fuel filter MITSUBISHI ECLIPSE 1991 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 459 of 1216

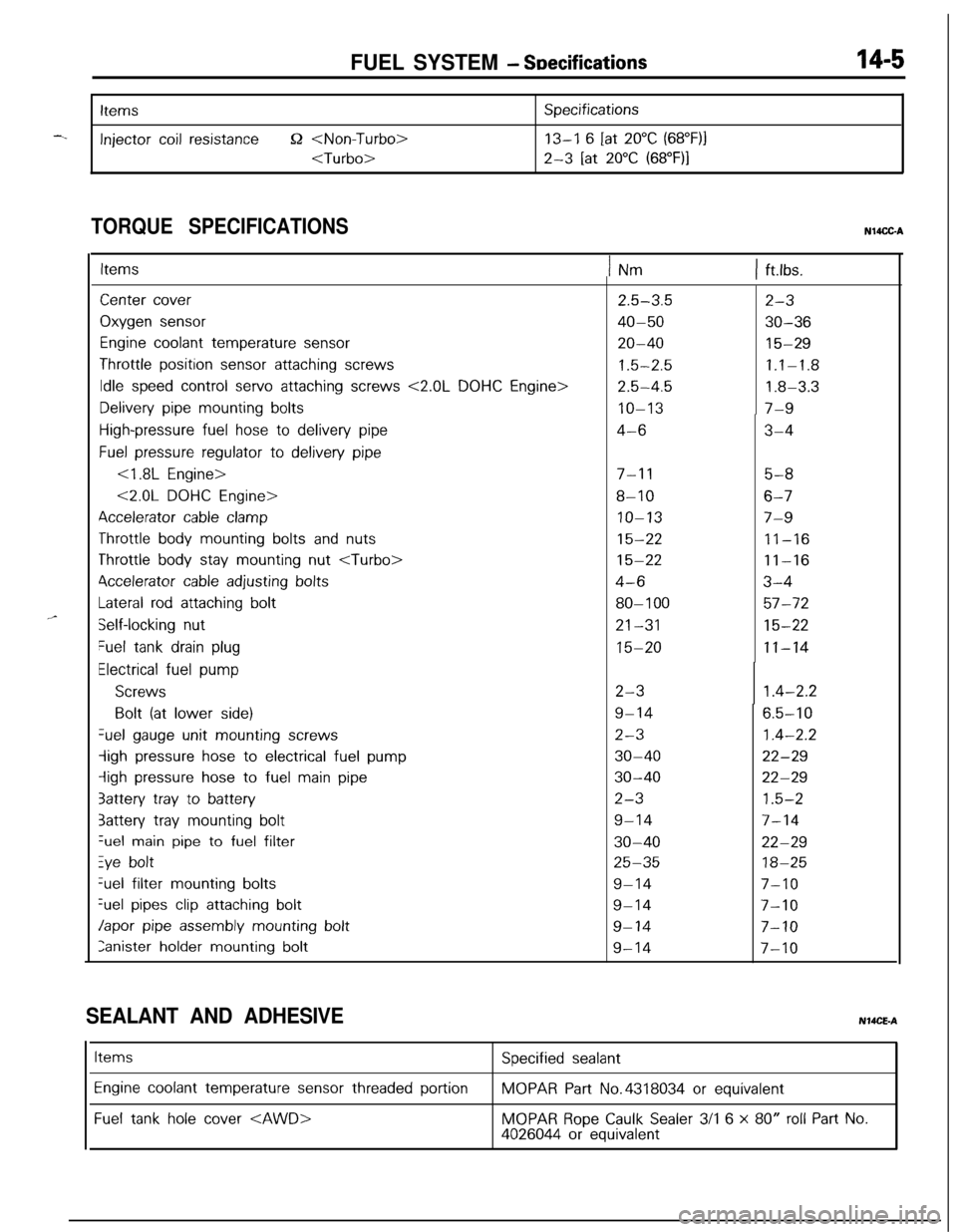

FUEL SYSTEM - SDecifications14-5

-.

Items

Injector coil resistance52

Specifications

13-I 6 [at 20°C (68”F)j

2-3 [at 20°C (68”F)I

TORQUE SPECIFICATIONSN14CC-A

,,-

ItemsINm1 ft.lbs.

