oil MITSUBISHI ECLIPSE 1991 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 713 of 1216

MANUAL TRANSAXLE

TRANSAXLE

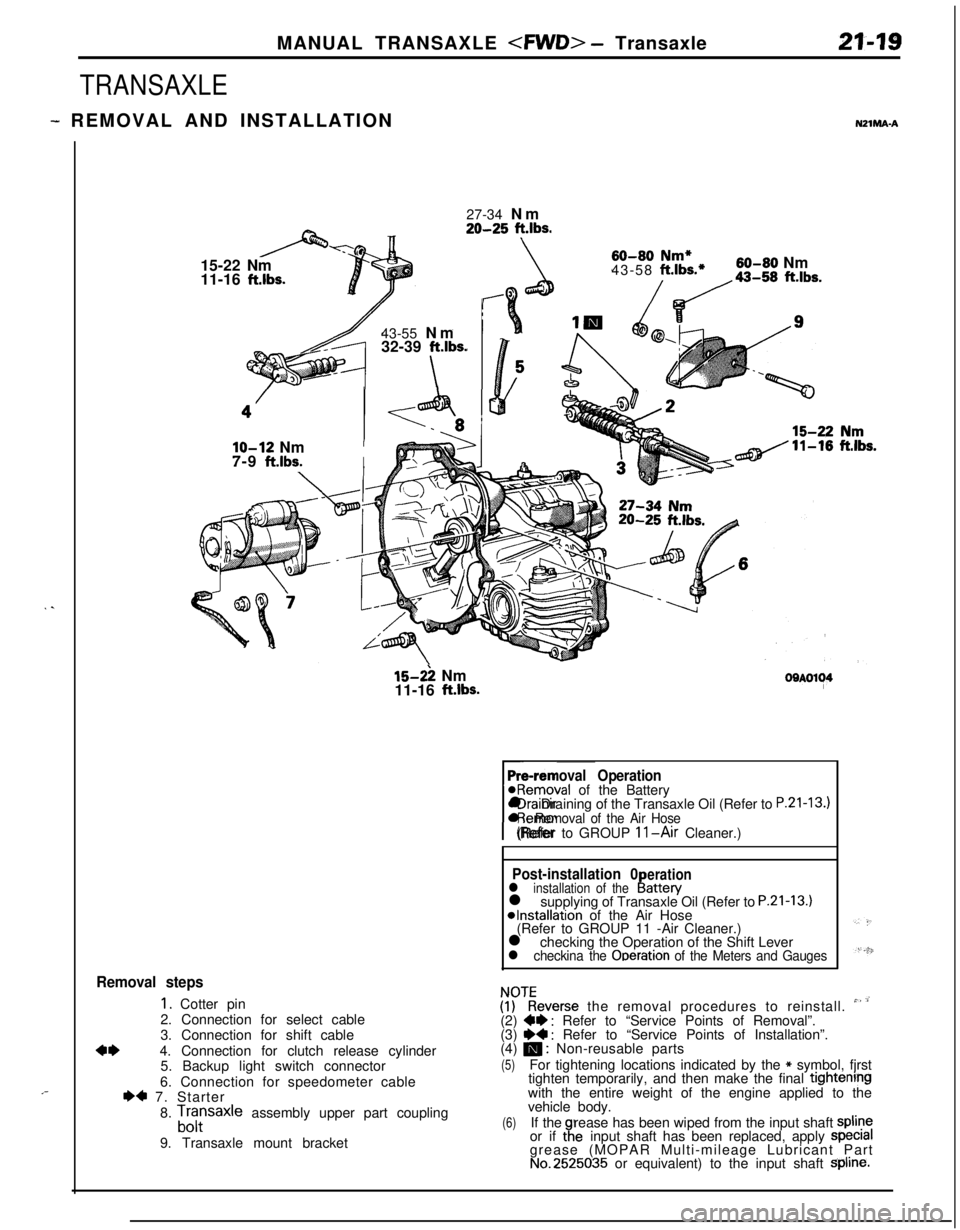

- REMOVAL AND INSTALLATIONNZlMA-A

. .

,-27-34 Nm

20-25 ft.lbs.15-22 Nm

11-16

ft.lbs.43-55 Nm

32-39

ft.lbs.

\

60-80 Nm*43-58 ft.lbs.*60-80 Nm

/da-,, ft.lbs.

lo-12 NmI7-9

ft.lbs.I

15-2: Nm

11-16 ft.lbs.OOAOl~4

Pre-removal Operation@Removal of the Battery

rl Draining of the Transaxle Oil (Refer to

P.21-13.)l Removal of the Air Hose(Refer to GROUP 11-Air Cleaner.)

Post-installation 0erationl installation of theI!attery

l supplying of Transaxle Oil (Refer to P.21-13.)*Installation of the Air Hose

(Refer to GROUP 11 -Air Cleaner.)

l checking the Operation of the Shift Lever

l checkina the Ooeration of the Meters and Gauges

Removal steps

1. Cotter pin

2. Connection for select cable

3. Connection for shift cable

4*4. Connection for clutch release cylinder

5. Backup light switch connector

6. Connection for speedometer cable

I)* 7. Starter

8.

Lfrsaxle assembly upper part coupling

9. Transaxle mount bracket

ZKeverse the removal procedures to reinstall. ” ’(2) W : Refer to “Service Points of Removal”.

(3) ~~ : Refer to “Service Points of Installation”.

(4) m : Non-reusable parts

(5)For tightening locations indicated by the * symbol, fjrst

tighten temporarily, and then make the final tightenrngwith the entire weight of the engine applied to the

vehicle body.

(6)If therease has been wiped from the input shaft spline

or if taeinput shaft has been replaced, apply specralgrease (MOPAR Multi-mileage Lubricant Part

No.2525035 or equivalent) to the input shaft Spline.

Page 715 of 1216

MANUAL TRANSAXLE

---

-..

