MITSUBISHI ECLIPSE 1991 Service Manual

Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 611 of 1216

1 pq

,s I’

:

REAR

SUSPENSION

LATERAL ROD.................................................11

REAR AXLE HUB............................................14

REARSUSPENSIONASSEMBLY..................5

SERVICE ADJUSTMENT PROCEDURES.......3Rear Hub Rotary-Sliding Resistance

(Torque)Adjustment.....................................4Rear Wheel Alignment Inspection

...............3Wheel Bearing End Play Adjustment

..........3

SHOCKABSORBERASSEMBLY...................8

SPECIAL TOOL................................................3

SPECIFICATIONS.............................................2

GeneralSpecifications..................................2

ServiceSpecifications...................................2Torque Specifications

...................................2

TORSION AXLE AND ARM ASSEMBLY......12

TROUBLESHOOTING......................................3

REARSUSPENSIONASSEMBLY . . . . . . . . . . . . . . . . . .21

SHOCK ABSORBER ASSEMBLY...................32

SERVICE ADJUSTMENT PROCEDURES.......20Rear WheelAlignment

Inspection................20

SPECIAL TOOLS.............................................18

SPECIFICATIONS.............................................16

GeneralSpecifications..................................16

ServiceSpecifications...................................16LTorqueSpecifications...................................17

Lubricant.......................................................17

STABILIZER BAR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

TRAILING ARM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

TROUBLESHOOTING......................................19

UPPER AND LOWER ARM............................25

CONTENTSN17AA-

Page 612 of 1216

17-2REAR SUSPENSION

GENERAL SPECIFICATIONS

LN17CAA

ItemsVehicles with 1.8L EngineVehicles with 2.0L DOHC

Engine

jSuspension system

3-link, torsion axle with coil spring type

Coil spring

Wire dia.

x O.D. x free length

mm (in.) 10.1 x 105.1 x 336.510.2 x 105.2 x 316.5

(40 x 4.14 x 13.25)(40 x 4.14 x 12.46)

[Coil spring identification color]

[Light Blue

x 11[Orange x 11Spring constant

N/mm

(Ibs./in.) 20 (112.0)23 (128.8)

Shock absorber

TypeHydraulic, cylindrical, double-acting type

Max. length

mm (in.) 495 (19.5)485 (19.1)

Min. length

mm (in.) 315 (12.4)315 (12.4)

Strokemm (in.) 180 (7.1)170 (6.7)Damping force [at 0.3 m/set. (0.9

ft./set.)]

ExpansionN (Ibs.)800 (176)

ContractionN (Ibs.)300 (66)

Wheel bearing

TypeUnit ball bearing

SERVICE SPECIFICATIONS

Items

Standard valueToe-in (Left-right difference)

Camber

LimitWheel bearing end play

Rear hub rotary-sliding resistance

Rear hub rotary-sliding torque

NOTEToe-in and camber cannot be adjusted.mm (in.)

mm (in.)

N (Ibs.)

Nm

(ftlbs.)

TORQUE SPECIFICATIONS

Specifications

0+3 (Of.1 18)

-45’

f 30’

0.01 (004) or less

31

(7) or less

1.8

(1.30) or lessNI’ICB-A

ItemsNmft.lbs.

Wheel bearing nut

Shock absorber upper mounting nut

Shock absorber lower mounting nut

Lateral rod mounting nut (body side)

Lateral rod mounting bolt (axle beam side)

Trailing arm mounting bolt

Piston rod tightening nut

Brake hose and tube bracket mounting bolt

Caliper assembly mounting nut

Rear speed sensor mounting bolt

200-260

40-50

80- 100

80-100

100-120

100-120

20-2517-26

50-609-14144-188

29-36

58-72

58-72

72-87

72-87

14-18

12-19

36-43

I7-10

Nl7CGA

Page 613 of 1216

Special Tools/Troubleshooting/REAR SUSPENSION

SPECIAL TOOLN17DA.A

ToolNumberName1 Use1

L-451 4

Spring compressorRemoval and installation of the coil spring

bodyTROUBLESHOOTINGNI’IEA-A

Symptom

Squeaks or other

abnormal noiseProbable cause

Loose rear suspension installation bolts and nuts

Malfunction of shock absorber

Worn bushings

Remedy

Retighten

Replace

Poor rideExcessive tire inflation pressure

Malfunction of shock absorberWeak or broken springs

Adjust the pressure

Replace

Body tiltingWeak or deteriorated bushings

Weak or broken springs

Replace

SERVICE ADJUSTMENT PROCEDURES

REAR WHEEL ALIGNMENT INSPECTIONN17FAAC

The rear suspension assembly must be free of worn, loosen or

damaged parts prior to measurement of rear wheel alignment.

Standard value:

Toe-in (Left-right difference)

Of3 mm (Of.118 in.)

Camber-45’ + 30’

NOTEThe rear wheel alignment is set at the factory and cannot be

adjusted.If toe-in or camber is not within the standard value, replace

bent or damaged parts.

