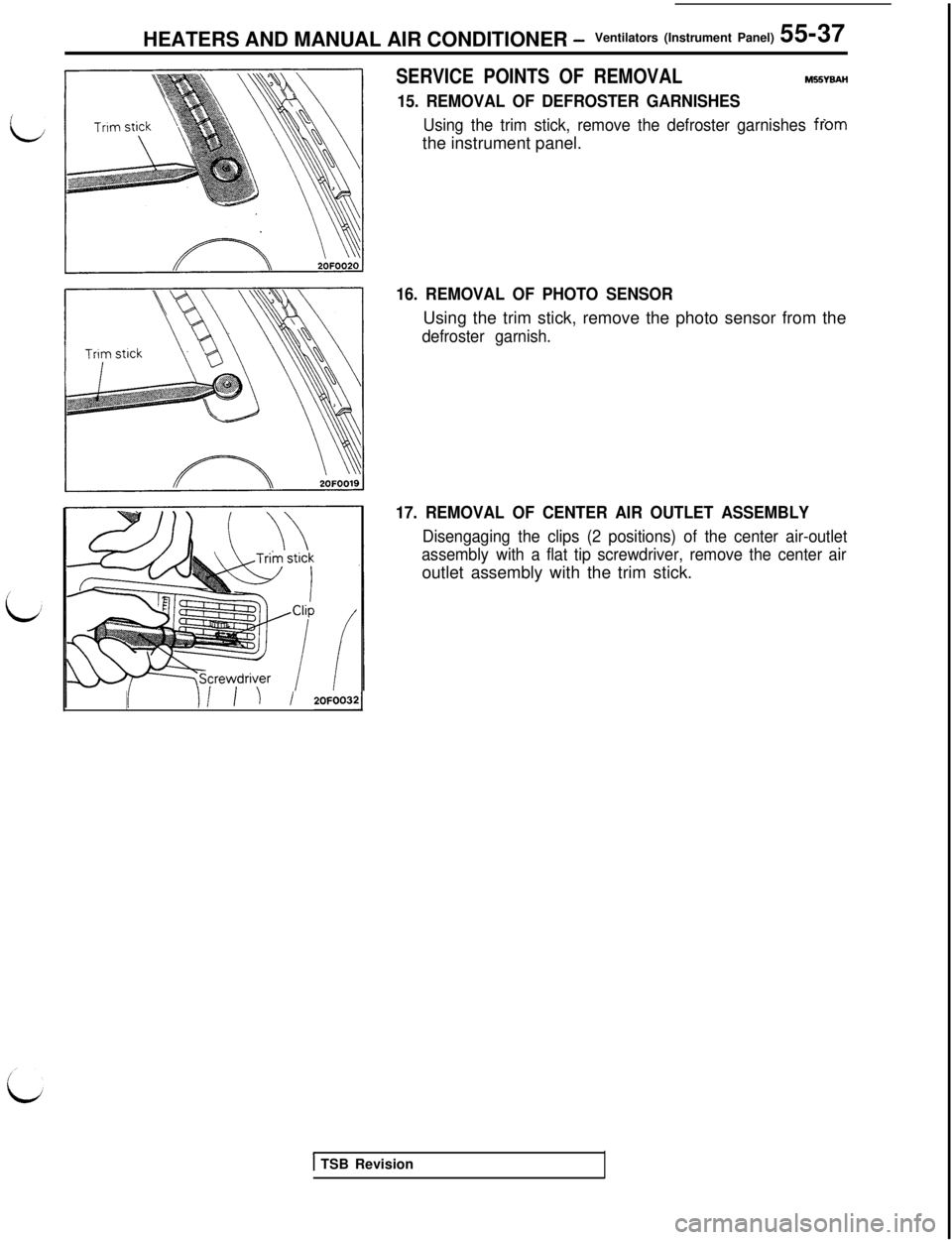

SERVICE POINTS OF REMOVALM55YBAH

15. REMOVAL OF DEFROSTER GARNISHES

Using the trim stick, remove the defroster garnishes fromthe instrument panel.

16. REMOVAL OF PHOTO SENSORUsing the trim stick, remove the photo sensor from the

defroster garnish.

17. REMOVAL OF CENTER AIR OUTLET ASSEMBLY

Disengaging the clips (2 positions) of the center air-outlet

assembly with a flat tip screwdriver, remove the center airoutlet assembly with the trim stick.

