engine MITSUBISHI 3000GT 1991 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 76 of 1146

11-26ENGINE - Timing Belt

TIMING BELT

REMOVAL AND INSTALLATION

MllKA-BI

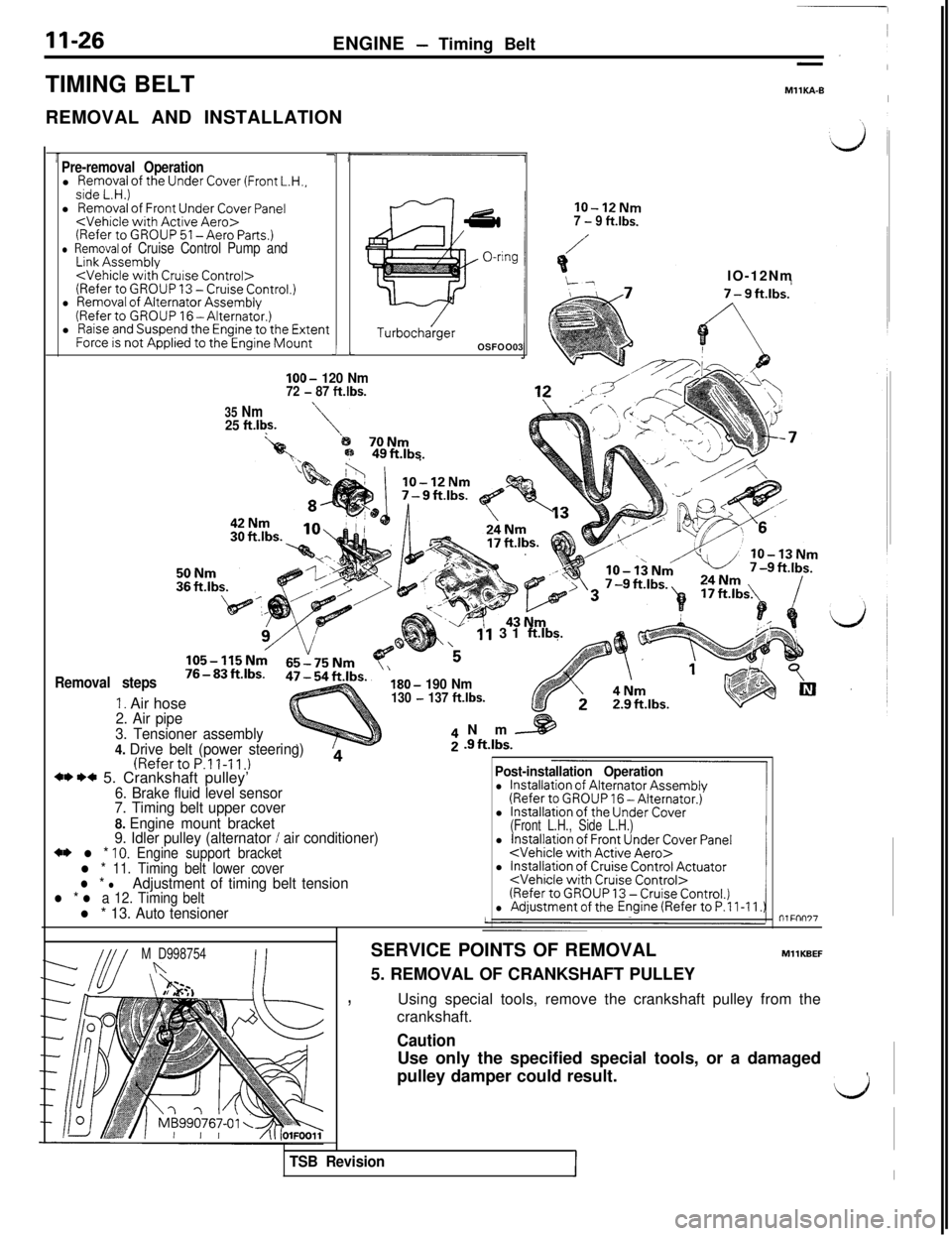

Pre-removal Operationl Removal of the Under Cover (Front L.H.,side L.H.)l Removal of Front Under Cover Panel

l Raise and Suspend the Engine to the ExtentForce is not Applied to the Engine Mounti LIOO-

120 Nm72 - 87 ft.lbs.

35 Nm25 ft.l$.

TurbochargerOSFOO03

lo-12Nm7 - 9 ft.lbs.

Removal steps

1. Air hose

11 31 ftlbs.

‘5IO-12Nm

B;p 49ftJbs.

\

180- 190 Nm130 - 137 ft.lbs.

2. Air pipe

3. Tensioner assembly

4. Drive belt (power steering)

(RefertoP.ll-11.)4** I)* 5. Crankshaft pulley’6. Brake fluid level sensor

7. Timing belt upper cover

8. Engine mount bracket

9. Idler pulley (alternator

/ air conditioner)+* l * 10. Engine support bracketl * 11. Timing belt lower coverl * lAdjustment of timing belt tensionl * l a 12. Timing beltl * 13. Auto tensionerNm

[email protected].

Post-installation Operation

l Installation of Alternator Assembly(Refer to GROUP 16 -Alternator.)

l Installation of the Under Cover(Front L.H., Side L.H.)l Installation of Front Under Cover Panel

l Installation of Cruise Control Actuator

M D998754nSERVICE POINTS OF REMOVAL

5. REMOVAL OF CRANKSHAFT PULLEYMllKBEF

,Using special tools, remove the crankshaft pulley from the

crankshaft.

TSB RevisionII

CautionUse only the specified special tools, or a damaged

pulley damper could result.

