Ignition MITSUBISHI 380 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 1099 of 1500

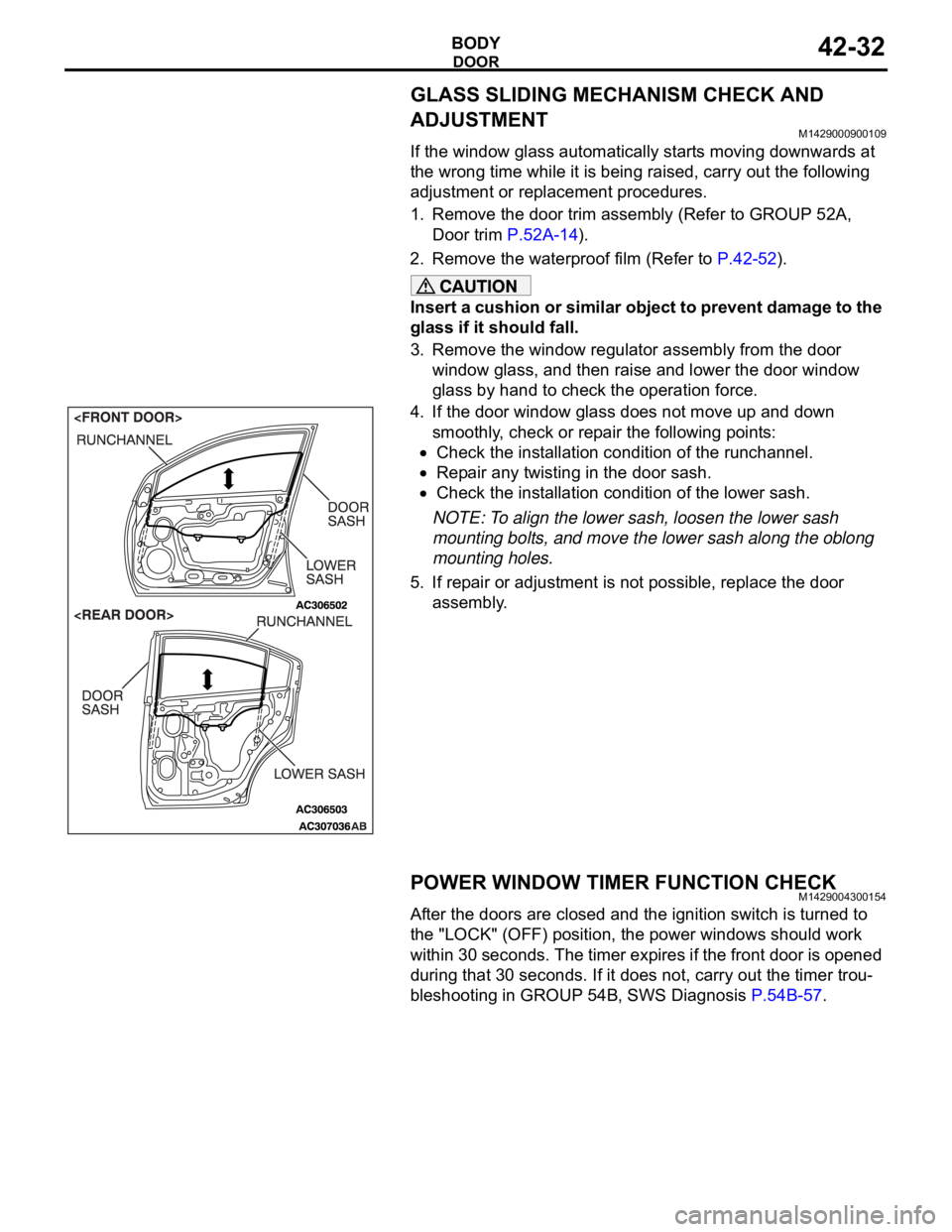

DOOR

BODY42-32

GLASS SLIDING MECHANISM CHECK AND

ADJUSTMENT

M1429000900109

If the window glass automatically starts moving downwards at

the wrong time while it is being raised, carry out the following

adjustment or replacement procedures.

1. Remove the door trim assembly (Refer to GROUP 52A,

Door trim P.52A-14).

2. Remove the waterproof film (Refer to P.42-52).

Insert a cushion or similar object to prevent damage to the

glass if it should fall.

3. Remove the window regulator assembly from the door

window glass, and then raise and lower the door window

glass by hand to check the operation force.

4. If the door window glass does not move up and down

smoothly, check or repair the following points:

Check the installation condition of the runchannel.

Repair any twisting in the door sash.

Check the installation condition of the lower sash.

NOTE: To align the lower sash, loosen the lower sash

mounting bolts, and move the lower sash along the oblong

mounting holes.

5. If repair or adjustment is not possible, replace the door

assembly.

POWER WINDOW TIMER FUNCTION CHECKM1429004300154

After the doors are closed and the ignition switch is turned to

the "LOCK" (OFF) position, the power windows should work

within 30 seconds. The timer expires if the front door is opened

during that 30 seconds. If it does not, carry out the timer trou-

bleshooting in GROUP 54B, SWS Diagnosis P.54B-57.

Page 1135 of 1500

KEYLESS ENTRY SYSTEM

BODY42-68

If none of the doors is opened or the ignition key

is not inserted in the ignition switch within 30 sec-

onds after the doors are unlocked using the

transmitter, the ETACS-ECU will relock the doors

automatically. This is called "Timer lock function."

