ignition MITSUBISHI 3000GT 1991 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 225 of 1146

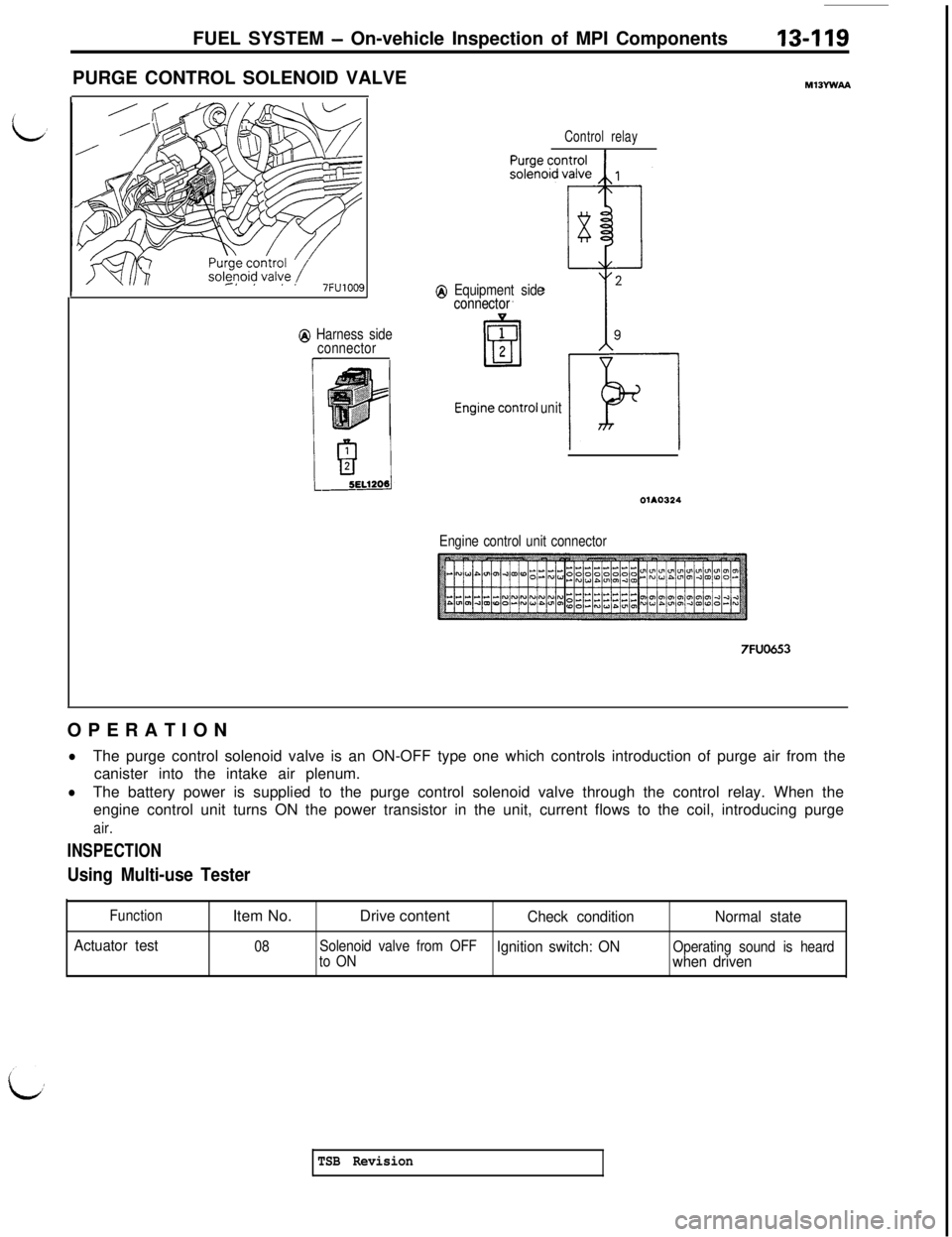

FUEL SYSTEM - On-vehicle Inspection of MPI Components13-119PURGE CONTROL SOLENOID VALVE

Q Harness side

connector

I

Control relay

@ Equipment side

connector connector

unit

OlAO324

Engine control unit connector

7FUO653OPERATION

lThe purge control solenoid valve is an ON-OFF type one which controls introduction of purge air from the

canister into the intake air plenum.

lThe battery power is supplied to the purge control solenoid valve through the control relay. When the

engine control unit turns ON the power transistor in the unit, current flows to the coil, introducing purge

air.

