light MITSUBISHI ECLIPSE 1991 Manual PDF

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 580 of 1216

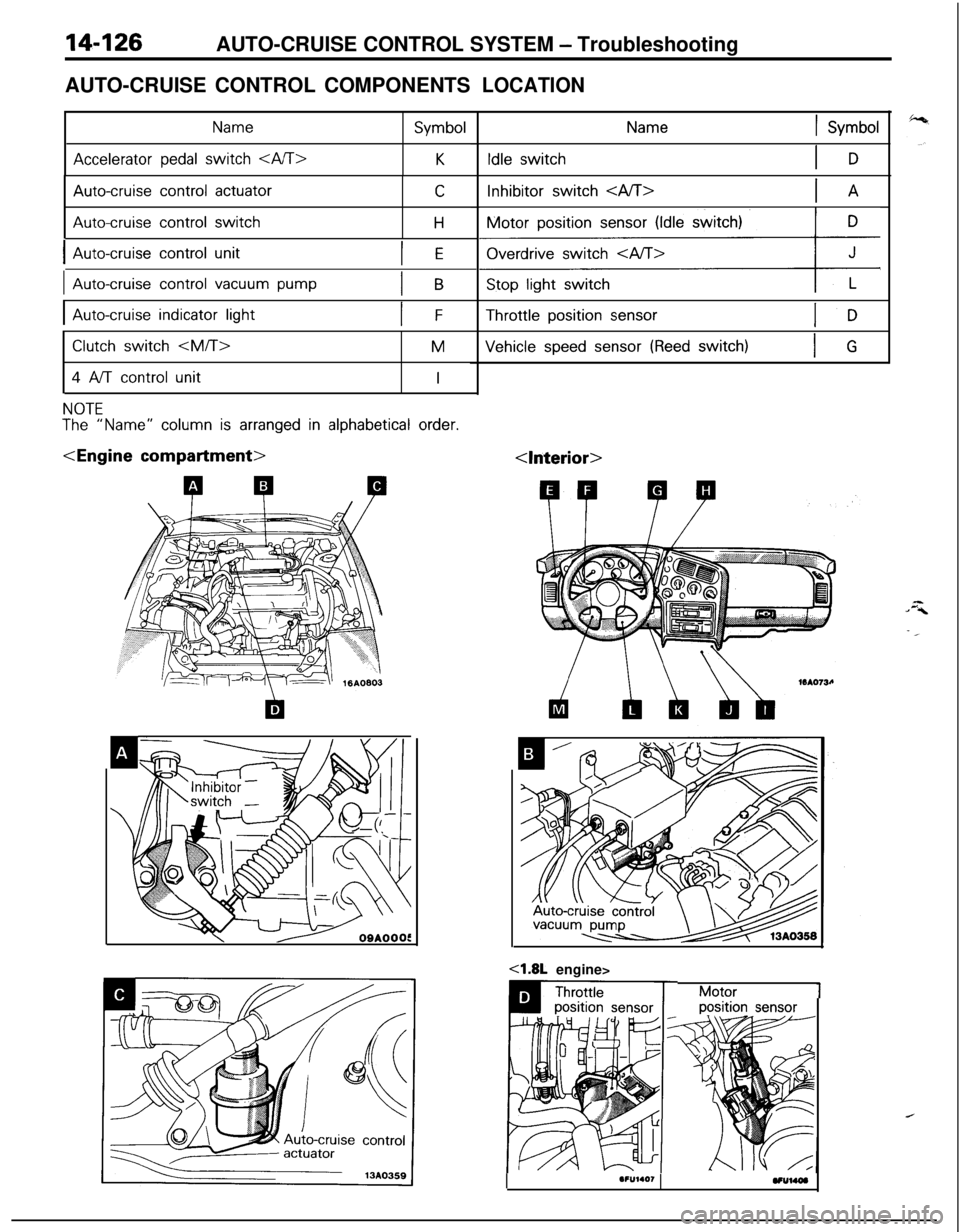

14-126AUTO-CRUISE CONTROL SYSTEM - Troubleshooting

AUTO-CRUISE CONTROL COMPONENTS

Name

Accelerator pedal switch

Symbol

K

Auto-cruise control actuator

Auto-cruise control switch

C

H

IAuto-cruise control unitIE

IAuto-cruise control vacuum pumpIB

IAuto-cruise indicator lightIF

Clutch switch

4 A/T control unit

M

I

NOTE

The “Name” column is arranged in alphabetical order.

