radiator MITSUBISHI ECLIPSE 1991 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 262 of 1216

7-14COOLING - Radiator

A

OFF

ON

h

--- ,

BWatertemperature

16v1100

Standard value:Continuity

at 82-88X (180-190°F). . . . . . . . . . .at A pointNo continuity at

78°C (172°F) or less . . . . . . . . at 6 point.r;;;

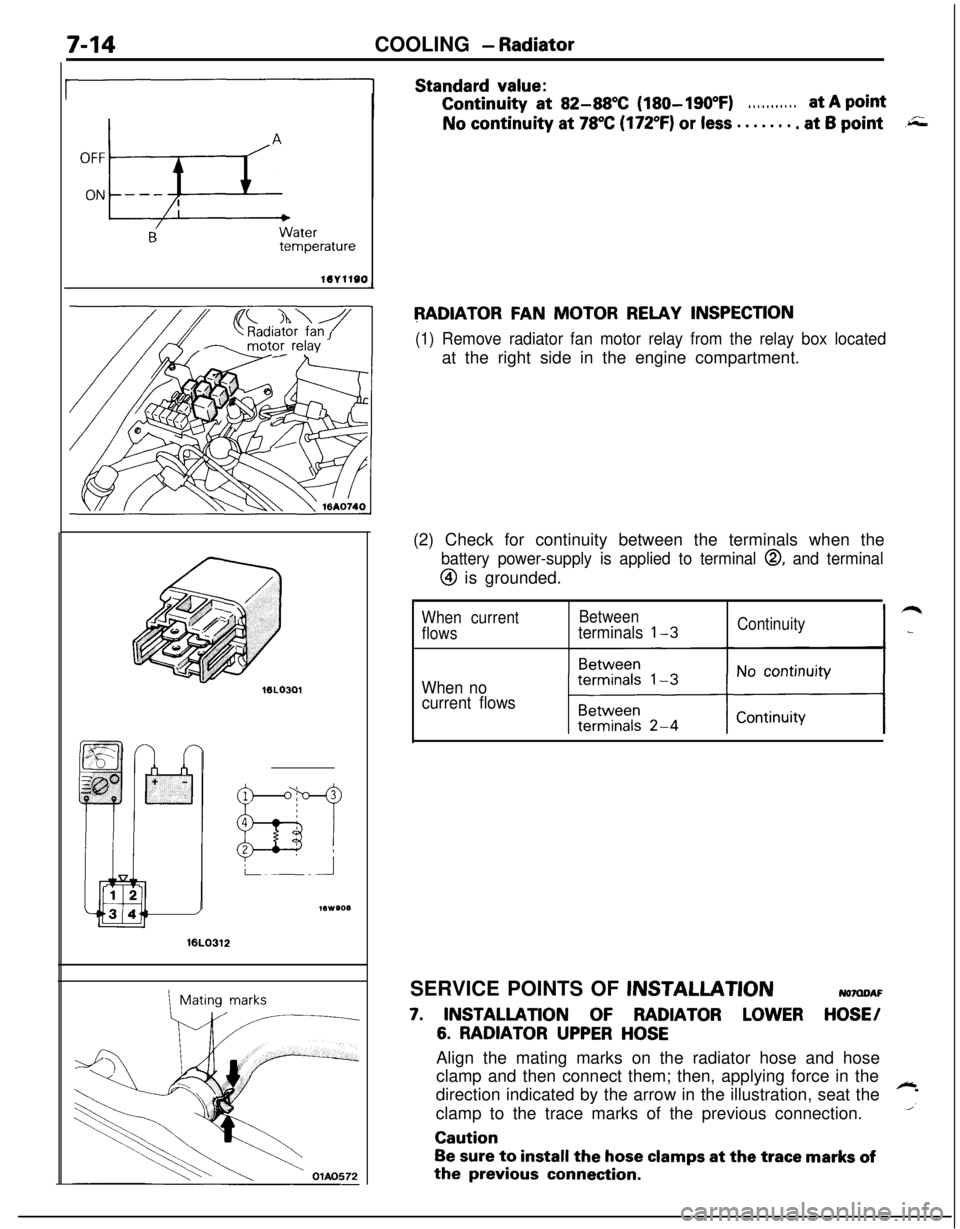

RADIATOR FAN MOTOR RELAY INSPECTION

(1) Remove radiator fan motor relay from the relay box locatedat the right side in the engine compartment.

16LO312

1Mating marks(2) Check for continuity between the terminals when the

battery power-supply is applied to terminal 0, and terminal

@ is grounded.

When currentBetween

flowsterminals l-3Continuity

When no

current flowsSERVICE POINTS OF

JNSTALLATIONNOMDAF

7. INSTALLATION OF RADIATOR LOWER HOSE/

6. RADIATOR UPPER HOSEAlign the mating marks on the radiator hose and hose

clamp and then connect them; then, applying force in the

direction indicated by the arrow in the illustration, seat the

~

1clamp to the trace marks of the previous connection.Caution

Be sure to install the hose clamps at the trace marks ofthe

previous connection.