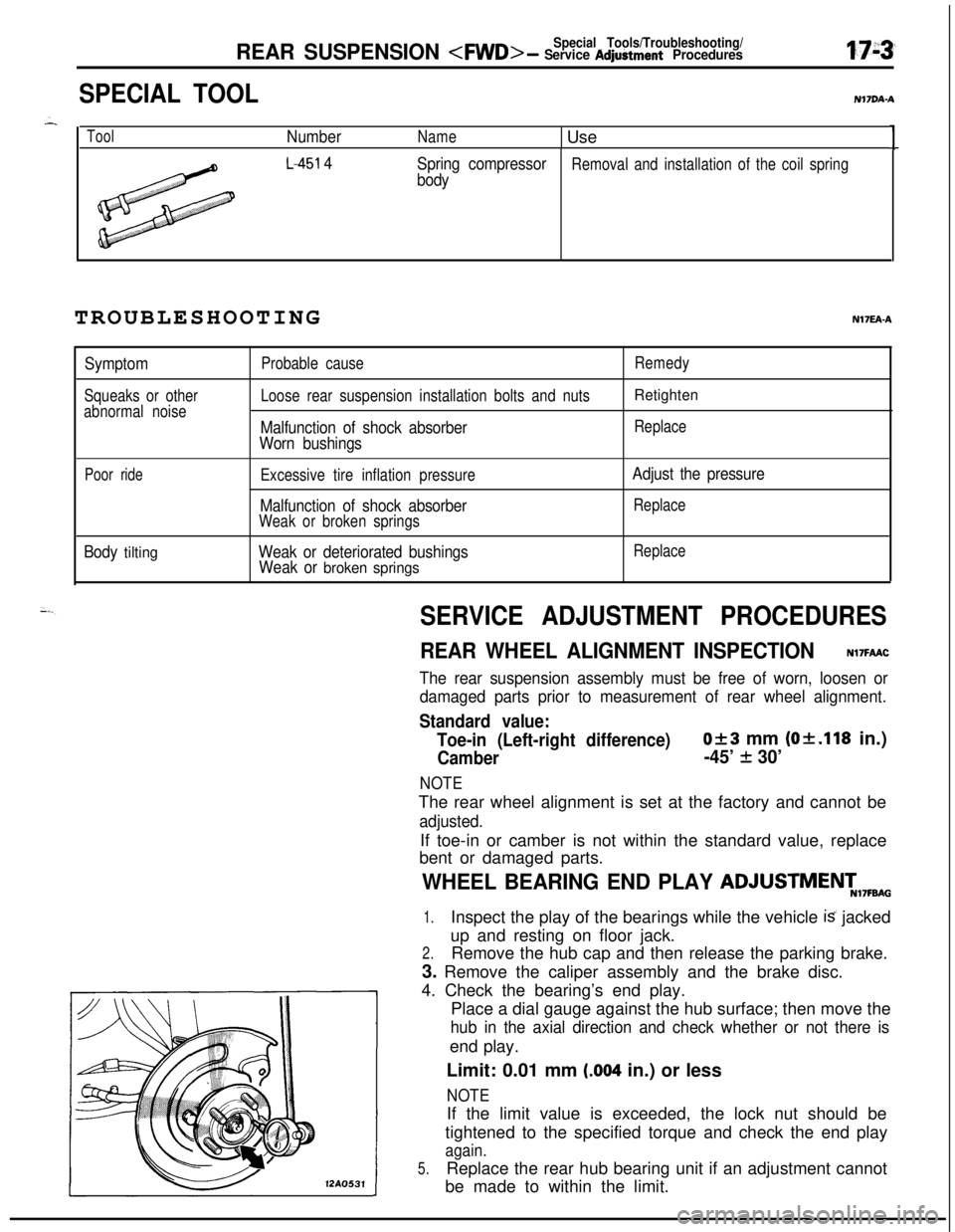

WHEEL BEARING END PLAY ADJUSTMENT,7FBA0

1.Inspect the play of the bearings while the vehicle is jacked

up and resting on floor jack.

2.Remove the hub cap and then release the parking brake.

3. Remove the caliper assembly and the brake disc.

4. Check the bearing’s end play.

Place a dial gauge against the hub surface; then move the

hub in the axial direction and check whether or not there isend play.

Limit: 0.01 mm

(.004 in.) or less

NOTE12AO531If the limit value is exceeded, the lock nut should be

tightened to the specified torque and check the end play

again.

5.Replace the rear hub bearing unit if an adjustment cannot

be made to within the limit.

Page 614 of 1216

17-4REAR SUSPENSION

12A0533

3REAR HUB ROTARY-SLIDING

RESISTANCE

(TORQUE) ADJUSTMENTN17FCAC -

1.Inspect the play of the bearings while the vehicle is jacked.

up and resting on floor jack.

2. Release the parking brake.

3. Remove the caliper assembly and the brake disc.

4. After turnina the hub a few times to seat the bearing,

attach a spriig balance to the hub bolt, and, pulling at a 9@angle from the hub bolt, measure to determine whether or

not the rotary-sliding resistance of the rear hub (the

rotary-sliding torque of the rear hub) is the standard value.

Limit:

Rear hub rotary-sliding resistance

31N (7 Ibs.) or less

Rear hub rotary-sliding torque1.8 Nm (1.30

ft.lbs.) or less

NOTEIf the limit value is exceed, loosen the nut and then tighten

it to the specified torque, and check the rear hub

rotary-sliding torque again.

