lock MITSUBISHI 3000GT 1991 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 251 of 1146

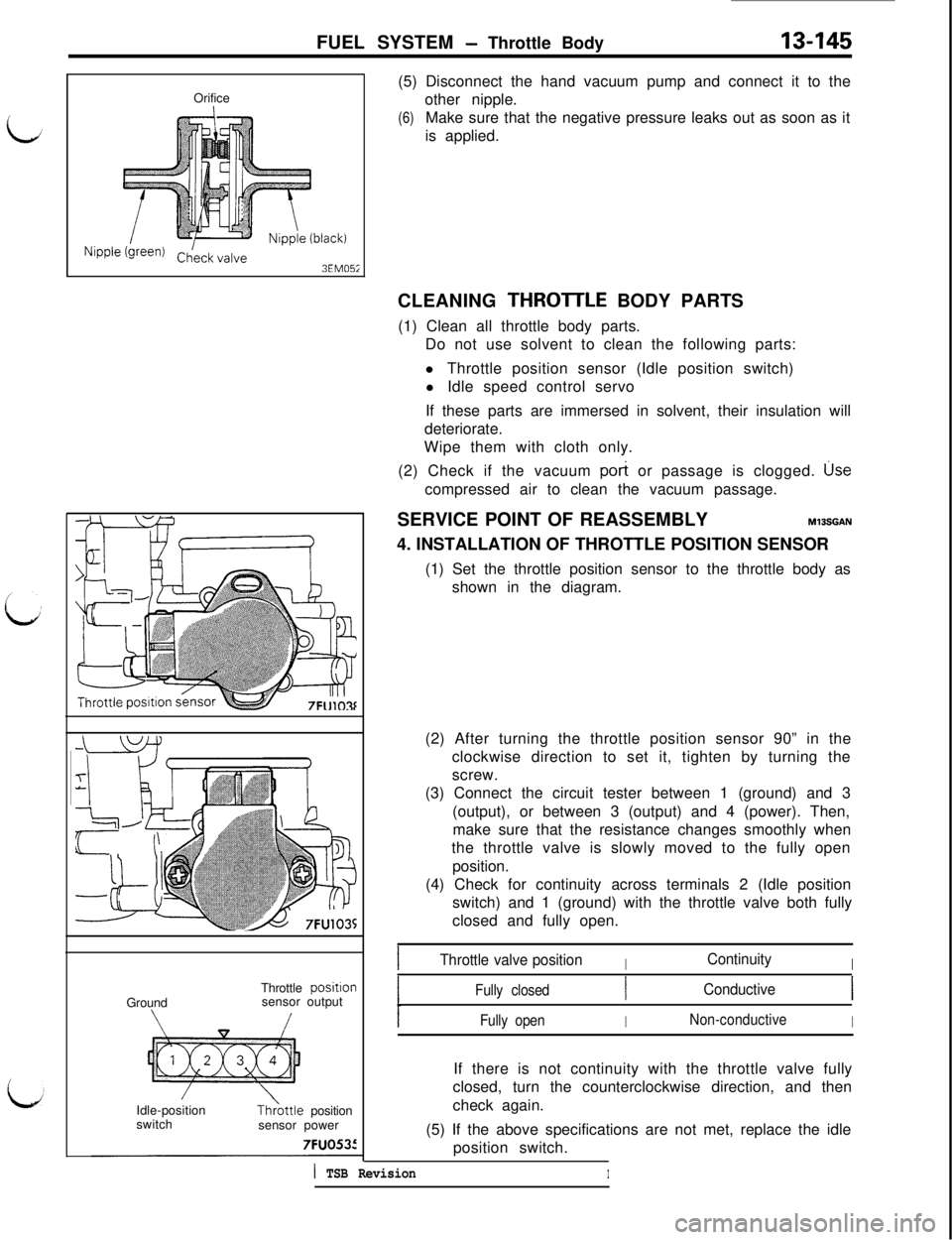

FUEL SYSTEM - Throttle Body13-145Orifice

Nipple (green)3EM05iGroundThrottle

positlonsensor output

Idle-position

switchTh>ottle position

sensor power7FUO535(5) Disconnect the hand vacuum pump and connect it to the

other nipple.

(6)Make sure that the negative pressure leaks out as soon as it

is applied.

CLEANING THROTTLE BODY PARTS

(1) Clean all throttle body parts.

Do not use solvent to clean the following parts:

l Throttle position sensor (Idle position switch)

l Idle speed control servo

If these parts are immersed in solvent, their insulation will

deteriorate.

Wipe them with cloth only.

(2) Check if the vacuum

pot-t or passage is clogged. usecompressed air to clean the vacuum passage.

SERVICE POINT OF REASSEMBLY

M13SGAN4. INSTALLATION OF THROTTLE POSITION SENSOR

(1) Set the throttle position sensor to the throttle body as

shown in the diagram.

(2) After turning the throttle position sensor 90” in the

clockwise direction to set it, tighten by turning the

screw.

(3) Connect the circuit tester between 1 (ground) and 3

(output), or between 3 (output) and 4 (power). Then,

make sure that the resistance changes smoothly when

the throttle valve is slowly moved to the fully open

position.

(4) Check for continuity across terminals 2 (Idle position

switch) and 1 (ground) with the throttle valve both fully

closed and fully open.

IThrottle valve positionIContinuityI

Fully closedConductive

Fully openINon-conductiveIIf there is not continuity with the throttle valve fully

closed, turn the counterclockwise direction, and then

check again.

(5) If the above specifications are not met, replace the idle

position switch.

