ignition MITSUBISHI ECLIPSE 1991 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 494 of 1216

FUEL SYSTEM - Troubleshooting

&.25_-R

QIWII

(VEHICLES FORCALIFORNIA)

VAI__--_--__-_--- ------94Gizi

1: I

II31 IFI I. .

_____----_-----__4-SPEEDAUTOMATIC~W&WfLE

UNITC-60

IGNITIONTIMINGADJUSTMENTCONNECTOR >

A-601

ml cr,

-1F

a s=

$ fW&NATION

\/

2"ml2 11 1 1

:,cal,,4

" " w

SELFDIAGNOSISlCHECK CONNECTOR

D-06

1

4-l

t

4

""Y#TION &$fjf!j

07B-26 m

-1c-45

5

i

'011

c-h-

c-30FRONT SIDE

p!lGJRq

REVERSE SIDE

p!Raq

,234 C-54

m6678

q

Page 495 of 1216

FUEL SYSTEM - Service Adjustment Procedures <1.8L Engine>l-4-41

SERVICE ADJUSTMENT PROCEDURES

CURB IDLE SPEED INSPECTION

CautionNlIFiiAE

The improper setting (throttle valve opening) will increase

exhaust gas temperature at deceleration, reducing catalystlife greatly and deteriorating exhaust gas cleaning per-

formance. It also has effect on fuel consumption and

engine braking.

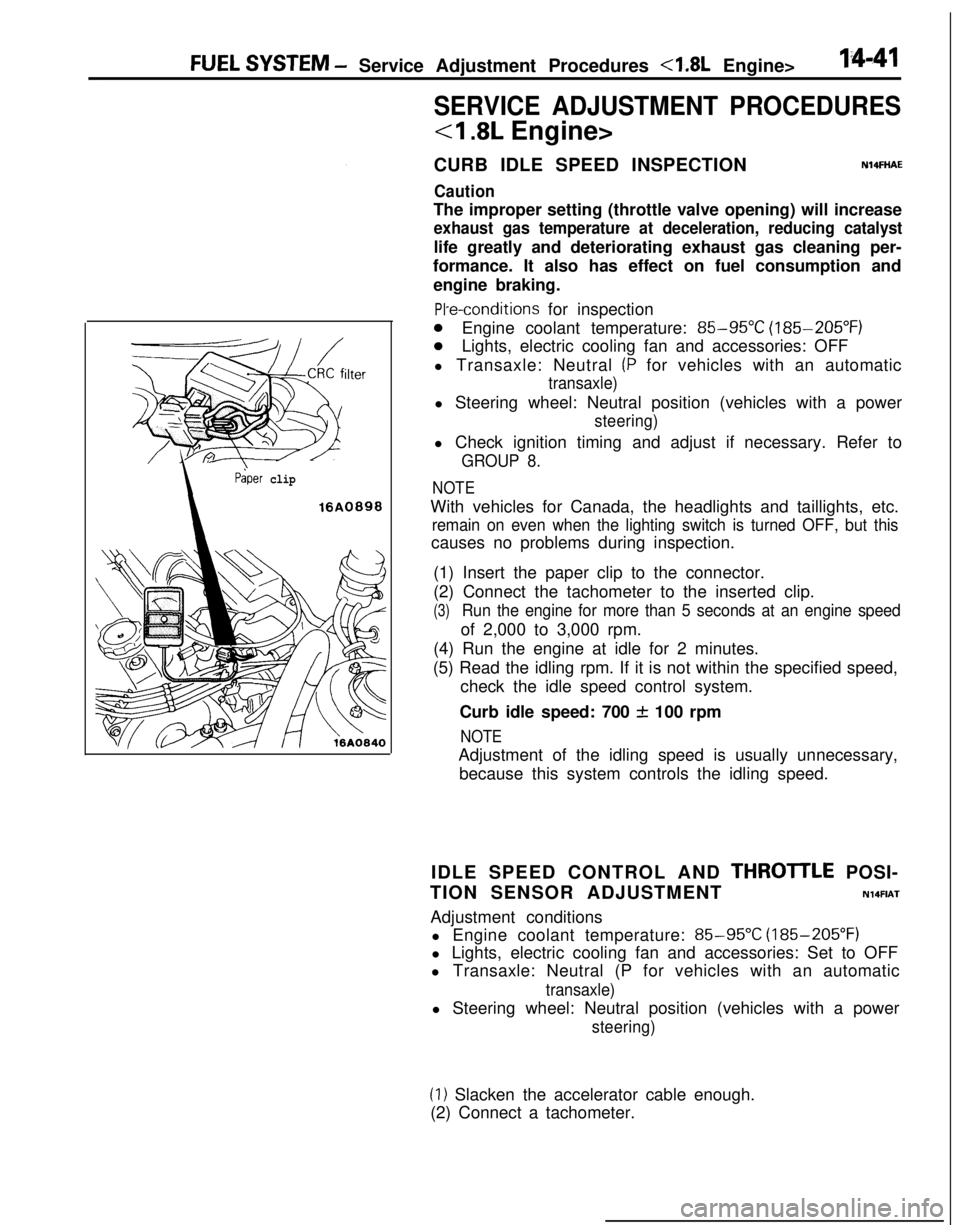

ilter

Paper clip

16A0898

PI-e-conditions for inspection

0Engine coolant temperature: 85-95°C (185-205°F)

0Lights, electric cooling fan and accessories: OFF

l Transaxle: Neutral

(P for vehicles with an automatic

transaxle)l Steering wheel: Neutral position (vehicles with a power

steering)l Check ignition timing and adjust if necessary. Refer to

GROUP 8.

NOTEWith vehicles for Canada, the headlights and taillights, etc.

remain on even when the lighting switch is turned OFF, but thiscauses no problems during inspection.

(1) Insert the paper clip to the connector.

(2) Connect the tachometer to the inserted clip.

(3)Run the engine for more than 5 seconds at an engine speedof 2,000 to 3,000 rpm.

(4) Run the engine at idle for 2 minutes.

(5) Read the idling rpm. If it is not within the specified speed,

check the idle speed control system.

Curb idle speed: 700

f 100 rpm

NOTEAdjustment of the idling speed is usually unnecessary,

because this system controls the idling speed.

