MITSUBISHI 380 2005 Workshop Manual

Manufacturer: MITSUBISHI, Model Year: 2005, Model line: 380, Model: MITSUBISHI 380 2005Pages: 1500, PDF Size: 47.87 MB

Page 781 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-80

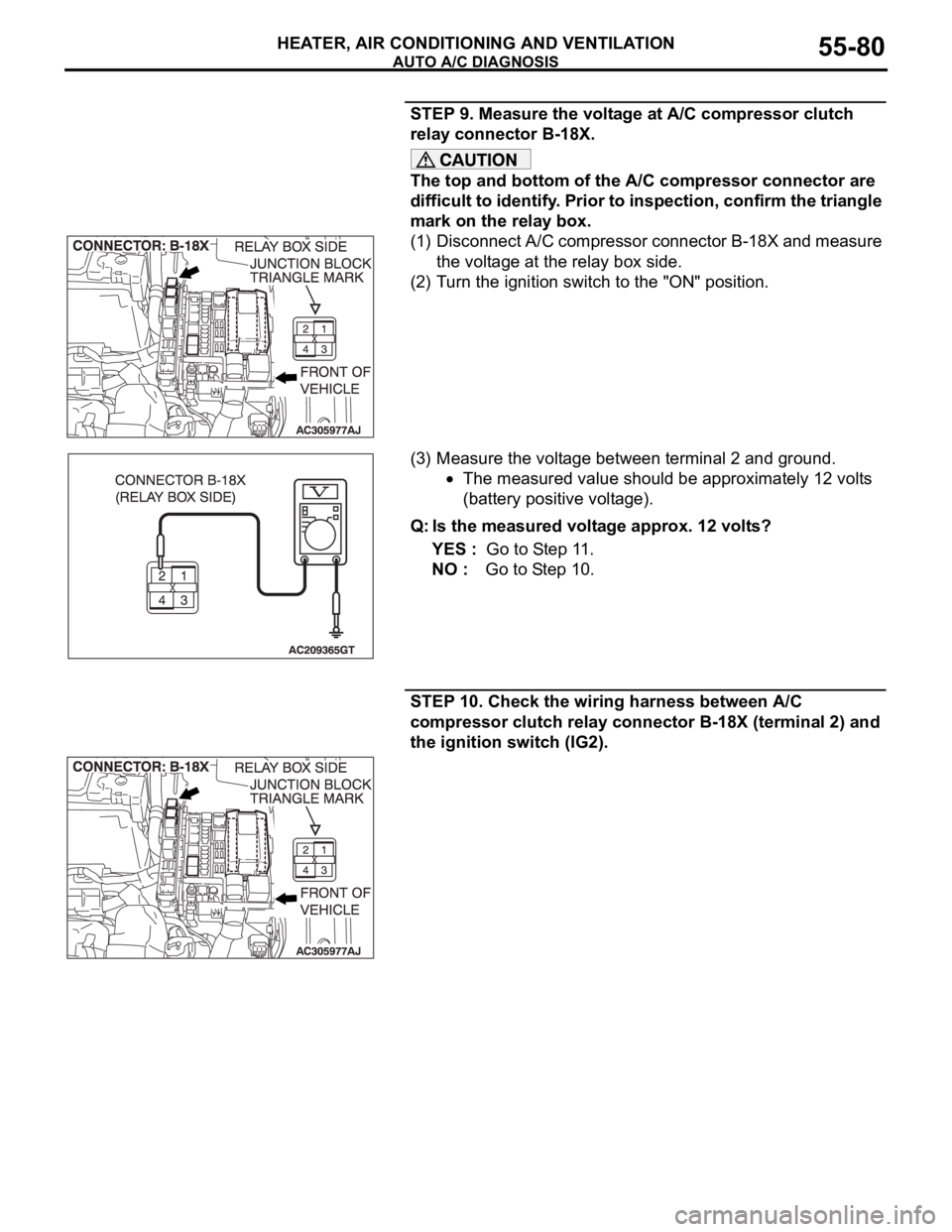

STEP 9. Measure the voltage at A/C compressor clutch

relay connector B-18X.

The top and bottom of the A/C compressor connector are

difficult to identify. Prior to inspection, confirm the triangle

mark on the relay box.

(1) Disconnect A/C compressor connector B-18X and measure

the voltage at the relay box side.

(2) Turn the ignition switch to the "ON" position.

(3) Measure the voltage between terminal 2 and ground.

The measured value should be approximately 12 volts

(battery positive voltage).

Q: Is the measured voltage approx. 12 volts?

YES : Go to Step 11.

NO : Go to Step 10.

STEP 10. Check the wiring harness between A/C

compressor clutch relay connector B-18X (terminal 2) and

the ignition switch (IG2).