Page 263 of 1216

COOLING - Radiator Fan Motor AssemblvIThermostat7-15

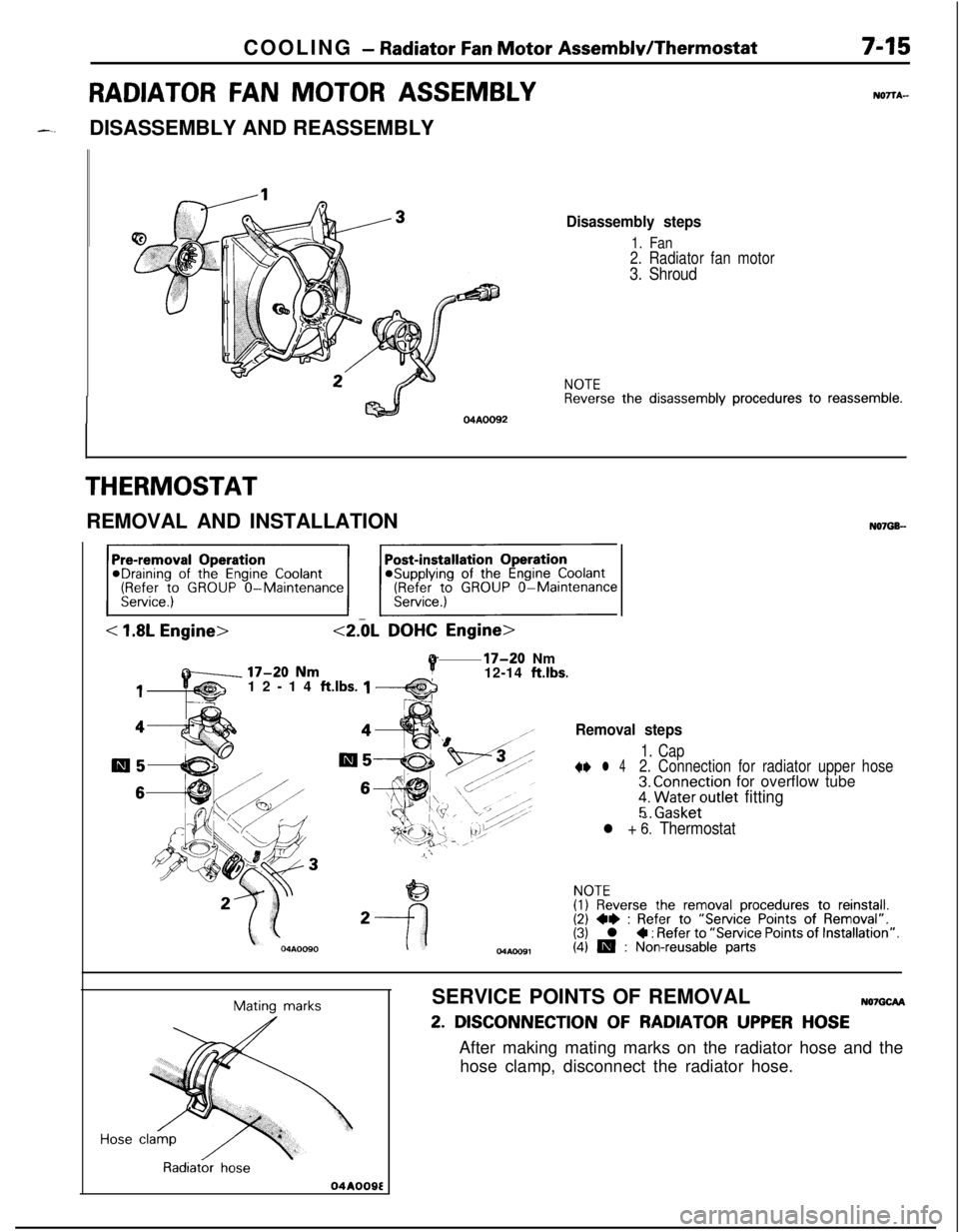

RADIATOR FAN MOTOR ASSEMBLYDISASSEMBLY AND REASSEMBLY

04AOO92

NOTTA-

Disassembly steps

1. Fan2. Radiator fan motor

3. Shroud

NOTEReverse the disassembly procedures to reassemble.

THERMOSTATREMOVAL AND INSTALLATION

N07G6-

< 1.8LDOHC

P17-20 Nm

12-14 ft.lbs.

112-14 ftlbs. 1

44Removal steps

m5al51. Cap+e l 42. Connection for radiator upper hose

663. Connection for overflow tube

;. ra;t;er;utlet fitting

l + 6: Thermostat

NOTE

2(I) Reverse the removal procedures to reinstall.(2) ~~ : Refer to “Service Points of Removal”.(3) l 4 : Refer to “Service Points of Installation”.

04Aoo91(4) 19 : Non-reusable parts

Mating marks

Radiator hose

04A009ESERVICE POINTS OF REMOVAL

NO7GCFU

2. DISCONNECTION OF RADIATOR UPPER HOSEAfter making mating marks on the radiator hose and the

hose clamp, disconnect the radiator hose.