IDLE SPEED CONTROL AND

THROTlLE POSI-

TION SENSOR ADJUSTMENT

N14FIATAdjustment conditions

l Engine coolant temperature:

85-95X (185-205°F)

l Lights, electric cooling fan and accessories: Set to OFF

l Transaxle: Neutral (P for vehicles with an automatic

transaxle)l Steering wheel: Neutral position (vehicles with a power

steering)

(1) Slacken the accelerator cable enough.

(2) Connect a tachometer.

Page 496 of 1216

14-42FUEL SYSTEM - Service Adjustment Procedures C1.8L Engine>

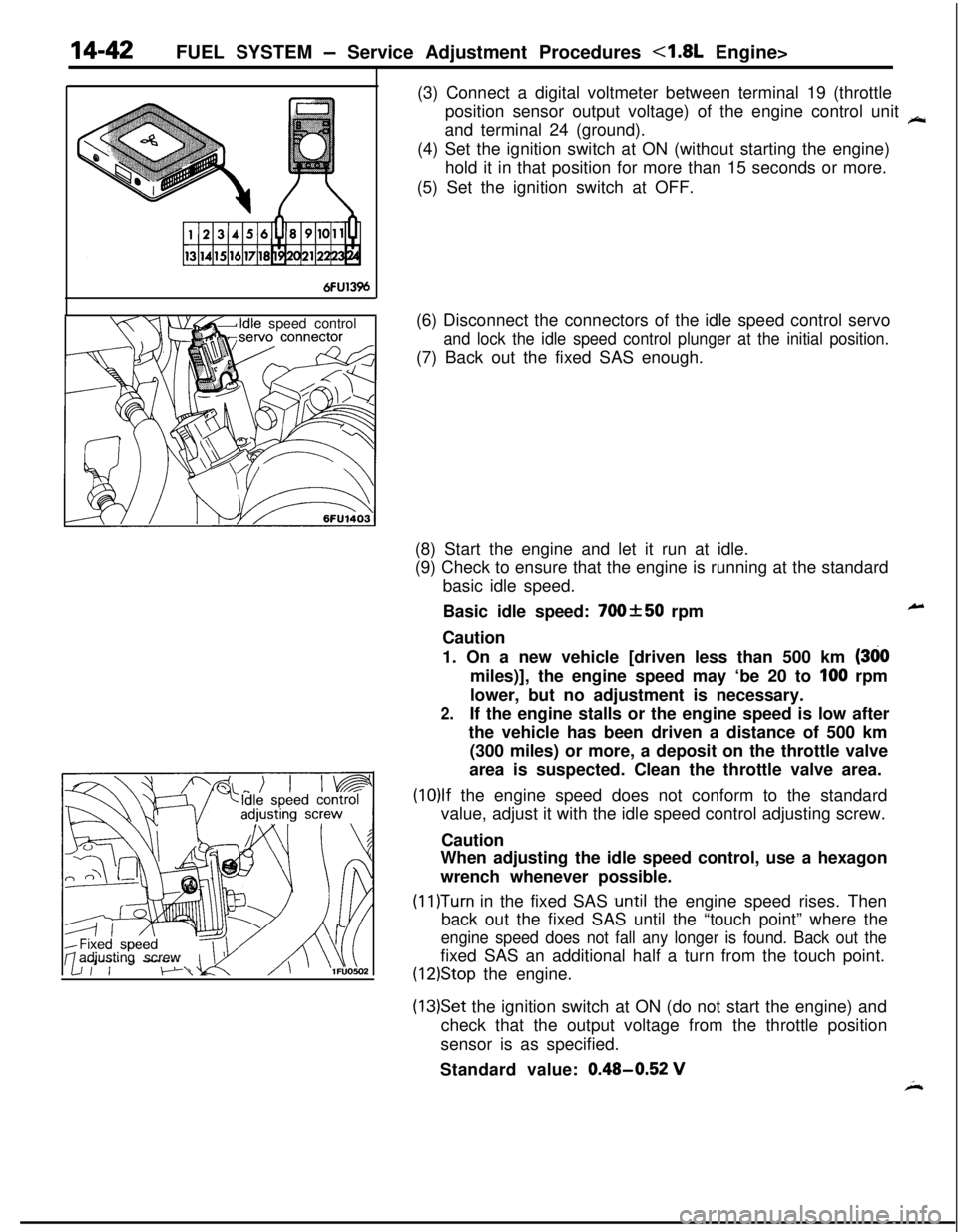

6FU13%

Idle speed control

adjusting screw(3) Connect a digital voltmeter between terminal 19 (throttle

position sensor output voltage) of the engine control unit

kand terminal 24 (ground).

(4) Set the ignition switch at ON (without starting the engine)

hold it in that position for more than 15 seconds or more.

(5) Set the ignition switch at OFF.

(6) Disconnect the connectors of the idle speed control servo

and lock the idle speed control plunger at the initial position.(7) Back out the fixed SAS enough.

(8) Start the engine and let it run at idle.

(9) Check to ensure that the engine is running at the standard

basic idle speed.

Basic idle speed:

700&50 rpm

CautionLr1. On a new vehicle [driven less than 500 km

(380miles)], the engine speed may ‘be 20 to

100 rpm

lower, but no adjustment is necessary.

2.If the engine stalls or the engine speed is low after

the vehicle has been driven a distance of 500 km

(300 miles) or more, a deposit on the throttle valve

area is suspected. Clean the throttle valve area.

(10)lf the engine speed does not conform to the standard

value, adjust it with the idle speed control adjusting screw.

Caution

When adjusting the idle speed control, use a hexagon

wrench whenever possible.

(11)Turn in the fixed SAS .until the engine speed rises. Then

back out the fixed SAS until the “touch point” where the

engine speed does not fall any longer is found. Back out thefixed SAS an additional half a turn from the touch point.

(12)Stop the engine.

(13)Set the ignition switch at ON (do not start the engine) and

check that the output voltage from the throttle position

sensor is as specified.

