engine oil MITSUBISHI ECLIPSE 1990 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 8 of 391

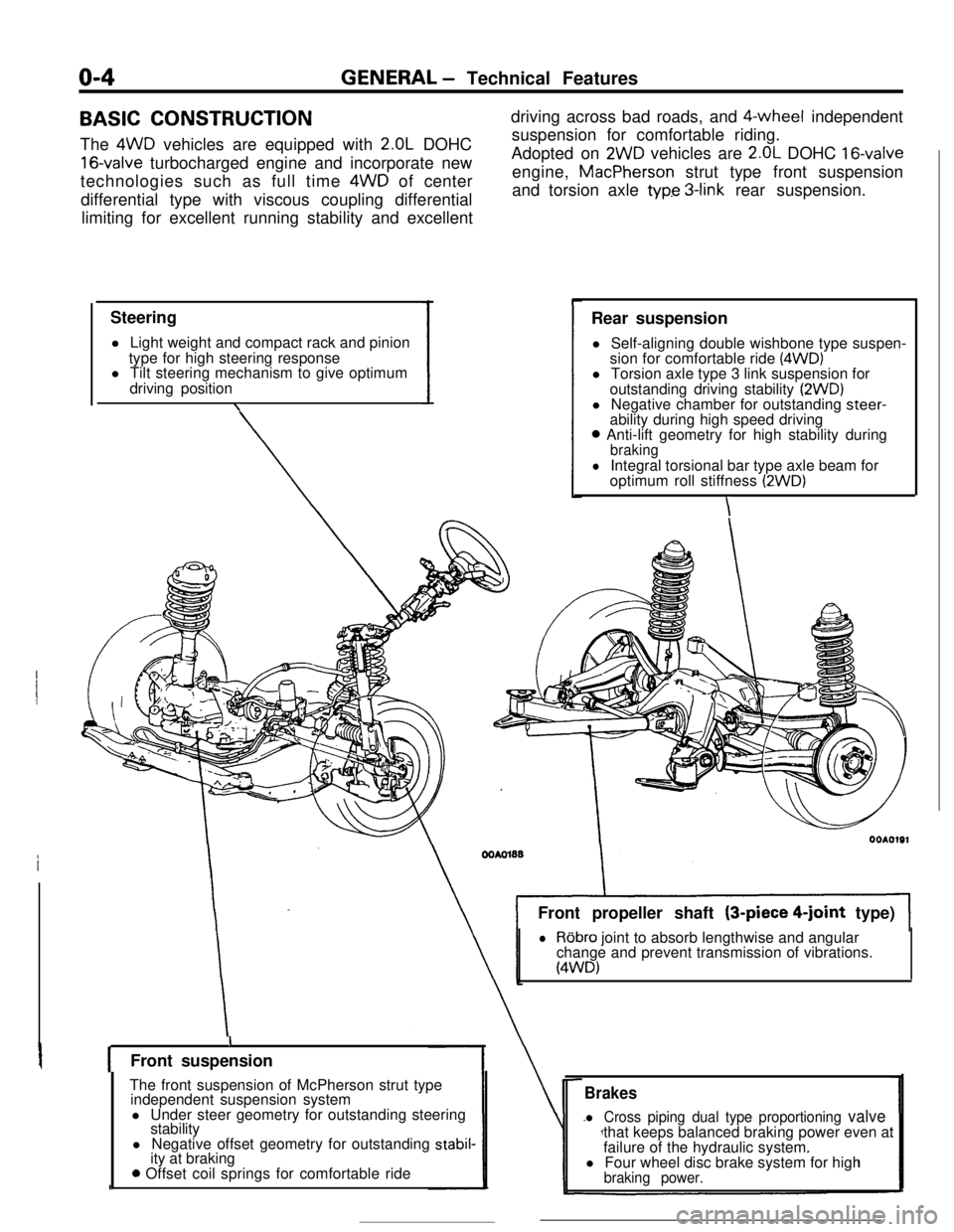

o-4GENERAL - Technical Features

BASIC CONSTRUCTION

The 4WD vehicles are equipped with

2.OL DOHC

16-valve turbocharged engine and incorporate new

technologies such as full time 4WD of center

differential type with viscous coupling differential

limiting for excellent running stability and excellent

Steering

l Light weight and compact rack and pinion

type for high steering response

l Tilt steering mechanism to give optimum

driving position

\driving across bad roads, and $-wheel independent

suspension for comfortable riding.

Adopted on

2WD vehicles are 2.OL DOHC 16-valveengine, MacPherson strut type front suspension

and torsion axle

typ.e 3-link rear suspension.

Rear suspension

l Self-aligning double wishbone type suspen-

sion for comfortable ride

(4WD)l Torsion axle type 3 link suspension for

outstanding driving stability

(2WD)l Negative chamber for outstanding steer-

ability during high speed driving

0 Anti-lift geometry for high stability duringbraking

lIntegral torsional bar type axle beam for

optimum roll stiffness (2WD)

\Front propeller shaft (3-piece

4-joint type)

lRobro joint to absorb lengthwise and angular

change and prevent transmission of vibrations.

(4WD)

IFront suspension

The front suspension of McPherson strut type

independent suspension system

l Under steer geometry for outstanding steering

stability

l Negative offset geometry for outstanding

stabil-ity at braking

0 Offset coil springs for comfortable ride

Brakes

l Cross piping dual type proportioning valvethat keeps balanced braking power even at

failure of the hydraulic system.

l Four wheel disc brake system for high

braking power.