INSPECTION

Using Multi-use Tester

Function

Actuator testItem No.Drive content

Check conditionNormal state

08Solenoid valve from OFFIgnition switch: ONOperating sound is heard

to ONwhen driven

TSB Revision

Page 226 of 1146

13-120FUEL SYSTEM - On-vehicle Inspection of MPI Components

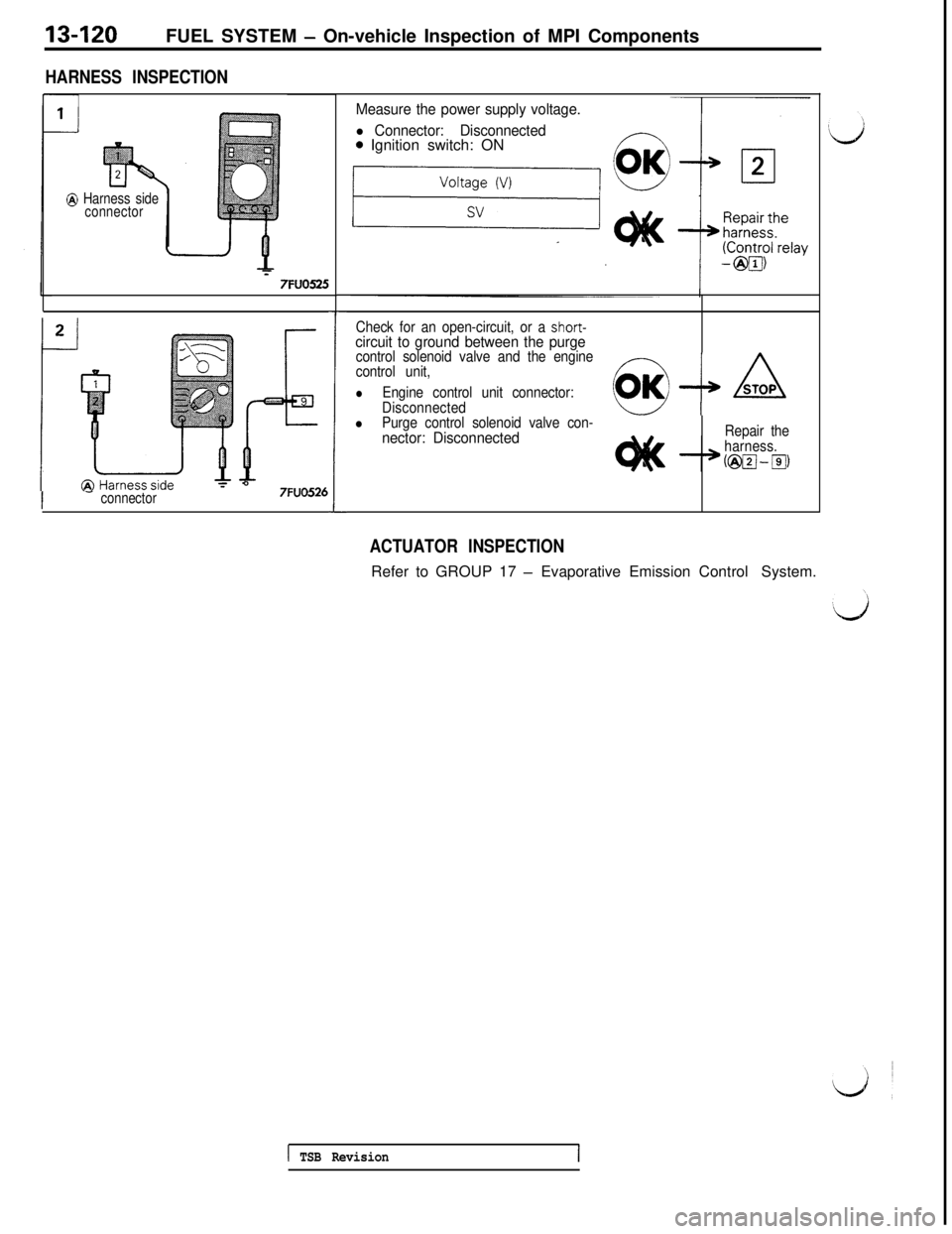

HARNESS INSPECTION

@ Harness side

connector

T7FUO525

I -connector57FUO526

1

Measure the power supply voltage.

l Connector: Disconnected0 Ignition switch: ON

Check for an open-circuit, or a short-circuit to ground between the purgecontrol solenoid valve and the engine

control unit,

lEngine control unit connector:

Disconnected@-+A

lPurge control solenoid valve con-nector: DisconnectedRepair the

harness.

ACTUATOR INSPECTIONRefer to GROUP 17

- Evaporative Emission Control System.