1 TSB Revision

Page 1123 of 1146

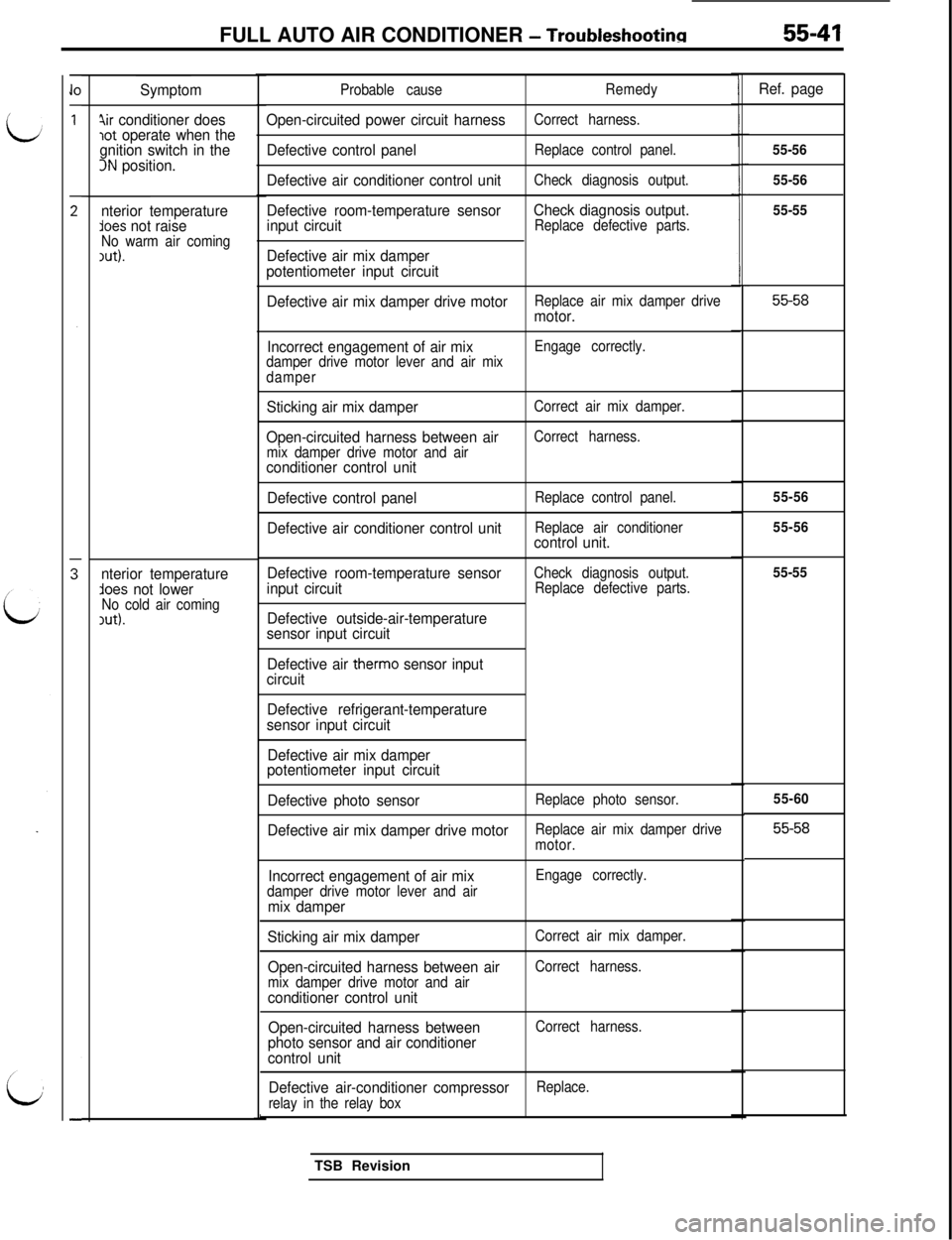

FULL AUTO AIR CONDITIONER - Troubleshootina55-41

Symptom

4ir conditioner doeslot operate when the

gnition switch in the

3N position.

nterior temperature

lees not raiseNo warm air coming1ut).

nterior temperatureAoes not lowerNo cold air coming,ut).Probable cause

Open-circuited power circuit harness

Defective control panel

Defective air conditioner control unit

Defective room-temperature sensor

input circuit

Defective air mix damper

potentiometer input circuit

Remedy

Correct harness.