Page 9 of 391

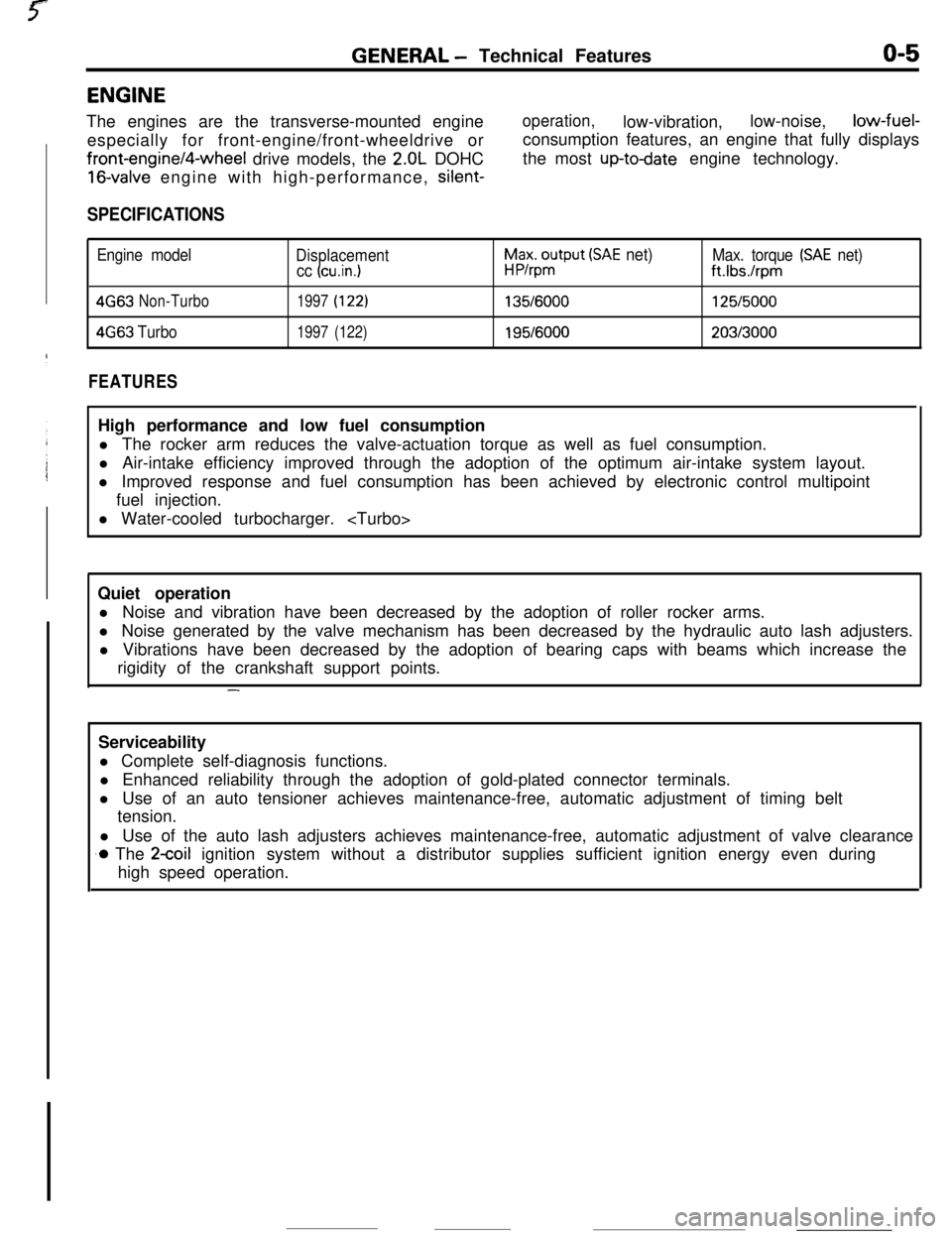

GENERAL - Technical Featureso-5ENGINE

The engines are the transverse-mounted engine

especially for front-engine/front-wheeldrive orfront-engine/4-wheel drive models, the

2.OL DOHC

16-valve engine with high-performance, silent-

operation,low-vibration,low-noise,low-fuel-

consumption features, an engine that fully displays

the most

up-todate engine technology.

SPECIFICATIONS

Engine model

Displacement

cc (cu.in.1

h$xo$put (SAE net)Max. torque (SAE net)

ft.Ibs./rpm

4G63Non-Turbo1997(122)135/6000125/5000

4663Turbo1997(122)195/6000203/3000

FEATURESHigh performance and low fuel consumption

l The rocker arm reduces the valve-actuation torque as well as fuel consumption.

l Air-intake efficiency improved through the adoption of the optimum air-intake system layout.

l Improved response and fuel consumption has been achieved by electronic control multipoint

fuel injection.

l Water-cooled turbocharger.

Quiet operation

l Noise and vibration have been decreased by the adoption of roller rocker arms.

l Noise generated by the valve mechanism has been decreased by the hydraulic auto lash adjusters.

l Vibrations have been decreased by the adoption of bearing caps with beams which increase the

rigidity of the crankshaft support points.

-Serviceability

l Complete self-diagnosis functions.

l Enhanced reliability through the adoption of gold-plated connector terminals.

l Use of an auto tensioner achieves maintenance-free, automatic adjustment of timing belt

tension.

l Use of the auto lash adjusters achieves maintenance-free, automatic adjustment of valve clearance

.o The 2coil ignition system without a distributor supplies sufficient ignition energy even during

high speed operation.

Page 46 of 391

-. ..- ,..__ _. I-., . . . . -. . “-Ix.. ...~‘,.;;&;,-*~;