,

LJ

Page 77 of 1146

ENGINE - Timinn Belt11-27

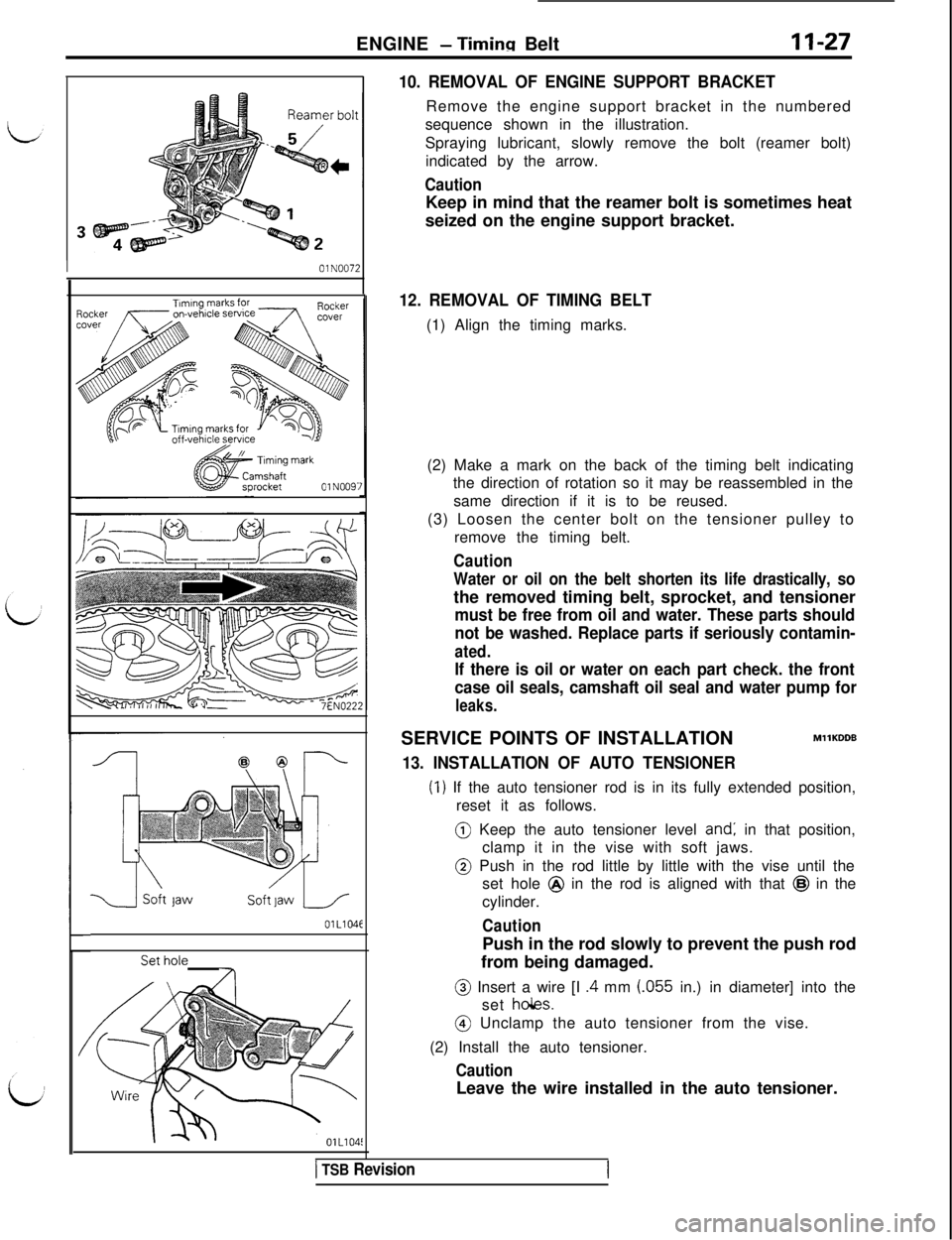

r bol

I01 NO07

10. REMOVAL OF ENGINE SUPPORT BRACKETRemove the engine support bracket in the numbered

sequence shown in the illustration.

Spraying lubricant, slowly remove the bolt (reamer bolt)

indicated by the arrow.

CautionKeep in mind that the reamer bolt is sometimes heat

seized on the engine support bracket.

Timing mark

mshaftrocket01 N009:

d Soft jawSoft jaw

OlL104E

Set hole

n

12. REMOVAL OF TIMING BELT(1) Align the timing marks.

(2) Make a mark on the back of the timing belt indicating

the direction of rotation so it may be reassembled in the

same direction if it is to be reused.

(3) Loosen the center bolt on the tensioner pulley to

remove the timing belt.

Caution

Water or oil on the belt shorten its life drastically, sothe removed timing belt, sprocket, and tensioner

must be free from oil and water. These parts should

not be washed. Replace parts if seriously contamin-

ated.

If there is oil or water on each part check. the front

case oil seals, camshaft oil seal and water pump for

leaks.SERVICE POINTS OF INSTALLATION

MllKDDB

13. INSTALLATION OF AUTO TENSIONER

(‘I) If the auto tensioner rod is in its fully extended position,

reset it as follows.@ Keep the auto tensioner level

and: in that position,

clamp it in the vise with soft jaws.@ Push in the rod little by little with the vise until the

set hole @ in the rod is aligned with that @ in the

cylinder.

CautionPush in the rod slowly to prevent the push rod

from being damaged.@ Insert a wire [I

.4 mm (.055 in.) in diameter] into the

set

ho&.@ Unclamp the auto tensioner from the vise.

(2) Install the auto tensioner.

CautionLeave the wire installed in the auto tensioner.