2) ’TransaxlellK611

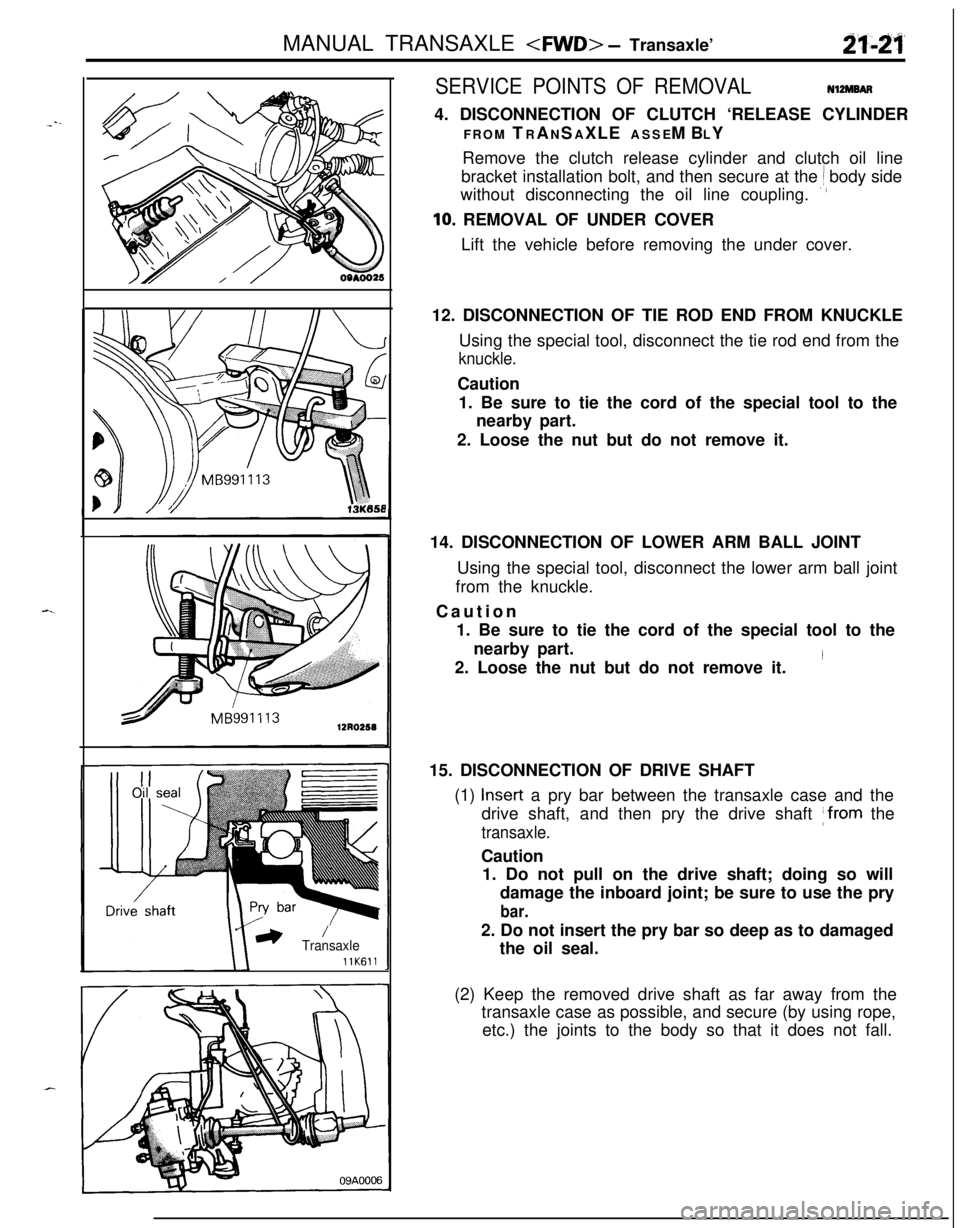

SERVICE POINTS OF REMOVALNlZMBAR4. DISCONNECTION OF CLUTCH ‘RELEASE CYLINDER

FROM TRANSAXLE ASSEMBLY

Remove the clutch release cylinder and clutch oil line

bracket installation bolt, and then secure at the

! body side

without disconnecting the oil line coupling.

”

10. REMOVAL OF UNDER COVER

Lift the vehicle before removing the under cover.

12. DISCONNECTION OF TIE ROD END FROM KNUCKLE

Using the special tool, disconnect the tie rod end from the

knuckle.Caution

1. Be sure to tie the cord of the special tool to the

nearby part.

2. Loose the nut but do not remove it.

14. DISCONNECTION OF LOWER ARM BALL JOINT

Using the special tool, disconnect the lower arm ball joint

from the knuckle.

Caution

1. Be sure to tie the cord of the special tool to the

nearby part.

2. Loose the nut but do not remove it.

I15. DISCONNECTION OF DRIVE SHAFT

(1)

Insert a pry bar between the transaxle case and the

drive shaft, and then pry the drive shaft

~from the

transaxle.Caution

1. Do not pull on the drive shaft; doing so will

damage the inboard joint; be sure to use the pry

bar.2. Do not insert the pry bar so deep as to damaged

the oil seal.

(2) Keep the removed drive shaft as far away from the

transaxle case as possible, and secure (by using rope,

etc.) the joints to the body so that it does not fall.

