light MITSUBISHI ECLIPSE 1991 Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 178 of 1216

![MITSUBISHI ECLIPSE 1991 Owners Guide 5-38BRAKES - Anti-lock Braking System Troubleshooting

E-5Abnormality of solenoid valve drive circuit

[Explanation]*>The ABS ECU normally monitors the solenoid valve

when turned OFF, the ECU determines MITSUBISHI ECLIPSE 1991 Owners Guide 5-38BRAKES - Anti-lock Braking System Troubleshooting

E-5Abnormality of solenoid valve drive circuit

[Explanation]*>The ABS ECU normally monitors the solenoid valve

when turned OFF, the ECU determines](/img/19/57104/w960_57104-177.png)

5-38BRAKES - Anti-lock Braking System Troubleshooting

E-5Abnormality of solenoid valve drive circuit

[Explanation]*>The ABS ECU normally monitors the solenoid valve

when turned OFF, the ECU determines the solenoid%’ -’drive circuit.coil wire is broken/short circuited or the harness is

If no current flows in the solenoid even if the ECUbroken/short circuited and then the warning light

turns the solenoid ON or if it continues to flow evenlights up.

IGNITIONSWITCH(IGI)

7JIB------_-_tor and check with the

side connector.

Connect HU

1OP connec-

disconnect ECU con-

>Is the solenoid valve resis-

tance value within the range

of the standard values when

measured at the ECU con-

nector?Standard value:

3.0-3.2 Q

Yes1

II

I

Solenoid valve drive circuit isnormal.I

NoReplace HU.I

NoIs the resistance value for

the solenoid valve within the

range ofthe standard

values?Standard value:

3.0-3.2 Q, IYes ,

1

JThe harness wire for the

solenoidvalvecircuit

whose resistance value is

outside the range of the

standard value is broken

or short circuited.,-‘he-

-Repair

Page 179 of 1216

![MITSUBISHI ECLIPSE 1991 Owners Guide BRAKES - Anti-lock Braking System Troubleshooting5-39

E-6Abnormality of valve relay drive circuitI

j-a [Explanation]When the ignition switch is turned ON, the ABSnormal. In addition, normally it monit MITSUBISHI ECLIPSE 1991 Owners Guide BRAKES - Anti-lock Braking System Troubleshooting5-39

E-6Abnormality of valve relay drive circuitI

j-a [Explanation]When the ignition switch is turned ON, the ABSnormal. In addition, normally it monit](/img/19/57104/w960_57104-178.png)

BRAKES - Anti-lock Braking System Troubleshooting5-39

E-6Abnormality of valve relay drive circuitI

j-a [Explanation]When the ignition switch is turned ON, the ABSnormal. In addition, normally it monitors whether or

ECU switches the valve relay OFF and ON for annot there is power in the valve power monitor line

initial check, compares the voltage of the signal tosince the valve relay is normally ON. Then, if the

the valve relay and valve power monitor line voltagesupply of power to the valve power monitor line is

to check whether the valve relay operation is

interrupted, the warning light illuminates.

IGNITIONMAIN FUSIBLESWITCHLINK @W-31)When the valve relay is

checked, are the followingconditions found?No.85-No.86:resistancevalue 60-120 Q

No.30-No.87a: continuityNo.30-No.87: No continui-

When battery voltage is ap-plied between terminals

No.86 and No. 85 grounded.

No. 30-No. 87: continuity

No.

30-No. 87a: no continui-

tyremove the HU connec-

NoValve relay malfunction

Replace valve relay.

IConnect the HU

remove the ECU con-

I Yes

IValve relay drive circuit isnormal.I

Page 180 of 1216

![MITSUBISHI ECLIPSE 1991 Owners Guide 5-40BRAKES - Anti-lock Braking System Troubleshooting

E-7Abnormality of motor drive circuit

[Explanation]The ABS ECU illuminates the warning light for the

motor relay and motor in the following cases. MITSUBISHI ECLIPSE 1991 Owners Guide 5-40BRAKES - Anti-lock Braking System Troubleshooting

E-7Abnormality of motor drive circuit

[Explanation]The ABS ECU illuminates the warning light for the

motor relay and motor in the following cases.](/img/19/57104/w960_57104-179.png)

5-40BRAKES - Anti-lock Braking System Troubleshooting

E-7Abnormality of motor drive circuit

[Explanation]The ABS ECU illuminates the warning light for the

motor relay and motor in the following cases.

l When the motor relay does not function

lWhen there is trouble with the motor itself and it

does not revolve

[Hint]If there is motor operation noise when wheel speed

exceeds

Gkm/h (4mph) when starting up after the

engine is started, there is a broken or short circuitedmotor monitor wire.

lWhen the motor ground line is disconnected andthe motor does not revolve

l When the motor continues to revolve

Does the motor make a

YesBroken wire or short cir-noise when wheel speed

-cuit in motor monitor line

exceeds 6 km/h (4 mph)?

b

NoRepair the harness between HU and ECU.

emove the motor rela

ABS ECU

14A0105

Remove the motor relav and

check resistance values.

No.

85-No. 86:resistancevalue 30-60 QNo.30-No.87: no continui-

ty

Battery voltage is applied on

terminals No. 86 and No. 85

grounded

No. 30-No. 87: continuity

Yes

q Motor relay malfunction 1

Replace motor relay.I

Is pump motor ground con-netted normally?Connect ground wire.I

b

Does voltage between bodyNo

connector terminal 51 andIBroken wire in pumpmotor power circuit

ground indicate battery vol-

tage?1Repair the harness.