1 TSB RevisionI

Page 252 of 1146

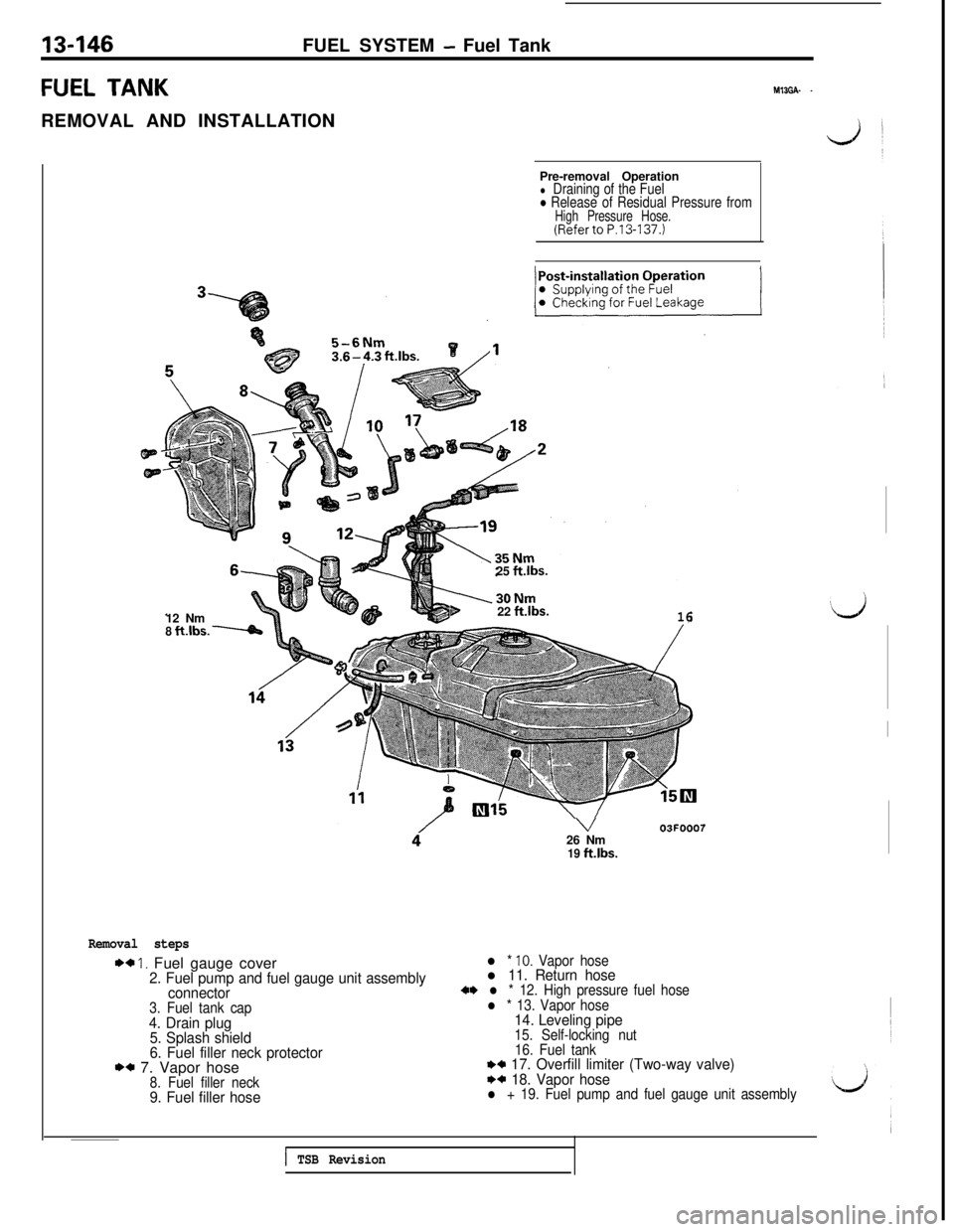

13-146FUEL SYSTEM - Fuel Tank

FUEL TANKREMOVAL AND INSTALLATIONM13GA- -12 Nm

8 ft.lbs. WPre-removal Operation

l Draining of the Fuel0 Release of Residual Pressure fromHigh Pressure Hose.(Referto P.13-137.)

5-6Nm25 ft.lbs.

b22 ftlbs.16

V26 Nm

19 ft.lbs.

03FOOO7

Removal steps

** I. Fuel gauge cover2. Fuel pump and fuel gauge unit assembly

connector

3. Fuel tank cap4. Drain plug

5. Splash shield

6. Fuel filler neck protector

** 7. Vapor hose8. Fuel filler neck9. Fuel filler hose

l * IO. Vapor hosel 11. Return hose+* l * 12. High pressure fuel hosel * 13. Vapor hose14. Leveling pipe15. Self-locking nut