Replace control panel.

Check diagnosis output.

Check diagnosis output.Replace defective parts.

Defective air mix damper drive motorReplace air mix damper drivemotor.

Incorrect engagement of air mix

damper drive motor lever and air mix

damperEngage correctly.

Sticking air mix damper

Open-circuited harness between air

mix damper drive motor and airconditioner control unit

Defective control panel

Defective air conditioner control unit

Correct air mix damper.

Correct harness.

Replace control panel.

Replace air conditioner

control unit.

Defective room-temperature sensor

input circuit

Defective outside-air-temperature

sensor input circuit

Check diagnosis output.

Replace defective parts.

Defective air therm0 sensor input

circuit

Defective refrigerant-temperature

sensor input circuit

Defective air mix damper

potentiometer input circuit

Defective photo sensor

Replace photo sensor.

Defective air mix damper drive motorReplace air mix damper drive

motor.

Incorrect engagement of air mixdamper drive motor lever and airmix damper

Engage correctly.

Sticking air mix damper

Open-circuited harness between air

mix damper drive motor and airconditioner control unit

Open-circuited harness between

photo sensor and air conditioner

control unit

Correct air mix damper.

Correct harness.

Correct harness.

Defective air-conditioner compressorReplace.

relay in the relay boxTSB Revision

Ref. page

55-56

55-56

55-55

55-58

55-56

55-56

55-55

55-60

55-58

Page 1126 of 1146

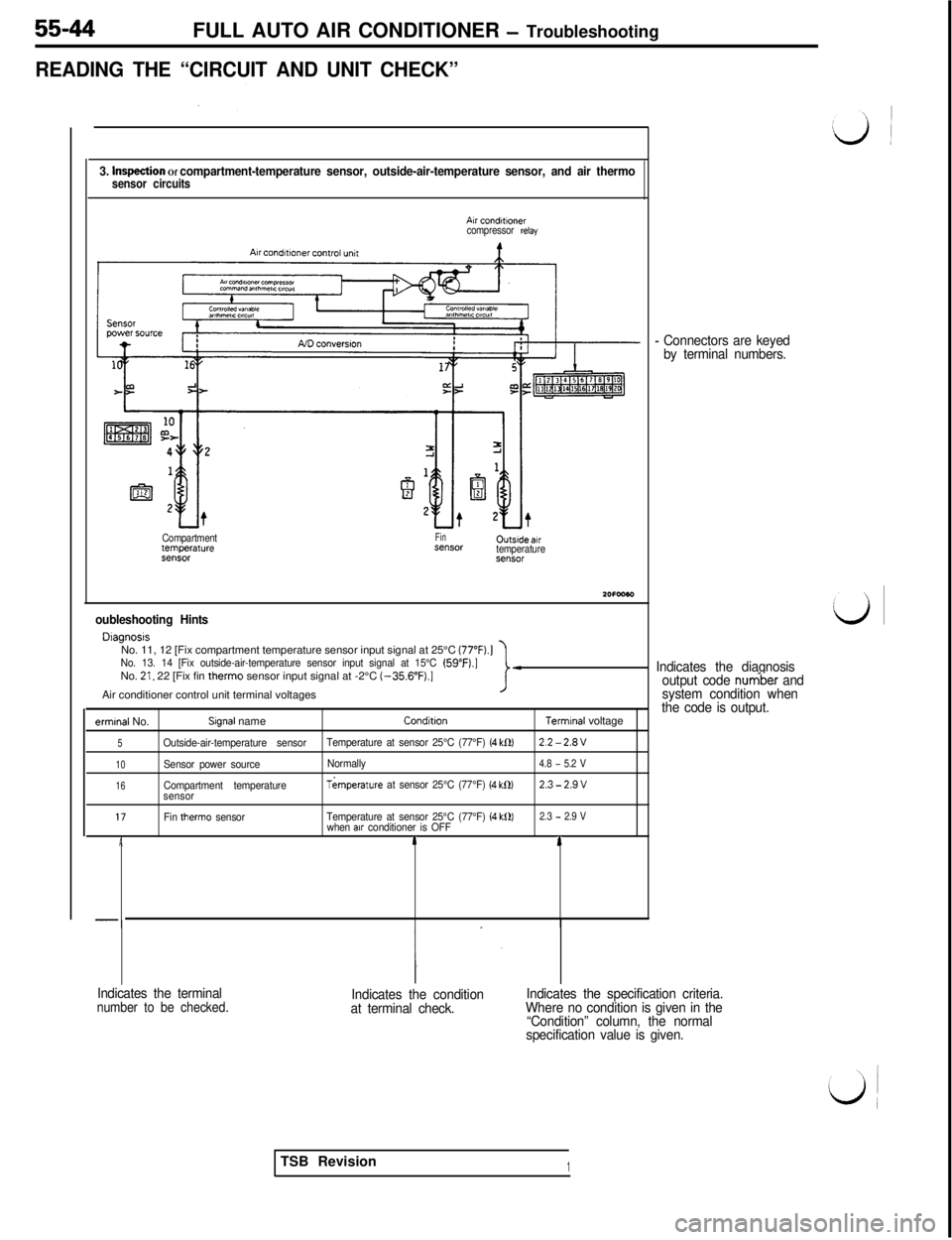

55-44FULL AUTO AIR CONDITIONER - Troubleshooting

READING THE “CIRCUIT AND UNIT CHECK”

3. hvqection Of compartment-temperature sensor, outside-air-temperature sensor, and air thermosensor circuits

Air condMnercompressor relay

Compartmenttemperat”re93”SCNFinX”SCH0utsrde.wtemperatureX”SOl

oubleshooting Hints

DlagnosrsNo. 11, 12 [Fix compartment temperature sensor input signal at 25°C (77”F).]

No. 13. 14 [Fix outside-air-temperature sensor input signal at 15°C (59”F).]No. 21, 22 [Fix fin therm0 sensor input signal at -2°C (-356”F).]Air conditioner control unit terminal voltagesI-

ermrnal No.Slgnal nameConditronTerrmnal voltage

5Outside-air-temperature sensorTemperature at sensor 25°C (77°F) (4 kf2)2.2-2.8V

10Sensor power sourceNormally4.8 - 5.2 V

16Compartment temperatureTkmperature at sensor 25°C (77°F) (4 k0)2.3-2.9vsensor

17Fin therm0 sensorTemperature at sensor 25°C (77°F) (4 k0)2.3 - 2.9 Vwhen alr conditioner is OFFA14

-

- Connectors are keyed

by terminal numbers.

Indicates the diagnosis

output code

nur6be.r and

system condition when

the code is output.

Indicates the terminal

number to be checked.Indicates the condition

at terminal check.Indicates the specification criteria.