YesIs resistance between body

- No L Malfunction of harness

connector terminal No. 2 andbetween HU and ECU

No.26 30-60 ohms?b

YesRepair harness.

Motor drive circuit is normal.

Page 181 of 1216

BRAKES - Service Adjustment Procedures5-47switch

switch

v14F516

Idown ,./

F14517

F14518

F14519

SERVICE ADJUSTMENT PROCEDURES

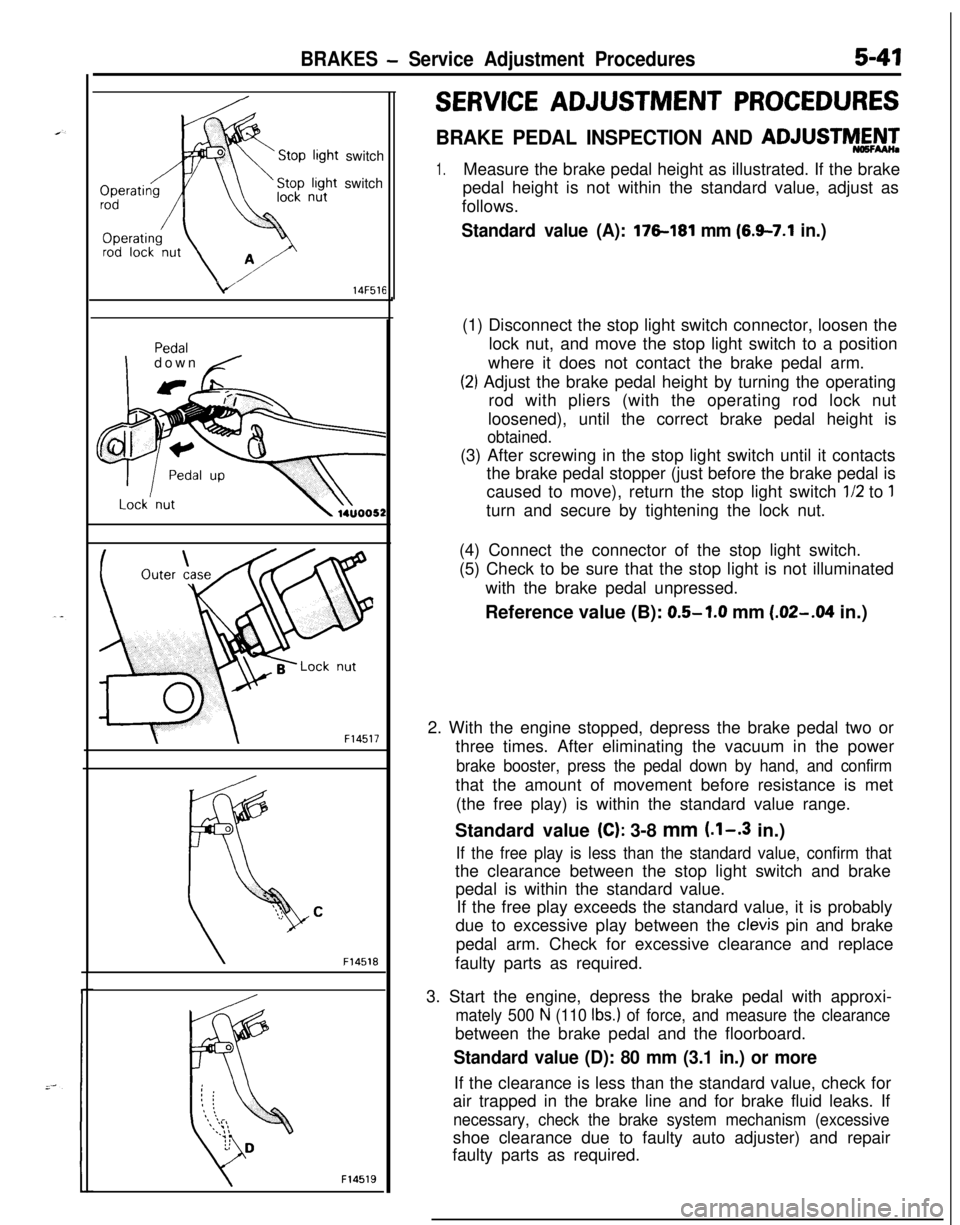

BRAKE PEDAL INSPECTION AND ADJUSTM&g

1.Measure the brake pedal height as illustrated. If the brake

pedal height is not within the standard value, adjust as

follows.

Standard value (A): 176181 mm (6.9-7.1 in.)(1) Disconnect the stop light switch connector, loosen the

lock nut, and move the stop light switch to a position

where it does not contact the brake pedal arm.

(2) Adjust the brake pedal height by turning the operating

rod with pliers (with the operating rod lock nut

loosened), until the correct brake pedal height is

obtained.(3) After screwing in the stop light switch until it contacts

the brake pedal stopper (just before the brake pedal is

caused to move), return the stop light switch

l/2 to 1turn and secure by tightening the lock nut.

(4) Connect the connector of the stop light switch.

(5) Check to be sure that the stop light is not illuminated

with the brake pedal unpressed.

Reference value (B): 0.5-1.0 mm

(.02-M in.)

2. With the engine stopped, depress the brake pedal two or

three times. After eliminating the vacuum in the power

brake booster, press the pedal down by hand, and confirmthat the amount of movement before resistance is met

(the free play) is within the standard value range.

Standard value

(C): 3-8 mm (.l-.3 in.)

If the free play is less than the standard value, confirm thatthe clearance between the stop light switch and brake

pedal is within the standard value.