Center cover

Oxygen sensor

Engine coolant temperature sensor

Throttle position sensor attaching screws

Idle speed control servo attaching screws <2.0L DOHC Engine>

Delivery pipe mounting bolts

High-pressure fuel hose to delivery pipe

Fuel pressure regulator to delivery pipe

<1.8L Engine>

<2.0L DOHC Engine>

Accelerator cable clamp

Throttle body mounting bolts and nuts

Throttle body stay mounting nut

4ccelerator cable adjusting bolts

Lateral rod attaching bolt

Self-locking nut

Fuel tank drain plug

Electrical fuel pump

Screws

Bolt (at lower side)Gel

gauge unit mounting screws

-ligh pressure hose to electrical fuel pump

iigh pressure hose to fuel main pipe

3attery tray to battery

3attery tray mounting boltGel

main pipe to fuel filter

Zye boltGel filter

mounting bolts

%el pipes clip attaching bolt

Japor pipe assembly mounting bolt

Ianister holder mounting bolt

2.5-3.5

40-50

20-40

1.5-2.5

2.5-4.5

IO-13

4-6

7-l 15-8

8-106-7

IO-137-9

15-2211-16

15-2211-16

4-63-4

80-l 0057-72

21-3115-22

15-2011-14

2-3

9-14

2-3

30-40

30-40

2-3

9-14

30-40

25-35

9-14

9-14

9-14

9-14

2-3

30-36

15-29

1.1-1.8

1.8-3.3

7-9

3-4

1.4-2.2

6.5-10

1.4-2.2

22-29

22-29

1.5-2

7-14

22-29

18-25

7-10

7-10

7-10

7-10

SEALANT AND ADHESIVENMCE-A

Items

Engine coolant temperature sensor threaded portion

Fuel tank hole cover

Specified sealant

MOPAR Part No.4318034 or equivalent

MOPAR Rope Caulk Sealer 3/l 6 x 80” roll Part No.4026044 or equivalent

Page 460 of 1216

14-6FUEL SYSTEM - Special Tools/Troubleshooting

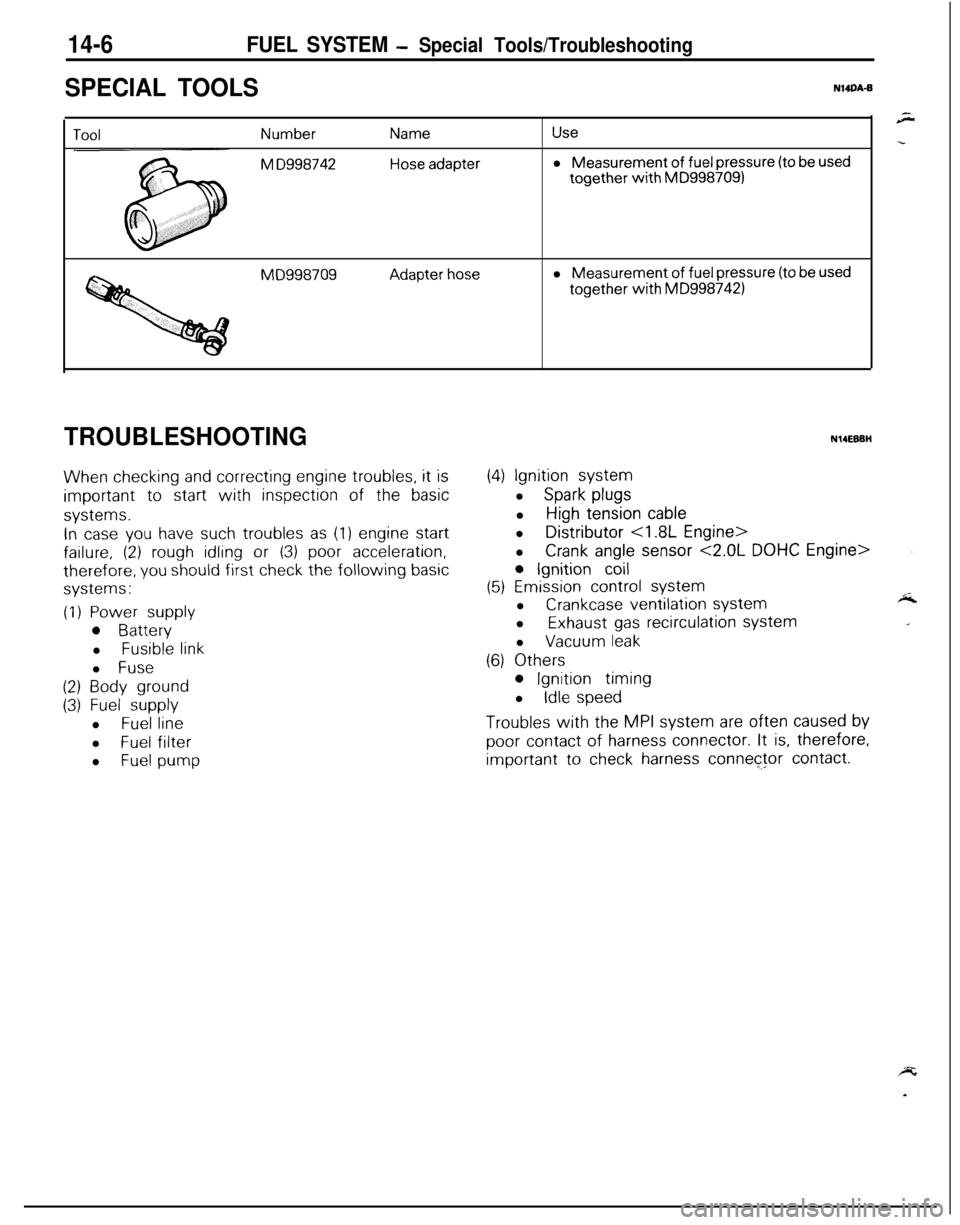

SPECIAL TOOLSNWA-B

Number

M D998742

Name

Hose adapter

Usel Measurement

of fuel pressure (to be usedtogether

with MD9987091

MD998709Adapter hosel Measurement of fuel pressure (to be usedtogether

with MD9987421

TROUBLESHOOTING

When checking and correcting engine troubles, it is

important to start with inspection of the basic

systems.

