ABS MITSUBISHI 3000GT 1991 Manual Online

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: 3000GT, Model: MITSUBISHI 3000GT 1991Pages: 1146, PDF Size: 76.68 MB

Page 794 of 1146

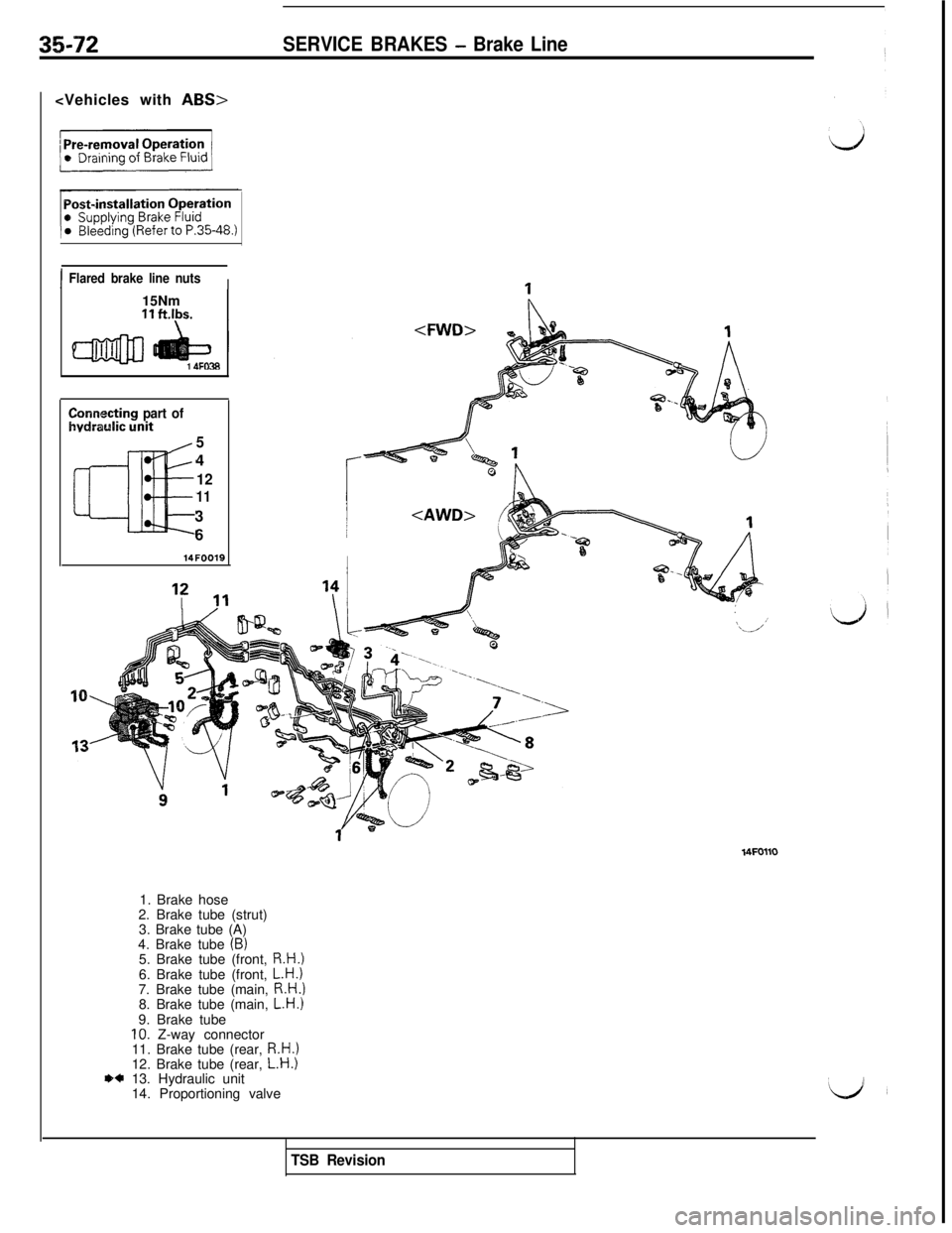

35-72SERVICE BRAKES - Brake Line

IFlared brake line nutsI15Nm

11 ft.lbs.

1 AFO38

Cormecting part ofhvdraulic wnit

54

12

113

614FOOlS

,1. Brake hose

2. Brake tube (strut)

3. Brake tube (A)

4. Brake tube

(B)5. Brake tube (front, R.H.)6. Brake tube (front, L.H.)7. Brake tube (main, R.H.)8. Brake tube (main, L.H.)9. Brake tube