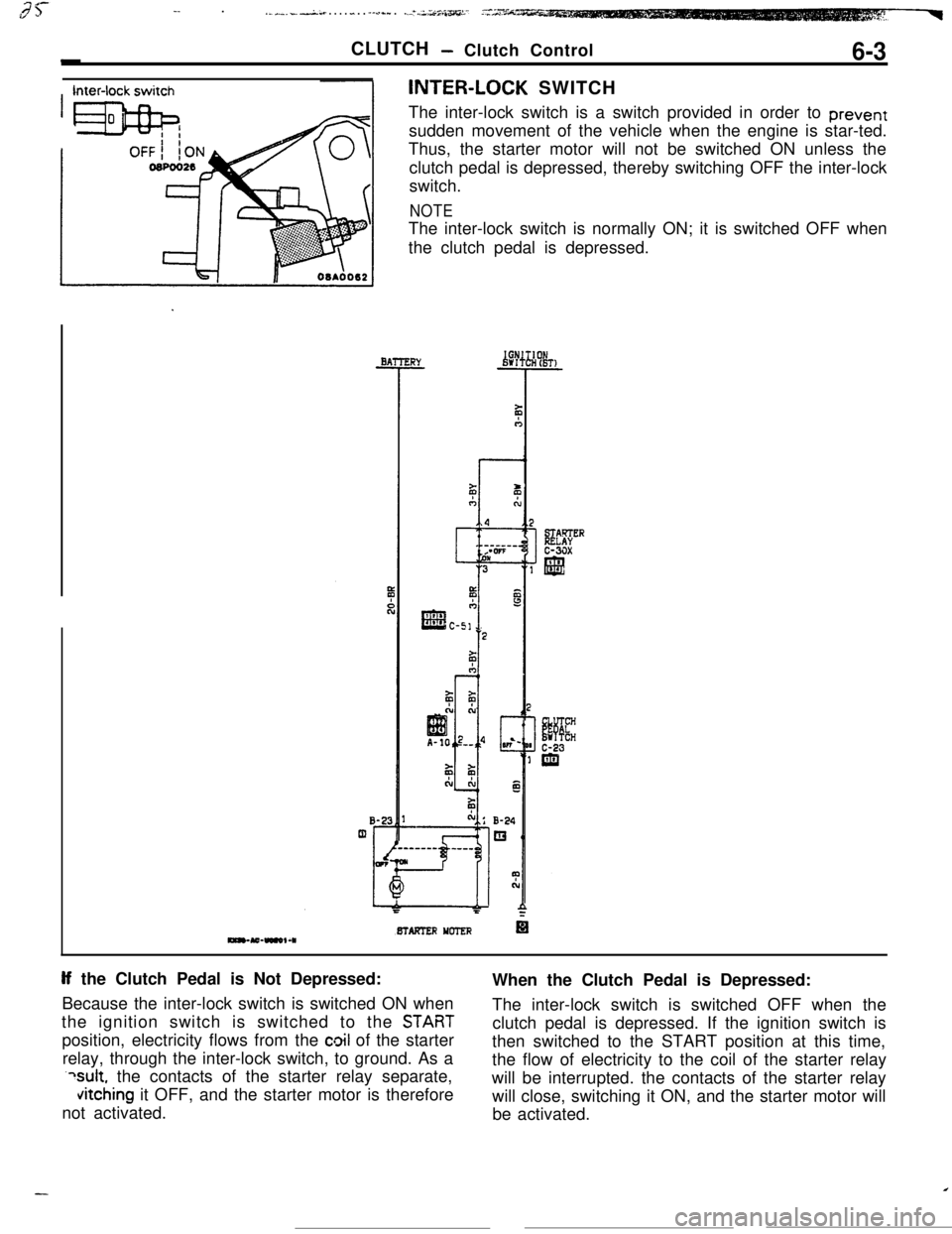

CLUTCH- Clutch Control6-3

-

Inter-lock switchINTER-LOCK SWITCH

The inter-lock switch is a switch provided in order to prevent

sudden movement of the vehicle when the engine is star-ted.

BTAFTER YCTER

If the Clutch Pedal is Not Depressed:

Because the inter-lock switch is switched ON when

STABT

position, electricity flows from the cloil of the starter

relay, through the inter-lock switch, to ground. As a

?sult, the contacts of the starter relay separate,

vitching it OFF, and the starter motor is therefore

not activated.

Page 77 of 391

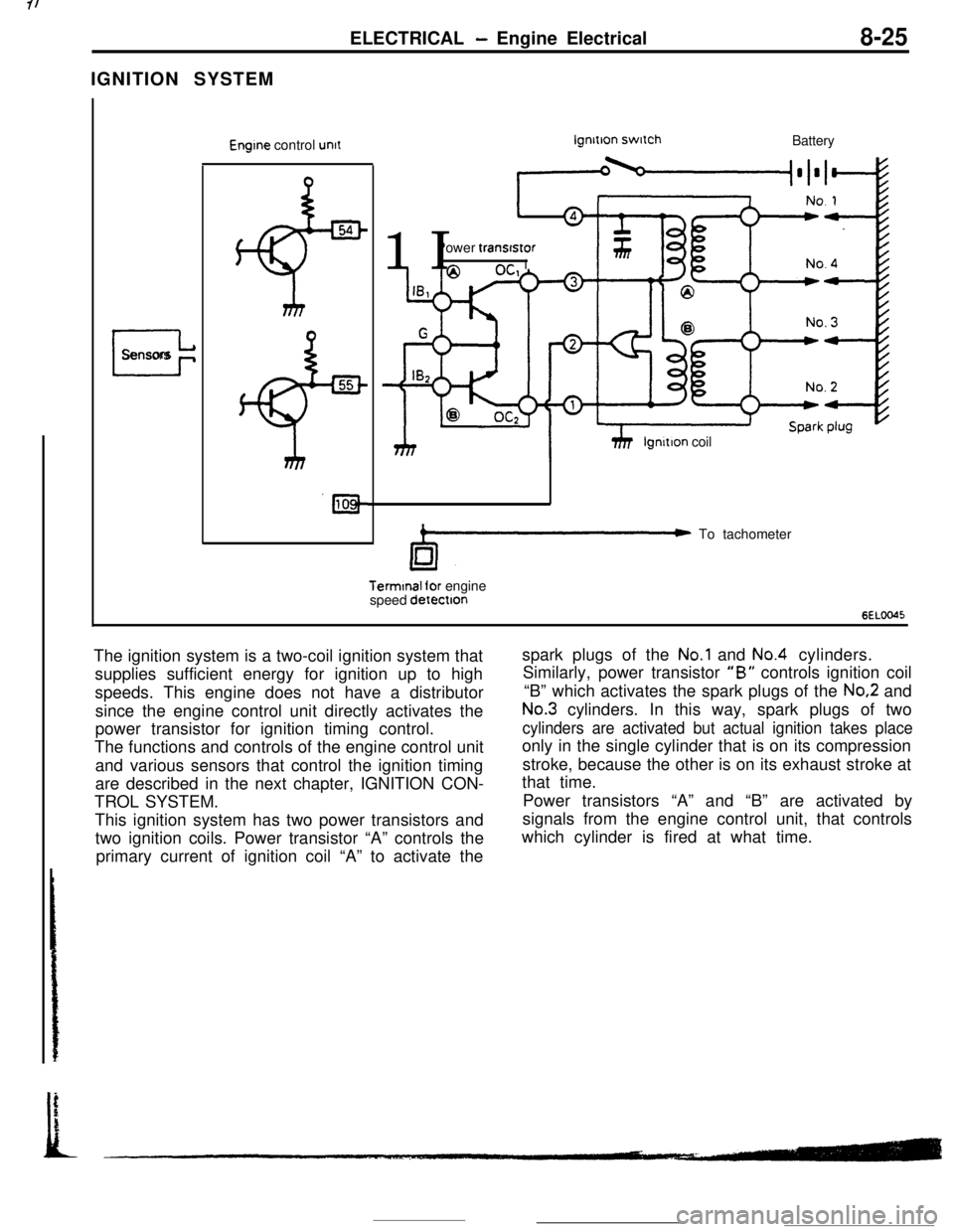

IGNITION SYSTEMELECTRICAL - Engine Electrical8-25

I

Sensors

Engine control unitlgnltlon switch

Battery

11 IPower transfstor

hhP 1

Ilgnltion coil

C To tachometerTerminal for engine

speed detectton

6ELOO45The ignition system is a two-coil ignition system that

supplies sufficient energy for ignition up to high

speeds. This engine does not have a distributor

since the engine control unit directly activates the

power transistor for ignition timing control.

The functions and controls of the engine control unit

and various sensors that control the ignition timing

are described in the next chapter, IGNITION CON-

TROL SYSTEM.

This ignition system has two power transistors and

two ignition coils. Power transistor “A” controls the

primary current of ignition coil “A” to activate thespark plugs of the

No.1 and No.4 cylinders.