LOCATION

1 Symbol

Idle switchIDInhibitor switch

Motor position

sensor (Idle switch)

ziz&Gy+Throttle position

sensor

Vehicle speed sensor (Reed switch)IG

Motor1position sensor

I.F”l.O,VUUW

Page 581 of 1216

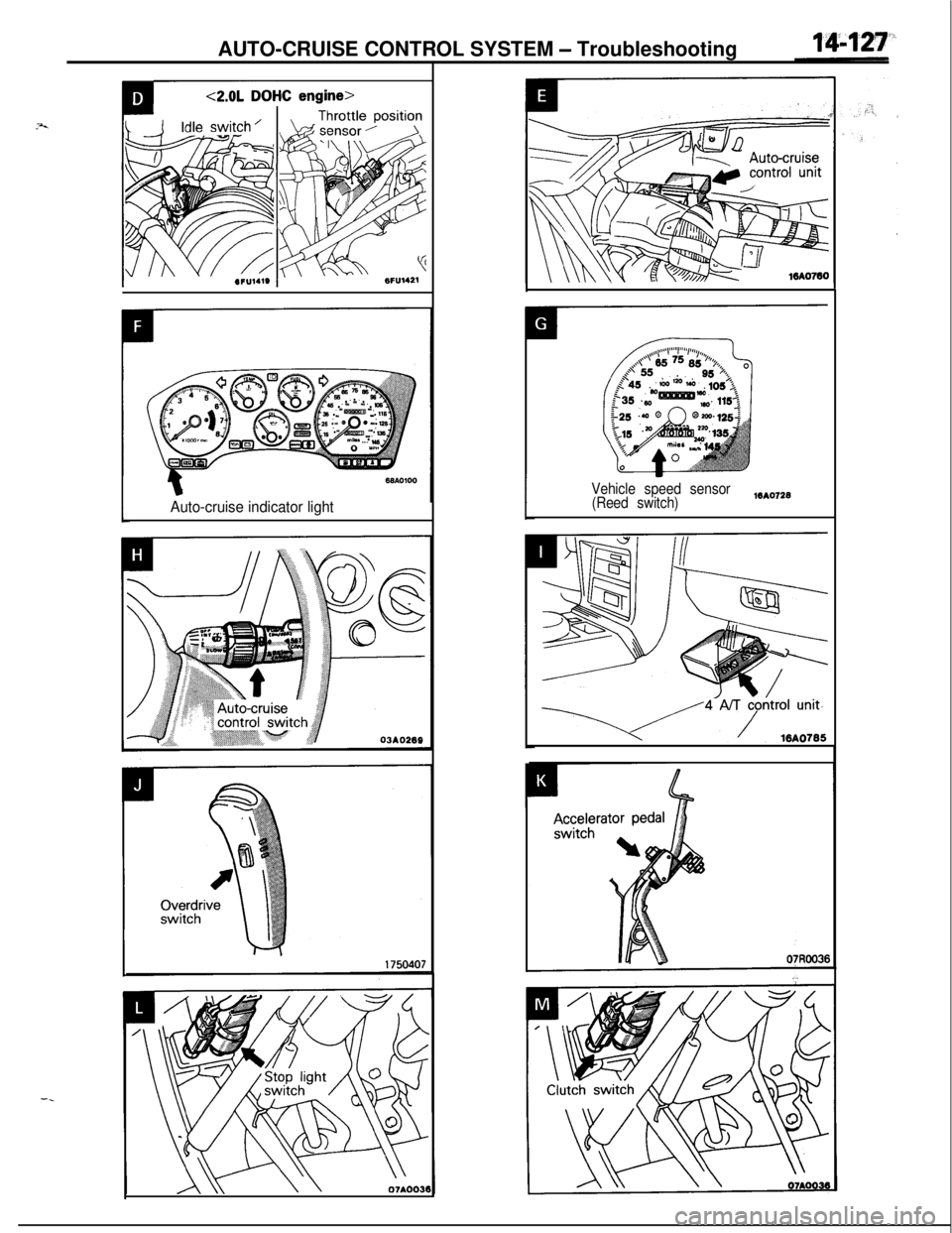

AUTO-CRUISE CONTROL SYSTEM - Troubleshooting

--

Auto-cruise indicator light

Vehicle speed sensor

(Reed switch)WA0728

l/4’NTj$trol unit-

Page 586 of 1216

14-132AUTO-CRUISE CONTROL SYSTEM - Troubleshooting

4ci

IGNITIONSWITCHtlGl)

CR”

I

AUTO-CRUISE

CONTROL UNIT

c-01

B

1COLUMN SWITCH

AUTO-CRUISE

>CONTROL SWITCH

T C-06

I

\,4

STOPLIGHT '~------

"ITCH OP?“ONc-03ON

+I1

2

hS3 O

0

s0.65-G

SUB 1LINK

!i

L!

