Ignition MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 1228 of 1500

HOW TO USE TROUBLESHOOTING/INSPECTION SERVICE POINTS

GENERAL00-7

HOW TO USE TROUBLESHOOTING/INSPECTION SERVICE

POINTS

TROUBLESHOOTING CONTENTSM1001013300062

During diagnosis, a DTC code associated with

other system may be set when the ignition

switch is turned on with connector(s) discon-

nected. On completion, confirm all systems

for DTC code(s). If DTC code(s) are set, erase

them all.

When the DIAGNOSTIC TOOL (MUT-III)

detects a diagnostic trouble code, its display

informs users whether a mechanical problem

currently exists (“current trouble”) or whether

it existed before but normal operation has

been restored (“past trouble”). However, if an

MPI, TPMS or SRS airbag-related DTC is set,

“Active DTC/Stored DTC” is not displayed. In

this case, follow the diagnosis procedure for

current trouble.

If a trouble, detected in a CAN communica-

tion-capable system, can be reproduced,

diagnose the CAN bus lines (Refer to GROUP

54C, Can Bus Line Diagnostics Chart

P.54C-15 or P.54C-15).

Troubleshooting of electronic control systems for

which the MUT -III can be used follows the basic out-

line described below. Even in systems for which the

MUT-III cannot be used, part of these systems still

follow this outline.

1. STANDARD FLOW OF DIAGNOSTIC

TROUBLESHOOTING

Troubleshooting strategy is shown in each group.

2. SYSTEM OPERATION AND SYMPTOM

VERIFICATION TESTS

If verification of the symptom(s) is difficult, proce-

dures for checking operation and verifying symptoms

are shown.

3. DIAGNOSTIC FUNCTION

The following trouble code diagnoses are shown.

How to read diagnostic trouble codes

How to erase diagnostic trouble codes

Input inspection service points

4. DIAGNOSTIC TROUBLE CODE CHART

If the MUT-III displays a diagnostic trouble code, find

the applicable inspection procedure according to this

chart.

5. SYMPTOM CHART

If there are symptoms, even though the MUT-III

shows that no DTCs are set, inspection procedures

for each symptom will be found by using this chart.

6. DIAGNOSTIC TROUBLE CODE

PROCEDURES

Indicates the inspection procedures corresponding to

each diagnostic trouble code. (Refer to P.00-9).

7. SYMPTOM PROCEDURES

Indicates the inspection procedures corresponding to

each symptom listed in the Symptom Chart (Refer to

P.00-9).

8. SERVICE DATA REFERENCE TABLE

Inspection items and normal judgment values have

been provided in this chart as reference information.

9. CHECK AT ECU TERMINALS

Terminal numbers for the ECU connectors, inspec-

tion items, and standard values have been provided

in this chart as reference information.

.

TERMINAL VOLTAGE CHECKS

1. Use correct tool to check each pin location on the

ENGINE-ECU Check harnes MB992044 and

measure with voltmeter.

Short-circuiting the positive (+) test probe

between a connector terminal and ground could

damage the vehicle wiring, the sensor, the ECU,

or all three. Use care to prevent this!

2. Insert the correct terminal tool into each of the

ENGINE-ECU check harness connector

terminals, and measure the voltage while referring

to the check chart.

NOTE: Measure voltage with the ECU connectors

connected.

You may find it convenient to pull out the ECU to

make it easier to connect the ENGINE-ECU check

harness.

Page 1229 of 1500

HOW TO USE TROUBLESHOOTING/INSPECTION SERVICE POINTS

GENERAL00-8

Checks don't have to be carried out in the order

given in the chart.

3. If voltage readings differ from normal condition

values, check related sensors, actuators, and

wiring. Replace or repair as needed.

4. After repair or replacement, recheck with the

voltmeter to confirm that the repair has corrected

the problem.

.

TERMINAL RESISTANCE AND

CONTINUITY CHECKS

1. Turn the ignition switch to the “LOCK” (OFF)

position.

2. Disconnect the ECU connector.

If resistance and continuity checks are per-

formed on the wrong terminals, damage to the

vehicle wiring, sensors, ECU, and/or ohmmeter

may occur. Use care to prevent this!

3. Measure the resistance and check for continuity

between the terminals of the ENGIN-ECU check

harness MB992044 connector while referring to

the check chart.

NOTE: Checks don't have to be carried out in the

order given in the chart.