5. Replace the rear hub bearing unit if an adjustment cannot

+.be made to within the limit.

A

Page 615 of 1216

REAR SUSPENSION

REAR SUSPENSION ASSEMBLYu

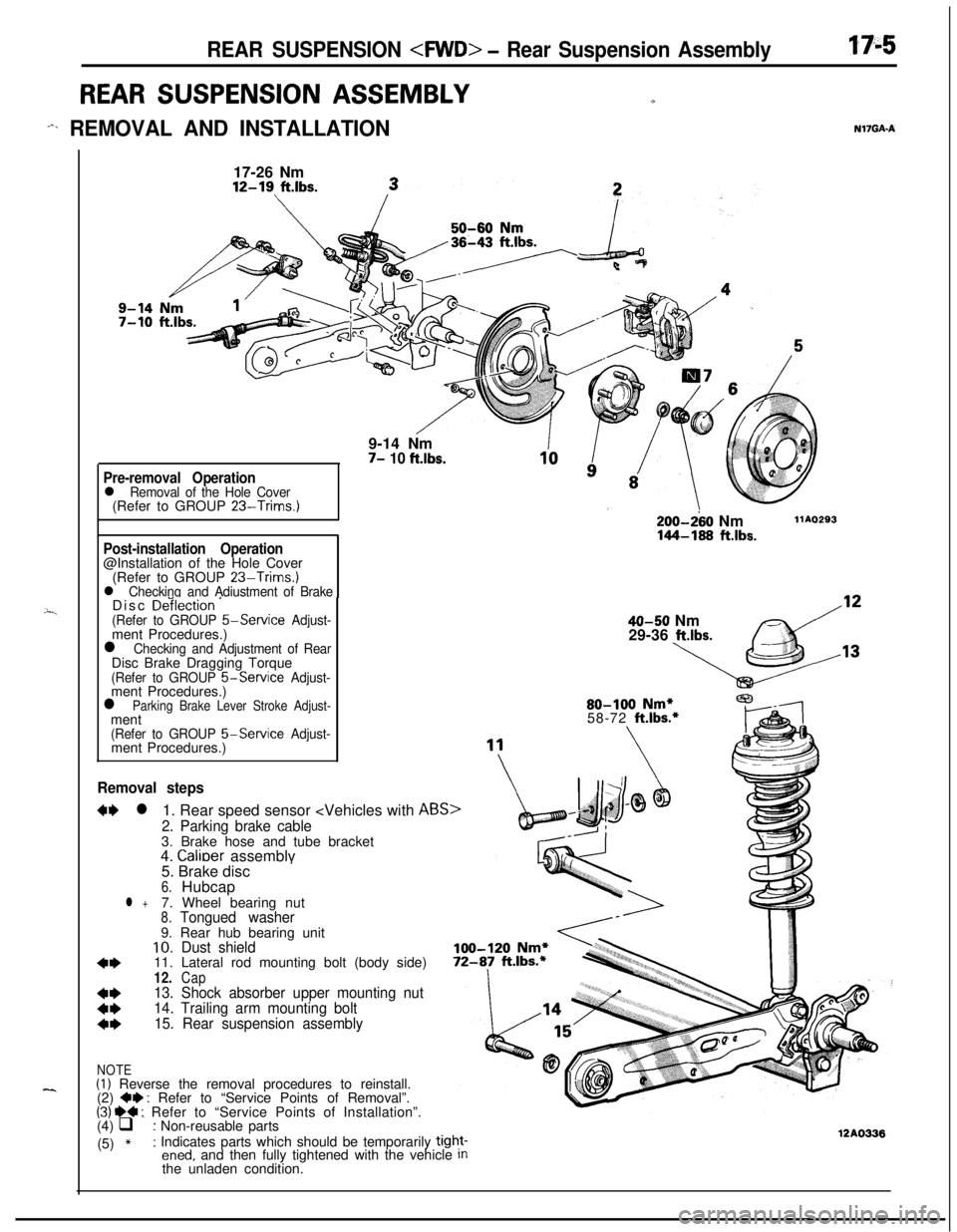

-%. REMOVAL AND INSTALLATIONN17GAA

---i

--..17-26 Nm12-19

ft.lbs.9-14 Nm

7- 10 ft.lbs.

Pre-removal Operationl Removal of the Hole Cover(Refer to GROUP 23-Trims.)

Post-installation Operation@Installation of the Hole Cover

(Refer to GROUP

23-Trims.)l Checking and Adiustment of BrakeDisc De‘ilection ’(Refer to GROUP 5-Service Adjust-ment Procedures.)

l Checking and Adjustment of RearDisc Brake Dragging Torque

(Refer to GROUP &Service Adjust-ment Procedures.)

l Parking Brake Lever Stroke Adjust-ment

(Refer to GROUP 5-Service Adjust-ment Procedures.)

Removal steps

W l1. Rear speed sensor

2. Parking brake cable3. Brake hose and tube bracket

4.