Page 716 of 1216

21-22MANUAL TRANSAXLE

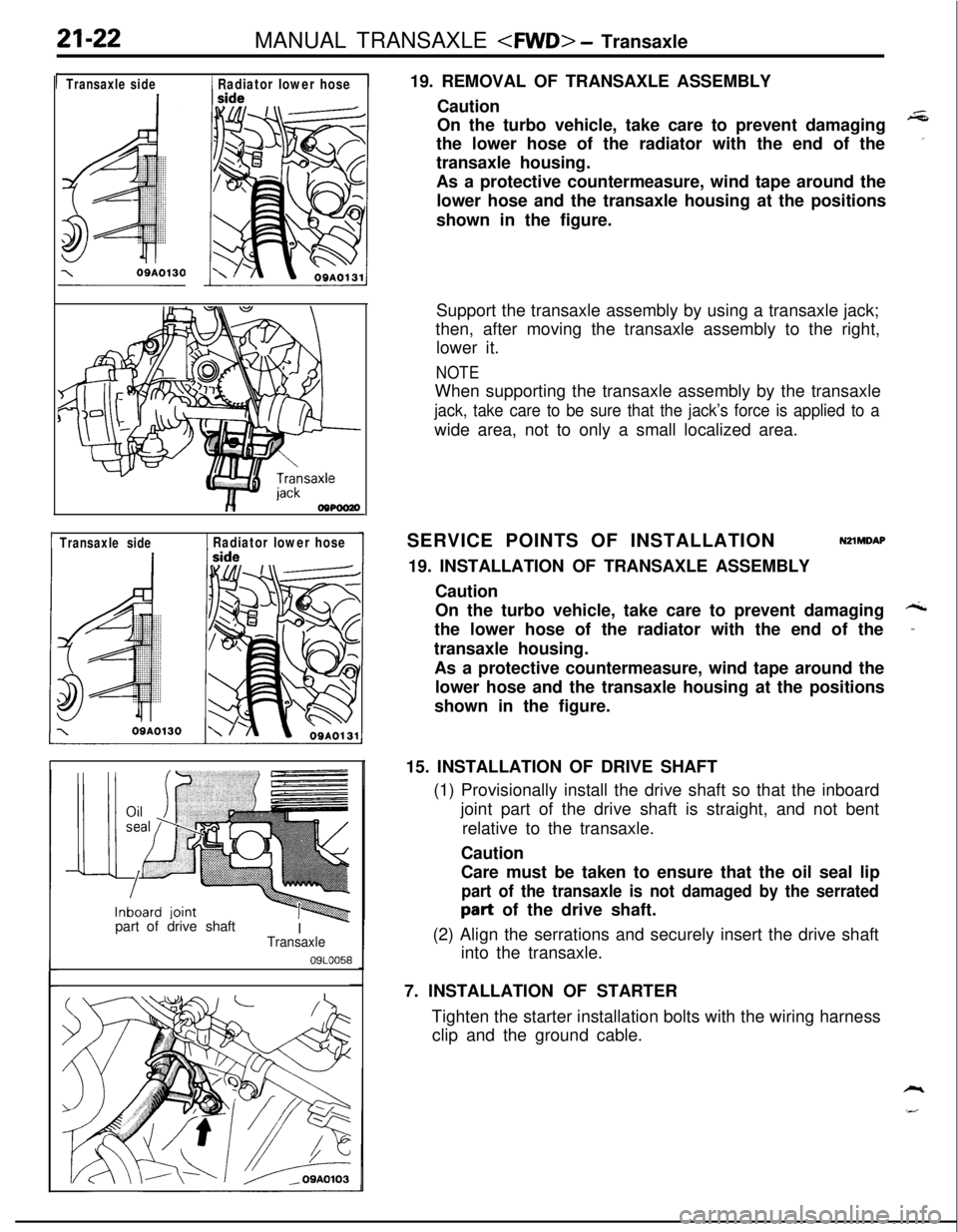

1 Transaxleside1 Radiator lower hose

1 Transaxle side1 Radiator lower hosepart ofdrive shaft

I

-Transaxle

09LOO5819. REMOVAL OF TRANSAXLE ASSEMBLY

Caution

On the turbo vehicle, take care to prevent damaging

+Gthe lower hose of the radiator with the end of the

’transaxle housing.

As a protective countermeasure, wind tape around the

lower hose and the transaxle housing at the positions

shown in the figure.

Support the transaxle assembly by using a transaxle jack;

then, after moving the transaxle assembly to the right,

lower it.

NOTEWhen supporting the transaxle assembly by the transaxle

jack, take care to be sure that the jack’s force is applied to awide area, not to only a small localized area.

SERVICE POINTS OF INSTALLATION

NZlMDAP19. INSTALLATION OF TRANSAXLE ASSEMBLY

Caution

On the turbo vehicle, take care to prevent damaging

Athe lower hose of the radiator with the end of the

-transaxle housing.

As a protective countermeasure, wind tape around the

lower hose and the transaxle housing at the positions

shown in the figure.

15. INSTALLATION OF DRIVE SHAFT

(1) Provisionally install the drive shaft so that the inboard

joint part of the drive shaft is straight, and not bent

relative to the transaxle.

Caution

Care must be taken to ensure that the oil seal lip

part of the transaxle is not damaged by the serratedpart of the drive shaft.

(2) Align the serrations and securely insert the drive shaft

into the transaxle.

7. INSTALLATION OF STARTER

Tighten the starter installation bolts with the wiring harness

clip and the ground cable.