If the free play exceeds the standard value, it is probably

due to excessive play between the

clevis pin and brake

pedal arm. Check for excessive clearance and replace

faulty parts as required.

3. Start the engine, depress the brake pedal with approxi-

mately 500 N (110 Ibs.) of force, and measure the clearancebetween the brake pedal and the floorboard.

Standard value (D): 80 mm (3.1 in.) or moreIf the clearance is less than the standard value, check for

air trapped in the brake line and for brake fluid leaks. If

necessary, check the brake system mechanism (excessiveshoe clearance due to faulty auto adjuster) and repair

faulty parts as required.

Page 183 of 1216

BRAKES - Service Adjustment Procedures5-43When engine is

stoppedNo good

0

wtwo061

VV;Videngine is

t4uoo60

Caution

If the number of brake lever notches engaged is less

than the standard value, the cable has been pulledexcessively, and failure of the automatic adjuster

mechanism will result. Be sure tti adjust it to within the

standard value.(6) After making the adjustment, check to be sure that there is

no play between the adjusting nut and the pin. Also check

to be sure that the adjusting nut is securely held at the nut

holder.(7) After adjusting the lever stroke, jack up the rear of the

vehicle.(8) With the parking brake lever in the released position, turn

the rear wheel to confirm that the rear brakes are not

dragging.

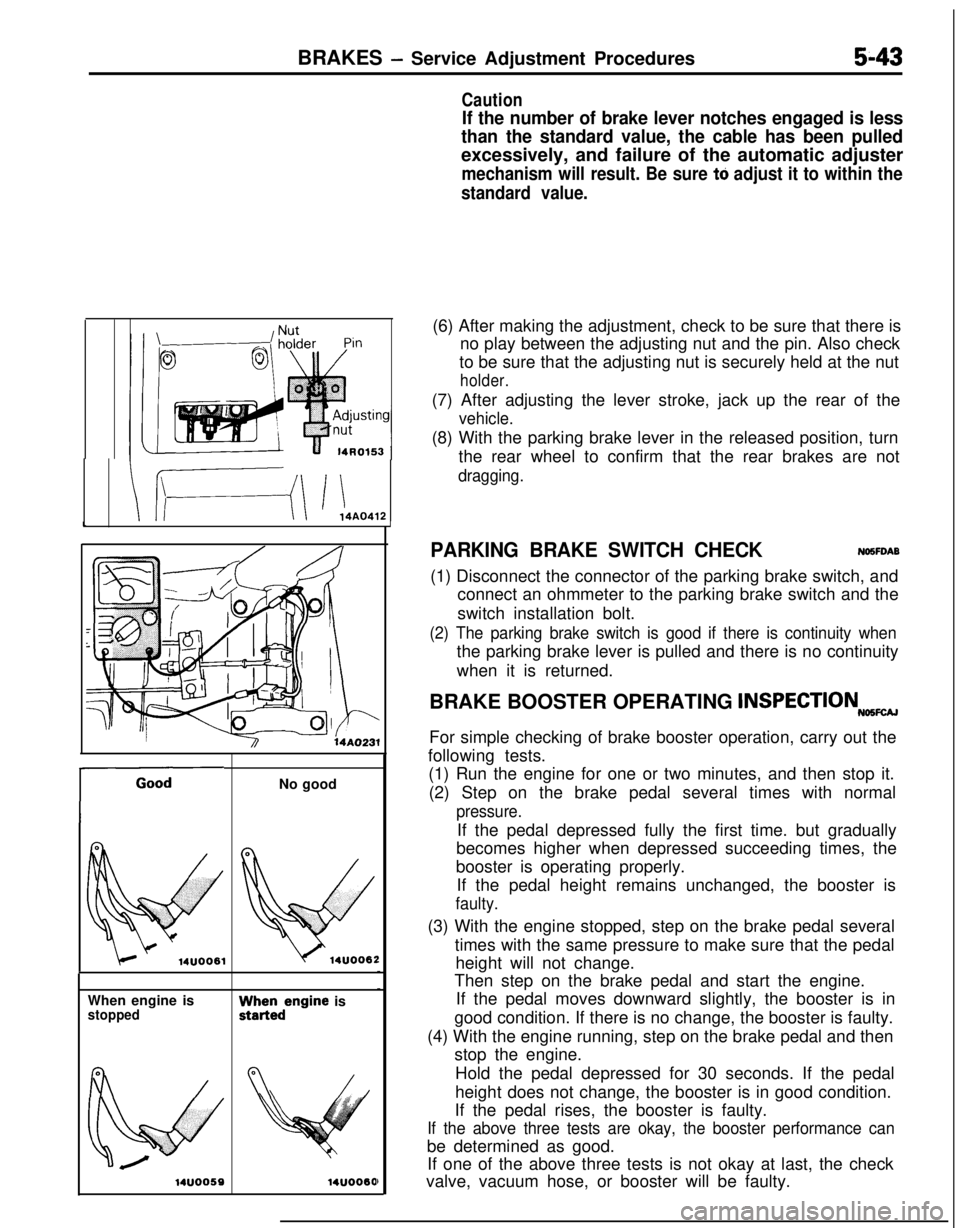

PARKING BRAKE SWITCH CHECKN05FDAB

(1) Disconnect the connector of the parking brake switch, and

connect an ohmmeter to the parking brake switch and the

switch installation bolt.

(2) The parking brake switch is good if there is continuity whenthe parking brake lever is pulled and there is no continuity

when it is returned.

BRAKE BOOSTER OPERATING

lNSPECTIONNoSFcuFor simple checking of brake booster operation, carry out the

following tests.