1 TSB Revision1

Page 228 of 1146

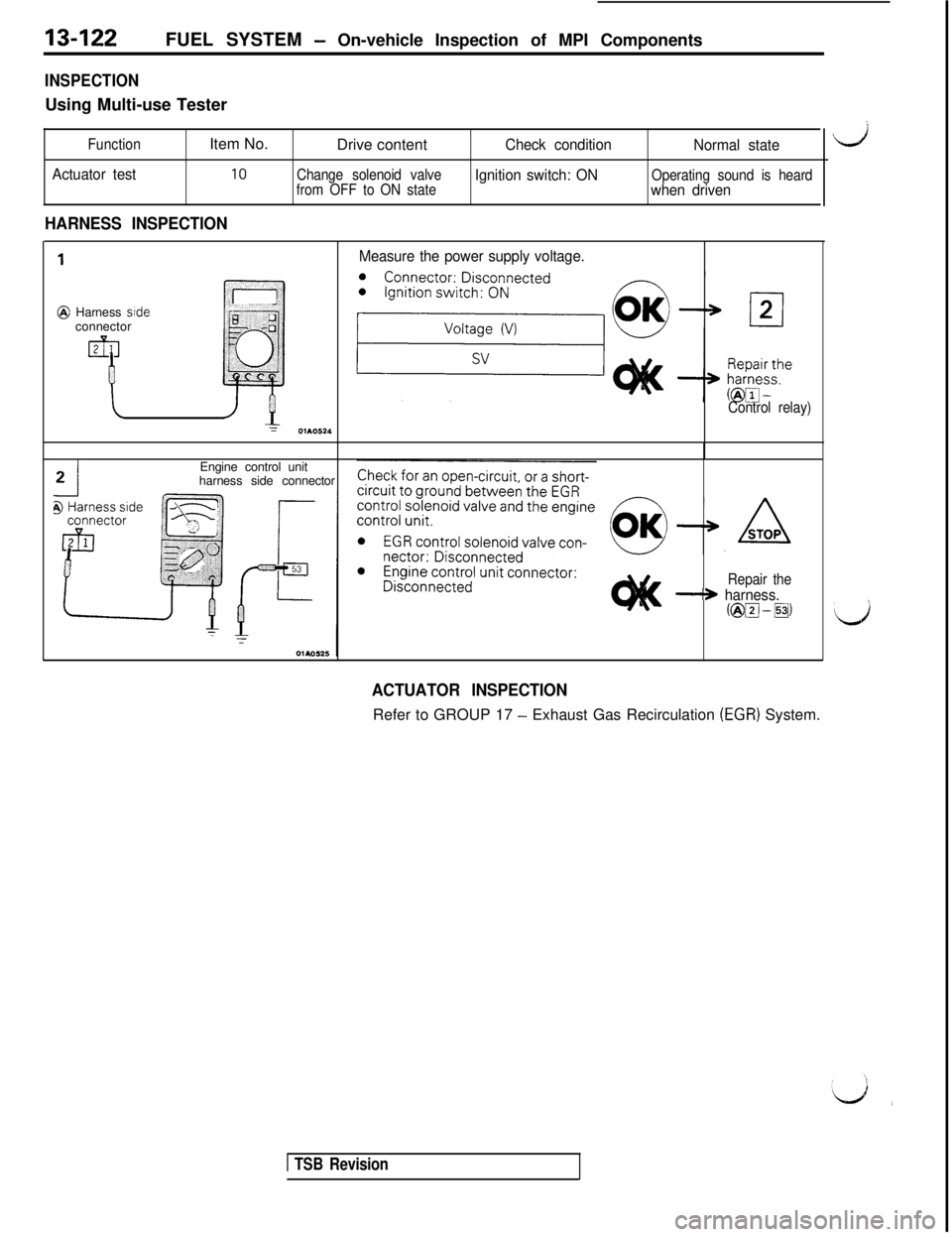

13-122FUEL SYSTEM - On-vehicle Inspection of MPI Components

INSPECTIONUsing Multi-use Tester

Function

Actuator testItem No.

Drive content

Check condition

Normal state

10Change solenoid valve

from OFF to ON stateIgnition switch: ONOperating sound is heardwhen driven

HARNESS INSPECTION

1

@ Harness side

connector

Measure the power supply voltage.

Y01105*4Engine control unit

harness side connector

Control relay)

Repair the

-S harness.C@vJ-~)

d

Ls

ACTUATOR INSPECTIONRefer to GROUP 17

- Exhaust Gas Recirculation (EGR) System.

1 TSB Revision

Page 230 of 1146

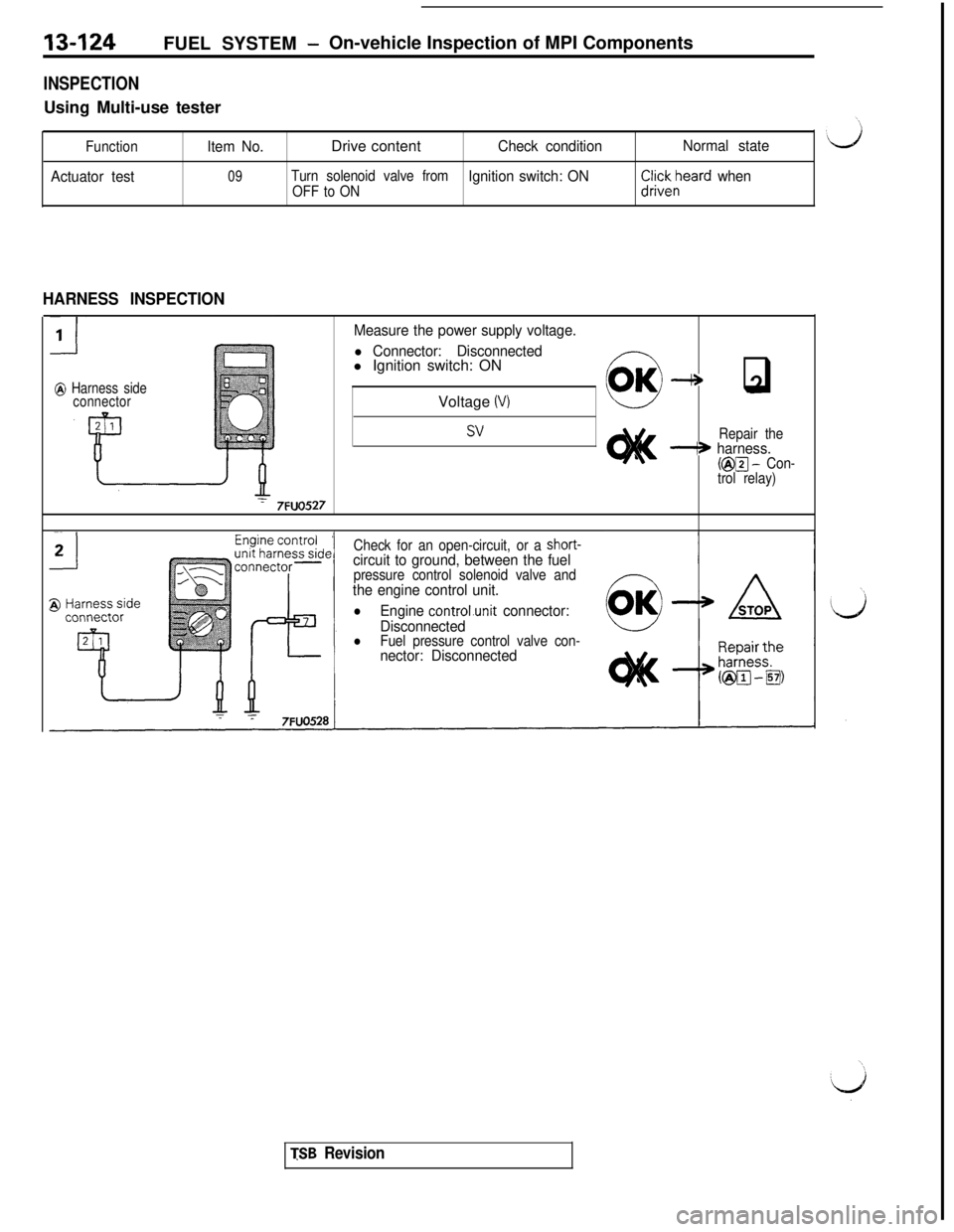

13-124FUEL SYSTEM -On-vehicle Inspection of MPI Components

INSPECTIONUsing Multi-use tester

Function

Actuator testItem No.Drive content

Check conditionNormal state

09Turn solenoid valve fromIgnition switch: ONOFF to ONr%;reard when

HARNESS INSPECTION

@ Harness side

connector

Measure the power supply voltage.