0

L15A

I0.85-GW-0.85-GW1

!5

OPEN

CONNECTORc-02

1IQI2E

;SIBLE

qB

1 d-47

J/B6

C-55

16

AUTO-CRUISEc-01CONTROL UNIT

Page 589 of 1216

AUTO-CRUISE CONTROL SYSTEM L service Adjustkt Procedw&

03A0258

YSET

03AO258

03AO250

SET

03A025t

JI

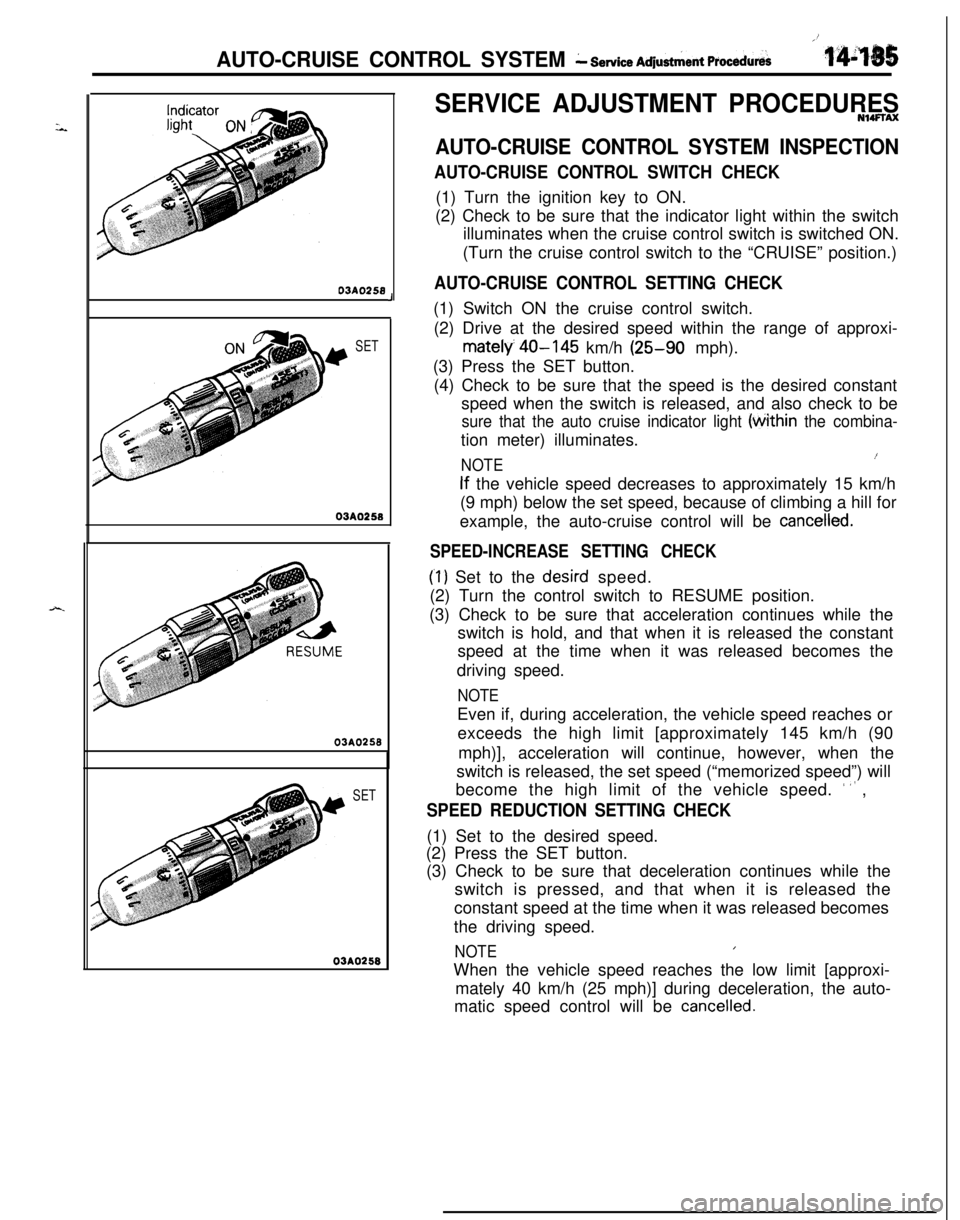

SERVICE ADJUSTMENT PROCEDURESNl4FUU

AUTO-CRUISE CONTROL SYSTEM INSPECTION

AUTO-CRUISE CONTROL SWITCH CHECK(1) Turn the ignition key to ON.

(2) Check to be sure that the indicator light within the switch

illuminates when the cruise control switch is switched ON.

(Turn the cruise control switch to the “CRUISE” position.)

AUTO-CRUISE CONTROL SETTING CHECK(1) Switch ON the cruise control switch.

(2) Drive at the desired speed within the range of approxi-

mately 40-145 km/h (25-90 mph).

(3) Press the SET button.

(4) Check to be sure that the speed is the desired constant

speed when the switch is released, and also check to be

sure that the auto cruise indicator light (tithin the combina-tion meter) illuminates.

NOTE1(

If the vehicle speed decreases to approximately 15 km/h

(9 mph) below the set speed, because of climbing a hill for

example, the auto-cruise control will be

cancelled.

SPEED-INCREASE SETTING CHECK

(‘1) Set to the desird speed.

(2) Turn the control switch to RESUME position.

(3) Check to be sure that acceleration continues while the

switch is hold, and that when it is released the constant

speed at the time when it was released becomes the

driving speed.

NOTEEven if, during acceleration, the vehicle speed reaches or

exceeds the high limit [approximately 145 km/h (90

mph)], acceleration will continue, however, when the

switch is released, the set speed (“memorized speed”) will

become the high limit of the vehicle speed.