This timer lock function prevents accidental

unlocking of doors. The adjustment function

allows you to change the timer lock period from 30 seconds (default setting) to 60, 120 or 180

seconds. For further details on using the

multi-center display (middle grade type) to adjust

the timer lock period, refer to GROUP 54B,

On-vehicle Service P.54B-486.

NOTE: The timer lock period begins when the doors

are unlocked, and ends when the doors is relocked

automatically.

KEYLESS ENTRY SYSTEM DIAGNOSISBGBCJGAI

The keyless entry system is controlled by the Simpli-

fied Wiring System (SWS). Refer to GROUP 54B,

SWS Diagnosis P.54B-57.

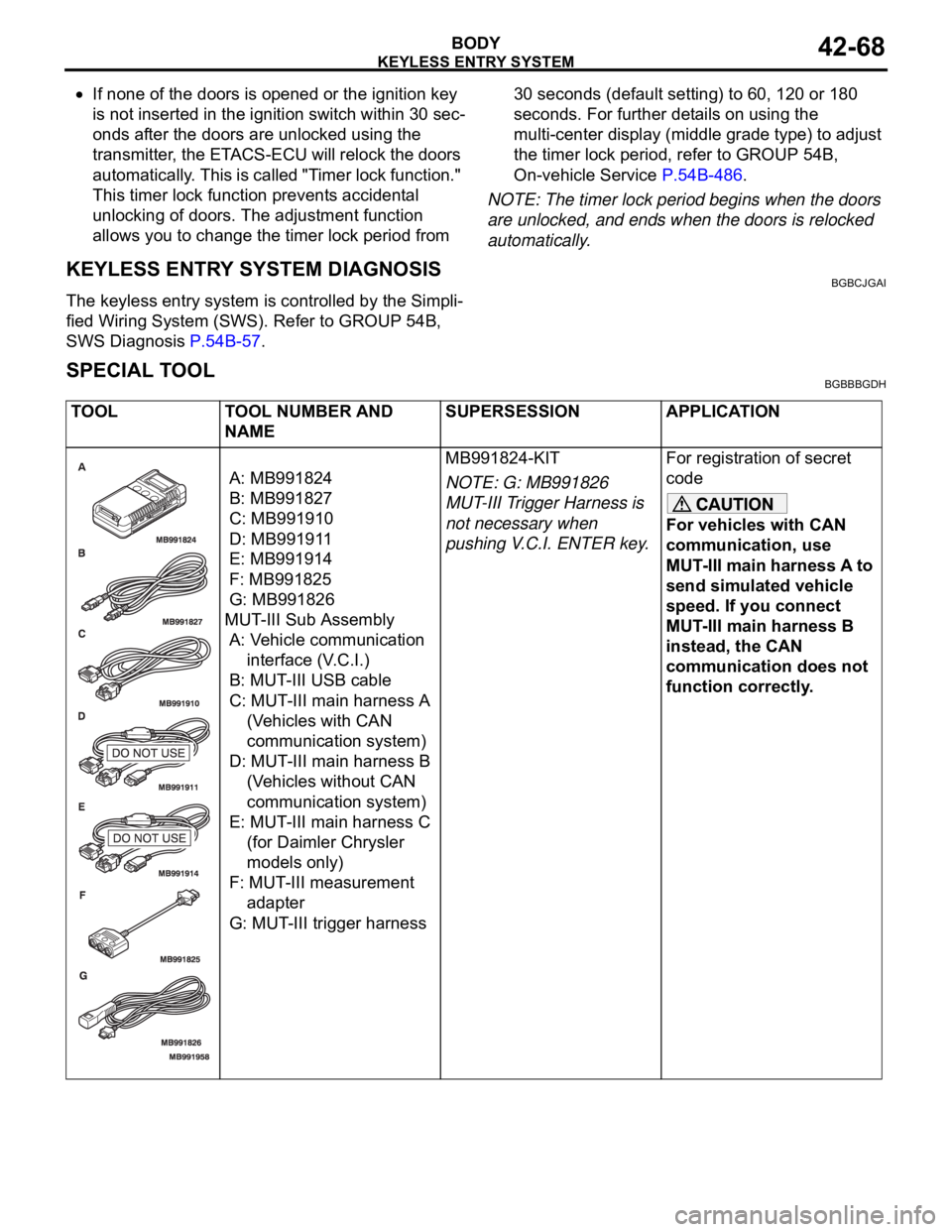

SPECIAL TOOLBGBBBGDH

TOOL TOOL NUMBER AND

NAMESUPERSESSION APPLICATION

A: MB991824

B: MB991827

C: MB991910

D: MB991911

E: MB991914

F: MB991825

G: MB991826

MUT-III Sub Assembly

A: Vehicle communication

interface (V.C.I.)

B: MUT-III USB cable

C: MUT-III main harness A

(Vehicles with CAN

communication system)

D: MUT-III main harness B

(Vehicles without CAN

communication system)

E: MUT-III main harness C

(for Daimler Chrysler

models only)

F: MUT-III measurement

adapter

G: MUT-III trigger harnessMB991824-KIT

NOTE: G: MB991826

MUT-III Trigger Harness is

not necessary when

pushing V.C.I. ENTER key.For registration of secret

code

For vehicles with CAN

communication, use

MUT-III main harness A to

send simulated vehicle

speed. If you connect

MUT-III main harness B

instead, the CAN

communication does not

function correctly.

