engine MITSUBISHI 3000GT 1991 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 86 of 1146

11-36ENGINE - Cylinder Head and Valve

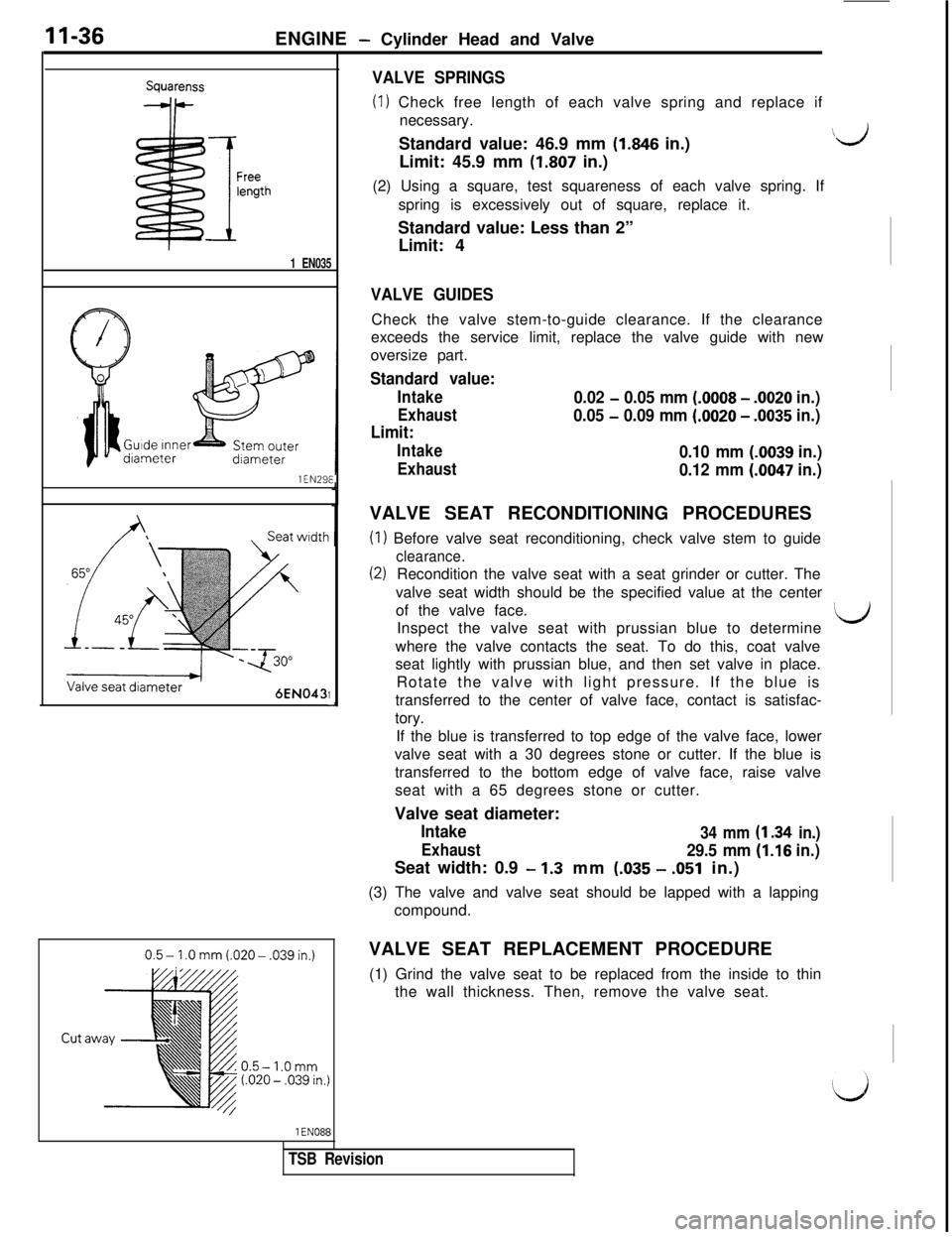

SquarenssVALVE SPRINGS

(1) Check free length of each valve spring and replace if

necessary.

!

FreelengthStandard value: 46.9 mm

(1.846 in.)\bJLimit: 45.9 mm

(1.807 in.)

(2) Using a square, test squareness of each valve spring. If

spring is excessively out of square, replace it.

Standard value: Less than 2”

Limit: 4

1 EN035

VALVE GUIDES

1 EN29ECheck the valve stem-to-guide clearance. If the clearance

exceeds the service limit, replace the valve guide with new

oversize part.

Standard value:

Intake

Exhaust0.02 - 0.05 mm (0008 - .0020 in.)

Limit:0.05

- 0.09 mm (.0020 - .0035 in.)

Intake

Exhaust0.10 mm (0039 in.)

0.12 mm (0047

in.)6EN043

1AVALVE SEAT RECONDITIONING PROCEDURES

(I 1 Before valve seat reconditioning, check valve stem to guide

clearance.

(2)Recondition the valve seat with a seat grinder or cutter. The

valve seat width should be the specified value at the center

of the valve face.

Inspect the valve seat with prussian blue to determine

LJwhere the valve contacts the seat. To do this, coat valve

seat lightly with prussian blue, and then set valve in place.

Rotate the valve with light pressure. If the blue is

transferred to the center of valve face, contact is satisfac-

tory.

If the blue is transferred to top edge of the valve face, lower

valve seat with a 30 degrees stone or cutter. If the blue is

transferred to the bottom edge of valve face, raise valve

seat with a 65 degrees stone or cutter.

Valve seat diameter:

Intake34 mm (I .34 in.)

ExhaustSeat width: 0.9

29.5 mm (1.16 in.)

- 1.3 mm (035 - .051 in.)

(3) The valve and valve seat should be lapped with a lapping

compound.

VALVE SEAT REPLACEMENT PROCEDURE

(1) Grind the valve seat to be replaced from the inside to thin

the wall thickness. Then, remove the valve seat.