’ ” ,

SPEED REDUCTION SETTING CHECK(1) Set to the desired speed.

(2) Press the SET button.

(3) Check to be sure that deceleration continues while the

switch is pressed, and that when it is released the

constant speed at the time when it was released becomes

the driving speed.

NOTEIWhen the vehicle speed reaches the low limit [approxi-

mately 40 km/h (25 mph)] during deceleration, the auto-

matic speed control will be

cancelled.

Page 592 of 1216

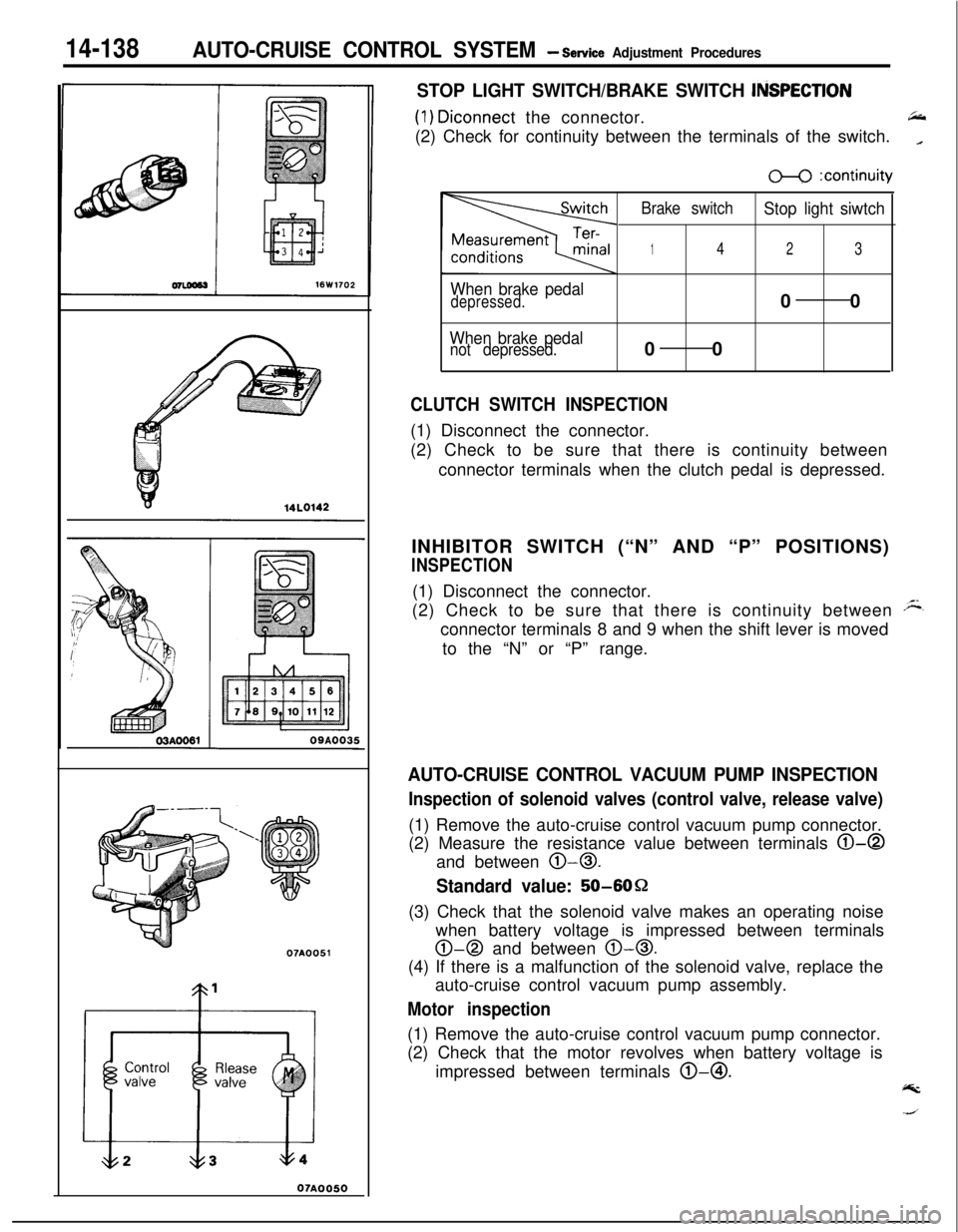

14-138AUTO-CRUISE CONTROL SYSTEM - Service Adjustment Procedures

07A0051

07AOO50

STOP LIGHT SWITCH/BRAKE SWITCH ItiSPECTlON

(1) Diconnect the connector.66(2) Check for continuity between the terminals of the switch.

_

When brake pedaldepressed.

When brake pedalnot depressed.

m :continuity

Brake switch

Stop light siwtch

142300

00

CLUTCH SWITCH INSPECTION(1) Disconnect the connector.

(2) Check to be sure that there is continuity between

connector terminals when the clutch pedal is depressed.

INHIBITOR SWITCH (“N” AND “P” POSITIONS)

INSPECTION(1) Disconnect the connector.