(1) Run the engine for one or two minutes, and then stop it.

(2) Step on the brake pedal several times with normal

pressure.If the pedal depressed fully the first time. but gradually

becomes higher when depressed succeeding times, the

booster is operating properly.

If the pedal height remains unchanged, the booster is

faulty.(3) With the engine stopped, step on the brake pedal several

times with the same pressure to make sure that the pedal

height will not change.

Then step on the brake pedal and start the engine.

If the pedal moves downward slightly, the booster is in

good condition. If there is no change, the booster is faulty.

(4) With the engine running, step on the brake pedal and then

stop the engine.

Hold the pedal depressed for 30 seconds. If the pedal

height does not change, the booster is in good condition.

If the pedal rises, the booster is faulty.

If the above three tests are okay, the booster performance canbe determined as good.

If one of the above three tests is not okay at last, the check

valve, vacuum hose, or booster will be faulty.

Page 192 of 1216

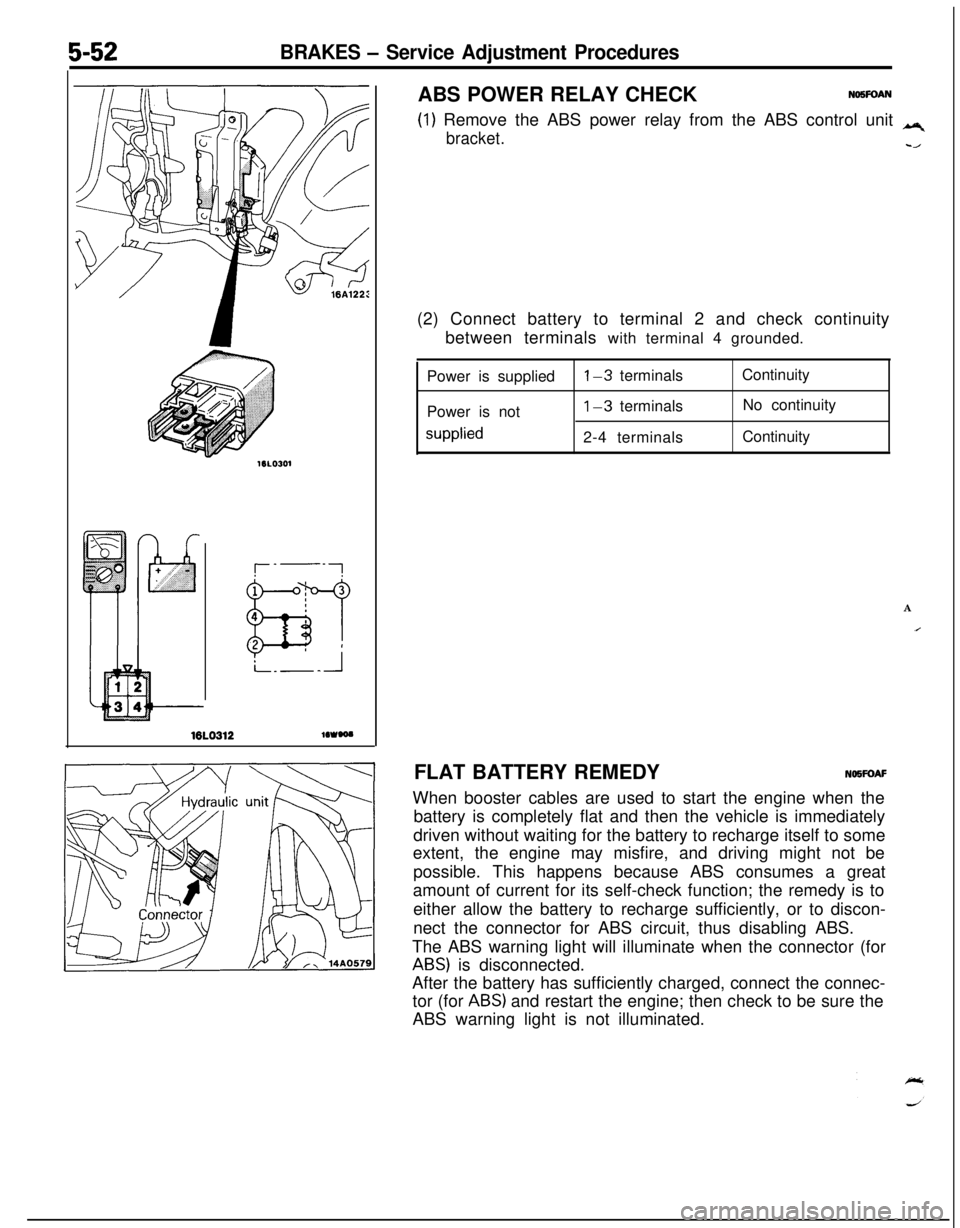

5-52BRAKES - Service Adjustment Procedures

16LO312lOWOO

(1) Remove the ABS power relay from the ABS control unit q

bracket.-/ABS POWER RELAY CHECK

NO5FOAN(2) Connect battery to terminal 2 and check continuity

between terminals with terminal 4 grounded.

Power is supplied

Power is not

supplied

l-3 terminals

1-3 terminals

2-4 terminalsContinuity

No continuity

Continuity

A

IFLAT BATTERY REMEDYNOWOAF

When booster cables are used to start the engine when the

battery is completely flat and then the vehicle is immediately

driven without waiting for the battery to recharge itself to some

extent, the engine may misfire, and driving might not be

possible. This happens because ABS consumes a great

amount of current for its self-check function; the remedy is to

either allow the battery to recharge sufficiently, or to discon-

nect the connector for ABS circuit, thus disabling ABS.