In case you have such troubles as (1) engine start

failure, (2) rough idling or (3) poor acceleration,

therefore, you should first check the following basic

systems:

(1) Power supply

0 Batteryl

Fusible linkl

Fuse

(2) Body ground

(3) Fuel supplyl

Fuel linel

Fuel filter

l

Fuel pump

N14EBBH

(4) Ignition systeml

Spark plugsl

High tension cablel Distributor

<1.8L Engine>

l

Crank angle sensor <2.0L DOHC Engine>

0 Ignition coil

(5) Emission control systeml

Crankcase ventilation systeml

Exhaust gas recirculation systeml

Vacuum leak

(6) Others

0 Ignition timing

l

Idle speed

Troubles with the MPI system are often caused by

poor contact of harness connector. It is, therefore,

important to check harness connector contact.

Page 500 of 1216

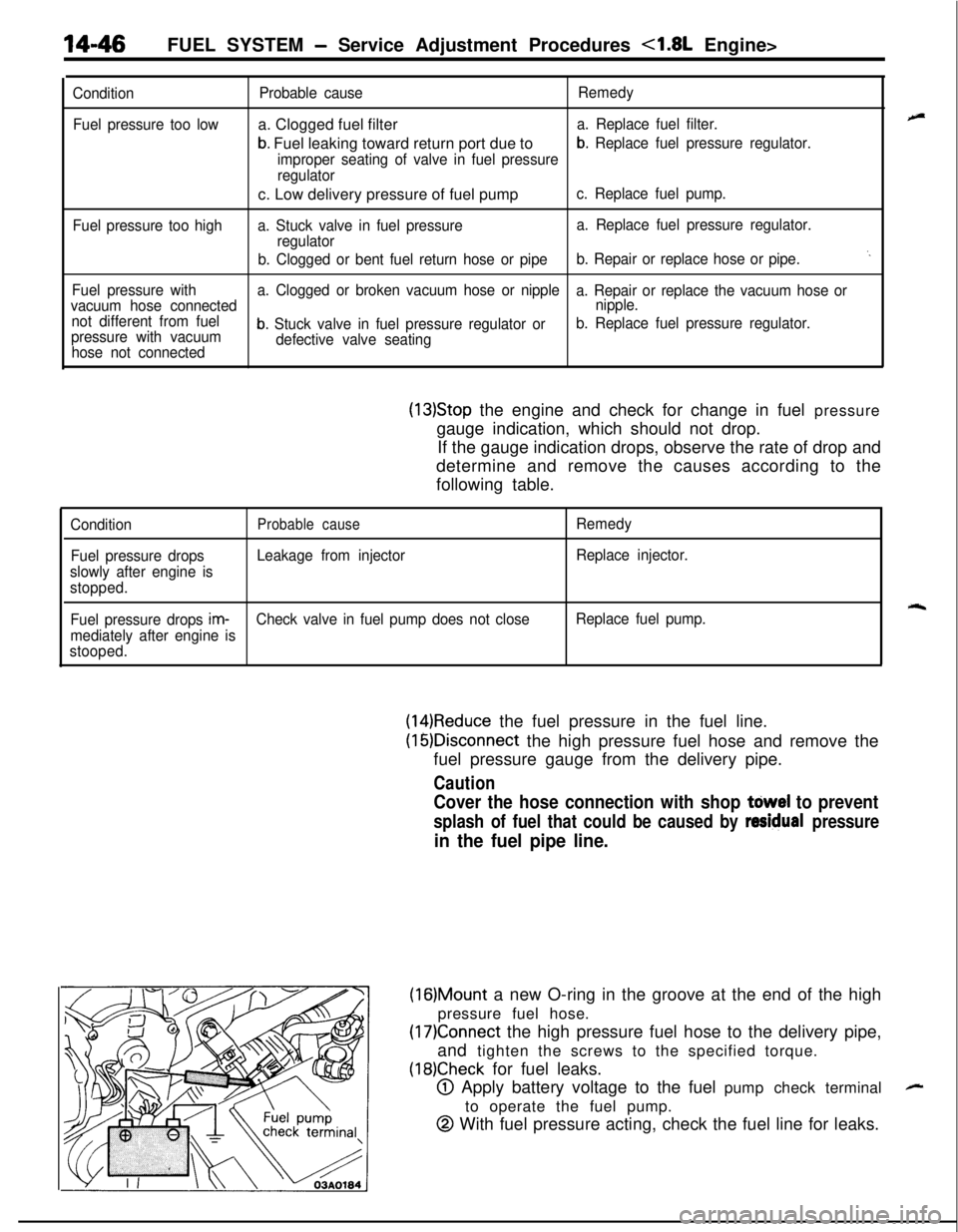

14-46FUEL SYSTEM - Service Adjustment Procedures <1.8L Engine>

Condition

Fuel pressure too low

Fuel pressure too highProbable causea. Clogged fuel filter

b. Fuel leaking toward return port due to

Remedy

a. Replace fuel filter.

improper seating of valve in fuel pressure

b. Replace fuel pressure regulator.

regulatorc. Low delivery pressure of fuel pump

c. Replace fuel pump.

a. Stuck valve in fuel pressurea. Replace fuel pressure regulator.

regulator

b. Clogged or bent fuel return hose or pipeb. Repair or replace hose or pipe.