Similarly, power transistor

“B” controls ignition coil

“B” which activates the spark plugs of the

No.2 and

No.3 cylinders. In this way, spark plugs of two

cylinders are activated but actual ignition takes placeonly in the single cylinder that is on its compression

stroke, because the other is on its exhaust stroke at

that time.

Power transistors “A” and “B” are activated by

signals from the engine control unit, that controls

which cylinder is fired at what time.

Page 78 of 391

8-26ELECTRICAL - Engine Electrical

No.:

4Signal unit for

, tachometer

71

x

No. 3

6EL0025

Capa &orCylinderNo. mark

6EL0057

To No. 1spark plug

To No. 4

spark plug

To No. 3spark plug

To No. 2spark plug

6EL005t

OC,IB, G

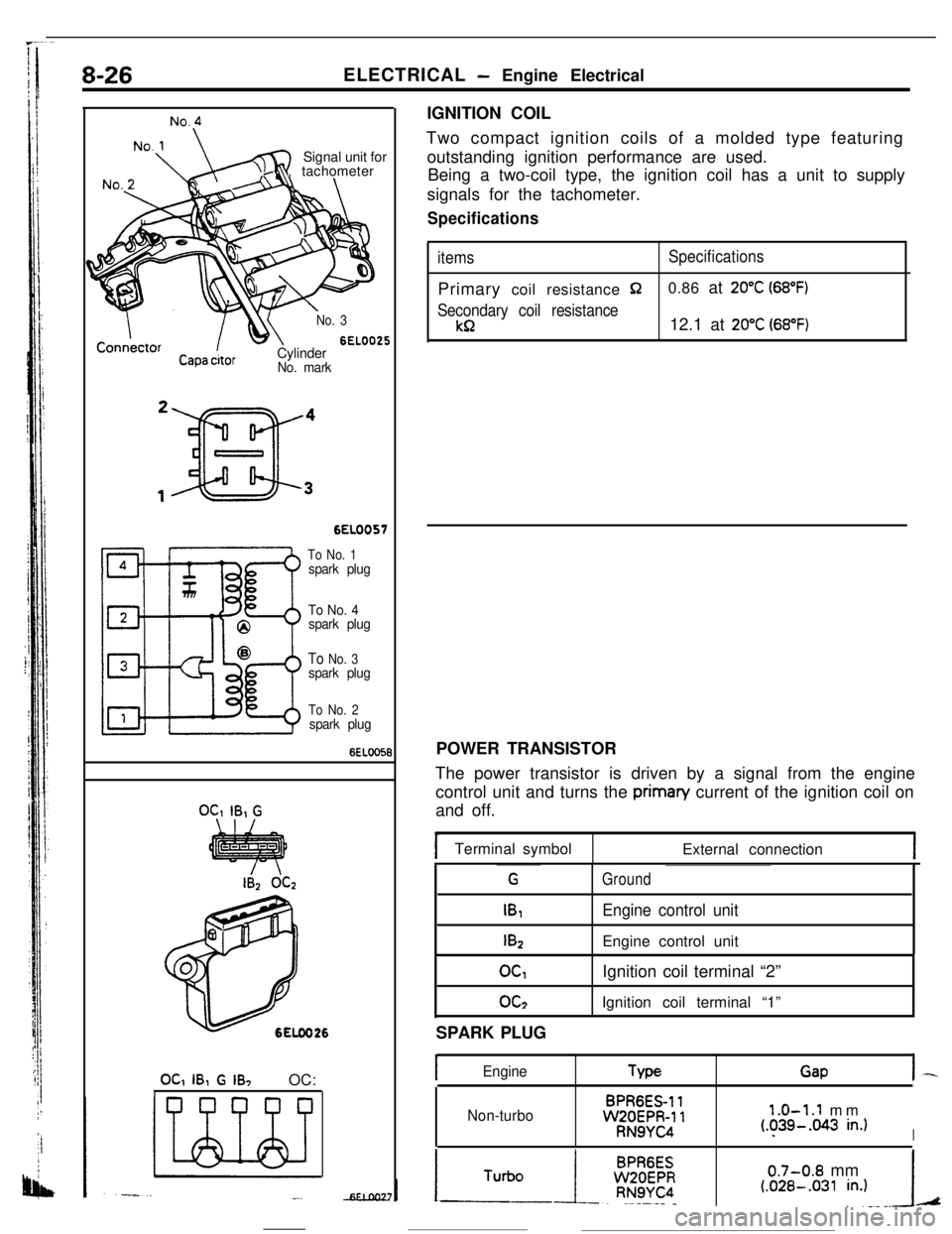

OC, IB, G IB, OC:IGNITION COIL

Two compact ignition coils of a molded type featuring

outstanding ignition performance are used.

Being a two-coil type, the ignition coil has a unit to supply

signals for the tachometer.

Specifications

itemsSpecificationsPrimary coil resistance

$20.86 at 20°C (68°F)

Secondary coil resistance

kR12.1 at 20°C (68°F)POWER TRANSISTOR

The power transistor is driven by a signal from the engine

control unit and turns the priman/ current of the ignition coil on

and off.

Terminal symbol

External connection

G

IB,

I&

Ground

Engine control unitEngine control unit

OGoc2Ignition coil terminal “2”

Ignition coil terminal “1”

