relay MITSUBISHI ECLIPSE 1990 Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 158 of 391

.

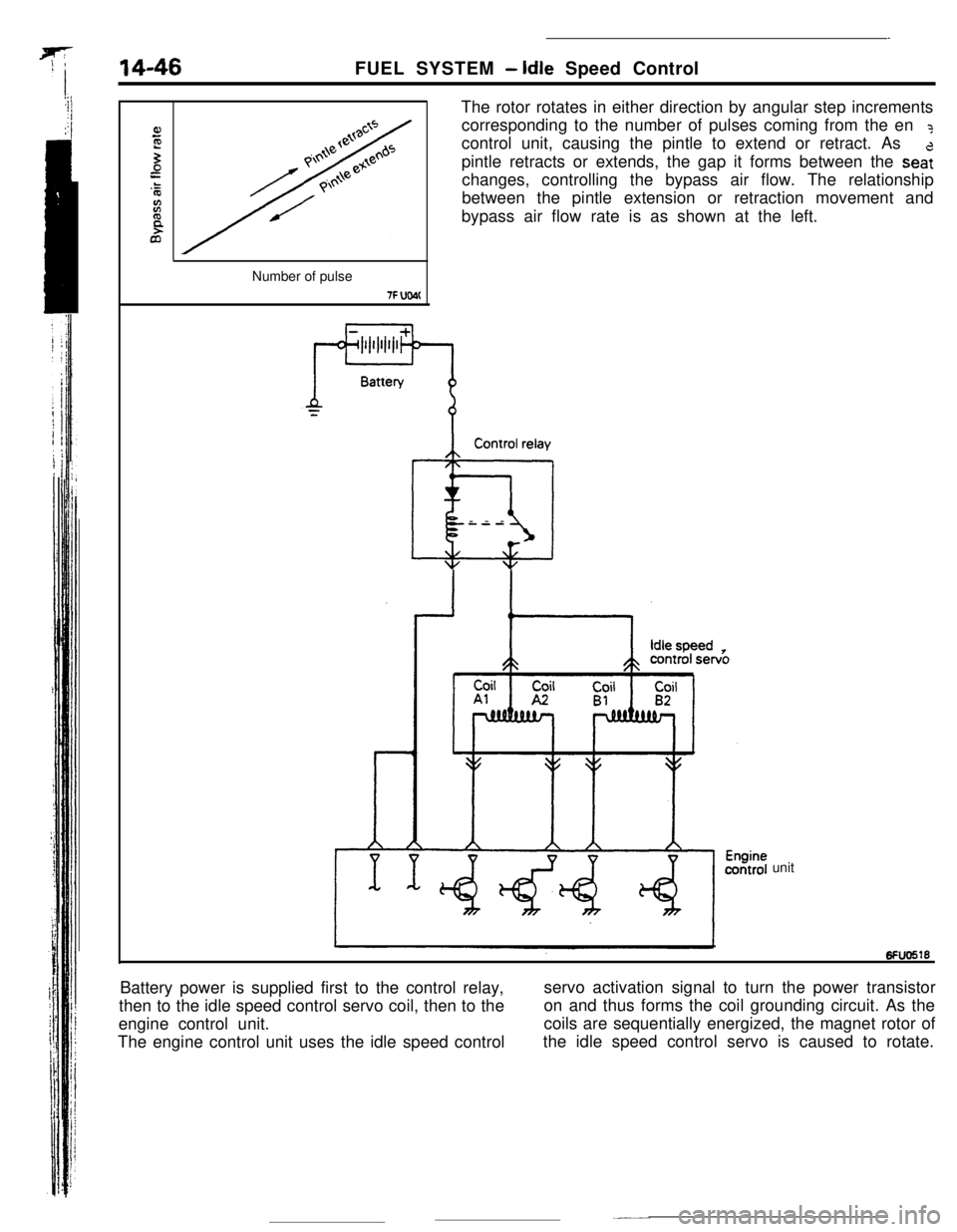

14-46FUEL SYSTEM- Idle Speed Control

The rotor rotates in either direction by angular step increments

corresponding to the number of pulses coming from the en

?control unit, causing the pintle to extend or retract. As

pintle retracts or extends, the gap it forms between the

sea:changes, controlling the bypass air flow. The relationship

between the pintle extension or retraction movement and

bypass air flow rate is as shown at the left.

Number of pulse

7F UW(Control relay

@iI---

unit

Battery power is supplied first to the control relay,

then to the idle speed control servo coil, then to theservo activation signal to turn the power transistor

engine control unit.on and thus forms the coil grounding circuit. As the

The engine control unit uses the idle speed controlcoils are sequentially energized, the magnet rotor of

the idle speed control servo is caused to rotate.