16. Fuel tank++

17. Overfill limiter (Two-way valve)I)+ 18. Vapor hosel + 19. Fuel pump and fuel gauge unit assembly

;d

I

1 TSB Revision

Page 275 of 1146

Page 279 of 1146

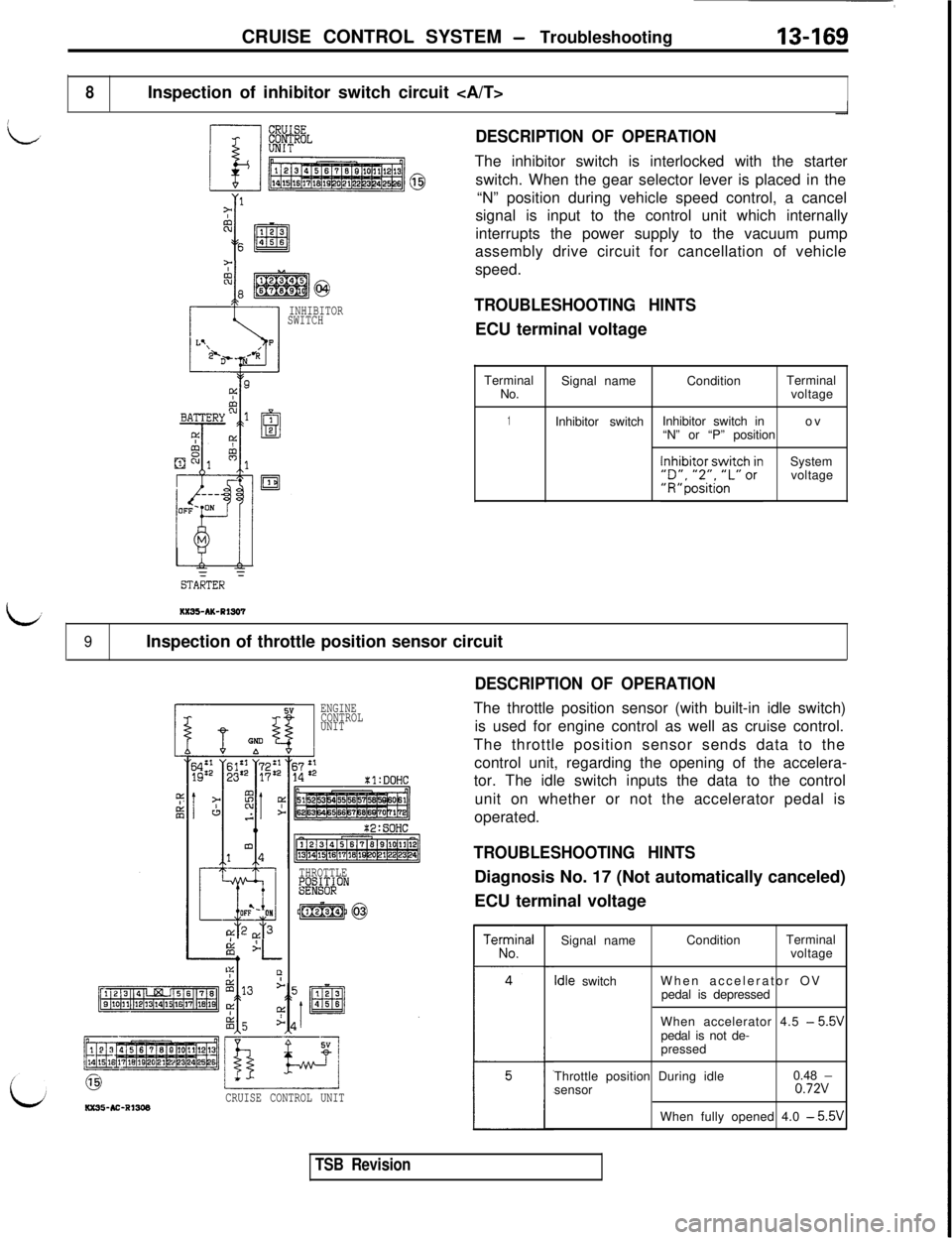

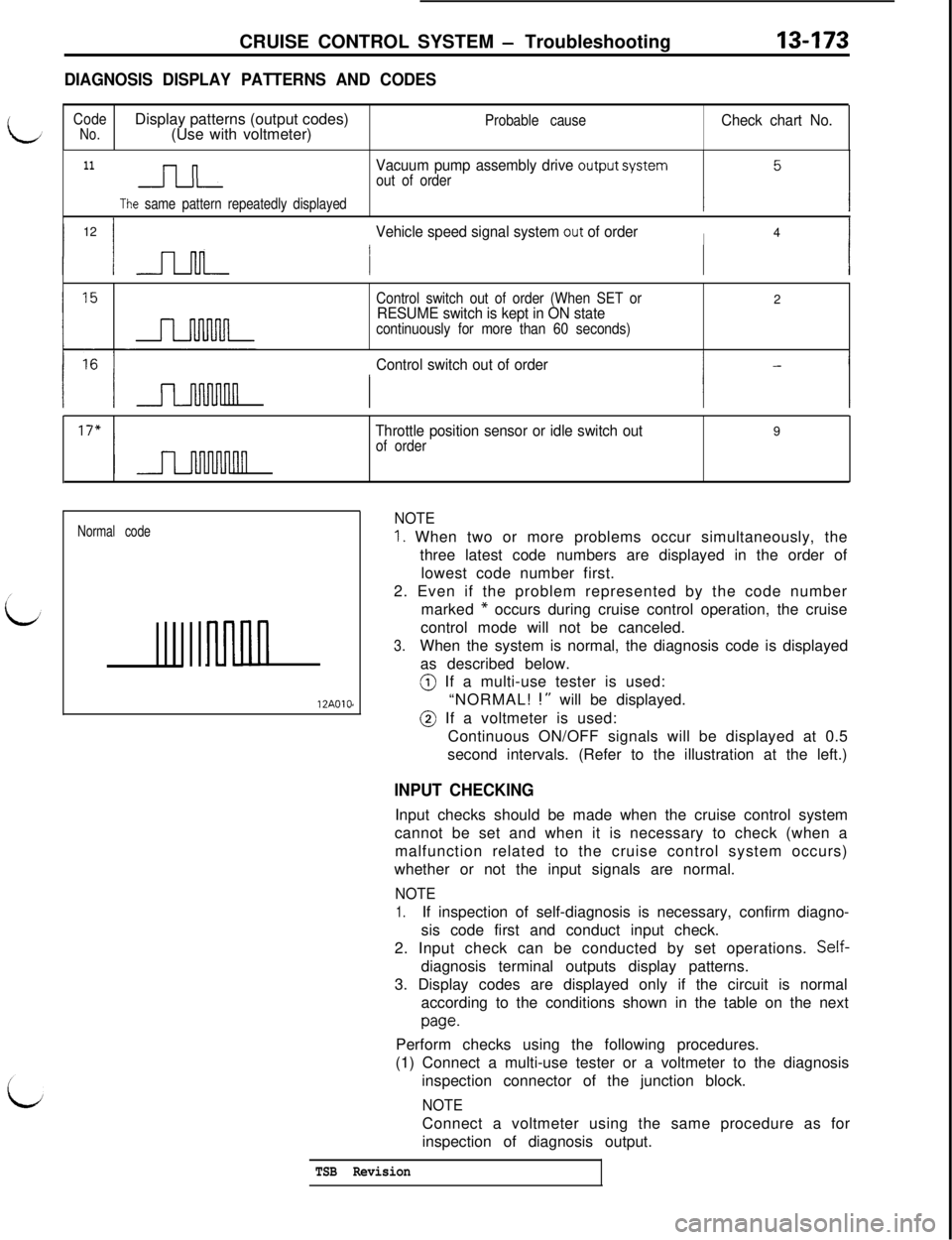

CRUISE CONTROL SYSTEM - Troubleshooting

DIAGNOSIS DISPLAY PATTERNS AND CODES

13473

CodeDisplay patterns (output codes)Probable causeCheck chart No.No.(Use with voltmeter)

11l-l n-JILL

The same pattern repeatedly displayed

Vacuum pump assembly drive output systemout of order5

I I12Vehicle speed signal system out of orderI4I

I In

Control switch out of order (When SET or2RESUME switch is kept in ON statecontinuously for more than 60 seconds)

Control switch out of order

Throttle position sensor or idle switch out9

of order

Normal code

12AOlOa

NOTE

1. When two or more problems occur simultaneously, the

three latest code numbers are displayed in the order of

lowest code number first.

2. Even if the problem represented by the code number

marked * occurs during cruise control operation, the cruise

control mode will not be canceled.

3.When the system is normal, the diagnosis code is displayed

as described below.@ If a multi-use tester is used:

“NORMAL!

! I’ will be displayed.@ If a voltmeter is used:

Continuous ON/OFF signals will be displayed at 0.5

second intervals. (Refer to the illustration at the left.)