4. If the ohmmeter shows any deviation from the

Normal Condition value, check the corresponding

sensor, actuator and related electrical wiring, then

repair or replace.

5. After repair or replacement, recheck with the

ohmmeter to confirm that the repair has corrected

the problem.

10. INSPECTION PROCEDURES USING

AN OSCILLOSCOPE

When there are inspection procedures using an

oscilloscope, these are listed.

Page 1232 of 1500

HOW TO USE TROUBLESHOOTING/INSPECTION SERVICE POINTS

GENERAL00-11

MEASURES TO TAKE AFTER

REPLACING THE ECU

If the trouble symptoms have not disappeared even

after replacing the ECU, repeat the inspection proce-

dure from the beginning.

CONNECTOR MEASUREMENT SERVICE POINTSM1001013600063

Turn the ignition switch to the "LOCK" (OFF) position when

connecting and disconnecting the connectors. Turn the ignition

switch to "ON" when measuring, unless there are instructions

to the contrary.

IF INSPECTING WITH THE CONNECTOR

CONNECTED

Be sure to use special tool. Never insert a test probe from the

harness side, as this will reduce the waterproof performance

and result in corrosion.

IF INSPECTING WITH THE CONNECTOR

CONNECTED

Check by inserting the multi-meter test probe from the harness

side. Note that if the connector (control unit, etc.) is too small to

permit insertion of the test probe, it should not be forced; use

the test probe tool for this purpose.

Page 1244 of 1500

PRECAUTIONS BEFORE SERVICE

GENERAL00-23

HOW TO PERFORM VEHICLE IDENTIFICATION

NUMBER (VIN) WRITING

M1001011400063

The Vehicle Identification Number (VIN) is stored in the ECU by

the vehicle manufacture. If the VIN to be stored in the ECU is

eliminated fraudulently, the Malfunction Indicator Lamp (Check

Engine Lamp) illuminates and Diagnostic Trouble Code (DTC)

No.P0630 (VIN malfunction) is shown. When the ECU is

replaced, and entry of the VIN necessary due to DTC No.

P0630 (VIN malfunction). Enter the VIN in accordance with the

procedure as follows:

.

WRITING PROCEDURE

Required Special Tools:

Diagnostic Tool (MUT-III)

MB991824: V.C.I.

MB991827: MUT-III USB Cable

MB991910: MUT-III Main Harness A (BLUE)

To prevent damage to DIAGNOSTIC TOOL (MUT-III), always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting.

1. Connect Diagnostic Tool to the data link connector.

2. Turn the ignition switch to the "ON" position.

3. Confirm DTC No.P0630 (EEPROM malfunction) is not

shown.

NOTE: When DTC No. P0630 (EEPROM malfunction) is

shown, the VIN cannot be stored even if entered. Therefore,

the troubleshooting is performed when this DTC is shown.

4. Select "Coding" form the menu screen.

5. Select "VIN writing" form the menu screen.

6. Enter the VIN.

7. After entry of the VIN, turn the ignition switch to the "LOCK"

(OFF) position. After ten seconds or more passed, turn to

the "ON" position again.

8. Confirm DTC No.P0630 (VIN malfunction) is not shown.

NOTE: When DTC No.P0630 (VIN malfunction) is shown,

enter the VIN again because that would be not appropriate.

Page 1245 of 1500

PRECAUTIONS BEFORE SERVICE

GENERAL00-24

SERVICING ELECTRICAL SYSTEMM1001011900057

Battery posts, terminals and related accessories con-

tain lead and lead compounds. WASH HANDS AFTER

HANDLING.

1. Note the following before proceeding with working on the

electrical system.

Never perform unauthorized modifications to any electrical

device or wiring. Such modifications might lead to a vehicle

malfunction, over-capacity or short-circuit that could result in

a fire in the vehicle.

Before connecting or disconnecting the negative bat-

tery cable, be sure to turn the ignition switch to the

"LOCK" (OFF) position and turn off the lights (If this is

not done, there is the possibility of semiconductor

parts being damaged).

After completion of the work (and the negative battery

terminals is connected), warm up the engine and allow

it to idle for approximately 10 minutes under the condi-

tions described below in order to stabilize engine con-

trol conditions, and then check to be sure that the idle

is satisfactory.

Engine coolant temperature: 85 to 95C (185 to

203

F)

Lights and all accessories: OFF

Transaxle: "N" or "P" position

Steering wheel: straight-forward position

2. When servicing the electrical system, disconnect the

negative cable terminal from the battery.