Page 1138 of 1500

KEYLESS ENTRY SYSTEM

BODY42-71

KEYLESS ENTRY SYSTEM INSPECTIONBGBHCDAE

Check the following items. If defective, refer to GROUP 54B,

SWS Diagnosis P.54B-10).

1. Operate the transmitter to check that the doors can be

locked and unlocked.

NOTE: The adjustment function allows you to change the

unlock operation setting as follows. Prior to that check, con-

firm which setting is activated.

.

a. When the unlock button is pressed once, the driver's

door will be unlocked. Then when the button is pressed

once again, all the doors will be opened (initial setting).

b. When the unlock button is pressed only once, all the

doors will be opened.

2. Press the trunk lid button of transmitter twice (press once,

and then press again within 5 seconds) and confirm that the

trunk lid opens.

3. Operate the transmitter to check that the answerback

function works in response to doors locking/unlocking.

NOTE: The adjustment function allows you to change the

hazard answerback setting as follows. Prior to that check,

confirm which setting is activated.

.

a. Turn-signal lights: Flash once when doors are locked,

and twice when unlocked (initial setting)

b. Turn-signal lights: Flash once when doors are locked,

but does not flash when unlocked.

c. Turn-signal lights: Do not flash when doors are locked,

but flash twice when unlocked.

d. Turn-signal lights: Do not flash when doors are locked

and unlocked.

NOTE: The adjustment function allows you to change the

horn answerback setting as follows. Prior to that check, con-

firm which setting is activated.

.

a. Horn: Sounds once when the lock button is pressed.

b. Horn: Sounds once when the lock button is pressed (ini-

tial setting).

c. Horn: Does not sound.

KEYLESS ENTRY SYSTEM TIMER LOCK

FUNCTION INSPECTION

BGBEBDIA

If the doors are not locked within 30 seconds after the unlock

button is pressed, refer to GROUP 54B, SWS Diagnosis

P.54B-10.

NOTE: If either of the doors is opened or the key is inserted in

the ignition switch within that 30-second period, the timer lock

function will be cancelled.

Page 1139 of 1500

KEYLESS ENTRY SYSTEM

BODY42-72

NOTE: The adjustment function allows you to change the timer

lock period from 30 seconds (initial setting) to 60, 120 or 180

seconds. Prior to this inspection, confirm which setting is acti-

vated.

ENABLING/DISABLING THE ANSWERBACK

FUNCTION

BGBDGCGD

When the doors are locked or unlocked by using the transmit-

ter, the dome light will flash/illuminate, the turn-signal lights will

flash (hazard answerback), or the horn will sound (horn

answerback) to inform the driver.

The hazard answerback and horn answerback functions can be

enabled or disabled according to the following procedure:

ENABLING/DISABLING THE HAZARD

ANSWERBACK FUNCTION

.

How to adjust hazard answerback when the trans-

mitter is used to lock doors

1. Remove the ignition key.

2. Push the ”unlock” button and then push the ”lock“ button

within 4 seconds to 10 seconds.

3. Release the ”lock” button within 10 seconds after Step 2 and

then release the “unlock” button. The ETACS-ECU tone

alarm will sound, indicating that the hazard answerback

function can be enabled or disabled when the doors are

locked.

Enable the hazard answerback function when the

doors are locked: The ETACS-ECU tone alarm will

sound once.

Disable the hazard answerback function when the

doors are locked: The ETACS-ECU tone alarm will

sound twice.

.

How to adjust hazard answerback when the

transmitter is used to unlock doors

1. Remove the ignition key.

2. Push the ”unlock” button and then push the ”lock“ button

within 4 seconds to 10 seconds.

3. Release the ”lock” button within 10 seconds after Step 2 and

then release the “unlock” button. The ETACS-ECU tone

alarm will sound, indicating that the hazard answerback

function can be enabled or disabled when the door are

unlocked.

Enable the hazard answerback function when the

doors are unlocked: The ETACS-ECU tone alarm

will sound once.

Disable the hazard answerback function when the

doors are unlocked: The ETACS-ECU tone alarm

will sound twice.

Page 1140 of 1500

KEYLESS ENTRY SYSTEM

BODY42-73

ENABLING/DISABLING THE HORN

ANSWERBACK FUNCTION

.

1. Remove the ignition key.

2. Push the ”unlock” button and then push the ”lock“ button

within 4 seconds to 10 seconds.

3. Release the ”lock” button within 10 seconds after Step 2 and

then release the “unlock” button. The ETACS-ECU tone

alarm will sound, indicating that the horn answerback

function can be enabled or disabled.

Enable the horn answerback function*: The

ETACS-ECU tone alarm will sound once.

Disable the horn answerback function: The

ETACS-ECU tone alarm will sound twice.

Enable the horn answerback function**: The

ETACS-ECU tone alarm will sound three times.

NOTE: .

*: The horn will sound if "LOCK" button is pressed with the

doors locked.

**: The horn will sound if the doors are locked with the key-

less entry system.

HOW TO REGISTER SECRET CODEBGBHCCCB

Required Special Tools:

: MUT-III Sub Assembly

MB991824: Vehicle Communication Interface (V.C.I.)

MB991910: MUT-III Main harness A

Each individual secret code is registered inside the transmitter,

and so it is necessary to resister these codes with the

EEPROM inside the receiver in the following cases.