10. Z-way connector

11. Brake tube (rear, R.H.)12. Brake tube (rear, L.H.)O+ 13. Hydraulic unit

14. Proportioning valve

TSB Revision

Page 808 of 1146

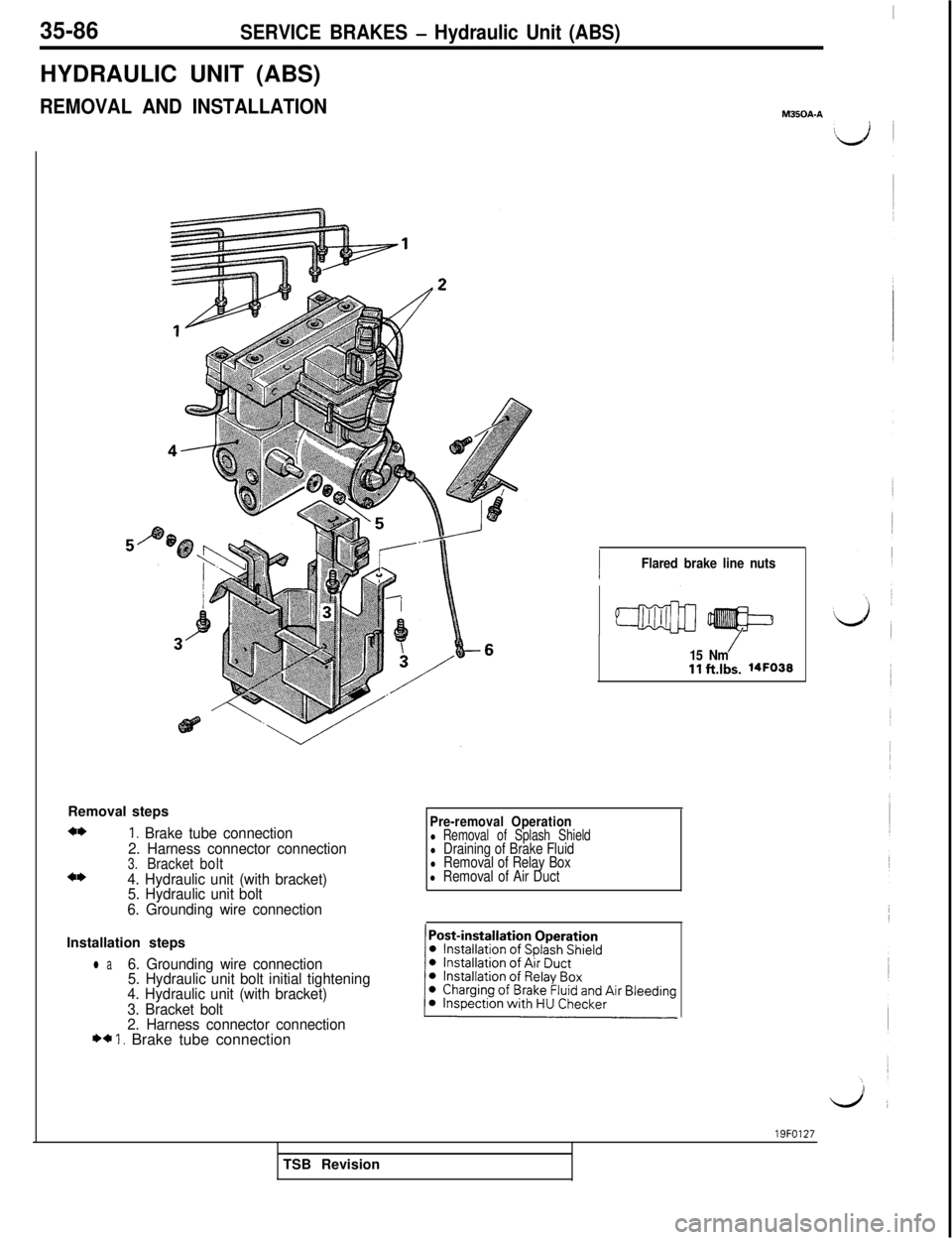

35-86SERVICE BRAKES - Hydraulic Unit (ABS)HYDRAULIC UNIT (ABS)

REMOVAL AND INSTALLATION

I

M350A.ARemoval steps

4*1. Brake tube connection

2. Harness connector connection

3.Bracketbolt4*4. Hydraulic unit (with bracket)

5. Hydraulic unit bolt

6. Grounding wire connection

1Flared brake line nuts

/15 Nmllftlbs. 14FO33

Pre-removal Operationl Removal of Splash Shieldl Draining of Brake Fluidl Removal of Relay Boxl Removal of Air DuctInstallation steps

l a6. Grounding wire connection

5. Hydraulic unit bolt initial tightening

4. Hydraulic unit (with bracket)

3. Bracket bolt

2. Harness connector connection

** 1. Brake tube connection19FO127

TSB Revision

Page 809 of 1146

SERVICE BRAKES - Hvdraulic Unit (ABS)35-87

14FOO8:

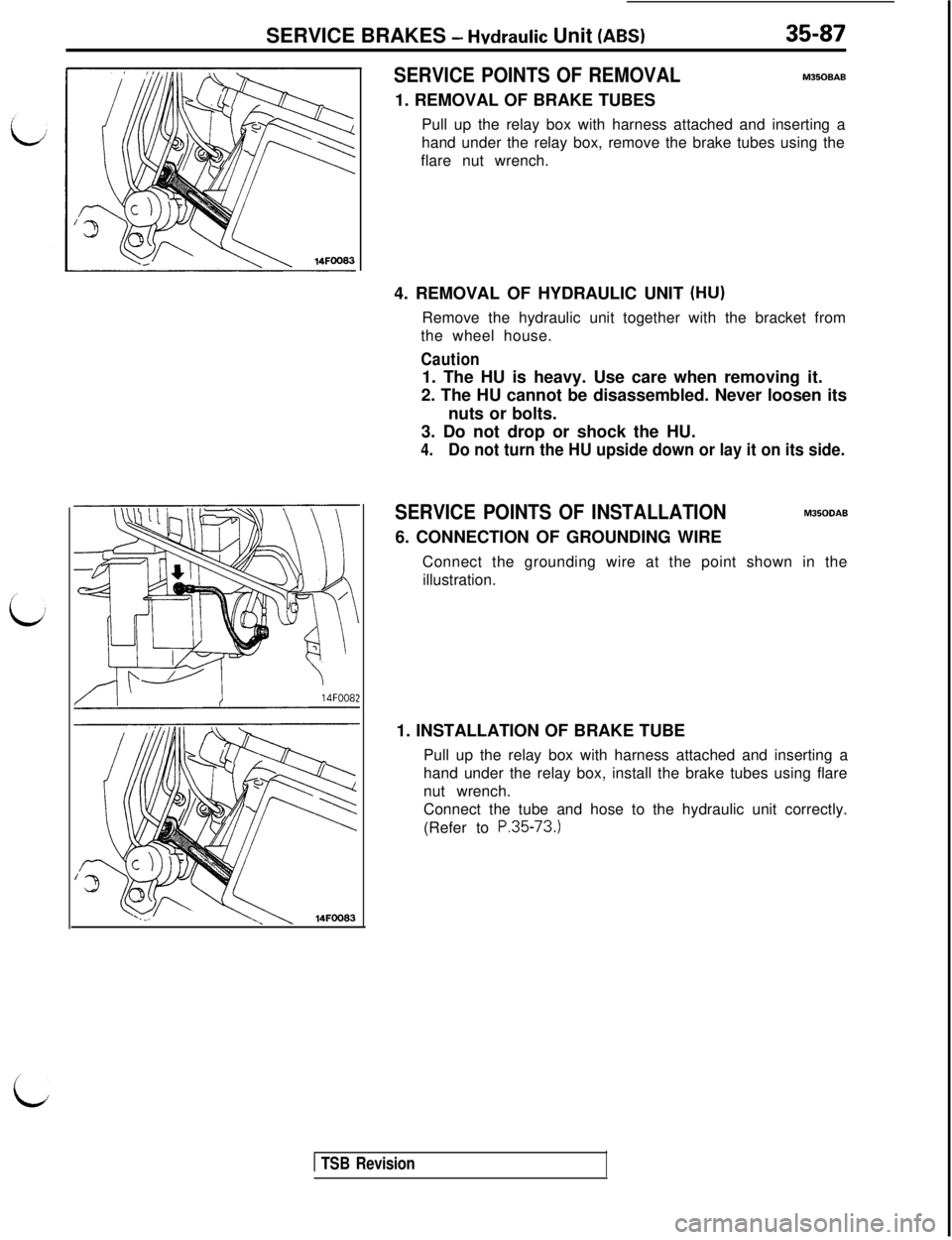

SERVICE POINTS OF REMOVALM350BAB1. REMOVAL OF BRAKE TUBES

Pull up the relay box with harness attached and inserting a

hand under the relay box, remove the brake tubes using the

flare nut wrench.

4. REMOVAL OF HYDRAULIC UNIT

(HU)Remove the hydraulic unit together with the bracket from

the wheel house.

Caution1. The HU is heavy. Use care when removing it.

2. The HU cannot be disassembled. Never loosen its

nuts or bolts.

3. Do not drop or shock the HU.

4.Do not turn the HU upside down or lay it on its side.

SERVICE POINTS OF INSTALLATIONM350DAB6. CONNECTION OF GROUNDING WIRE

Connect the grounding wire at the point shown in the

illustration.

1. INSTALLATION OF BRAKE TUBE

Pull up the relay box with harness attached and inserting a

hand under the relay box, install the brake tubes using flare

nut wrench.

Connect the tube and hose to the hydraulic unit correctly.

(Refer to

P.35-73.)

c

1 TSB Revision

Page 810 of 1146

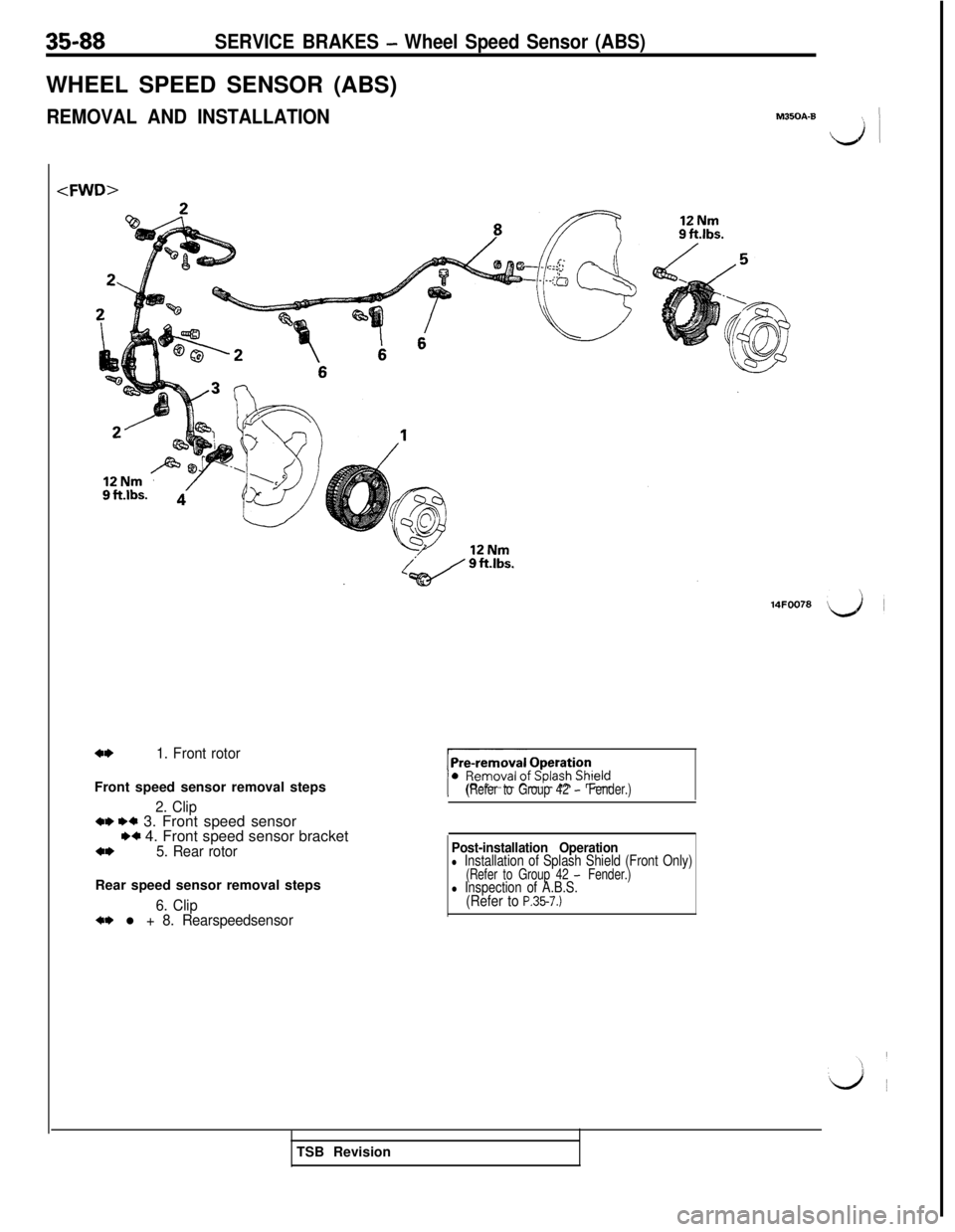

3588SERVICE BRAKES - Wheel Speed Sensor (ABS)WHEEL SPEED SENSOR (ABS)

REMOVAL AND INSTALLATION

a*1. Front rotorFront speed sensor removal steps

2. Clip*I) ++ 3. Front speed sensorw 4. Front speed sensor bracket*I)5. Rear rotorRear speed sensor removal steps

6. Clipa* l + 8. Rearspeedsensor

M350A-B L/ 1

(Refer to Group 42 - Fender.)