Page 264 of 1216

7-16COOLING - Thermostat

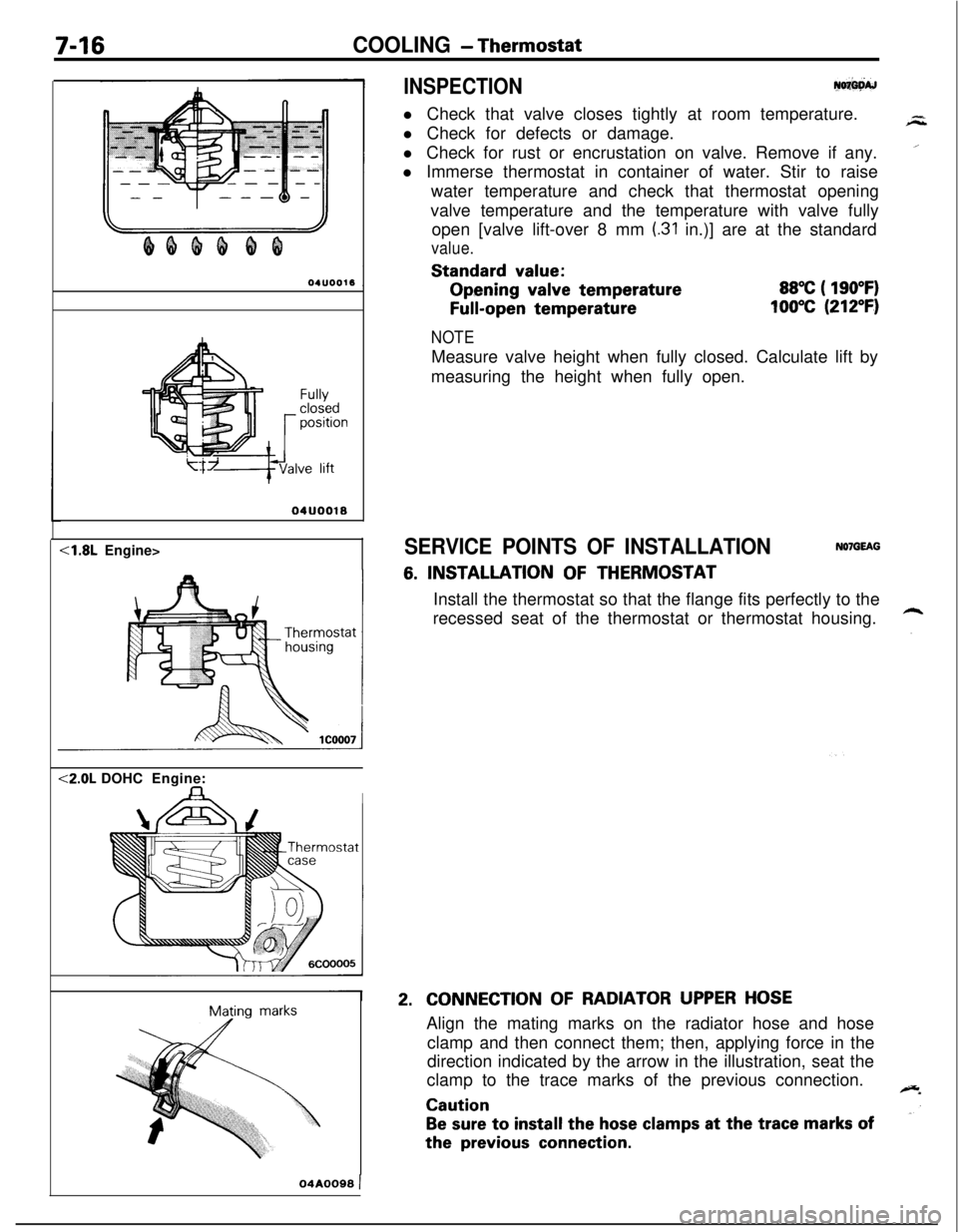

INSPECTIONy+w

l Check that valve closes tightly at room temperature.

l Check for defects or damage.

l Check for rust or encrustation on valve. Remove if any.

l Immerse thermostat in container of water. Stir to raise

water temperature and check that thermostat opening

valve temperature and the temperature with valve fully

open [valve lift-over 8 mm

(.31 in.)] are at the standard

value.Standard

value:Opening

valve temperature

Full-open temperature

88°C ( 190°F)

100°C (212°F)

Fullyclosedpositionve lift

04UOO18<1.8L Engine><2.0L DOHCEngine:

IMating

marks

NOTEMeasure valve height when fully closed. Calculate lift by

measuring the height when fully open.

SERVICE POINTS OF INSTALLATIONNOlGEAG

6. INSTALLATION OF THERMOSTAT

Install the thermostat so that the flange fits perfectly to the

recessed seat of the thermostat or thermostat housing.

2.CONNECTION OF RADIATOR UPPER HOSEAlign the mating marks on the radiator hose and hose

clamp and then connect them; then, applying force in the

direction indicated by the arrow in the illustration, seat the

clamp to the trace marks of the previous connection.

Caution

Be sure to install the hose clamps at the trace marks ofthe

previous connection.

04A0099 )

Page 274 of 1216

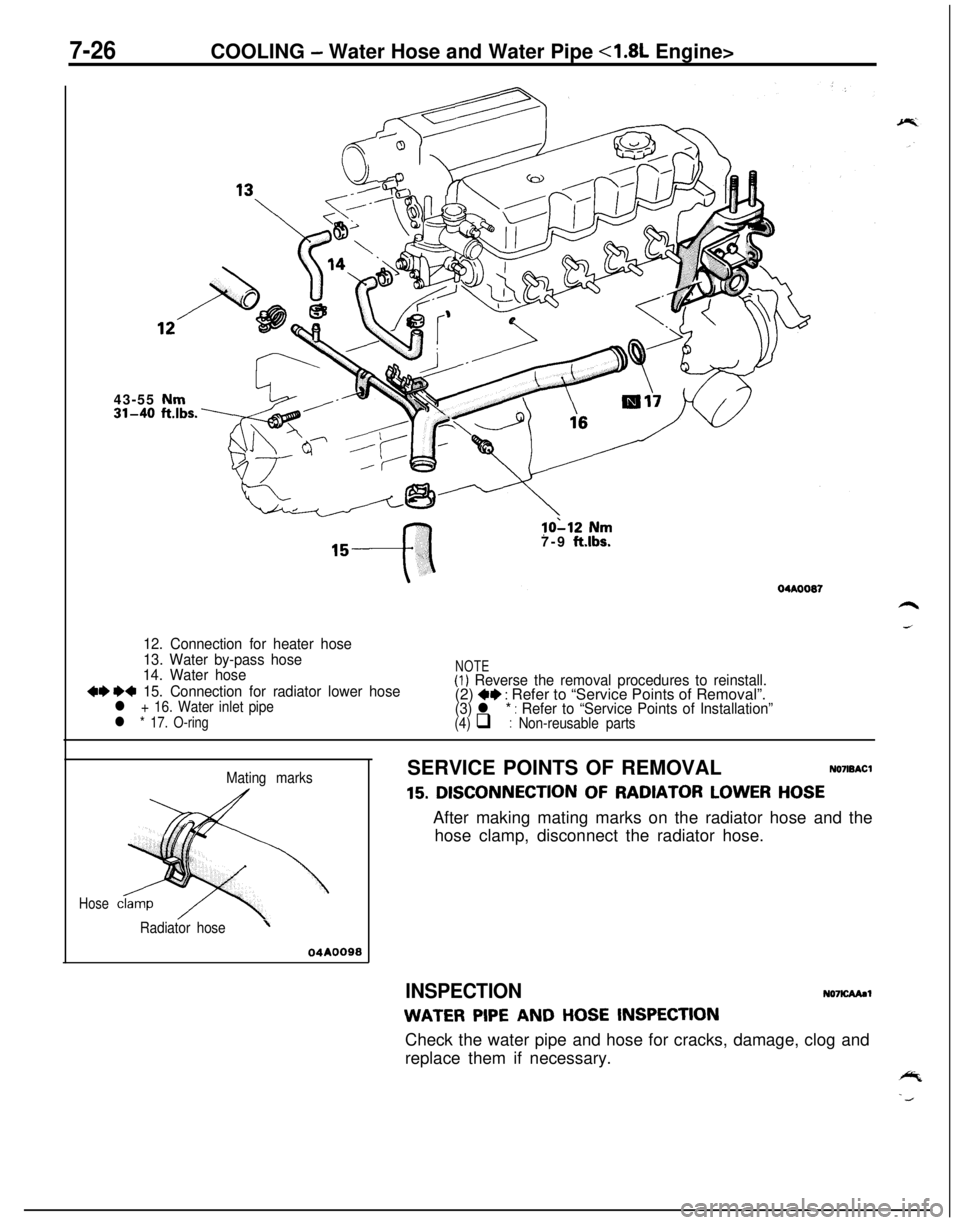

7-26COOLING - Water Hose and Water Pipe <1.8L Engine>

43-55 Nm

31-40 ft.lbs.

lo‘-12 Nm

7-9 ft.lbs.