Standard value:

0.48-0.52 VA

Page 497 of 1216

FUEL SYSTEM - Service Adjustment Procedures <1.8L Engine>14-43

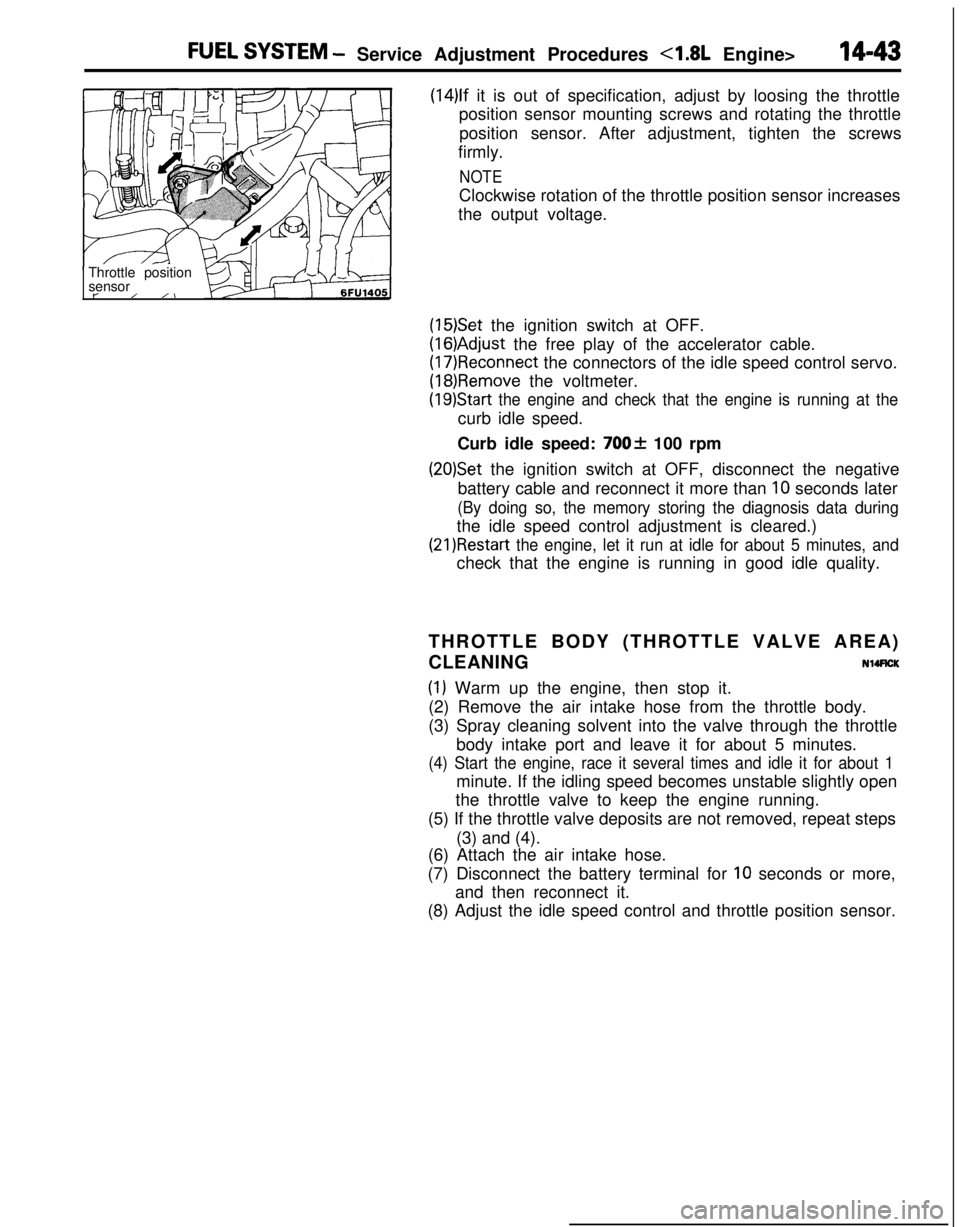

(14)lf it is out of specification, adjust by loosing the throttle

position sensor mounting screws and rotating the throttle

position sensor. After adjustment, tighten the screws

firmly.

NOTEClockwise rotation of the throttle position sensor increases

the output voltage.

Throttle position

sensor

t-/ /I

(15)Set the ignition switch at OFF.

(16)Adjust the free play of the accelerator cable.

(17)Reconnect the connectors of the idle speed control servo.

(18)Remove the voltmeter.

(19)Start the engine and check that the engine is running at thecurb idle speed.

Curb idle speed:

700f 100 rpm

(20)Set the ignition switch at OFF, disconnect the negative

battery cable and reconnect it more than

10 seconds later

(By doing so, the memory storing the diagnosis data duringthe idle speed control adjustment is cleared.)

(21)Restart the engine, let it run at idle for about 5 minutes, andcheck that the engine is running in good idle quality.

THROTTLE BODY (THROTTLE VALVE AREA)

CLEANING

NllRCK

(1) Warm up the engine, then stop it.

(2) Remove the air intake hose from the throttle body.

(3) Spray cleaning solvent into the valve through the throttle

body intake port and leave it for about 5 minutes.

(4) Start the engine, race it several times and idle it for about 1minute. If the idling speed becomes unstable slightly open

the throttle valve to keep the engine running.

(5) If the throttle valve deposits are not removed, repeat steps

(3) and (4).

(6) Attach the air intake hose.

(7) Disconnect the battery terminal for

10 seconds or more,

and then reconnect it.

(8) Adjust the idle speed control and throttle position sensor.