Page 782 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-81

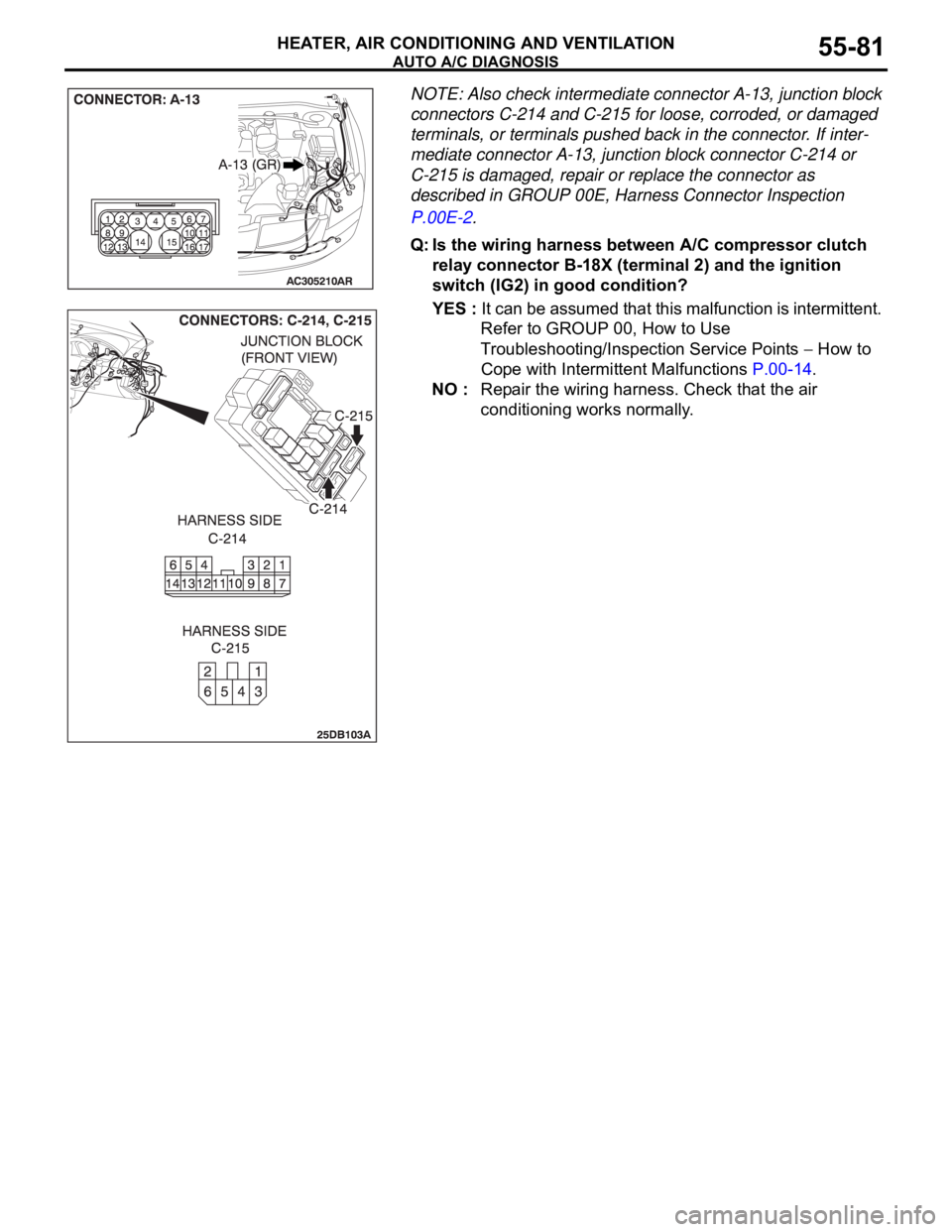

NOTE: Also check intermediate connector A-13, junction block

connectors C-214 and C-215 for loose, corroded, or damaged

terminals, or terminals pushed back in the connector. If inter-

mediate connector A-13, junction block connector C-214 or

C-215 is damaged, repair or replace the connector as

described in GROUP 00E, Harness Connector Inspection

P.00E-2.

Q: Is the wiring harness between A/C compressor clutch

relay connector B-18X (terminal 2) and the ignition

switch (IG2) in good condition?

YES : It can be assumed that this malfunction is intermittent.

Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How to

Cope with Intermittent Malfunctions P.00-14.

NO : Repair the wiring harness. Check that the air

conditioning works normally.

