sensor MITSUBISHI 3000GT 1991 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 120 of 1146

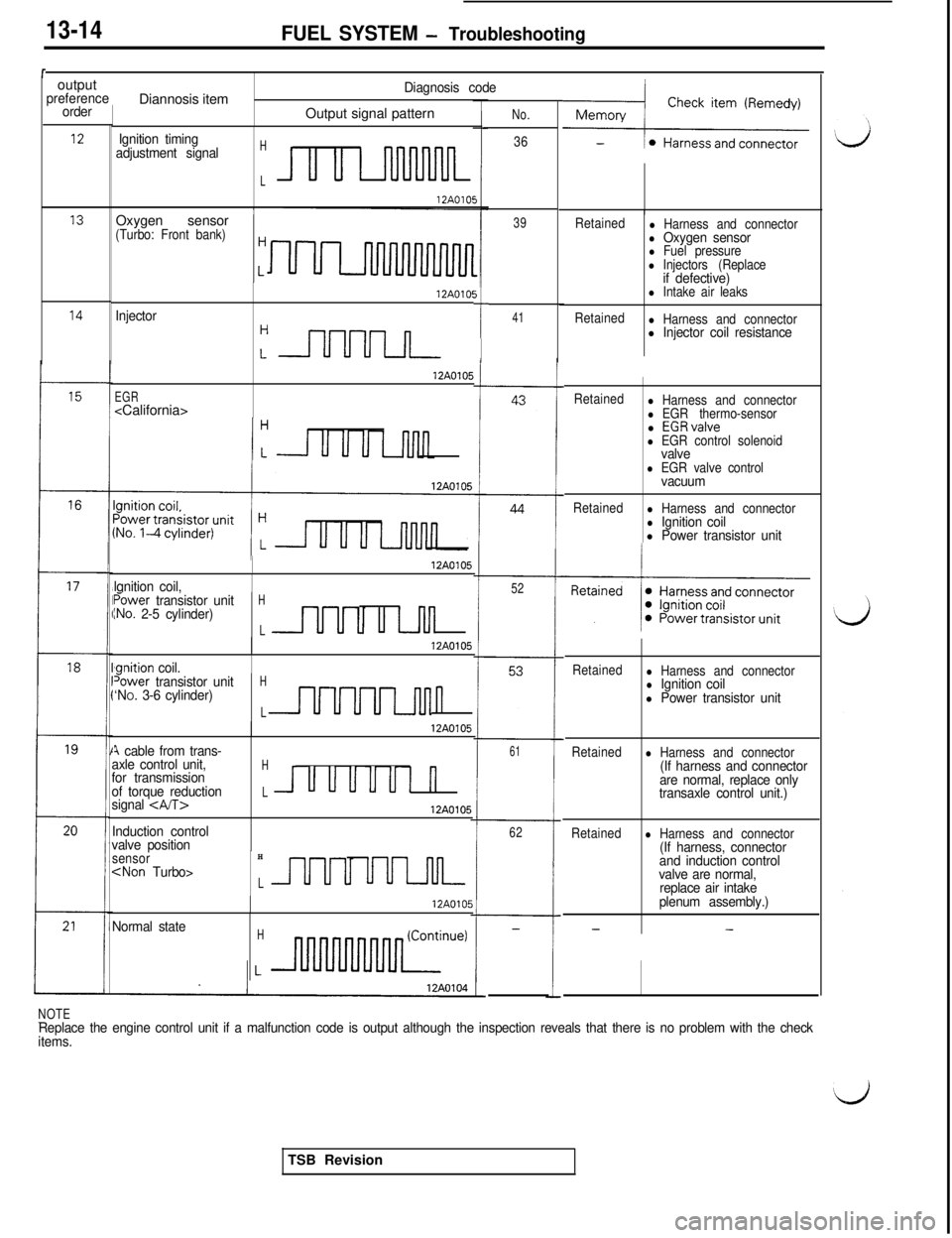

13-14FUEL SYSTEM - Troubleshooting

routput

preference

order

7Diannosis item

Diagnosis code

IOutput signal patternNo.

36

39

121 Ignition timing

adjustment signalH

L

13Oxygen sensor ’(Turbo: Front bank)HRetainedl Harness and connectorl Oxygen sensorl Fuel pressurel Injectors (Replaceif defective)l Intake air leaks

Retained

l Harness and connectorl Injector coil resistance

5

I--

Injector12AOlO!

:nnnn

EGR

12A0105

14

41

Retainedl Harness and connectorl EGR thermo-sensorl EGRvalvel EGR control solenoidvalvel EGR valve controlvacuum

Retainedl Harness and connectorl Ignition coill Power transistor unit

16

lqnition coil,

12A0105

52power transistor unitINO. 2-5 cylinder)H

Lu Lnll

‘qnition coil.

12AO105

18Retainedl Harness and connectorl Ignition coill Power transistor unit

Retainedl Harness and connector(If harness and connector

are normal, replace only

transaxle control unit.)

Retainedl Harness and connector(If harness, connector

and induction control

valve are normal,

replace air intake

plenum assembly.)

--

Tower transistor unitH‘NO. 3-6 cylinder)