1 ENOE18

TSB Revision

Page 87 of 1146

ENGINE - Cylinder Head and Valve

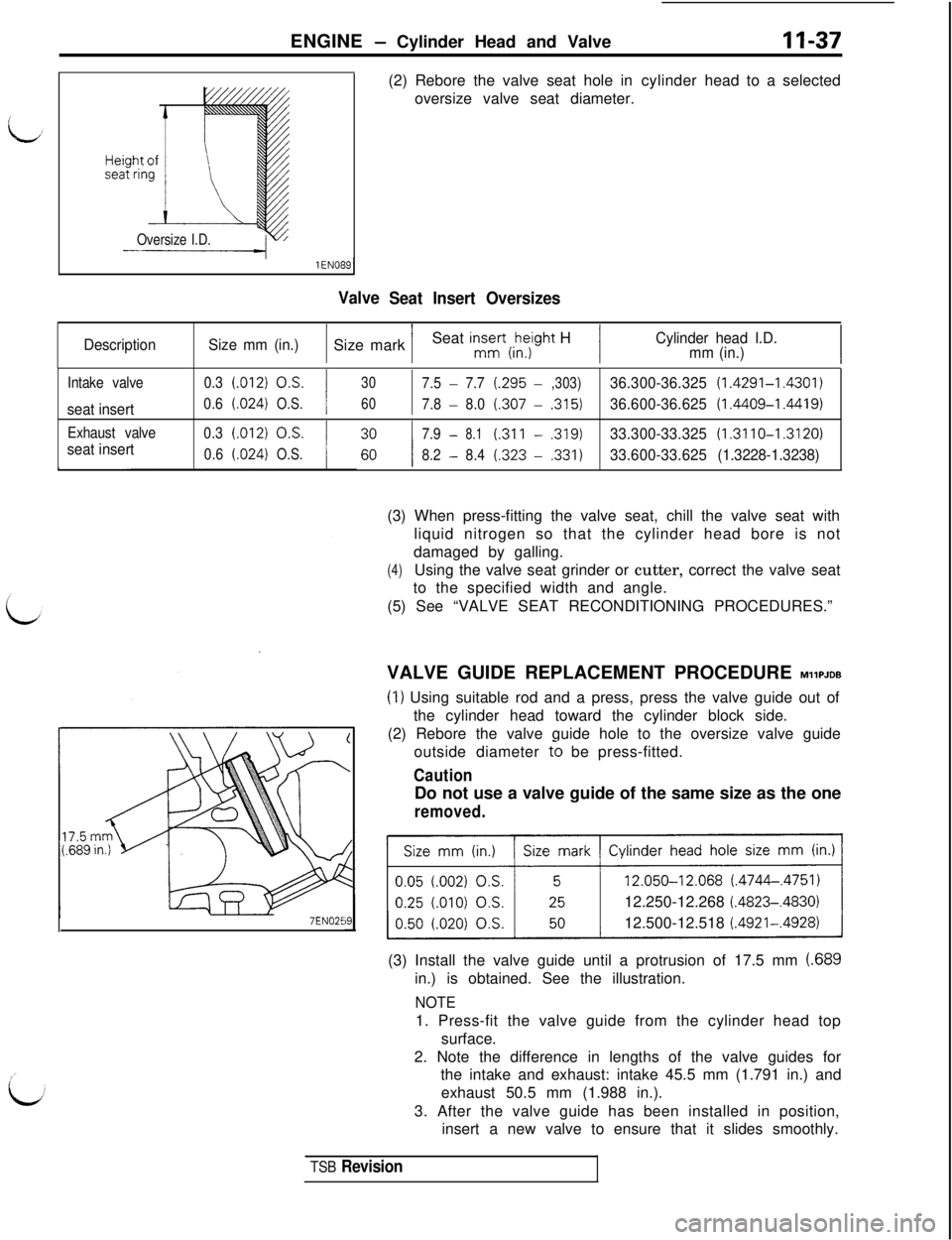

Oversize I.D.

Valve(2) Rebore the valve seat hole in

oversize valve seat diameter.Seat Insert Oversizescylinderhead to a selected

DescriptionSize mm (in.)1 Size mark /Seat insEt(,ke;ght H/Cylinder head I.D.

mm (in.)

Intake valve0.3i.012)0,s.

I

30

I

7.5-7.7(.295-,303)36.300-36.325(1.4291-1.4301)

seat insert

0.6(.024)O.S.607.8-8.0(.307-,315)36.600-36.625(1.4409-1.4419)

Exhaust valve

seat insert

0.3l.012)0,s.7.9-8.1(.311-.319)33.300-33.325(1.3110-1.3120)

0.6(.024)O.S.8.2-8.4t.323-,331)33.600-33.625(1.3228-1.3238)

7EN02E(3) When press-fitting the valve seat, chill the valve seat with

liquid nitrogen so that the cylinder head bore is not

damaged by galling.

(4)Using the valve seat grinder or cutter, correct the valve seat

to the specified width and angle.

(5) See “VALVE SEAT RECONDITIONING PROCEDURES.”

VALVE GUIDE REPLACEMENT PROCEDURE

MllPJDB

(1) Using suitable rod and a press, press the valve guide out of

the cylinder head toward the cylinder block side.

(2) Rebore the valve guide hole to the oversize valve guide

outside diameter

to be press-fitted.

CautionDo not use a valve guide of the same size as the one

removed.12.250-12.268

(.4823-.4830)12.500-12.518

(.4921-.4928)(3) Install the valve guide until a protrusion of 17.5 mm

(.689in.) is obtained. See the illustration.

NOTE1. Press-fit the valve guide from the cylinder head top

surface.

2. Note the difference in lengths of the valve guides for

the intake and exhaust: intake 45.5 mm (1.791 in.) and

exhaust 50.5 mm (1.988 in.).

3. After the valve guide has been installed in position,

insert a new valve to ensure that it slides smoothly.