Page 783 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-82

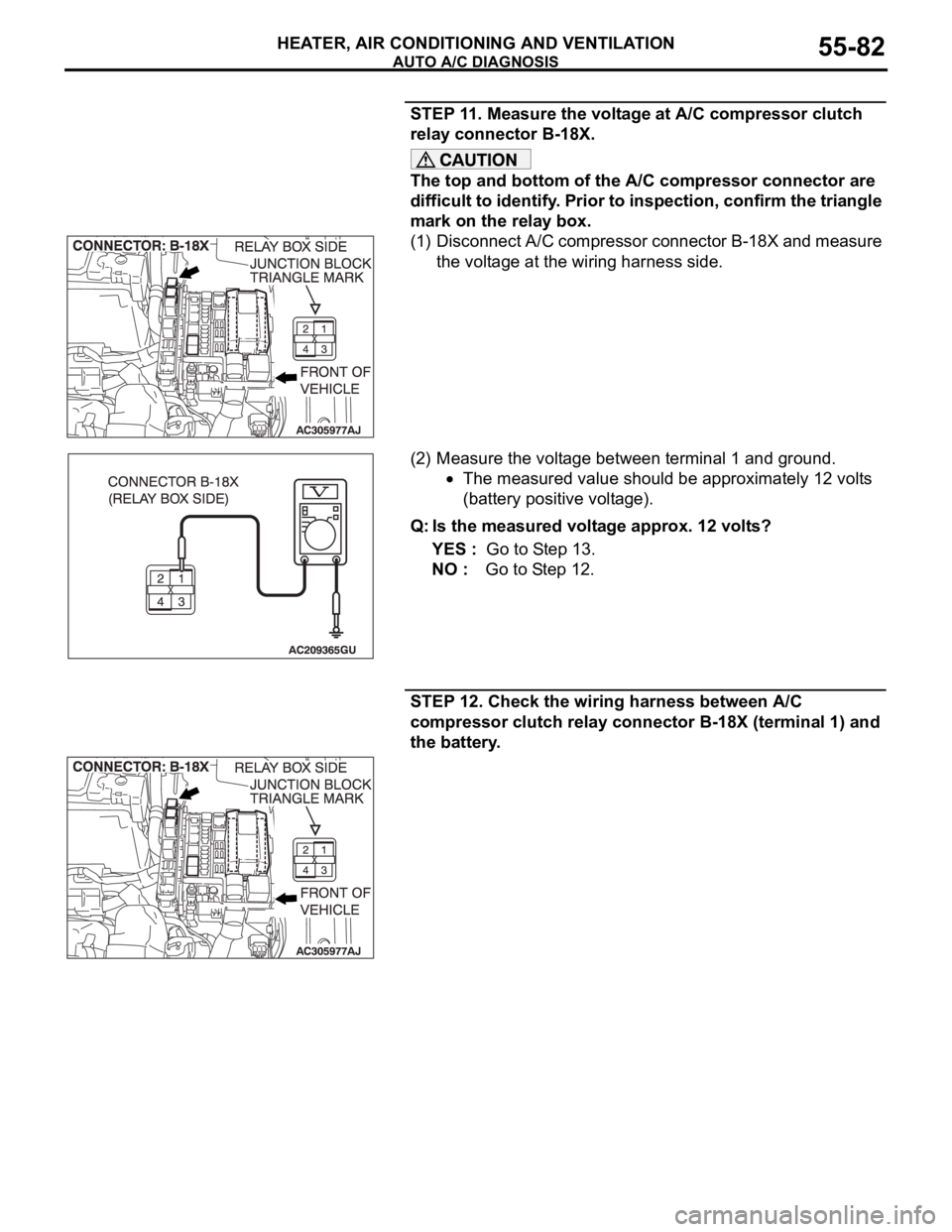

STEP 11. Measure the voltage at A/C compressor clutch

relay connector B-18X.

The top and bottom of the A/C compressor connector are

difficult to identify. Prior to inspection, confirm the triangle

mark on the relay box.

(1) Disconnect A/C compressor connector B-18X and measure

the voltage at the wiring harness side.

(2) Measure the voltage between terminal 1 and ground.

The measured value should be approximately 12 volts

(battery positive voltage).

Q: Is the measured voltage approx. 12 volts?

YES : Go to Step 13.

NO : Go to Step 12.

STEP 12. Check the wiring harness between A/C

compressor clutch relay connector B-18X (terminal 1) and

the battery.

Page 784 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-83

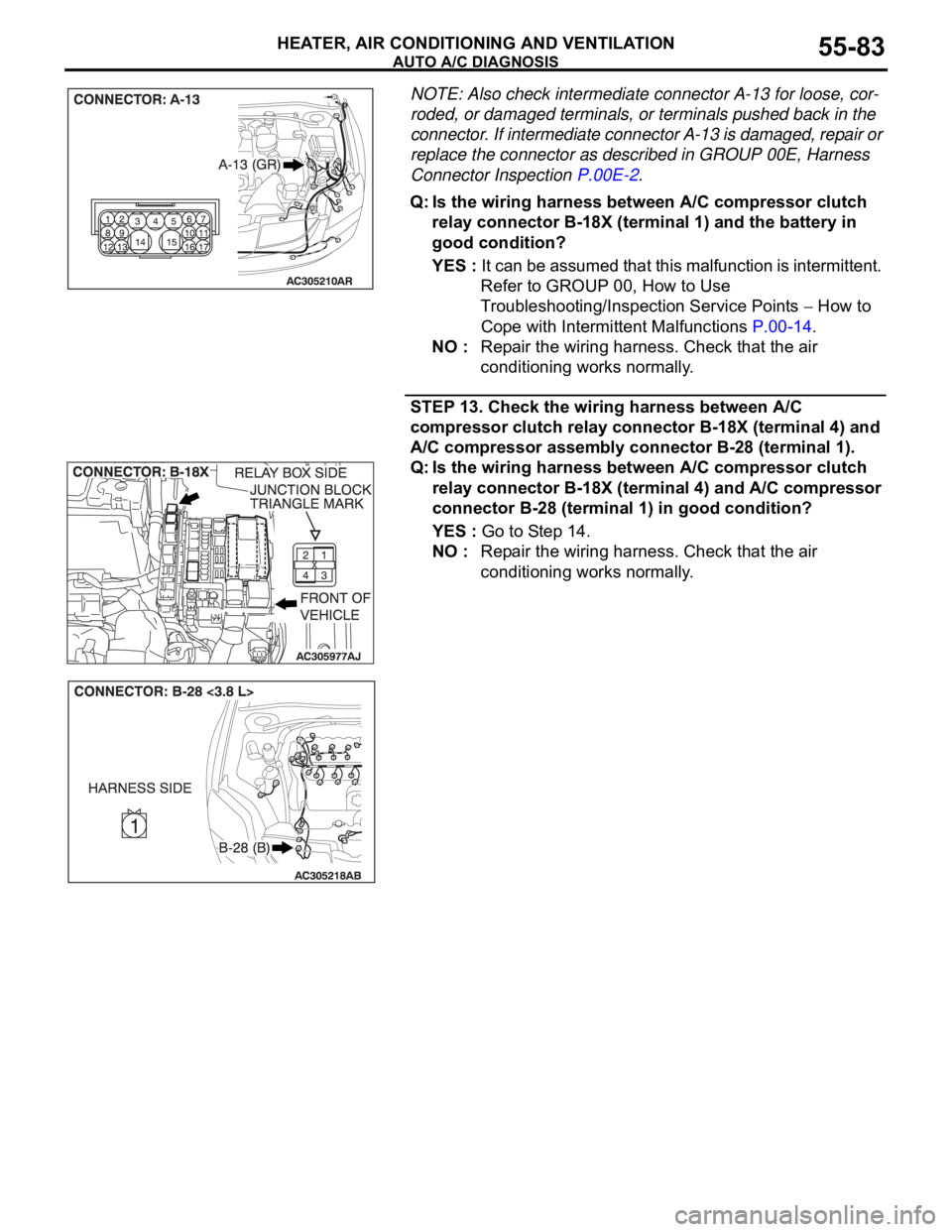

NOTE: Also check intermediate connector A-13 for loose, cor-

roded, or damaged terminals, or terminals pushed back in the

connector. If intermediate connector A-13 is damaged, repair or

replace the connector as described in GROUP 00E, Harness

Connector Inspection P.00E-2.