Ln

12A0105

A cable from trans-

axle control unit,Hfor transmission

of torque reductionLUUUUUI n

signal 12A0105

Induction control

valve position

61

62

sensorH

12A0105

Normal stateH-

NOTE-Replace the engine control unit if a malfunction code is output although the inspection reveals that there is no problem with the check

items.TSB Revision

Page 126 of 1146

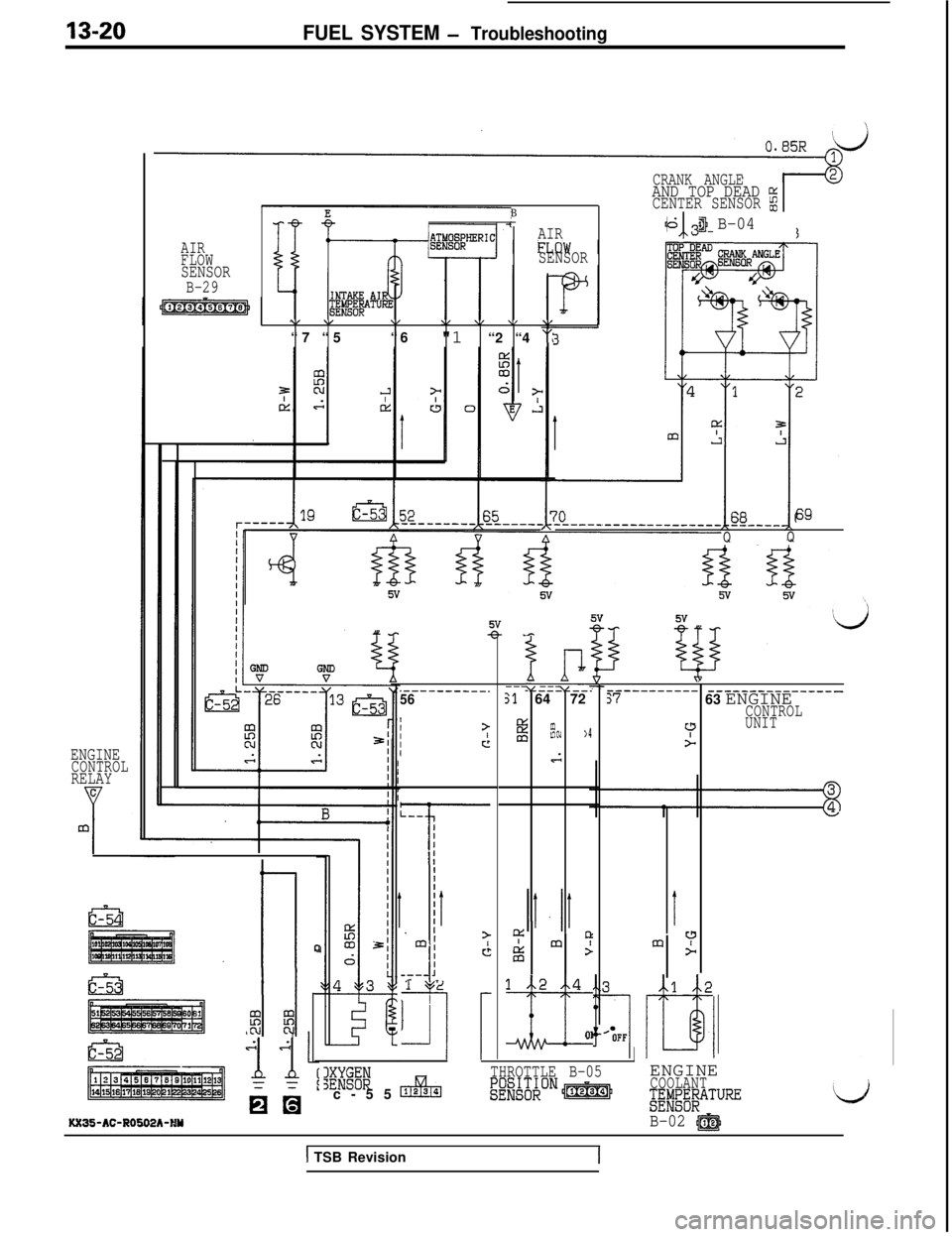

13-20FUEL SYSTEM - Troubleshooting

CRANK ANGLEAND TOP DEAD z

BCENTER SENSOR $j

AIR4-j B-04613

SENSOR

\/ v\/\, \I \/\I“7 “5“6

"1 “2 “4 “l

AIR

FLOW

SENSORB-29

69

QQ

ip--------.Sl6472

4:g$w cu> 4

d

m95

”----------- __---------_____:763 ENGINECONTROL?UNIT>

I

m?>

.----------.56

III?IcIENGINECONTROLRELAYc

Y

mL--I

1;