Page 166 of 391

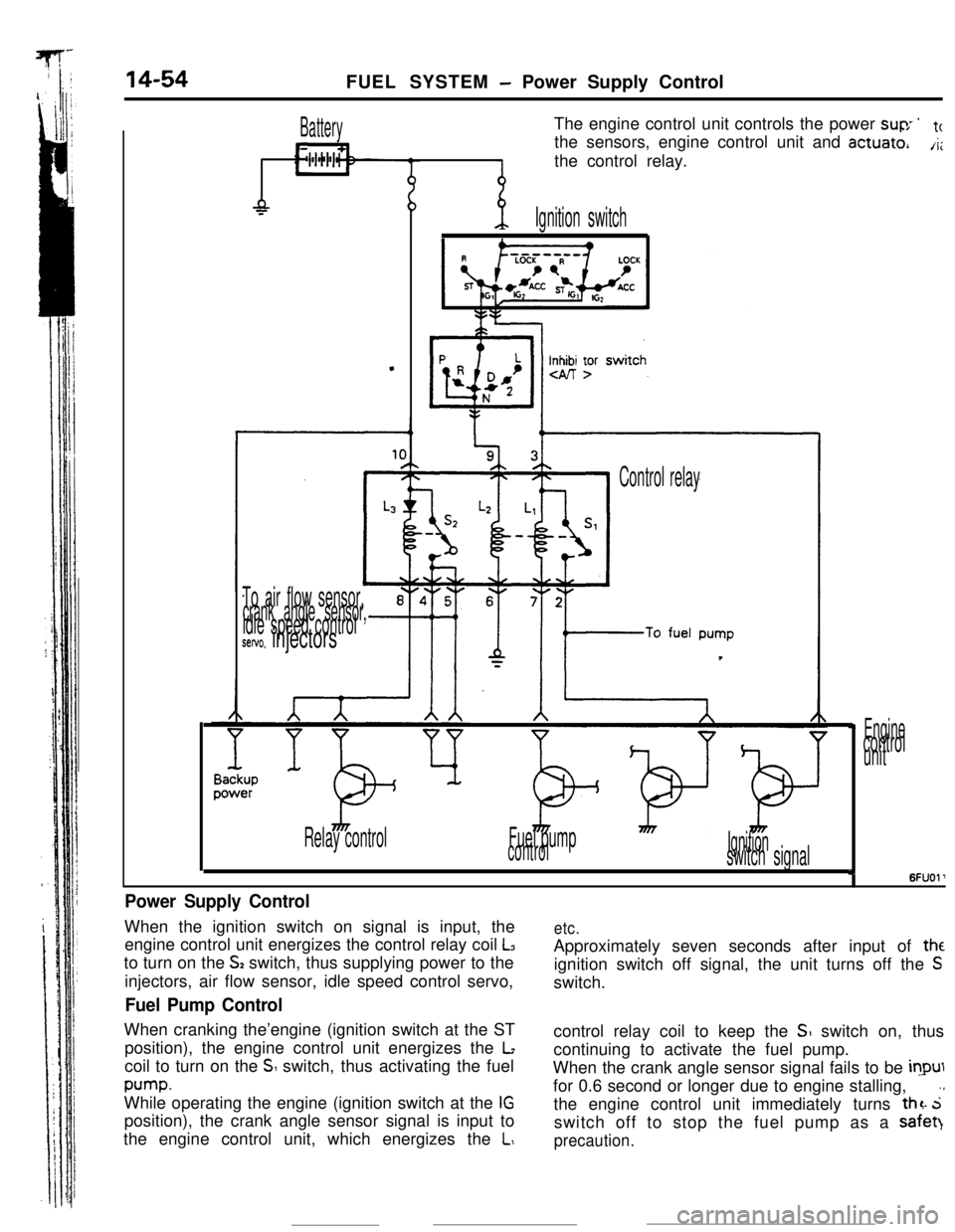

FUEL SYSTEM- Power Supply Control

Battery

L11The engine control unit controls the power

suv ’tcthe sensors, engine control unit and

actuate,A;the control relay.

-P

.

-p.Ignition switch

Inn yr

To air flow sensor,crank angle sensor,idle speed controlsetvo. injectors

Control relay

Relay controlFuel pump

controlIgnitionswitch signal

Enginecontrol

unit

I6FUOl’

Power Supply ControlWhen the ignition switch on signal is input, the

engine control unit energizes the control relay coil

L3to turn on the

S2 switch, thus supplying power to the

injectors, air flow sensor, idle speed control servo,

Fuel Pump ControlWhen cranking the’engine (ignition switch at the ST

position), the engine control unit energizes the

Lcoil to turn on the

S switch, thus activating the fuel

pump.While operating the engine (ignition switch at the

IGposition), the crank angle sensor signal is input to

the engine control unit, which energizes the

L,

etc.Approximately seven seconds after input of

theignition switch off signal, the unit turns off the

Sswitch.

control relay coil to keep the

SI switch on, thus

continuing to activate the fuel pump.

When the crank angle sensor signal fails to be

inputfor 0.6 second or longer due to engine stalling,

.,the engine control unit immediately turns

thz. 5switch off to stop the fuel pump as a safet)

precaution.