‘.

Fuel pressure witha. Clogged or broken vacuum hose or nipple

a. Repair or replace the vacuum hose or

vacuum hose connectednipple.

not different from fuel

pressure with vacuum

b. Stuck valve in fuel pressure regulator orb. Replace fuel pressure regulator.

hose not connecteddefective valve seating

(13)Stop the engine and check for change in fuel pressure

gauge indication, which should not drop.

If the gauge indication drops, observe the rate of drop and

determine and remove the causes according to the

following table.

ConditionProbable causeRemedy

Fuel pressure dropsLeakage from injectorReplace injector.

slowly after engine is

stopped.

rqFuel pressure drops im-Check valve in fuel pump does not closeReplace fuel pump.

mediately after engine is

stooped.

(14)Reduce the fuel pressure in the fuel line.

(16)Disconnect the high pressure fuel hose and remove the

fuel pressure gauge from the delivery pipe.

Caution

Cover the hose connection with shop tdwel to prevent

splash of fuel that could be caused by residual pressure

in the fuel pipe line.

(16)Mount a new O-ring in the groove at the end of the high

pressure fuel hose.

(17)Connect the high pressure fuel hose to the delivery pipe,

and tighten the screws to the specified torque.

(18)Check for fuel leaks.

@ Apply battery voltage to the fuel pump check terminal

to operate the fuel pump.

@ With fuel pressure acting, check the fuel line for leaks.