III

jr

I>ml

-II

d

--- 11 2

I

~~

12 4

~01

Ii%ml

c-55

c&m

THROTTLE B-05ENGINE

~~~Q~~oNp&q+COOLANT$E!E$BATURELj

B-02 @J

.h

0

I I

$I I$KX35-AC-R0502h-HY

1 TSB Revision

Page 130 of 1146

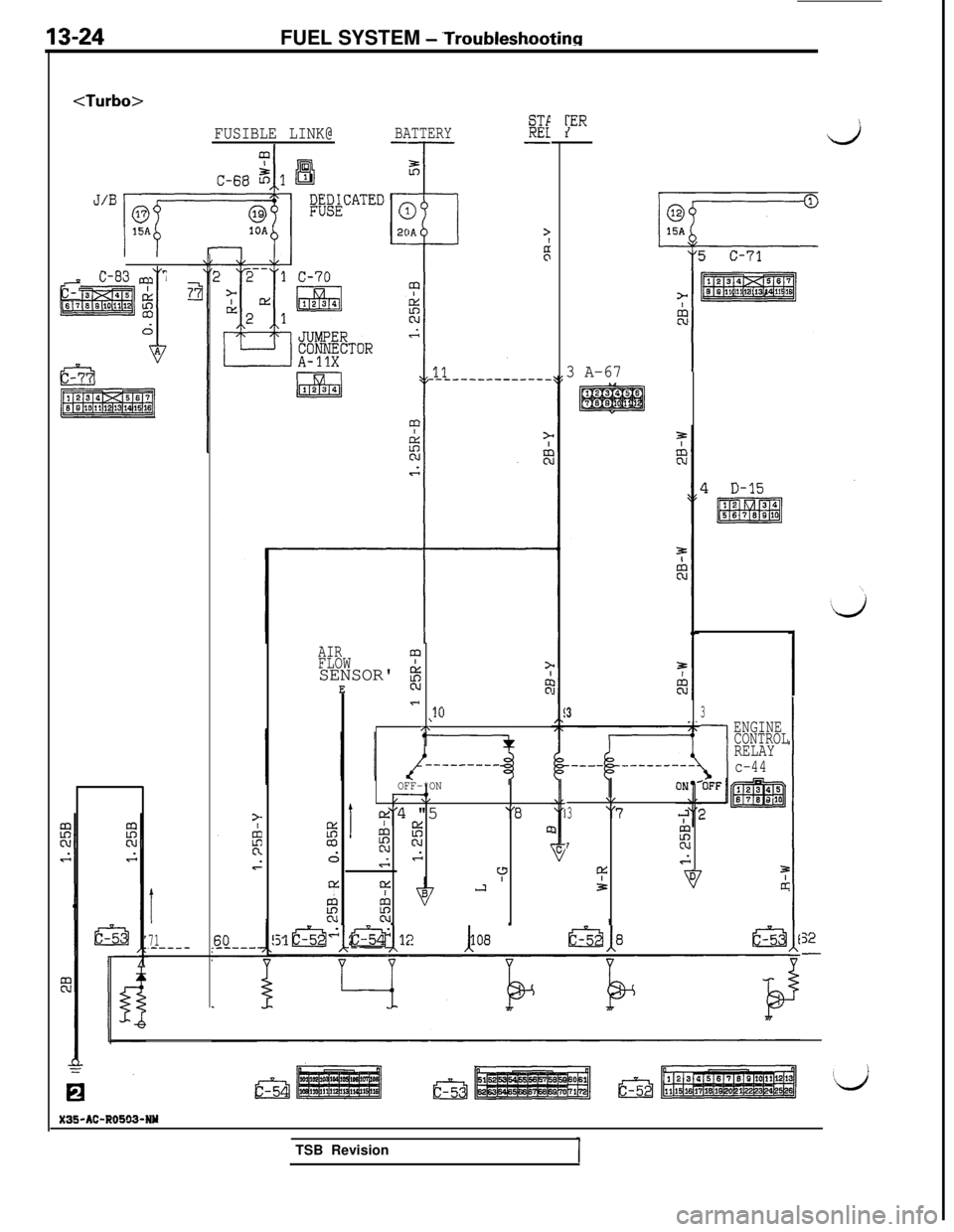

13-24FUEL SYSTEM - ‘Troubleshootinn

FUSIBLE LINK@BATTERY%

--T-- -J/Bqa1

B;&CATED

;ER

0

1

15A

c-71

I-

jLEl3za

12345675 s *01112* , 1616

w

15A

I t

IOA

-1l-

C-83 m 7

pTEiEsq&is

1

6

Efi;;l

p!i!Ezq;

3 A-67

I

71,-----

AIRmFLOWSENSOR' i?

EN:

- ,lOI\

---------

OFF-*ON__O/ \I

1

cte"4 "5"0%

%D

dN INGlc

CLYYIJ

EN

33

-I

ENGINE

CONTROL

RELAY

c-44

\,

3"7

T!c

4:?3[II

1-;125 +2a 108 &1852-5

X35-AC-R0503-NY

EaaTSB Revision

Page 132 of 1146

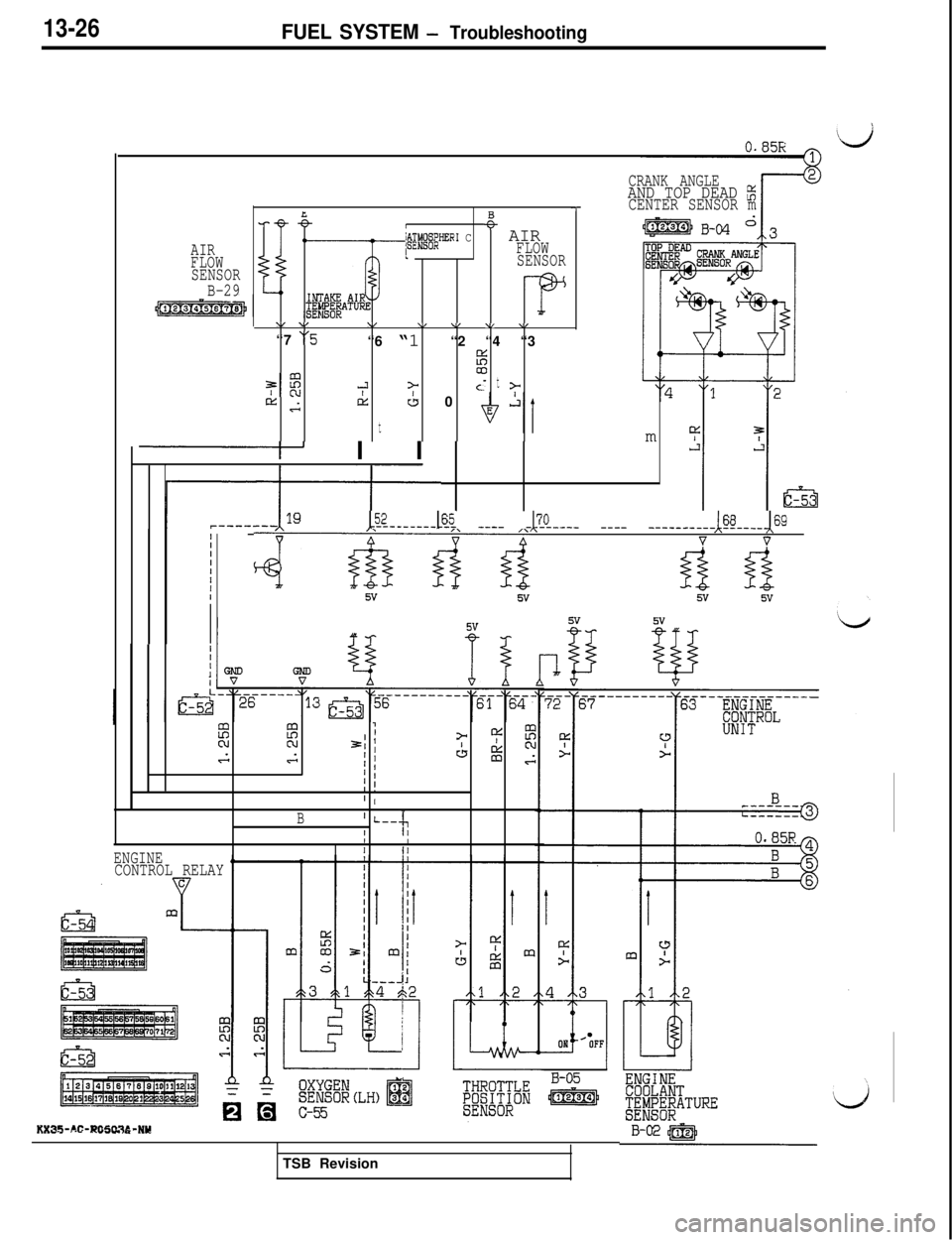

13-26FUEL SYSTEM - Troubleshooting

AIR

FLOW

SENSOR

B-29

LB-eI~@.@JER’ C+- AIRIFLOW

SENSOR

\/ v\/\/ \/ \I \,“7

“5“6 “1 “2 “4 “3

%

7:

00-3>t

Ac- z-rtis

t

CL 0

I I I

iIIIIIIII

III1I

~ZL---&i ____ -&L--- ____ --------&----&9

4&&d vv

CRANK ANGLEAND TOP DEAD z-7CENTER SENSOR mm

2E?7IN21 )= 4:EGGI ’CL g

) 1G

I !’ I

B’ L--l‘;rII

ENGINEIII

CONTROL RELAY