Page 718 of 1216

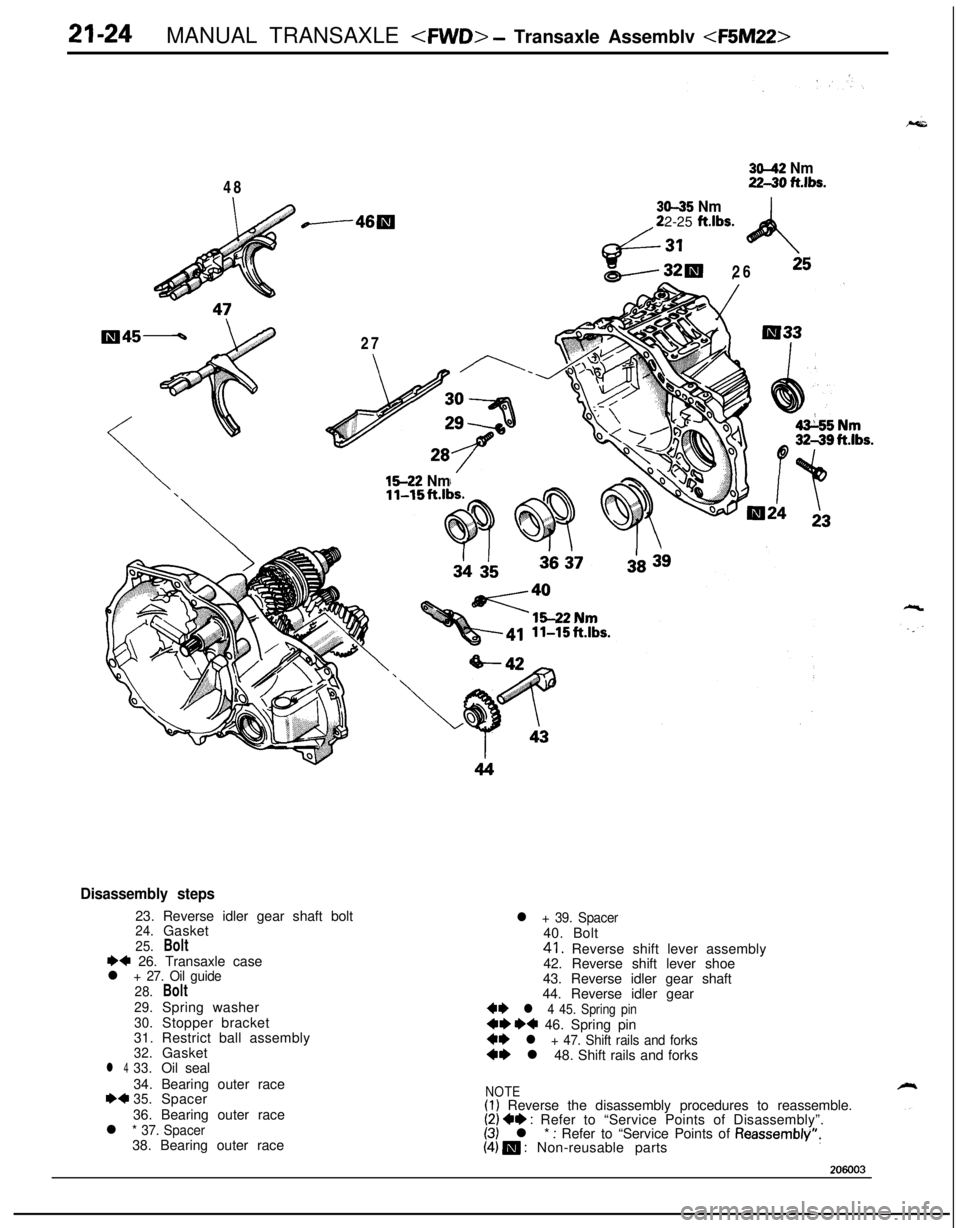

21-24MANUAL TRANSAXLE

3e42 Nm22-30 ft.lbs.30-35

NmI

122-25 ft.lbs.26

2527

1!&22 Nm\

\

Disassembly steps23. Reverse idler gear shaft bolt

24.Gasket25.Bolt++ 26. Transaxle casel + 27. Oil guide

28.Bolt

29.Spring washer30.Stopper bracket

31. Restrict ball assembly

32.Gasketl 433.Oil seal

34. Bearing outer race

+*35.Spacer

36. Bearing outer race

l * 37. Spacer38. Bearing outer race

l + 39. Spacer40. Bolt41. Reverse shift lever assembly

42. Reverse shift lever shoe

43. Reverse idler gear shaft

44. Reverse idler gear

+I) l 4 45. Spring pin~~ ~~ 46. Spring pin+* l + 47. Shift rails and forks+* l 48. Shift rails and forks

NOTE(1) Reverse the disassembly procedures to reassemble.(2) +* : Refer to “Service Points of Disassembly”.(3) l * : Refer to “Service Points of Reassembly”y(4) m : Non-reusable parts

Page 719 of 1216

MANUAL TRANSAXLE

2i &

15-22 Nm50 11-15 ft.lbs.

Disassembly steps

l +49. Bolt50. Screw

51. Bearing retainer

+e l + 52.Intermediate gear assemblyl + 53.Input shaft assembly54. Output shaft assembly

55. Differential gear assembly

56. Bearing outer race57. Oil guide

58. Bearing outer race

59. Bearing outer race

l 4 60. Oil seal

W 61. Oil seal

62. Magnet

63. Magnet holder

64. Clutch housing assembly

NOTE(1) Reverse the disassembly procedures to reassemble.(2) ~~ : Refer to “Service Points of Disassembly”.(3) e+ : Refer to “Service Points of Reassembly”.