INPUT CHECKINGInput checks should be made when the cruise control system

cannot be set and when it is necessary to check (when a

malfunction related to the cruise control system occurs)

whether or not the input signals are normal.

NOTE

1.If inspection of self-diagnosis is necessary, confirm diagno-

sis code first and conduct input check.

2. Input check can be conducted by set operations.

Self-diagnosis terminal outputs display patterns.

3. Display codes are displayed only if the circuit is normal

according to the conditions shown in the table on the next

paw.Perform checks using the following procedures.

(1) Connect a multi-use tester or a voltmeter to the diagnosis

inspection connector of the junction block.

NOTEConnect a voltmeter using the same procedure as for

inspection of diagnosis output.

TSB Revision

Page 283 of 1146

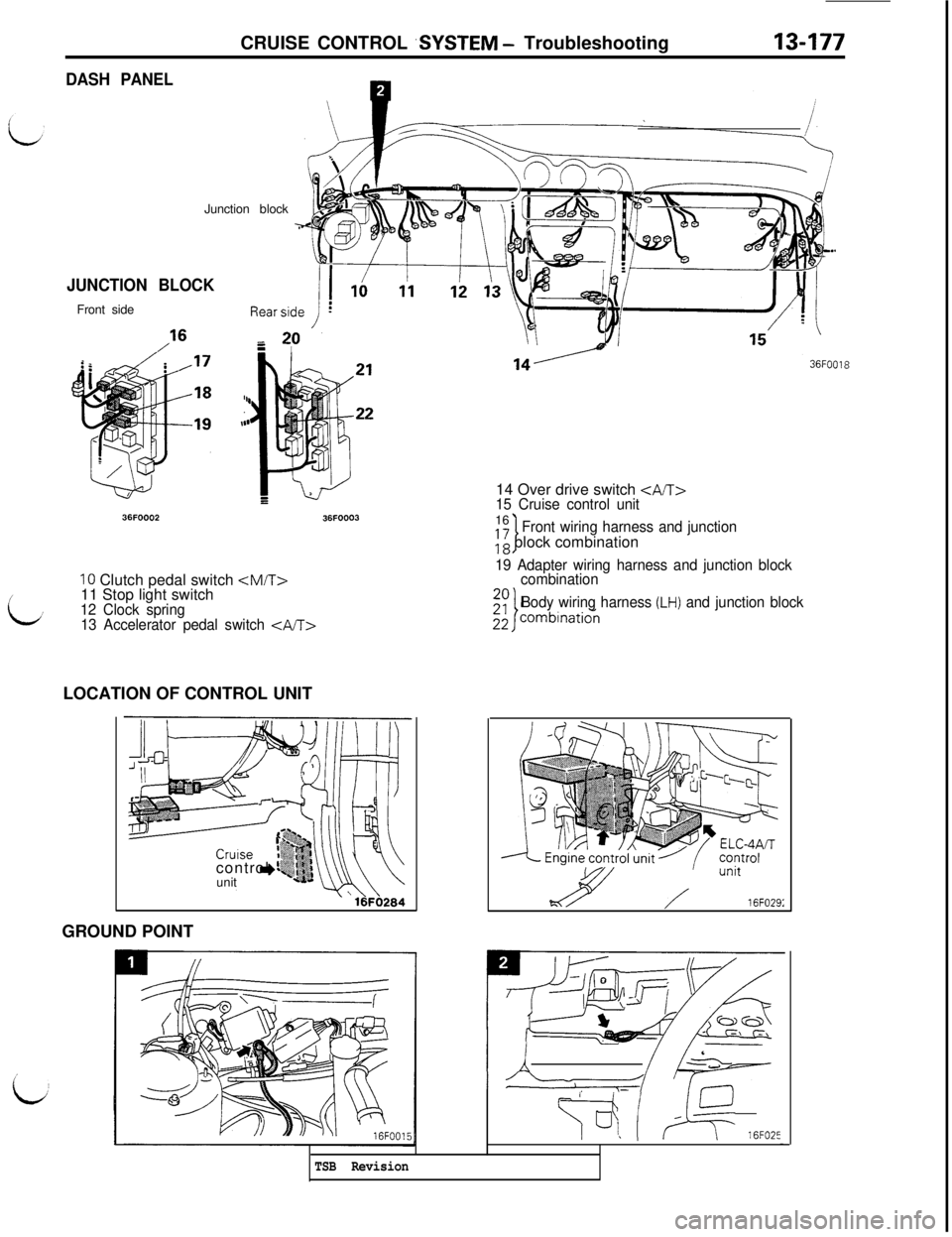

CRUISE CONTROL .SYSTEM - Troubleshooting13-177

DASH PANELJunction block

JUNCTION BLOCKFront side

36FOOO236FOOO3

i

10 Clutch pedal switch

12 Clock spring

13 Accelerator pedal switch

LOCATION OF CONTROL UNIT

E%sQ/I.LIlll-I BCrutse

!tcontrol

unit

GROUND POINT14 Over drive switch

15 Cruise control unit16

l 7

1

Front wiring harness and junctionl 8 block combination

19 Adapter wiring harness and junction block

combination

Body wiring harness

(LH) and junction block

I-\ --*

I d