Page 167 of 391

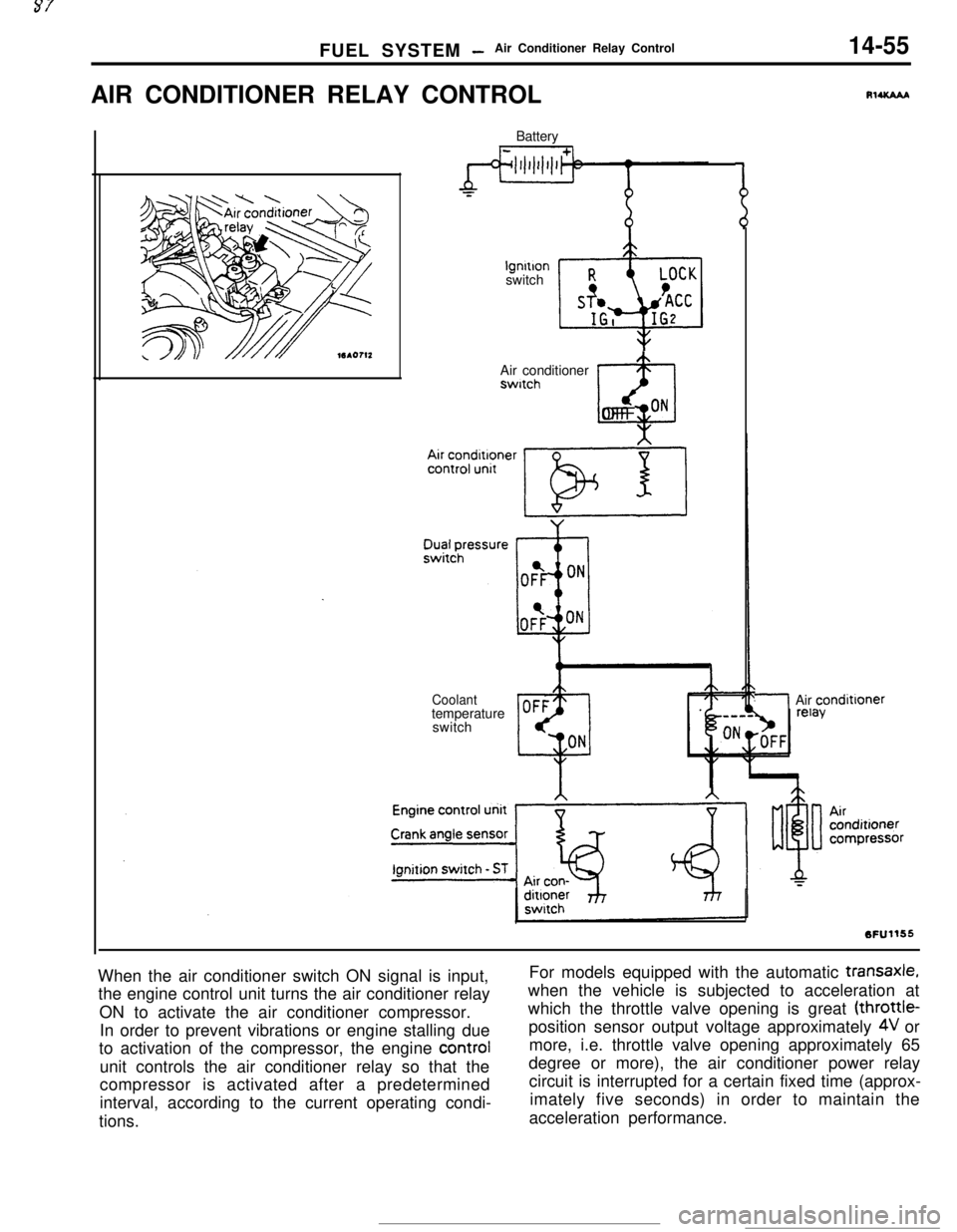

FUEL SYSTEM -Air Conditioner Relay Control14-55AIR CONDITIONER RELAY CONTROL

Batterylgnltlon

switch

Air conditionerswitch

@OFF ON

Coolanttemperature

switch

RlUCAAA

/Air condittoner

When the air conditioner switch ON signal is input,

the engine control unit turns the air conditioner relay

ON to activate the air conditioner compressor.

In order to prevent vibrations or engine stalling due

to activation of the compressor, the engine control

unit controls the air conditioner relay so that the

compressor is activated after a predetermined

interval, according to the current operating condi-

tions.For models equipped with the automatic

transaxle,when the vehicle is subjected to acceleration at

which the throttle valve opening is great (throttle-

position sensor output voltage approximately

4V or

more, i.e. throttle valve opening approximately 65

degree or more), the air conditioner power relay

circuit is interrupted for a certain fixed time (approx-

imately five seconds) in order to maintain the

acceleration performance.

Page 168 of 391

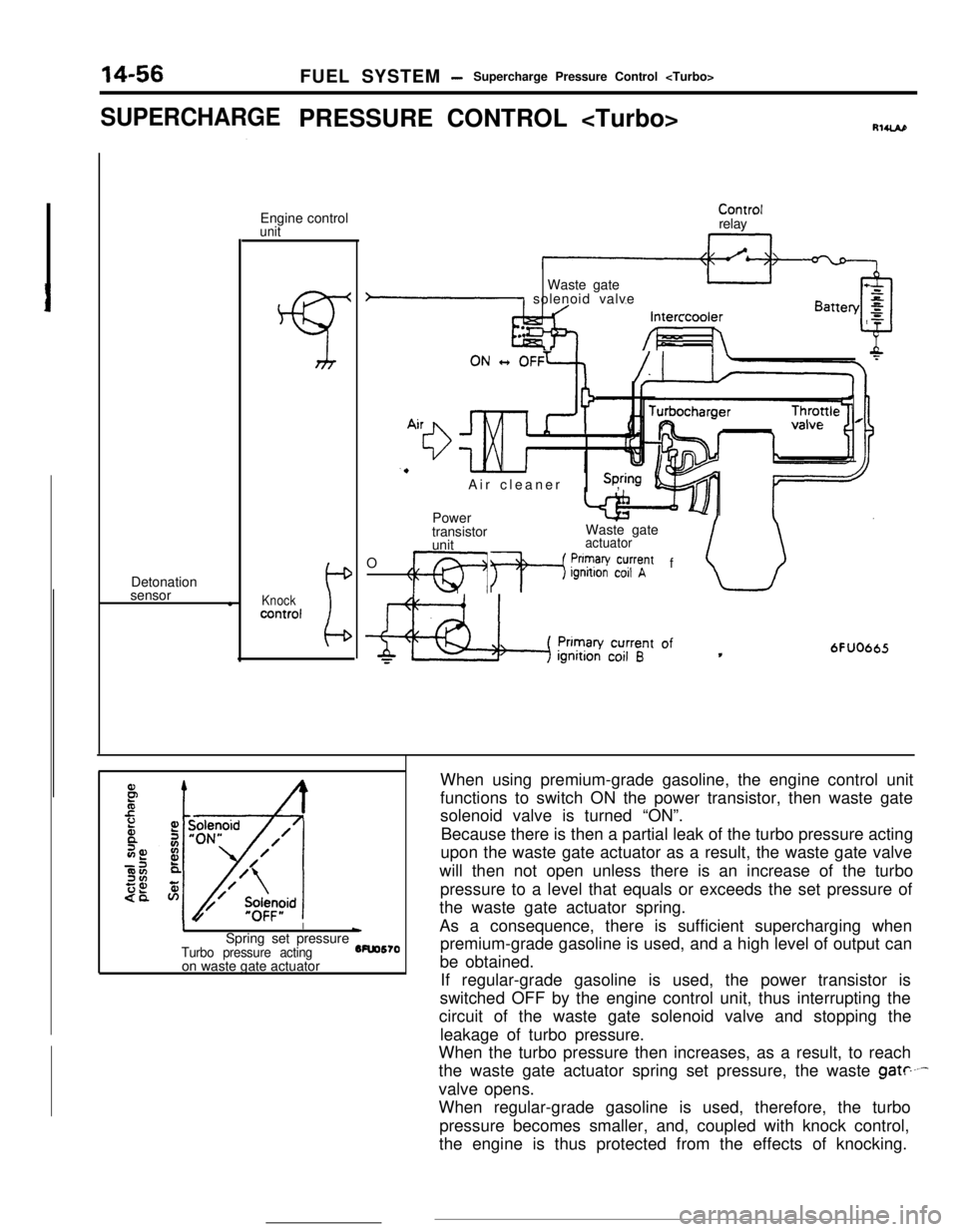

14-56FUEL SYSTEM -Supercharge Pressure Control

SUPERCHARGEPRESSURE CONTROL

sensor

lEngine control

unit

Knockcontrol

ControlrelayIntercooler

h&l --/I- h

.. .Waste gate

P solenoid valve

Air cleaner,

Power

transistorWaste gate

unit

actuatorOf

CT1 +p$?V~~~t

6FUO665

II\Spring set pressure

Turbo pressure acting5Fuo570

on waste gate actuatorWhen using premium-grade gasoline, the engine control unit

functions to switch ON the power transistor, then waste gate

solenoid valve is turned “ON”.

Because there is then a partial leak of the turbo pressure acting

upon the waste gate actuator as a result, the waste gate valve

will then not open unless there is an increase of the turbo

pressure to a level that equals or exceeds the set pressure of

the waste gate actuator spring.

As a consequence, there is sufficient supercharging when

premium-grade gasoline is used, and a high level of output can

be obtained.

If regular-grade gasoline is used, the power transistor is

switched OFF by the engine control unit, thus interrupting the

circuit of the waste gate solenoid valve and stopping the

leakage of turbo pressure.