VEHICLE WASHINGM1001012000057

If high-pressure car-washing equipment or steam car-washing

equipment is used to wash the vehicle, be sure to maintain the

spray nozzle at a distance of at least approximately 50 cm (20

inches) from any plastic parts and all opening parts (doors, lug-

gage compartment, etc.).

Page 1246 of 1500

PRECAUTIONS BEFORE SERVICE

GENERAL00-25

APPLICATION OF ANTI-CORROSION AGENTS

AND UNDERCOATS

M1001011000043

Do not to apply oil or grease to the heated oxygen sensor. If

applied, the sensor may malfunction. Protect the heated oxy-

gen sensor with a cover before applying anti-corrosion agent,

etc.

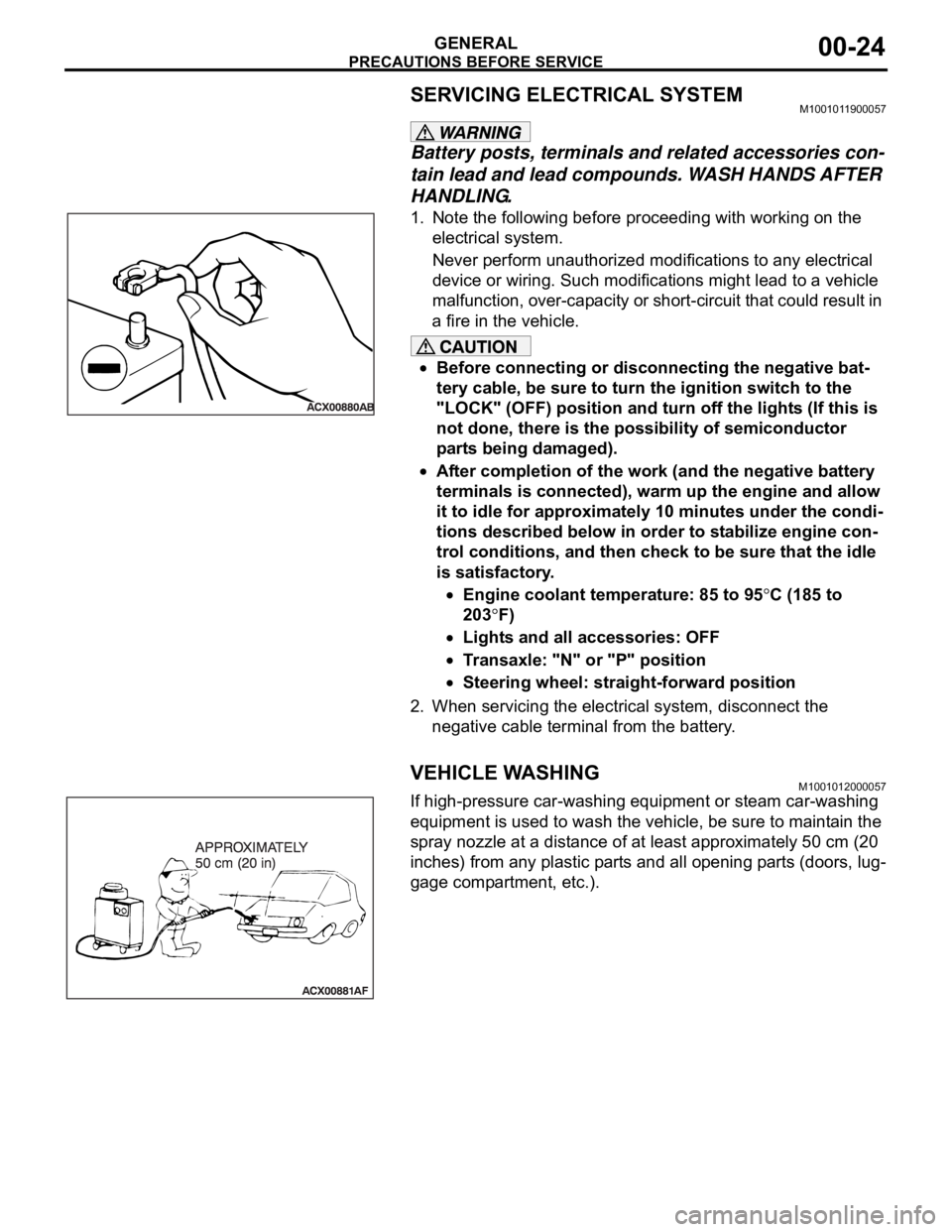

DIAGNOSTIC TOOL (MUT-III)M1001012200062

Turn the ignition switch to the "LOCK" (OFF) position

before disconnecting or connecting the diagnostic tool

(MUT-III).