-

Page 508 of 1216

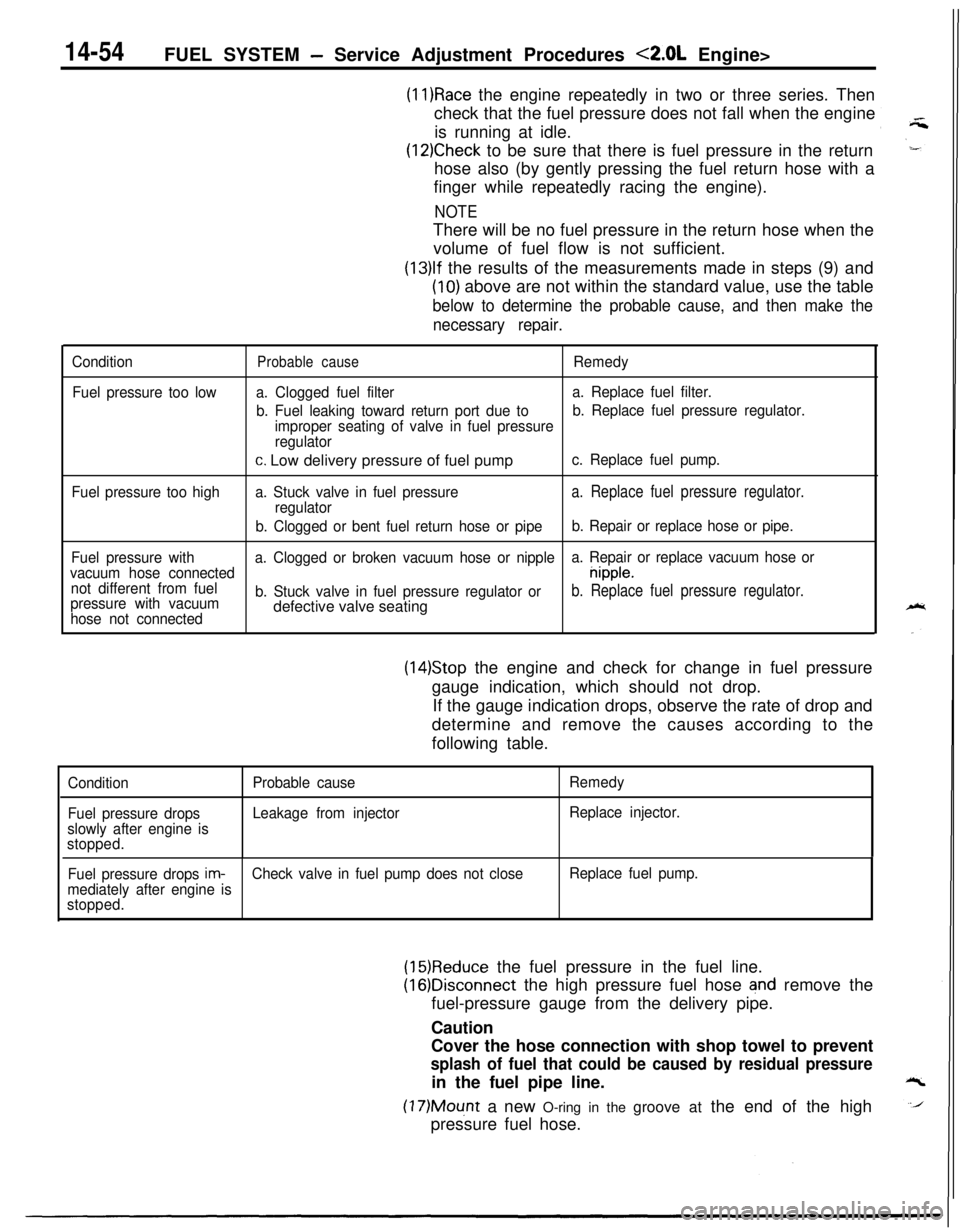

14-54FUEL SYSTEM - Service Adjustment Procedures <2.0L Engine>

(11)Race the engine repeatedly in two or three series. Then

check that the fuel pressure does not fall when the engine

is running at idle.

(12)Check to be sure that there is fuel pressure in the return

hose also (by gently pressing the fuel return hose with a

finger while repeatedly racing the engine).

NOTEThere will be no fuel pressure in the return hose when the

volume of fuel flow is not sufficient.

(13)lf the results of the measurements made in steps (9) and

(10) above are not within the standard value, use the table

below to determine the probable cause, and then make the

necessary repair.

Condition

Fuel pressure too lowProbable causeRemedy

a. Clogged fuel filtera. Replace fuel filter.

b. Fuel leaking toward return port due tob. Replace fuel pressure regulator.

improper seating of valve in fuel pressure

regulator

c. Low delivery pressure of fuel pumpc. Replace fuel pump.

Fuel pressure too higha. Stuck valve in fuel pressure

a. Replace fuel pressure regulator.regulator

b. Clogged or bent fuel return hose or pipeb. Repair or replace hose or pipe.

Fuel pressure witha. Clogged or broken vacuum hose or nipplea. Repair or replace vacuum hose or

vacuum hose connected

nipple.

not different from fuel

pressure with vacuumb. Stuck valve in fuel pressure regulator or

b. Replace fuel pressure regulator.

hose not connecteddefective valve seating

(14)Stop the engine and check for change in fuel pressure

gauge indication, which should not drop.

If the gauge indication drops, observe the rate of drop and

determine and remove the causes according to the

following table.

Condition

Fuel pressure drops

slowly after engine is

stopped.Probable cause

Leakage from injectorRemedy

Replace injector.

Fuel pressure drops

im-Check valve in fuel pump does not closeReplace fuel pump.

mediately after engine is

stopped.

(15)Reduce the fuel pressure in the fuel line.

(16)Disconnect the high pressure fuel hose and remove the

fuel-pressure gauge from the delivery pipe.

Caution

Cover the hose connection with shop towel to prevent

splash of fuel that could be caused by residual pressurein the fuel pipe line.

(17)Mount a new O-ring in the groove at the end of the high

pressure fuel hose.