(2) Check to be sure that there is continuity between

Aconnector terminals 8 and 9 when the shift lever is moved

to the “N” or “P” range.

AUTO-CRUISE CONTROL VACUUM PUMP INSPECTION

Inspection of solenoid valves (control valve, release valve)(1) Remove the auto-cruise control vacuum pump connector.

(2) Measure the resistance value between terminals

0-0and between

0-0.

Standard value: 50-6OQ

(3) Check that the solenoid valve makes an operating noise

when battery voltage is impressed between terminals

0-0 and between 0-0.(4) If there is a malfunction of the solenoid valve, replace the

auto-cruise control vacuum pump assembly.

Motor inspection(1) Remove the auto-cruise control vacuum pump connector.

(2) Check that the motor revolves when battery voltage is

impressed between terminals @-@I.

@k

Page 594 of 1216

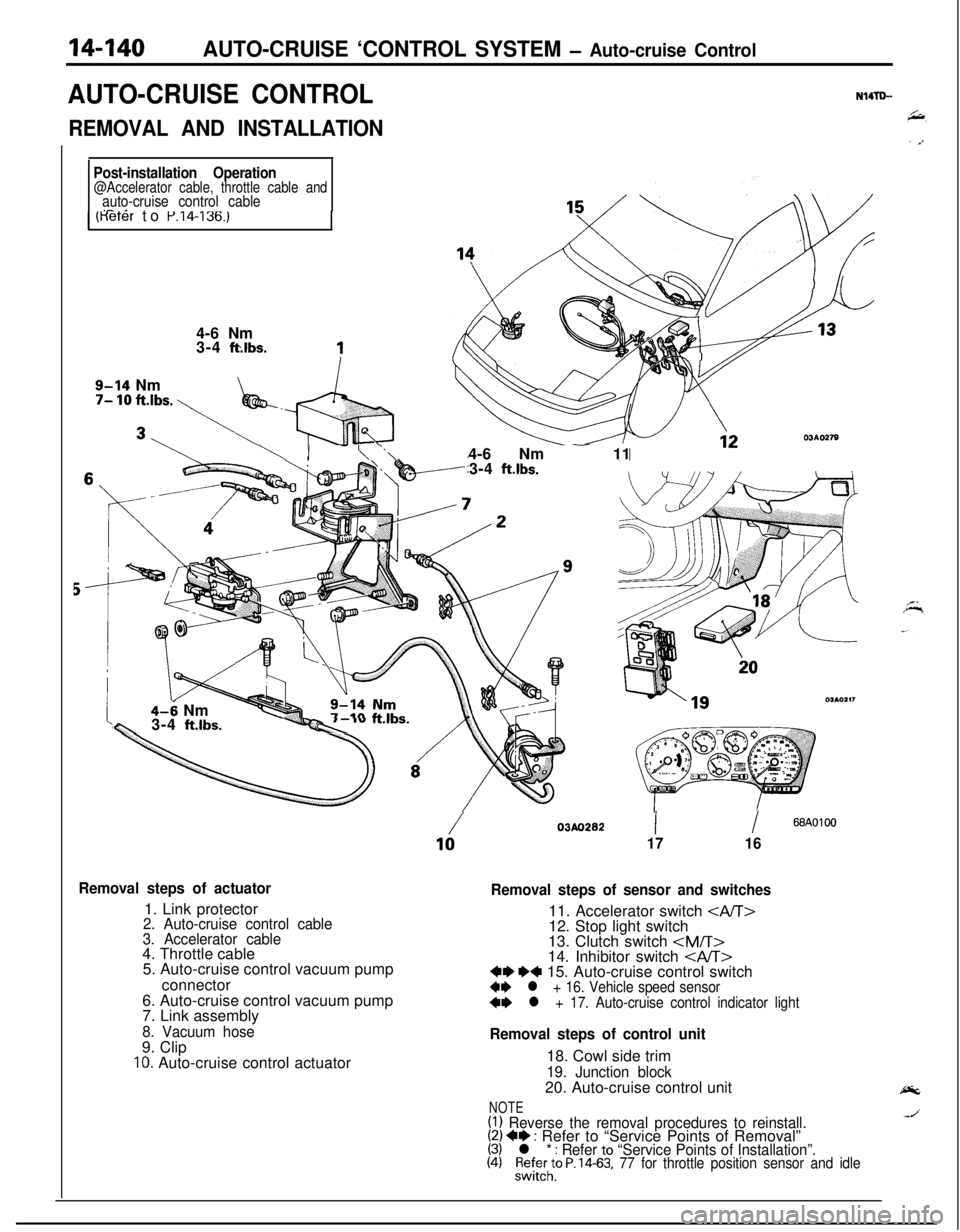

14-140AUTO-CRUISE ‘CONTROL SYSTEM - Auto-cruise Control

AUTO-CRUISE CONTROLN14TLL

REMOVAL AND INSTALLATION

Post-installation Operation@Accelerator cable, throttle cable andauto-cruise control cableI- _1 (Keter to P.14-136.)4-6 Nm

3-4

ft:lbs.