1 TSB Revision

Page 78 of 1146

11-28ENGINE - Timing Belt

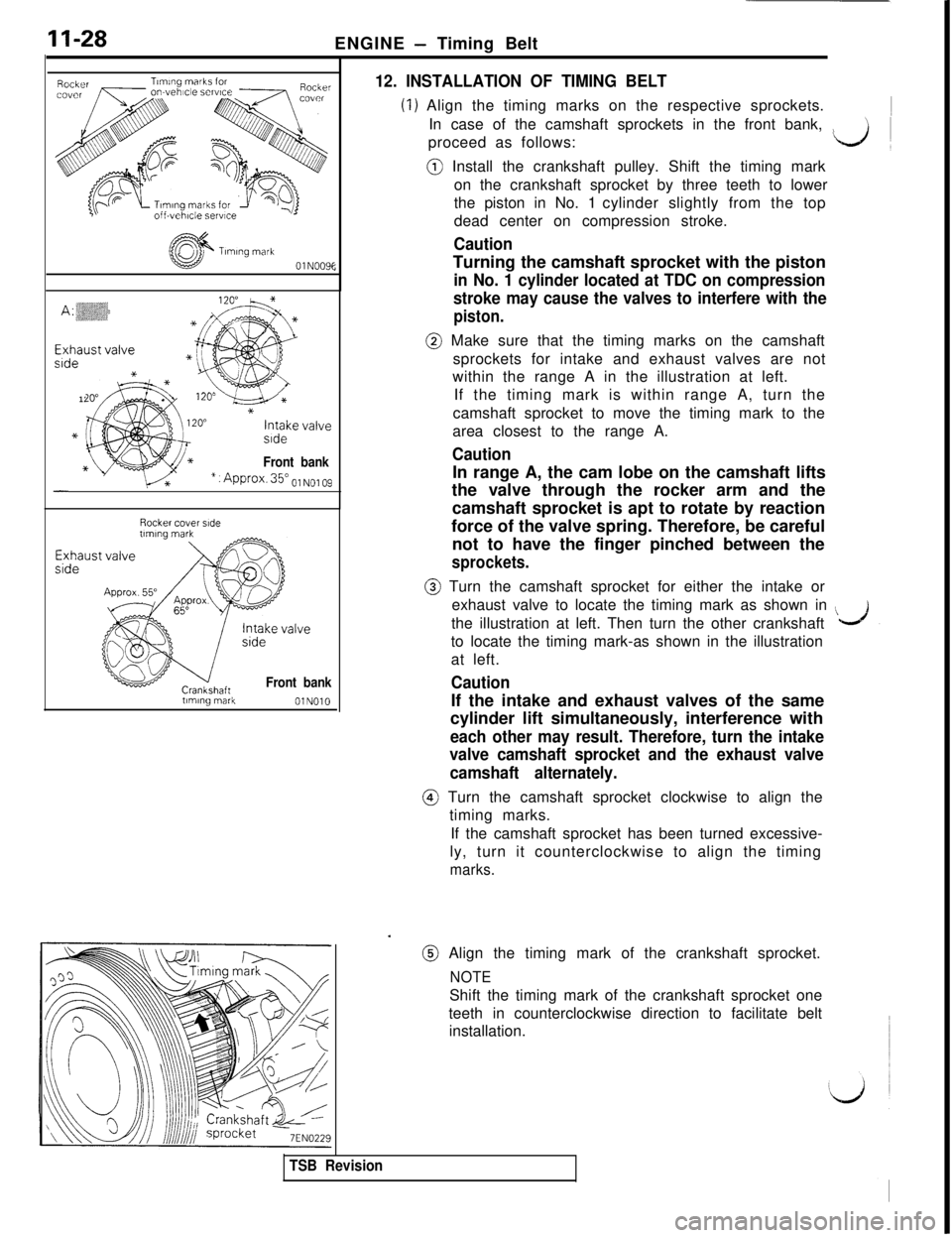

Tlmlng mark01 N009E

A : :y,y;i;,$yi *&:;.~:;>

Exhaust valveside

*

/’*

120"* -1"

(*

6

7.^^^J‘c;Y

1zv w**

Intake valveside

Front bank

* : Approx. 35” o1 N0, og

Rockercoverslde

Exhaust valveside

Front bank

t~mng markOlNOlO

12. INSTALLATION OF TIMING BELT

(1) Align the timing marks on the respective sprockets.

In case of the camshaft sprockets in the front bank,

I~

proceed as follows:@ Install the crankshaft pulley. Shift the timing mark

on the crankshaft sprocket by three teeth to lower

the piston in No. 1 cylinder slightly from the top

dead center on compression stroke.

CautionTurning the camshaft sprocket with the piston

in No. 1 cylinder located at TDC on compression

stroke may cause the valves to interfere with the

piston.@ Make sure that the timing marks on the camshaft

sprockets for intake and exhaust valves are not

within the range A in the illustration at left.

If the timing mark is within range A, turn the

camshaft sprocket to move the timing mark to the

area closest to the range A.

CautionIn range A, the cam lobe on the camshaft lifts

the valve through the rocker arm and the

camshaft sprocket is apt to rotate by reaction

force of the valve spring. Therefore, be careful

not to have the finger pinched between the

sprockets.@ Turn the camshaft sprocket for either the intake or

exhaust valve to locate the timing mark as shown in

\the illustration at left. Then turn the other crankshaft

to locate the timing mark-as shown in the illustration

at left.

CautionIf the intake and exhaust valves of the same

cylinder lift simultaneously, interference with

each other may result. Therefore, turn the intake

valve camshaft sprocket and the exhaust valve

camshaft alternately.@ Turn the camshaft sprocket clockwise to align the

timing marks.

If the camshaft sprocket has been turned excessive-

ly, turn it counterclockwise to align the timing

marks.

TSB Revision

.@ Align the timing mark of the crankshaft sprocket.

NOTEShift the timing mark of the crankshaft sprocket one

teeth in counterclockwise direction to facilitate belt

installation.