(4) m : Non-reusable parts

21421

Page 721 of 1216

MANUAL TRANSAXLE

206001E

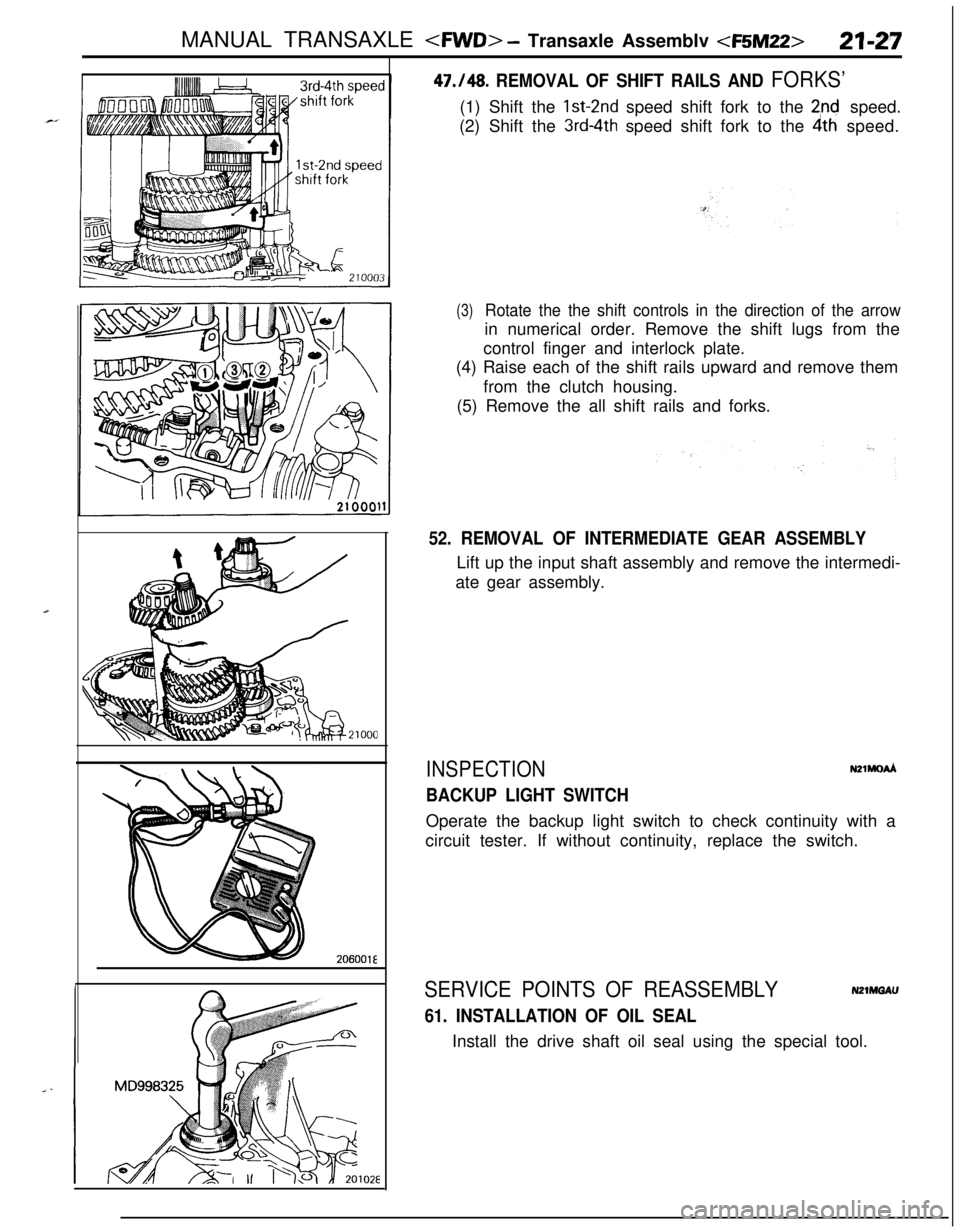

47./48. REMOVAL OF SHIFT RAILS AND FORKS’(1) Shift the Ist-2nd speed shift fork to the

2nd speed.

(2) Shift the

3rd~4th speed shift fork to the 4th speed.

(3)Rotate the the shift controls in the direction of the arrowin numerical order. Remove the shift lugs from the

control finger and interlock plate.

(4) Raise each of the shift rails upward and remove them

from the clutch housing.

(5) Remove the all shift rails and forks.

52. REMOVAL OF INTERMEDIATE GEAR ASSEMBLYLift up the input shaft assembly and remove the intermedi-

ate gear assembly.

INSPECTION

BACKUP LIGHT SWITCH

N21MOdOperate the backup light switch to check continuity with a

circuit tester. If without continuity, replace the switch.

