coolant MITSUBISHI ECLIPSE 1991 Manual PDF

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 1197 of 1216

.^

EMISSION CONTROL

SYSTEMS

CONTENTSN25AA-

CATALYTICCONVERTER...............................20CRANKCASE EMISSION CONTROL

SYSTEM...........................................................7Components Location

...................................7Crankcase Ventilation System

Inspection......................................................8Positive Crankcase Ventilation Valve

...........8EVAPORATIVE EMISSION CONTROL

SYSTEM...........................................................9

AirConditionerSwitch.................................14Air Flow Sensor, Engine Coolant

Temperature Sensor and Intake Air

Temperature Sensor

.....................................14

Canister.........................................................14Components Location

...................................9

FuelFillerCapInspection............................14Overfill Limiter (Two-way Valve)

..................14

PurgeControlSolenoidValve......................13Purge Control

SystemInspection................11

PurgeControlValve

SYSTEM...........................................................15Air-fuel Ratio Control (MPI) System

............20Components Location

...................................15EGR Control Solenoid Valve

.................................................19

EGR

SystemInspection...............................17EGR Temperature Sensor

......19

EGR Valve.....................................................18

Therm0 Valve

SPECIFICATIONS.............................................2General Specifications

..................................2

Sealant..........................................................2Service Specifications