NOTE: MUT-III trigger harness is not necessary when pushing

V.C.I. ENTER key.

Page 1247 of 1500

TOWING AND HOISTING

GENERAL00-26

TOWING AND HOISTINGM1001000800380

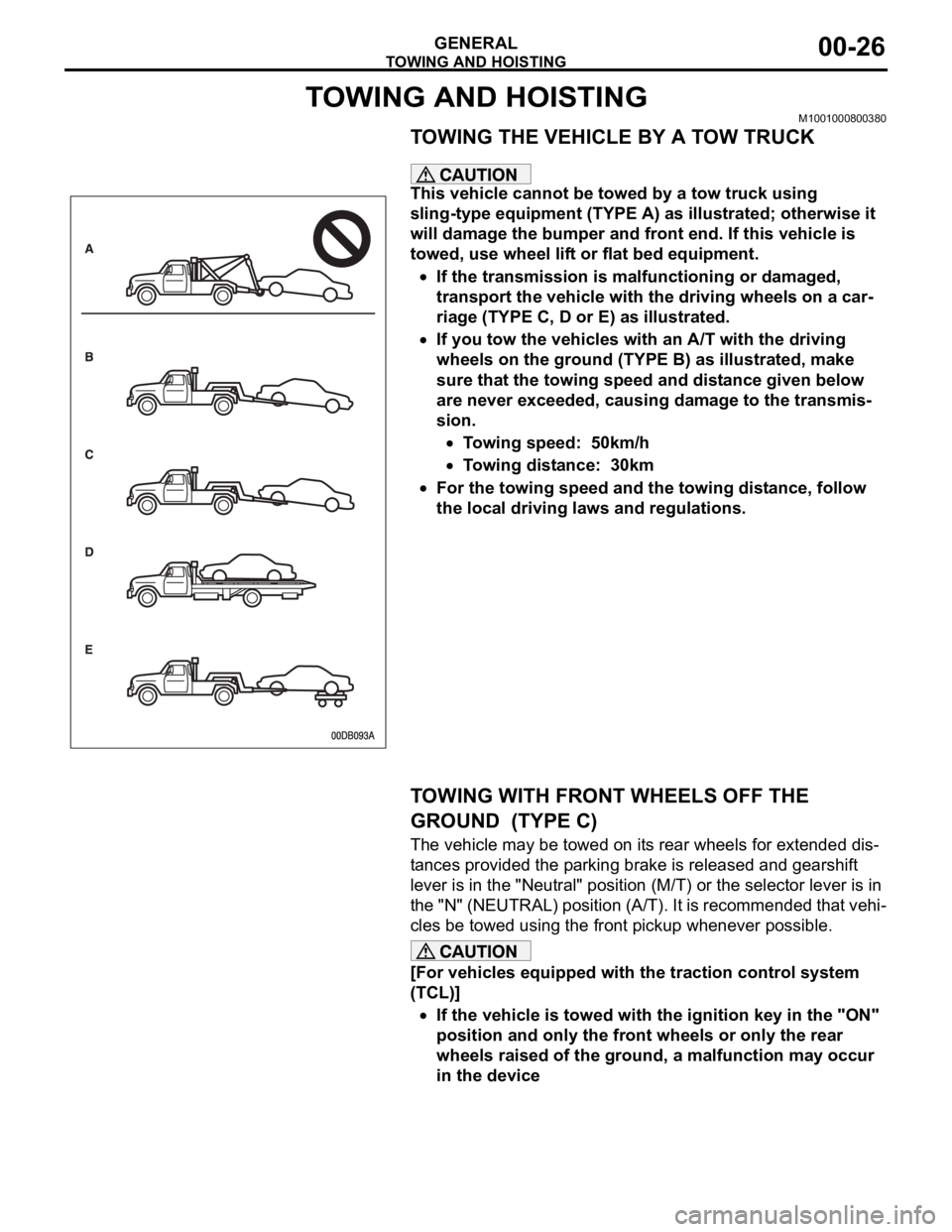

TOWING THE VEHICLE BY A TOW TRUCK

.