Page 79 of 1146

ENGINE - Timing Belt11-29

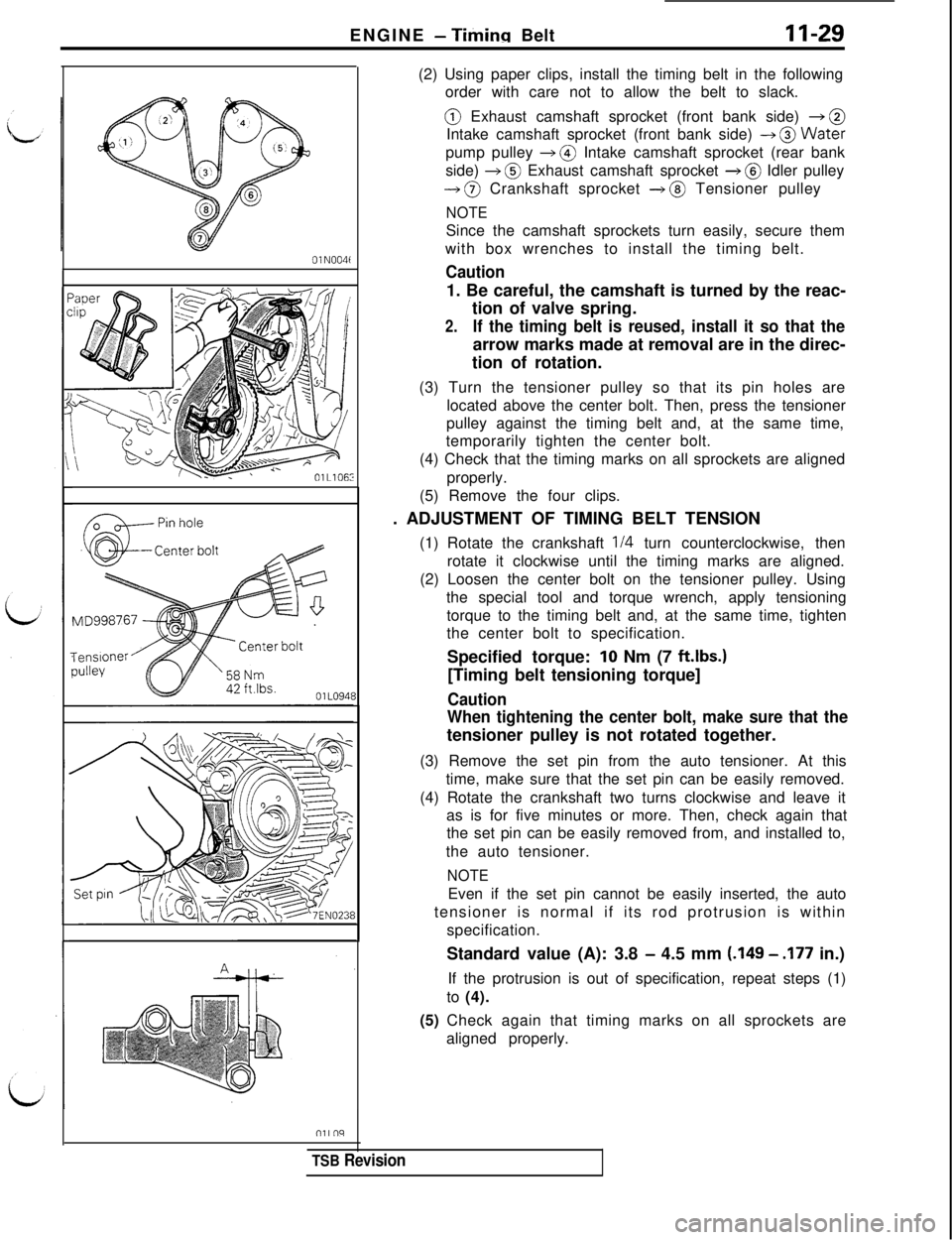

OlN004t

& Pin hole

nilnq

8(2) Using paper clips, install the timing belt in the following

order with care not to allow the belt to slack.@ Exhaust camshaft sprocket (front bank side)

+ @

Intake camshaft sprocket (front bank side)

-+ @Waterpump pulley

+ @ Intake camshaft sprocket (rear bank

side)

+ @ Exhaust camshaft sprocket + @ Idler pulley

-+ @ Crankshaft sprocket + @ Tensioner pulley

NOTESince the camshaft sprockets turn easily, secure them

with box wrenches to install the timing belt.

Caution1. Be careful, the camshaft is turned by the reac-

tion of valve spring.

2.If the timing belt is reused, install it so that thearrow marks made at removal are in the direc-

tion of rotation.

(3) Turn the tensioner pulley so that its pin holes are

located above the center bolt. Then, press the tensioner

pulley against the timing belt and, at the same time,

temporarily tighten the center bolt.

(4) Check that the timing marks on all sprockets are aligned

properly.

(5) Remove the four clips.

. ADJUSTMENT OF TIMING BELT TENSION

(1) Rotate the crankshaft

114 turn counterclockwise, then

rotate it clockwise until the timing marks are aligned.

(2) Loosen the center bolt on the tensioner pulley. Using

the special tool and torque wrench, apply tensioning

torque to the timing belt and, at the same time, tighten

the center bolt to specification.

Specified torque:

10 Nm (7 ftlbs.)

[Timing belt tensioning torque]

Caution

When tightening the center bolt, make sure that thetensioner pulley is not rotated together.

(3) Remove the set pin from the auto tensioner. At this

time, make sure that the set pin can be easily removed.

(4) Rotate the crankshaft two turns clockwise and leave it

as is for five minutes or more. Then, check again that

the set pin can be easily removed from, and installed to,

the auto tensioner.

NOTEEven if the set pin cannot be easily inserted, the auto

tensioner is normal if its rod protrusion is within

specification.

Standard value (A): 3.8

- 4.5 mm (.I49 - .I77 in.)

If the protrusion is out of specification, repeat steps (1)

to (4).

(5) Check again that timing marks on all sprockets are

aligned properly.

TSB Revision

Page 80 of 1146

II-30ENGINE - Timing Belt

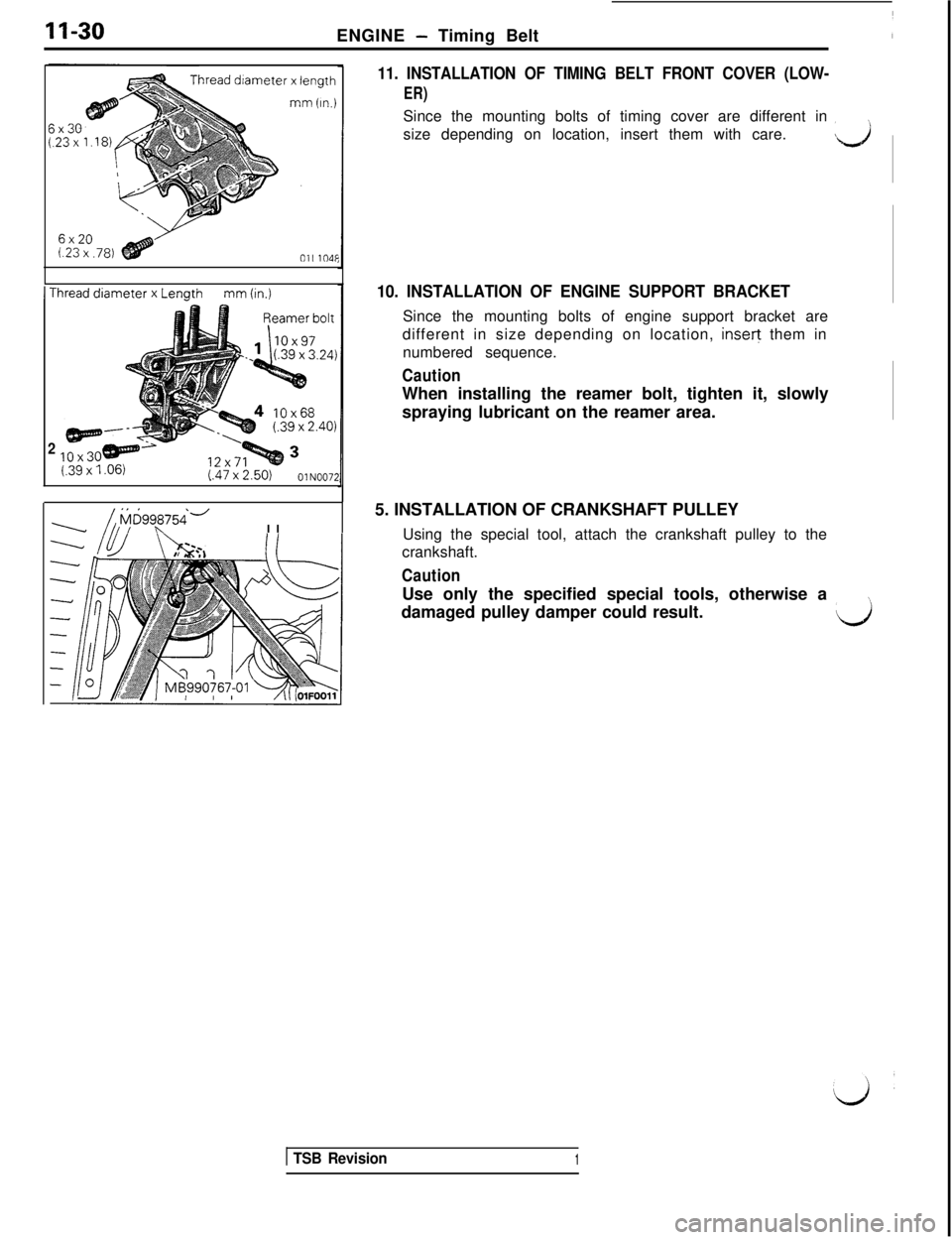

hread diameter x length

mm (In.)