When the transmitter or ETACS-ECU is replaced

If more transmitters are to be used

If it appears that a problem is occurring because of faulty

registration of a code.

A maximum of four different codes can be stored in the

EEPROM memory (four different transmitters can be used).

When the code for the first transmitter is registered, the previ-

ously registered codes for all transmitters are cleared. There-

fore, if you are using four transmitters or are adding more

transmitters, the codes for all transmitters must be registered at

the same time.

WHEN SPECIAL TOOL MB991824 (V.C.I.) IS USED

.

1. Check that the doors lock normally when the key is used.

2. Insert the ignition key.

Page 1141 of 1500

KEYLESS ENTRY SYSTEM

BODY42-74

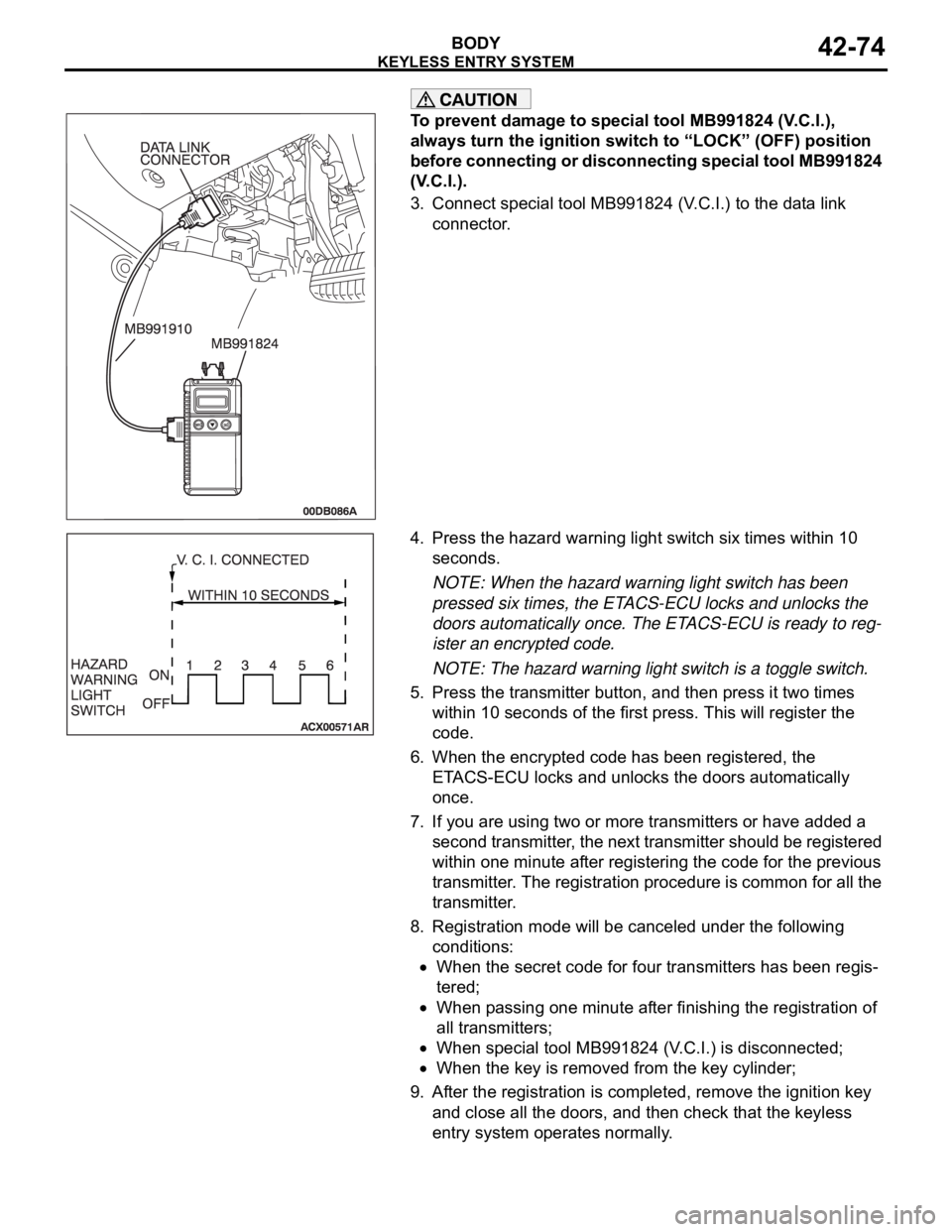

To prevent damage to special tool MB991824 (V.C.I.),

always turn the ignition switch to “LOCK” (OFF) position

before connecting or disconnecting special tool MB991824

(V.C.I.).

3. Connect special tool MB991824 (V.C.I.) to the data link

connector.

4. Press the hazard warning light switch six times within 10

seconds.

NOTE: When the hazard warning light switch has been

pressed six times, the ETACS-ECU locks and unlocks the

doors automatically once. The ETACS-ECU is ready to reg-

ister an encrypted code.

NOTE: The hazard warning light switch is a toggle switch.

5. Press the transmitter button, and then press it two times

within 10 seconds of the first press. This will register the

code.

6. When the encrypted code has been registered, the

ETACS-ECU locks and unlocks the doors automatically

once.

7. If you are using two or more transmitters or have added a

second transmitter, the next transmitter should be registered

within one minute after registering the code for the previous

transmitter. The registration procedure is common for all the

transmitter.