TSB Revision

Page 88 of 1146

11-38ENGINE - Cylinder Head and Valve

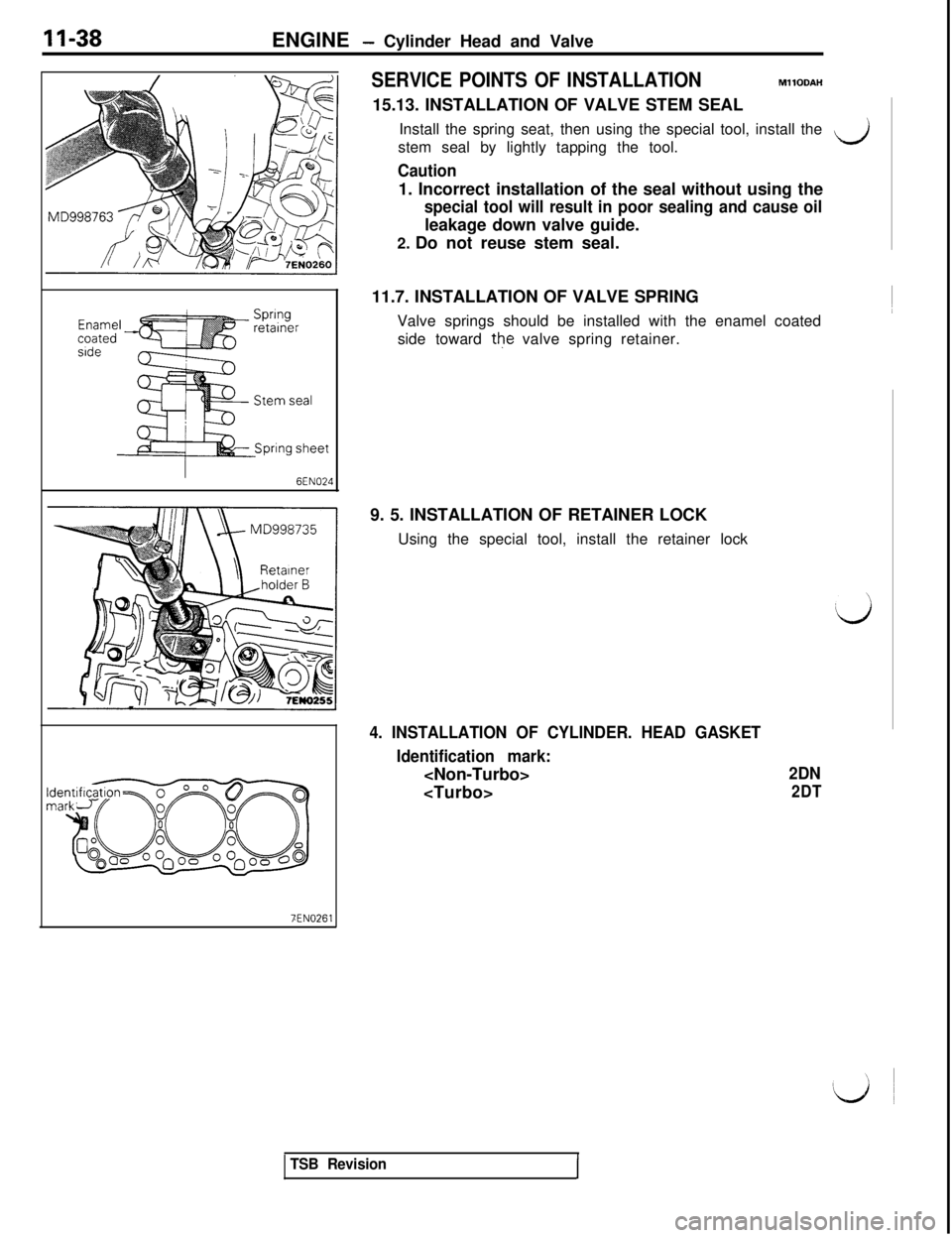

Enamelcoatedside

Springretainer

Stem seal

pring sheet

6EN024SERVICE POINTS OF INSTALLATION

MllODAH15.13. INSTALLATION OF VALVE STEM SEAL

Install the spring seat, then using the special tool, install the

stem seal by lightly tapping the tool.

d

Caution1. Incorrect installation of the seal without using the

special tool will result in poor sealing and cause oilleakage down valve guide.

2. Do not reuse stem seal.

11.7. INSTALLATION OF VALVE SPRING

Valve springs should be installed with the enamel coated

side toward the valve spring retainer.

9. 5. INSTALLATION OF RETAINER LOCK

Using the special tool, install the retainer lock

4. INSTALLATION OF CYLINDER. HEAD GASKET

Identification mark:

2DN

2DT

TSB Revision

Page 89 of 1146

L

,

LENGINE

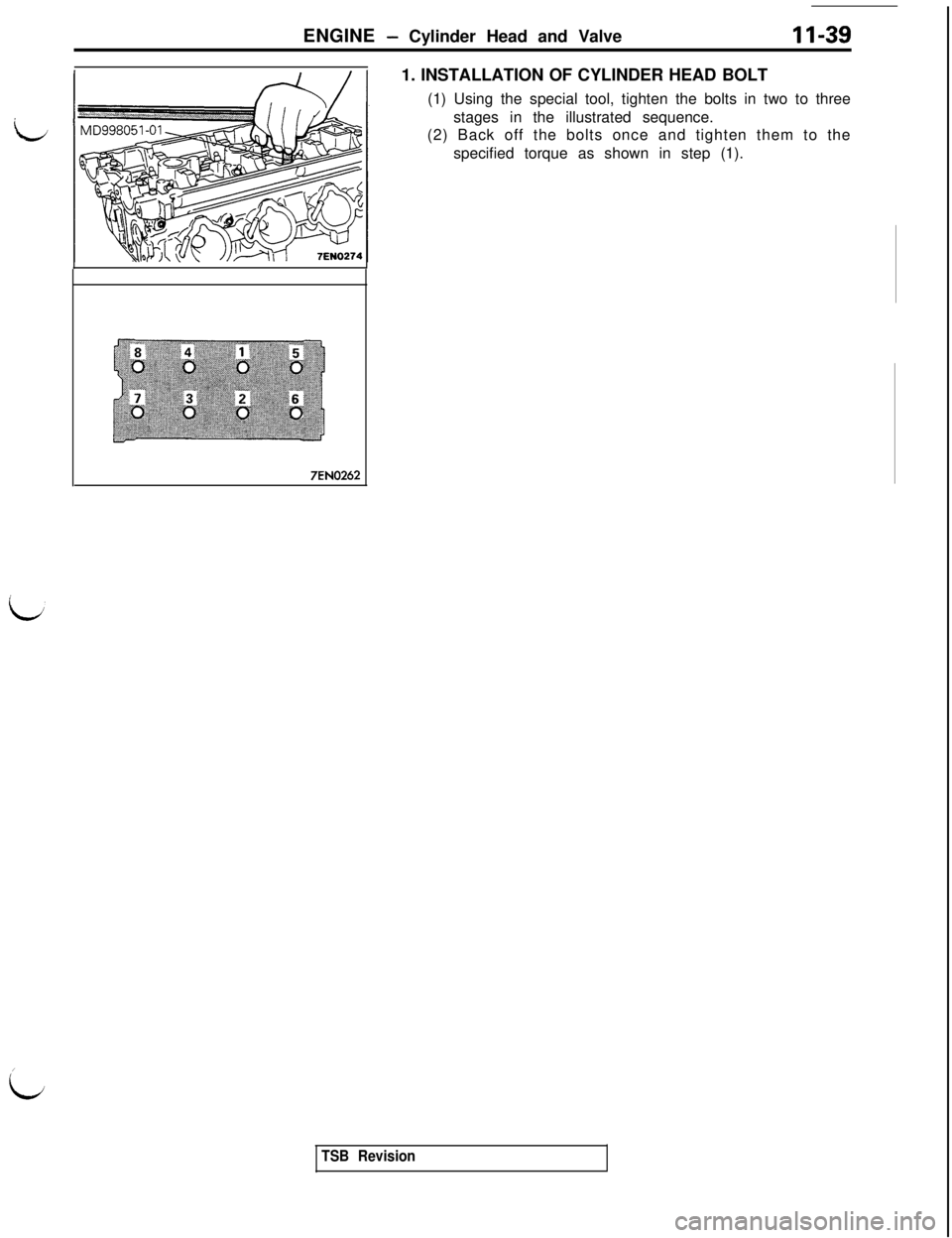

- Cylinder Head and Valve11-391. INSTALLATION OF CYLINDER HEAD BOLT

(1) Using the special tool, tighten the bolts in two to three

stages in the illustrated sequence.

(2) Back off the bolts once and tighten them to the

specified torque as shown in step (1).

7EN0262

TSB Revision

Page 90 of 1146

II-40ENGINE - Oil Pan and Oil Pump

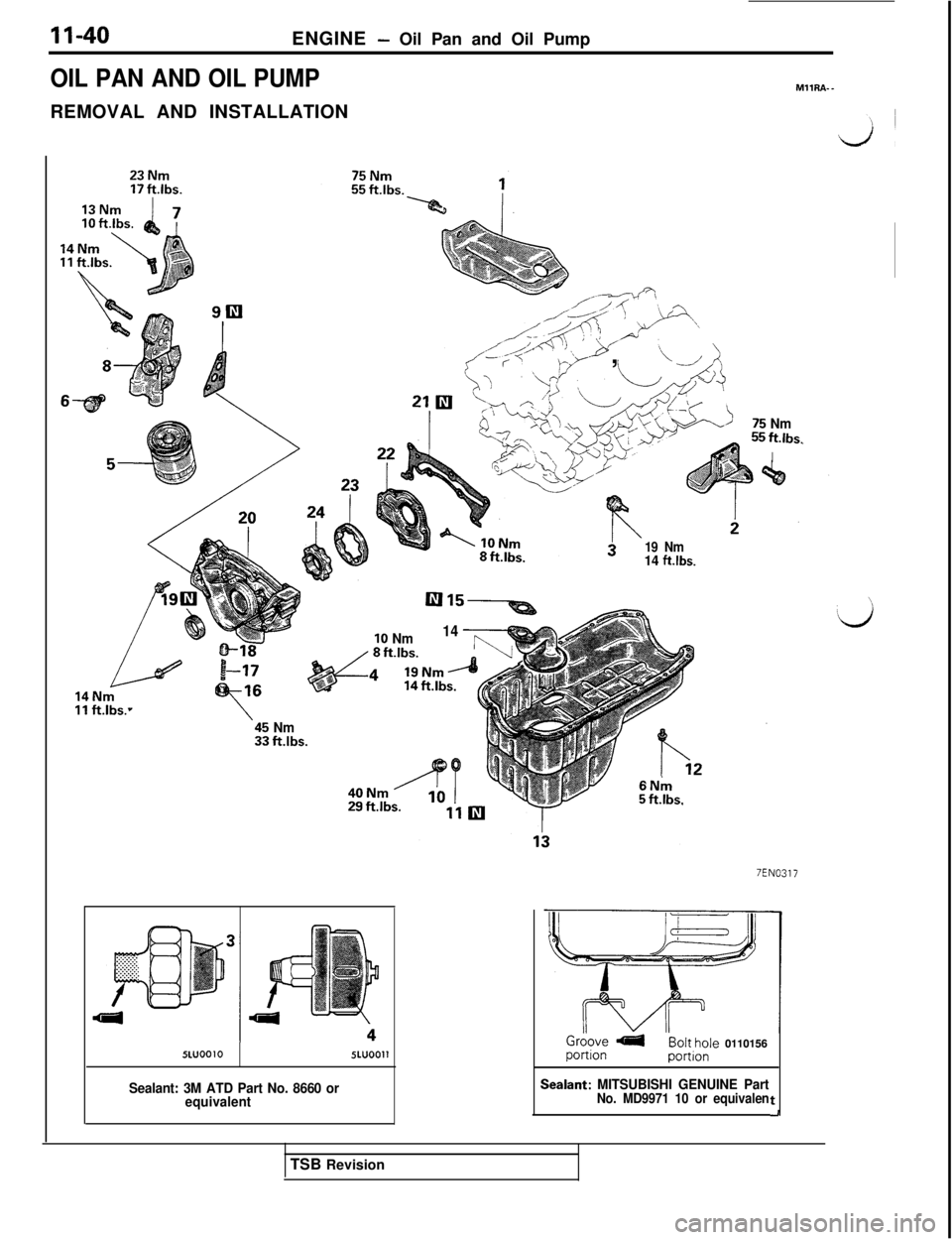

OIL PAN AND OIL PUMPREMOVAL AND INSTALLATIONMllRA--

d

,,,/jgfq/Y “

10 Nm14

75 Nm55 ftlbs.

I

19 Nm14 ft.lbs.

45 Nm33 ft.lbs.

51u00105LUOOll

Sealant: 3M ATD Part No. 8660 or

equivalent6Nrn

5 tklbs.

7EN0317

!