Q: Is the wiring harness between A/C compressor clutch

relay connector B-18X (terminal 1) and the battery in

good condition?

YES : It can be assumed that this malfunction is intermittent.

Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How to

Cope with Intermittent Malfunctions P.00-14.

NO : Repair the wiring harness. Check that the air

conditioning works normally.

STEP 13. Check the wiring harness between A/C

compressor clutch relay connector B-18X (terminal 4) and

A/C compressor assembly connector B-28 (terminal 1).

Q: Is the wiring harness between A/C compressor clutch

relay connector B-18X (terminal 4) and A/C compressor

connector B-28 (terminal 1) in good condition?

YES : Go to Step 14.

NO : Repair the wiring harness. Check that the air

conditioning works normally.

Page 785 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-84

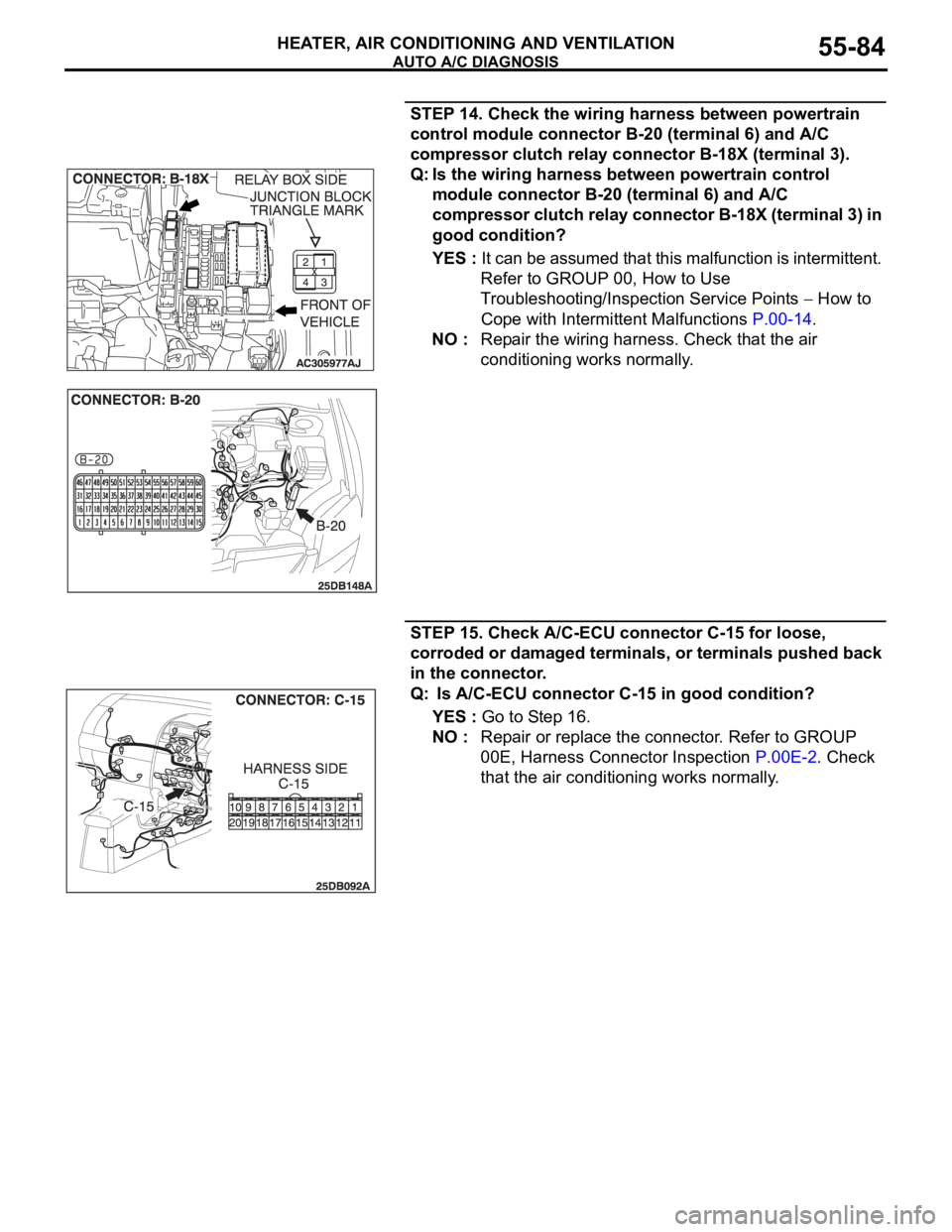

STEP 14. Check the wiring harness between powertrain

control module connector B-20 (terminal 6) and A/C

compressor clutch relay connector B-18X (terminal 3).

Q: Is the wiring harness between powertrain control

module connector B-20 (terminal 6) and A/C

compressor clutch relay connector B-18X (terminal 3) in

good condition?

YES : It can be assumed that this malfunction is intermittent.

Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How to

Cope with Intermittent Malfunctions P.00-14.

NO : Repair the wiring harness. Check that the air

conditioning works normally.

STEP 15. Check A/C-ECU connector C-15 for loose,

corroded or damaged terminals, or terminals pushed back

in the connector.

Q: Is A/C-ECU connector C-15 in good condition?

YES : Go to Step 16.

NO : Repair or replace the connector. Refer to GROUP

00E, Harness Connector Inspection P.00E-2. Check

that the air conditioning works normally.