When the turbo pressure then increases, as a result, to reach

the waste gate actuator spring set pressure, the waste

gate----valve opens.

When regular-grade gasoline is used, therefore, the turbo

pressure becomes smaller, and, coupled with knock control,

the engine is thus protected from the effects of knocking.

Page 169 of 391

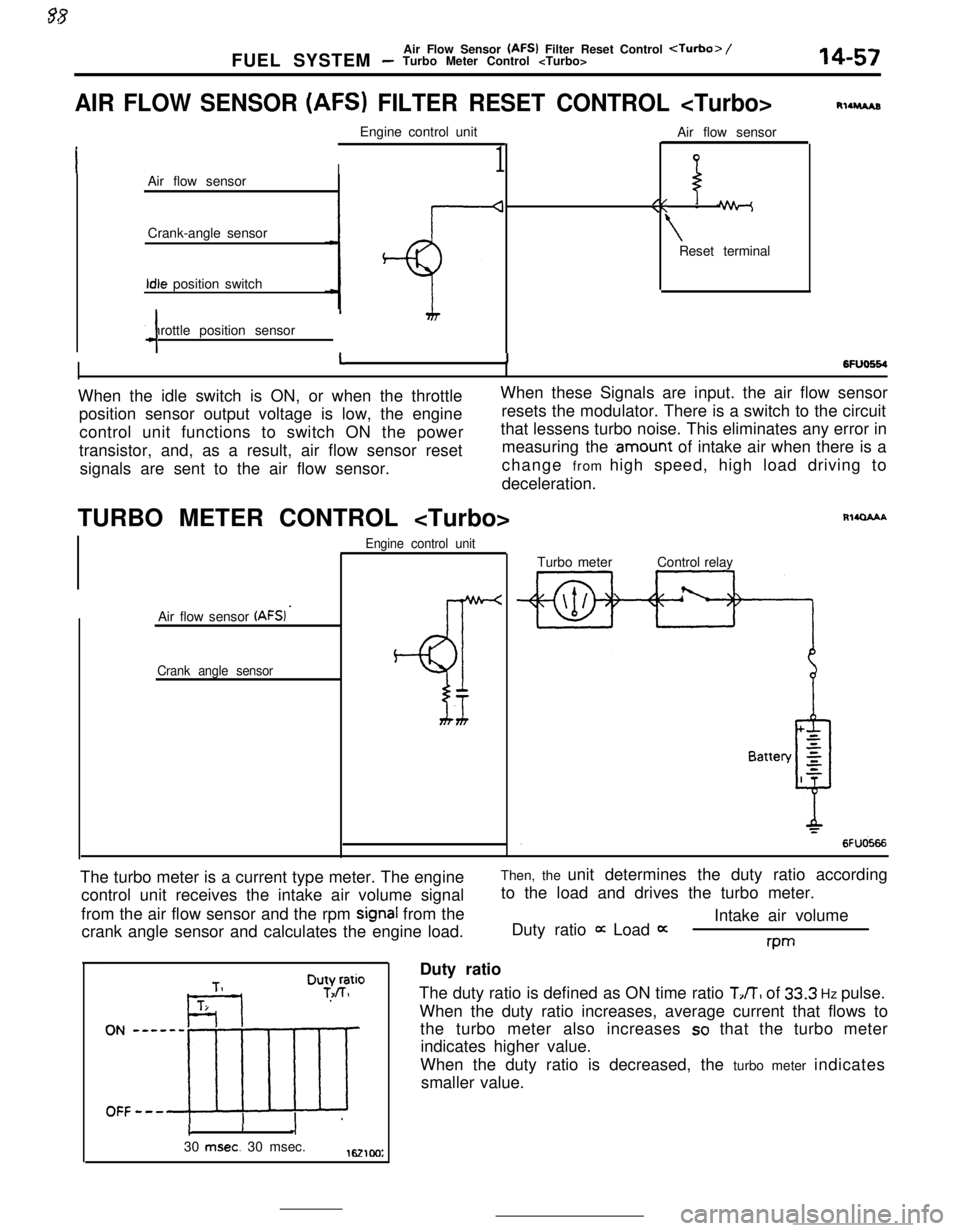

FUEL SYSTEMAir Flow Sensor (AFSI Filter Reset Control

AIR FLOW SENSOR (AFS) FILTER RESET CONTROL

I1Air flow sensor

Crank-angle sensorIdle position switch

Throttle position sensor

4Air flow sensor

//\\ -

\Reset terminal

RllruAs

6FlJo664I11When the idle switch is ON, or when the throttleWhen these Signals are input. the air flow sensor

position sensor output voltage is low, the engineresets the modulator. There is a switch to the circuit

control unit functions to switch ON the powerthat lessens turbo noise. This eliminates any error in

transistor, and, as a result, air flow sensor resetmeasuring the

.amount of intake air when there is a

signals are sent to the air flow sensor.change from high speed, high load driving to

deceleration.

TURBO METER CONTROL

Air flow sensor

(AFSI ’

Crank angle sensorEngine control unit

BT

Rl4QAAATurbo meterControl relay

The turbo meter is a current type meter. The engine

control unit receives the intake air volume signal

from the air flow sensor and the rpm

signal from the

crank angle sensor and calculates the engine load.Then, the unit determines the duty ratio according

to the load and drives the turbo meter.

Intake air volume

Duty ratio

it Load 0:rwDuty ratio

The duty ratio is defined as ON time ratio

TJT, of 33.3 Hz pulse.

When the duty ratio increases, average current that flows to

the turbo meter also increases

so that the turbo meter

indicates higher value.