l Connector: Disconnectedl Ignition switch: ON

Voltage

(V)2-* q

SVRepair thei* harness.(@m - Con-

trol relay)

7FUO527

Check for an open-circuit, or a short-circuit to ground, between the fuelpressure control solenoid valve andthe engine control unit.

lEngine controLunit connector:

Disconnected

lFuel pressure control valve con-nector: Disconnected

TSB Revision

Page 233 of 1146

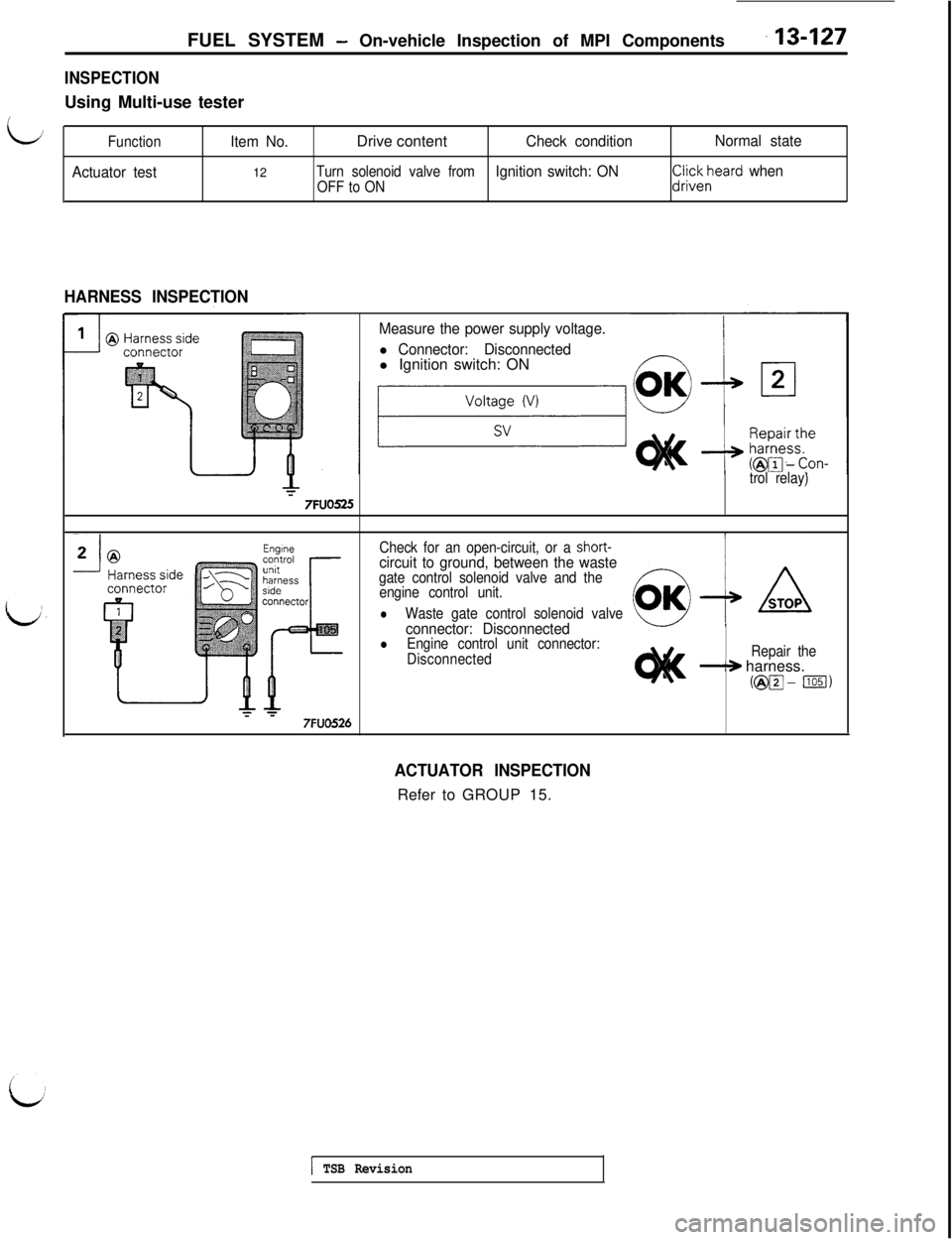

FUEL SYSTEM - On-vehicle Inspection of MPI Components'13-127

INSPECTIONUsing Multi-use tester

LFunctionItem No.Drive contentCheck conditionNormal state

Actuator test12

Turn solenoid valve fromIgnition switch: ONOFF to ON

CliZli~,“eard when

HARNESS INSPECTION

Measure the power supply voltage.

l Connector: Disconnectedl Ignition switch: ON

trol relay)

7FUO525

Check for an open-circuit, or a short-circuit to ground, between the wastegate control solenoid valve and the

engine control unit.

lWaste gate control solenoid valveconnector: DisconnectedlEngine control unit connector:

DisconnectedRepair the

-+ harness.

(@m- ml)

7FUO526

ACTUATOR INSPECTIONRefer to GROUP 15.