5vii

KX35-AC-RO5tX36-NYTSB Revision

Page 139 of 1146

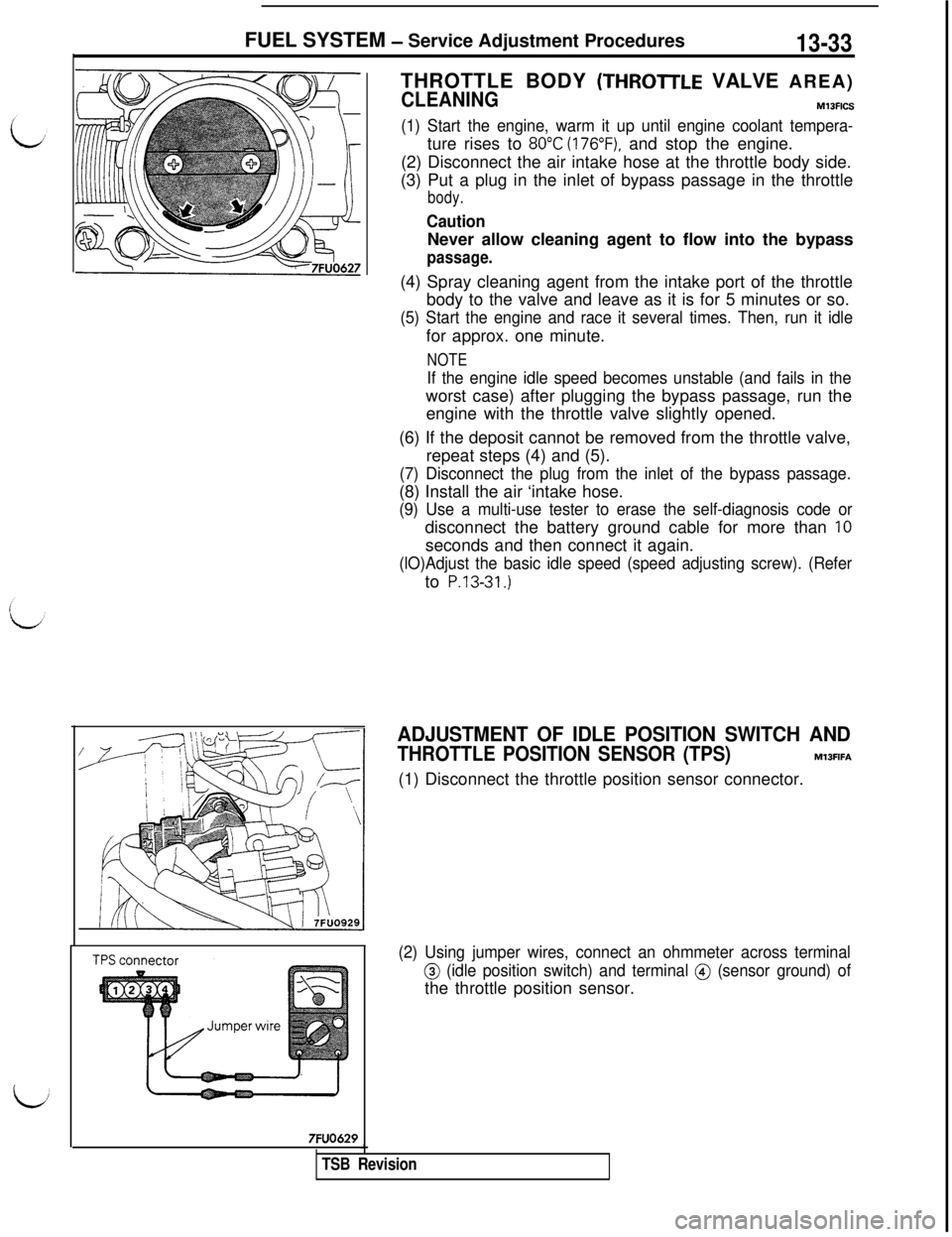

FUEL SYSTEM - Service Adjustment Procedures13-33THROTTLE BODY

(THROTrLE VALVE AREA)

CLEANINGM13FICS

(1) Start the engine, warm it up until engine coolant tempera-ture rises to

80°C (176”F), and stop the engine.

(2) Disconnect the air intake hose at the throttle body side.

(3) Put a plug in the inlet of bypass passage in the throttle

body.

CautionNever allow cleaning agent to flow into the bypass

passage.(4) Spray cleaning agent from the intake port of the throttle

body to the valve and leave as it is for 5 minutes or so.

(5) Start the engine and race it several times. Then, run it idlefor approx. one minute.

NOTE

If the engine idle speed becomes unstable (and fails in theworst case) after plugging the bypass passage, run the

engine with the throttle valve slightly opened.

(6) If the deposit cannot be removed from the throttle valve,

repeat steps (4) and (5).

(7) Disconnect the plug from the inlet of the bypass passage.(8) Install the air ‘intake hose.