14FOO78LJ

Post-installation Operationl Installation of Splash Shield (Front Only)(Refer to Group 42 - Fender.)l Inspection of A.B.S.(Refer to P.35-7.)TSB Revision

Page 811 of 1146

L

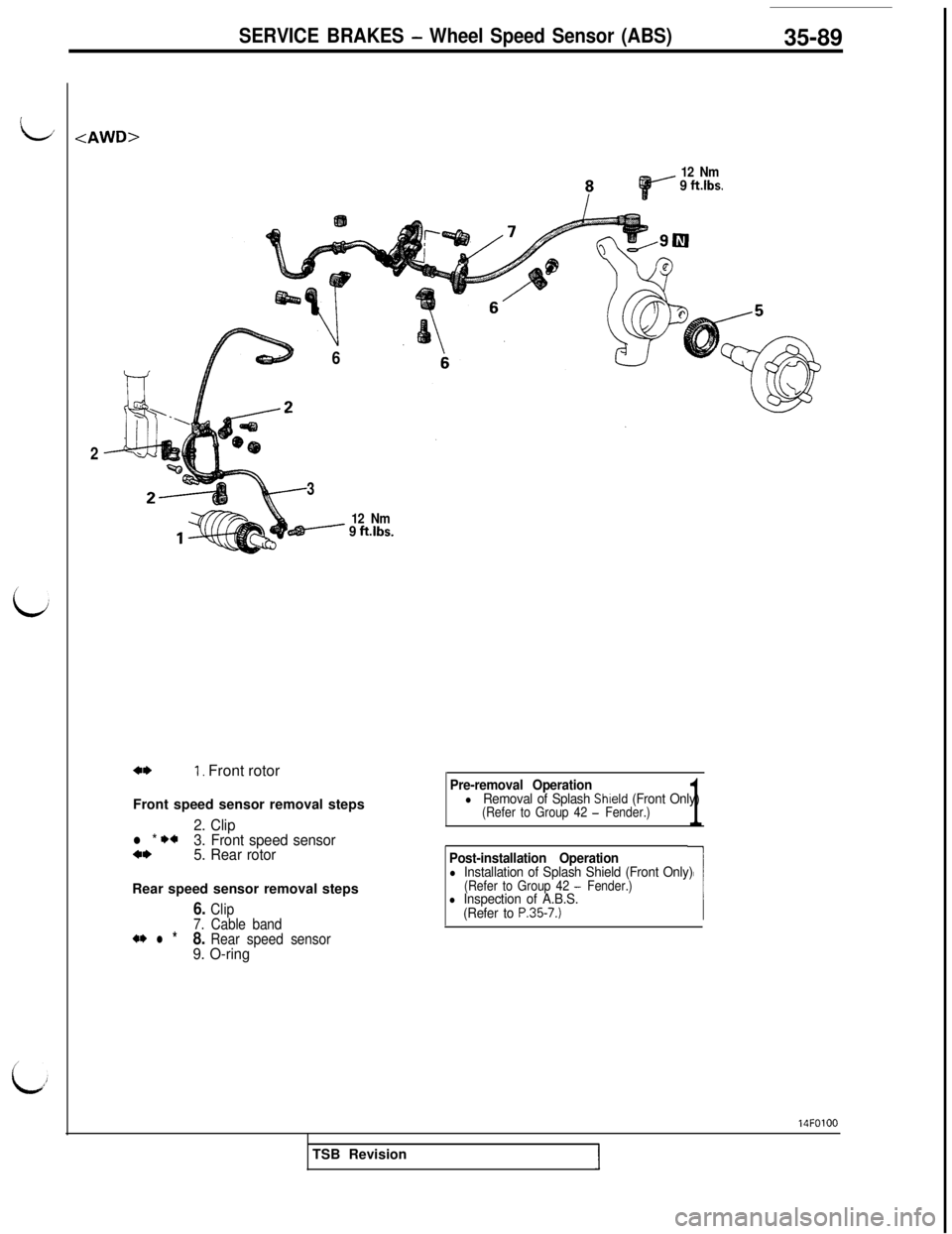

SERVICE BRAKES - Wheel Speed Sensor (ABS)35-89

12 Nm9 ft.lbs.

6

2

3

12 Nm- 9 ft.lbs.

a*I, Front rotor

Front speed sensor removal steps

2. Clipl * I)*3. Front speed sensora*5. Rear rotorRear speed sensor removal steps

6. Clip

7. Cable band

+I) l *8. Rear speed sensor9. O-ringPre-removal Operation

lRemoval of Splash Shield (Front Only)(Refer to Group 42 - Fender.)1

Post-installation Operationl Installation of Splash Shield (Front Only)(Refer to Group 42 - Fender.)l Inspection of A.B.S.

(Refer to P.35-7.)14FOlOO

TSB Revision

Page 812 of 1146

SERVICE BRAKES - Wheel Speed Sensor (ABS)