8. Registration mode will be canceled under the following

conditions:

When the secret code for four transmitters has been regis-

tered;

When passing one minute after finishing the registration of

all transmitters;

When special tool MB991824 (V.C.I.) is disconnected;

When the key is removed from the key cylinder;

9. After the registration is completed, remove the ignition key

and close all the doors, and then check that the keyless

entry system operates normally.

Page 1143 of 1500

SUNROOF ASSEMBLY

BODY42-76

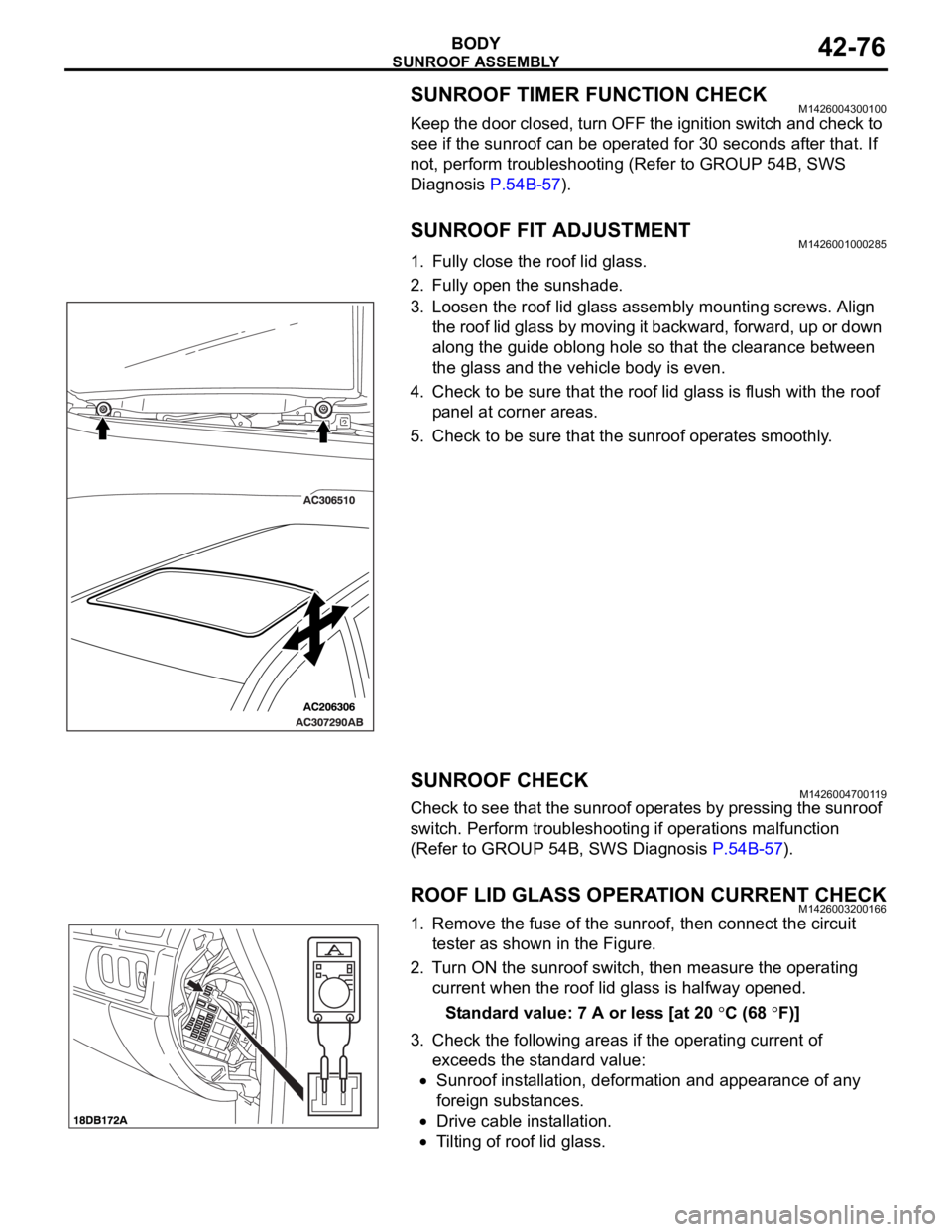

SUNROOF TIMER FUNCTION CHECKM1426004300100

Keep the door closed, turn OFF the ignition switch and check to

see if the sunroof can be operated for 30 seconds after that. If

not, perform troubleshooting (Refer to GROUP 54B, SWS

Diagnosis P.54B-57).

SUNROOF FIT ADJUSTMENTM1426001000285

1. Fully close the roof lid glass.

2. Fully open the sunshade.

3. Loosen the roof lid glass assembly mounting screws. Align

the roof lid glass by moving it backward, forward, up or down

along the guide oblong hole so that the clearance between

the glass and the vehicle body is even.

4. Check to be sure that the roof lid glass is flush with the roof

panel at corner areas.

5. Check to be sure that the sunroof operates smoothly.

SUNROOF CHECKM1426004700119

Check to see that the sunroof operates by pressing the sunroof

switch. Perform troubleshooting if operations malfunction

(Refer to GROUP 54B, SWS Diagnosis P.54B-57).

ROOF LID GLASS OPERATION CURRENT CHECKM1426003200166

1. Remove the fuse of the sunroof, then connect the circuit

tester as shown in the Figure.