Page 498 of 1216

FUEL SYSTEM - Service Adjustment Procedures 4.8L Engine>

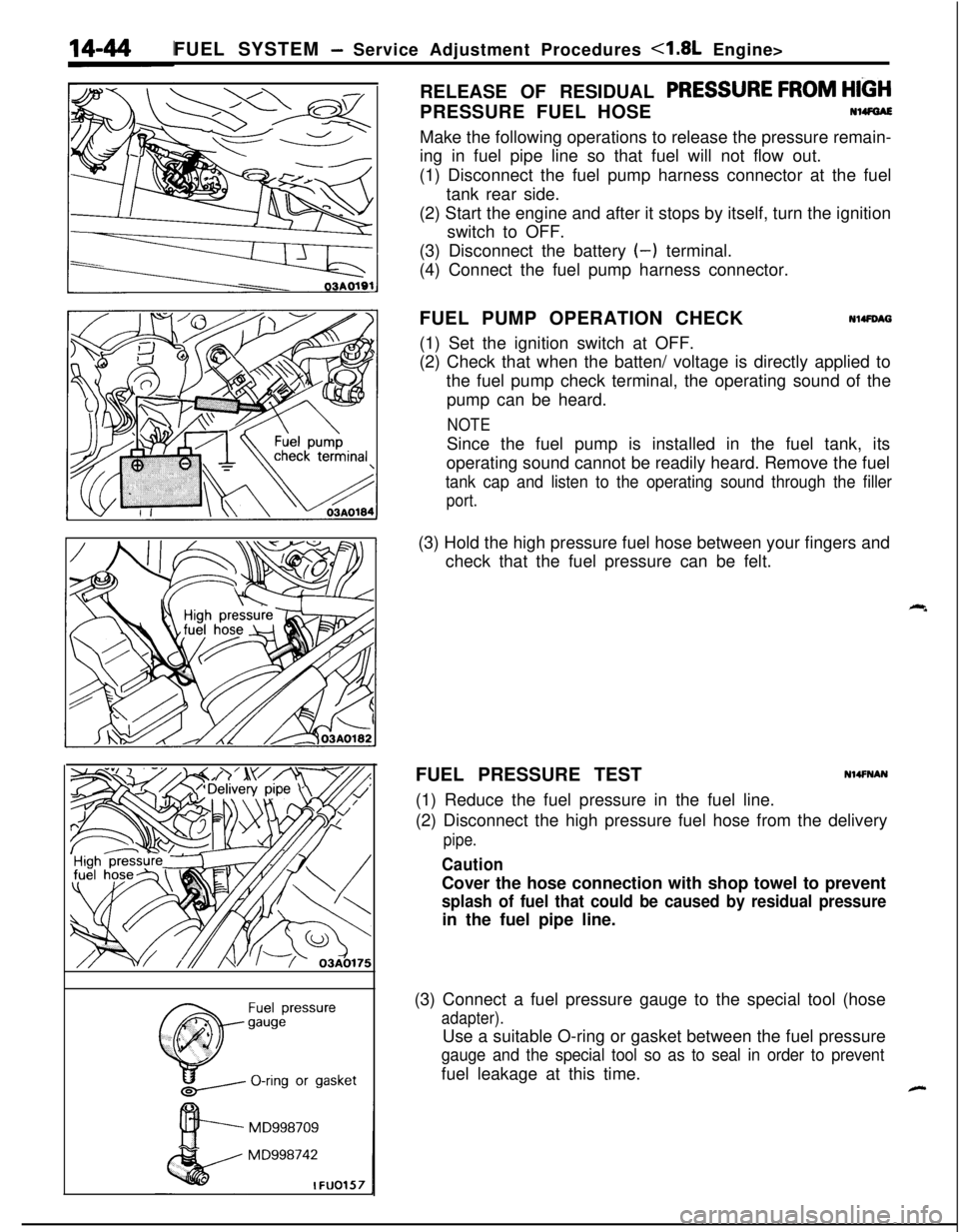

RELEASE OF RESIDUAL

PRESSURE FROM HIGHPRESSURE FUEL HOSE

N14FGAE

MD998709

MD998742

IFUO157Make the following operations to release the pressure remain-

ing in fuel pipe line so that fuel will not flow out.

(1) Disconnect the fuel pump harness connector at the fuel

tank rear side.

(2) Start the engine and after it stops by itself, turn the ignition

switch to OFF.

(3) Disconnect the battery

(-) terminal.

(4) Connect the fuel pump harness connector.

FUEL PUMP OPERATION CHECK

Nl4FDAG(1) Set the ignition switch at OFF.

(2) Check that when the batten/ voltage is directly applied to

the fuel pump check terminal, the operating sound of the

pump can be heard.

NOTESince the fuel pump is installed in the fuel tank, its

operating sound cannot be readily heard. Remove the fuel

tank cap and listen to the operating sound through the filler

port.(3) Hold the high pressure fuel hose between your fingers and

check that the fuel pressure can be felt.

FUEL PRESSURE TEST

Nl4FNAN(1) Reduce the fuel pressure in the fuel line.

(2) Disconnect the high pressure fuel hose from the delivery

pipe.

CautionCover the hose connection with shop towel to prevent

splash of fuel that could be caused by residual pressurein the fuel pipe line.

(3) Connect a fuel pressure gauge to the special tool (hose

adapter).Use a suitable O-ring or gasket between the fuel pressure

gauge and the special tool so as to seal in order to preventfuel leakage at this time.

-

Page 502 of 1216

14-48FUEL SYSTEM - Service Adjustment Procedures <2.0L Engine>

SERVICE ADJUSTMENT PROCEDURES

<2.0L DOHC Engine>

CURB IDLE SPEED INSPECTION

Caution

N14FHADThe improper setting (throttle valve opening) will increase

exhaust gas temperature at deceleration, reducing

catalys-tic converter life greatly and deteriorating exhaust gas

cleaning performance. It also has effect on fuel ‘consump-

tion and engine braking.

Pre-conditions for inspection

l Engine coolant temperature:

85-95°C (185-205°F)

l Lights, electric cooling fan and accessories: OFF

lTransaxle: Neutral (P for vehicles with automatic transaxle)l Steering wheel: Neutral position (vehicles with a power-

steering)l Check ignition timing and adjust if necessary. Refer to

GROUP 8.

NOTEWith vehicles for Canada, the headlights and taillights, etc.

remain on even when the lighting switch is turned OFF, but thiscauses no problems during inspection.