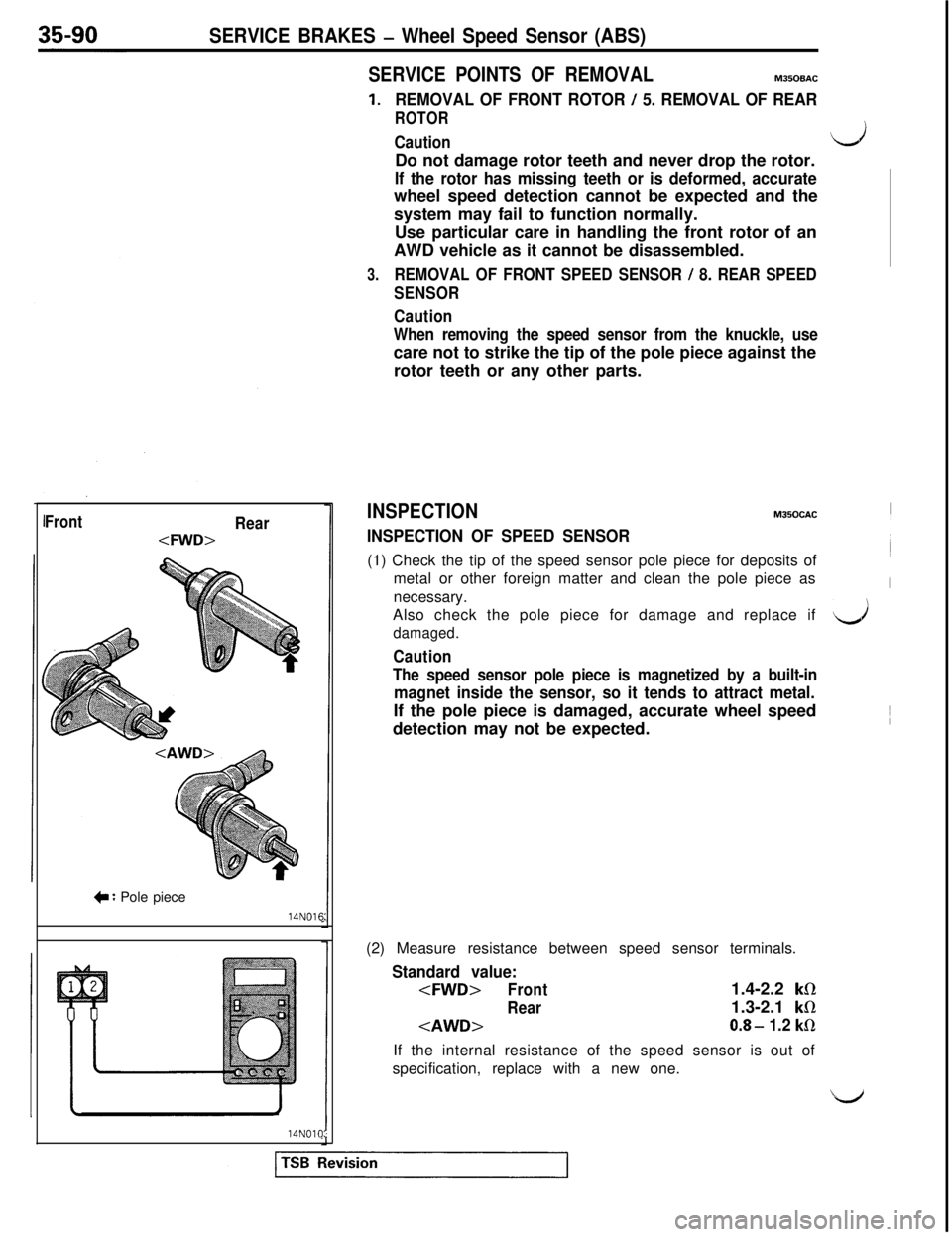

IFrontRear

+ : Pole piece14N016:14NOlO:

SERVICE POINTS OF REMOVALM35OBAC

1.REMOVAL OF FRONT ROTOR / 5. REMOVAL OF REAR

ROTOR

CautiondDo not damage rotor teeth and never drop the rotor.

If the rotor has missing teeth or is deformed, accuratewheel speed detection cannot be expected and the

system may fail to function normally.

Use particular care in handling the front rotor of an

AWD vehicle as it cannot be disassembled.

3.REMOVAL OF FRONT SPEED SENSOR / 8. REAR SPEED

SENSOR

Caution

When removing the speed sensor from the knuckle, usecare not to strike the tip of the pole piece against the

rotor teeth or any other parts.

INSPECTIONMJSOCAC

INSPECTION OF SPEED SENSOR(1) Check the tip of the speed sensor pole piece for deposits of

metal or other foreign matter and clean the pole piece as

necessary.

Also check the pole piece for damage and replace if

damaged.d

Caution

The speed sensor pole piece is magnetized by a built-in

magnet inside the sensor, so it tends to attract metal.If the pole piece is damaged, accurate wheel speed

detection may not be expected.

(2) Measure resistance between speed sensor terminals.

Standard value:

Rear

kR1.3-2.1

kR

0.8- 1.2 kfl

If the internal resistance of the speed sensor is out of

specification, replace with a new one.