When the duty ratio is decreased, the turbo meter indicates

smaller value.

cI30

msec. 30 msec.1621cm:

Page 271 of 391

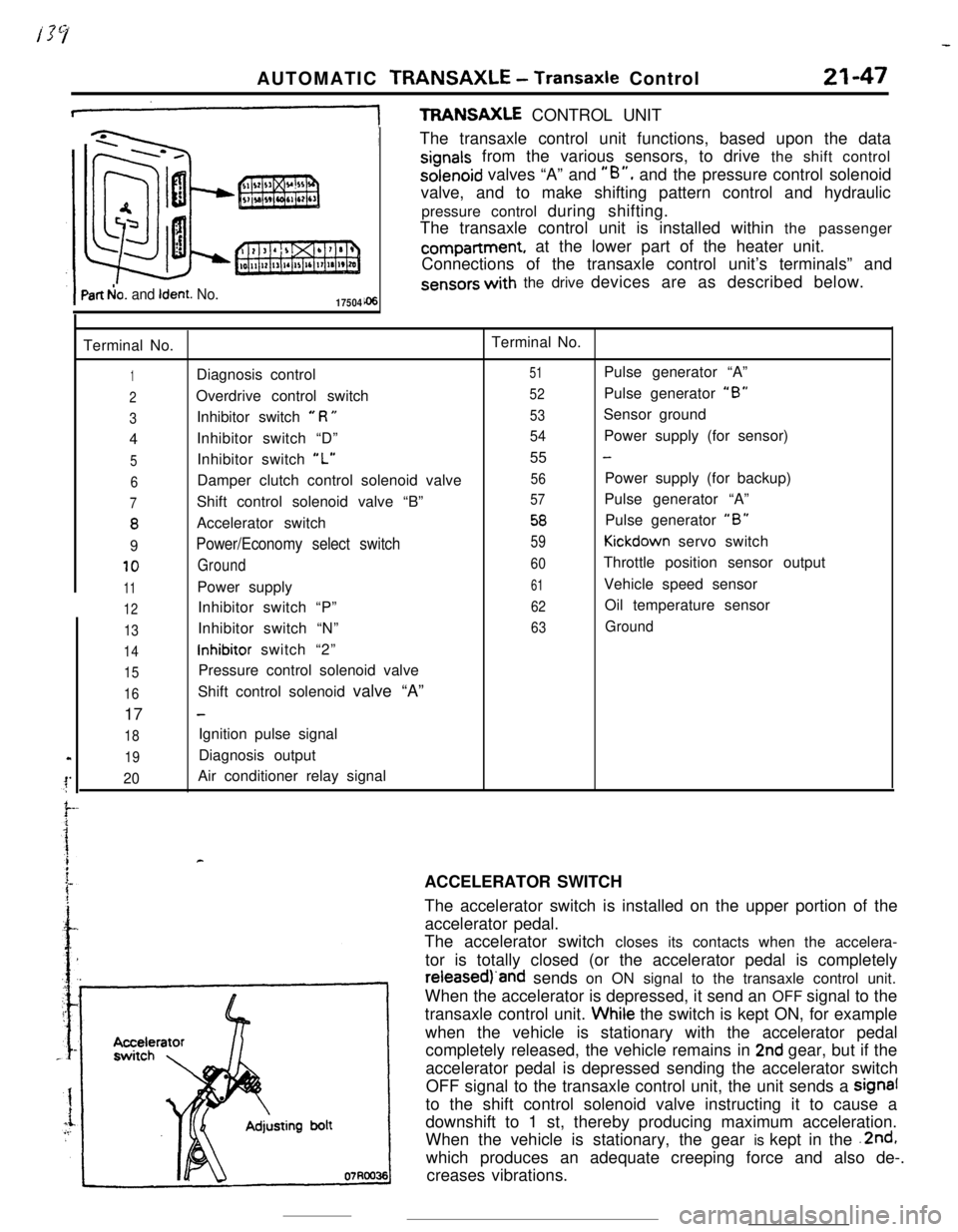

AUTOMATIC TRANSAXLE - Transaxle Control21-47

+TFWNSAXLE CONTROL UNIT

Part b!o. and Ident. No.17504The transaxle control unit functions, based upon the data

signals from the various sensors, to drive the shift controlsolenoid valves “A” and

“B”, and the pressure control solenoid

valve, and to make shifting pattern control and hydraulic

pressure control during shifting.

The transaxle control unit is installed within the passengercompartment, at the lower part of the heater unit.

Connections of the transaxle control unit’s terminals” and

sensors with the drive devices are as described below.

Terminal No.Terminal No.

1Diagnosis control51Pulse generator “A”

2Overdrive control switch52Pulse generator “B”

3Inhibitor switch e R U53Sensor ground

4Inhibitor switch “D”

54Power supply (for sensor)

5Inhibitor switch “L”55 -

6Damper clutch control solenoid valve56Power supply (for backup)

7Shift control solenoid valve “B”57Pulse generator “A”

8Accelerator switch58Pulse generator “B”

9Power/Economy select switch59Kickdown servo switch

10Ground60Throttle position sensor output

11Power supply61Vehicle speed sensor

12Inhibitor switch “P”62Oil temperature sensor

13Inhibitor switch “N”63Ground

14inhibitor switch “2”

15Pressure control solenoid valve

16Shift control solenoid valve “A”

17

-

18Ignition pulse signal

19Diagnosis output

20Air conditioner relay signal

rACCELERATOR SWITCH

The accelerator switch is installed on the upper portion of the

accelerator pedal.

The accelerator switch closes its contacts when the accelera-

tor is totally closed (or the accelerator pedal is completelyreieasedj‘and sends on ON signal to the transaxle control unit.

When the accelerator is depressed, it send an OFF signal to the

transaxle control unit. Whiie the switch is kept ON, for example

when the vehicle is stationary with the accelerator pedal

completely released, the vehicle remains in

2nd gear, but if the

accelerator pedal is depressed sending the accelerator switch

OFF signal to the transaxle control unit, the unit sends a signal

to the shift control solenoid valve instructing it to cause a

downshift to 1 st, thereby producing maximum acceleration.

When the vehicle is stationary, the gear is kept in the .2nd,

which produces an adequate creeping force and also de-.

creases vibrations.