Groove 4Groove 4Bolt hole 0110156Bolt hole 0110156portionportionportionportion

sealant: MITSUBISHI GENUINE PartNo. MD9971 10 or equivalen

\

‘d

t-ITSB Revision

Page 91 of 1146

ENGINE - Oil Pan and Oil Pump

Removal steps

1. Transaxle stay (front)

2. Transaxle stay (rear)

3. Oil pressure switch4.

Z:

;:9.10.l+11.l*12.** l * 13.

Oil pressure gauge unitOil filterOil cooler by-pass valve

Oil filter bracket stay

Oil filter bracket

Oil filter bracket gasket

Drain plugDrain plug gasket0; y; boltI

16. Relief plug17. Relief spring18. Relief plunger** 19. Crankshaft front oil seal

20. Oil pump case

21. Oil pump gasket

22. Oil pump cover

23. Oil pump outer rotor

24. Oil pump inner rotor

14. Oil screen

15. Oil screen gasket

Side

clearance

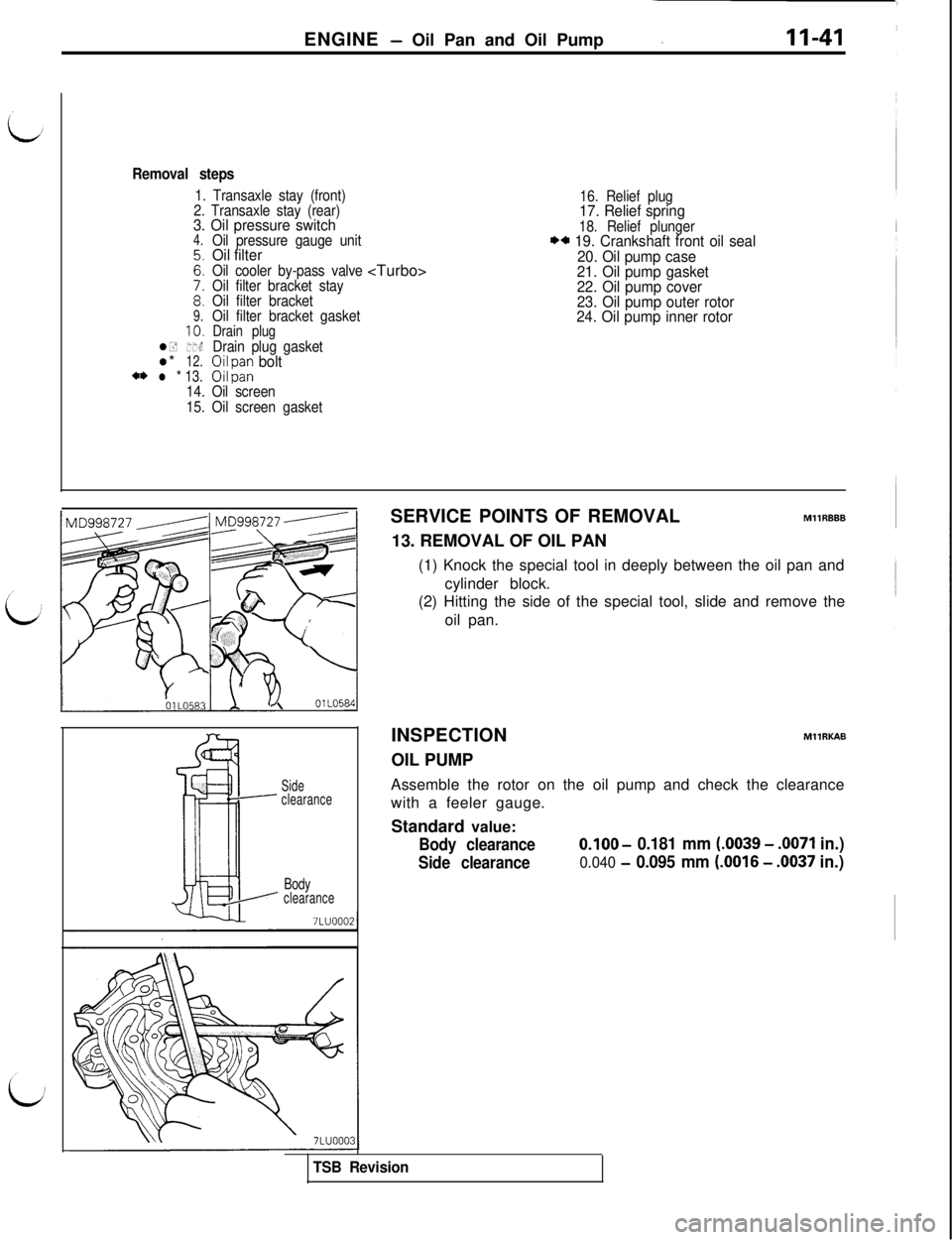

BodyclearanceSERVICE POINTS OF REMOVALMllRBBB

13. REMOVAL OF OIL PAN

(1) Knock the special tool in deeply between the oil pan and

cylinder block.

(2) Hitting the side of the special tool, slide and remove the

oil pan.

INSPECTION

OIL PUMPMllRKAB

Assemble the rotor on the oil pump and check the clearance

with a feeler gauge.

Standard value:

Body clearanceO.lOO- 0.181 mm (.0039 - .0071 in.)

Side clearance0.040 - 0.095 mm (.0016 - .0037 in.)