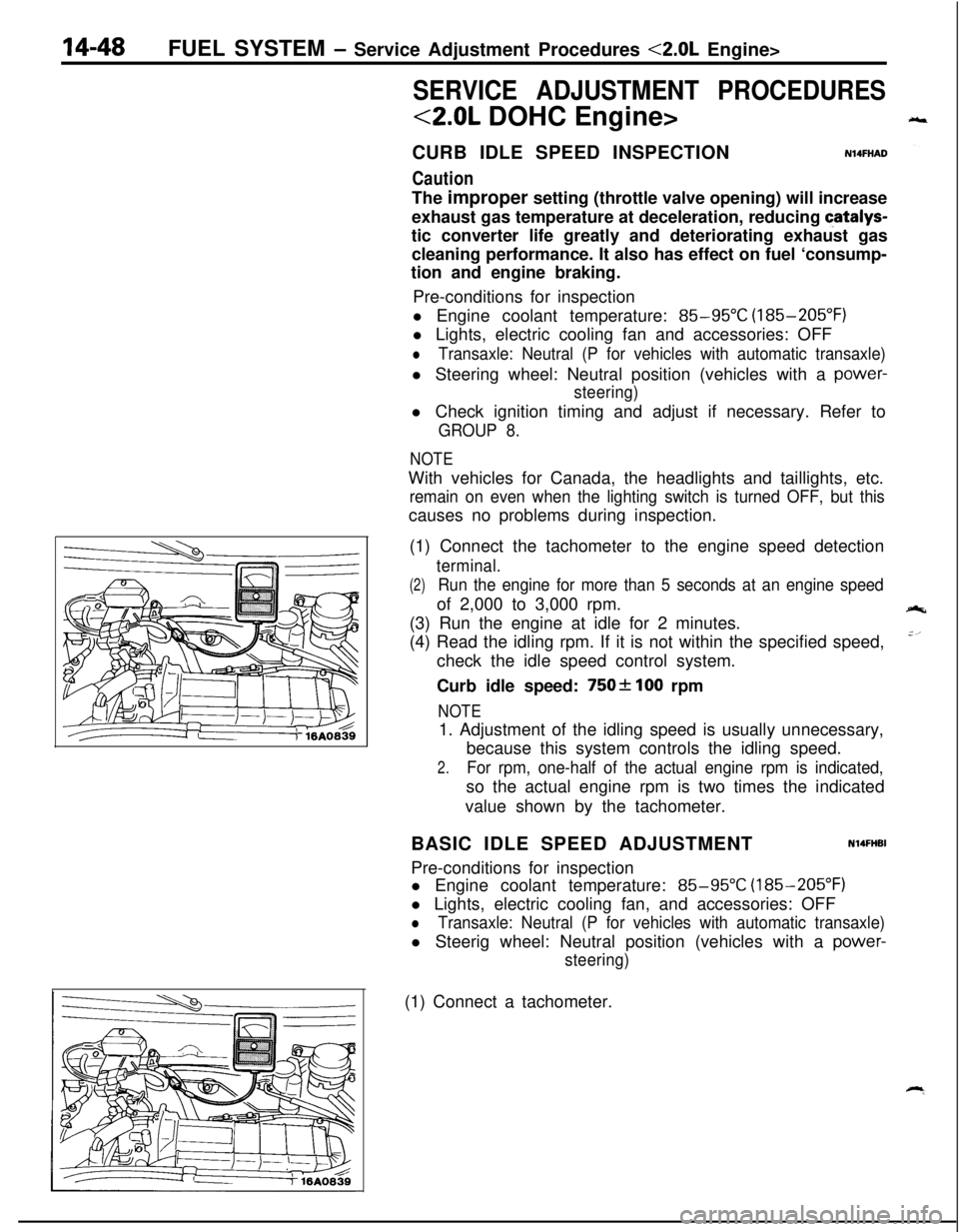

(1) Connect the tachometer to the engine speed detection

terminal.

(2)Run the engine for more than 5 seconds at an engine speedof 2,000 to 3,000 rpm.

(3) Run the engine at idle for 2 minutes.

(4) Read the idling rpm. If it is not within the specified speed,

check the idle speed control system.

Curb idle speed:

750f 100 rpm

NOTE1. Adjustment of the idling speed is usually unnecessary,

because this system controls the idling speed.

2.For rpm, one-half of the actual engine rpm is indicated,so the actual engine rpm is two times the indicated

value shown by the tachometer.

BASIC IDLE SPEED ADJUSTMENT

N14FHBIPre-conditions for inspection

l Engine coolant temperature:

85-95°C (185-205°F)

l Lights, electric cooling fan, and accessories: OFF

lTransaxle: Neutral (P for vehicles with automatic transaxle)l Steerig wheel: Neutral position (vehicles with a

power-

steering)(1) Connect a tachometer.