12. Connection for heater hose

13. Water by-pass hose

14. Water hose

++ e+ 15. Connection for radiator lower hosel + 16. Water inlet pipe

l * 17. O-ring

NOTE(1) Reverse the removal procedures to reinstall.(2) +e : Refer to “Service Points of Removal”.(3) l * : Refer to “Service Points of Installation”(4) q : Non-reusable parts

Mating marks

Hose

Radiator hose’

04AOOSSSERVICE POINTS OF REMOVAL

NO7ISACl

15. DISCONNECTION OF RADIATOR LOWER HOSEAfter making mating marks on the radiator hose and the

hose clamp, disconnect the radiator hose.

INSPECTIONNO7KAAaI

WATER PIPE AND HOSE INSPECTIONCheck the water pipe and hose for cracks, damage, clog and

replace them if necessary.

Page 275 of 1216

COOLING - Water Hose and Water Pipe <1.8L Engine>7-27

r

L

0410024

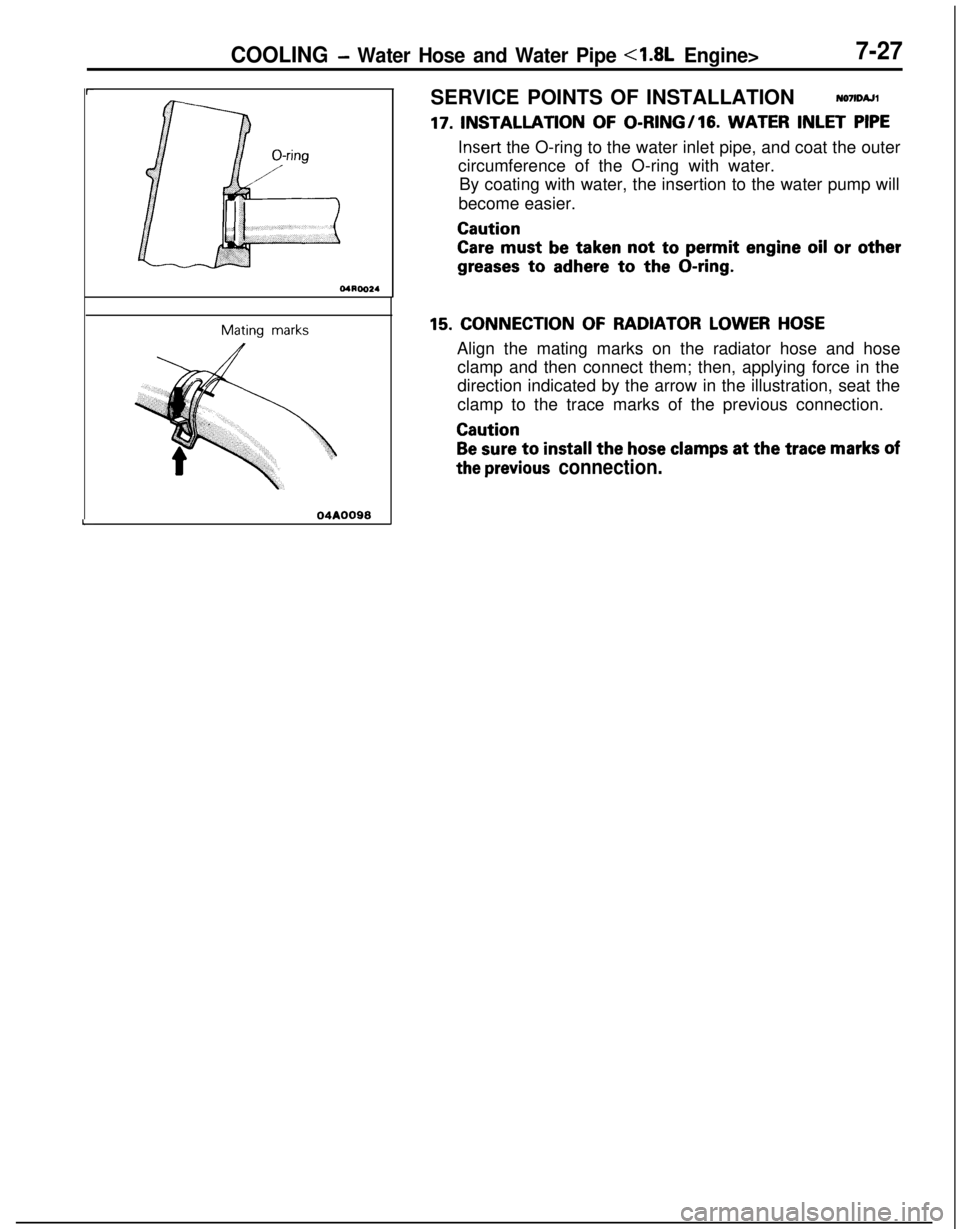

Mating marksSERVICE POINTS OF INSTALLATIONNO7lDAJl

17. INSTALLATION OF 0-l?ING/lG. WATER INLET PIPE

Insert the O-ring to the water inlet pipe, and coat the outer

circumference of the O-ring with water.

By coating with water, the insertion to the water pump will

become easier.

Caution

Care must be taken not to permit engine oil or other

greases to adhere to the O-ring.

15. CONNECTION OF RADIATOR LOWER HOSEAlign the mating marks on the radiator hose and hose

clamp and then connect them; then, applying force in the

direction indicated by the arrow in the illustration, seat the

clamp to the trace marks of the previous connection.

Caution

Be sure to install the hose clamps at the trace marks of

the previous connection.