SPARK PLUG

IEngineTypeGapI-

Non-turboBPR6ES-11WZOEPR-11RN9YC4

1.0-1.1 mm(.?39-.043 in.)I

0.7-0.8 mm(.OZB-.031 in.)A

Page 79 of 391

-----. _-- ___ELECTRICAL

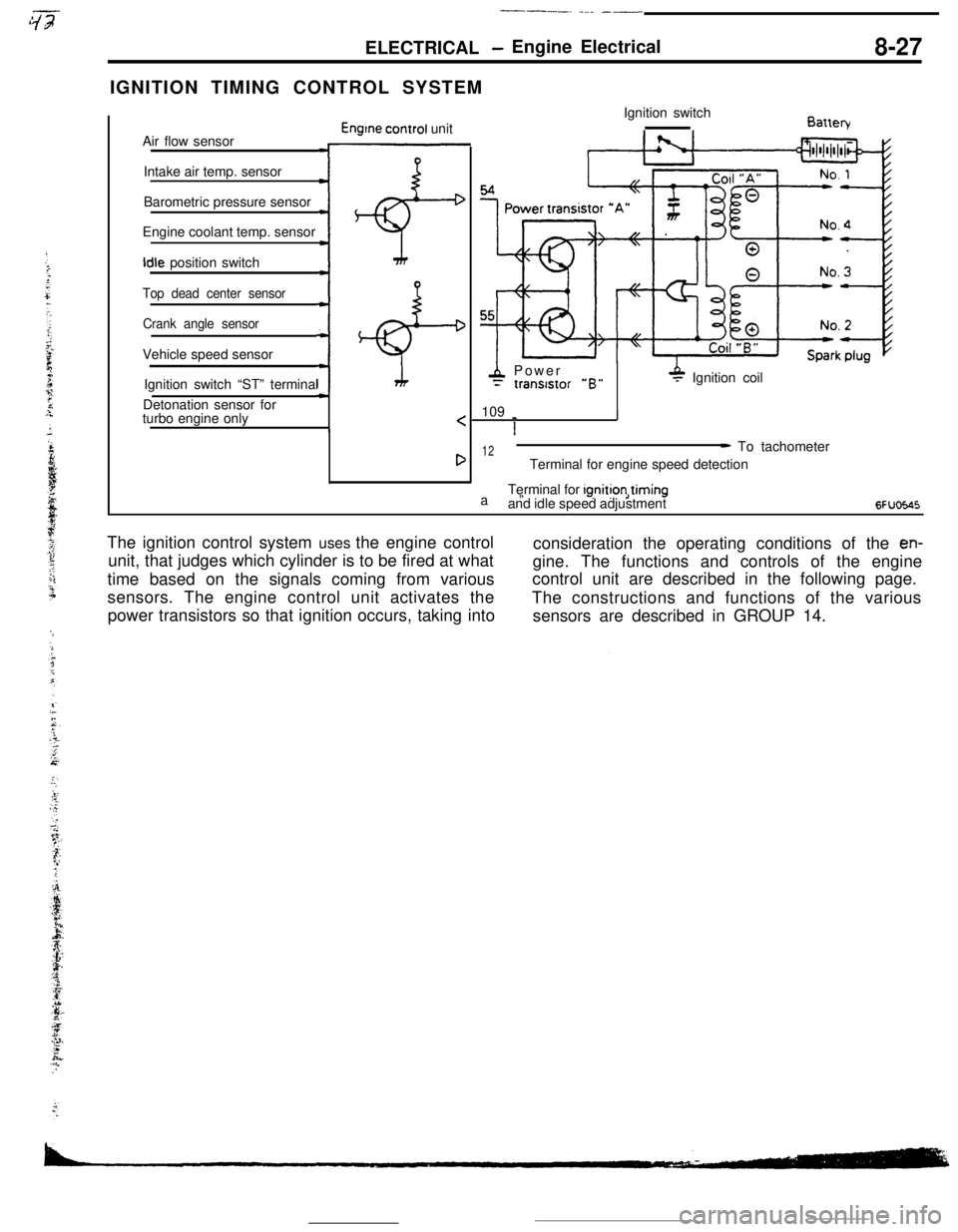

- Engine Electrical8-27IGNITION TIMING CONTROL SYSTEM

Air flow sensor

Engtne control unit

Intake air temp. sensor

Barometric pressure sensor

Engine coolant temp. sensorIdle position switch

:+

Top dead center sensor

Crank angle sensorVehicle speed sensor

;+Ignition switch “ST” terminal

Detonation sensor for

turbo engine only

4 Power= tranststor “B”P Ignition coil

109

_

I

1

12a”- To tachometer

Terminal for engine speed detection

Terminal for ignition,timing

and idle speed adjustment

6FUoE.45The ignition control system uses the engine control

consideration the operating conditions of the

en-unit, that judges which cylinder is to be fired at what

gine. The functions and controls of the engine

time based on the signals coming from variouscontrol unit are described in the following page.

sensors. The engine control unit activates the

The constructions and functions of the various

power transistors so that ignition occurs, taking into

sensors are described in GROUP 14.

Page 80 of 391

8-28ELECTRICAL- Engine Electrical

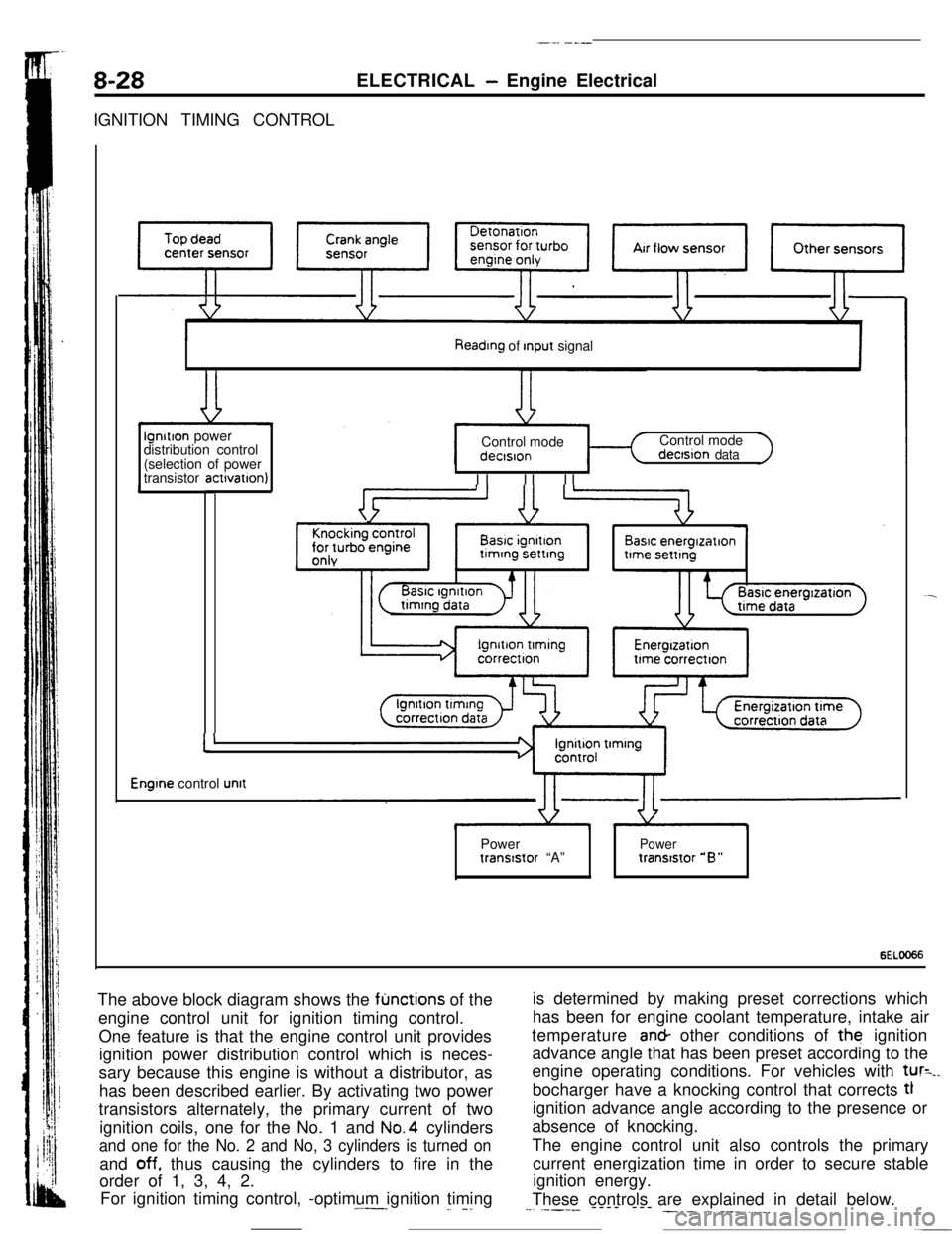

IGNITION TIMING CONTROL

Reading of Input signallgnitlon power

distribution control

(selection of power

transistor actlvatlon)Control mode

I II II IControl mode

dectsion data

Basic energlzatlon

I’