6x201.23 x ,781fllllO4F

1 Thread diameter x Lengthmm (in.)

2(39

x1.06)l.47 x 2.50)OlN0072

11. INSTALLATION OF TIMING BELT FRONT COVER (LOW-

ER)Since the mounting bolts of timing cover are different in

size depending on location, insert them with care.

.\J

10. INSTALLATION OF ENGINE SUPPORT BRACKETSince the mounting bolts of engine support bracket are

different in size depending on location, insert them in

numbered sequence.

CautionWhen installing the reamer bolt, tighten it, slowly

spraying lubricant on the reamer area.

\/,,fjd99p54-II5. INSTALLATION OF CRANKSHAFT PULLEY

Using the special tool, attach the crankshaft pulley to the

crankshaft.

CautionUse only the specified special tools, otherwise a

:damaged pulley damper could result.

d

1 TSB Revision1

Page 81 of 1146

ENGINE - Rocker Arm and Camshaft11-31

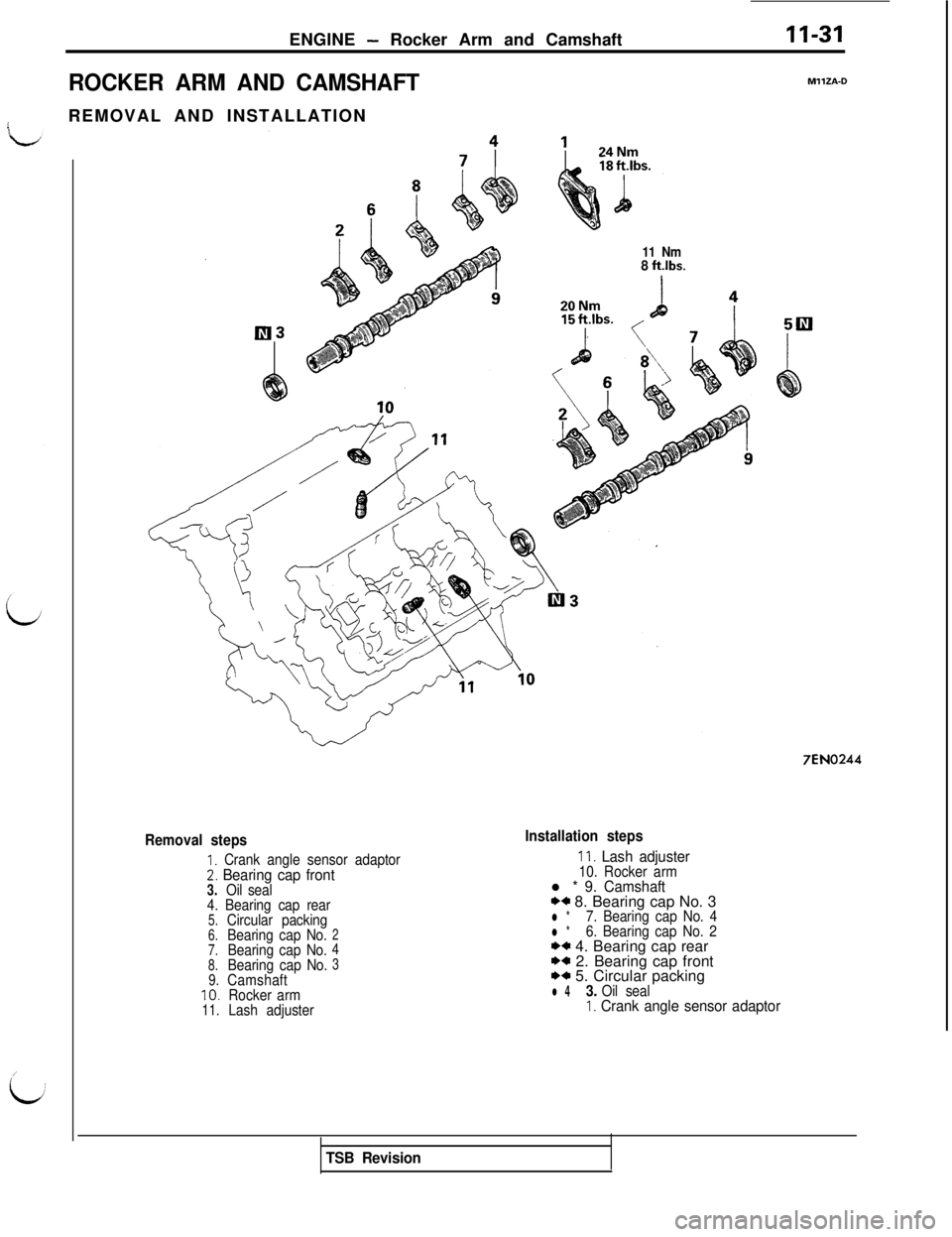

ROCKER ARM AND CAMSHAFTREMOVAL AND INSTALLATION

11 Nm8 ftlbs.

MllZA-0

7EN0244

Removal steps

I. Crank angle sensor adaptor2. Bearing cap front3.Oil seal

4. Bearing cap rear

5.Circular packing6.Bearing cap No.27.Bearing cap No.4

8.Bearing cap No.3

9.Camshaft10.Rocker arm11.Lash adjuster

Installation steps

11. Lash adjuster10. Rocker arml * 9. Camshaft*a 8. Bearing cap No. 3l *7. Bearing cap No. 4l *6. Bearing cap No. 2** 4. Bearing cap rearI)* 2. Bearing cap front*+ 5. Circular packingl 43. Oil sealI. Crank angle sensor adaptor

TSB Revision

Page 82 of 1146

11-32ENGINE - Rocker Arm and Camshaft

r

I

/7EN024E

Small wire

8ENOO58

Identification mark(stamped on hexagon section)