Page 277 of 1216

,-

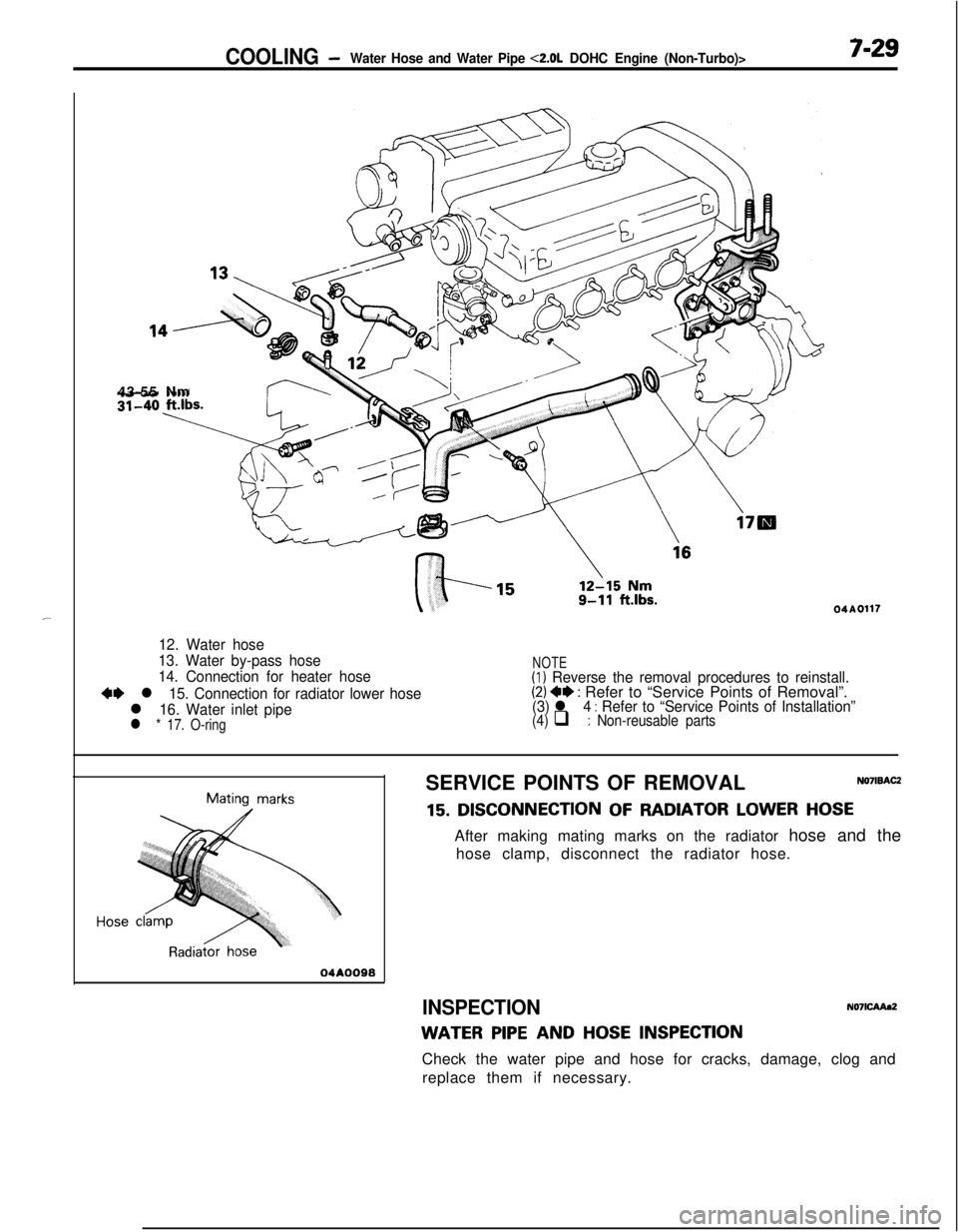

COOLING -Water Hose and Water Pipe <2.0L DOHC Engine (Non-Turbo)>7-2943-55 Nm

04A0117

12. Water hose

13. Water by-pass hose

14. Connection for heater hose

+I) l 15. Connection for radiator lower hose

l 16. Water inlet pipel * 17. O-ring

NOTE(1) Reverse the removal procedures to reinstall.(2) 4* : Refer to “Service Points of Removal”.(3) l 4 : Refer to “Service Points of Installation”(4) q : Non-reusable parts

Mating marks

04AOO98SERVICE POINTS OF REMOVAL

NO’IISACZ

15. DISCONNECTION OF RADIATOR LOWER HOSEAfter making mating marks on the radiator hose and the

hose clamp, disconnect the radiator hose.

INSPECTIONN071CAAa2

WATER PIPE AND HOSE INSPECTIONCheck the water pipe and hose for cracks, damage, clog and

replace them if necessary.