The ABS warning light will illuminate when the connector (for

ABS) is disconnected.

After the battery has sufficiently charged, connect the connec-

tor (for

ABS) and restart the engine; then check to be sure the

ABS warning light is not illuminated.

Page 193 of 1216

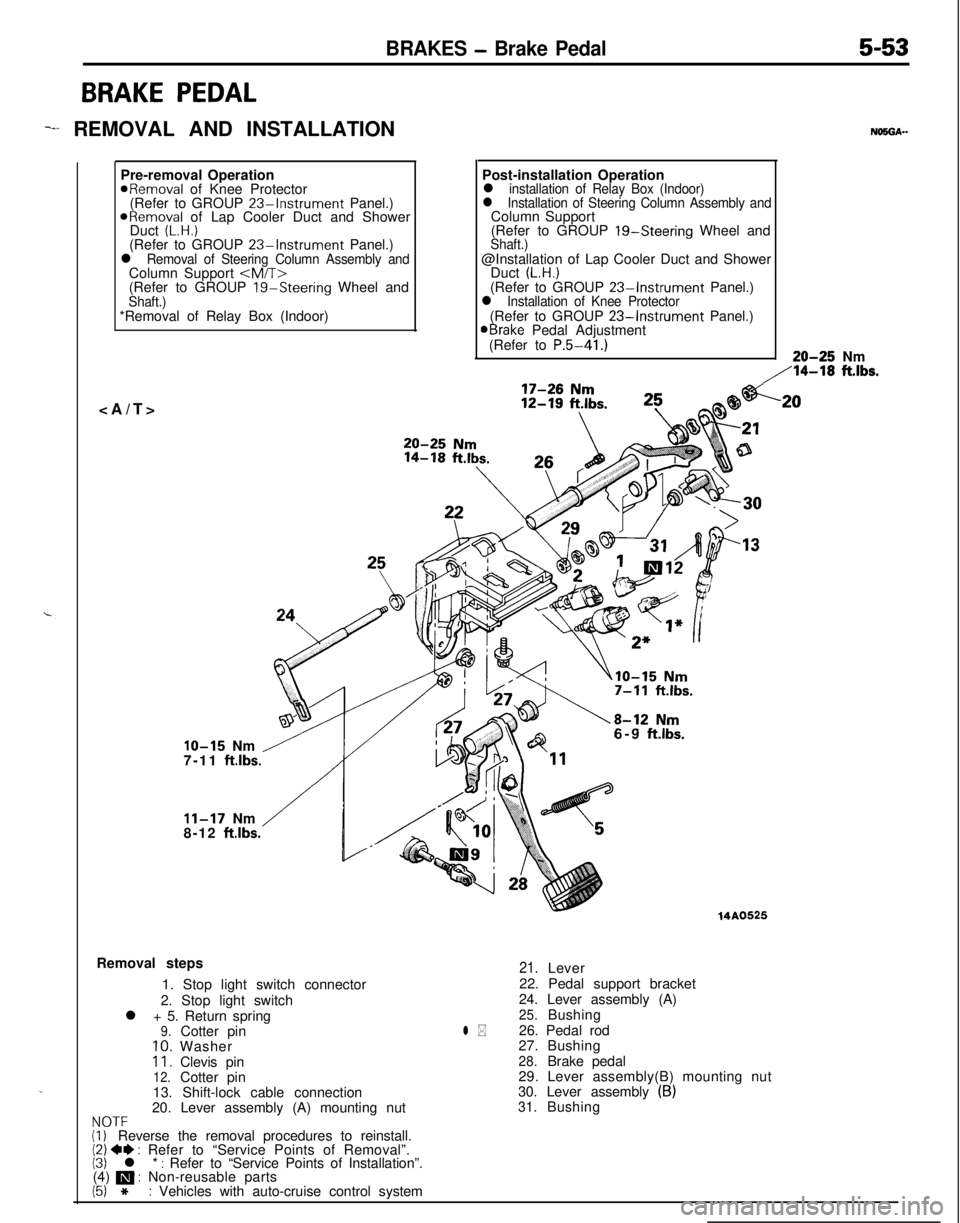

BRAKES - Brake Pedal5-53

BRAKE PEDAL

-I REMOVAL AND INSTALLATION

.Pre-removal Operation

aRemoval of Knee Protector

(Refer to GROUP 23%Instrument Panel.)

ORemoval of Lap Cooler Duct and Shower

Duct (L.H.)(Refer to GROUP 23-Instrument Panel.)l Removal of Steering Column Assembly andColumn Support

(Refer to GROUP

19-Steering Wheel andShaft.)*Removal of Relay Box (Indoor)

NO5OA--Post-installation Operation

l installation of Relay Box (Indoor)l Installation of Steering Column Assembly andColumn Support

(Refer to GROUP 19-Steering Wheel and

Shaft.)@Installation of Lap Cooler Duct and Shower

Duct

(L.H.)(Refer to GROUP 23-Instrument Panel.)l Installation of Knee Protector(Refer to GROUP 23-Instrument Panel.)aBrake Pedal Adjustment

(Refer to P.5-41.)20-25 Nm

,‘14-18 ft.lbs.

IO-15 Nm /7-11 ft.lbs.

/

11-17 Nm

8-12 ftlbs.6-9

ftlbs.Removal steps

1. Stop light switch connector

2. Stop light switch

l + 5. Return spring

9.Cotter pin10.Washer11.Clevis pin12.Cotter pin

13. Shift-lock cable connection

20. Lever assembly (A) mounting nut

NOTF(i, Reverse the removal procedures to reinstall.(2) 4I) : Refer to “Service Points of Removal”.(3) l * : Refer to “Service Points of Installation”.