Page 786 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-85

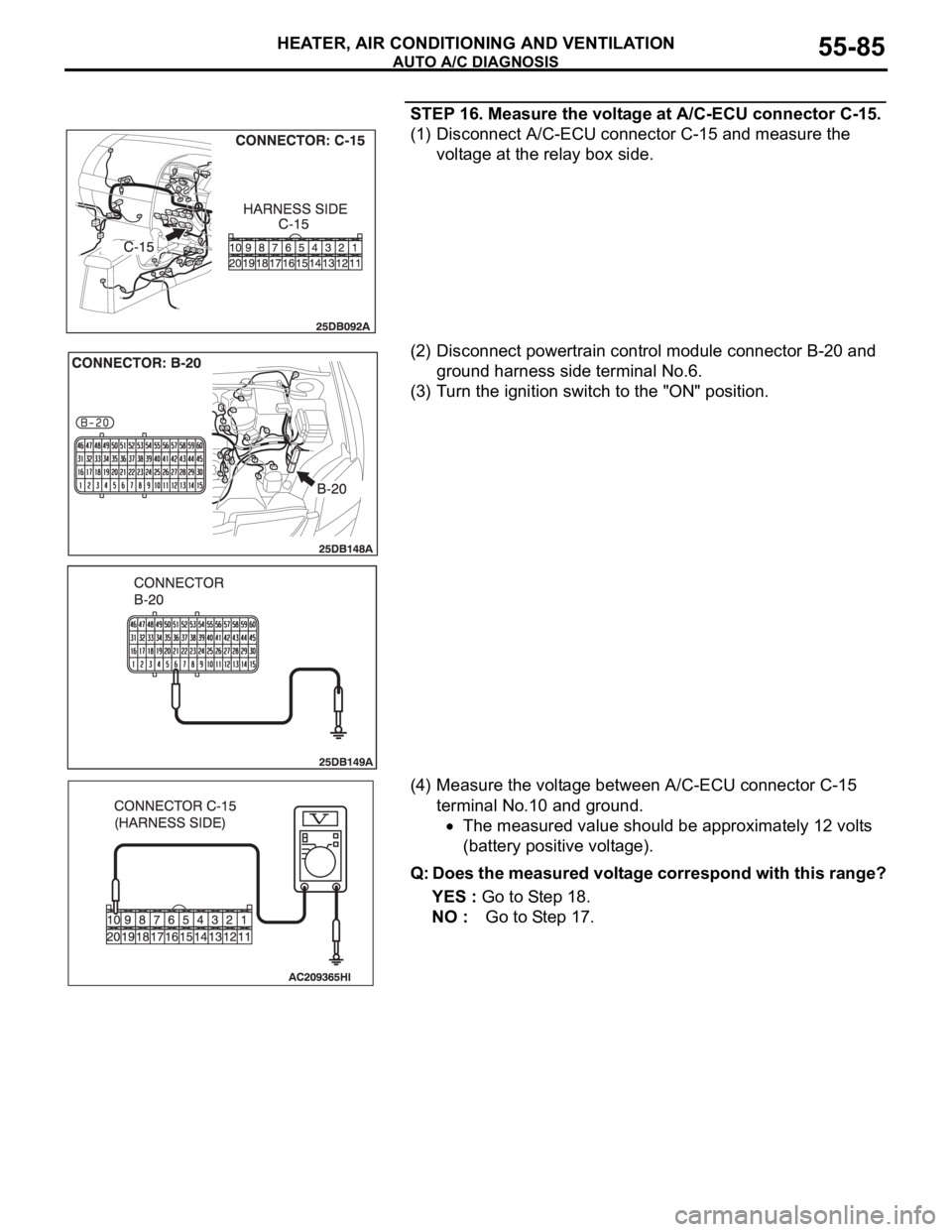

STEP 16. Measure the voltage at A/C-ECU connector C-15.

(1) Disconnect A/C-ECU connector C-15 and measure the

voltage at the relay box side.

(2) Disconnect powertrain control module connector B-20 and

ground harness side terminal No.6.

(3) Turn the ignition switch to the "ON" position.

(4) Measure the voltage between A/C-ECU connector C-15

terminal No.10 and ground.

The measured value should be approximately 12 volts

(battery positive voltage).

Q: Does the measured voltage correspond with this range?

YES : Go to Step 18.

NO : Go to Step 17.