Calioer assemblv

200-280 Nm144-168 ftlbs.

llAO293

40-50 Nm

29-36 ltlbs.80-100

Nm*58-72 ft.lbs.*5. Brake disc

’6.Hubcapl +7. Wheel bearing nut8.Tongued washer9. Rear hub bearing unit

10.Dust shield

4*11. Lateral rod mounting bolt (body side)12.Cap

t:

13. Shock absorber upper mounting nut

14. Trailing arm mounting bolt

4*15. Rear suspension assembly

NOTE(I) Reverse the removal procedures to reinstall.

(2) +e : Refer to “Service Points of Removal”.(31 ~~ : Refer to “Service Points of Installation”.

(4) q : Non-reusable parts

(5)

*: Indicates parts which should be temporarily tight-ened, and then fully tightened with the vehicle Inthe unladen condition.12AO336

Page 616 of 1216

17-6REAR SUSPENSION

Drive out

BayArbor

Race

BearingSERVICE POINTS OF REMOVAL

Nl7QBh

1.REMOVAL OF REAR SPEED SENSOR

5-Wheel Speed Sensor.

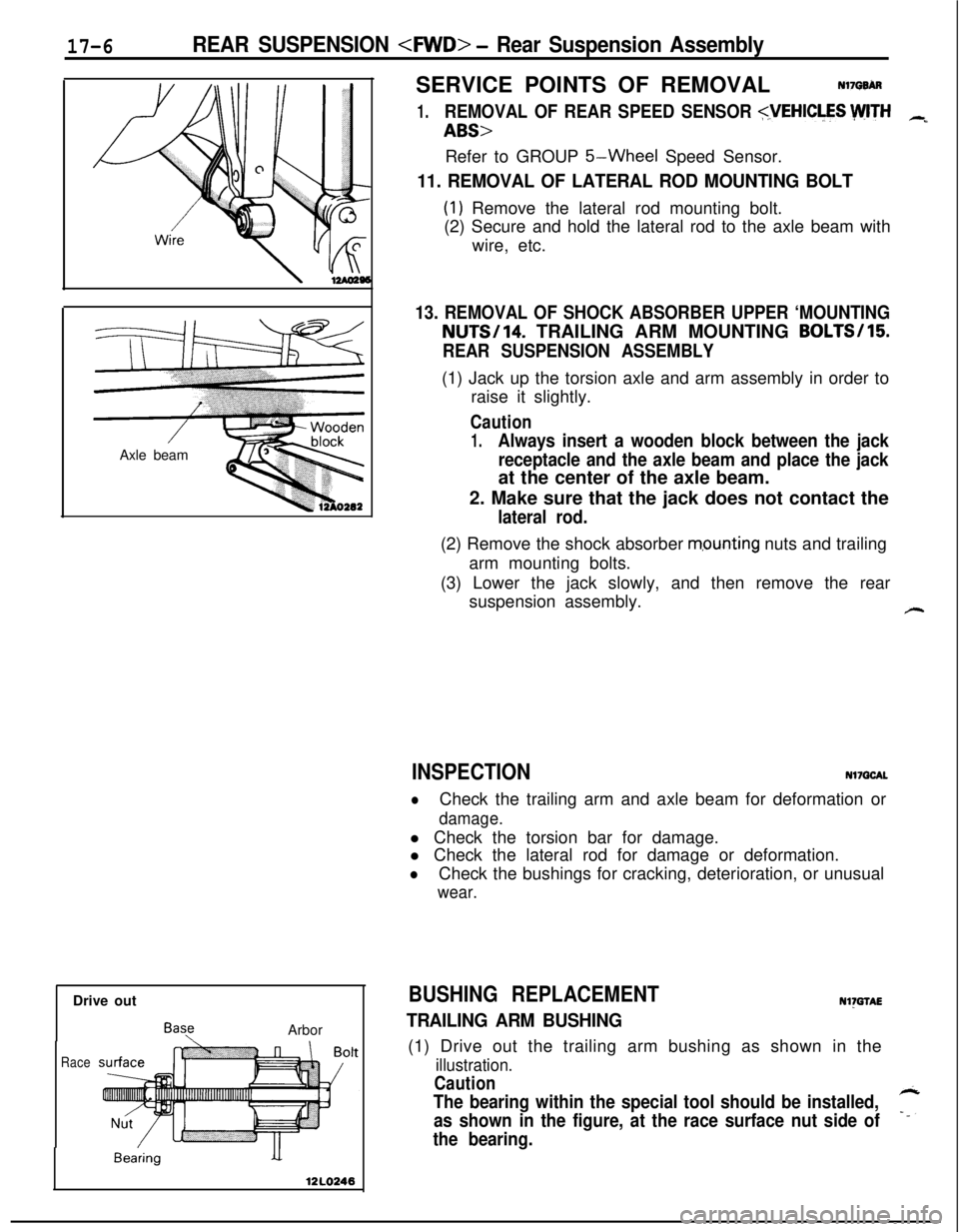

11. REMOVAL OF LATERAL ROD MOUNTING BOLT

(1) Remove the lateral rod mounting bolt.

(2) Secure and hold the lateral rod to the axle beam with

wire, etc.

13. REMOVAL OF SHOCK ABSORBER UPPER ‘MOUNTINGNUTS/14. TRAILING ARM MOUNTING BOLTS/15

REAR SUSPENSION ASSEMBLY(1) Jack up the torsion axle and arm assembly in order to

raise it slightly.