Where no condition is given in the

“Condition” column, the normal

specification value is given.TSB Revision

1

Page 1128 of 1146

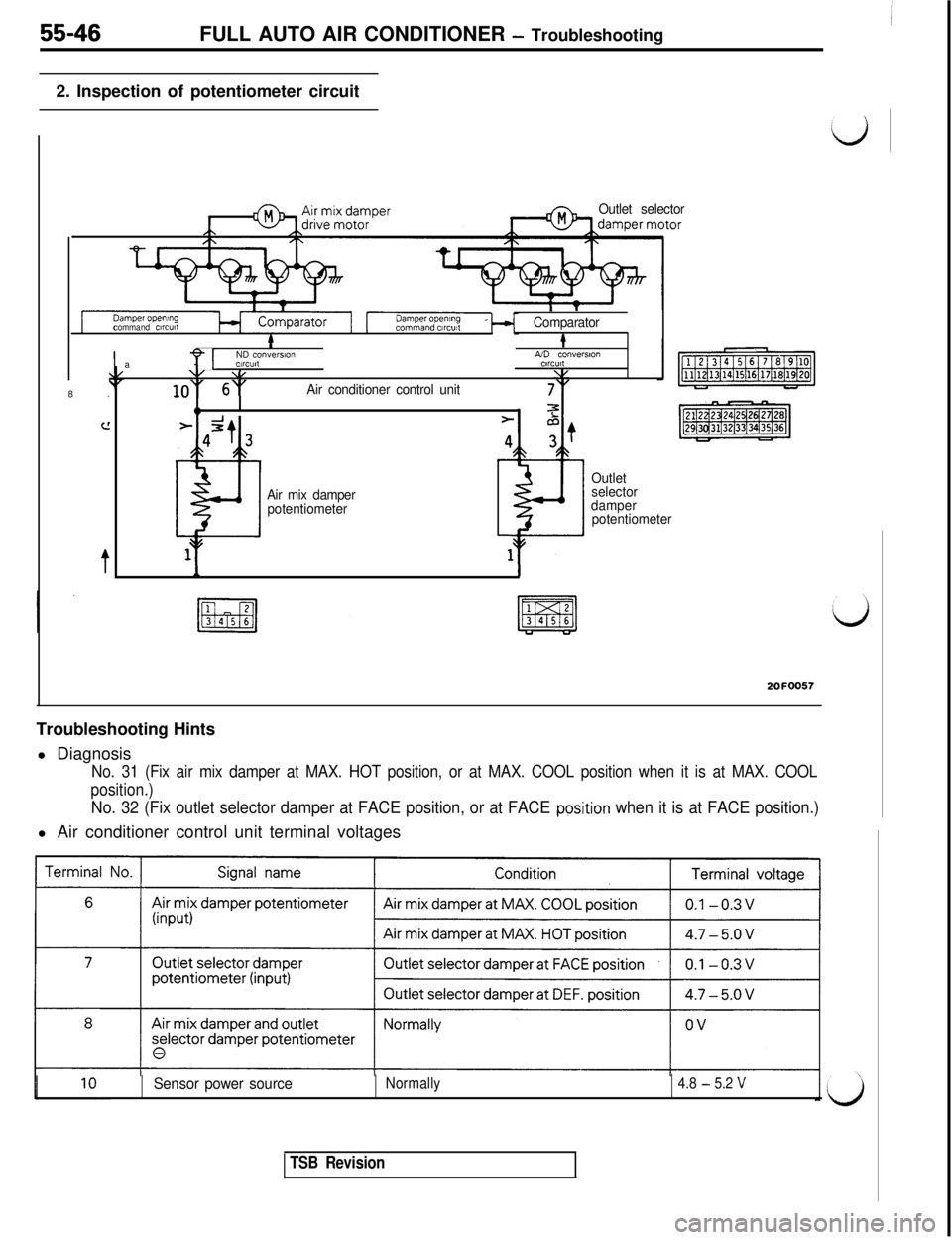

55-46FULL AUTO AIR CONDITIONER - Troubleshooting

2. Inspection of potentiometer circuit

Outlet selector

command c~rcutl

i IComparator&8.

c!

t

Ia

Y[ND conversionA/D conversvmWC”l,CllCUll\/ \,1.y

lo” 6”Air conditioner control unit7‘”

94 72-2t4 3

~1

Air mix damper

potentiometer

z=-

4;t

e11I

Outlet

selector

damper

potentiometer

2OFOO57Troubleshooting Hints

l Diagnosis

No. 31 (Fix air mix damper at MAX. HOT position, or at MAX. COOL position when it is at MAX. COOL

position.)

No. 32 (Fix outlet selector damper at FACE position, or at FACE pgsition when it is at FACE position.)l Air conditioner control unit terminal voltages