TSB Revision

Page 92 of 1146

II-42ENGINE - Oil Pan and Oil Pump

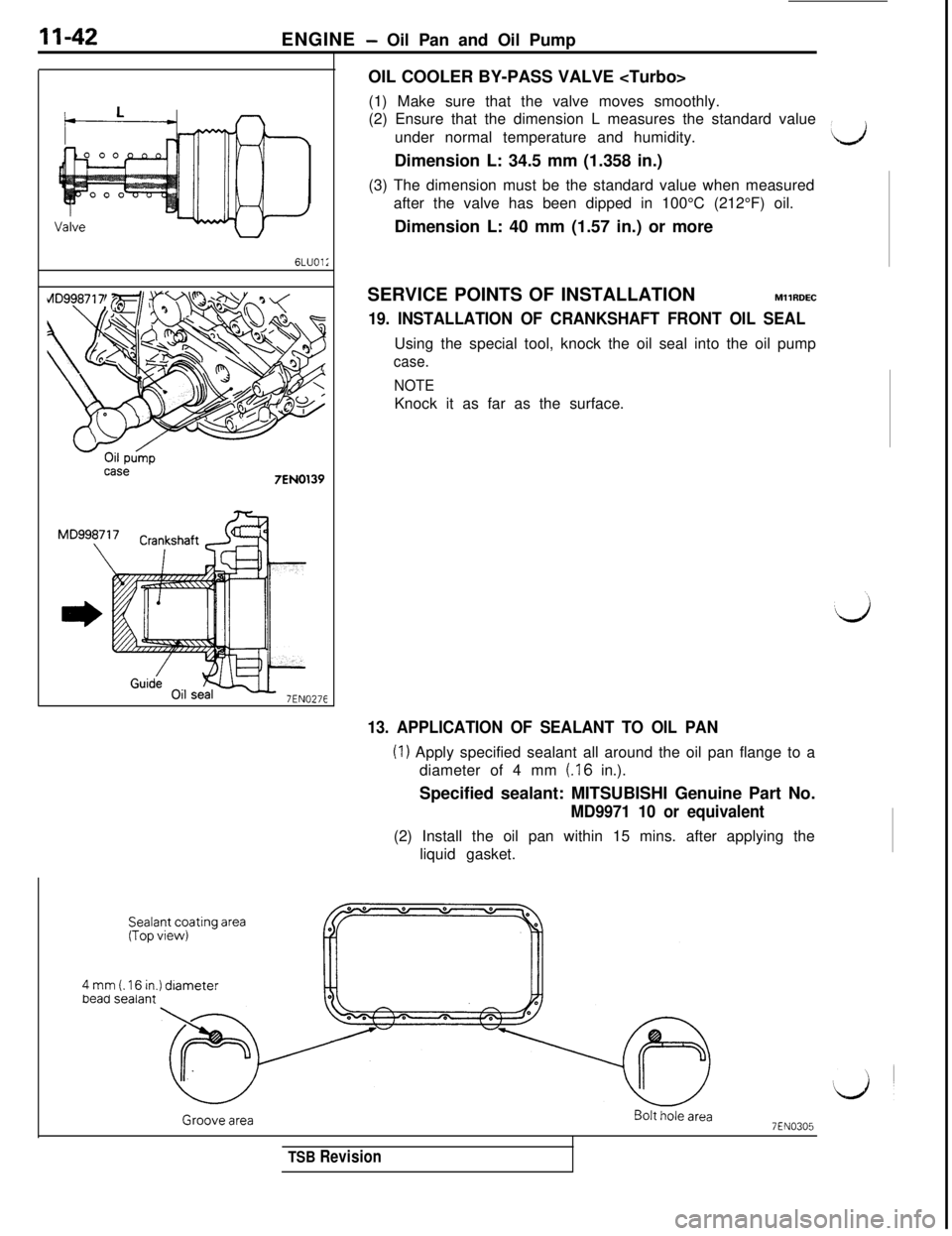

6LUOl;

Oil pumpcase7EN0139

Sealant coating area(Top view)

4 mm (. 16 in.) diameterOIL COOLER BY-PASS VALVE

(1) Make sure that the valve moves smoothly.

(2) Ensure that the dimension L measures the standard value

under normal temperature and humidity.

Dimension L: 34.5 mm (1.358 in.)

(3) The dimension must be the standard value when measured

after the valve has been dipped in 100°C (212°F) oil.

Dimension L: 40 mm (1.57 in.) or more

SERVICE POINTS OF INSTALLATIONMllRDEC

19. INSTALLATION OF CRANKSHAFT FRONT OIL SEALUsing the special tool, knock the oil seal into the oil pump

case.

NOTEKnock it as far as the surface.

13. APPLICATION OF SEALANT TO OIL PAN

(1) Apply specified sealant all around the oil pan flange to a

diameter of 4 mm

(.I6 in.).

Specified sealant: MITSUBISHI Genuine Part No.

MD9971 10 or equivalent(2) Install the oil pan within 15 mins. after applying the

liquid gasket.