7EN0249

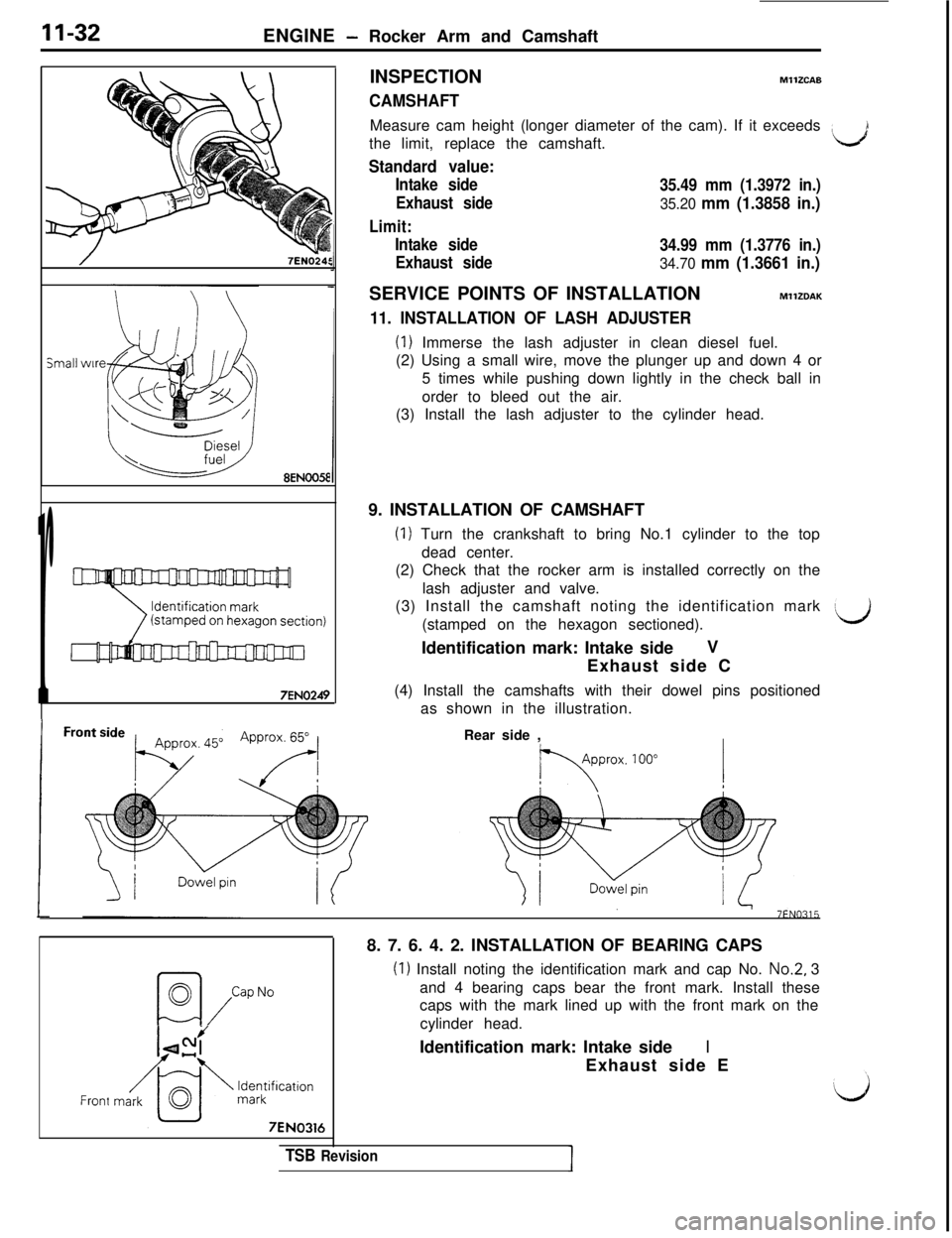

Front sideINSPECTION

MllZCAB

CAMSHAFTMeasure cam height (longer diameter of the cam). If it exceeds

the limit, replace the camshaft.

Standard value:

Intake side

35.49 mm (1.3972 in.)

Exhaust side

35.20 mm (1.3858 in.)

Limit:

Intake side

34.99 mm (1.3776 in.)

Exhaust side

34.70 mm (1.3661 in.)SERVICE POINTS OF INSTALLATION

MllZDAK

11. INSTALLATION OF LASH ADJUSTER

(1) Immerse the lash adjuster in clean diesel fuel.

(2) Using a small wire, move the plunger up and down 4 or

5 times while pushing down lightly in the check ball in

order to bleed out the air.

(3) Install the lash adjuster to the cylinder head.

9. INSTALLATION OF CAMSHAFT

(1) Turn the crankshaft to bring No.1 cylinder to the top

dead center.

(2) Check that the rocker arm is installed correctly on the

lash adjuster and valve.

(3) Install the camshaft noting the identification mark

(stamped on the hexagon sectioned).

Identification mark: Intake sideV

Exhaust side C

(4) Install the camshafts with their dowel pins positioned

as shown in the illustration.

Rear side ,

Approx. 100”

Pl

Frontm&k

M

0

/

Cap No

TSB Revision

Identificationmark

7EN03168. 7. 6. 4. 2. INSTALLATION OF BEARING CAPS

(1) Install noting the identification mark and cap No. No.2, 3

and 4 bearing caps bear the front mark. Install these

caps with the mark lined up with the front mark on the

cylinder head.