Page 278 of 1216

7-30COOLING - waterHose and Water Piue <2.0L DOHC Ermine (Non-Turbo)>

04ROO24

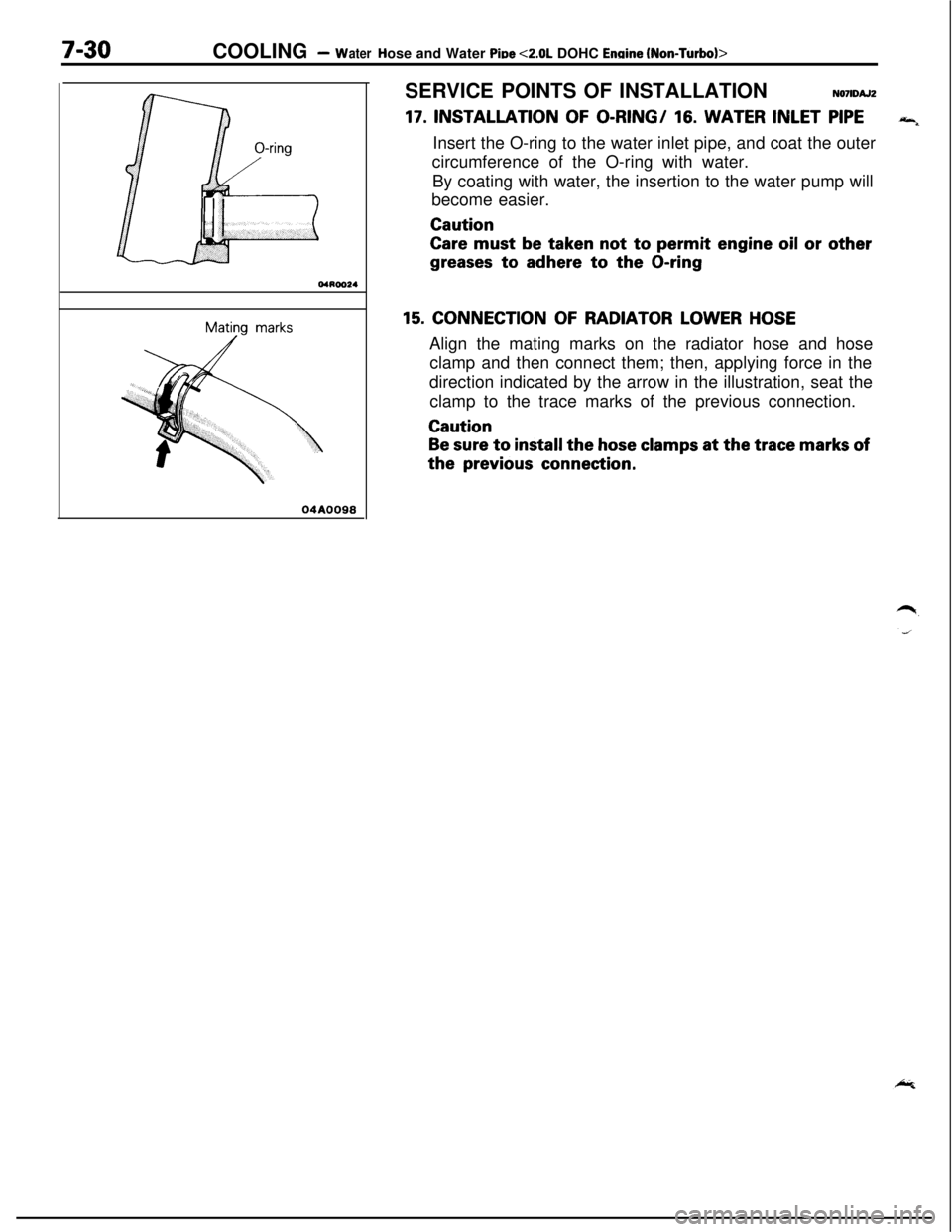

04AOO98SERVICE POINTS OF INSTALLATION

N071DAJZ

17. INSTALLATION OF O-RING/ 16. WATER INLET PIPE“4Insert the O-ring to the water inlet pipe, and coat the outer

circumference of the O-ring with water.

By coating with water, the insertion to the water pump will

become easier.Caution

Care must be taken not to permit engine oil or other

greases to adhere to the O-ring

15. CONNECTION OF RADIATOR LOWER HOSEAlign the mating marks on the radiator hose and hose

clamp and then connect them; then, applying force in the

direction indicated by the arrow in the illustration, seat the

clamp to the trace marks of the previous connection.Caution

Be sure to install the hose clamps at the trace marks ofthe

previous connection.

Page 280 of 1216

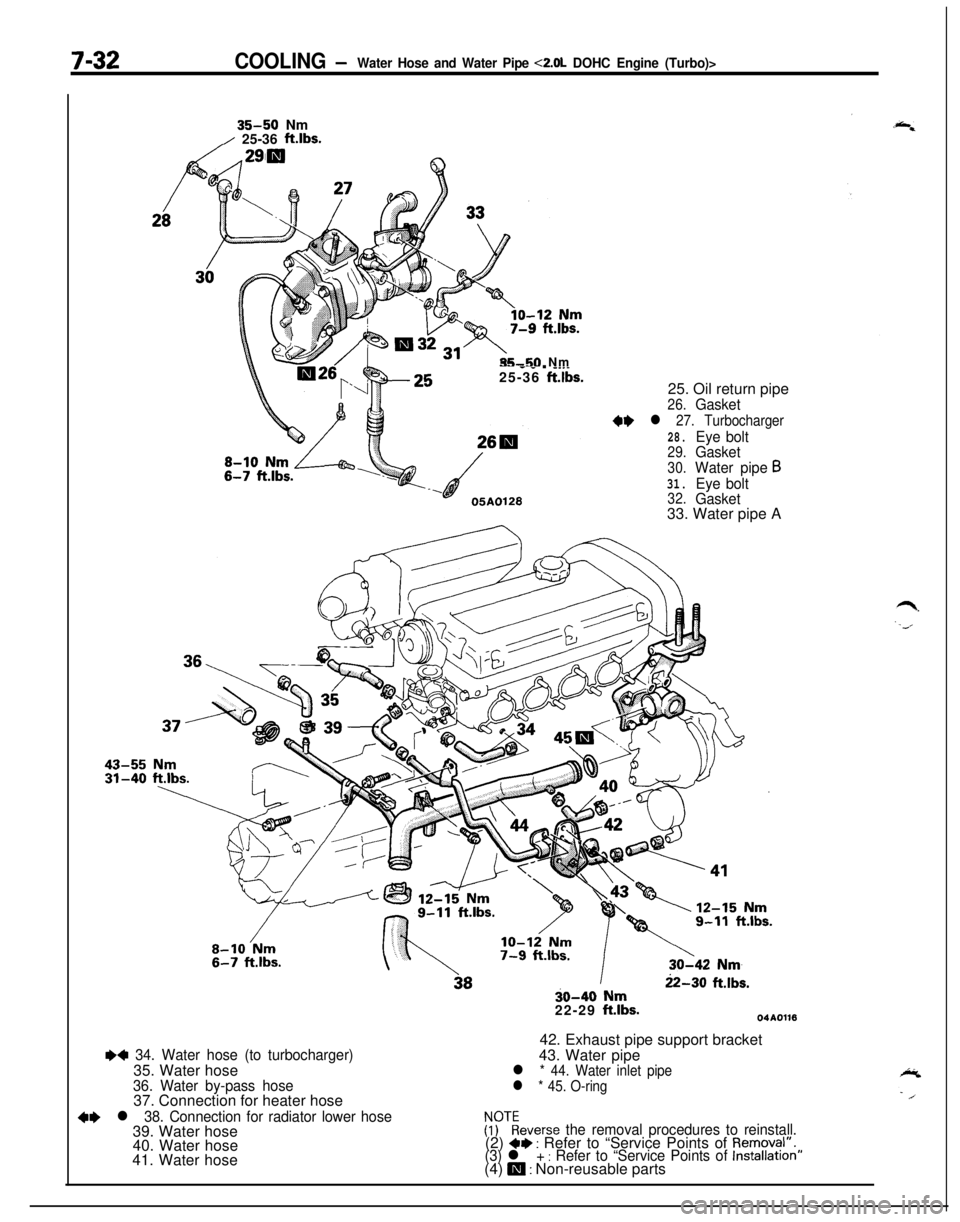

7-32COOLING -Water Hose and Water Pipe <2.0L DOHC Engine (Turbo)>

35-50 Nm/ 25-36 ft.lbs.