Page 813 of 1146

SERVICE BRAKES - Wheel SDeed Sensor lABSI35-91

/

i

lARnlA6

14N012‘

3

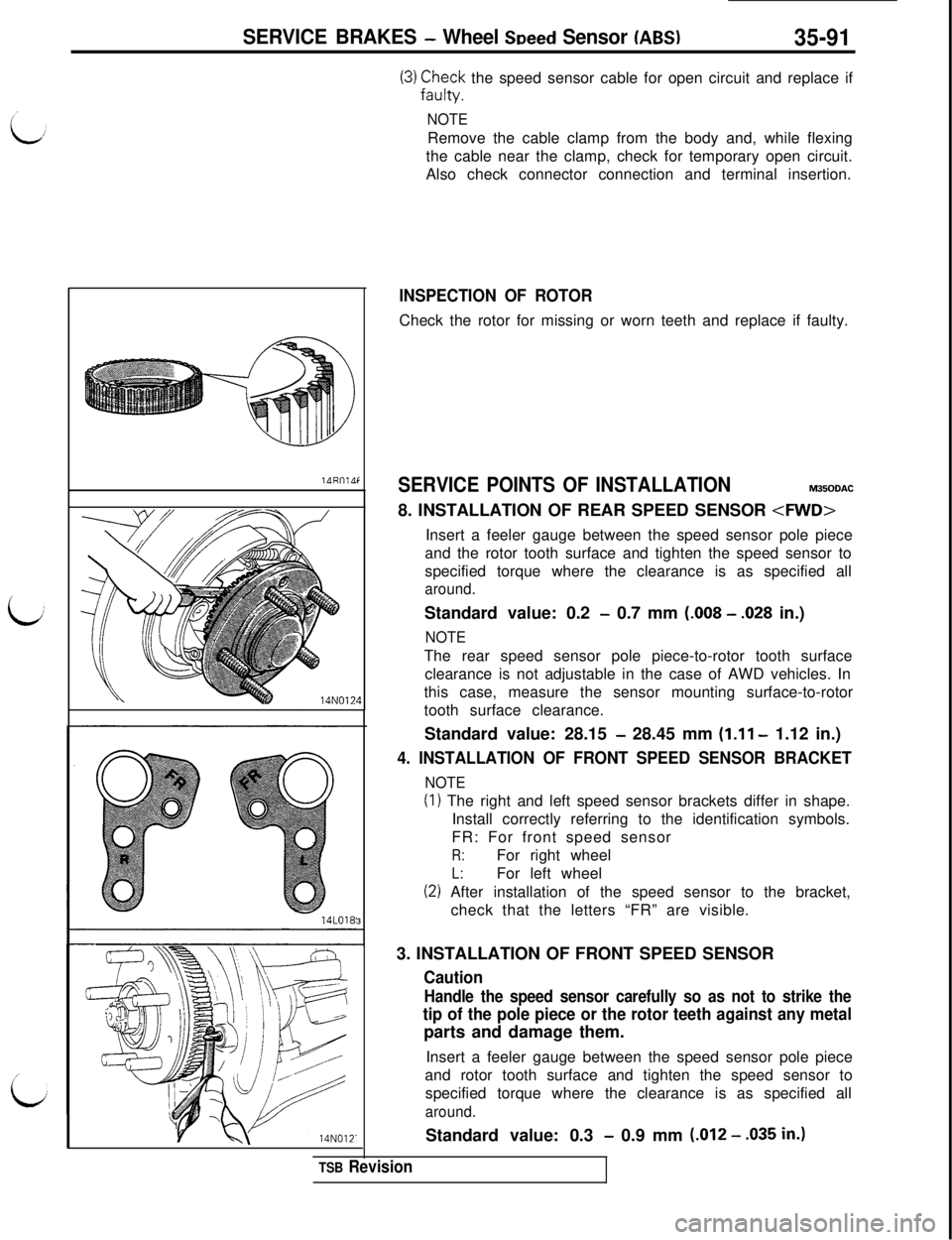

(3) zue$ the speed sensor cable for open circuit and replace if

NOTERemove the cable clamp from the body and, while flexing

the cable near the clamp, check for temporary open circuit.

Also check connector connection and terminal insertion.

INSPECTION OF ROTORCheck the rotor for missing or worn teeth and replace if faulty.

SERVICE POINTS OF INSTALLATIONM350DAC8. INSTALLATION OF REAR SPEED SENSOR

and the rotor tooth surface and tighten the speed sensor to

specified torque where the clearance is as specified all

around.Standard value: 0.2

- 0.7 mm (.008 - .028 in.)

NOTEThe rear speed sensor pole piece-to-rotor tooth surface

clearance is not adjustable in the case of AWD vehicles. In

this case, measure the sensor mounting surface-to-rotor

tooth surface clearance.

Standard value: 28.15

- 28.45 mm (1.11 - 1.12 in.)

4. INSTALLATION OF FRONT SPEED SENSOR BRACKET

NOTE

(I) The right and left speed sensor brackets differ in shape.

Install correctly referring to the identification symbols.

FR: For front speed sensor

R:For right wheel

L:For left wheel

(2) After installation of the speed sensor to the bracket,

check that the letters “FR” are visible.

3. INSTALLATION OF FRONT SPEED SENSOR

Caution

Handle the speed sensor carefully so as not to strike the

tip of the pole piece or the rotor teeth against any metalparts and damage them.

Insert a feeler gauge between the speed sensor pole piece

and rotor tooth surface and tighten the speed sensor to

specified torque where the clearance is as specified all

around.Standard value: 0.3

- 0.9 mm (.012 - .035 in.)