Caution

1.Always insert a wooden block between the jack

receptacle and the axle beam and place the jackat the center of the axle beam.

2. Make sure that the jack does not contact the

lateral rod.(2) Remove the shock absorber

m,ounting nuts and trailing

arm mounting bolts.

(3) Lower the jack slowly, and then remove the rear

suspension assembly.

#-

INSPECTIONNl7QCAL

lCheck the trailing arm and axle beam for deformation or

damage.l Check the torsion bar for damage.

l Check the lateral rod for damage or deformation.

lCheck the bushings for cracking, deterioration, or unusual

wear.

BUSHING REPLACEMENTNl)GTAE

TRAILING ARM BUSHING(1) Drive out the trailing arm bushing as shown in the

illustration.

Caution

The bearing within the special tool should be installed,

as shown in the figure, at the race surface nut side of7

the bearing.

Page 617 of 1216

-.REAR SUSPENSION

- Rear Suspension Assembly

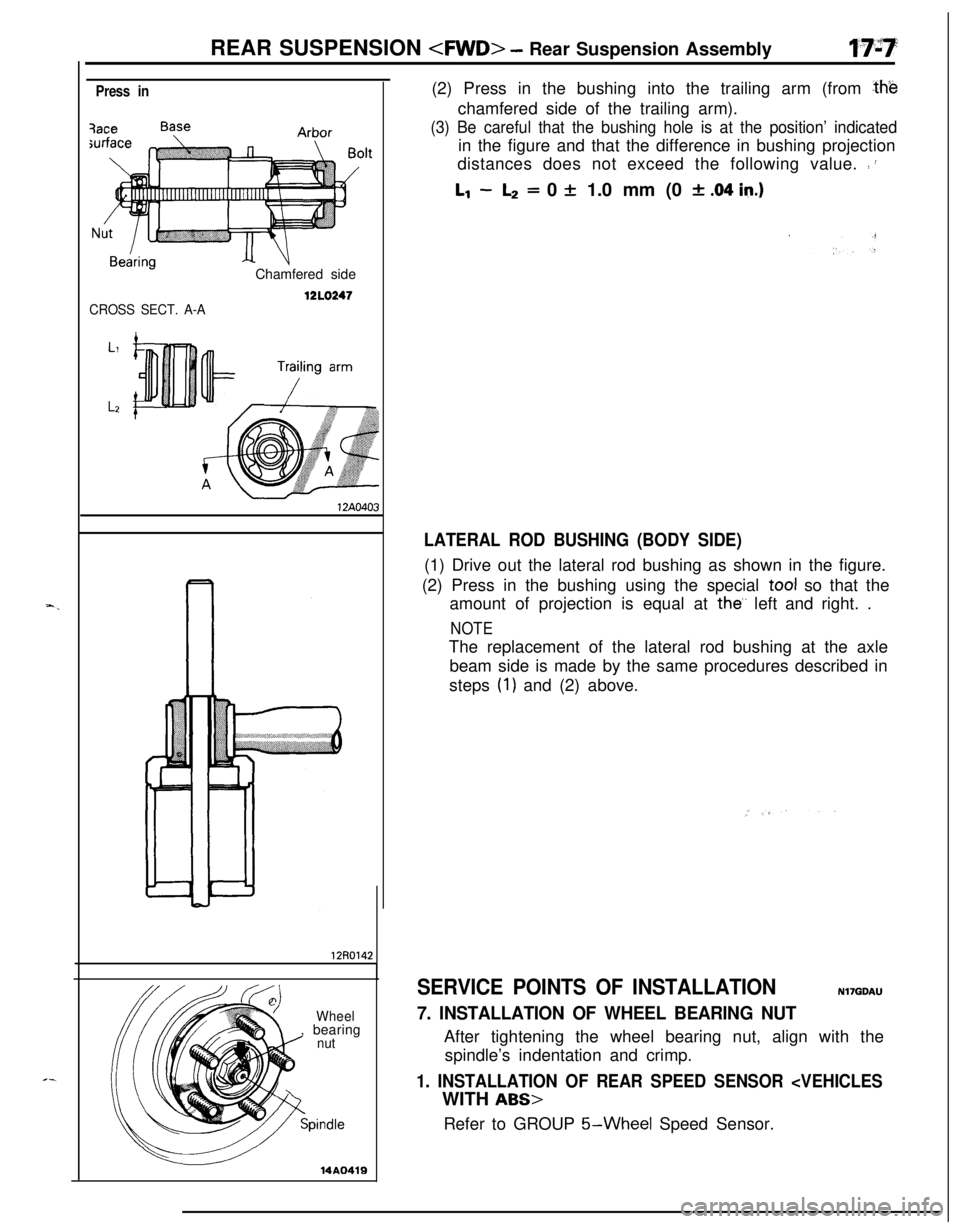

Press in

BearingChamfered side

12l.0247CROSS SECT. A-A

Wheel, bearing

nut

pindle(2) Press in the bushing into the trailing arm (from

ahechamfered side of the trailing arm).

(3) Be careful that the bushing hole is at the position’ indicatedin the figure and that the difference in bushing projection

distances does not exceed the following value.

: :

Ll -L2= 0 + 1.0 mm (0 * .04 in.)