35-50 Nm-- - _ . __._25-36 ft.lbs.25. Oil return pipe

26.Gasket

++ l 27. Turbocharger

28.Eye bolt29.Gasket

30.Water pipe631.Eye bolt32.Gasket33. Water pipe A

++ 34. Water hose (to turbocharger)35. Water hose

36. Water by-pass hose37. Connection for heater hose

+e l 38. Connection for radiator lower hose39. Water hose

40. Water hose

41. Water hose

22-30 ft.lbs.30-40 Nm

22-29 ft.lbs.04A011642. Exhaust pipe support bracket

43. Water pipe

l * 44. Water inlet pipe

l * 45. O-ring

FFTkeverse the removal procedures to reinstall.(2) a+ : Refer to “Service Points of Removal”.(3) l + : Refer to “Service Points of Installation”(4) m : Non-reusable parts

Page 281 of 1216

COOLING- Water Hose and Water Pipe <2.0L DOHC Engine (Turbo)>7-330140552

Mating marks

04A0090

rMating marks

04A0090

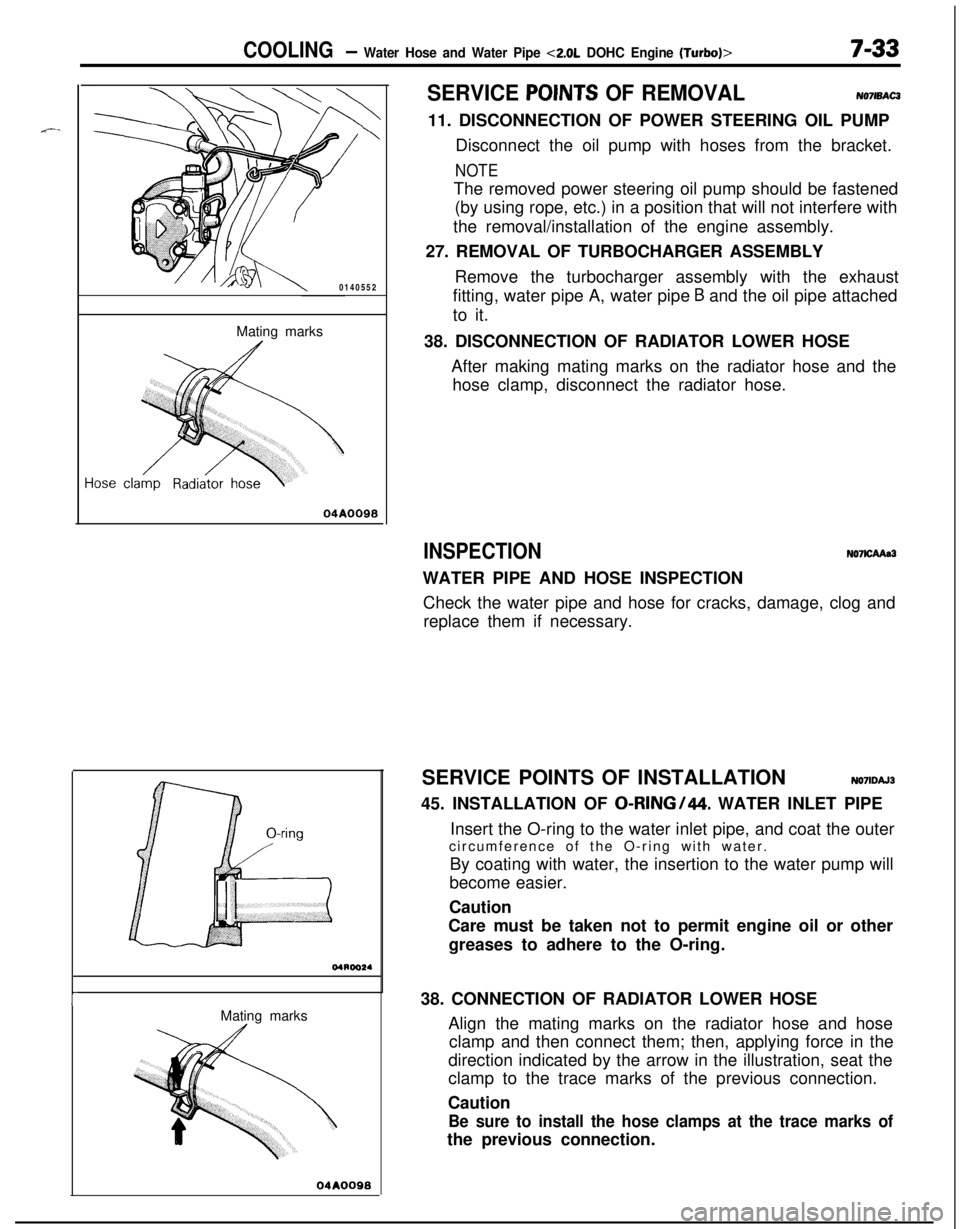

SERVICE POINTS OF REMOVALNO7lBAC311. DISCONNECTION OF POWER STEERING OIL PUMP

Disconnect the oil pump with hoses from the bracket.

NOTEThe removed power steering oil pump should be fastened

(by using rope, etc.) in a position that will not interfere with

the removal/installation of the engine assembly.

27. REMOVAL OF TURBOCHARGER ASSEMBLY

Remove the turbocharger assembly with the exhaust

fitting, water pipe A, water pipe

B and the oil pipe attached

to it.

38. DISCONNECTION OF RADIATOR LOWER HOSE

After making mating marks on the radiator hose and the

hose clamp, disconnect the radiator hose.

INSPECTIONN07lCAAa3WATER PIPE AND HOSE INSPECTION

Check the water pipe and hose for cracks, damage, clog and

replace them if necessary.

SERVICE POINTS OF INSTALLATION

N071DAJ345. INSTALLATION OF

0-RING/44. WATER INLET PIPE

Insert the O-ring to the water inlet pipe, and coat the outer

circumference of the O-ring with water.