1 TSB Revision

Page 234 of 1146

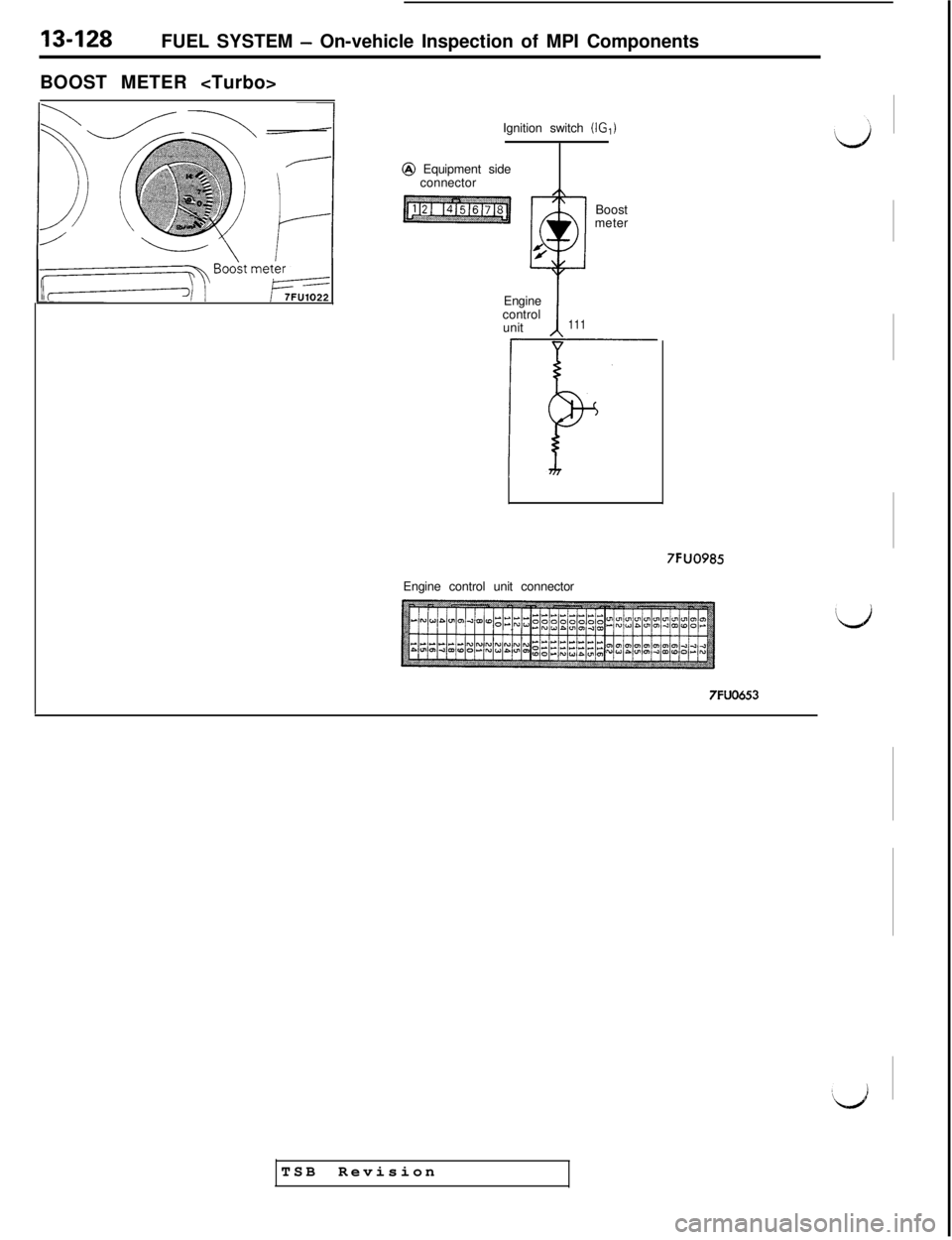

13-128FUEL SYSTEM - On-vehicle Inspection of MPI Components

BOOST METER

Ignition switch

(IG,)@ Equipment side

connector

Boost

meter

Engine

control

unit

111

i-F7FUO985

Engine control unit connector

TSB Revision

Page 235 of 1146

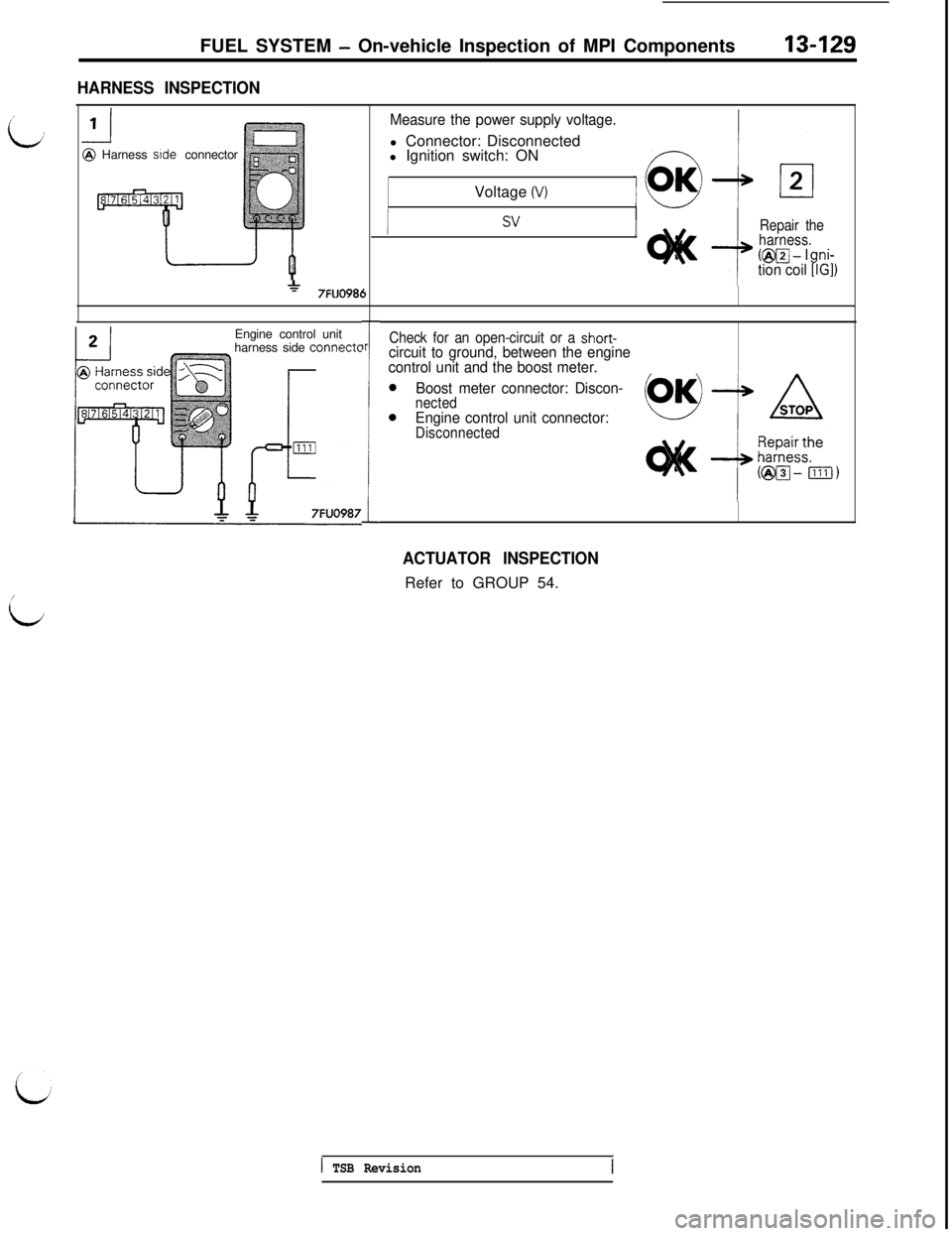

FUEL SYSTEM - On-vehicle Inspection of MPI Components13-129

i

HARNESS INSPECTION@ Harness side connector

*7FUO986Engine control unit

harness side

connect0r

1

Measure the power supply voltage.l Connector: Disconnected

l Ignition switch: ON

Voltage

(V)

svRepair the

harness.

(@I@-- Ini-tion coil9IG])

Check for an open-circuit or a short-circuit to ground, between the engine

control unit and the boost meter.

Boost meter connector: Discon-