LATERAL ROD BUSHING (BODY SIDE)(1) Drive out the lateral rod bushing as shown in the figure.

(2) Press in the bushing using the special tool so that the

amount of projection is equal at

the’, left and right. .

NOTEThe replacement of the lateral rod bushing at the axle

beam side is made by the same procedures described in

steps

(1) and (2) above.

SERVICE POINTS OF INSTALLATIONNI’IGDAU

7. INSTALLATION OF WHEEL BEARING NUTAfter tightening the wheel bearing nut, align with the

spindle’s indentation and crimp.

1. INSTALLATION OF REAR SPEED SENSOR

5-Wheel Speed Sensor.

Page 618 of 1216

17-8REAR SUSPENSION

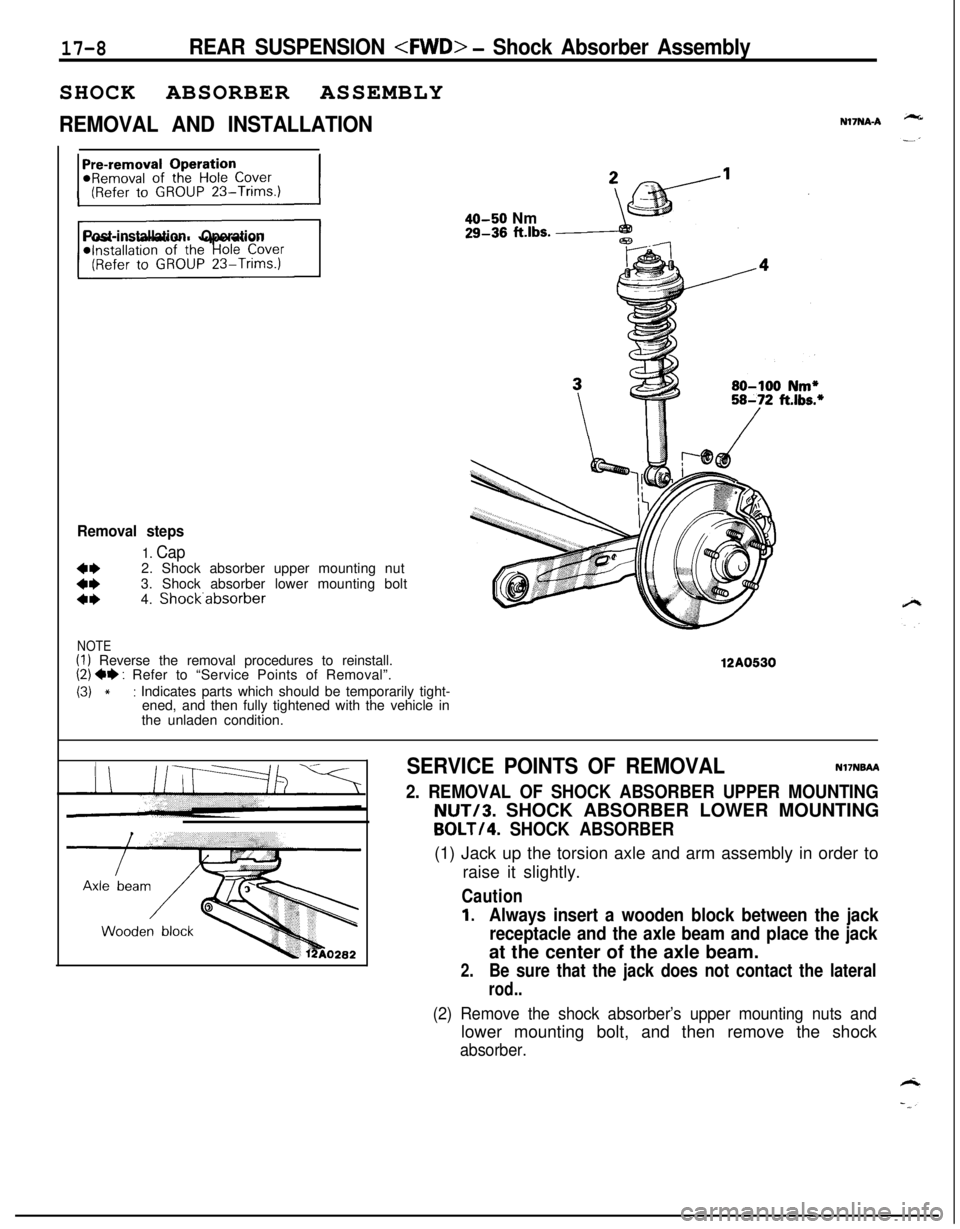

REMOVAL AND INSTALLATIONN17NA-A

Post-installation Operation

Removal steps

1. Cap

::2. Shock absorber upper mounting nut

3. Shock absorber lower mounting bolta*4. Shock.absorber

NOTE(I) Reverse the removal procedures to reinstall.(2) ** : Refer to “Service Points of Removal”.

(3) *: Indicates parts which should be temporarily tight-

ened, and then fully tightened with the vehicle in

the unladen condition.

40-50 Nm29-36 ft.lbs.