...................................2

TorqueSpecifications...................................2

TROUBLESHOOTING......................................3

VACUUMHOSES...........................................4

VacuumHosesRouting...............................4

Page 1207 of 1216

EMISSION CONTROL SYSTEMS- Evaporative Emission Control SYStem25-m

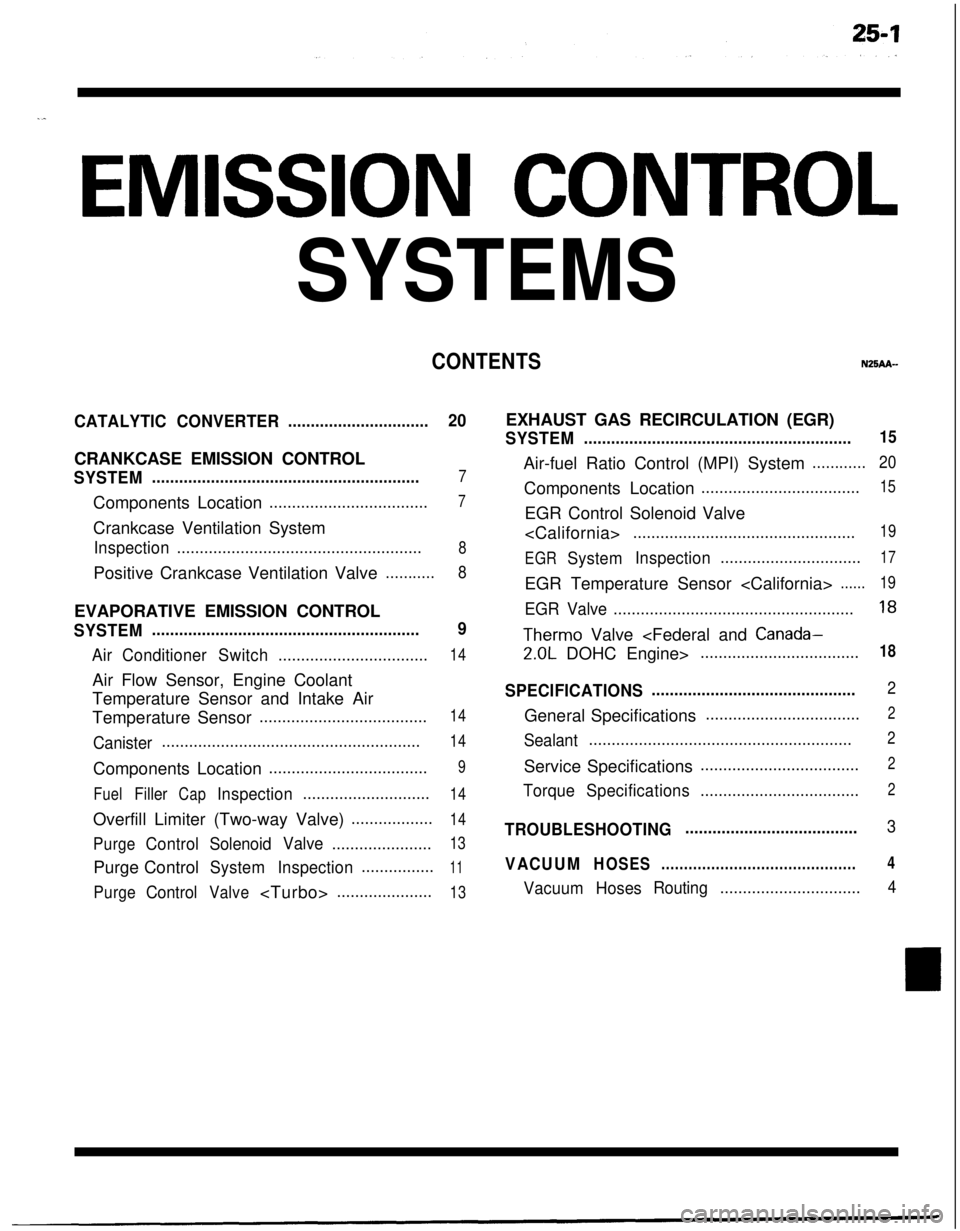

PURGE CONTROL SYSTEM INSPECTION

sensor

P+

Engine control unit

IlEM0086(1) Disconnect the vacuum hose (red stripes) from the throttle

body and connect it to a hand vacuum pump.

(2) Plug the nipple from which the vacuum hose is discon-

nected.(3) Under the engine conditions shown below, check by

applying vacuum from a hand vacuum pump.

When engine is cold-engine coolant temperature:

60% (140°F) or less

Engine operating Applying vacuum

>When engine is hot-engine coolant temperature:

70°C (158°F) or higher

Engine operating

condition

Idling3,000 rpm within

three minutes afterstarting engine

3,000 rpm after

three minutes

have elapsedafter starting

engineApplying vacuum

375

mmHg(14.8 in.Hg.1

Try wpMwvacuum375

mmHg(14.8 in.Hg.1

ResultVacuum is maintained

Vacuum leaks

Vacuum will be main-

tained momentarily,

after which it will

leaks.

NOTEThe vacuum will leak

continuously if the

altitude is 2,200

m(7,200 ft.) or higher,or the intake air

temperature is

50°C(122°F) or higher.