(4) m : Non-reusable parts

(5) *: Vehicles with auto-cruise control system

14A0525

l *

21.Lever

22. Pedal support bracket

24. Lever assembly (A)

25.Bushing

26. Pedal rod

27.Bushing

28.Brake pedal

29. Lever assembly(B) mounting nut

30. Lever assembly

(B)31.Bushing

.20

Page 194 of 1216

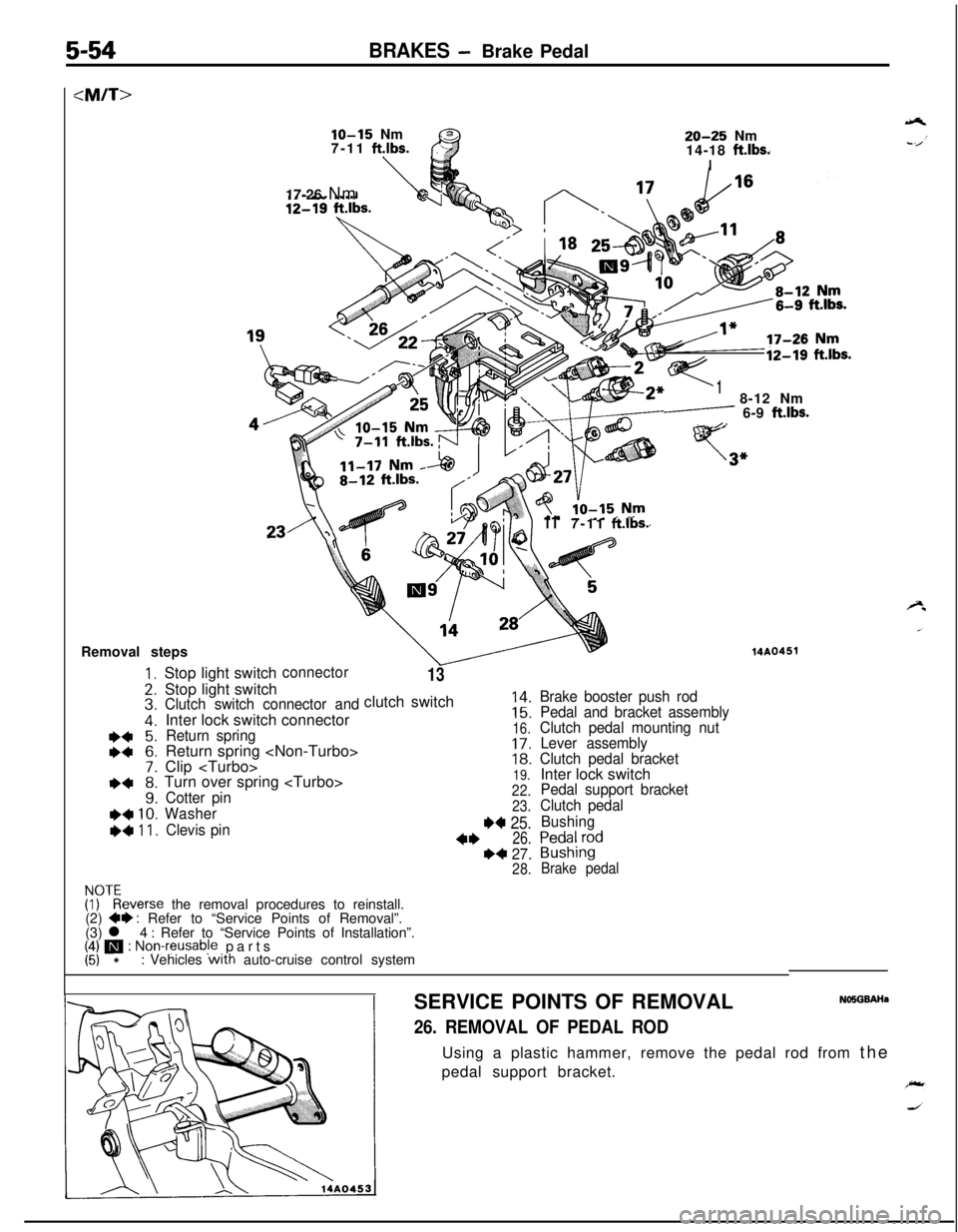

5-54BRAKES -Brake Pedal

IO-15 Nm

7-11 ft.lbs.

\

20-25 Nm

14-18 ft.lbs.I17-26 Nm

12-19 ft.lbs.

18-12 Nm

- 6-9 ft.lbs.- /-

117-11 ft.lbs.

13clutch switch Stop light switchconnectorStop light switch

Clutch switch connector andInter lock switch connector

Return springReturn spring

Clip

Turn over spring

Cotter pin

Washer

Clevis pin

1::16.

1::19.

22.

23.

W 25.

4*26.I)4 27.28.

Brake booster push rod

Pedal and bracket assembly

Clutch pedal mounting nut

Lever assembly

Clutch pedal bracketInter lock switch

Pedal support bracket

Clutch pedal

Bushing

P,;$;d

Brake pedal

14AG451

Fyfeverse the removal procedures to reinstall.

(2) 4* : Refer to “Service Points of Removal”.

(3) l 4 : Refer to “Service Points of Installation”.# m : Non-reusabje parts*: Vehicles with auto-cruise control system

SERVICE POINTS OF REMOVAL

NO5GBAHa

26. REMOVAL OF PEDAL RODUsing a plastic hammer, remove the pedal rod from the

pedal support bracket.