SERVICE POINTS OF REASSEMBLYN2mnGAU

61. INSTALLATION OF OIL SEALInstall the drive shaft oil seal using the special tool.

Page 722 of 1216

21-28MANUAL TRANSAXLE

seal

201025Apply

adhesive

(.2 in.)TFMOO63

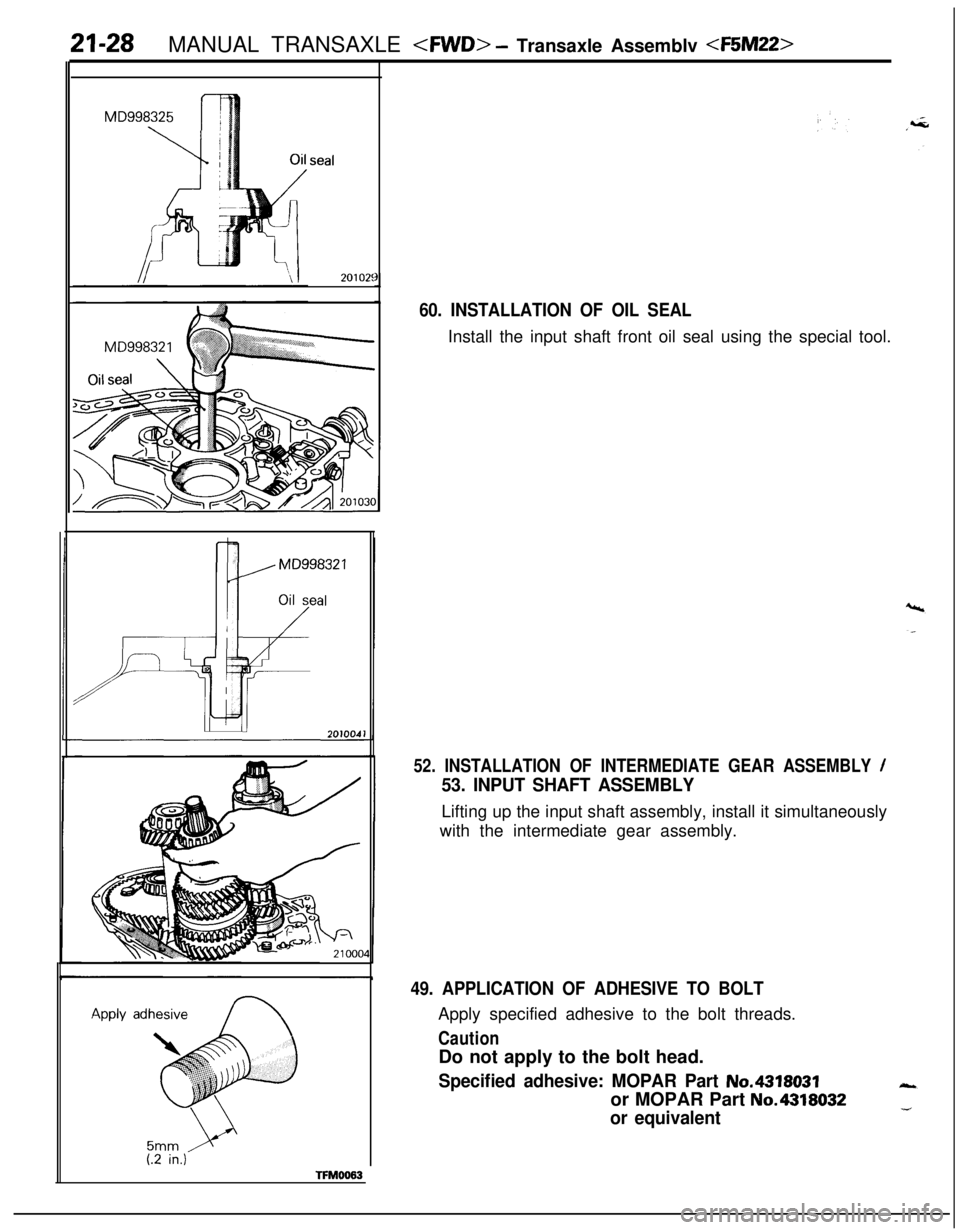

60. INSTALLATION OF OIL SEALInstall the input shaft front oil seal using the special tool.

52. INSTALLATION OF INTERMEDIATE GEAR ASSEMBLY /

53. INPUT SHAFT ASSEMBLYLifting up the input shaft assembly, install it simultaneously

with the intermediate gear assembly.

49. APPLICATION OF ADHESIVE TO BOLTApply specified adhesive to the bolt threads.

CautionDo not apply to the bolt head.

Specified adhesive: MOPAR Part No.4318031or MOPAR Part

No.4318032

or equivalent

Page 724 of 1216

21-30MANUAL TRANSAXLE

2200048

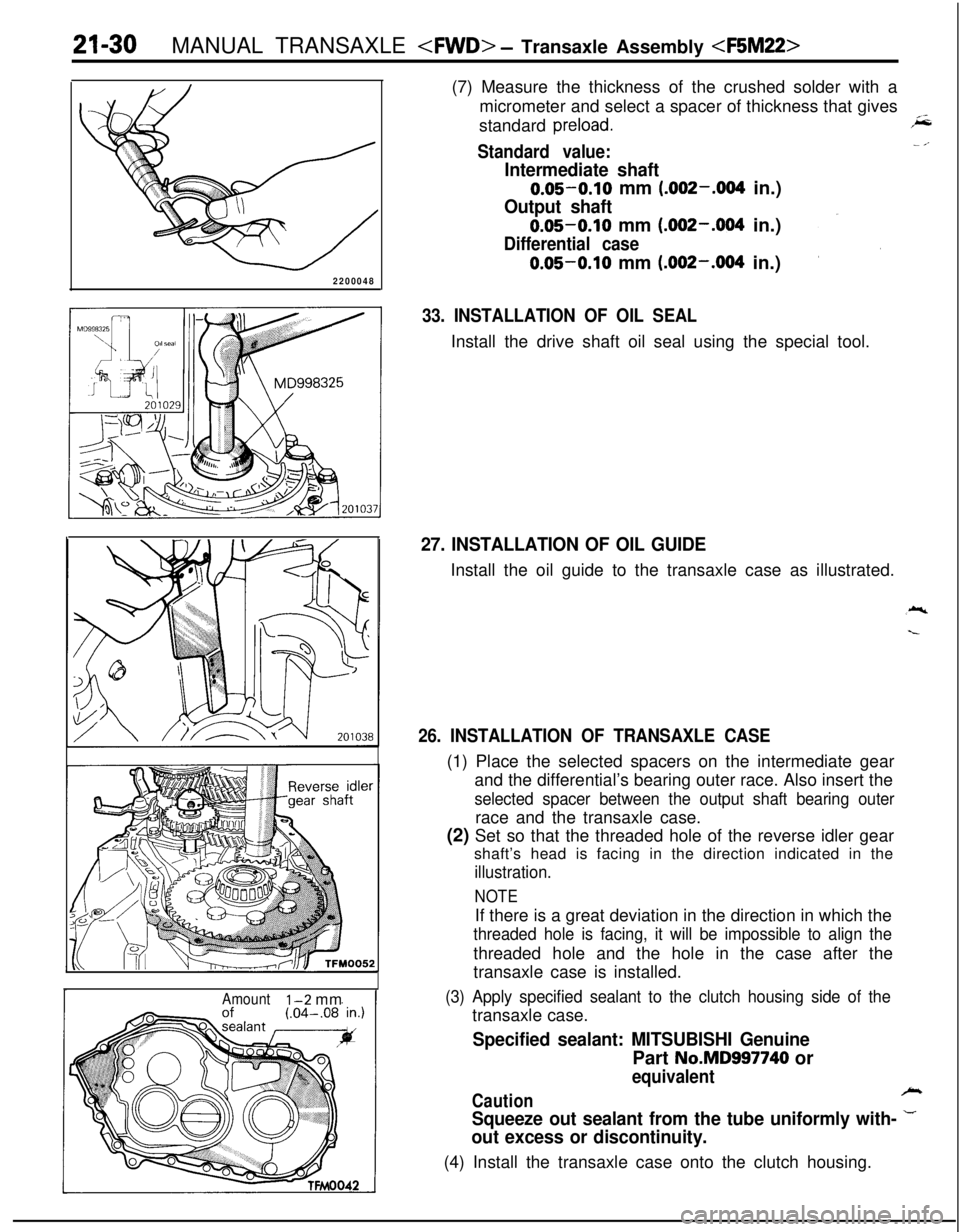

IAmountl-2 mm(7) Measure the thickness of the crushed solder with a

micrometer and select a spacer of thickness that gives

standard

preload.,&

Standard value:

Intermediate shaft0.05-0.10 mm (.002-,004 in.)