(9) Use a multi-use tester to erase the self-diagnosis code ordisconnect the battery ground cable for more than

IOseconds and then connect it again.

(lO)Adjust the basic idle speed (speed adjusting screw). (Referto

P.13-31.)

7FUO629

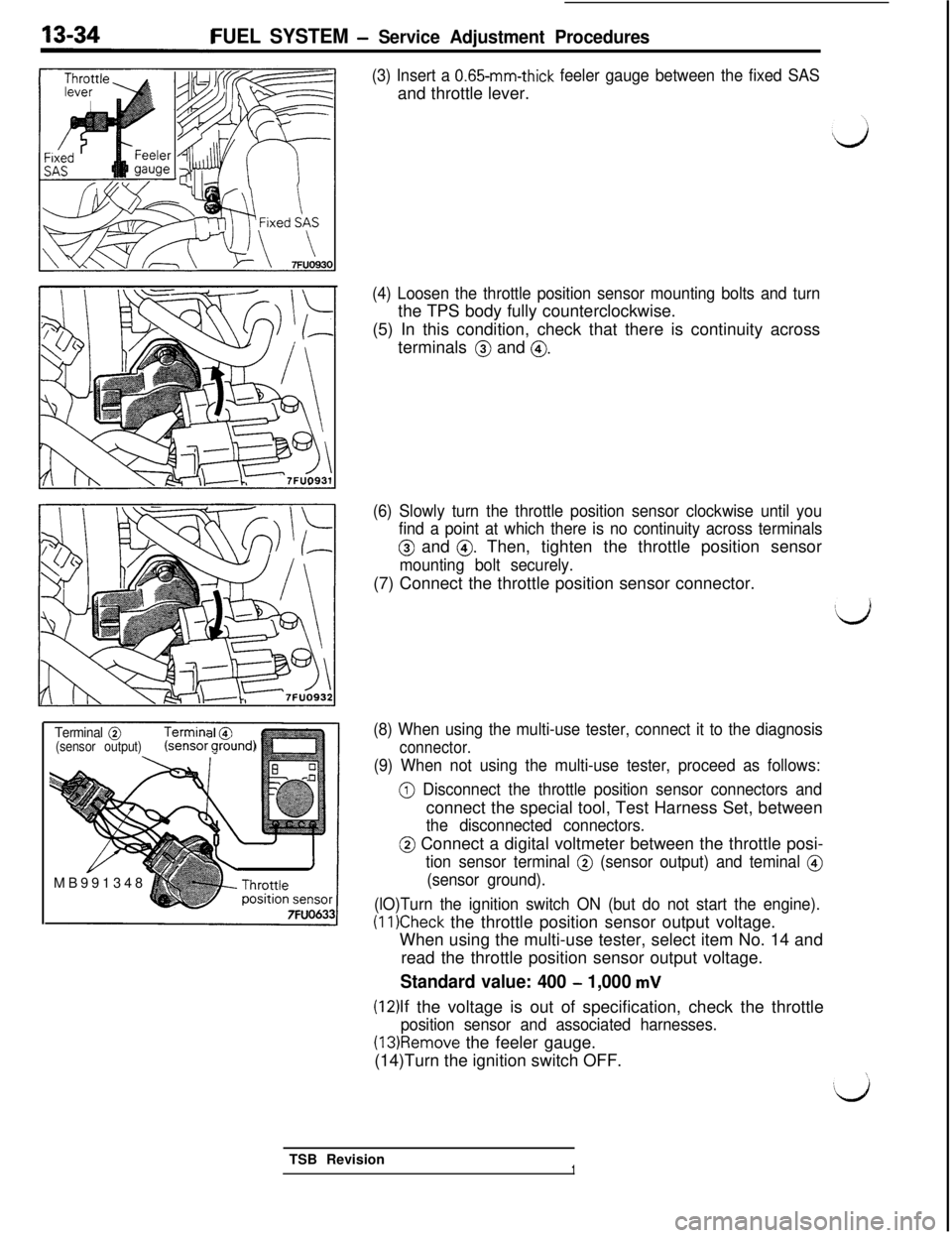

ADJUSTMENT OF IDLE POSITION SWITCH AND

THROTTLE POSITION SENSOR (TPS)M13FIFA(1) Disconnect the throttle position sensor connector.

(2) Using jumper wires, connect an ohmmeter across terminal

@ (idle position switch) and terminal @ (sensor ground) ofthe throttle position sensor.

TSB Revision

Page 140 of 1146

FUEL SYSTEM - Service Adjustment Procedures

(3) Insert a 0.65-mm-thick feeler gauge between the fixed SASand throttle lever.

Terminal @

(sensor output)zensor g&nd)MB991348

1

(4) Loosen the throttle position sensor mounting bolts and turnthe TPS body fully counterclockwise.

(5) In this condition, check that there is continuity across

terminals

@ and @.

(6) Slowly turn the throttle position sensor clockwise until you

find a point at which there is no continuity across terminals

@ and 0. Then, tighten the throttle position sensor

mounting bolt securely.(7) Connect the throttle position sensor connector.