4tT

-G

1

q\ ($$ 16F02E

36FOO18

TSB Revision

Page 284 of 1146

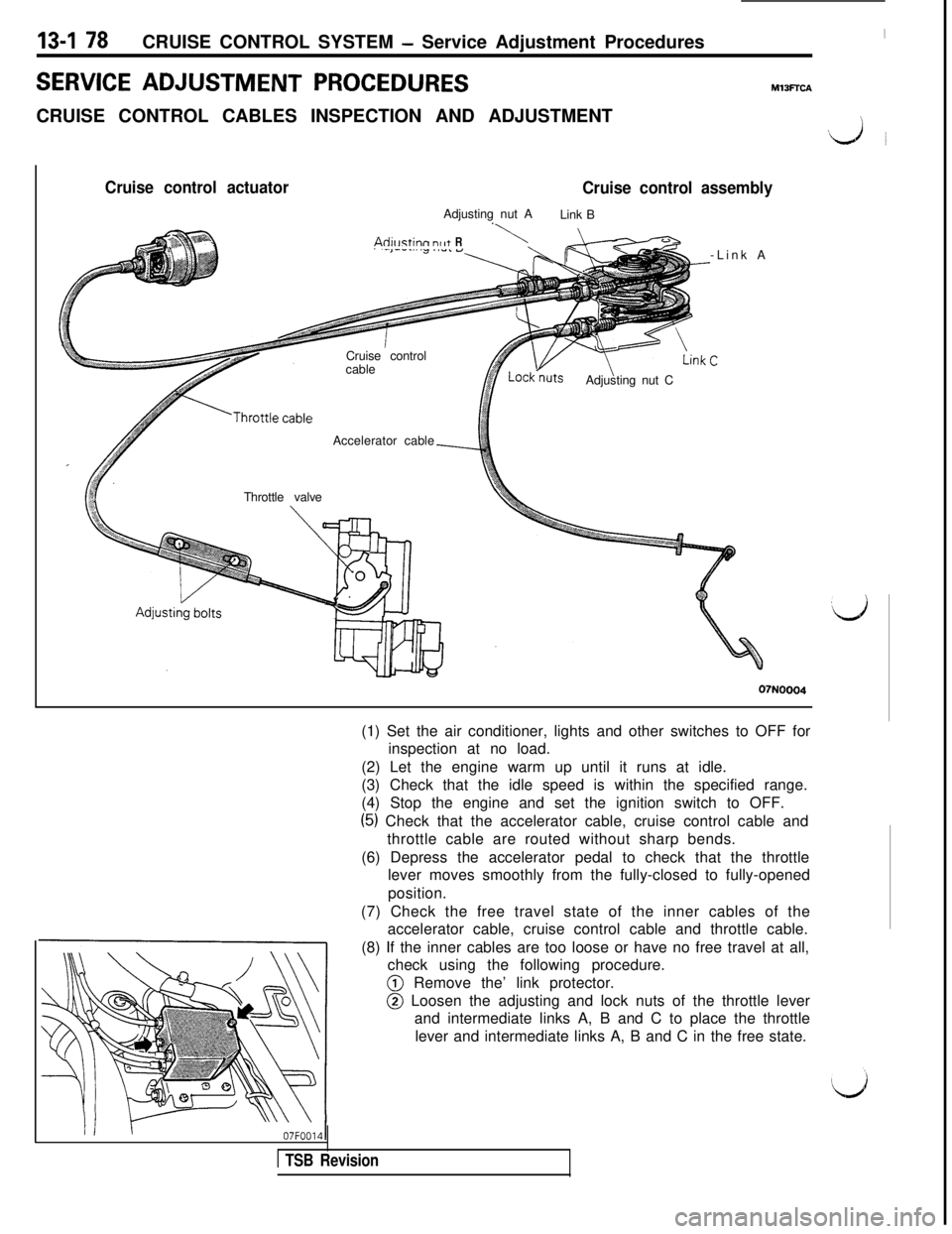

13-I 78CRUISE CONTROL SYSTEM - Service Adjustment ProceduresSERVICE

ADJUSTMENT PROCEDURESCRUISE CONTROL CABLES INSPECTION AND ADJUSTMENT

I

MlSFTCA

‘\J ~

Cruise control actuator

Cruise control assemblyAdjusting nut A

Link B

.

Adillstinn nr~+ R\Cruise control

cable

Adjusting nut C

Accelerator cable

Throttle valve-Link A

07N0004(1) Set the air conditioner, lights and other switches to OFF for

inspection at no load.

(2) Let the engine warm up until it runs at idle.

(3) Check that the idle speed is within the specified range.

(4) Stop the engine and set the ignition switch to OFF.

(5) Check that the accelerator cable, cruise control cable and

throttle cable are routed without sharp bends.

(6) Depress the accelerator pedal to check that the throttle

lever moves smoothly from the fully-closed to fully-opened

position.

(7) Check the free travel state of the inner cables of the

accelerator cable, cruise control cable and throttle cable.

(8) If the inner cables are too loose or have no free travel at all,

check using the following procedure.@ Remove the’ link protector.

@ Loosen the adjusting and lock nuts of the throttle lever

and intermediate links A, B and C to place the throttle

lever and intermediate links A, B and C in the free state.