12A0530

SERVICE POINTS OF REMOVALNI’INBAA

2. REMOVAL OF SHOCK ABSORBER UPPER MOUNTINGNUT/3. SHOCK ABSORBER LOWER MOUNTING

BOLT/4. SHOCK ABSORBER(1) Jack up the torsion axle and arm assembly in order to

raise it slightly.

Caution

1.Always insert a wooden block between the jack

receptacle and the axle beam and place the jackat the center of the axle beam.

2.Be sure that the jack does not contact the lateral

rod..

(2) Remove the shock absorber’s upper mounting nuts andlower mounting bolt, and then remove the shock

absorber.

Page 619 of 1216

REAR SUSPENSION

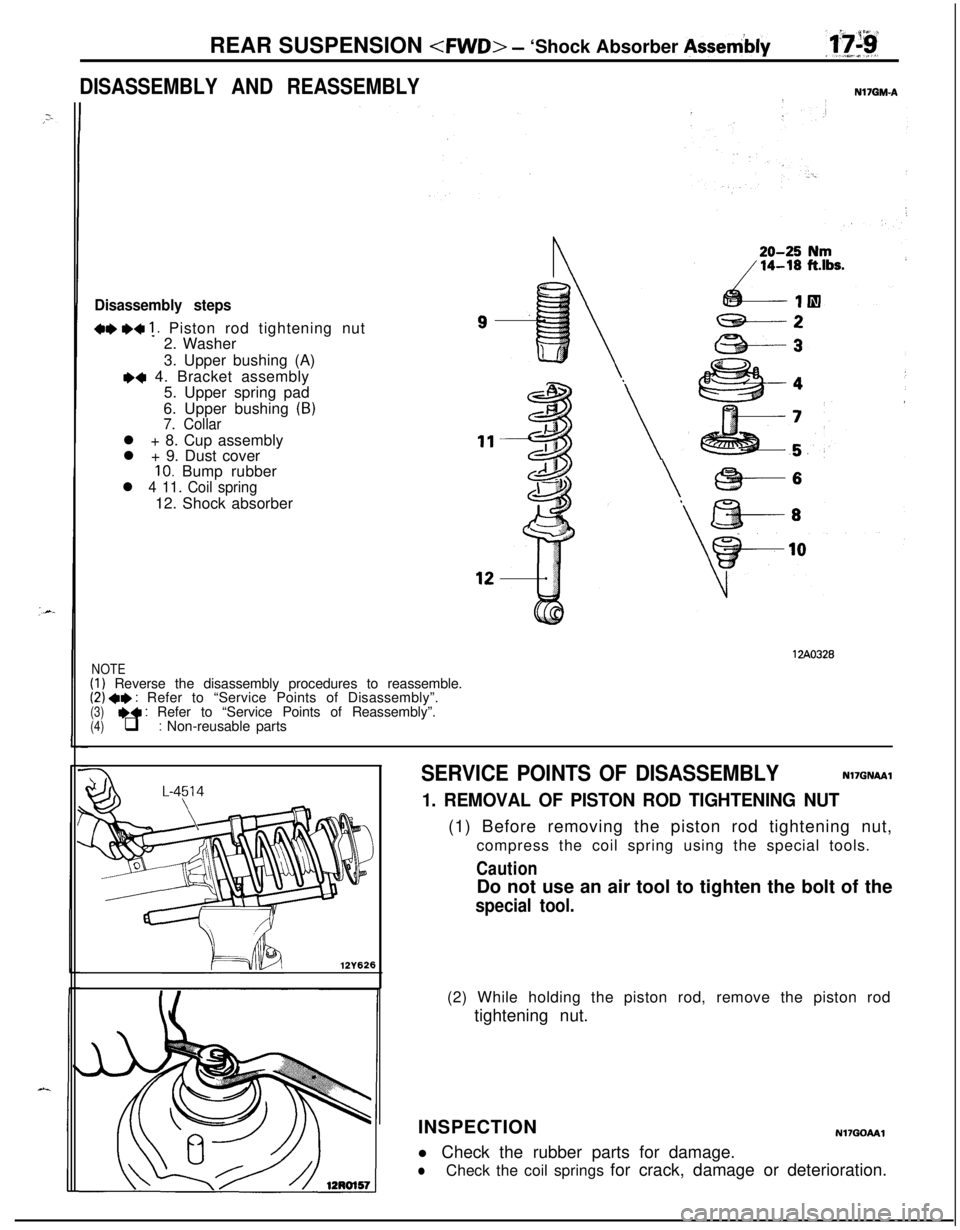

DISASSEMBLY AND REASSEMBLYNI’IOM-A

Disassembly steps

+e ~~ ?. Piston rod tightening nut

2. Washer

3. Upper bushing (A)

e+ 4. Bracket assembly

5. Upper spring pad

6. Upper bushing

(B)7. Collarl + 8. Cup assembly

l + 9. Dust cover

10. Bump rubber

l 4 11. Coil spring12. Shock absorber

NOTE(1) Reverse the disassembly procedures to reassemble.(2) +I) : Refer to “Service Points of Disassembly”.(3)~~ : Refer to “Service Points of Reassembly”.(4)q : Non-reusable parts

\@3----612AO328

12Y626

SERVICE POINTS OF DISASSEMBLYNI’IGNAAI

1. REMOVAL OF PISTON ROD TIGHTENING NUT(1) Before removing the piston rod tightening nut,

compress the coil spring using the special tools.