Page 503 of 1216

FUEL SYSTEM - Service Adjustment Procedures <2.0L Engine>14-49

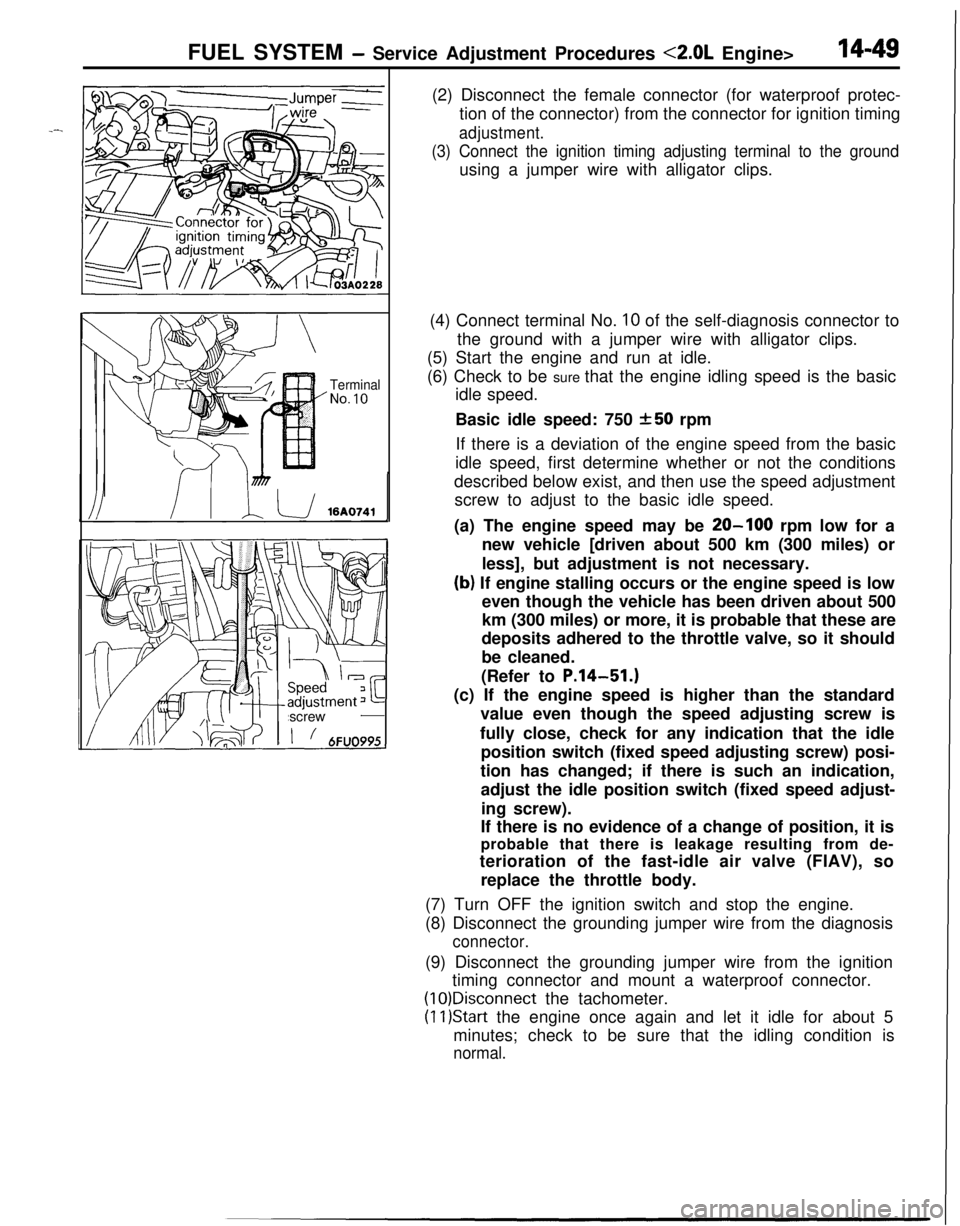

TerminalNo.10screw(2) Disconnect the female connector (for waterproof protec-

tion of the connector) from the connector for ignition timing

adjustment.

(3) Connect the ignition timing adjusting terminal to the groundusing a jumper wire with alligator clips.

(4) Connect terminal No.

10 of the self-diagnosis connector to

the ground with a jumper wire with alligator clips.

(5) Start the engine and run at idle.

(6) Check to be sure that the engine idling speed is the basic

idle speed.

Basic idle speed: 750

250 rpm

If there is a deviation of the engine speed from the basic

idle speed, first determine whether or not the conditions

described below exist, and then use the speed adjustment

screw to adjust to the basic idle speed.

(a) The engine speed may be

20-100 rpm low for a

new vehicle [driven about 500 km (300 miles) or

less], but adjustment is not necessary.

(b) If engine stalling occurs or the engine speed is low

even though the vehicle has been driven about 500

km (300 miles) or more, it is probable that these are

deposits adhered to the throttle valve, so it should

be cleaned.

(Refer to

P.14-51.)(c) If the engine speed is higher than the standard

value even though the speed adjusting screw is

fully close, check for any indication that the idle

position switch (fixed speed adjusting screw) posi-

tion has changed; if there is such an indication,

adjust the idle position switch (fixed speed adjust-

ing screw).

If there is no evidence of a change of position, it is

probable that there is leakage resulting from de-

terioration of the fast-idle air valve (FIAV), so

replace the throttle body.

(7) Turn OFF the ignition switch and stop the engine.

(8) Disconnect the grounding jumper wire from the diagnosis

connector.(9) Disconnect the grounding jumper wire from the ignition

timing connector and mount a waterproof connector.

(1O)Disconnect the tachometer.

(11)Star-t the engine once again and let it idle for about 5

minutes; check to be sure that the idling condition is

normal.