Output shaft0.05-0.10 mm (.002-.004 in.)

Differential case0.05-0.10 mm (.002-,004 in.)

33. INSTALLATION OF OIL SEALInstall the drive shaft oil seal using the special tool.

27. INSTALLATION OF OIL GUIDEInstall the oil guide to the transaxle case as illustrated.

26. INSTALLATION OF TRANSAXLE CASE(1) Place the selected spacers on the intermediate gear

and the differential’s bearing outer race. Also insert the

selected spacer between the output shaft bearing outerrace and the transaxle case.

(2) Set so that the threaded hole of the reverse idler gear

shaft’s head is facing in the direction indicated in the

illustration.

NOTEIf there is a great deviation in the direction in which the

threaded hole is facing, it will be impossible to align thethreaded hole and the hole in the case after the

transaxle case is installed.

(3) Apply specified sealant to the clutch housing side of thetransaxle case.

Specified sealant: MITSUBISHI GenuinePart

No.MD997740 or

equivalent

CautionB

Squeeze out sealant from the tube uniformly with- -

out excess or discontinuity.(4) Install the transaxle case onto the clutch housing.

Page 728 of 1216

21-34MANUAL TRANSAXLE

? ,‘,

30-35 Nm77-25 fLlbs.35-42 Nni26-30 ftlbs.

25

APi 77

--2lRl 26

\\15-22 Nm

---- -_ . .23

II-15 lt.lDS.

I

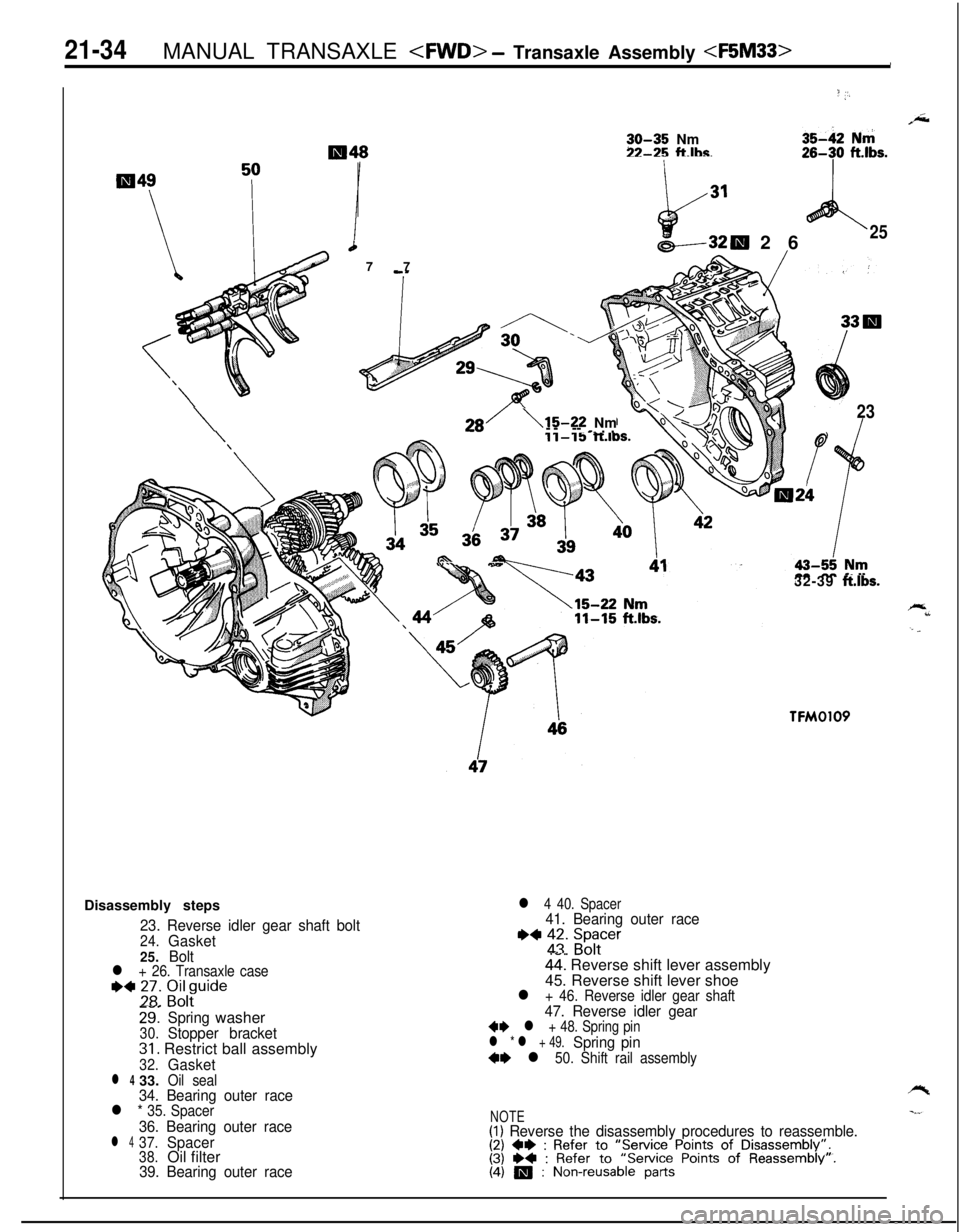

..d.. -Disassembly steps

23. Reverse idler gear shaft bolt24.Gasket

25.Bolt

l + 26. Transaxle case+4 ;I. ;$yrde

29:Springwasher30.Stopper bracket31. Restrict ball assembly

32.Gasketl 433.Oil seal34. Bearing outer racel * 35. Spacer

36. Bearing outer racel 437.Spacer38.Oil filter39. Bearing outer race32-39

ft.lbs.