Page 195 of 1216

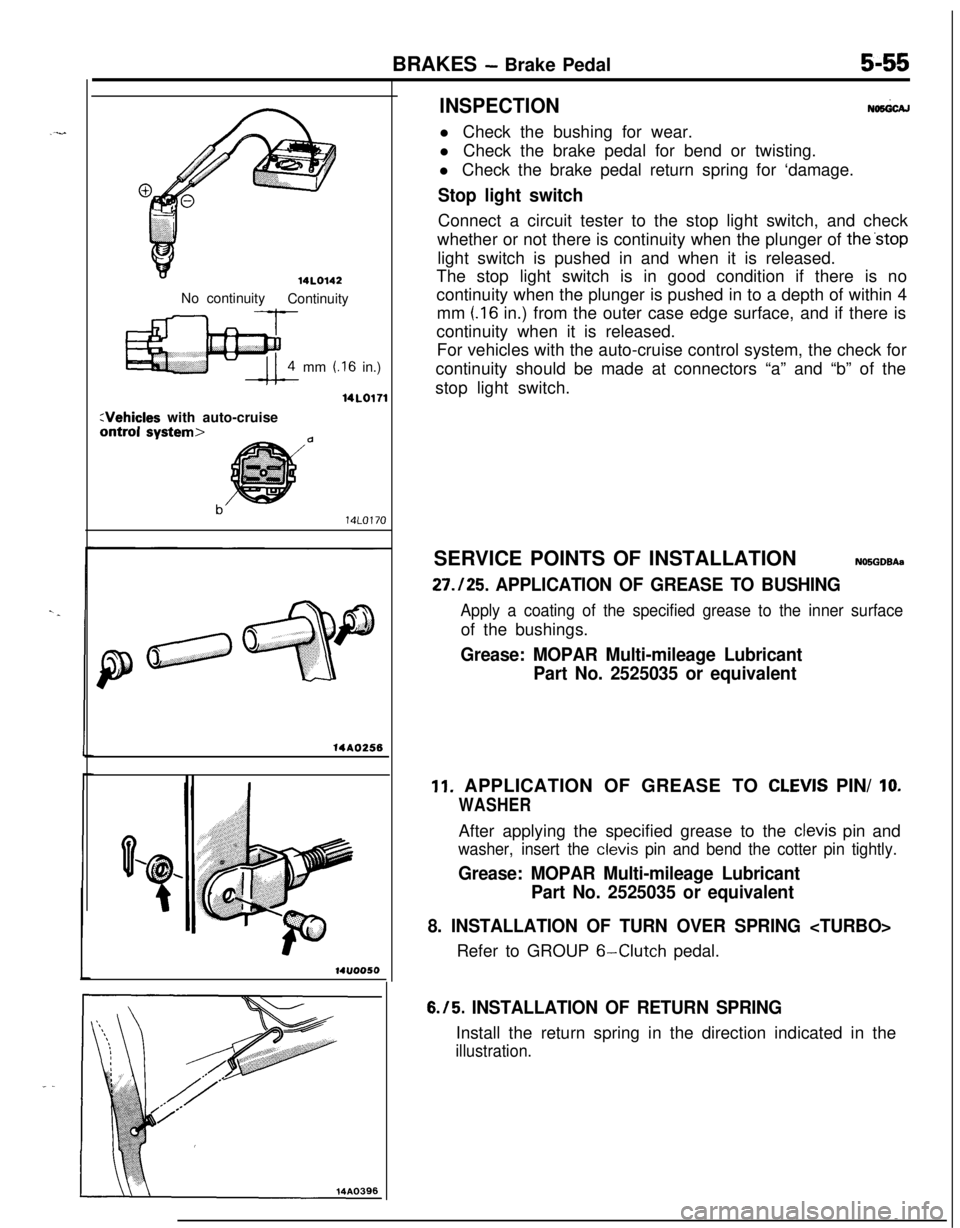

BRAKES - Brake Pedal5-55

14L0142No continuity

Continuity

mm

t.16 in.)

14LO171

:Vehicles with auto-cruiseontrol svstem>

14A0256

14ll0050

INSPECTIONNoMicAll Check the bushing for wear.

l Check the brake pedal for bend or twisting.

l Check the brake pedal return spring for ‘damage.

Stop light switchConnect a circuit tester to the stop light switch, and check

whether or not there is continuity when the plunger of the’stop

light switch is pushed in and when it is released.

The stop light switch is in good condition if there is no

continuity when the plunger is pushed in to a depth of within 4

mm

(.I6 in.) from the outer case edge surface, and if there is

continuity when it is released.

For vehicles with the auto-cruise control system, the check for

continuity should be made at connectors “a” and “b” of the

stop light switch.

SERVICE POINTS OF INSTALLATIONN05GDBAa

27.125. APPLICATION OF GREASE TO BUSHING

Apply a coating of the specified grease to the inner surfaceof the bushings.

Grease: MOPAR Multi-mileage Lubricant

Part No. 2525035 or equivalent

11. APPLICATION OF GREASE TO CLEVIS PIN/ IO.

WASHERAfter applying the specified grease to the

clevis pin and

washer, insert the clevis pin and bend the cotter pin tightly.

Grease: MOPAR Multi-mileage Lubricant

Part No. 2525035 or equivalent

8. INSTALLATION OF TURN OVER SPRING

6-Clutch pedal.

6.15. INSTALLATION OF RETURN SPRINGInstall the return spring in the direction indicated in the

illustration.