Page 504 of 1216

14-50FUEL SYSTEM - Service Adjustment Procedures <2.0L Engine>THROllLE

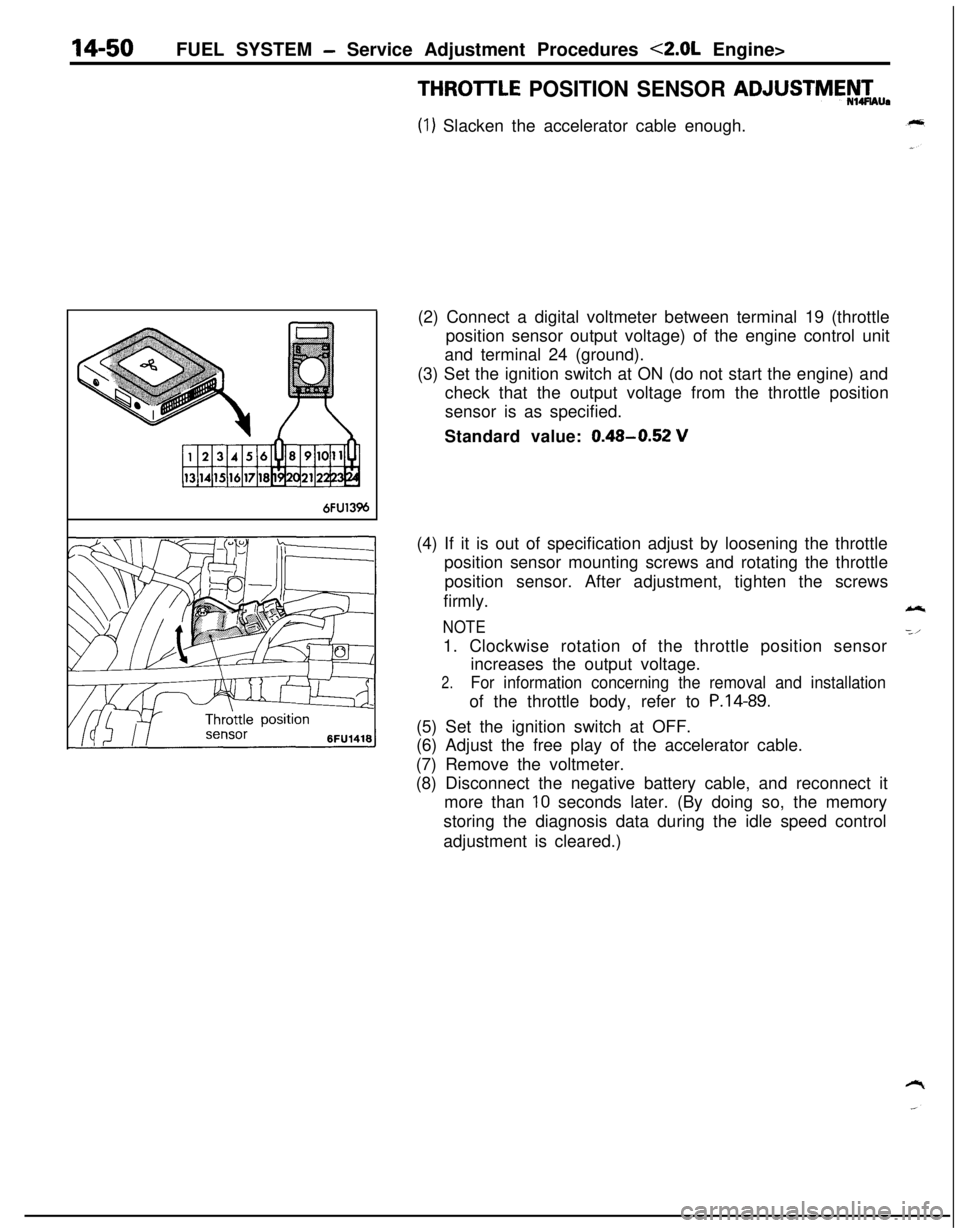

POSITION SENSOR ADJUSTME!-T’“.

(1) Slacken the accelerator cable enough.

6FU13%(2) Connect a digital voltmeter between terminal 19 (throttle

position sensor output voltage) of the engine control unit

and terminal 24 (ground).

(3) Set the ignition switch at ON (do not start the engine) and

check that the output voltage from the throttle position

sensor is as specified.

Standard value:

0.48-0.52 V(4) If it is out of specification adjust by loosening the throttle

position sensor mounting screws and rotating the throttle

position sensor. After adjustment, tighten the screws

firmly.

NOTE1. Clockwise rotation of the throttle position sensor

increases the output voltage.

2.For information concerning the removal and installationof the throttle body, refer to

P.14-89.(5) Set the ignition switch at OFF.

(6) Adjust the free play of the accelerator cable.

(7) Remove the voltmeter.

(8) Disconnect the negative battery cable, and reconnect it

more than

10 seconds later. (By doing so, the memory

storing the diagnosis data during the idle speed control

adjustment is cleared.)

Page 505 of 1216

FUEL SYSTEM - Service Adjustment Procedures <2.0L Engine>14-51THROTTLE BODY (THROTTLE VALVE AREA)

CLEANINGNl4FtU

(1) Warm up the engine, then stop it.

(2) Remove the air intake hose from the throttle body.

(3) Plug the bypass passage inlet of the throttle body.

CautionDo not allow cleaning solvent to enter the bypass

passage.(4) Spray cleaning solvent into the valve through the throttle

body intake port and leave it for about 5 minutes.

(5) Start the engine, race it several times and idle it for about 1minute. If the idling speed becomes unstable (or if the

engine stalls), slightly open the throttle valve to keep the

engine running.

(6) If the throttle valve deposits are not removed, repeat steps

(4) and (5).

(7) Unplug the bypass passage inlet.

(8) Attach the air intake hose.

(9) Disconnect the battery terminal for 10 seconds or more,

and then reconnect it.

(lO)Adjust the basic idle speed. (Refer to P.14-48.)