Engine control unitPower

Powertranststor “A”tranststor “B”

6ELOO66The above block diagram shows the

fljnctions of the

engine control unit for ignition timing control.

One feature is that the engine control unit provides

ignition power distribution control which is neces-

sary because this engine is without a distributor, as

has been described earlier. By activating two power

transistors alternately, the primary current of two

ignition coils, one for the No. 1 and No.4 cylinders

and one for the No. 2 and No, 3 cylinders is turned onand

off. thus causing the cylinders to fire in the

order of 1, 3, 4, 2.

For ignition timing control, -optimum ignition timing.^--_

_. -.is determined by making preset corrections which

has been for engine coolant temperature, intake air

temperature an& other conditions of the ignition

advance angle that has been preset according to the

engine operating conditions. For vehicles with

tur=_.bocharger have a knocking control that corrects tl

ignition advance angle according to the presence or

absence of knocking.

The engine control unit also controls the primary

current energization time in order to secure stable

ignition energy.

These controls are explained in detail below.

--. .----- ---- --- ___. .-. ___.,.__

Page 82 of 391

8-30ELECTRICAL - Engine Electrical

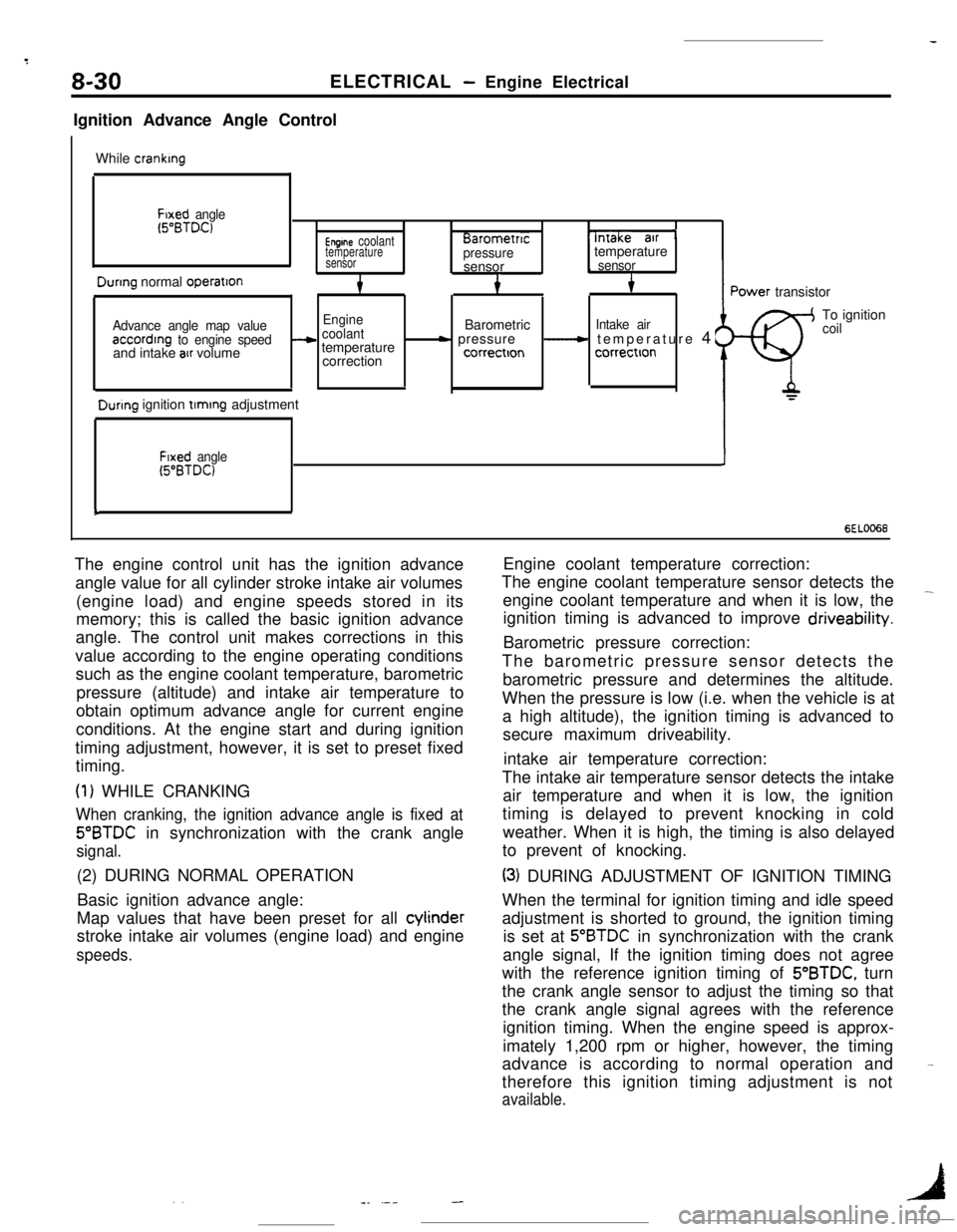

Ignition Advance Angle Control

While

cranking

Fixed angle(5”BTD.C)Engme coolantBarometnc‘-Intake air 1temperaturepressuretemperaturesensorsensor, sensor

Dunng normal operatlon4i+

Advance angle map valueEngine

coolantBarometricIntake airaccording to engine speed4and intake air volumetemperature- pressure__c temperature 4

correctioncorrectloncorrectton

Durtng ignition tlmmg adjustment

Fixed angle(5”BTDC)

c

=ower transistor

-$To ignition

coil

s

6EL0066The engine control unit has the ignition advance

angle value for all cylinder stroke intake air volumes

(engine load) and engine speeds stored in its

memory; this is called the basic ignition advance

angle. The control unit makes corrections in this

value according to the engine operating conditions

such as the engine coolant temperature, barometric

pressure (altitude) and intake air temperature to

obtain optimum advance angle for current engine

conditions. At the engine start and during ignition

timing adjustment, however, it is set to preset fixed

timing.