TSB Revision

Page 814 of 1146

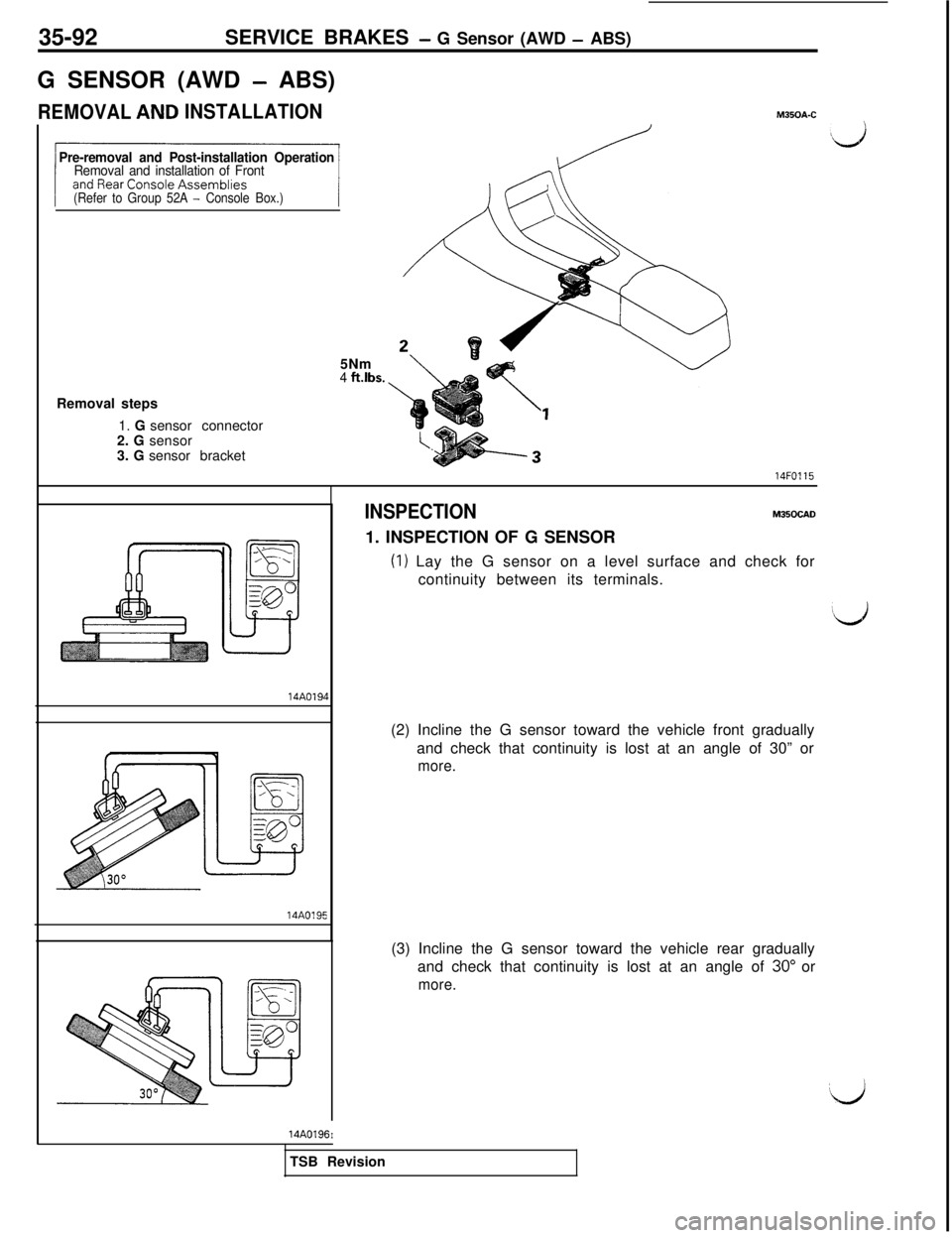

35-92SERVICE BRAKES - G Sensor (AWD - ABS)

G SENSOR (AWD

- ABS)

REMOVALINSTALLATION

Pre-removal and Post-installation OperationRemoval and installation of Front

(Refer to Group 52A - Console Box.)

M35OA-C5Nm

4 ft.lbs.Removal steps

1. G sensor connector

2. G sensor

3. G sensor bracket14FO115

114A019)14A0195

14A0196I

INSPECTIONM350CAD1. INSPECTION OF G SENSOR

(I) Lay the G sensor on a level surface and check for

continuity between its terminals.

(2) Incline the G sensor toward the vehicle front gradually

and check that continuity is lost at an angle of 30” or

more.(3) Incline the G sensor toward the vehicle rear gradually

and check that continuity is lost at an angle of 30” or

more.TSB Revision

Page 815 of 1146

SERVICE BRAKES - Electronic Control Unit (ABS)

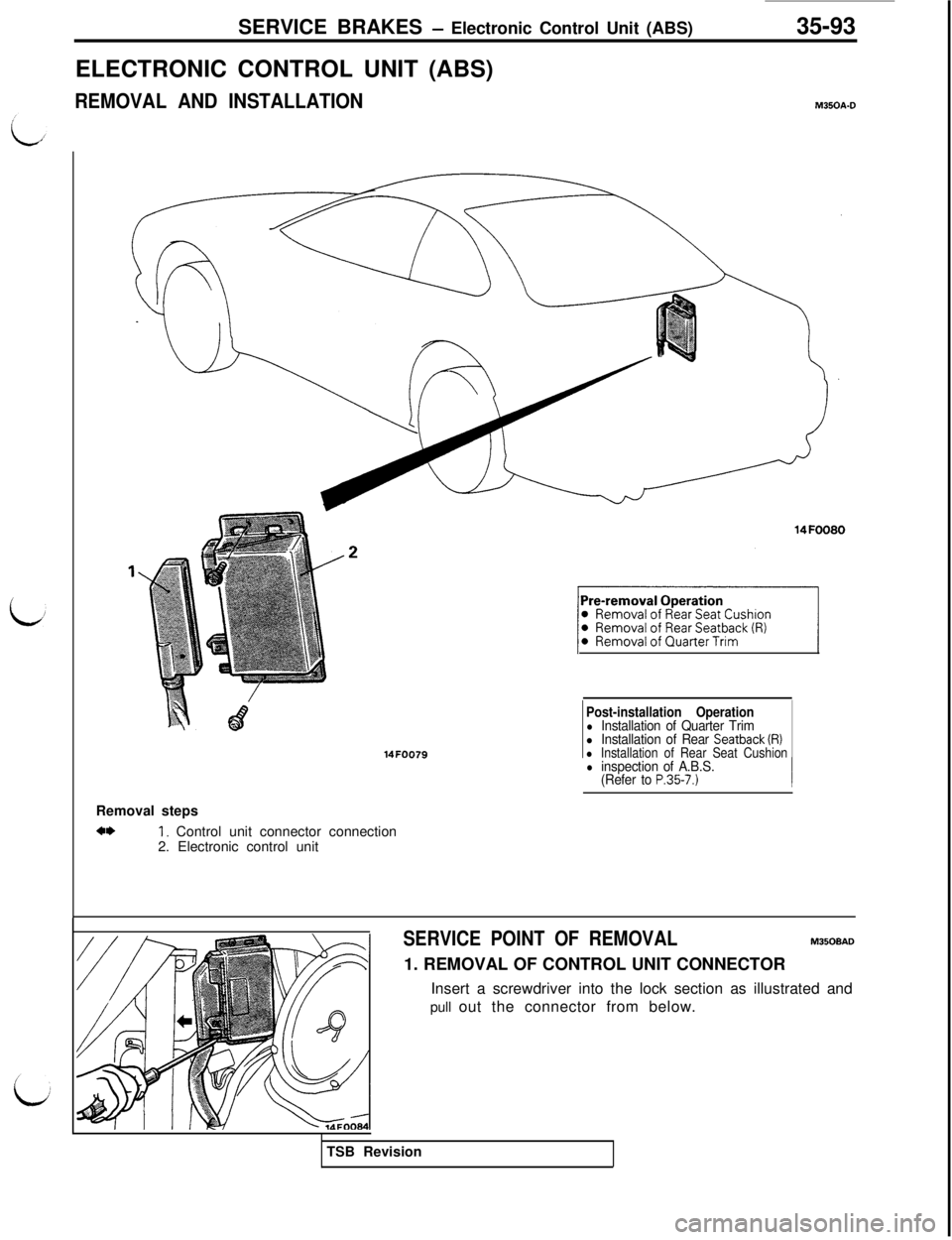

ELECTRONIC CONTROL UNIT (ABS)

REMOVAL AND INSTALLATION35-93M350A.D

14FOO79

Post-installation Operationl Installation of Quarter Triml Installation of Rear Seatback (R)l Installation of Rear Seat CushionRemoval steps

4*1, Control unit connector connection

2. Electronic control unit

l inspection of A.B.S.