Identification mark: Intake side

IExhaust side E

Page 83 of 1146

ENGINE - Rocker Arm and Camshaft11-33

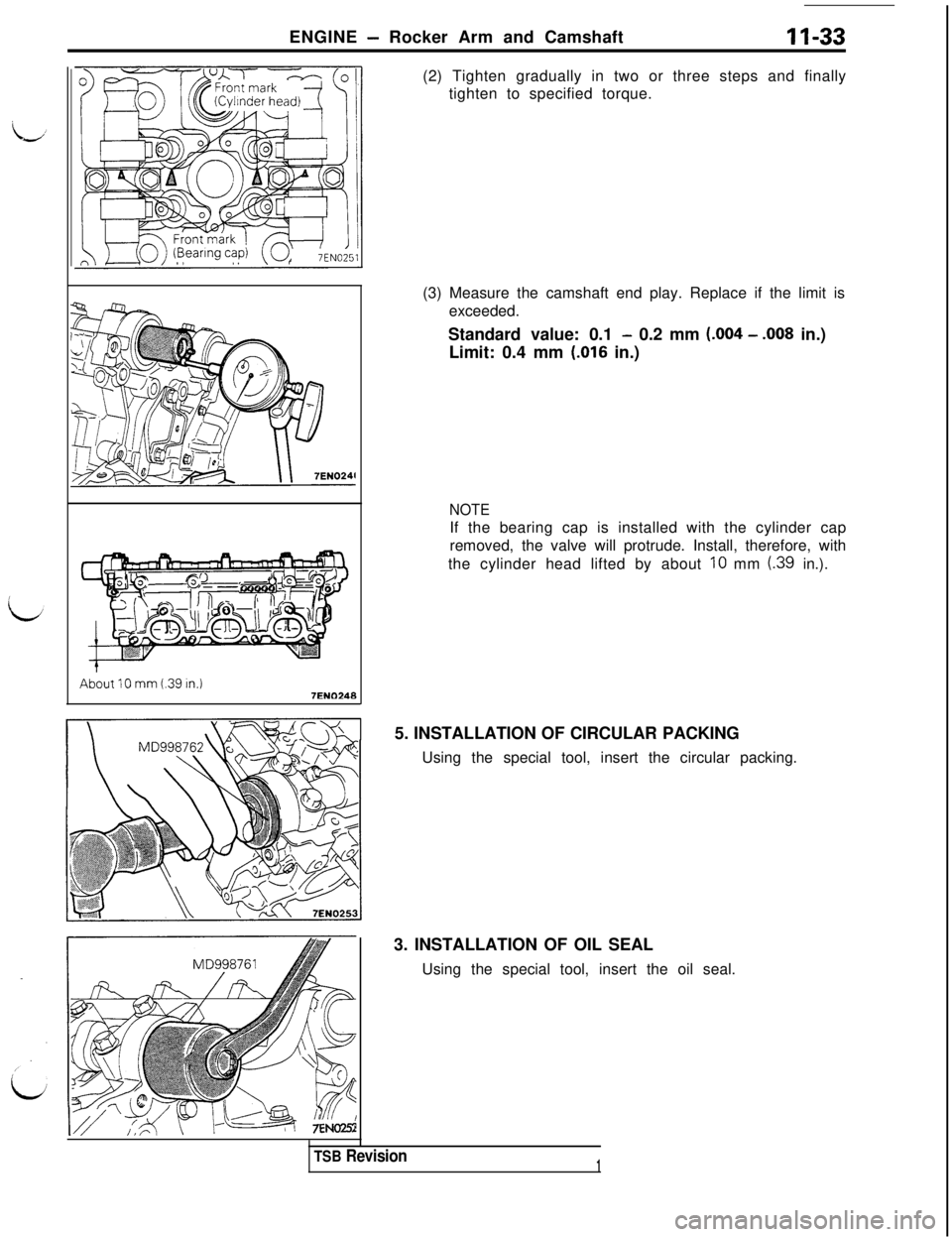

About 10 mm C.39 In.17ENO248

i,(2) Tighten gradually in two or three steps and finally

tighten to specified torque.

(3) Measure the camshaft end play. Replace if the limit is

exceeded.

Standard value: 0.1

- 0.2 mm (.004 - .008 in.)

Limit: 0.4 mm

(.016 in.)

NOTEIf the bearing cap is installed with the cylinder cap

removed, the valve will protrude. Install, therefore, with

the cylinder head lifted by about

10 mm (.39 in.).

5. INSTALLATION OF CIRCULAR PACKING

Using the special tool, insert the circular packing.

3. INSTALLATION OF OIL SEAL

Using the special tool, insert the oil seal.