9-14 Nm7- 10 ft.lbs. \

\ I- \ ‘.\-4-6 Nm - 11

3-4 ft.lbs.

4-6 Nmw3-4 ft.lbs.--Qc ‘”

Removal steps of actuator1. Link protector

2. Auto-cruise control cable

3. Accelerator cable4. Throttle cable

5. Auto-cruise control vacuum pump

connector

6. Auto-cruise control vacuum pump

7. Link assembly

8. Vacuum hose9. Clip

IO. Auto-cruise control actuator

/03AO28210II68AOlOO

1716

Removal steps of sensor and switches11. Accelerator switch

12. Stop light switch

13. Clutch switch

Removal steps of control unit18. Cowl side trim

19. Junction block20. Auto-cruise control unit

NOTE(1) Reverse the removal procedures to reinstall.(2) +* : Refer to “Service Points of Removal”(3) l * : Refer to “Service Points of Installation”.(4)%l;;to P. 14-63, 77 for throttle position sensor and idle

Page 595 of 1216

AUTO-CRUISE CONTROL SYSTEM - Auto-cruise Control14-141

SERVICE POINTS OF REMOVAL?trmNWpBC

15. REMOVAL OF AUTO-CRUISE CONTROL SWITCHRefer to GROUP

8-Column Switch.

16. REMOVAL OF VEHICLE SPEED SENSORRefer to GROUP

8-Meters and Gauges.

17. REMOVAL OF AUTO-CRUISE CONTROL INDICATOR

LIGHTRefer to GROUP

8-Meters and Gauges.

INSPECTIONN14lDCEl Check the inner and outer cable for damage.

l Check the cable for smooth movement.

l Check the link protector for damage.

CHECKING THE AUTO-CRUISE CONTROL ACTUATORRefer to

P.14-138.

SERVICE POINTS OF INSTALLATIONN14TDDDD

17. INSTALLATION OF AUTO-CRUISE CONTROL INDICA-

TOR LIGHTRefer to GROUP

8-Meters and Gauges.

16. INSTALLATION OF AUTO-CRUISE CONTROL SWITCHRefer to GROUP

8-Column Switch.

15. INSTALLATION OF VEHICLE SPEED SENSORRefer to GROUP

8-Meter and Gauges.

Page 612 of 1216

17-2REAR SUSPENSION

GENERAL SPECIFICATIONS

LN17CAA

ItemsVehicles with 1.8L EngineVehicles with 2.0L DOHC

Engine

jSuspension system

3-link, torsion axle with coil spring type

Coil spring

Wire dia.

x O.D. x free length

mm (in.) 10.1 x 105.1 x 336.510.2 x 105.2 x 316.5

(40 x 4.14 x 13.25)(40 x 4.14 x 12.46)

[Coil spring identification color]

[Light Blue

x 11[Orange x 11Spring constant

N/mm

(Ibs./in.) 20 (112.0)23 (128.8)

Shock absorber

TypeHydraulic, cylindrical, double-acting type

Max. length

mm (in.) 495 (19.5)485 (19.1)

Min. length

mm (in.) 315 (12.4)315 (12.4)

Strokemm (in.) 180 (7.1)170 (6.7)Damping force [at 0.3 m/set. (0.9

ft./set.)]

ExpansionN (Ibs.)800 (176)

ContractionN (Ibs.)300 (66)

Wheel bearing

TypeUnit ball bearing

SERVICE SPECIFICATIONS

Items

Standard valueToe-in (Left-right difference)

Camber

LimitWheel bearing end play

Rear hub rotary-sliding resistance

Rear hub rotary-sliding torque

NOTEToe-in and camber cannot be adjusted.mm (in.)

mm (in.)

N (Ibs.)

Nm

(ftlbs.)

TORQUE SPECIFICATIONS

Specifications

0+3 (Of.1 18)

-45’

f 30’

0.01 (004) or less

31

(7) or less

1.8

(1.30) or lessNI’ICB-A

ItemsNmft.lbs.

Wheel bearing nut

Shock absorber upper mounting nut

Shock absorber lower mounting nut

Lateral rod mounting nut (body side)

Lateral rod mounting bolt (axle beam side)