Dead sealant

Groove areaBolt hole area7EN0305

TSB Revision

Page 93 of 1146

/

iENGINE

- Oil Pan and Oil Pump11-43

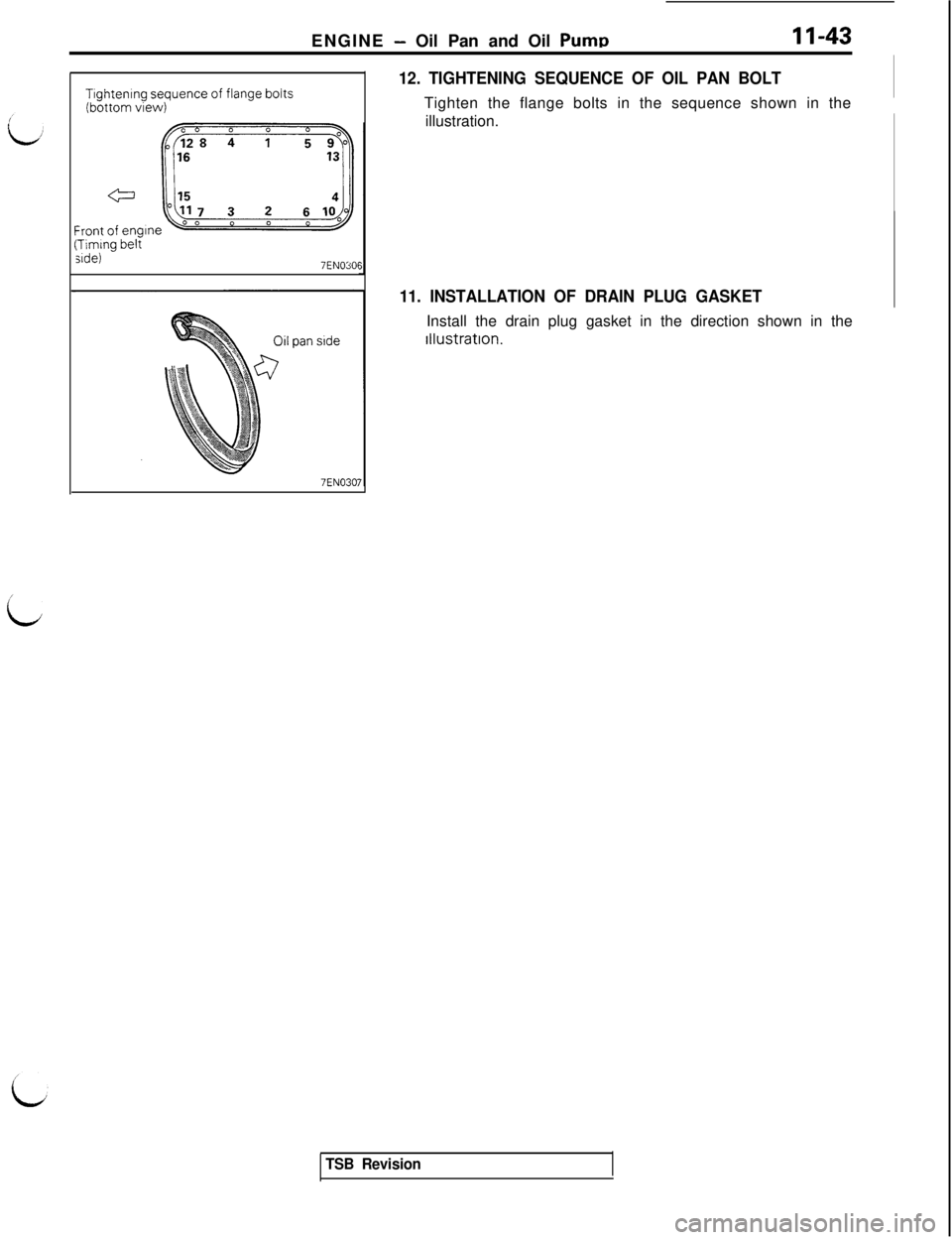

Tlghtenlng sequence of flange bolts(bottom view)

iTiming beltside)7EN030f

7EN030

12. TIGHTENING SEQUENCE OF OIL PAN BOLTTighten the flange bolts in the sequence shown in the

illustration.illustration.

11. INSTALLATION OF DRAIN PLUG GASKETInstall the drain plug gasket in the direction shown in the

TSB Revision

Page 94 of 1146

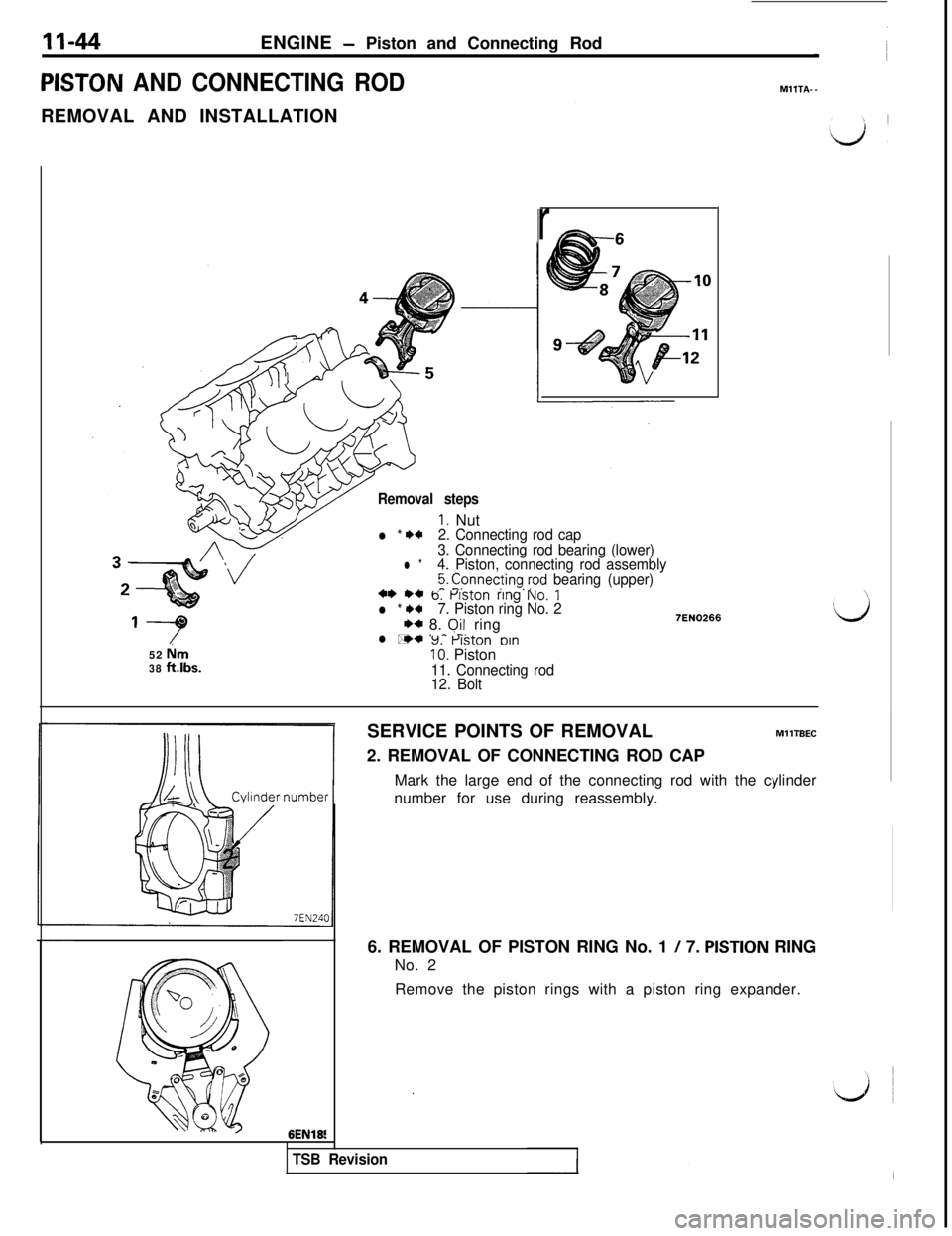

11-44ENGINE - Piston and Connecting Rod

PISTON AND CONNECTING RODREMOVAL AND INSTALLATIONMllTA--

r

Removal steps

1. Nutl * I)*2. Connecting rod cap

l *3. Connecting rod bearing (lower)

4. Piston, connecting rod assembly

1_ ._5. $nnec$ng. rod bearing (upper)WV WC 6. rrston ring No. 1l * **7. Piston ring No. 2

I)+ 8. Qil ringl * ._ - -’v* Y. Hston oin10. Piston11. Connecting rod

12. Bolt52

ihn38 fklbs.