Page 274 of 391

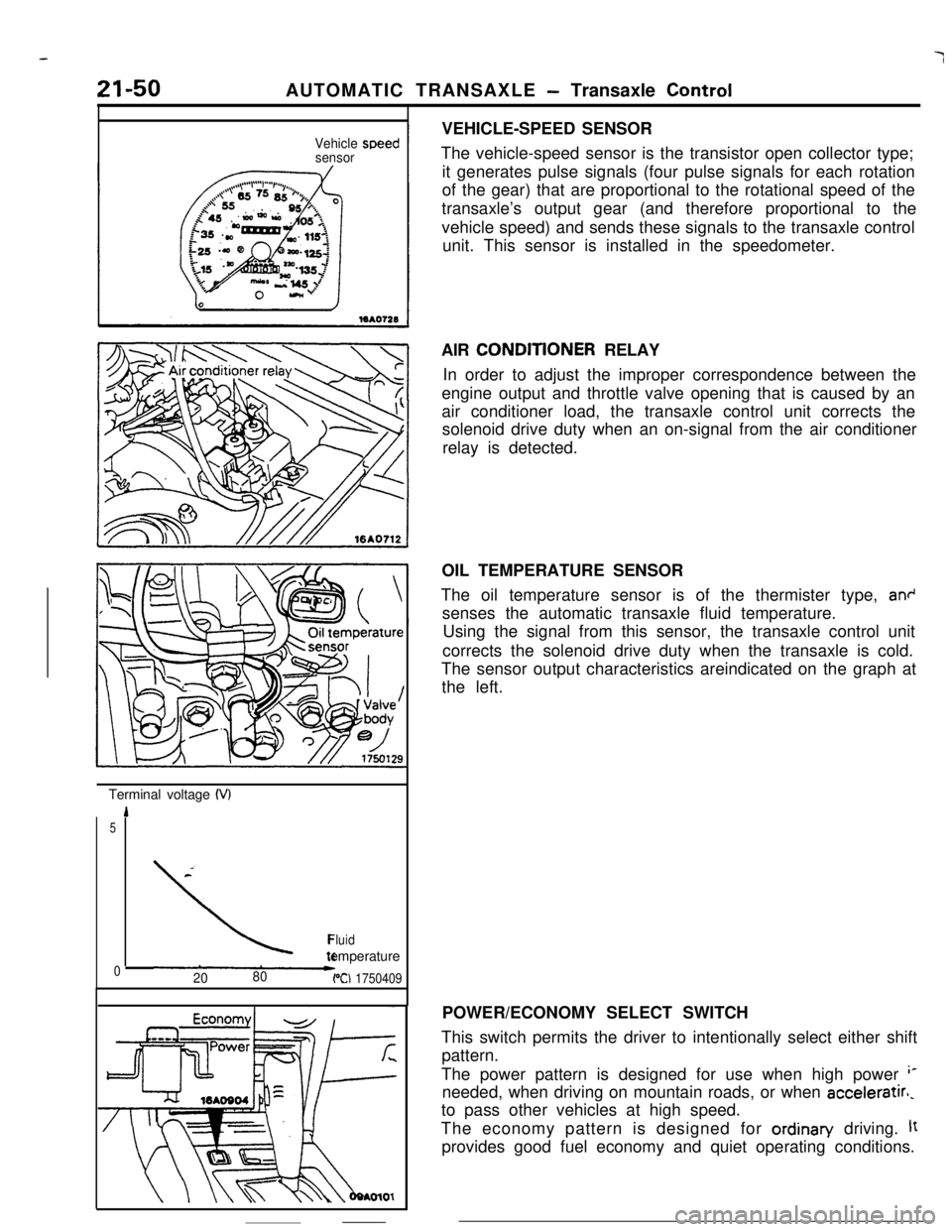

21-50AUTOMATIC TRANSAXLE - Transaxle Control

Vehicle

sensorspeedTerminal voltage

(VI

1

5

\*Fluidtemperature

02080PCI 1750409VEHICLE-SPEED SENSOR

The vehicle-speed sensor is the transistor open collector type;

it generates pulse signals (four pulse signals for each rotation

of the gear) that are proportional to the rotational speed of the

transaxle’s output gear (and therefore proportional to the

vehicle speed) and sends these signals to the transaxle control

unit. This sensor is installed in the speedometer.

AIR CONDlTlONER RELAY

In order to adjust the improper correspondence between the

engine output and throttle valve opening that is caused by an

air conditioner load, the transaxle control unit corrects the

solenoid drive duty when an on-signal from the air conditioner

relay is detected.

OIL TEMPERATURE SENSOR

The oil temperature sensor is of the thermister type,

an+senses the automatic transaxle fluid temperature.

Using the signal from this sensor, the transaxle control unit

corrects the solenoid drive duty when the transaxle is cold.

The sensor output characteristics areindicated on the graph at

the left.

POWER/ECONOMY SELECT SWITCH

This switch permits the driver to intentionally select either shift

pattern.

The power pattern is designed for use when high power

‘*needed, when driving on mountain roads, or when acceleratirl,

to pass other vehicles at high speed.

The economy pattern is designed for ordinan/ driving.

ltprovides good fuel economy and quiet operating conditions.