Trailing arm mounting bolt

Piston rod tightening nut

Brake hose and tube bracket mounting bolt

Caliper assembly mounting nut

Rear speed sensor mounting bolt

200-260

40-50

80- 100

80-100

100-120

100-120

20-2517-26

50-609-14144-188

29-36

58-72

58-72

72-87

72-87

14-18

12-19

36-43

I7-10

Nl7CGA

Page 616 of 1216

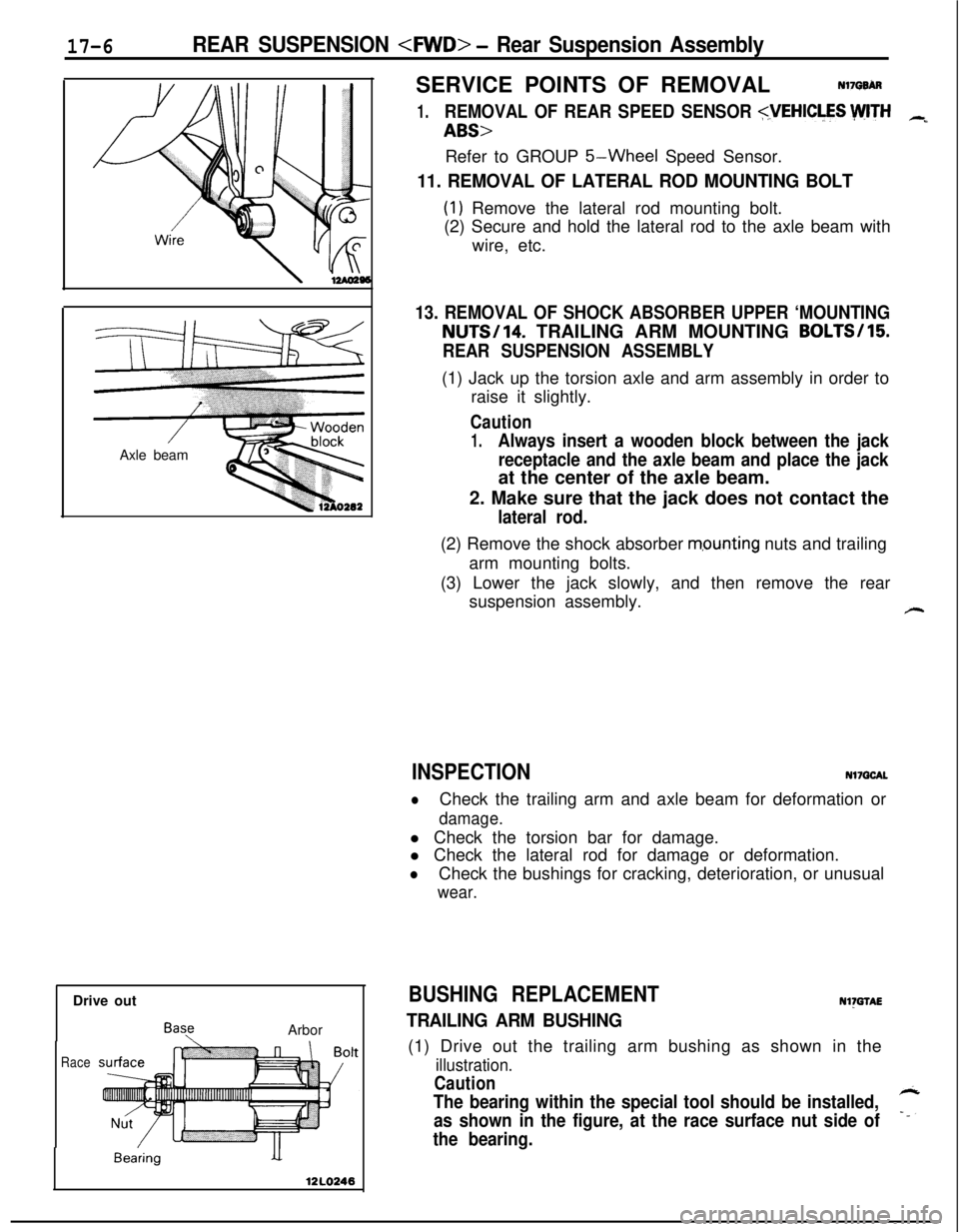

17-6REAR SUSPENSION

Drive out

BayArbor

Race

BearingSERVICE POINTS OF REMOVAL

Nl7QBh

1.REMOVAL OF REAR SPEED SENSOR

5-Wheel Speed Sensor.

11. REMOVAL OF LATERAL ROD MOUNTING BOLT

(1) Remove the lateral rod mounting bolt.

(2) Secure and hold the lateral rod to the axle beam with

wire, etc.

13. REMOVAL OF SHOCK ABSORBER UPPER ‘MOUNTINGNUTS/14. TRAILING ARM MOUNTING BOLTS/15

REAR SUSPENSION ASSEMBLY(1) Jack up the torsion axle and arm assembly in order to

raise it slightly.

Caution

1.Always insert a wooden block between the jack

receptacle and the axle beam and place the jackat the center of the axle beam.

2. Make sure that the jack does not contact the

lateral rod.(2) Remove the shock absorber

m,ounting nuts and trailing

arm mounting bolts.

(3) Lower the jack slowly, and then remove the rear

suspension assembly.

#-

INSPECTIONNl7QCAL

lCheck the trailing arm and axle beam for deformation or

damage.l Check the torsion bar for damage.

l Check the lateral rod for damage or deformation.

lCheck the bushings for cracking, deterioration, or unusual

wear.

BUSHING REPLACEMENTNl)GTAE

TRAILING ARM BUSHING(1) Drive out the trailing arm bushing as shown in the

illustration.

Caution

The bearing within the special tool should be installed,

as shown in the figure, at the race surface nut side of7

the bearing.