Sensor power sourceNormally4.8 - 5.2 V

TSB Revision

Page 1129 of 1146

FULL AUTO AIR CONDITIONER - Troubleshootinn55-47

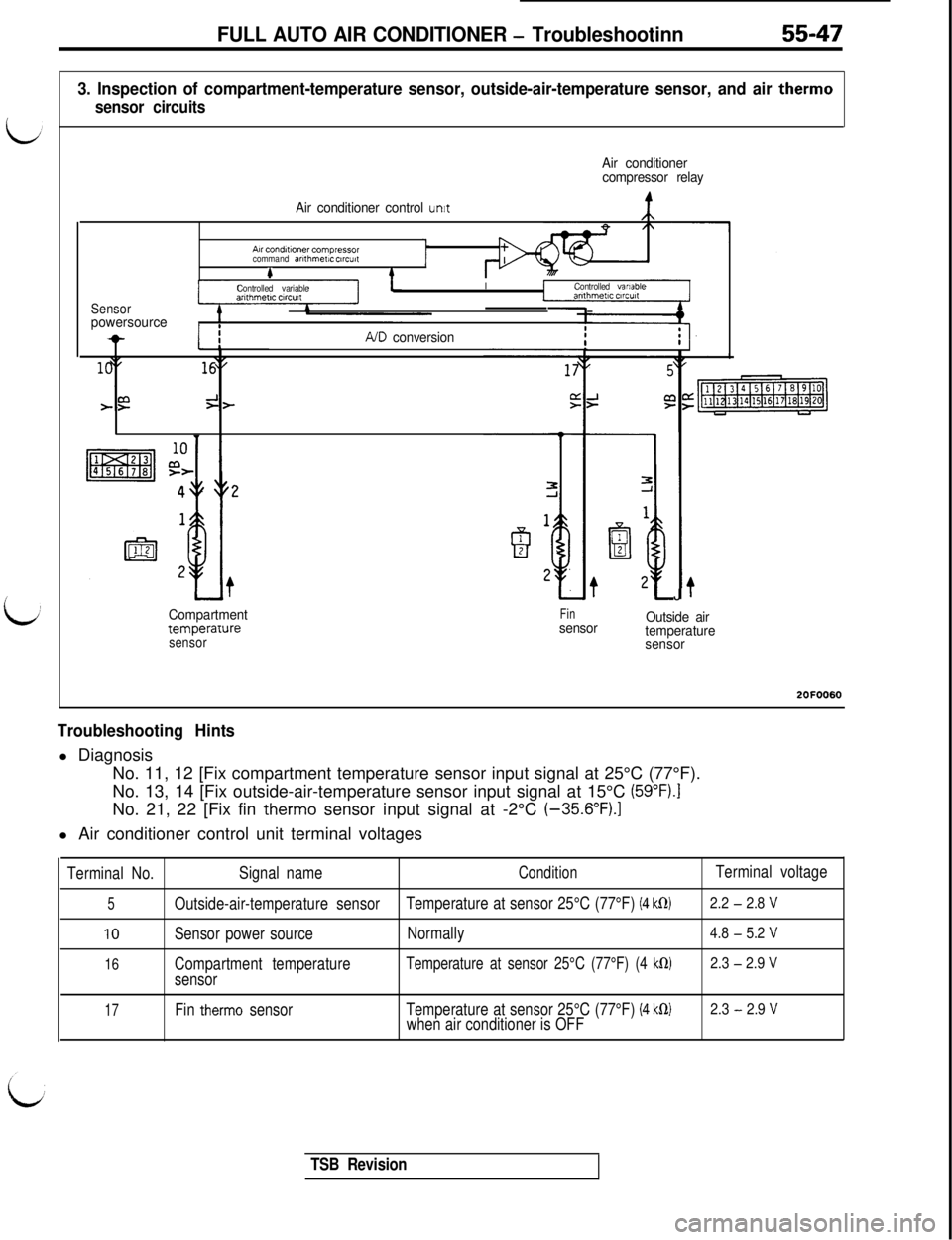

3. Inspection of compartment-temperature sensor, outside-air-temperature sensor, and air therm0

sensor circuits

Air conditioner

compressor relay

Air conditioner control

unitA~rconditlonercompiessor

command arllhmew ctrcutc#

Sensorpowersource

Controlled variableIControlled variable

-IIIA/D conversion

Compartment

temperaruresensor

Finsensor

?J

Outside air

temperature

sensor2OFOO60

Troubleshooting Hintsl Diagnosis

No. 11, 12 [Fix compartment temperature sensor input signal at 25°C (77°F).

No. 13, 14 [Fix outside-air-temperature sensor input signal at 15°C

(59”Fj.INo. 21, 22 [Fix fin

therm0 sensor input signal at -2°C (-35.6”FJ.ll Air conditioner control unit terminal voltages

Terminal No.Signal nameConditionTerminal voltage

5Outside-air-temperature sensorTemperature at sensor 25°C (77°F) (4 klR)2.2 - 2.8 V

10Sensor power sourceNormally4.8 - 5.2 V

16Compartment temperatureTemperature at sensor 25°C (77°F) (4 klR)2.3 - 2.9 V

sensor

17Fin therm0 sensorTemperature at sensor 25°C (77°F) (4 k0)2.3 - 2.9 Vwhen air conditioner is OFF