nectedEngine control unit connector:Disconnected

ACTUATOR INSPECTIONRefer to GROUP 54.

1 TSB Revision

Page 237 of 1146

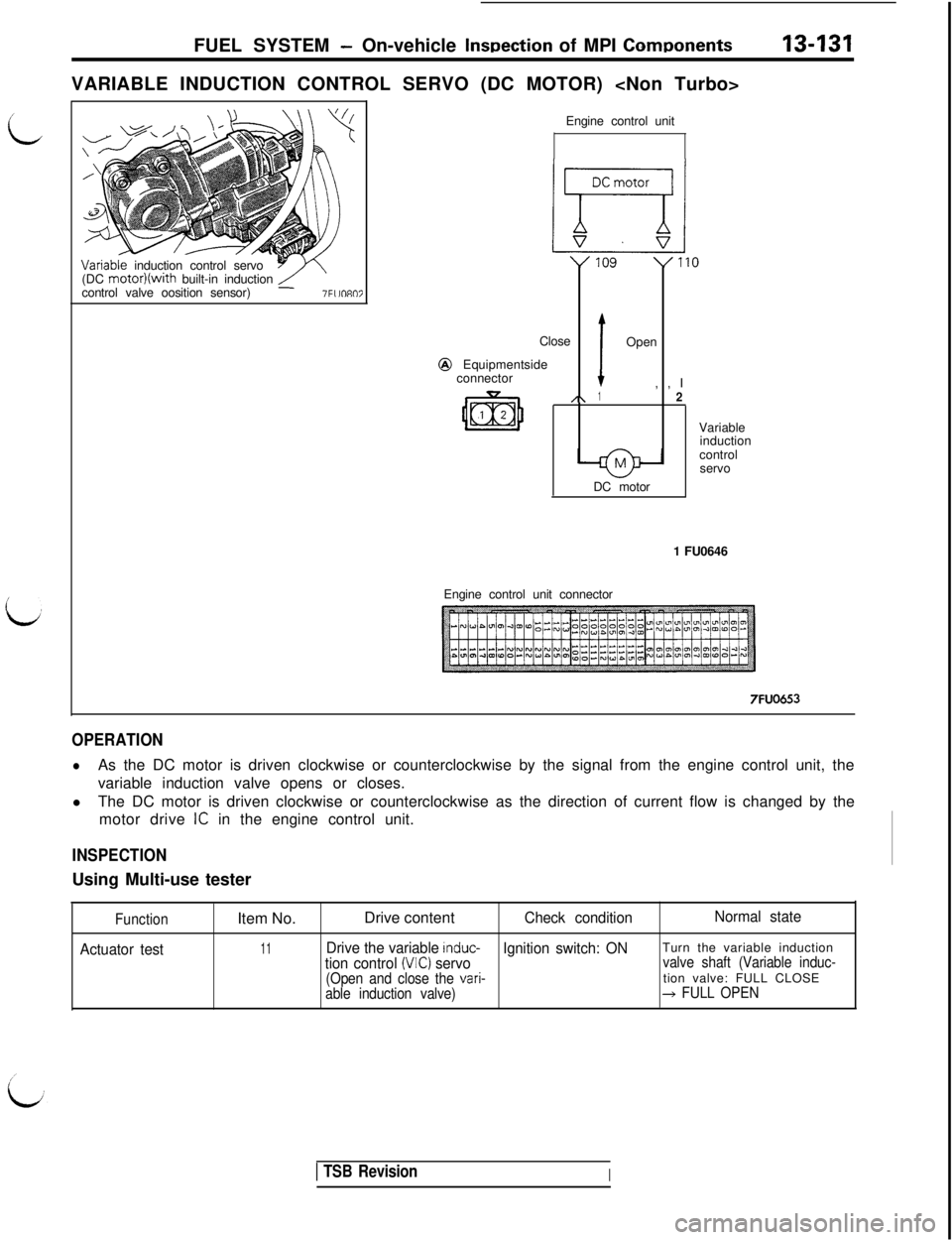

FUEL SYSTEM - On-vehicle lnwection of MPI ComDonents13-131

iVARIABLE INDUCTION CONTROL SERVO (DC MOTOR)

Y(DC motor)(with built-in induction/-control valve oosition sensor)-7Fllfl807Engine control unit

Close

connector

,\ IOpen@ Equipmentside1,,I2DC motorVariable

induction

control

servo

1 FU0646

Engine control unit connector

7FUO653

OPERATION

lAs the DC motor is driven clockwise or counterclockwise by the signal from the engine control unit, the

variable induction valve opens or closes.

lThe DC motor is driven clockwise or counterclockwise as the direction of current flow is changed by the

motor drive

IC in the engine control unit.