Page 618 of 1216

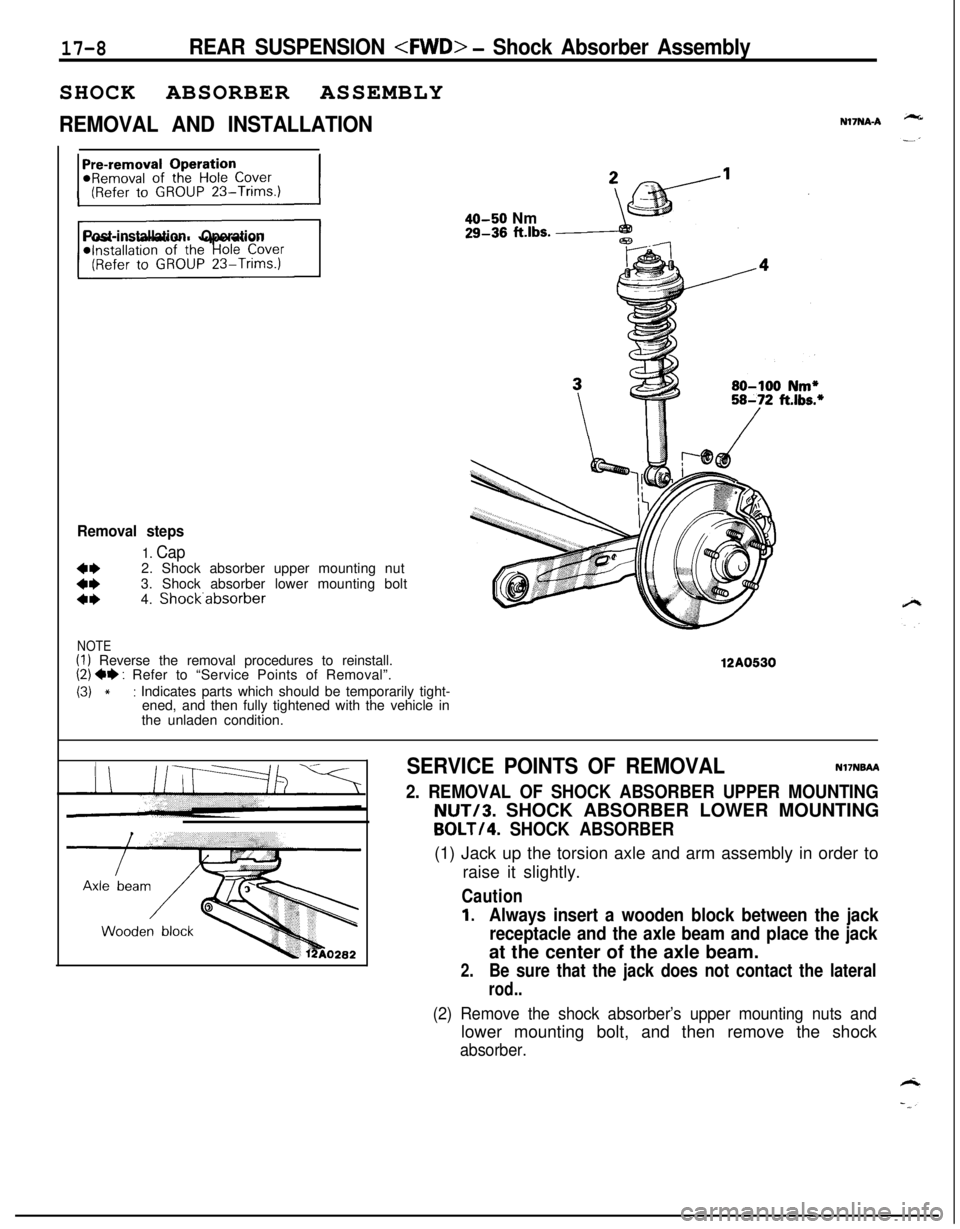

17-8REAR SUSPENSION

REMOVAL AND INSTALLATIONN17NA-A

Post-installation Operation

Removal steps

1. Cap

::2. Shock absorber upper mounting nut

3. Shock absorber lower mounting bolta*4. Shock.absorber

NOTE(I) Reverse the removal procedures to reinstall.(2) ** : Refer to “Service Points of Removal”.

(3) *: Indicates parts which should be temporarily tight-

ened, and then fully tightened with the vehicle in

the unladen condition.

40-50 Nm29-36 ft.lbs.

12A0530

SERVICE POINTS OF REMOVALNI’INBAA

2. REMOVAL OF SHOCK ABSORBER UPPER MOUNTINGNUT/3. SHOCK ABSORBER LOWER MOUNTING

BOLT/4. SHOCK ABSORBER(1) Jack up the torsion axle and arm assembly in order to

raise it slightly.

Caution

1.Always insert a wooden block between the jack

receptacle and the axle beam and place the jackat the center of the axle beam.

2.Be sure that the jack does not contact the lateral

rod..

(2) Remove the shock absorber’s upper mounting nuts andlower mounting bolt, and then remove the shock

absorber.