This vehicle cannot be towed by a tow truck using

sling-type equipment (TYPE A) as illustrated; otherwise it

will damage the bumper and front end. If this vehicle is

towed, use wheel lift or flat bed equipment.

If the transmission is malfunctioning or damaged,

transport the vehicle with the driving wheels on a car-

riage (TYPE C, D or E) as illustrated.

If you tow the vehicles with an A/T with the driving

wheels on the ground (TYPE B) as illustrated, make

sure that the towing speed and distance given below

are never exceeded, causing damage to the transmis-

sion.

Towing speed: 50km/h

Towing distance: 30km

For the towing speed and the towing distance, follow

the local driving laws and regulations.

.

TOWING WITH FRONT WHEELS OFF THE

GROUND (TYPE C)

The vehicle may be towed on its rear wheels for extended dis-

tances provided the parking brake is released and gearshift

lever is in the "Neutral" position (M/T) or the selector lever is in

the "N" (NEUTRAL) position (A/T). It is recommended that vehi-

cles be towed using the front pickup whenever possible.

[For vehicles equipped with the traction control system

(TCL)]

If the vehicle is towed with the ignition key in the "ON"

position and only the front wheels or only the rear

wheels raised of the ground, a malfunction may occur

in the device

.

Page 1248 of 1500

TOWING AND HOISTING

GENERAL00-27

TOWING WITH REAR WHEELS OFF THE

GROUND (TYPE B)

Place the gearshift lever in the "Neutral" position (M/T) or the

selector lever in the "N" (NEUTRAL) position (A/T). Turn the

ignition key to the "ACC" position and secure the steering

wheel in a straight-ahead position with a rope or tie-down strap.

Never place the ignition key in the "LOCK" position when tow-

ing.

Never tow an A/T vehicle with the rear wheels up (and

the front wheels on the ground) when the automatic

transmission fluid level is low. this may cause serious

and expensive damage to the transmission.

Do not use the steering column lock to secure the front

wheels for towing.

Make sure the transaxle is in Neutral if vehicle will have

drive wheels on the ground.

If these requirements cannot be met, the front wheels

must be placed on a tow dolly.

.

TOWING WHEN KEYS ARE NOT AVAILABLE

When a locked vehicle must be towed and keys are not avail-

able, the vehicle may be lifted and towed from the front, pro-

vided the parking brake is released. If not released, the rear

wheels should be placed on a tow dolly.

.

SAFETY PRECAUTIONS

The following precautions should be taken when towing the

vehicle:

1. DO NOT LIFT OR TOW THE VEHICLE BY ATTACHING

TO OR WRAPPING AROUND THE BUMPER.

2. Any loose, protruding, or damaged parts such as hoods,

doors, fenders, trim, etc. should be secured or removed

prior to moving the vehicle.

Page 1260 of 1500

MAINTENANCE SERVICE

GENERAL00-39

7. DRIVE BELTS (FOR ALTERNATOR, POWER

STEERING PUMP AND AIR CONDITIONING)

(CHECK)

M1001008700031

ALTERNATOR DRIVE BELT TENSION CHECK

<3.8L ENGINE>

.