Page 787 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-86

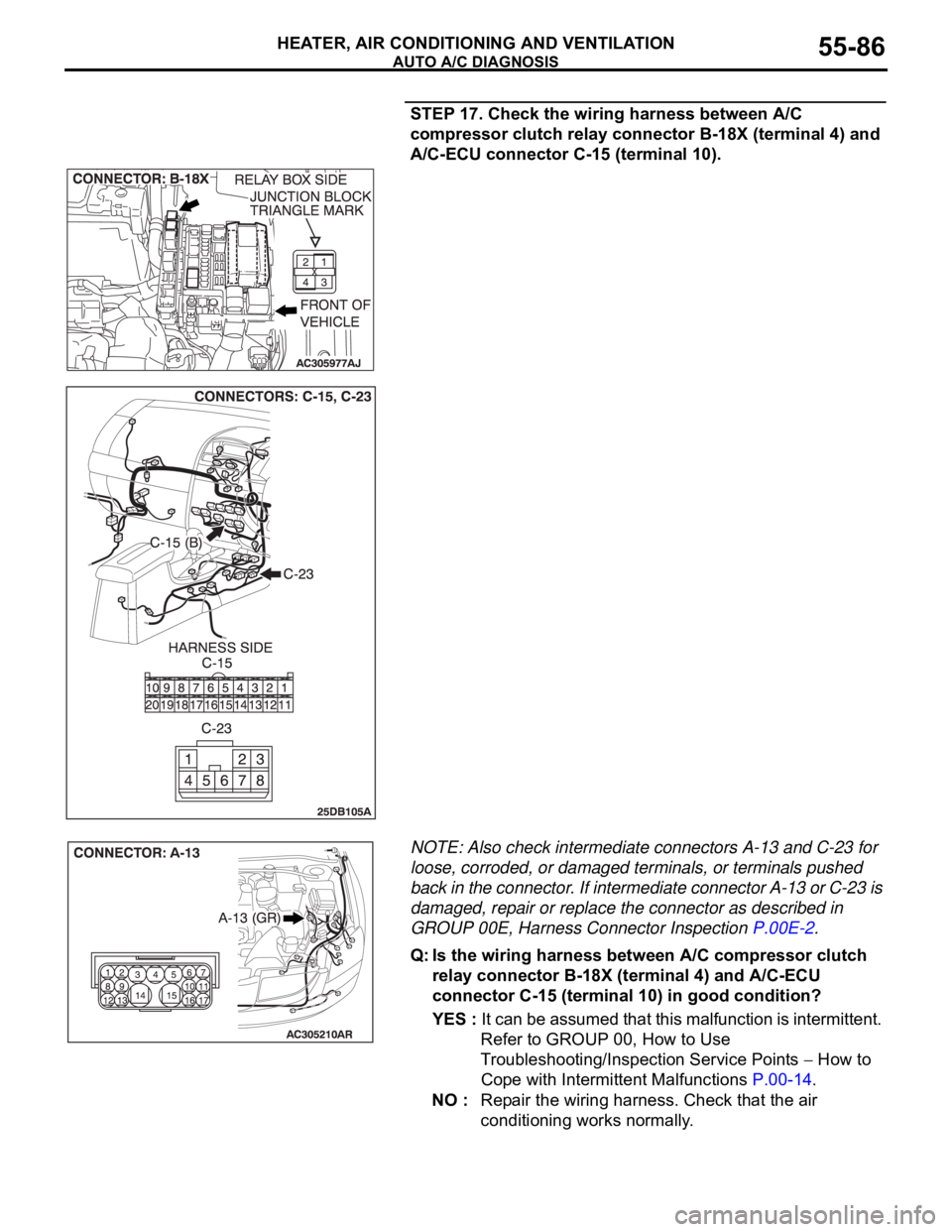

STEP 17. Check the wiring harness between A/C

compressor clutch relay connector B-18X (terminal 4) and

A/C-ECU connector C-15 (terminal 10).

NOTE: Also check intermediate connectors A-13 and C-23 for

loose, corroded, or damaged terminals, or terminals pushed

back in the connector. If intermediate connector A-13 or C-23 is

damaged, repair or replace the connector as described in

GROUP 00E, Harness Connector Inspection P.00E-2.

Q: Is the wiring harness between A/C compressor clutch

relay connector B-18X (terminal 4) and A/C-ECU

connector C-15 (terminal 10) in good condition?

YES : It can be assumed that this malfunction is intermittent.

Refer to GROUP 00, How to Use

Troubleshooting/Inspection Service Points

How to

Cope with Intermittent Malfunctions P.00-14.

NO : Repair the wiring harness. Check that the air

conditioning works normally.