CautionDo not use an air tool to tighten the bolt of the

special tool.(2) While holding the piston rod, remove the piston rod

tightening nut.

INSPECTION

Nl?GOAAll Check the rubber parts for damage.

lCheck the coil springs for crack, damage or deterioration.

Page 620 of 1216

L

)il spri

12A0049

REAR SUSPENSION

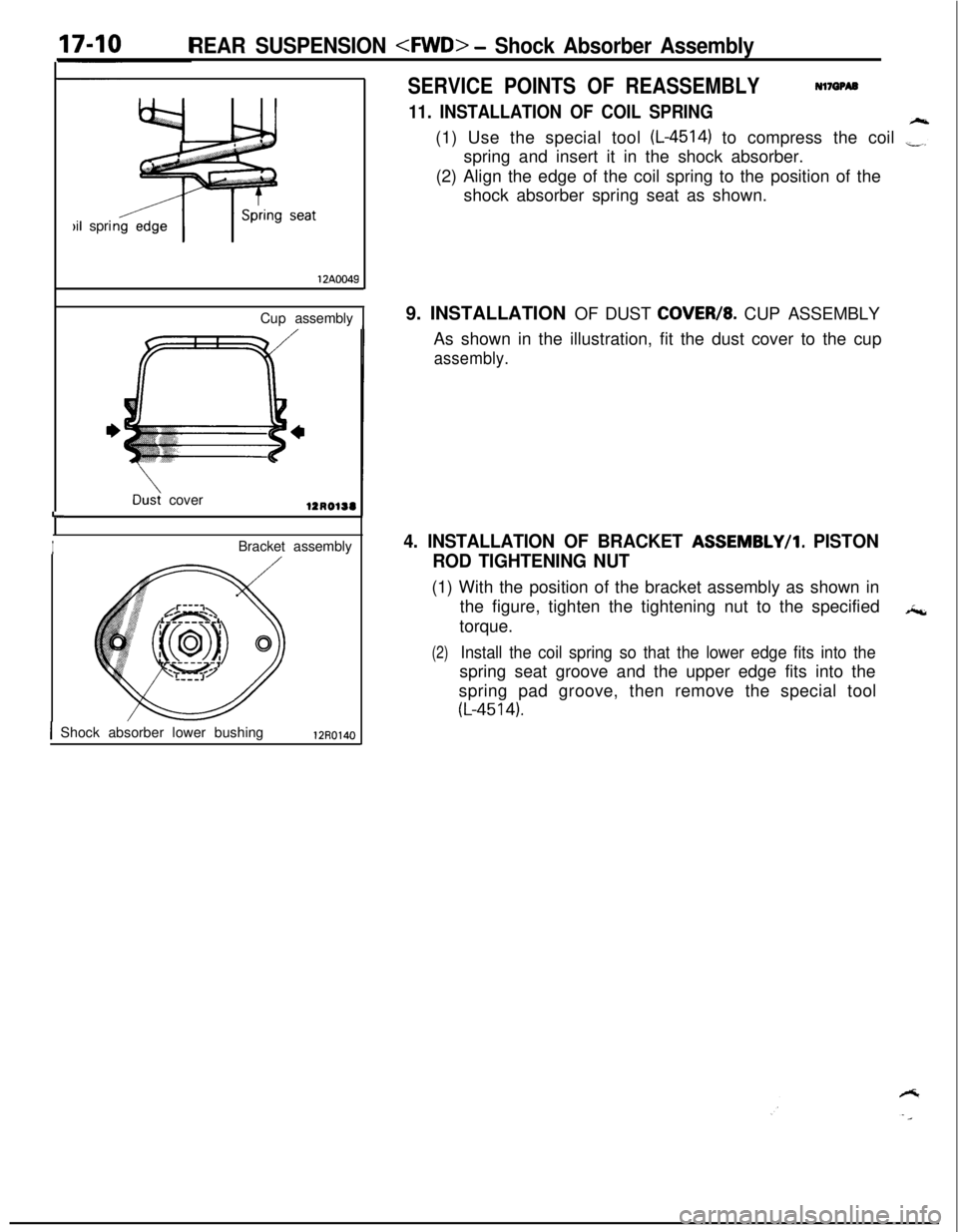

SERVICE POINTS OF REASSEMBLYNl7QPA2

11. INSTALLATION OF COIL SPRING(1) Use the special tool

(L-4514) to compress the coil ,“3”spring and insert it in the shock absorber.

(2) Align the edge of the coil spring to the position of the

shock absorber spring seat as shown.

Cup assembly

1

Dd cover

IBracket assembly

1 Shock absorber lower bushing12R01409. INSTALLATION OF DUST

COVEW8. CUP ASSEMBLY

As shown in the illustration, fit the dust cover to the cup

assembly.

4. INSTALLATION OF BRACKET ASSEMBLY/l. PISTON

ROD TIGHTENING NUT(1) With the position of the bracket assembly as shown in

the figure, tighten the tightening nut to the specified*c,

torque.

(2)Install the coil spring so that the lower edge fits into thespring seat groove and the upper edge fits into the

spring pad groove, then remove the special tool

(L-4514).