(8) When using the multi-use tester, connect it to the diagnosis

connector.

(9) When not using the multi-use tester, proceed as follows:

@ Disconnect the throttle position sensor connectors andconnect the special tool, Test Harness Set, between

the disconnected connectors.

@ Connect a digital voltmeter between the throttle posi-

tion sensor terminal @ (sensor output) and teminal @

(sensor ground).

(lO)Turn the ignition switch ON (but do not start the engine).

(IlKheck the throttle position sensor output voltage.

When using the multi-use tester, select item No. 14 and

read the throttle position sensor output voltage.

Standard value: 400 - 1,000 mV

(12)lf the voltage is out of specification, check the throttle

position sensor and associated harnesses.

(13)Remove the feeler gauge.

(14)Turn the ignition switch OFF.

TSB Revision

1

Page 141 of 1146

FUEL SYSTEM - Service Adjustment Procedures13-35

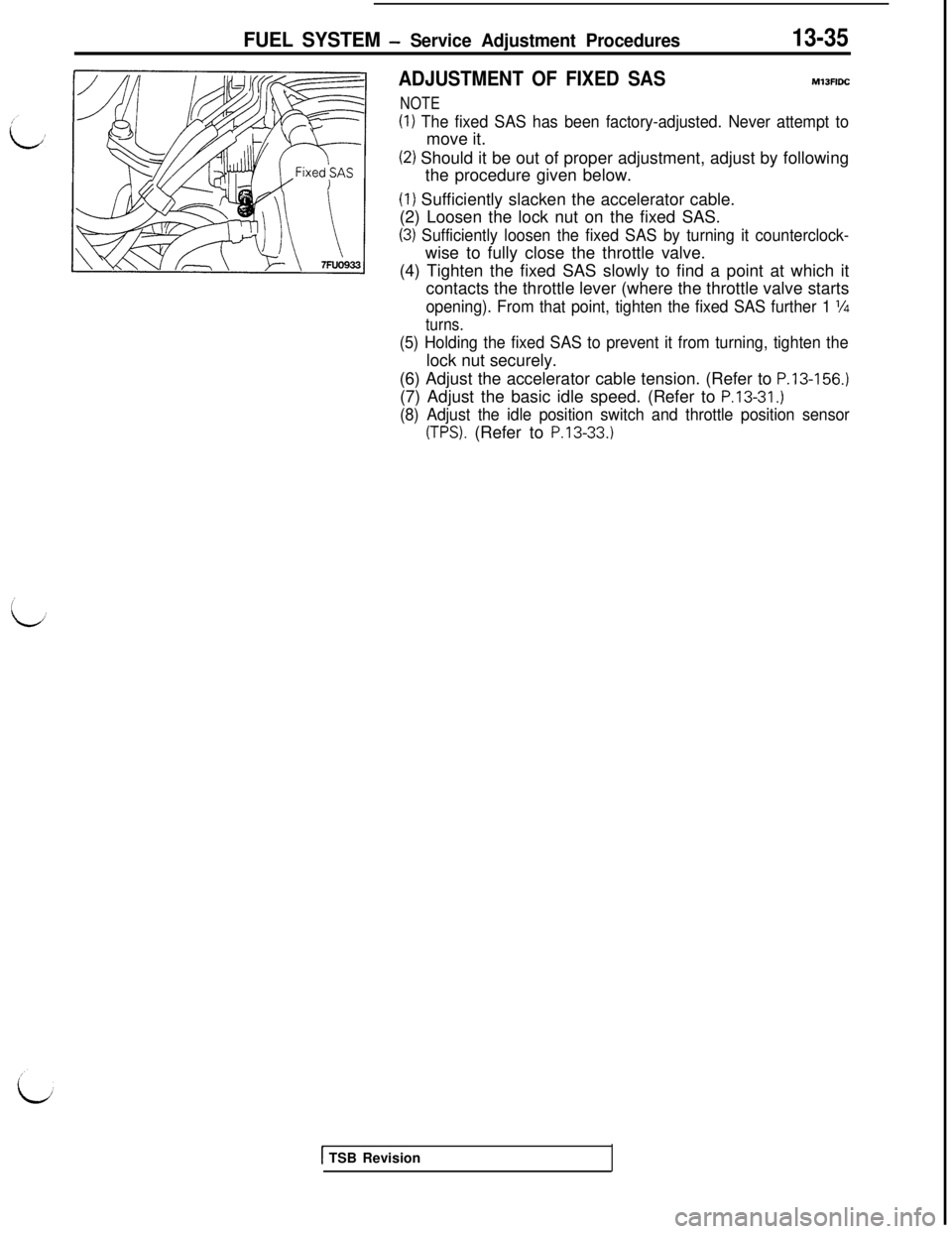

ADJUSTMENT OF FIXED SASMlJFlDC

NOTE

(1) The fixed SAS has been factory-adjusted. Never attempt tomove it.

(2) Should it be out of proper adjustment, adjust by following