TSB Revision

Page 1130 of 1146

55-48FULL AUTO AIR CONDITIONER - Troubleshooting

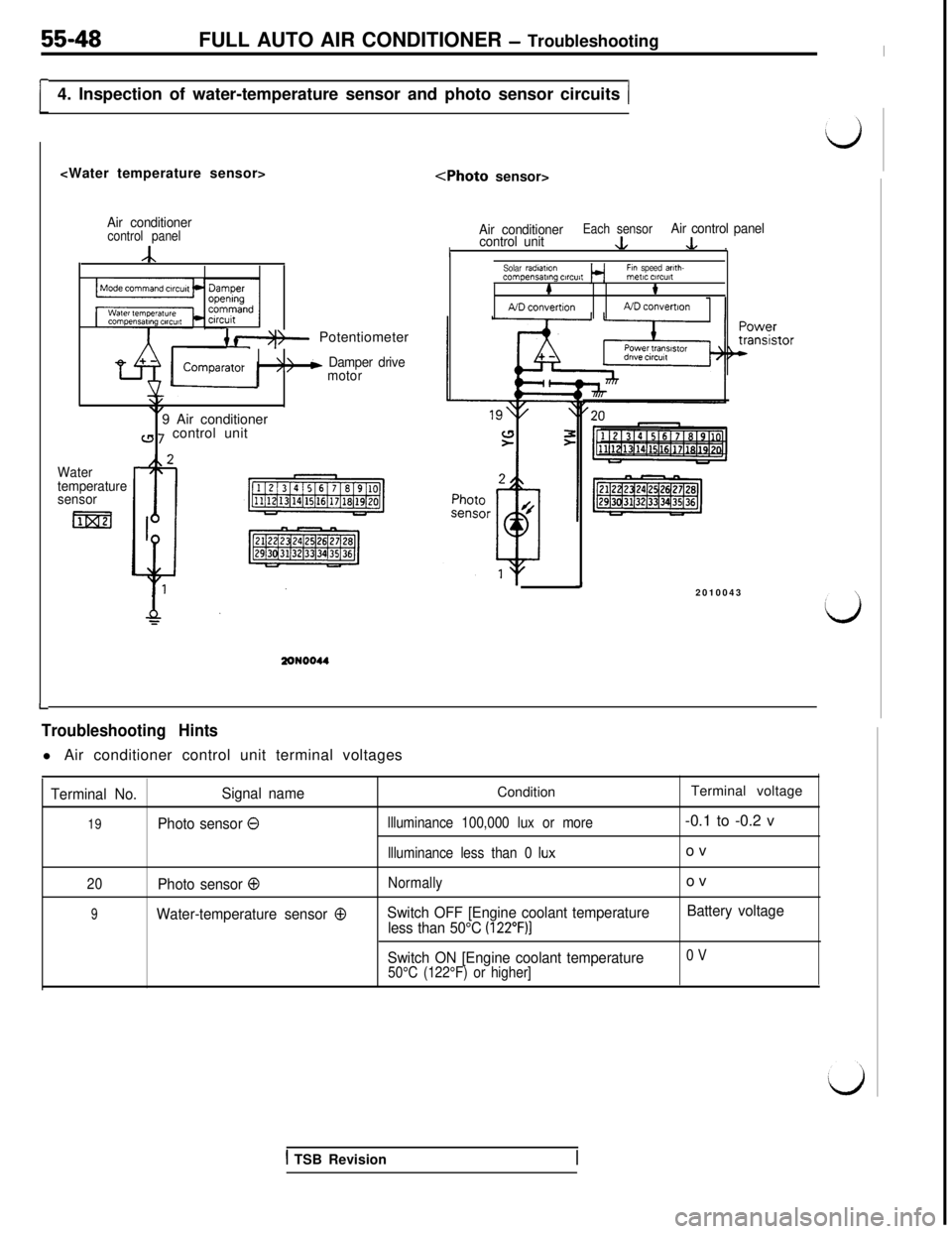

[4. Inspection of water-temperature sensor and photo sensor circuits (

Air conditionercontrol panel

A

{ f*)- Potentiometer

‘>/b Damper drive

motor

\/\,9 Air conditioner

a 7 control unit

Water

temperature

sensor

m

Air conditionerEach sensorcontrol unit&

Air control panel

I.L .Solar radmtmnFin speed arlth-compensating ClrC”itmetIC ClrCUlt#t

A/D convertionND convemon

J2010043

I-

Troubleshooting Hintsl Air conditioner control unit terminal voltages

Terminal No.Signal nameConditionTerminal voltage

19Photo sensor 0llluminance 100,000 lux or more-0.1 to -0.2 v

llluminance less than 0 Iuxov

20Photo sensor 0Normallyov

9Water-temperature sensor 0Switch OFF [Engine coolant temperature

less than 50°C (122”F)]

Battery voltage

Switch ON [Engine coolant temperature

0 V

50°C (122°F) or higher]

1 TSB Revision