RELEASE OF RESIDUAL PRESSURE FROM HIGH

PRESSURE FUEL HOSE

N14FGAFRefer to

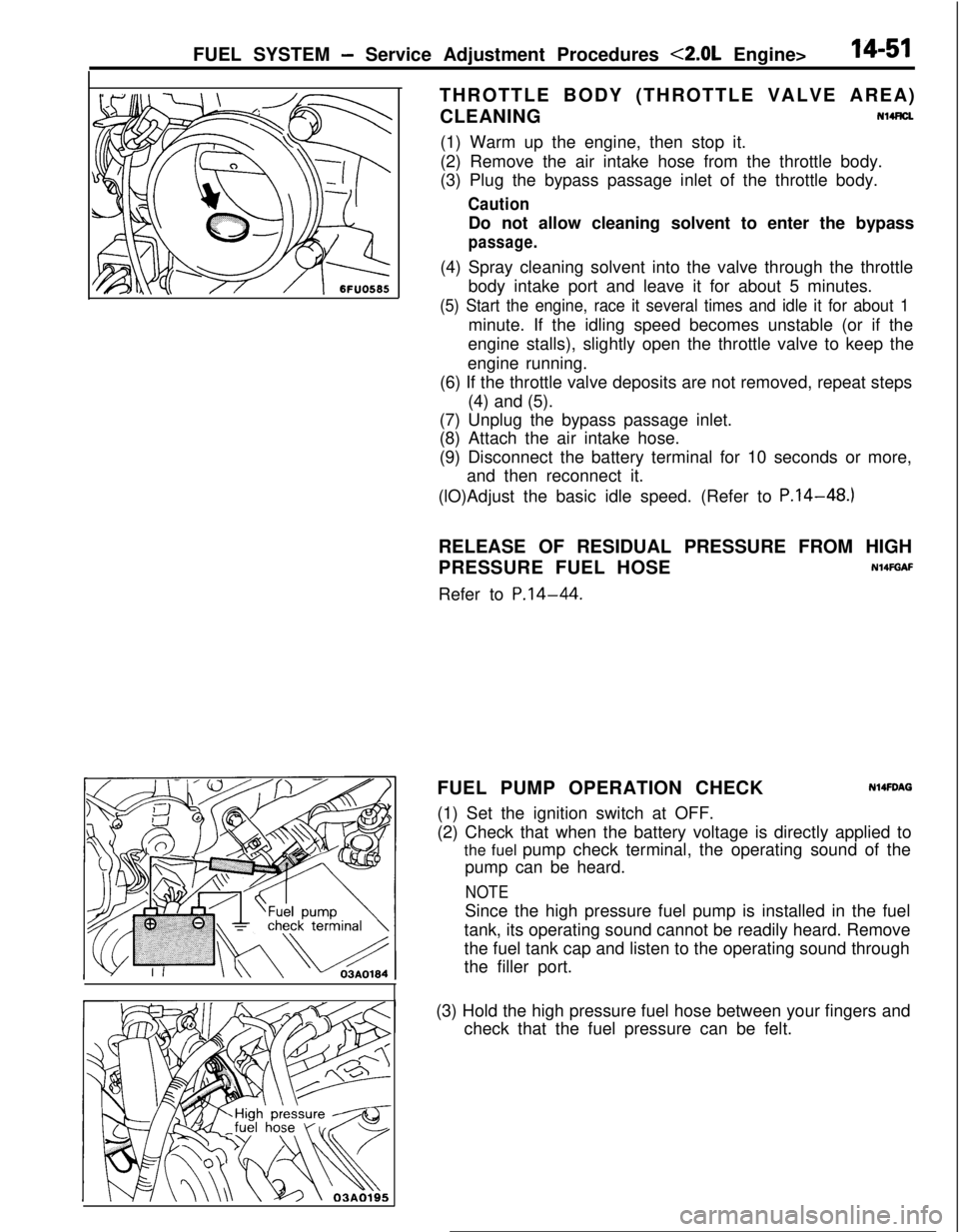

P.14-44.FUEL PUMP OPERATION CHECK

N14FDAG(1) Set the ignition switch at OFF.

(2) Check that when the battery voltage is directly applied to

the fuel pump check terminal, the operating sound of the

pump can be heard.

NOTESince the high pressure fuel pump is installed in the fuel

tank, its operating sound cannot be readily heard. Remove

the fuel tank cap and listen to the operating sound through

the filler port.

I(3) Hold the high pressure fuel hose between your fingers and

check that the fuel pressure can be felt.

Page 510 of 1216

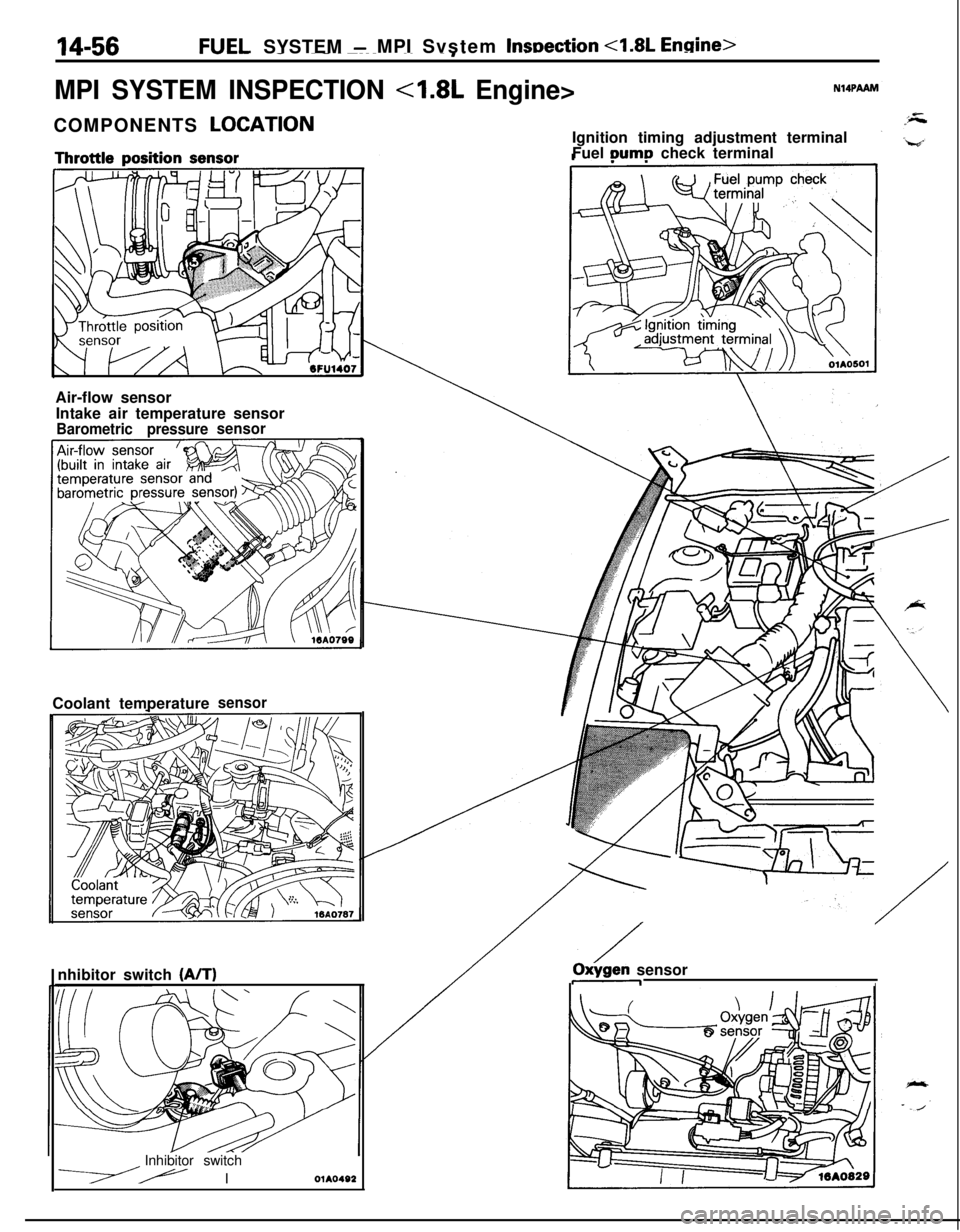

IL SYSTEM -MPI Svstem InsDection 4.8L Enaine>14-56FUE- _ ~-~~~~~ ~~ ~,~.

MPI SYSTEM INSPECTION <1.8L Engine>COMPONENTS

LncAT’n”’Ignition timing adjustment terminal

Fuel

ourno check terminal

Nl4PAAMAir-flow sensor

Intake air temperature sensor

Barometric pressuresensorCoolant temperature

sensornhibitor switch (A/T)

Inhibitor switch

-xT==-TL--==- IOlAO422

/Pxygen sensor