Page 337 of 391

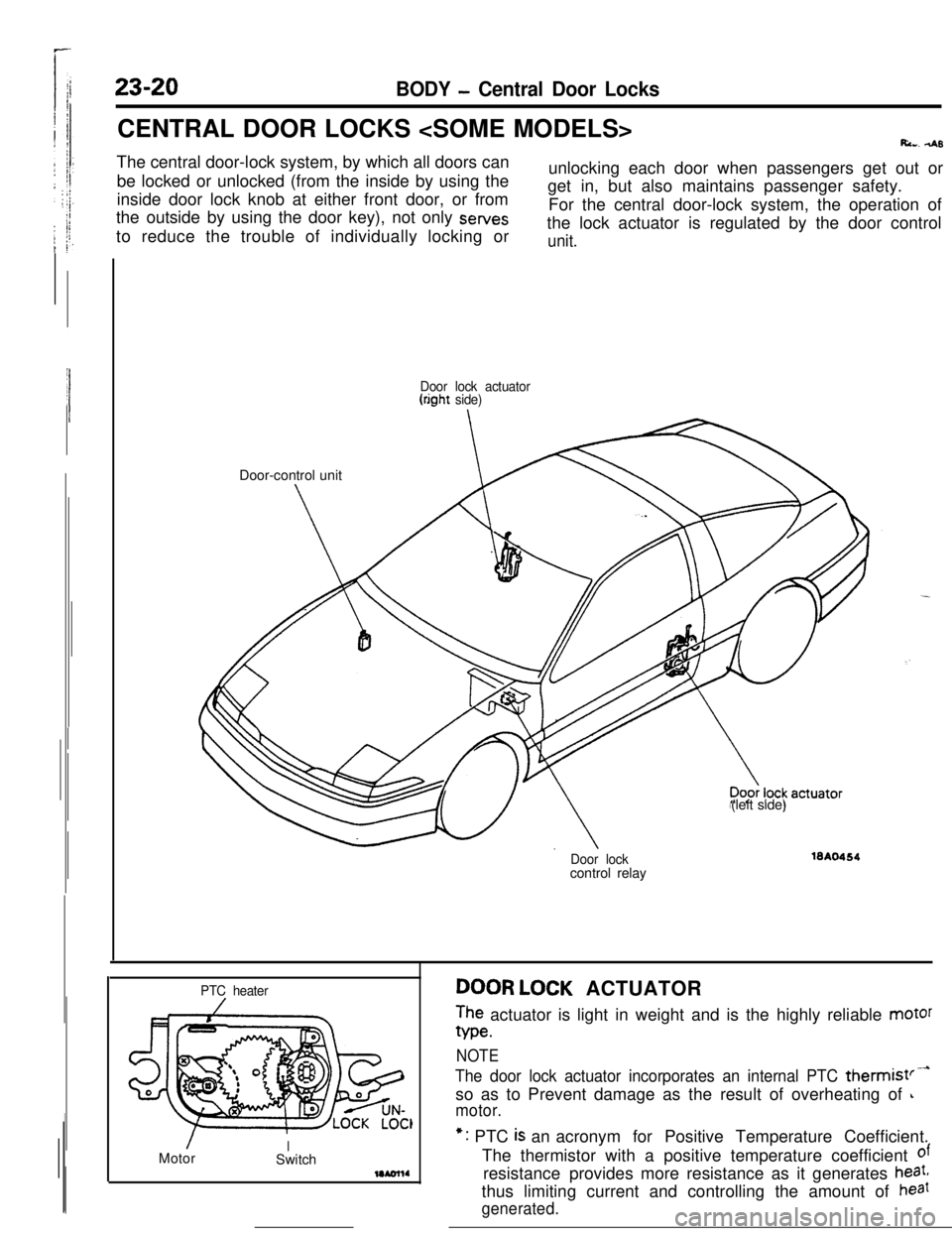

23-20BODY - Central Door LocksCENTRAL DOOR LOCKS

Ri... 4sThe central door-lock system, by which all doors can

be locked or unlocked (from the inside by using the

inside door lock knob at either front door, or from

the outside by using the door key), not only sewes

to reduce the trouble of individually locking orunlocking each door when passengers get out or

get in, but also maintains passenger safety.

For the central door-lock system, the operation of

the lock actuator is regulated by the door control

unit.

Door lock actuator(right side)Door-control unit

(left side)

Door lockcontrol relay16A0464

PTC heater

/MotorISwitchDOOR LOCK ACTUATOR

The actuator is light in weight and is the highly reliable motor

We.

NOTE

The door lock actuator incorporates an internal PTC thermist’-so as to Prevent damage as the result of overheating of

L

motor.*: PTC

is an acronym for Positive Temperature Coefficient.

The thermistor with a positive temperature coefficient

ofresistance provides more resistance as it generates

heat,thus limiting current and controlling the amount of

haat

generated.

Page 338 of 391

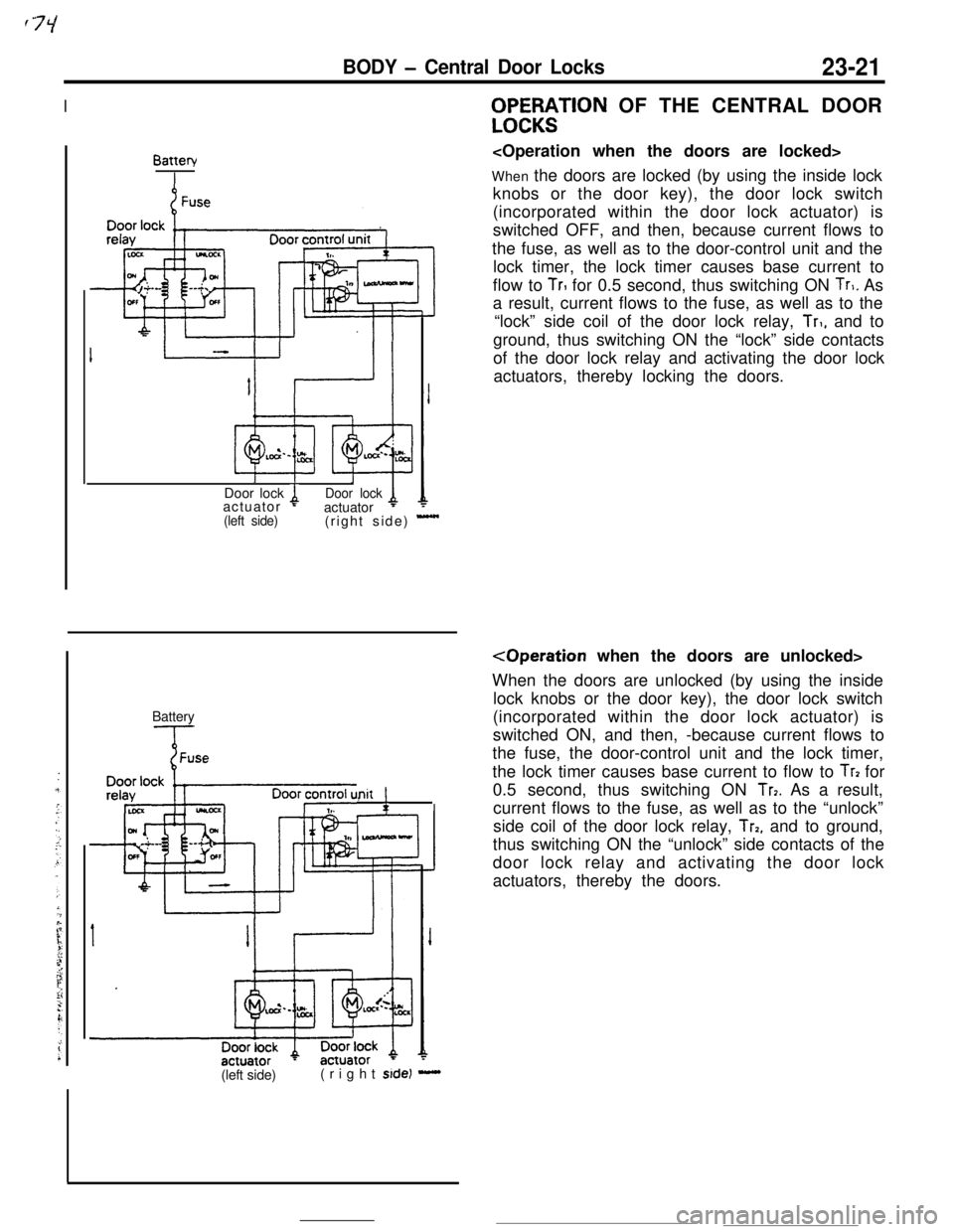

BODY - Central Door Locks23-21

IBattery

1IJDoor lock 4Door lockactuator t(left side)actuator

(right side) -Battery

Init !,WF%;$TlON OF THE CENTRAL DOOR

When the doors are locked (by using the inside lock

knobs or the door key), the door lock switch

(incorporated within the door lock actuator) is

switched OFF, and then, because current flows to

the fuse, as well as to the door-control unit and the

lock timer, the lock timer causes base current to

flow to

TrI for 0.5 second, thus switching ON Tr,. As

a result, current flows to the fuse, as well as to the

“lock” side coil of the door lock relay,

Tr,, and to

ground, thus switching ON the “lock” side contacts

of the door lock relay and activating the door lock

actuators, thereby locking the doors.