Page 556 of 1216

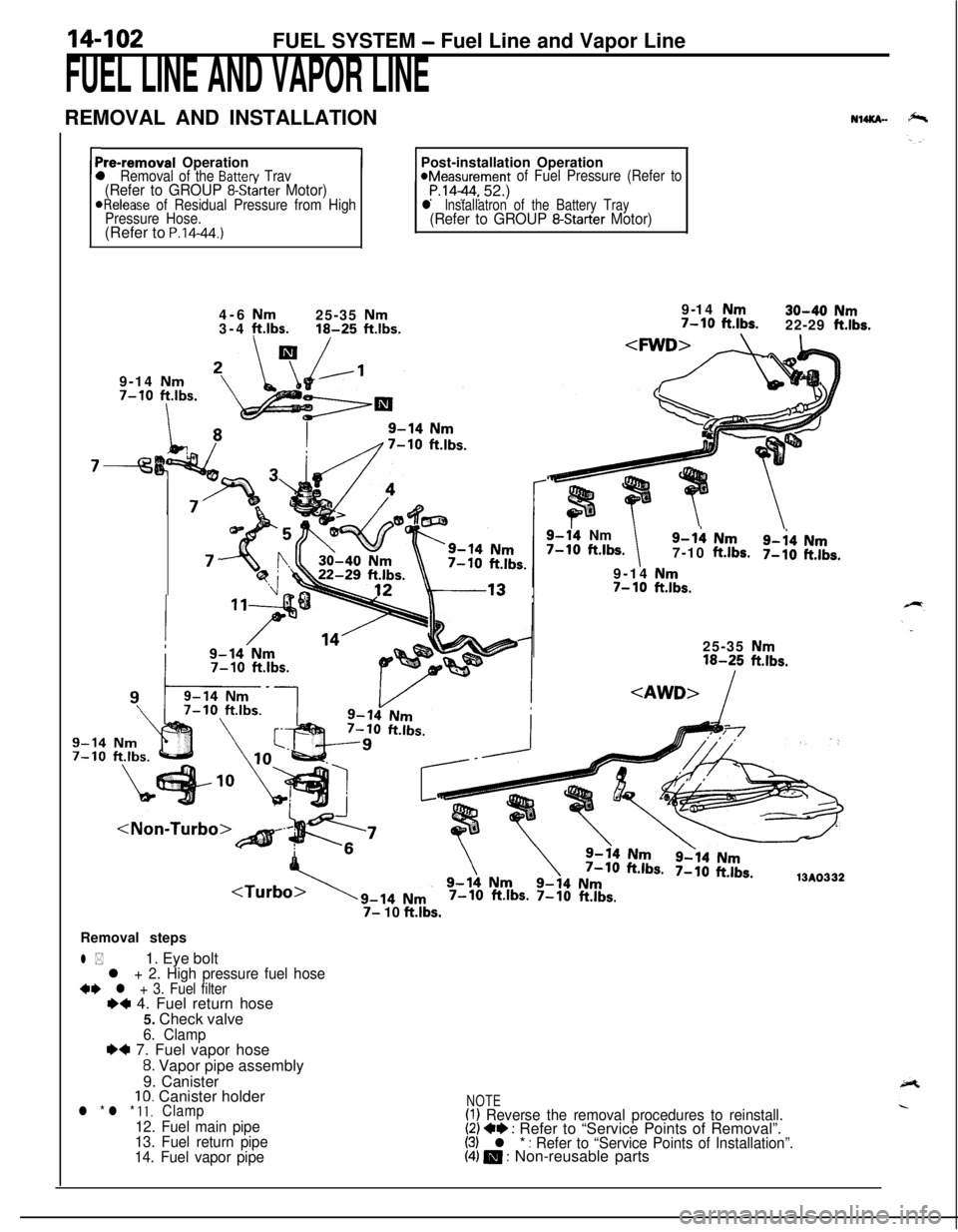

14-102FUEL SYSTEM - Fuel Line and Vapor Line

FUEL LINE AND VAPOR LINEREMOVAL AND INSTALLATION

NuKn-

rPre-removal Operationl Removal of the Batten/ Trav(Refer to GROUP 8-Starter Motor)ORelease of Residual Pressure from High

Pressure Hose.(Refer to

P.14-44.)

1Post-installation Operation*Measurement of Fuel Pressure (Refer toP.1444, 52.)l lnstallatron of the Battery Tray(Refer to GROUP 8-Starter Motor)4-6

Nm25-35 Nm3-4 ft.lbs.16-25 ftlbs.9-14 Nm7-10

ftlbs.

I

7-9-14

Nm30-40 Nm7-10 ft.lbs.22-29 ft.lbs.

9-14 Nm

7-10 ftlbs.

9-14Nm7-10 ft.lbs.9-h Nm

7-10ft.lbs.9-i4 Nm7-10ft.lbs.9-14

Nm7- 10ft.lbs.25-35

Nm16-25 ft.lbs.

7-10 ft.lbs. 7-10 ft.lbs.

7- 10 ft.lbs.Removal steps

l *1. Eye boltl + 2. High pressure fuel hose+e l + 3. Fuel filterI)+ 4. Fuel return hose

5. Check valve

6. Clamp~~ 7. Fuel vapor hose

8. Vapor pipe assembly

9. Canister

10. Canister holderl * l * 11.Clamp

12. Fuel main pipe

13. Fuel return pipe

14. Fuel vapor pipe

NOTE(I) Reverse the removal procedures to reinstall.(2) +e : Refer to “Service Points of Removal”.(3) l * : Refer to “Service Points of Installation”.(4) m : Non-reusable parts