Page 788 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-87

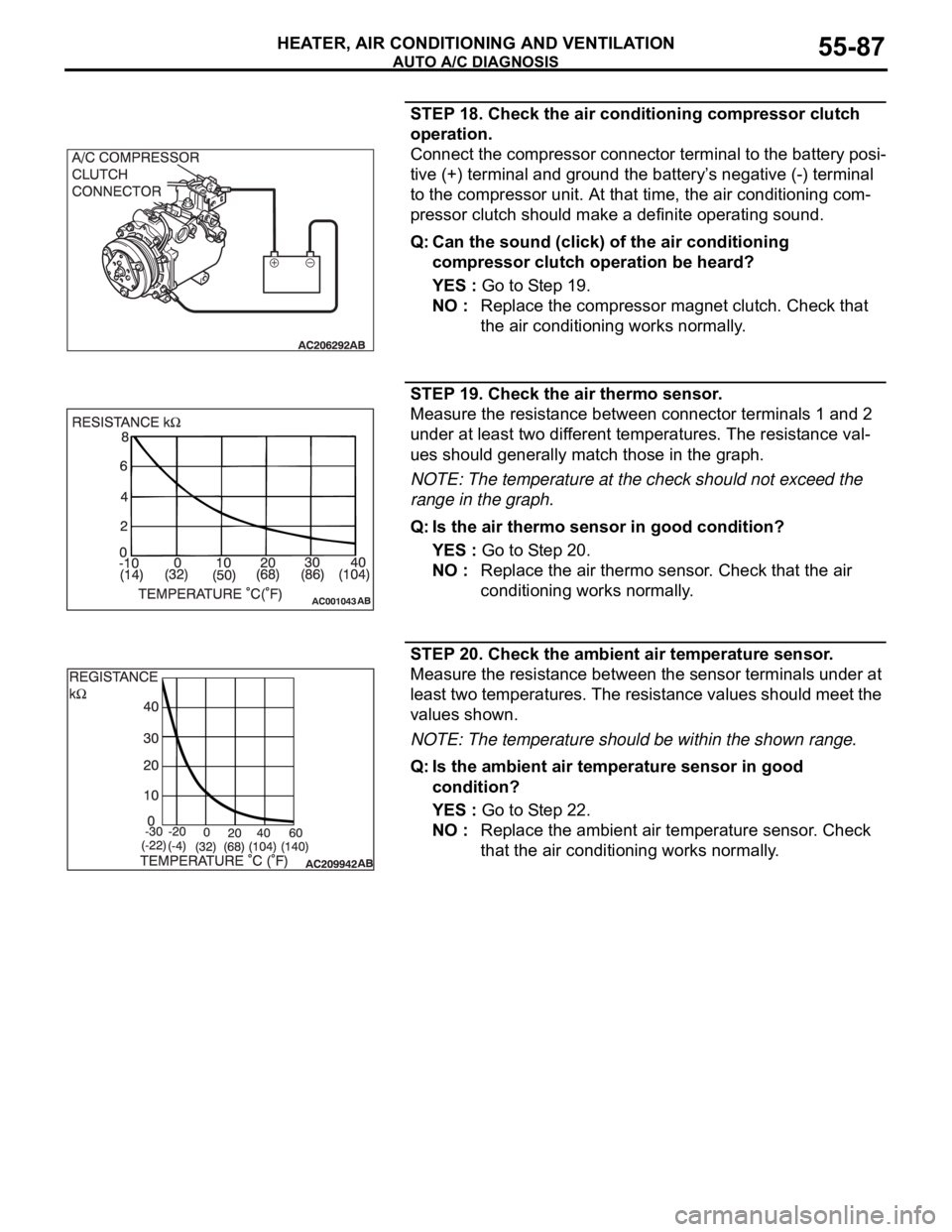

STEP 18. Check the air conditioning compressor clutch

operation.

Connect the compressor connector terminal to the battery posi-

tive (+) terminal and ground the battery’s negative (-) terminal

to the compressor unit. At that time, the air conditioning com-

pressor clutch should make a definite operating sound.

Q: Can the sound (click) of the air conditioning

compressor clutch operation be heard?

YES : Go to Step 19.

NO : Replace the compressor magnet clutch. Check that

the air conditioning works normally.

STEP 19. Check the air thermo sensor.

Measure the resistance between connector terminals 1 and 2

under at least two different temperatures. The resistance val-

ues should generally match those in the graph.

NOTE: The temperature at the check should not exceed the

range in the graph.

Q: Is the air thermo sensor in good condition?

YES : Go to Step 20.

NO : Replace the air thermo sensor. Check that the air

conditioning works normally.

STEP 20. Check the ambient air temperature sensor.

Measure the resistance between the sensor terminals under at

least two temperatures. The resistance values should meet the

values shown.

NOTE: The temperature should be within the shown range.

Q: Is the ambient air temperature sensor in good

condition?

YES : Go to Step 22.

NO : Replace the ambient air temperature sensor. Check

that the air conditioning works normally.

Page 789 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-88

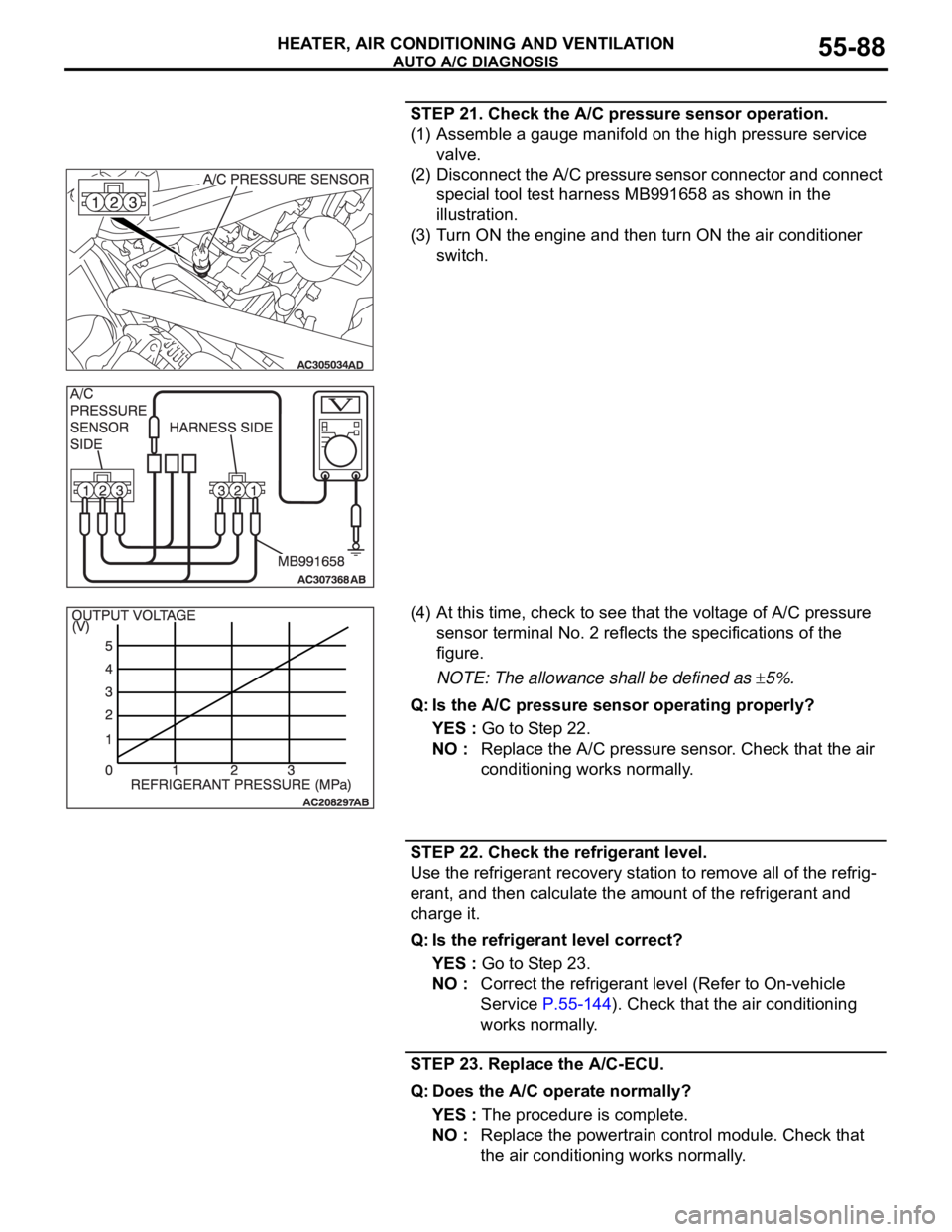

STEP 21. Check the A/C pressure sensor operation.