(Refer to P.35-7.)

SERVICE POINT OF REMOVALM350BAD1. REMOVAL OF CONTROL UNIT CONNECTOR

Insert a screwdriver into the lock section as illustrated and

pull out the connector from below.

TSB Revision

Page 838 of 1146

37A-10STEERING - Service Adjustment Procedures

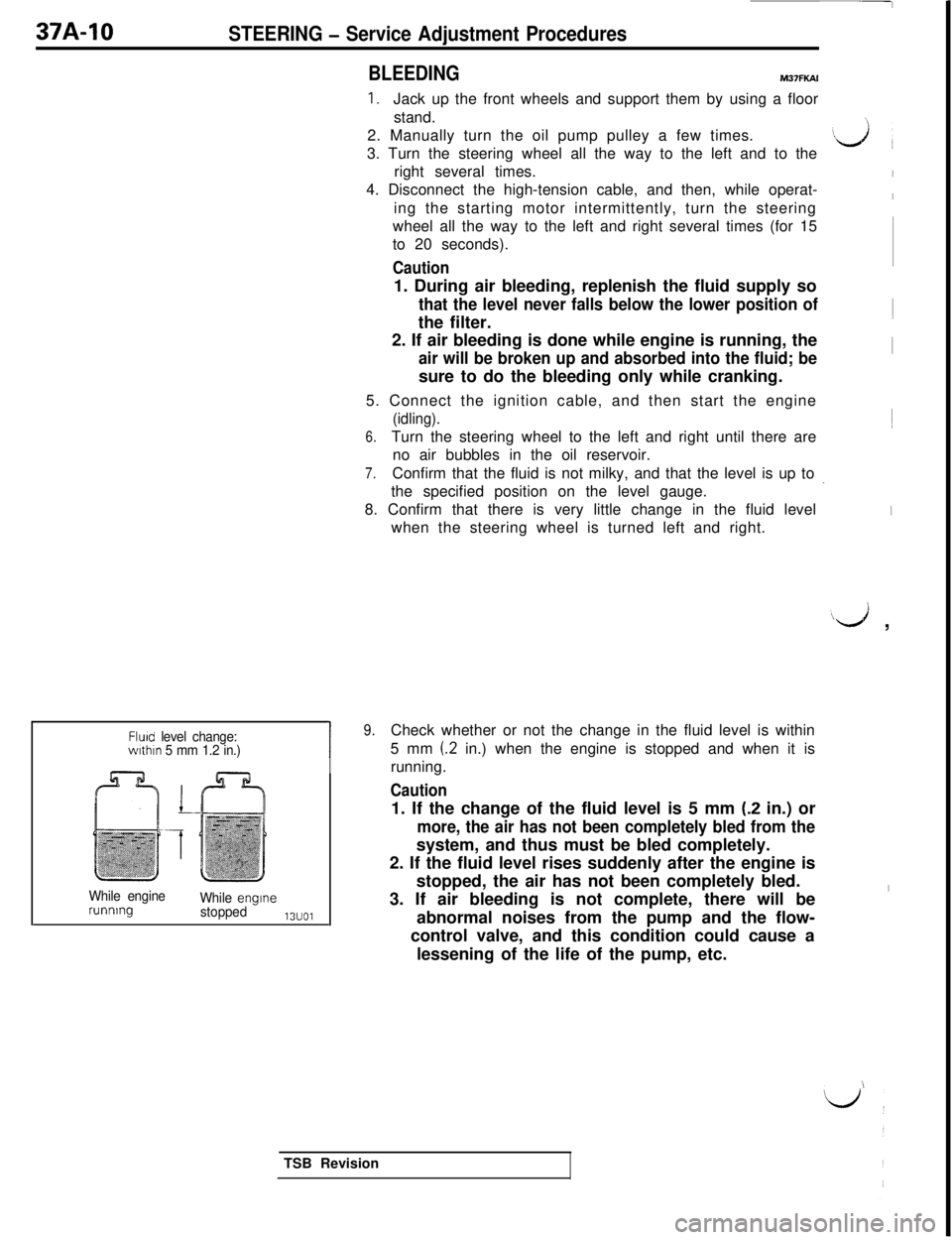

BLEEDINGM37FKAl

1.Jack up the front wheels and support them by using a floor

stand.

2. Manually turn the oil pump pulley a few times.

3. Turn the steering wheel all the way to the left and to the

right several times.

4. Disconnect the high-tension cable, and then, while operat-

ing the starting motor intermittently, turn the steering

wheel all the way to the left and right several times (for 15

to 20 seconds).

Caution1. During air bleeding, replenish the fluid supply so

that the level never falls below the lower position ofthe filter.

2. If air bleeding is done while engine is running, the

air will be broken up and absorbed into the fluid; besure to do the bleeding only while cranking.

5. Connect the ignition cable, and then start the engine

(idling).

6.Turn the steering wheel to the left and right until there are

no air bubbles in the oil reservoir.

7.Confirm that the fluid is not milky, and that the level is up to

the specified position on the level gauge.

8. Confirm that there is very little change in the fluid level

when the steering wheel is turned left and right.

Fluid level change:wlthln 5 mm 1.2 in.)I

9.Check whether or not the change in the fluid level is within

5 mm

(.2 in.) when the engine is stopped and when it is

Irunning.

Caution

While enginerunningWhile enginestopped13UOl1. If the change of the fluid level is 5 mm

I.2 in.) or

more, the air has not been completely bled from thesystem, and thus must be bled completely.

2. If the fluid level rises suddenly after the engine is

stopped, the air has not been completely bled.

3. If air bleeding is not complete, there will be

abnormal noises from the pump and the flow-

control valve, and this condition could cause a

lessening of the life of the pump, etc.

LJ

I

I~

I~

I

LJ ,

I

\TSB Revision