7EN0266

6EN18!SERVICE POINTS OF REMOVAL

MllT6EC2. REMOVAL OF CONNECTING ROD CAP

Mark the large end of the connecting rod with the cylinder

number for use during reassembly.

6. REMOVAL OF PISTON RING No. 1

/ 7. PISTION RING

No. 2

Remove the piston rings with a piston ring expander.

TSB Revision

Page 95 of 1146

ENGINE - Piston and. Connectina RodII-45

LJ

Front mark

-

MD998764

lEN0113

lEN0114

v5EN057

,, Push in by thepiston.

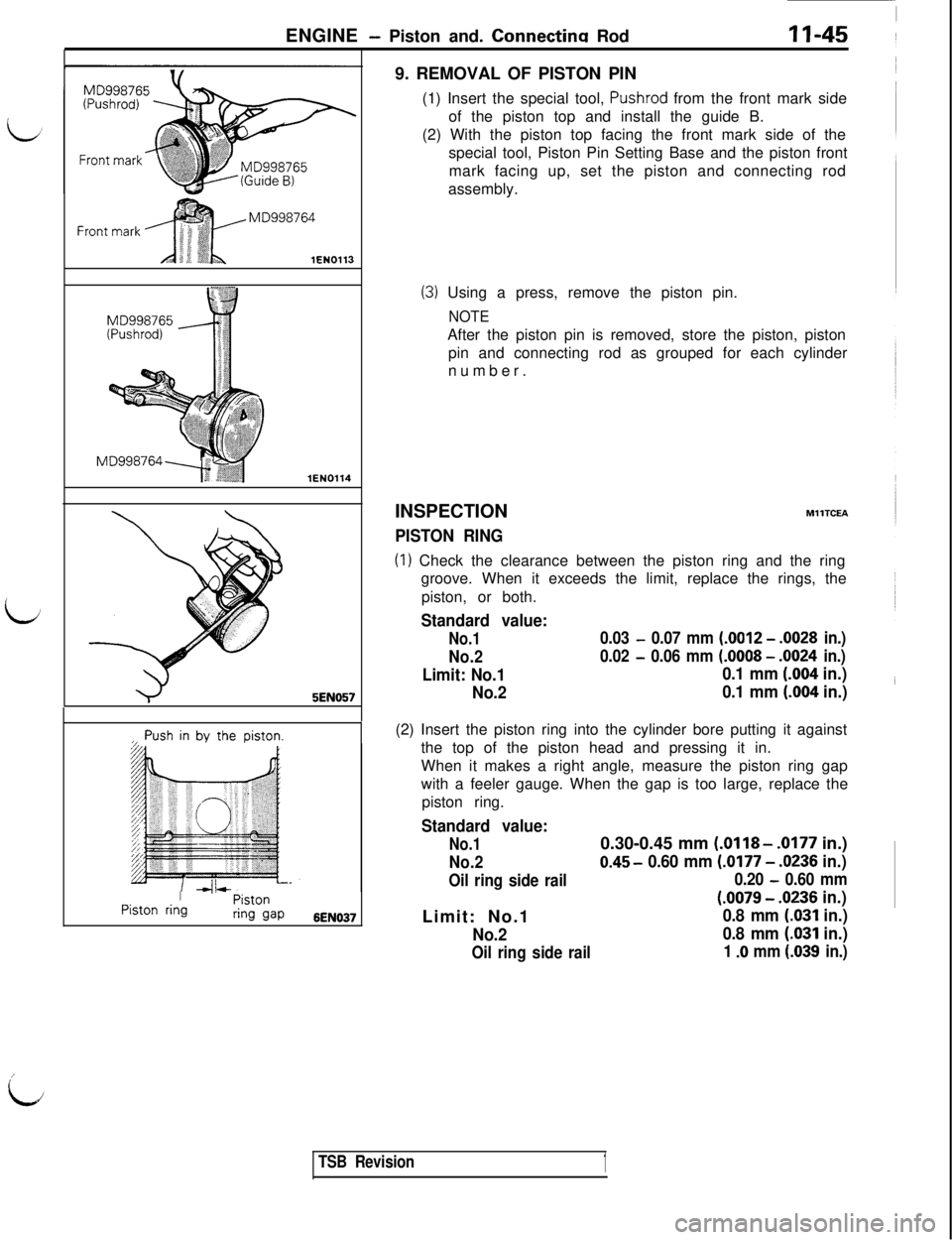

IPiston ringPistonring gap6EN0379. REMOVAL OF PISTON PIN

(1) Insert the special tool,

Pushrod from the front mark side

of the piston top and install the guide B.

(2) With the piston top facing the front mark side of the

special tool, Piston Pin Setting Base and the piston front

mark facing up, set the piston and connecting rod

assembly.

(3) Using a press, remove the piston pin.

NOTEAfter the piston pin is removed, store the piston, piston

pin and connecting rod as grouped for each cylinder

number.

INSPECTION

PISTON RING

MllTCEA

(1) Check the clearance between the piston ring and the ring

groove. When it exceeds the limit, replace the rings, the

piston, or both.

Standard value:

No.10.03 - 0.07 mm (.0012 - .0028 in.)

No.20.02

- 0.06 mm (.OOOS - ‘0024 in.)

Limit: No.10.1 mm (.004 in.)

No.20.1 mm

(.004 in.)(2) Insert the piston ring into the cylinder bore putting it against

the top of the piston head and pressing it in.

When it makes a right angle, measure the piston ring gap

with a feeler gauge. When the gap is too large, replace the

piston ring.

Standard value:

No.10.30-0.45 mm (.0118- .0177 in.)

No.20.45- 0.60 mm (.0177 - .0236 in.)

Oil ring side rail0.20 - 0.60 mmLimit: No.1

(.0079 - .0236 in.)

0.8 mm

(.031 in.)

No.20.8 mm

(.031 in.)

Oil ring side rail1 .O mm (.039 in.)

I

LJ

TSB Revision1