INSPECTIONUsing Multi-use tester

Function

Actuator testItem No.Drive content

Check conditionNormal state

11Drive the variable induc-Ignition switch: ONTurn the variable inductiontion control (MC) servovalve shaft (Variable induc-

(Open and close the

vari-tion valve: FULL CLOSEable induction valve)+ FULL OPEN

1 TSB RevisionI

Page 243 of 1146

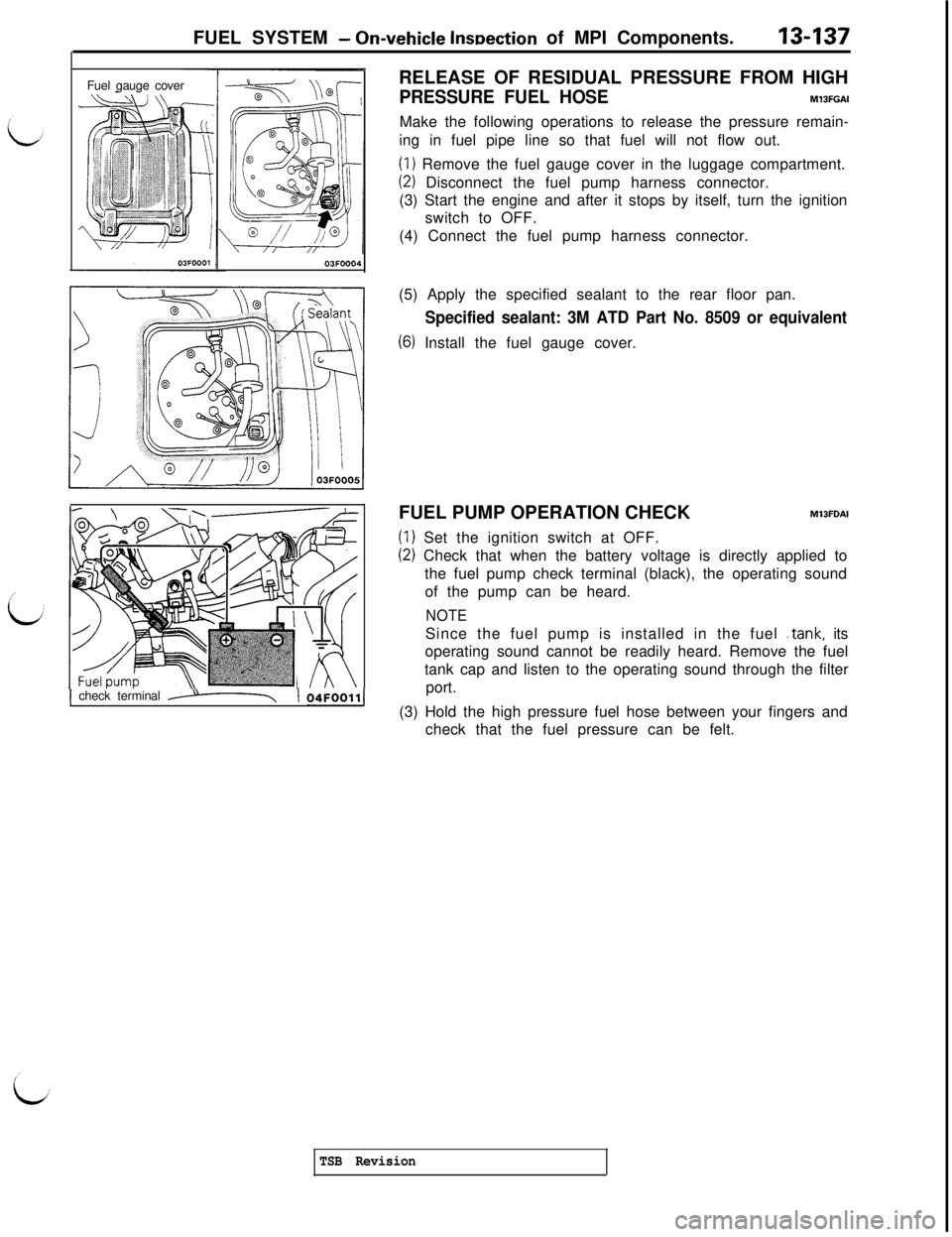

FUEL SYSTEM - Orwehicle lnwection of MPI Components.13-137Fuel gauge cover

03FOOO4

j check terminal ----T( 04~oo1,/RELEASE OF RESIDUAL PRESSURE FROM HIGH

PRESSURE FUEL HOSEM13FGAIMake the following operations to release the pressure remain-

ing in fuel pipe line so that fuel will not flow out.

(I) Remove the fuel gauge cover in the luggage compartment.

(2) Disconnect the fuel pump harness connector.

(3) Start the engine and after it stops by itself, turn the ignition

switch to OFF.

(4) Connect the fuel pump harness connector.

(5) Apply the specified sealant to the rear floor pan.

Specified sealant: 3M ATD Part No. 8509 or equivalent

(6) Install the fuel gauge cover.

FUEL PUMP OPERATION CHECK

M13FDAI

(1) Set the ignition switch at OFF.

(2) Check that when the battery voltage is directly applied to

the fuel pump check terminal (black), the operating sound

of the pump can be heard.

NOTESince the fuel pump is installed in the fuel

.tank, its

operating sound cannot be readily heard. Remove the fuel

tank cap and listen to the operating sound through the filter

port.