Page 557 of 1216

-.FUEL SYSTEM

- Fuel Line pnd Vapoi- @f&

L

Mounting

bolts

pipe

03FOOO

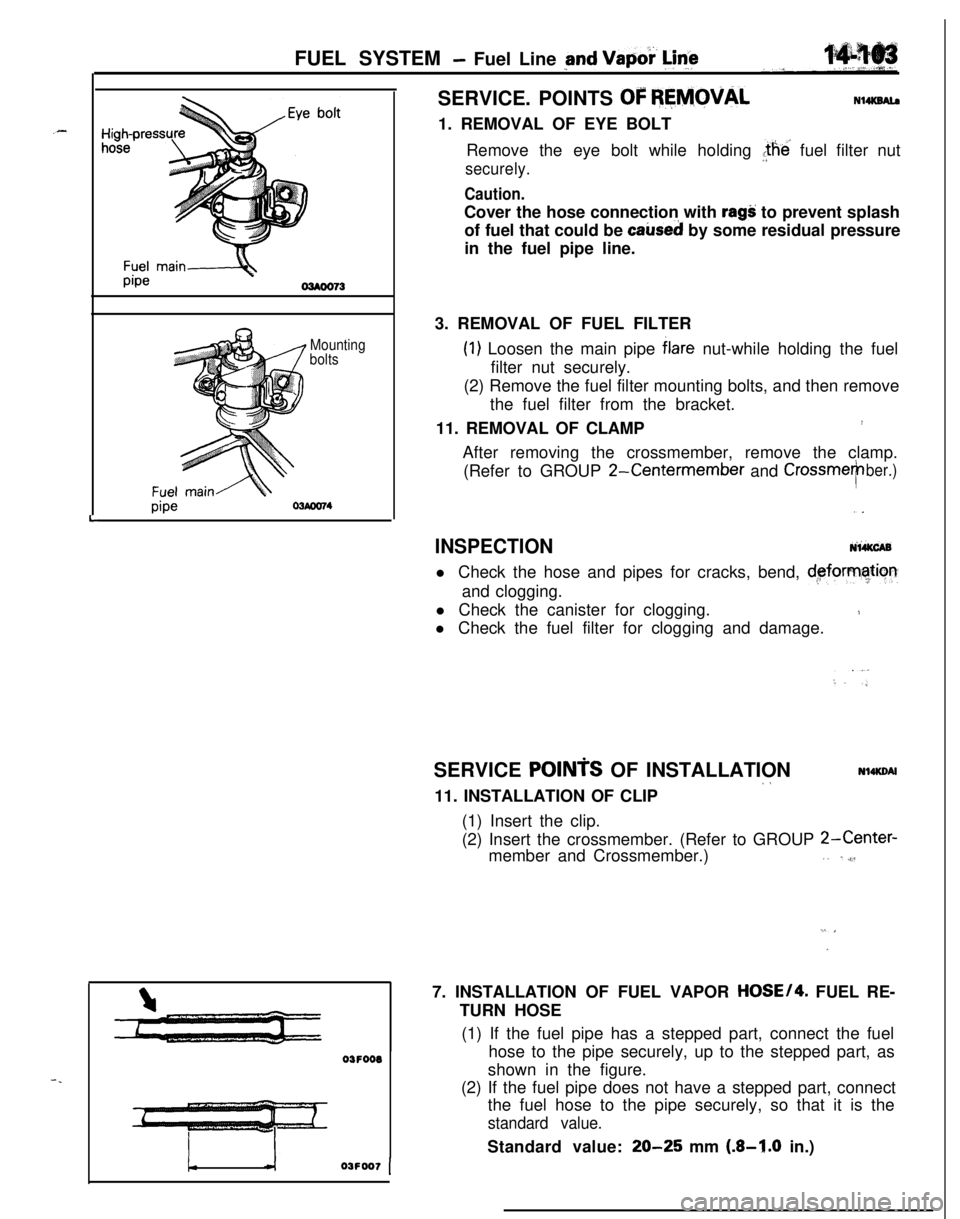

!-03FOO7 [SERVICE. POINTS

OF REMOVALN14KSAl.a1. REMOVAL OF EYE BOLT

Remove the eye bolt while holding the’ fuel filter nut

securely.

Caution.Cover the hose connection with

ragS: to prevent splash

of fuel that could be

caked by some residual pressure

in the fuel pipe line.

3. REMOVAL OF FUEL FILTER

(1) Loosen the main pipe blare nut-while holding the fuel

filter nut securely.

(2) Remove the fuel filter mounting bolts, and then remove

the fuel filter from the bracket.

11. REMOVAL OF CLAMP

!After removing the crossmember, remove the clamp.

(Refer to GROUP

2-Centermember and CrossmeTber.),.

INSPECTIONNi&CABl Check the hose and pipes for cracks, bend,

d,eforrnatiorrand clogging.

l Check the canister for clogging.

1l Check the fuel filter for clogging and damage.

SERVICE

POINTS OF INSTALLATION~aNl4KDAl11. INSTALLATION OF CLIP

(1) Insert the clip.

(2) Insert the crossmember. (Refer to GROUP

2-Center-member and Crossmember.),. ,,$l

”7. INSTALLATION OF FUEL VAPOR

HOSE/4. FUEL RE-

TURN HOSE

(1) If the fuel pipe has a stepped part, connect the fuel

hose to the pipe securely, up to the stepped part, as

shown in the figure.

(2) If the fuel pipe does not have a stepped part, connect

the fuel hose to the pipe securely, so that it is the

standard value.Standard value:

20-25 mm (.&I.0 in.)