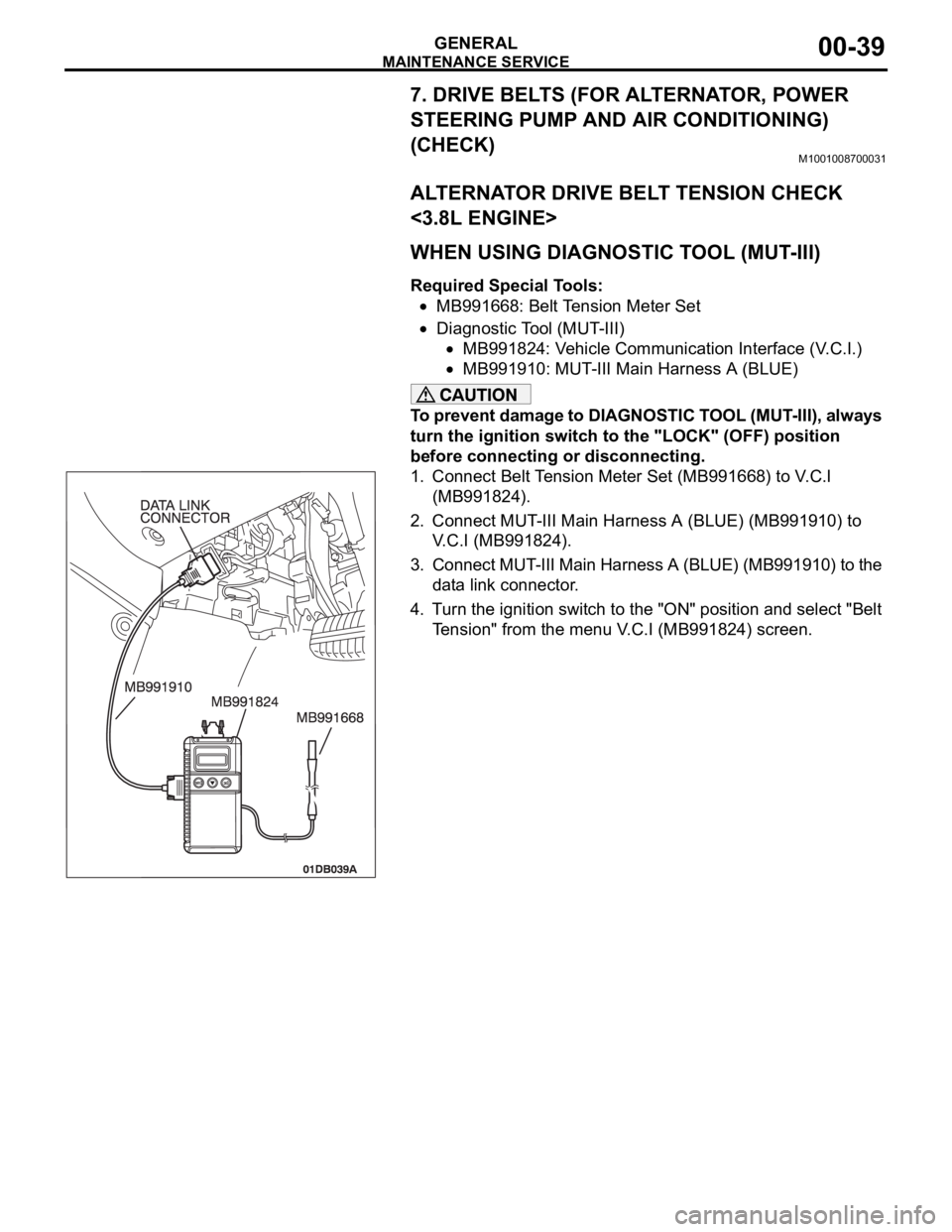

WHEN USING DIAGNOSTIC TOOL (MUT-III)

Required Special Tools:

MB991668: Belt Tension Meter Set

Diagnostic Tool (MUT-III)

MB991824: Vehicle Communication Interface (V.C.I.)

MB991910: MUT-III Main Harness A (BLUE)

To prevent damage to DIAGNOSTIC TOOL (MUT-III), always

turn the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting.

1. Connect Belt Tension Meter Set (MB991668) to V.C.I

(MB991824).

2. Connect MUT-III Main Harness A (BLUE) (MB991910) to

V.C.I (MB991824).

3. Connect MUT-III Main Harness A (BLUE) (MB991910) to the

data link connector.

4. Turn the ignition switch to the "ON" position and select "Belt

Tension" from the menu V.C.I (MB991824) screen.

Page 1272 of 1500

MAINTENANCE SERVICE

GENERAL00-51

18. SUSPENSION SYSTEM (INSPECT FOR

LOOSENESS AND DAMAGE)

M1001009600048

Visually inspect the front/rear suspension components for dete-

rioration and damage. Re-tighten the front/rear suspension

components retaining bolts to specified torque.