When the doors are unlocked (by using the inside

lock knobs or the door key), the door lock switch

(incorporated within the door lock actuator) is

switched ON, and then, -because current flows to

the fuse, the door-control unit and the lock timer,

the lock timer causes base current to flow to

Tr? for

0.5 second, thus switching ON

Tr7. As a result,

current flows to the fuse, as well as to the “unlock”

side coil of the door lock relay,

Trp, and to ground,

thus switching ON the “unlock” side contacts of the

door lock relay and activating the door lock

actuators, thereby the doors.

(left side)(right

side) -

Page 348 of 391

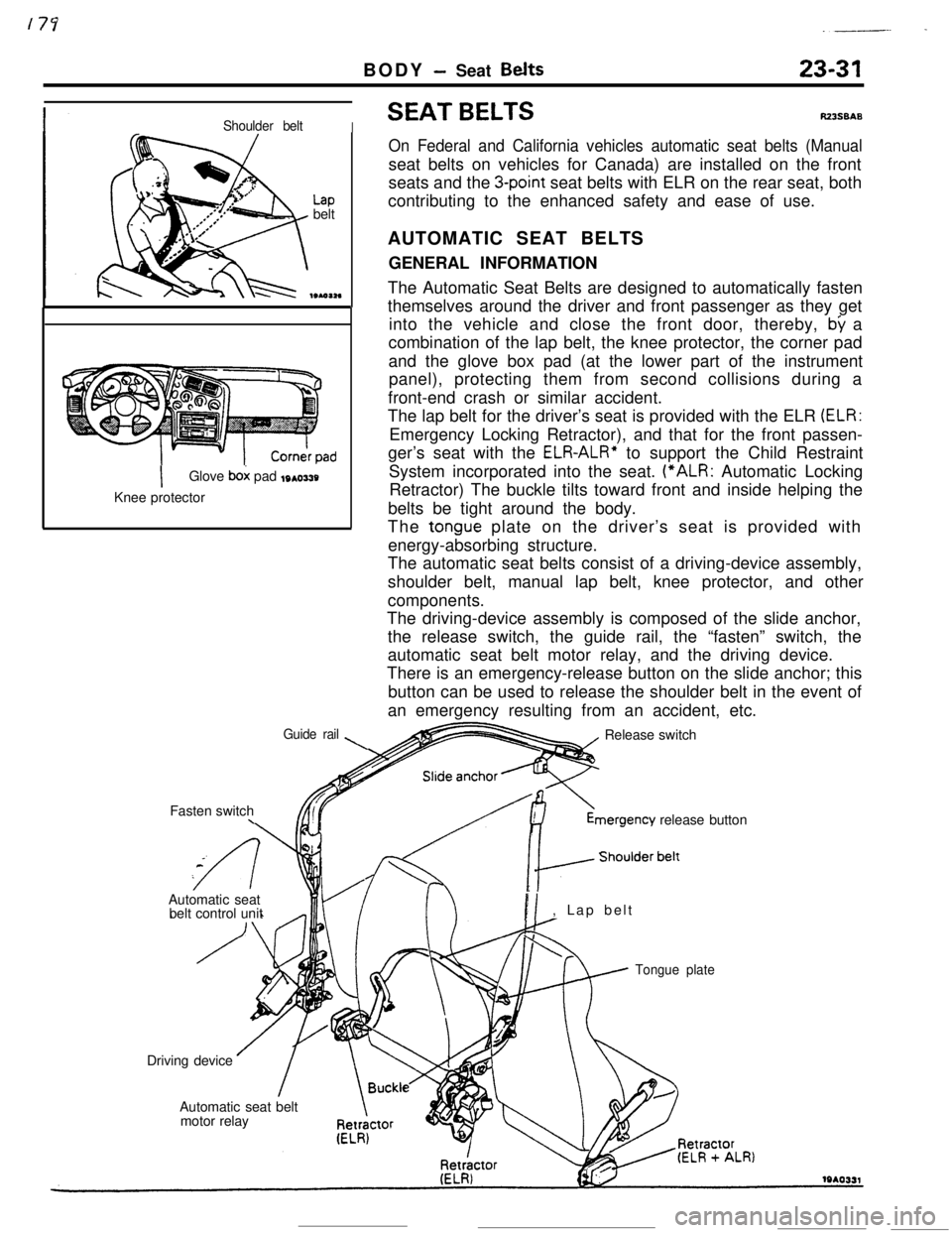

BODY - Seat Belts

._-- -

23-31

Shoulder beltI

Lapbelt

IGlove box pad toasty

Knee protector

Guide rail\Fasten switch

\

SEAT BELTSRZ3SBAS

On Federal and California vehicles automatic seat belts (Manualseat belts on vehicles for Canada) are installed on the front

seats and the

3-point seat belts with ELR on the rear seat, both

contributing to the enhanced safety and ease of use.

AUTOMATIC SEAT BELTS

GENERAL INFORMATION

The Automatic Seat Belts are designed to automatically fasten

themselves around the driver and front passenger as they get

into the vehicle and close the front door, thereby,

by a

combination of the lap belt, the knee protector, the corner pad

and the glove box pad (at the lower part of the instrument

panel), protecting them from second collisions during a

front-end crash or similar accident.

The lap belt for the driver’s seat is provided with the ELR

(ELR:Emergency Locking Retractor), and that for the front passen-

ger’s seat with the

ELR-ALR” to support the Child Restraint

System incorporated into the seat. (“ALR: Automatic Locking

Retractor) The buckle tilts toward front and inside helping the

belts be tight around the body.

The

tongue plate on the driver’s seat is provided with

energy-absorbing structure.

The automatic seat belts consist of a driving-device assembly,

shoulder belt, manual lap belt, knee protector, and other

components.

The driving-device assembly is composed of the slide anchor,

the release switch, the guide rail, the “fasten” switch, the

automatic seat belt motor relay, and the driving device.

There is an emergency-release button on the slide anchor; this

button can be used to release the shoulder belt in the event of

an emergency resulting from an accident, etc.

Release switchmergency

release button

Automatic seat

belt control unit

PI, Lap belt

Tongue plateDriving device

Automatic seat belt

motor relay