Page 558 of 1216

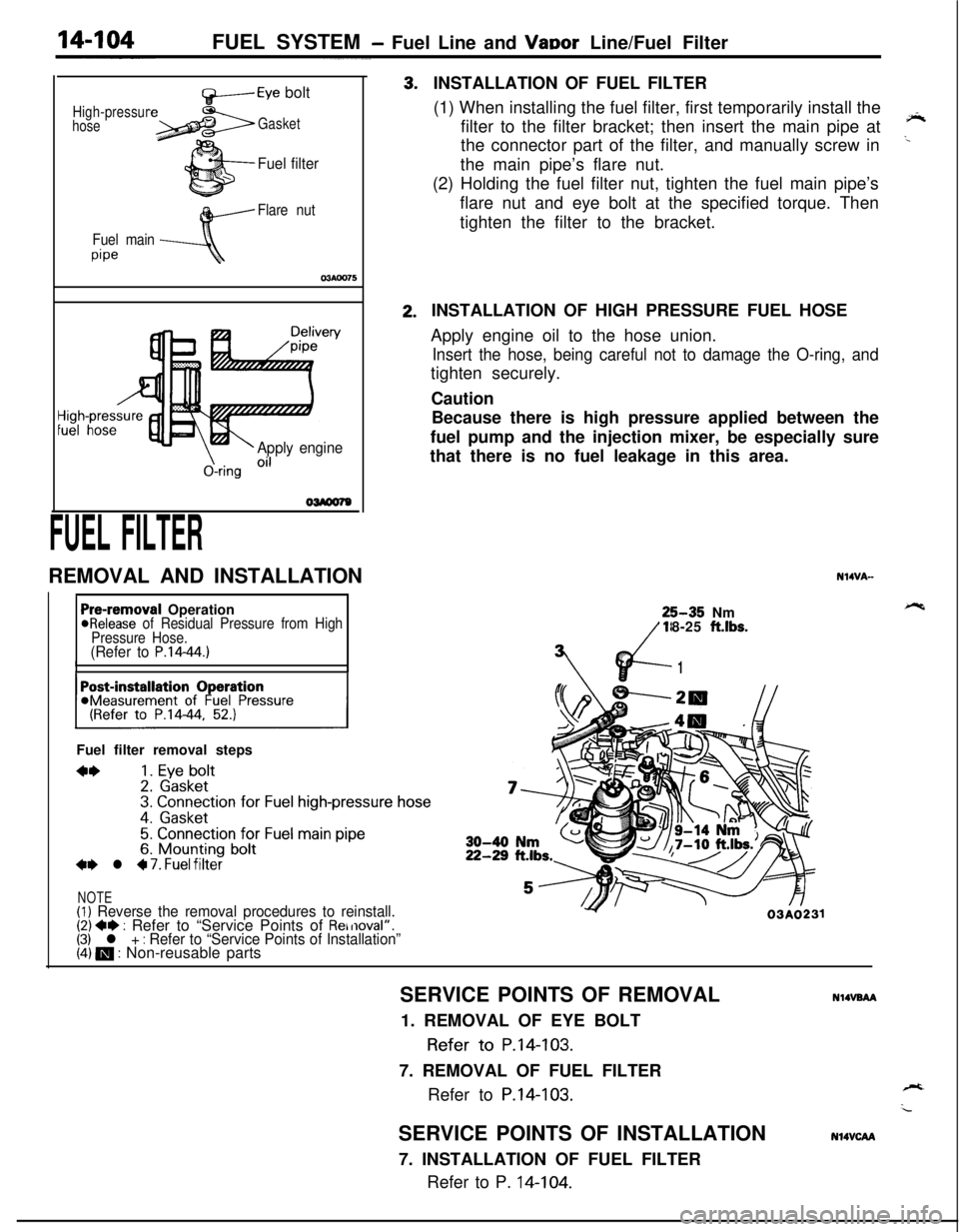

FUEL SYSTEM - Fuel Line and VaDor Line/Fuel Filter

High-pressur

hose

f+-----Eye bolt

Gasket

Fuel filter

Flare nut

Fuel main

pipe

\-Apply engine

&ring Oi’

FUEL FILTERREMOVAL AND INSTALLATION3.2.INSTALLATION OF FUEL FILTER

(1) When installing the fuel filter, first temporarily install the

filter to the filter bracket; then insert the main pipe at

‘*the connector part of the filter, and manually screw in

..the main pipe’s flare nut.

(2) Holding the fuel filter nut, tighten the fuel main pipe’s

flare nut and eye bolt at the specified torque. Then

tighten the filter to the bracket.

Pre-removal Operation@Release of Residual Pressure from High

Pressure Hose.

(Refer to P.14-44.)IIFuel filter removal steps

**1. Eye bolt2. Gasket3. Connection for Fuel high-pressure hose

4. Gasket

5. Connection for Fuel main pipe6. Mounting bolt+e l 4 7. Fuel filter

NOTE(1) Reverse the removal procedures to reinstall.(2) +e : Refer to “Service Points of Removal”.(3) l + : Refer to “Service Points of Installation”(4) m : Non-reusable partsINSTALLATION OF HIGH PRESSURE FUEL HOSE

Apply engine oil to the hose union.

Insert the hose, being careful not to damage the O-ring, andtighten securely.

Caution

Because there is high pressure applied between the

fuel pump and the injection mixer, be especially sure

that there is no fuel leakage in this area.

N14VA-25-35 Nm

18-25

ft.lbs.

vd-

7’

1

Y03A0231SERVICE POINTS OF REMOVAL

NlIVBAA1. REMOVAL OF EYE BOLT

Refer to P.14-103.

7. REMOVAL OF FUEL FILTER

Refer to

P.14-103.SERVICE POINTS OF INSTALLATION

7. INSTALLATION OF FUEL FILTER

Refer to P. 14-104.

N14VCAA