2. Turn ON the sunroof switch, then measure the operating

current when the roof lid glass is halfway opened.

Standard value: 7 A or less [at 20

C (68 F)]

3. Check the following areas if the operating current of

exceeds the standard value:

Sunroof installation, deformation and appearance of any

foreign substances.

Drive cable installation.

Tilting of roof lid glass.

Page 1145 of 1500

SUNROOF ASSEMBLY

BODY42-78

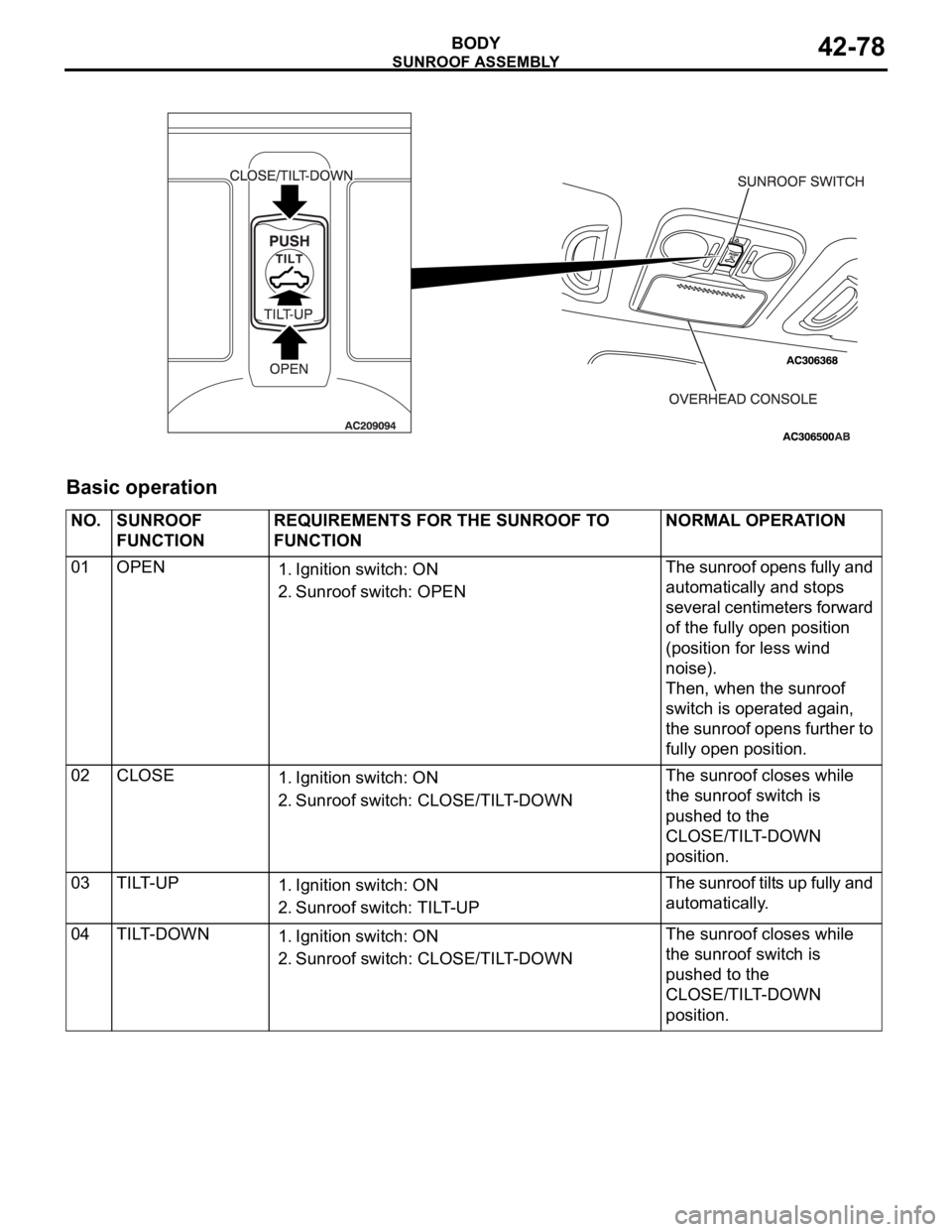

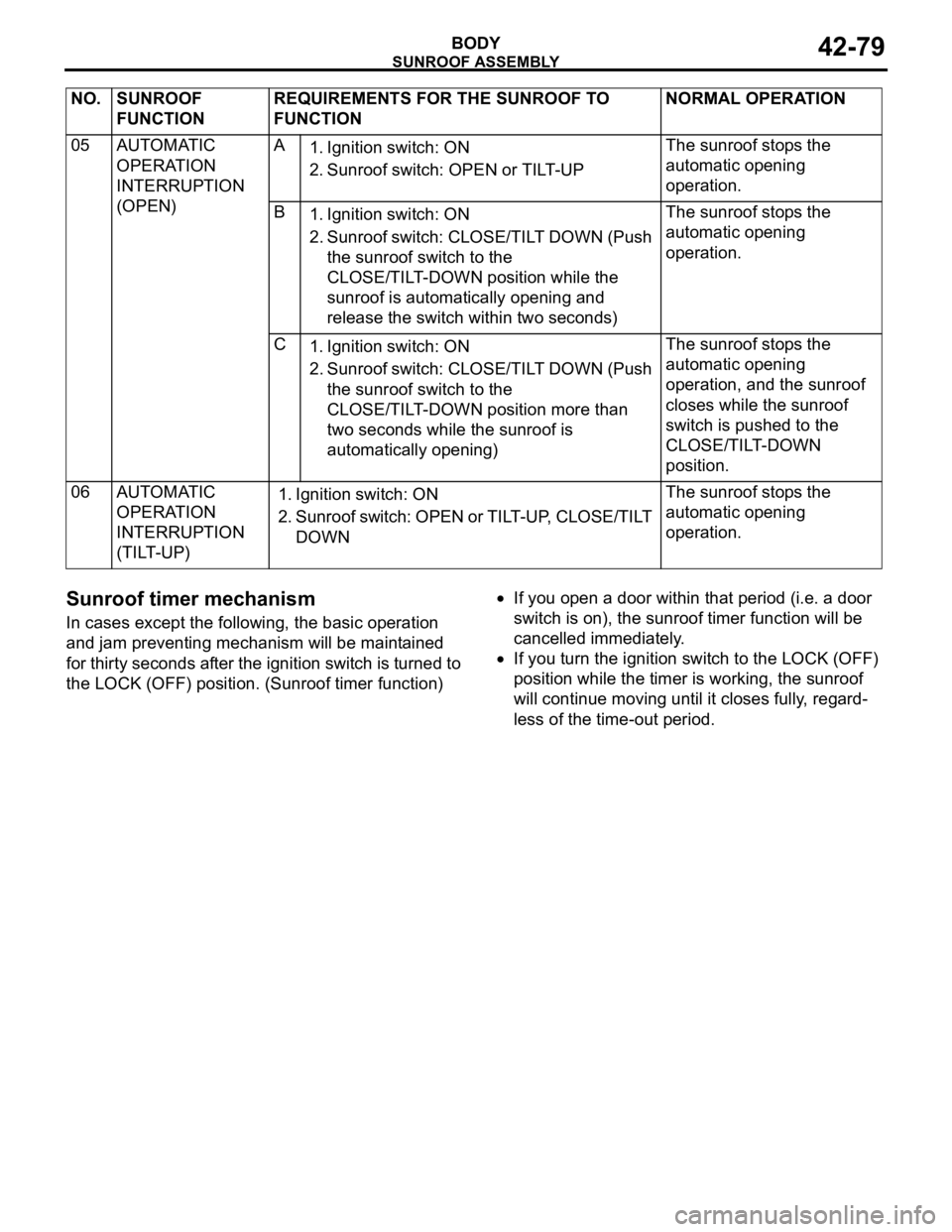

Basic operation

NO. SUNROOF

FUNCTIONREQUIREMENTS FOR THE SUNROOF TO

FUNCTIONNORMAL OPERATION

01 OPEN

1. Ignition switch: ON

2. Sunroof switch: OPENThe sunroof opens fully and

automatically and stops

several centimeters forward

of the fully open position

(position for less wind

noise).

Then, when the sunroof

switch is operated again,

the sunroof opens further to

fully open position.

02 CLOSE

1. Ignition switch: ON

2. Sunroof switch: CLOSE/TILT-DOWN The sunroof closes while

the sunroof switch is

pushed to the

CLOSE/TILT-DOWN

position.

03 TILT-UP

1. Ignition switch: ON

2. Sunroof switch: TILT-UPThe sunroof tilts up fully and

automatically.

04 TILT-DOWN

1. Ignition switch: ON

2. Sunroof switch: CLOSE/TILT-DOWNThe sunroof closes while

the sunroof switch is

pushed to the

CLOSE/TILT-DOWN

position.