By coating with water, the insertion to the water pump will

become easier.

Caution

Care must be taken not to permit engine oil or other

greases to adhere to the O-ring.

38. CONNECTION OF RADIATOR LOWER HOSE

Align the mating marks on the radiator hose and hose

clamp and then connect them; then, applying force in the

direction indicated by the arrow in the illustration, seat the

clamp to the trace marks of the previous connection.

Caution

Be sure to install the hose clamps at the trace marks ofthe previous connection.

Page 315 of 1216

ENGINE <1.8L Engine> - Engine Assembly9-31

ENGINE ASSEMBLY

. REMOVAL AND INSTALLATION

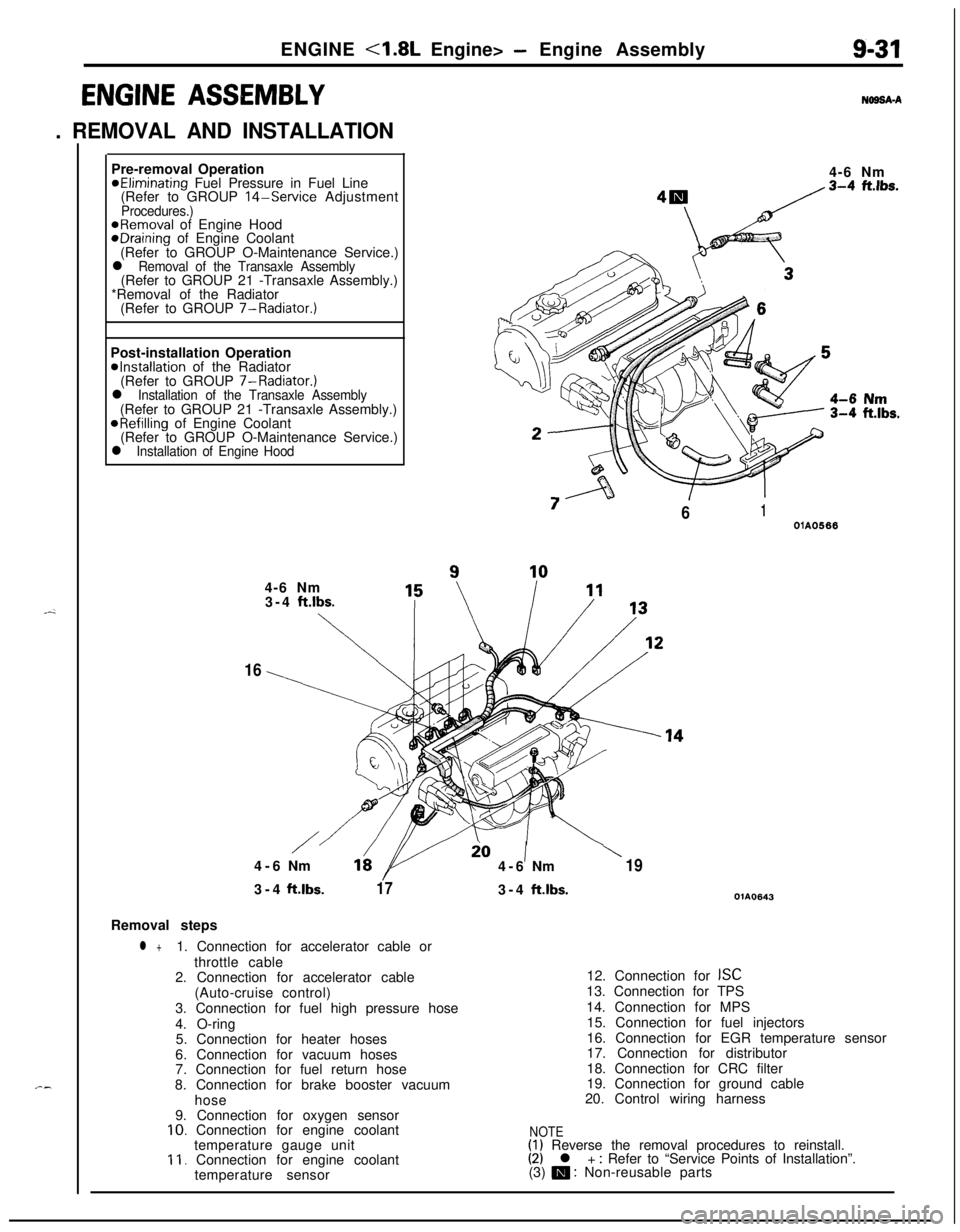

N69SA-APre-removal Operation

@Eliminating Fuel Pressure in Fuel Line

(Refer to GROUP 14-Service AdjustmentProcedures.)@Removal of Engine HoodeDraining of Engine Coolant

(Refer to GROUP O-Maintenance Service.)

l Removal of the Transaxle Assembly(Refer to GROUP 21 -Transaxle Assembly.)

*Removal of the Radiator

(Refer to GROUP 7-Radiator.)

Post-installation Operation

@Installation of the Radiator

(Refer to GROUP 7-Radiator.)

l Installation of the Transaxle Assembly(Refer to GROUP 21 -Transaxle Assembly.)

@Refilling of Engine Coolant

(Refer to GROUP O-Maintenance Service.)

l Installation of Engine Hood4-6 Nm

“7

/61OlA05664-6 Nm

3-4

ft.lbs.

\

16

/io1\4-6Nm164-6Nm193-4ft.lbs.

173-4ft.lbs.OlA0643Removal steps

l +1. Connection for accelerator cable or

throttle cable

2. Connection for accelerator cable

(Auto-cruise control)

3. Connection for fuel high pressure hose

4. O-ring

5. Connection for heater hoses

6. Connection for vacuum hoses

7. Connection for fuel return hose

8. Connection for brake booster vacuum

hose

9. Connection for oxygen sensor

10. Connection for engine coolant

temperature gauge unit

11. Connection for engine coolant

temperature sensor12. Connection for

ISC13. Connection for TPS

14. Connection for MPS

15. Connection for fuel injectors

16. Connection for EGR temperature sensor

17. Connection for distributor

18. Connection for CRC filter

19. Connection for ground cable

20. Control wiring harness

NOTE(1) Reverse the removal procedures to reinstall.(2) l + : Refer to “Service Points of Installation”.

(3) m : Non-reusable parts