1 TSB Revision

Page 285 of 1146

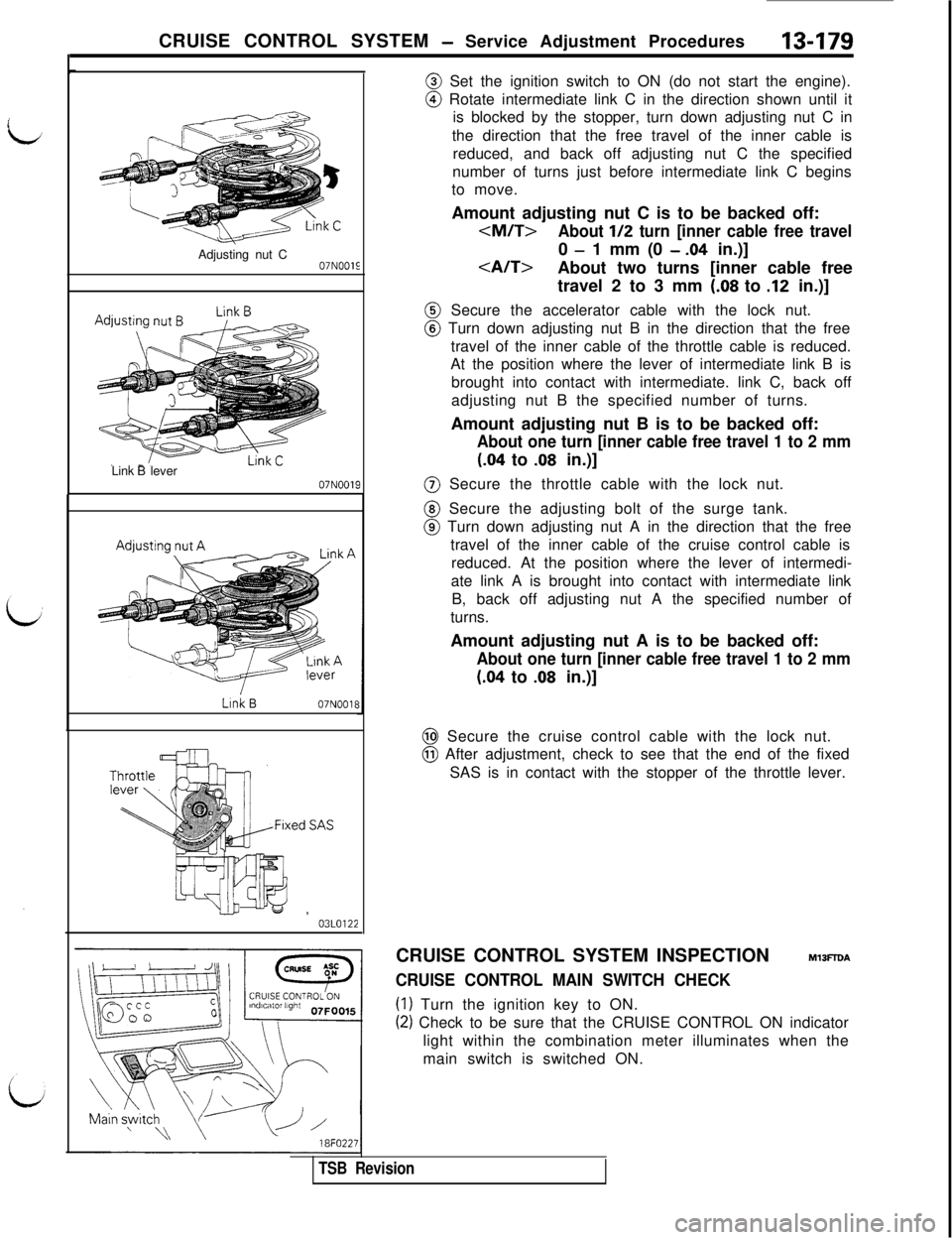

CRUISE CONTROL SYSTEM - Service Adjustment Procedures13-179Adjusting nut C

07NOOlELink Blever

07N0019Link

B07NOOlE

y,jj--ww ,03LO122

\\ \18FO2.2'@ Set the ignition switch to ON (do not start the engine).@ Rotate intermediate link C in the direction shown until it

is blocked by the stopper, turn down adjusting nut C in

the direction that the free travel of the inner cable is

reduced, and back off adjusting nut C the specified

number of turns just before intermediate link C begins

to move.

Amount adjusting nut C is to be backed off:

- 1 mm (0 - .04 in.)]

About two turns [inner cable free

travel 2 to 3 mm

(.08 to .12 in.)]@ Secure the accelerator cable with the lock nut.@ Turn down adjusting nut B in the direction that the free

travel of the inner cable of the throttle cable is reduced.

At the position where the lever of intermediate link B is

brought into contact with intermediate. link C, back off

adjusting nut B the specified number of turns.

Amount adjusting nut B is to be backed off:

About one turn [inner cable free travel 1 to 2 mm

(.04 to .08 in.)]@ Secure the throttle cable with the lock nut.@ Secure the adjusting bolt of the surge tank.@ Turn down adjusting nut A in the direction that the free

travel of the inner cable of the cruise control cable is

reduced. At the position where the lever of intermedi-

ate link A is brought into contact with intermediate link

B, back off adjusting nut A the specified number of

turns.

Amount adjusting nut A is to be backed off:

About one turn [inner cable free travel 1 to 2 mm

(.04 to .08 in.)]@ Secure the cruise control cable with the lock nut.@ After adjustment, check to see that the end of the fixed

SAS is in contact with the stopper of the throttle lever.

CRUISE CONTROL SYSTEM INSPECTION

MlBFlDA

CRUISE CONTROL MAIN SWITCH CHECK

(1) Turn the ignition key to ON.

(2) Check to be sure that the CRUISE CONTROL ON indicator

light within the combination meter illuminates when the

main switch is switched ON.