Page 1146 of 1500

SUNROOF ASSEMBLY

BODY42-79

Sunroof timer mechanism

In cases except the following, the basic operation

and jam preventing mechanism will be maintained

for thirty seconds after the ignition switch is turned to

the LOCK (OFF) position. (Sunroof timer function)

If you open a door within that period (i.e. a door

switch is on), the sunroof timer function will be

cancelled immediately.

If you turn the ignition switch to the LOCK (OFF)

position while the timer is working, the sunroof

will continue moving until it closes fully, regard-

less of the time-out period. 05 AUTOMATIC

OPERATION

INTERRUPTION

(OPEN)A

1. Ignition switch: ON

2. Sunroof switch: OPEN or TILT-UPThe sunroof stops the

automatic opening

operation.

B

1. Ignition switch: ON

2. Sunroof switch: CLOSE/TILT DOWN (Push

the sunroof switch to the

CLOSE/TILT-DOWN position while the

sunroof is automatically opening and

release the switch within two seconds)The sunroof stops the

automatic opening

operation.

C

1. Ignition switch: ON

2. Sunroof switch: CLOSE/TILT DOWN (Push

the sunroof switch to the

CLOSE/TILT-DOWN position more than

two seconds while the sunroof is

automatically opening)The sunroof stops the

automatic opening

operation, and the sunroof

closes while the sunroof

switch is pushed to the

CLOSE/TILT-DOWN

position.