(1) Assemble a gauge manifold on the high pressure service

valve.

(2) Disconnect the A/C pressure sensor connector and connect

special tool test harness MB991658 as shown in the

illustration.

(3) Turn ON the engine and then turn ON the air conditioner

switch.

(4) At this time, check to see that the voltage of A/C pressure

sensor terminal No. 2 reflects the specifications of the

figure.

NOTE: The allowance shall be defined as

5%.

Q: Is the A/C pressure sensor operating properly?

YES : Go to Step 22.

NO : Replace the A/C pressure sensor. Check that the air

conditioning works normally.

STEP 22. Check the refrigerant level.

Use the refrigerant recovery station to remove all of the refrig-

erant, and then calculate the amount of the refrigerant and

charge it.

Q: Is the refrigerant level correct?

YES : Go to Step 23.

NO : Correct the refrigerant level (Refer to On-vehicle

Service P.55-144). Check that the air conditioning

works normally.

STEP 23. Replace the A/C-ECU.

Q: Does the A/C operate normally?

YES : The procedure is complete.

NO : Replace the powertrain control module. Check that

the air conditioning works normally.

Page 790 of 1500

AUTO A/C DIAGNOSIS

HEATER, AIR CONDITIONING AND VENTILATION55-89

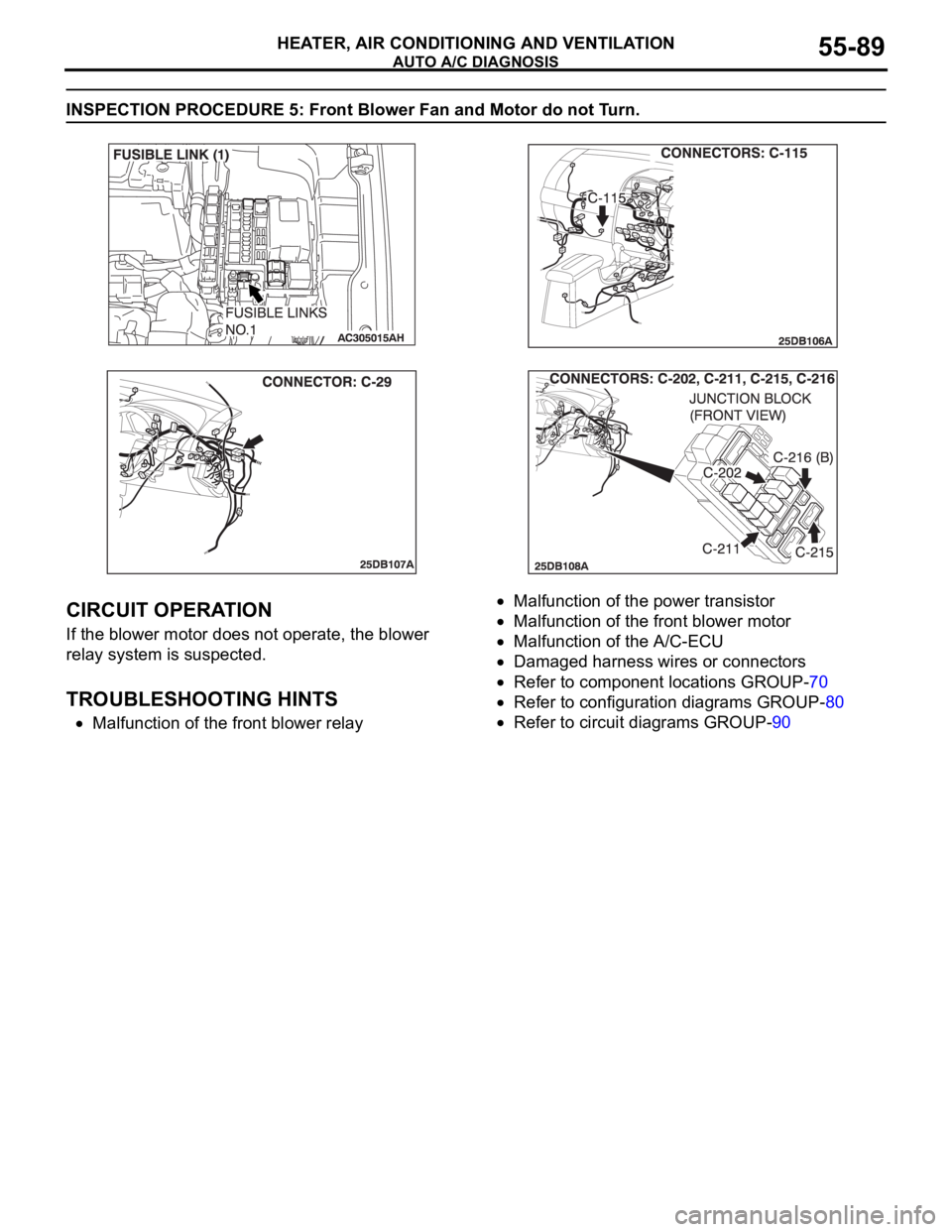

INSPECTION PROCEDURE 5: Front Blower Fan and Motor do not Turn.

.

CIRCUIT OPERATION

If the blower motor does not operate, the blower

relay system is suspected.

.

TROUBLESHOOTING HINTS

Malfunction of the front blower relay

Malfunction of the power transistor

Malfunction of the front blower motor

Malfunction of the A/C-ECU

Damaged harness wires or connectors

Refer to component locations GROUP-70

Refer to configuration diagrams GROUP-80

Refer to circuit diagrams GROUP-90