TSB Revision

Page 288 of 1146

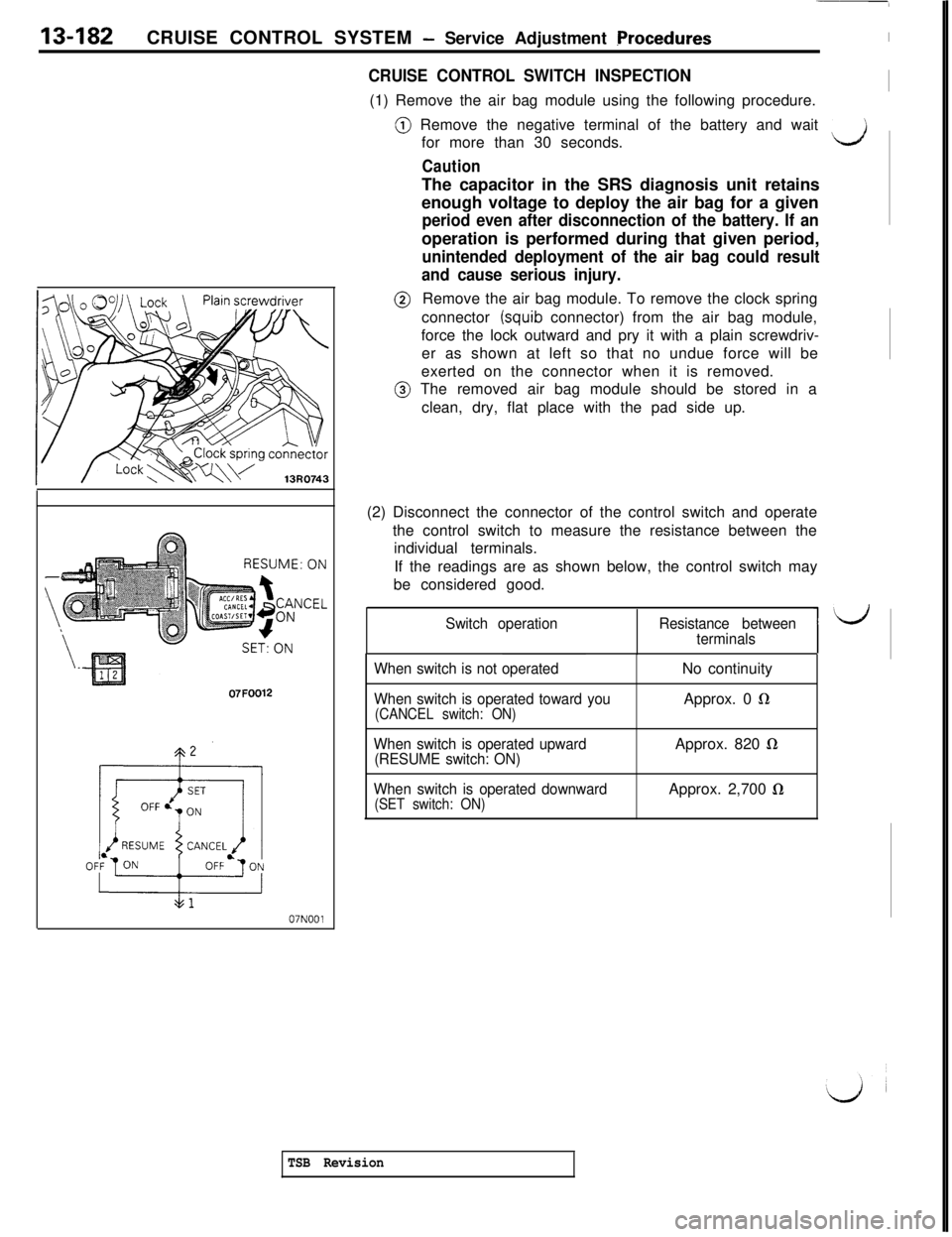

13-182CRUISE CONTROL SYSTEM - Service Adjustment ProceduresI

CRUISE CONTROL SWITCH INSPECTION(1) Remove the air bag module using the following procedure.I07FOO12

07NOOl@ Remove the negative terminal of the battery and wait

for more than 30 seconds.

d

CautionThe capacitor in the SRS diagnosis unit retains

enough voltage to deploy the air bag for a given

period even after disconnection of the battery. If anoperation is performed during that given period,

unintended deployment of the air bag could result

and cause serious injury.@Remove the air bag module. To remove the clock spring

connector

(squib connector) from the air bag module,

force the lock outward and pry it with a plain screwdriv-

er as shown at left so that no undue force will be

exerted on the connector when it is removed.@ The removed air bag module should be stored in a

clean, dry, flat place with the pad side up.

(2) Disconnect the connector of the control switch and operate

the control switch to measure the resistance between the

individual terminals.

If the readings are as shown below, the control switch may

be considered good.

Switch operationResistance between-iJ

terminals

When switch is not operated

When switch is operated toward you

(CANCEL switch: ON)

When switch is operated upward

(RESUME switch: ON)

When switch is operated downward

(SET switch: ON)No continuity

Approx. 0

1RApprox. 820

1RApprox. 2,700

fi

TSB Revision

Page 293 of 1146

CRUISE CONTROL SYSTEM - Cruise Control Svstem13-187Vacuum hoseSERVICE POINT OF REMOVAL

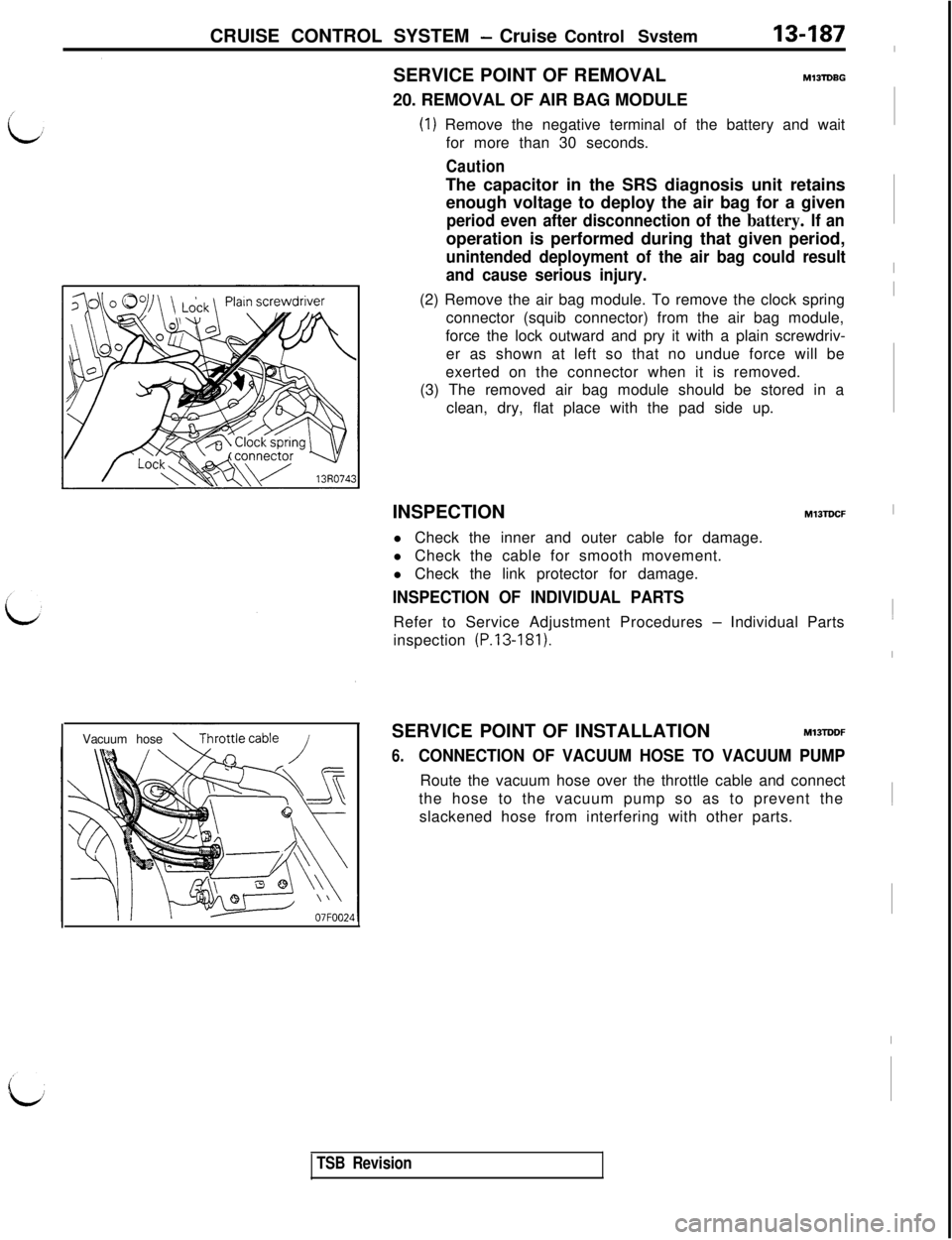

Ml3lDBG20. REMOVAL OF AIR BAG MODULE

(1) Remove the negative terminal of the battery and wait

for more than 30 seconds.