the procedure given below.(I) Sufficiently slacken the accelerator cable.

(2) Loosen the lock nut on the fixed SAS.

(3) Sufficiently loosen the fixed SAS by turning it counterclock-wise to fully close the throttle valve.

(4) Tighten the fixed SAS slowly to find a point at which it

contacts the throttle lever (where the throttle valve starts

opening). From that point, tighten the fixed SAS further 1 l/4

turns.

(5) Holding the fixed SAS to prevent it from turning, tighten thelock nut securely.

(6) Adjust the accelerator cable tension. (Refer to

P.13-156.)(7) Adjust the basic idle speed. (Refer to

P.13-31.)

(8) Adjust the idle position switch and throttle position sensor

(TPS). (Refer to P.13-33.)

1 TSB Revision

Page 142 of 1146

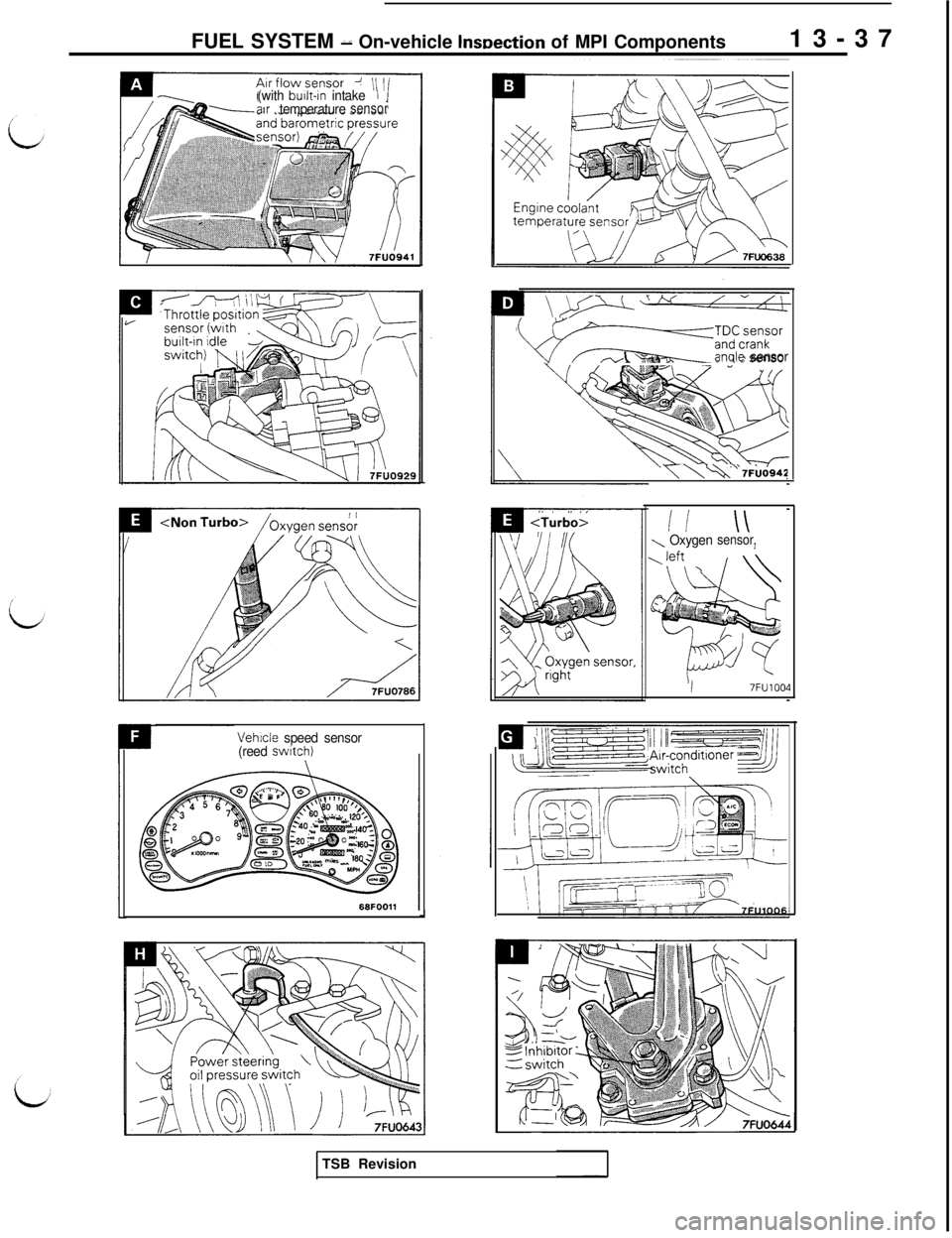

13-36FUEL SYSTEM - 0

n-vehicle Inspection of MPI Components

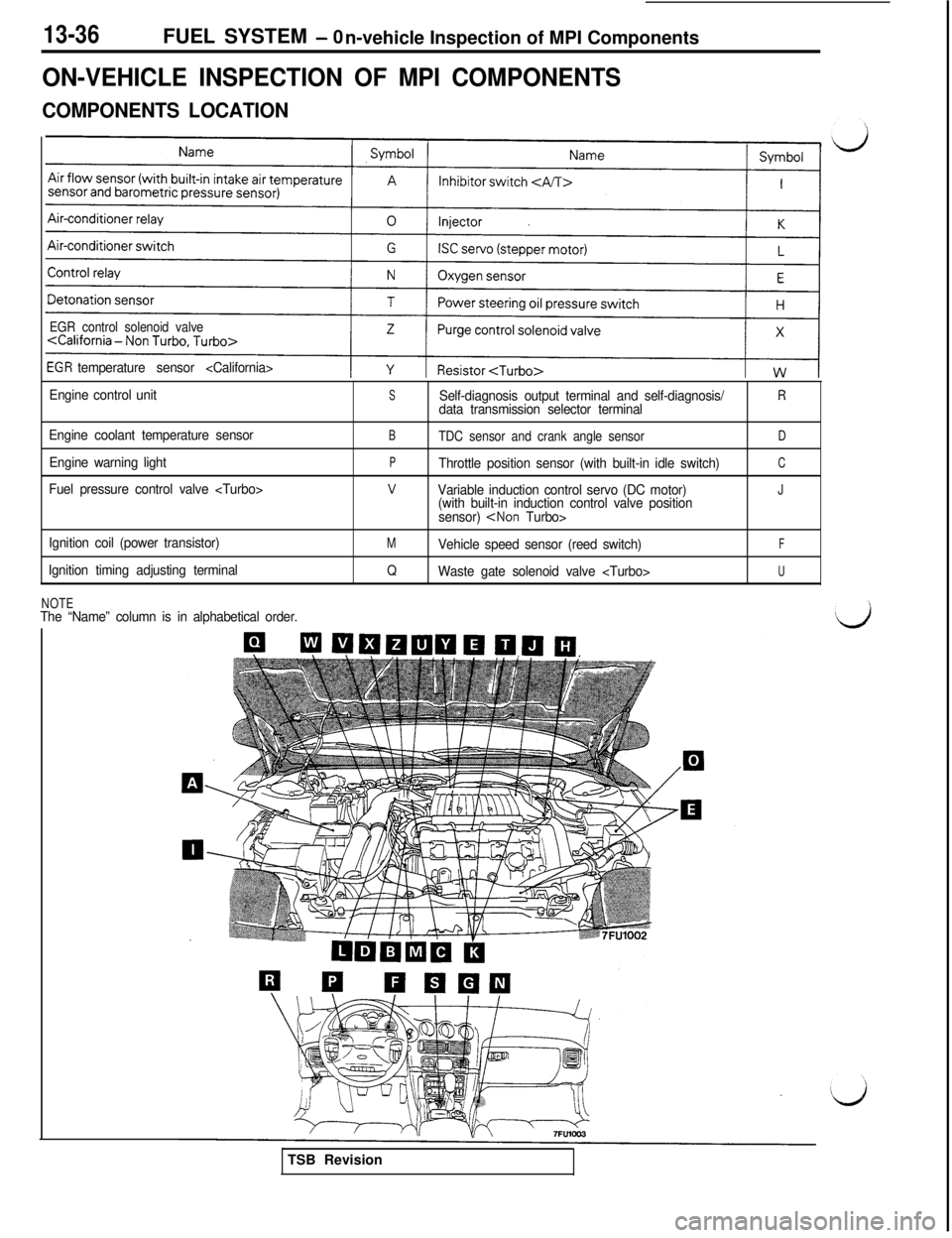

ON-VEHICLE INSPECTION OF MPI COMPONENTS

COMPONENTS LOCATION

EGR control solenoid valve

temperature sensor

Engine control unit

Engine coolant temperature sensor

Engine warning light

Fuel pressure control valve