(1) WHILE CRANKING

When cranking, the ignition advance angle is fixed at

5”BTDC in synchronization with the crank angle

signal.(2) DURING NORMAL OPERATION

Basic ignition advance angle:

Map values that have been preset for all cylinder

stroke intake air volumes (engine load) and engine

speeds.Engine coolant temperature correction:

The engine coolant temperature sensor detects the

engine coolant temperature and when it is low, the

-ignition timing is advanced to improve driveability.

Barometric pressure correction:

The barometric pressure sensor detects the

barometric pressure and determines the altitude.

When the pressure is low (i.e. when the vehicle is at

a high altitude), the ignition timing is advanced to

secure maximum driveability.

intake air temperature correction:

The intake air temperature sensor detects the intake

air temperature and when it is low, the ignition

timing is delayed to prevent knocking in cold

weather. When it is high, the timing is also delayed

to prevent of knocking.

(3) DURING ADJUSTMENT OF IGNITION TIMING

When the terminal for ignition timing and idle speed

adjustment is shorted to ground, the ignition timing

is set at

5”BTDC in synchronization with the crank

angle signal, If the ignition timing does not agree

with the reference ignition timing of 5’BTDC, turn

the crank angle sensor to adjust the timing so that

the crank angle signal agrees with the reference

ignition timing. When the engine speed is approx-

imately 1,200 rpm or higher, however, the timing

advance is according to normal operation and

therefore this ignition timing adjustment is not

available.

-

. .1-_ .---

Page 83 of 391

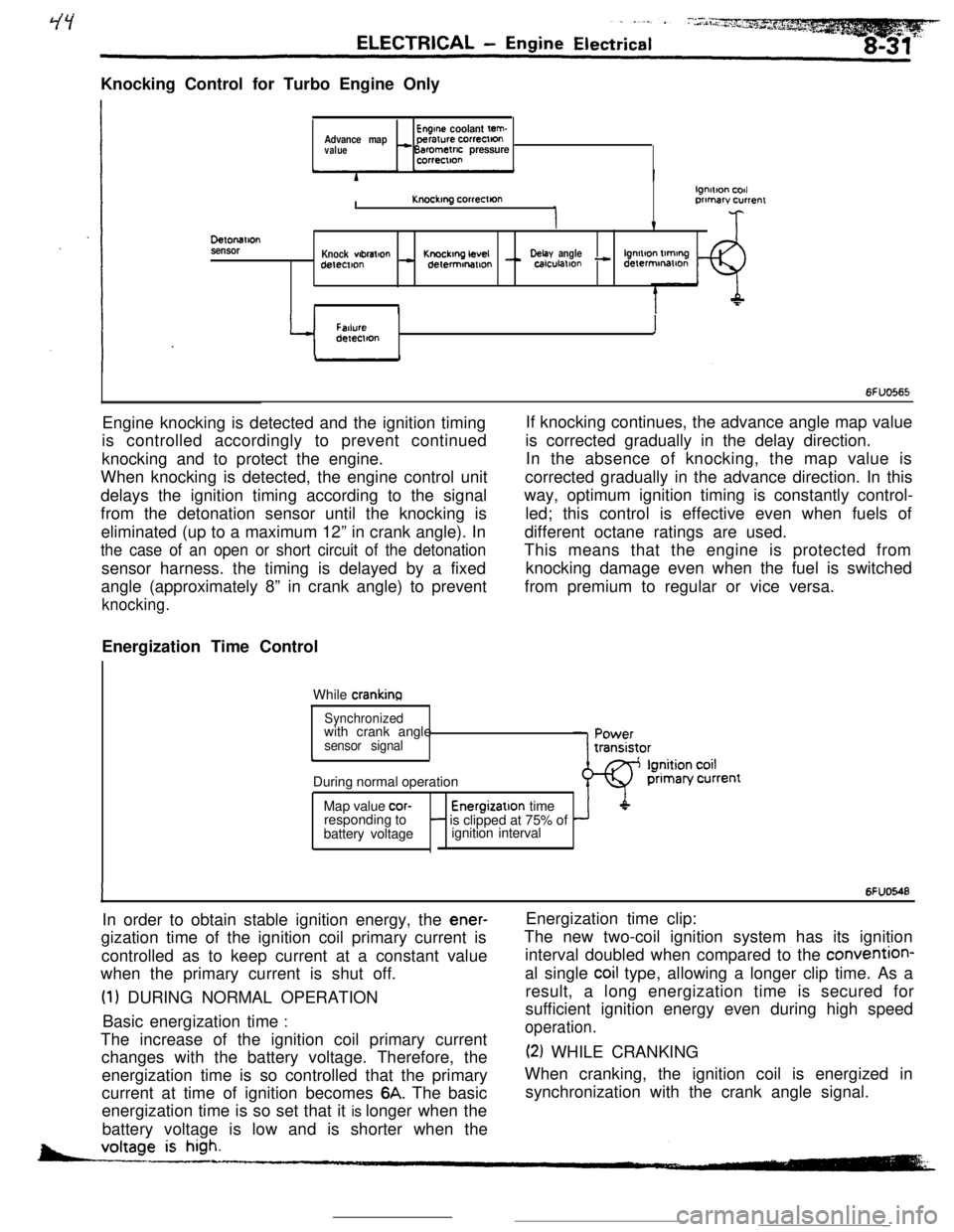

Knocking Control for Turbo Engine OnlyEngine coolant tern.Advance mapperarure correctton

value- Barometric pressurecorrectton

DelonaIlon

sensorI

lgnmon codKnockmg correcllonprimary currenr

v

Knock wbral+onKnockmg LevelDelay anglelgnmon tlmtngdetemon- delermonmon - calculallon - derermmatlon

II

Y

FatlureIdeIeclton

6FUO565Engine knocking is detected and the ignition timing

is controlled accordingly to prevent continued

knocking and to protect the engine.

When knocking is detected, the engine control unit

delays the ignition timing according to the signal

from the detonation sensor until the knocking is

eliminated (up to a maximum 12” in crank angle). In

the case of an open or short circuit of the detonationsensor harness. the timing is delayed by a fixed

angle (approximately 8” in crank angle) to prevent

knocking.Energization Time Control

While

crankinaIf knocking continues, the advance angle map value

is corrected gradually in the delay direction.

In the absence of knocking, the map value is

corrected gradually in the advance direction. In this

way, optimum ignition timing is constantly control-

led; this control is effective even when fuels of

different octane ratings are used.

This means that the engine is protected from

knocking damage even when the fuel is switched

from premium to regular or vice versa.