CautionThe capacitor in the SRS diagnosis unit retains

enough voltage to deploy the air bag for a given

period even after disconnection of the battery. If anoperation is performed during that given period,

unintended deployment of the air bag could result

and cause serious injury.(2) Remove the air bag module. To remove the clock spring

connector (squib connector) from the air bag module,

force the lock outward and pry it with a plain screwdriv-

er as shown at left so that no undue force will be

exerted on the connector when it is removed.

(3) The removed air bag module should be stored in a

clean, dry, flat place with the pad side up.

INSPECTION

MlJTDCFl Check the inner and outer cable for damage.

l Check the cable for smooth movement.

l Check the link protector for damage.

INSPECTION OF INDIVIDUAL PARTSRefer to Service Adjustment Procedures

- Individual Parts

inspection (P.l3-181).

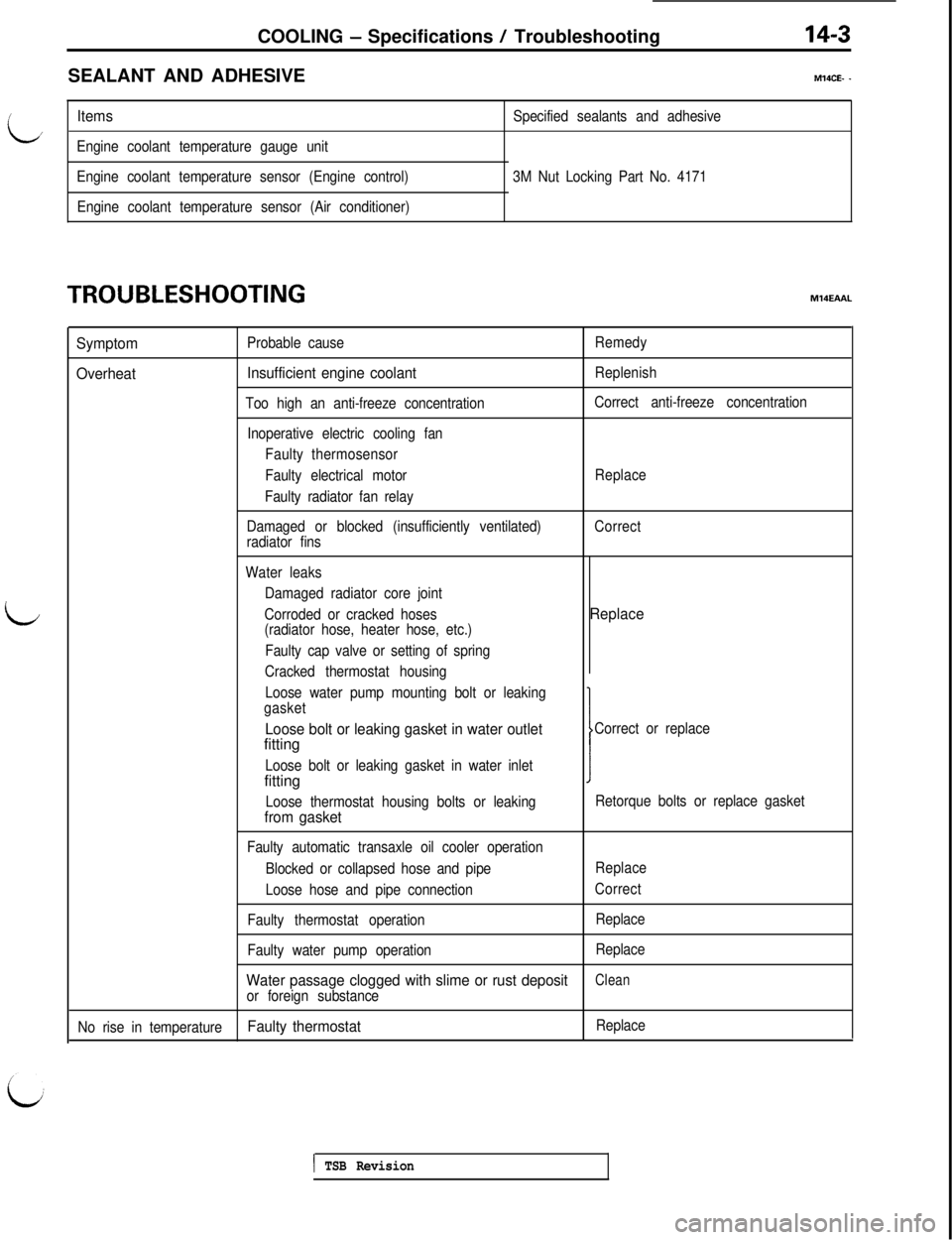

SERVICE POINT OF INSTALLATION

M13TDDF

6.CONNECTION OF VACUUM HOSE TO VACUUM PUMPRoute the vacuum hose over the throttle cable and connect

the hose to the vacuum pump so as to prevent the

slackened hose from interfering with other parts.

TSB Revision

I

I

I

I~

I~~

I

Page 297 of 1146

COOLING - Specifications / Troubleshooting

SEALANT AND ADHESIVE14-3

MMCE- -

/

id

ItemsSpecified sealants and adhesive/

Engine coolant temperature gauge unit

Engine coolant temperature sensor (Engine control)

Engine coolant temperature sensor (Air conditioner)3M Nut Locking Part No. 4171

TROUBLESHOOTING

L

MllEAAL

Symptom

OverheatProbable cause

Insufficient engine coolant

Too high an anti-freeze concentration

Inoperative electric cooling fan

Faulty thermosensor

Faulty electrical motor

Faulty radiator fan relayRemedy

Replenish

Correct anti-freeze concentration

Replace

Damaged or blocked (insufficiently ventilated)

radiator finsCorrect

Water leaks

Damaged radiator core joint

Corroded or cracked hoses

(radiator hose, heater hose, etc.)

Faulty cap valve or setting of spring

Cracked thermostat housing

Loose water pump mounting bolt or leaking

gasket

Replace

Loose bolt or leaking gasket in water outlet

I

Correct or replacefitting

Loose bolt or leaking gasket in water inletfitting

Loose thermostat housing bolts or leakingfrom gasket

Retorque bolts or replace gasket

Faulty automatic transaxle oil cooler operation

Blocked or collapsed hose and pipeReplace

Loose hose and pipe connectionCorrect

Faulty thermostat operationReplace

Faulty water pump operationReplace

Water passage clogged with slime or rust depositClean

or foreign substance

No rise in temperature

Faulty thermostatReplace

( TSB Revision