TSB Revision1

Page 84 of 1146

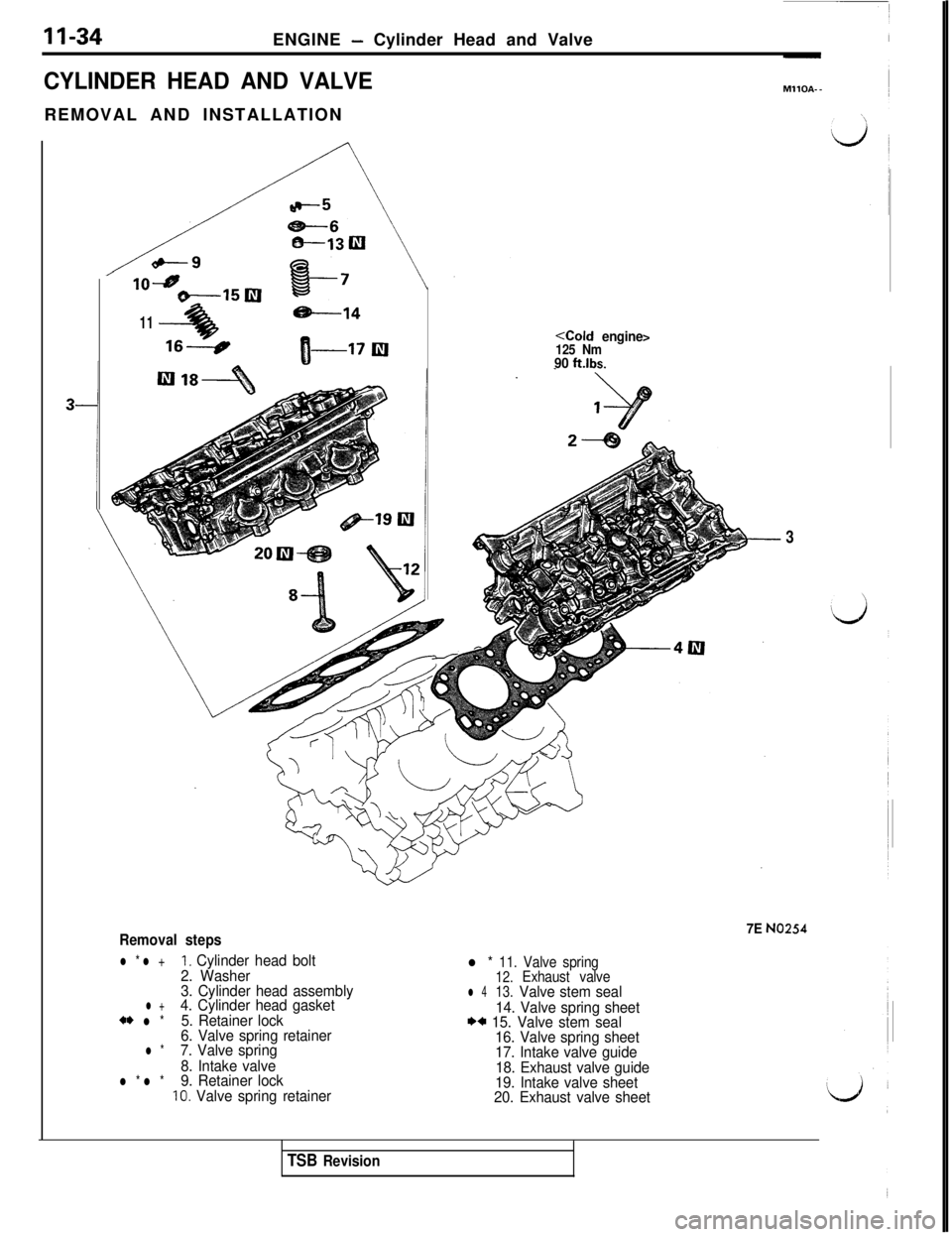

II-34ENGINE - Cylinder Head and Valve

CYLINDER HEAD AND VALVEREMOVAL AND INSTALLATION

’ 104e------1510

11-A16-----P

Removal steps

l * l +I. Cylinder head bolt

2. Washer

3. Cylinder head assembly

l +4. Cylinder head gasket

** l *5. Retainer lock

6. Valve spring retainer

l *7. Valve spring

8. Intake valve

l * l *9. Retainer lock10. Valve spring retainer

7E NO254

l * 11. Valve spring12.Exhaust valvel 413.Valve stem seal

14. Valve spring sheet

I)* 15. Valve stem seal

16. Valve spring sheet

17. Intake valve guide

18. Exhaust valve guide

19. Intake valve sheet

20. Exhaust valve sheet

3

TSB Revision

Page 85 of 1146

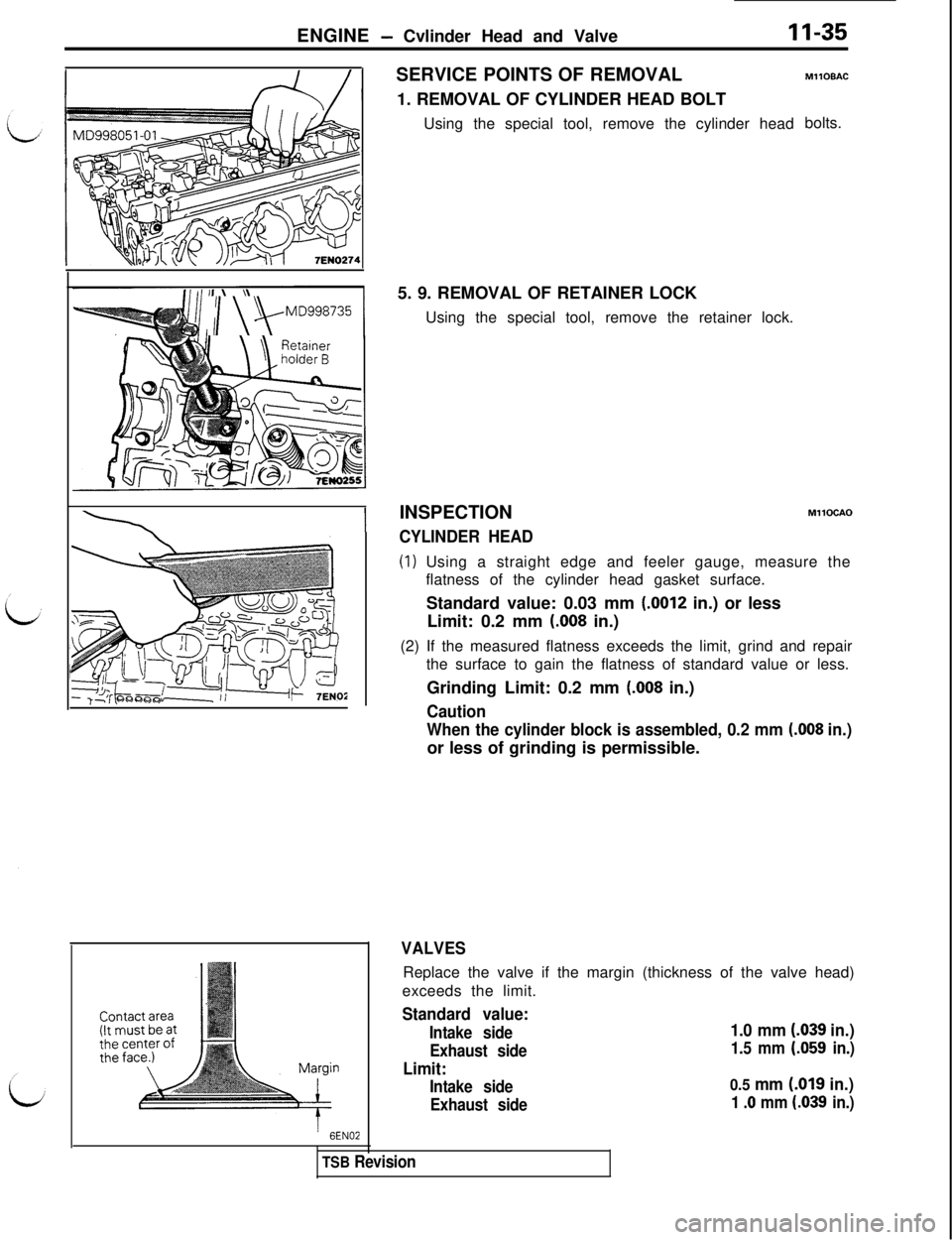

ENGINE - Cvlinder Head and ValveII-35SERVICE POINTS OF REMOVAL

1. REMOVAL OF CYLINDER HEAD BOLT

Using the special tool, remove the cylinder head

u 1 \+-MD998735 15. 9. REMOVAL OF RETAINER LOCK

Using the special tool, remove the retainer lock.

’ 6EN02INSPECTION

CYLINDER HEAD

MllOBACbolts.

MllOCAO

(1) Using a straight edge and feeler gauge, measure the

flatness of the cylinder head gasket surface.

Standard value: 0.03 mm (0012 in.) or less

Limit: 0.2 mm

(008 in.)

(2) If the measured flatness exceeds the limit, grind and repair

the surface to gain the flatness of standard value or less.

Grinding Limit: 0.2 mm

(.008 in.)

Caution

When the cylinder block is assembled, 0.2 mm

(.008 in.)or less of grinding is permissible.

VALVESReplace the valve if the margin (thickness of the valve head)

exceeds the limit.

Standard value:

Intake side1.0 mm (039 in.)

Exhaust side1.5 mm (.059 in.)

Limit:

Intake side0.5 mm (019 in.)

Exhaust side1 .O mm (.039 in.)

TSB Revision