Synchronizedwith crank angle

sensor signalcDuring normal operation

Map value

cor-Energizatlon time

responding to- is clipped at 75% of

battery voltageignition interval

IIn order to obtain stable ignition energy, the

ener-gization time of the ignition coil primary current is

controlled as to keep current at a constant value

when the primary current is shut off.

(1) DURING NORMAL OPERATION

Basic energization time

:The increase of the ignition coil primary current

changes with the battery voltage. Therefore, the

energization time is so controlled that the primary

current at time of ignition becomes

6A. The basic

energization time is so set that it is longer when the

battery voltage is low and is shorter when the

6FUO548Energization time clip:

The new two-coil ignition system has its ignition

interval doubled when compared to the convention-

al single

coil type, allowing a longer clip time. As a

result, a long energization time is secured for

sufficient ignition energy even during high speed

operation.

(2) WHILE CRANKING

When cranking, the ignition coil is energized in

synchronization with the crank angle signal.

-

Page 87 of 391

=--Y

jl

1 /

i "

_. ---“._ _ _ ._ ..-..+_LI_y_--- -

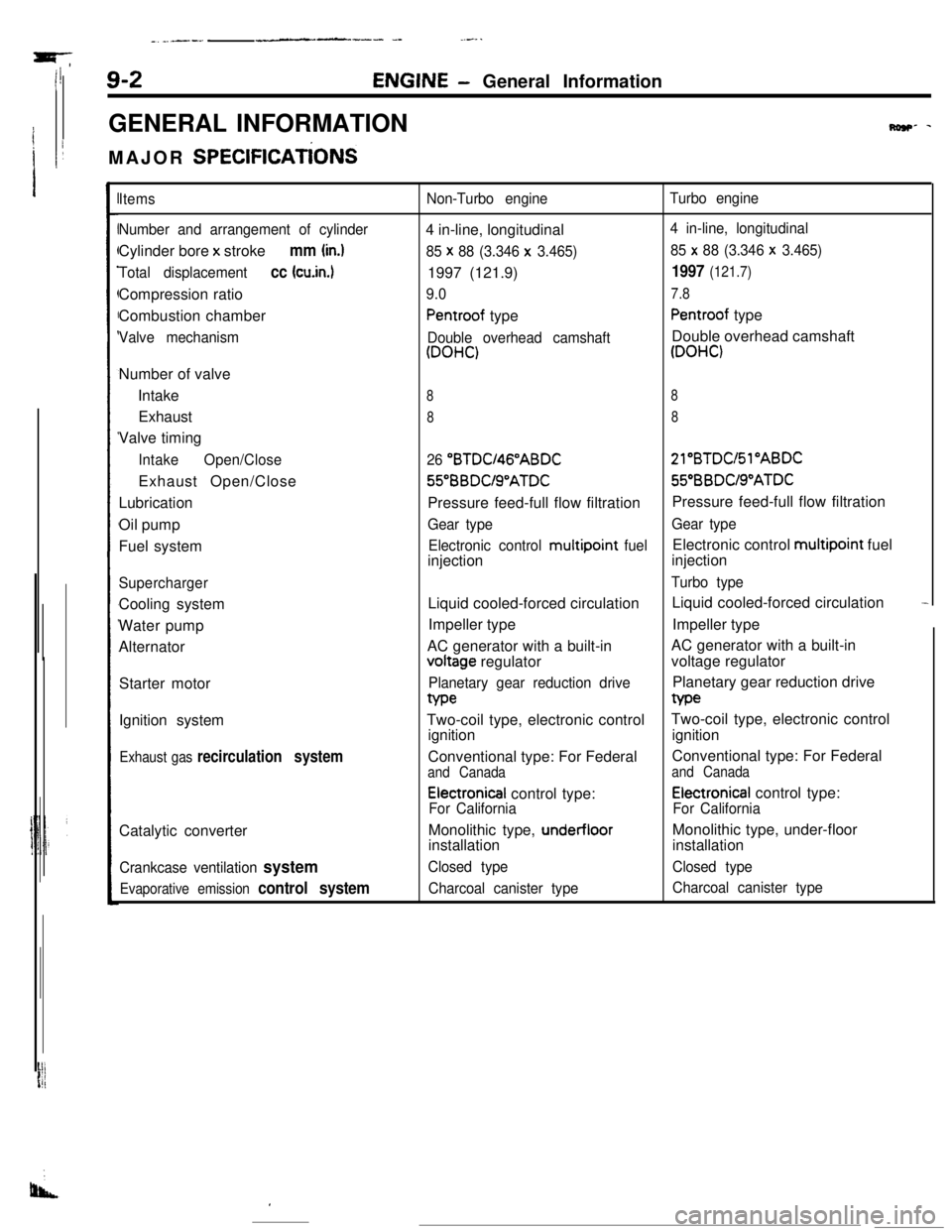

9-2ENGINE- General Information

GENERAL INFORMATION

MAJOR

SPEClFlCATiONS

Row- -

Items

Number and arrangement of cylinderCylinder bore x stroke

mm (in.)

Total displacementcc (cu.in.1Compression ratio

Combustion chamber

Valve mechanismNumber of valve

Intake

Exhaust

Valve timing

IntakeOpen/CloseExhaust Open/Close

Lubrication

Oil pump

Fuel system

SuperchargerCooling system

Water pump

Alternator

Starter motor

Ignition system

Exhaust gas recirculation systemCatalytic converter

Crankcase ventilation system

Evaporative emission control system

Non-Turbo engineTurbo engine4 in-line, longitudinal

4 in-line, longitudinal

85 x

88 (3.346 x 3.465)85 x 88 (3.346 x 3.465)1997 (121.9)

1997 (121.7)

9.07.8

Pentroof typePentroof type

Double overhead camshaftDouble overhead camshaft

(DOHC)(DOHC)

88

88

26 “BTDU46”ABDC21”BTDC/Sl”ABDC56BBDUS”ATDC55”BBDUS”ATDC

Pressure feed-full flow filtrationPressure feed-full flow filtration

Gear typeGear type

Electronic control multipoint

fuelElectronic control multipoint fuel

injectioninjection

Turbo typeLiquid cooled-forced circulationLiquid cooled-forced circulation

-Impeller typeImpeller type

AC generator with a built-involtage regulatorAC generator with a built-in

voltage regulator

Planetary gear reduction drivePlanetary gear reduction drivetype

Two-coil type, electronic controlTwo-coil type, electronic control

ignitionignition

Conventional type: For FederalConventional type: For Federal

and Canadaand Canada

Electronical control type:Electronical control type:

For CaliforniaFor CaliforniaMonolithic type,

under-floorMonolithic type, under-floor

installationinstallation

Closed typeClosed type

Charcoal canister typeCharcoal canister type

I