Page 233 of 1216

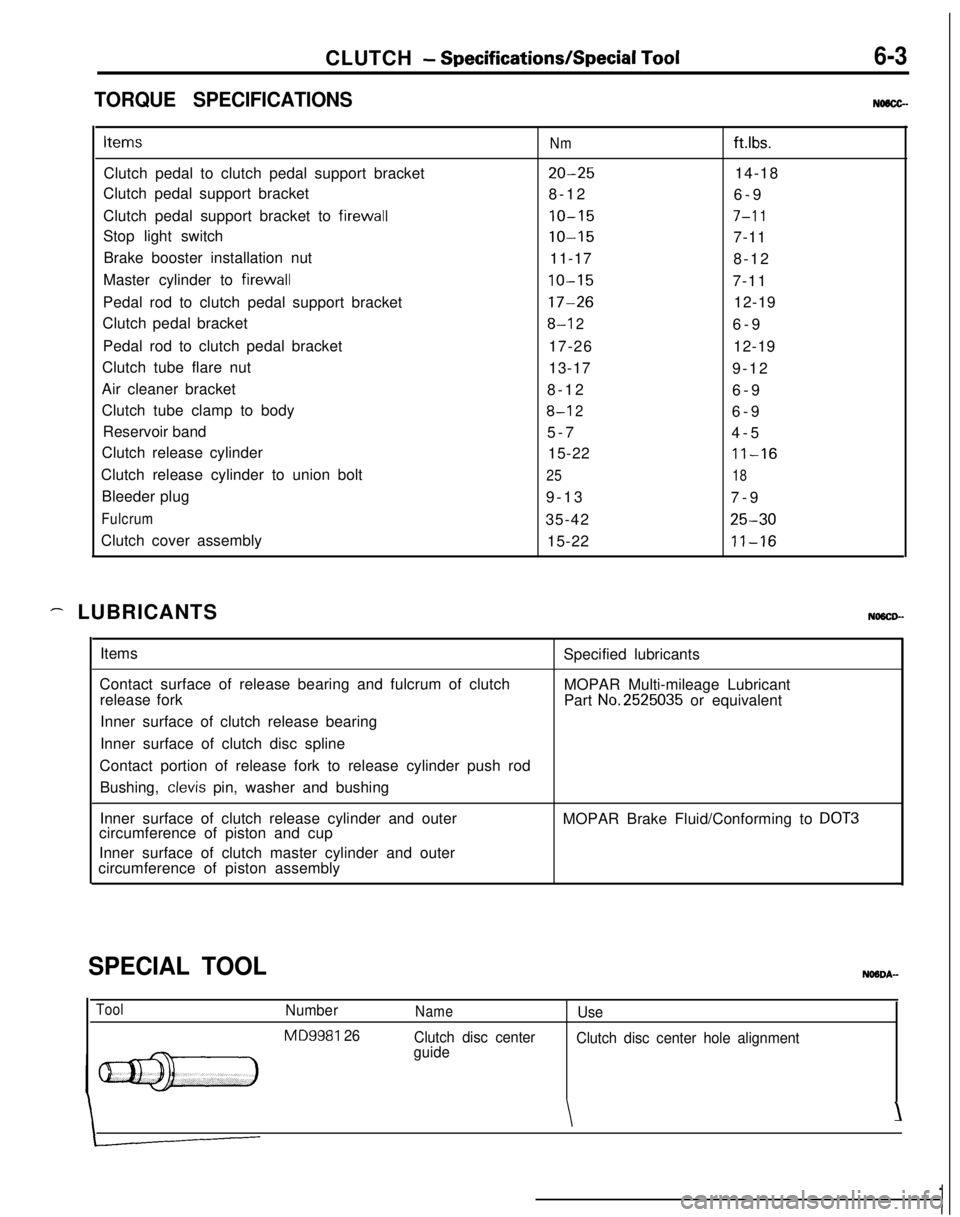

CLUTCH - Specifications/Special Tool6-3

TORQUE SPECIFICATIONSNMCC-Items

Nmftlbs.Clutch pedal to clutch pedal support bracket

20-2514-18

Clutch pedal support bracket

8-12

6-9

Clutch pedal support bracket to firewall

10-157-l 1Stop light switch

10-157-11

Brake booster installation nut

11-17

8-12

Master cylinder to firewall

10-157-11

Pedal rod to clutch pedal support bracket

17-2612-19

Clutch pedal bracket

8-l 26-9

Pedal rod to clutch pedal bracket

17-2612-19

Clutch tube flare nut

13-17

9-12

Air cleaner bracket

8-12

6-9

Clutch tube clamp to body

8-l 26-9

Reservoir band

5-7

4-5

Clutch release cylinder

15-22

11-16Clutch release cylinder to union bolt

2518Bleeder plug

9-13

7-9

Fulcrum35-4225-30Clutch cover assembly

15-22

11-16

- LUBRICANTSNOSCD-Items

Contact surface of release bearing and fulcrum of clutch

release fork

Inner surface of clutch release bearing

Inner surface of clutch disc splineSpecified lubricants

MOPAR Multi-mileage Lubricant

Part

No.2525035 or equivalent

Contact portion of release fork to release cylinder push rod

Bushing,

clevis pin, washer and bushing

Inner surface of clutch release cylinder and outer

circumference of piston and cupMOPAR Brake Fluid/Conforming to

DOT3Inner surface of clutch master cylinder and outer

circumference of piston assembly

SPECIAL TOOL

ToolNumber

MD9981 26

NameUse

Clutch disc center

guideClutch disc center hole alignment

\\