Ignition coil (power transistor)

Ignition timing adjusting terminal

SSelf-diagnosis output terminal and self-diagnosis/Rdata transmission selector terminal

BTDC sensor and crank angle sensorD

PThrottle position sensor (with built-in idle switch)C

vVariable induction control servo (DC motor)J(with built-in induction control valve position

sensor)

MVehicle speed sensor (reed switch)F

QWaste gate solenoid valve

NOTEThe “Name” column is in alphabetical order.TSB Revision

Page 143 of 1146

FUEL SYSTEM d On-vehicle lnwection of MPI Components13-37(with built-in intakeIair temperaturesensor

Vehicle speed sensor

(reed switch)J

wF~~::~:~~or- A.anale sensor

y\\ v 7Fbd942

ii \\\ Oxygensensor,

I7FU1004

//

\:/TSB Revision

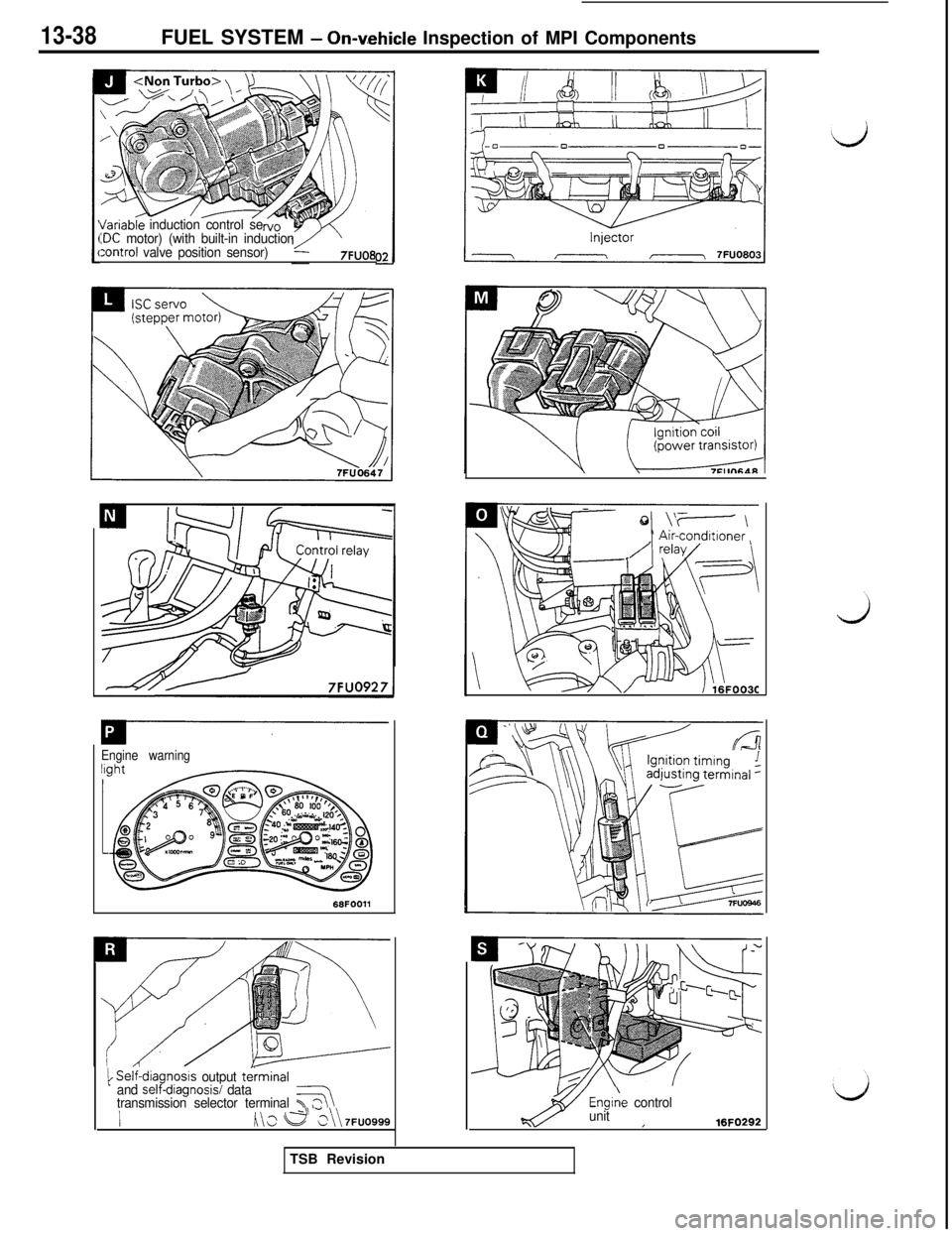

Page 144 of 1146

13-38FUEL SYSTEM - Onaehicle Inspection of MPI Components

I/ariableinduction control se:DC motor) (with built-in induction:ontrol valve position sensor)7FUO8

Engine warning

1 Self-diagn,osls output terminal

and self-dlagnosisi data

transmission selector terminal T37

h\s e >\\ 7FUO999Engiie

control

unit

I16FO292TSB Revision