06 AUTOMATIC

OPERATION

INTERRUPTION

(TILT-UP)1. Ignition switch: ON

2. Sunroof switch: OPEN or TILT-UP, CLOSE/TILT

DOWNThe sunroof stops the

automatic opening

operation. NO. SUNROOF

FUNCTIONREQUIREMENTS FOR THE SUNROOF TO

FUNCTIONNORMAL OPERATION

Page 1179 of 1500

ON-VEHICLE SERVICE

BASIC BRAKE SYSTEM35A-14

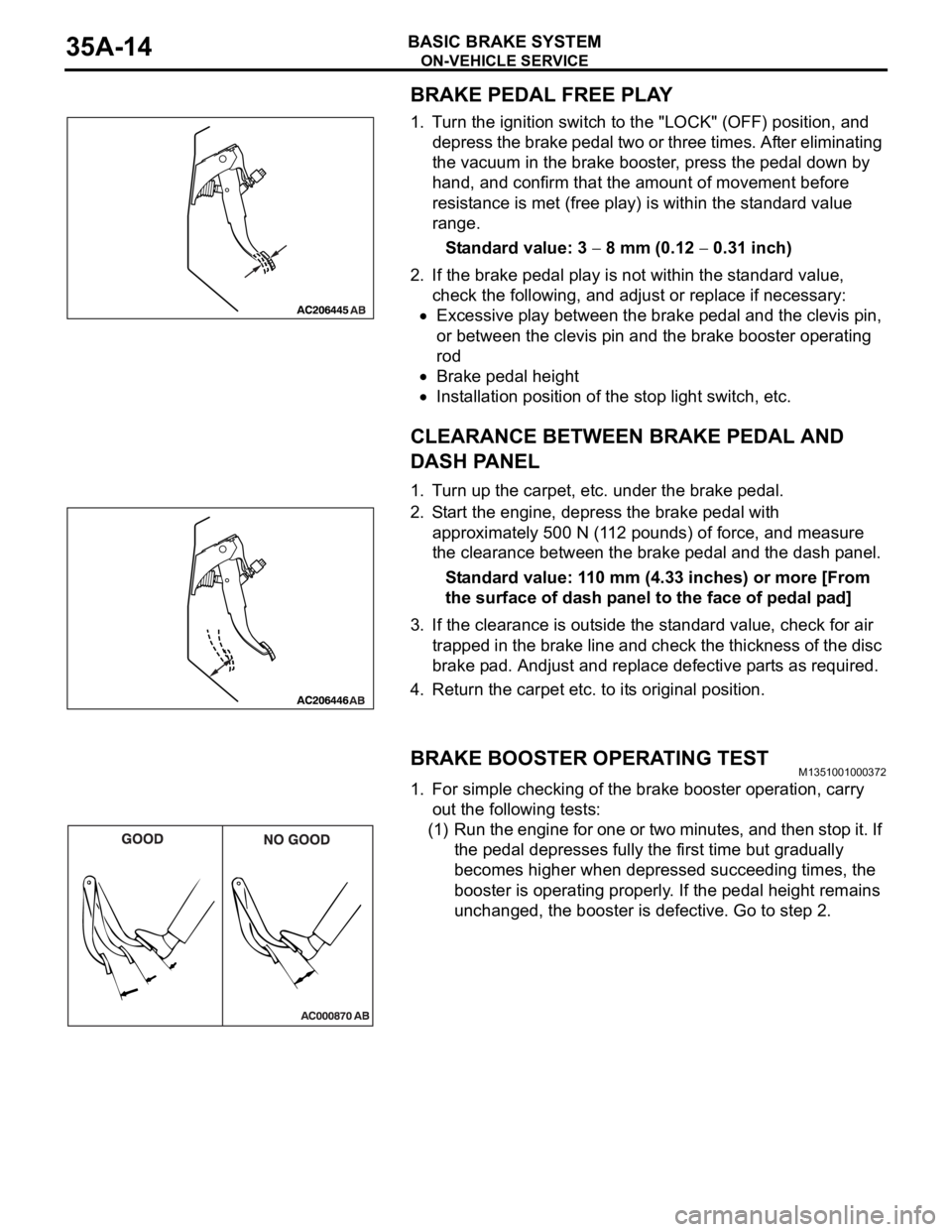

BRAKE PEDAL FREE PLAY

1. Turn the ignition switch to the "LOCK" (OFF) position, and

depress the brake pedal two or three times. After eliminating

the vacuum in the brake booster, press the pedal down by

hand, and confirm that the amount of movement before

resistance is met (free play) is within the standard value

range.

Standard value: 3

8 mm (0.12 0.31 inch)

2. If the brake pedal play is not within the standard value,

check the following, and adjust or replace if necessary:

Excessive play between the brake pedal and the clevis pin,

or between the clevis pin and the brake booster operating

rod

Brake pedal height

Installation position of the stop light switch, etc.

CLEARANCE BETWEEN BRAKE PEDAL AND

DASH PANEL

1. Turn up the carpet, etc. under the brake pedal.

2. Start the engine, depress the brake pedal with

approximately 500 N (112 pounds) of force, and measure

the clearance between the brake pedal and the dash panel.

Standard value: 110 mm (4.33 inches) or more [From

the surface of dash panel to the face of pedal pad]

3. If the clearance is outside the standard value, check for air

trapped in the brake line and check the thickness of the disc

brake pad. Andjust and replace defective parts as required.

4. Return the carpet etc. to its original position.

BRAKE BOOSTER OPERATING TESTM1351001000372

1. For simple checking of the brake booster operation, carry

out the following tests:

(1) Run the engine for one or two minutes, and then stop it. If

the pedal depresses fully the first time but gradually

becomes higher when depressed succeeding times, the

booster is operating properly. If the pedal height remains

unchanged, the booster is defective. Go to step 2.