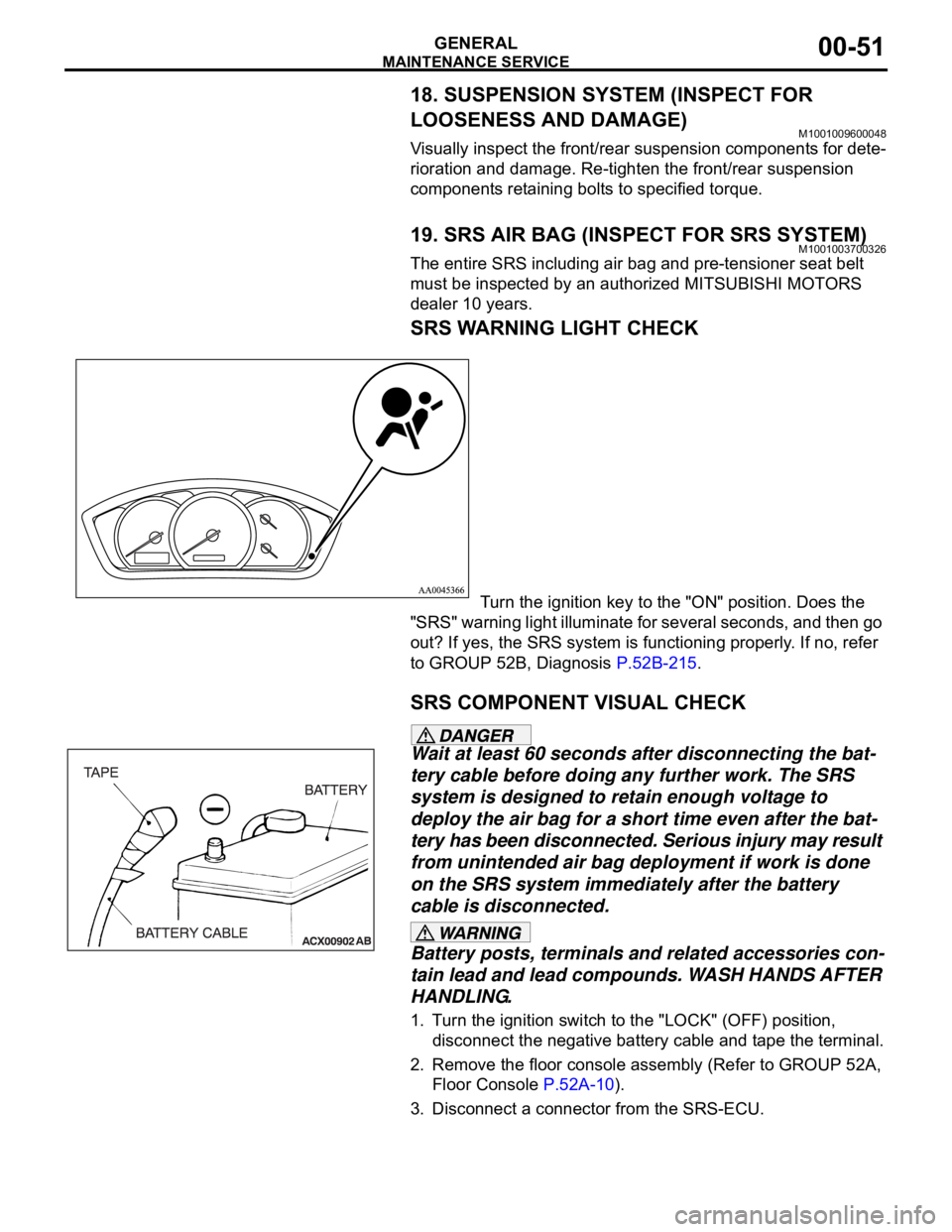

19. SRS AIR BAG (INSPECT FOR SRS SYSTEM)M1001003700326

The entire SRS including air bag and pre-tensioner seat belt

must be inspected by an authorized MITSUBISHI MOTORS

dealer 10 years.

SRS WARNING LIGHT CHECK

Turn the ignition key to the "ON" position. Does the

"SRS" warning light illuminate for several seconds, and then go

out? If yes, the SRS system is functioning properly. If no, refer

to GROUP 52B, Diagnosis P.52B-215.

SRS COMPONENT VISUAL CHECK

Wait at least 60 seconds after disconnecting the bat-

tery cable before doing any further work. The SRS

system is designed to retain enough voltage to

deploy the air bag for a short time even after the bat-

tery has been disconnected. Serious injury may result

from unintended air bag deployment if work is done

on the SRS system immediately after the battery

cable is disconnected.

Battery posts, terminals and related accessories con-

tain lead and lead compounds. WASH HANDS AFTER

HANDLING.

1. Turn the ignition switch to the "LOCK" (OFF) position,

disconnect the negative battery cable and tape the terminal.

2. Remove the floor console assembly (Refer to GROUP 52A,

Floor Console P.52A-10).

3. Disconnect a connector from the SRS-ECU.