(3) Hold the high pressure fuel hose between your fingers and

check that the fuel pressure can be felt.

TSB Revision

Page 262 of 1146

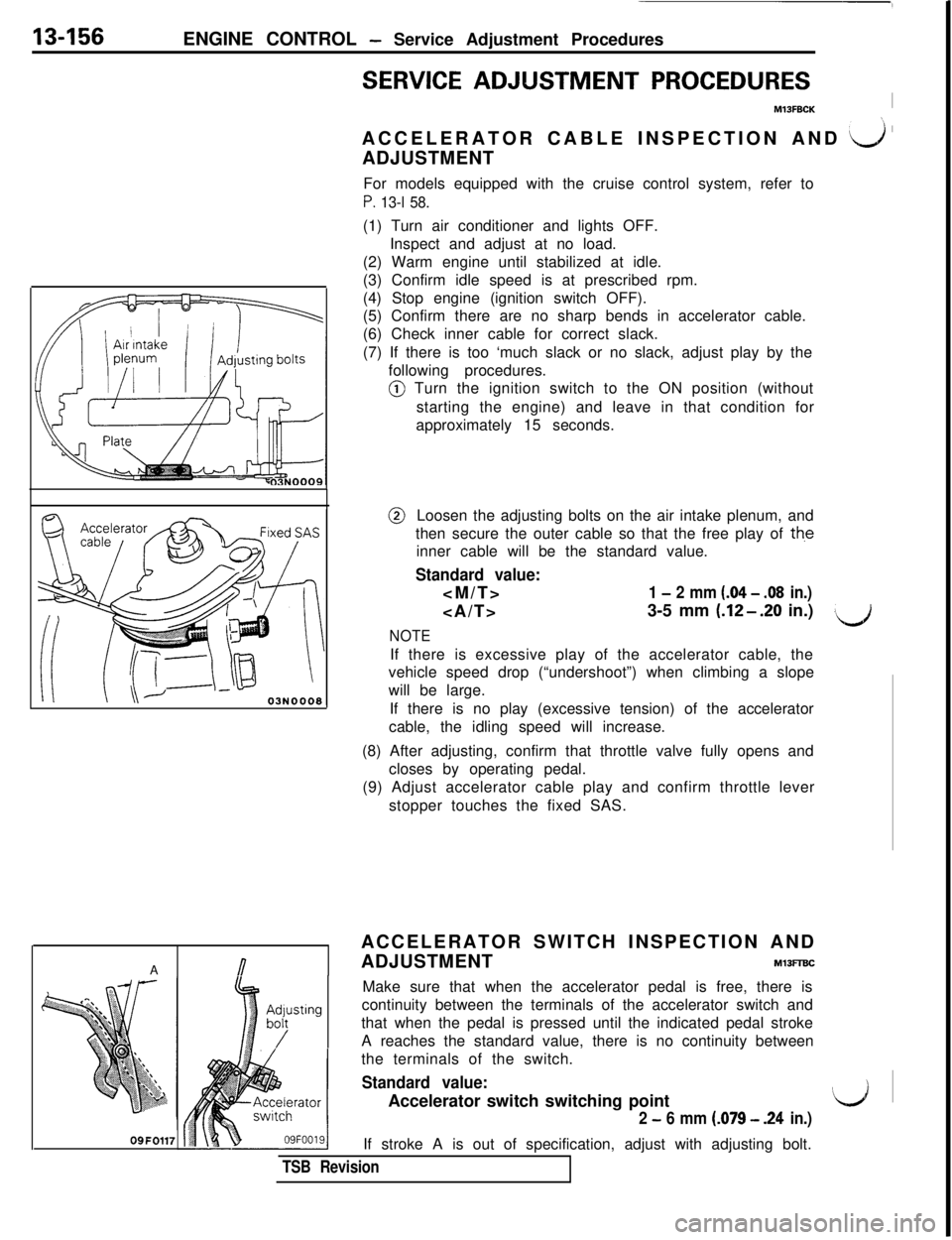

13-156ENGINE CONTROL - Service Adjustment Procedures

SERVICE ADJUSTMENT PROCEDURES

M13FBCKIACCELERATOR CABLE INSPECTION AND

a ’ADJUSTMENT

For models equipped with the cruise control system, refer to

P. 13-l 58.(1) Turn air conditioner and lights OFF.

Inspect and adjust at no load.

(2) Warm engine until stabilized at idle.

(3) Confirm idle speed is at prescribed rpm.

(4) Stop engine (ignition switch OFF).

(5) Confirm there are no sharp bends in accelerator cable.

(6) Check inner cable for correct slack.

(7) If there is too ‘much slack or no slack, adjust play by the

following procedures.@ Turn the ignition switch to the ON position (without

starting the engine) and leave in that condition for

approximately 15 seconds.@Loosen the adjusting bolts on the air intake plenum, and

then secure the outer cable so that the free play of

th,einner cable will be the standard value.

Standard value:

1 - 2 mm (.04 - .08 in.)3-5 mm

(.12-.20 in.)

NOTE

\JIf there is excessive play of the accelerator cable, the

vehicle speed drop (“undershoot”) when climbing a slope

will be large.

If there is no play (excessive tension) of the accelerator

cable, the idling speed will increase.

(8) After adjusting, confirm that throttle valve fully opens and

closes by operating pedal.

(9) Adjust accelerator cable play and confirm throttle lever

stopper touches the fixed SAS.

ACCELERATOR SWITCH INSPECTION AND

A

nADJUSTMENTMlBFlBC

09FO117Make sure that when the accelerator pedal is free, there is

;$ustingcontinuity between the terminals of the accelerator switch and

/that when the pedal is pressed until the indicated pedal stroke

A reaches the standard value, there is no continuity between

the terminals of the switch.

Standard value:Accelerator switch switching point

2 - 6 mm (.079 - .24 in.)If stroke A is out of specification, adjust with adjusting bolt.

TSB Revision

\

‘LJ ~