TFMOlO9

l 4 40. Spacer41. Bearing outer race

I)* ;I. Sggcer

44: Reverse shift lever assembly

45. Reverse shift lever shoe

l + 46. Reverse idler gear shaft47. Reverse idler gear+e l + 48. Spring pinl * l + 49.Spring pin+I) l 50. Shift rail assembly

NOTE(I) Reverse the disassembly procedures to reassemble.(2) +e : Refer to “Service Points of Disassembly”.(3) e* : Refer to “Service Points of Reassembly”.(4) 19 : Non-reusable parts

Page 729 of 1216

_-MANUAL TRANSAXLE

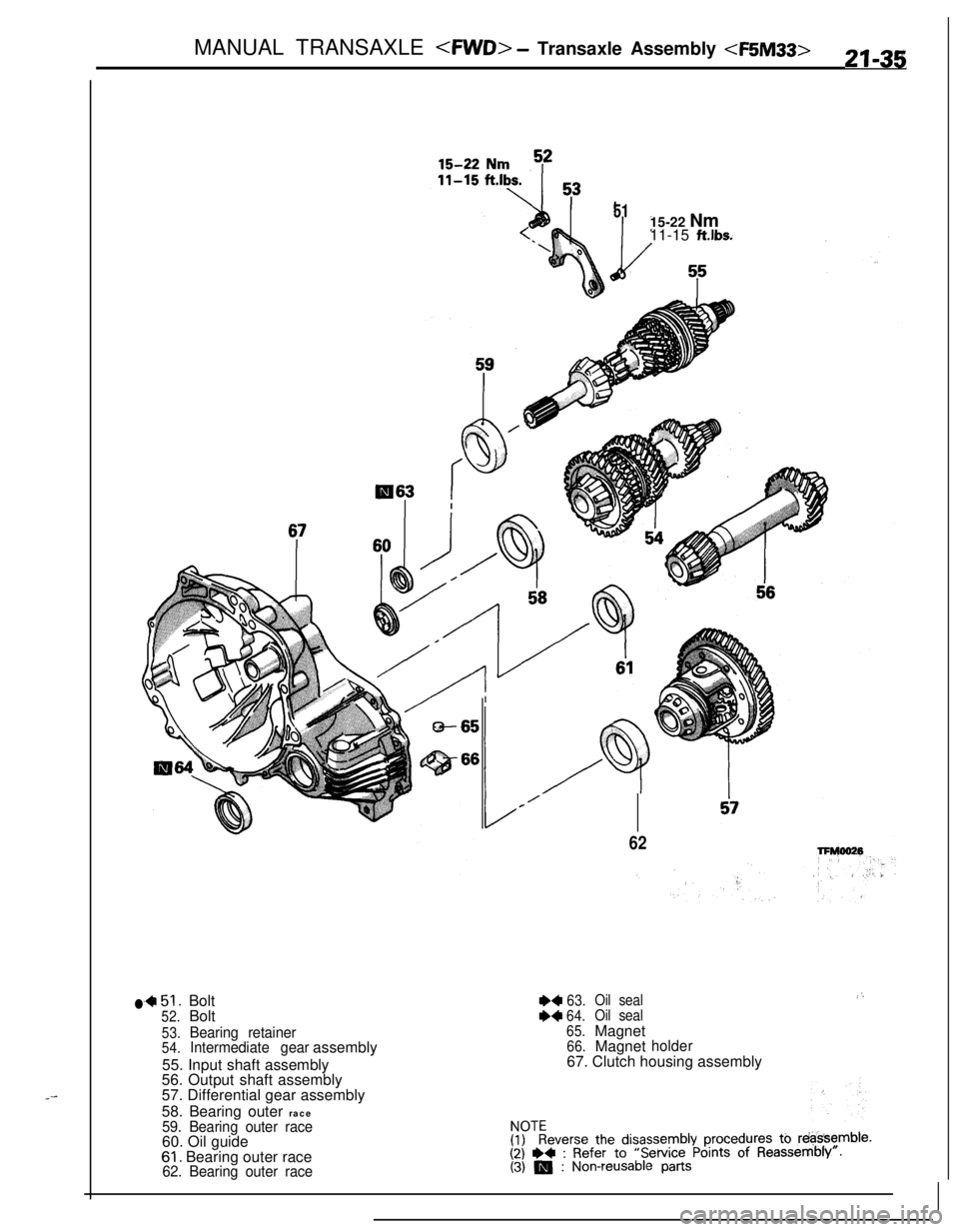

- Transaxle Assembly

11-15 ftlbs.

5115-22 Nm

11-15

ftlbs.

l,451.Bolt

52.Bolt

53.Bearing retainer54.Intermediate gearassembly

55. Input shaft assembly

56. Output shaft assembly

57. Differential gear assembly

58. Bearing outer race

59. Bearing outer race60. Oil guide

61. Bearing outer race62. Bearing outer race

/’

62

+463.Oil seal+464.Oil seal

65.Magnet

66.Magnetholder67. Clutch housing assembly

; .,

FFkeverse the disassembly procedures to rdassembte.(2) ++ : Refer to “Service Points of Reassem’bly”.(3) m : Non-reusable parts