Page 1208 of 1216

25-12EMISSION CONTROL SYSTEMS -Evaporative Emission Control System

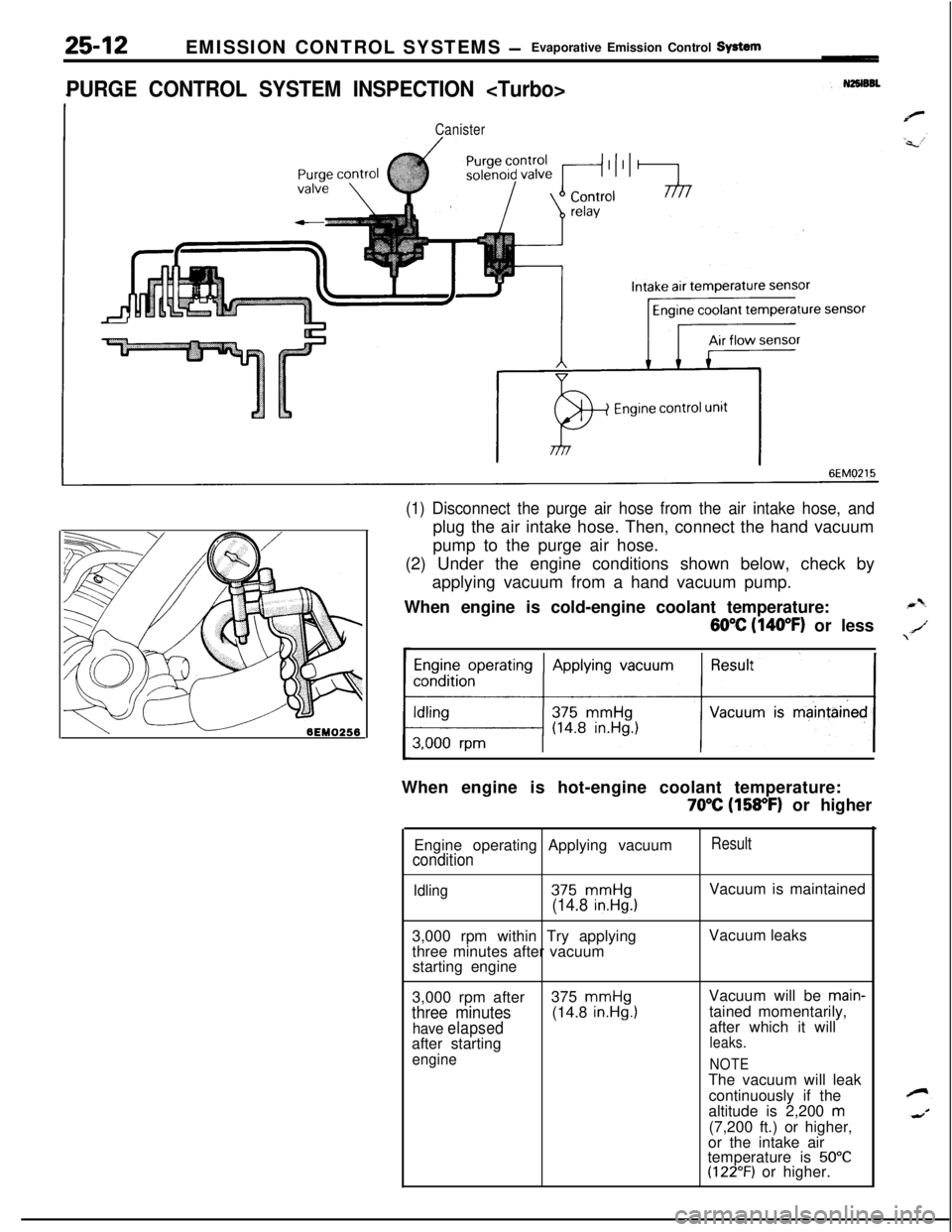

PURGE CONTROL SYSTEM INSPECTION

Canister

6EM0215

(1) Disconnect the purge air hose from the air intake hose, andplug the air intake hose. Then, connect the hand vacuum

pump to the purge air hose.

(2) Under the engine conditions shown below, check by

applying vacuum from a hand vacuum pump.

When engine is cold-engine coolant temperature:

60°C (140°F) or less

Engine operating Applying vacuum

11When engine is hot-engine coolant temperature:

70°C (158°F) or higher

Engine operating Applying vacuum

condition

Result

Idling375 mmHg(14.8 in.Hg.)Vacuum is maintained

3,000 rpm within Try applying

three minutes after vacuum

starting engineVacuum leaks

3,000 rpm after375

mmHgVacuum will be main-

three minutes(14.8 in.Hg.1tained momentarily,

have elapsedafter which it will

after startingleaks.

engineNOTEThe vacuum will leak

continuously if the

altitude is 2,200

m(7,200 ft.) or higher,

or the intake air

temperature is

50°C(122°F) or higher.

Page 1210 of 1216

![MITSUBISHI ECLIPSE 1991 Manual PDF 25-14EMISSION CONTROL SYSTEMS- Evaporative Emission Control System

(5) Measure the resistance between the terminals of the

solenoid valve.

Standard value: 36-44

Q [at 20°C (68OF)]_

6EM137

AIR FLOW S MITSUBISHI ECLIPSE 1991 Manual PDF 25-14EMISSION CONTROL SYSTEMS- Evaporative Emission Control System

(5) Measure the resistance between the terminals of the

solenoid valve.

Standard value: 36-44

Q [at 20°C (68OF)]_

6EM137

AIR FLOW S](/img/19/57104/w960_57104-1209.png)

25-14EMISSION CONTROL SYSTEMS- Evaporative Emission Control System

(5) Measure the resistance between the terminals of the

solenoid valve.

Standard value: 36-44

Q [at 20°C (68OF)]_

6EM137

AIR FLOW SENSOR, ENGINE COOLANT TEMPER-

ATURE SENSOR AND INTAKE AIR TEMPERA-

TURE SENSORTo inspect these parts, refer to GROUP

14-MPI System

Components.‘.

AIR CONDITIONER SWITCHTo inspect the air conditioner switch, refer to GROUP

24’--AirConditioner Switch.

OVERFILL LIMITER (TWO-WAY VALVE)N2BlBE&To inspect the overfill limiter (two-way valve), refer to GROUP

14-Fuel Tank.

CANISTERNzslBmTo inspect the canister, refer to GROUP

14-Fuel Line and

Vapor Line.

FUEL FILLER CAP INSPECTIONNZSIBJACheck the gasket of the fuel filler cap, and, the filler cap itself,

for damage or deformation; replace the cap if necessary.

Page 1213 of 1216

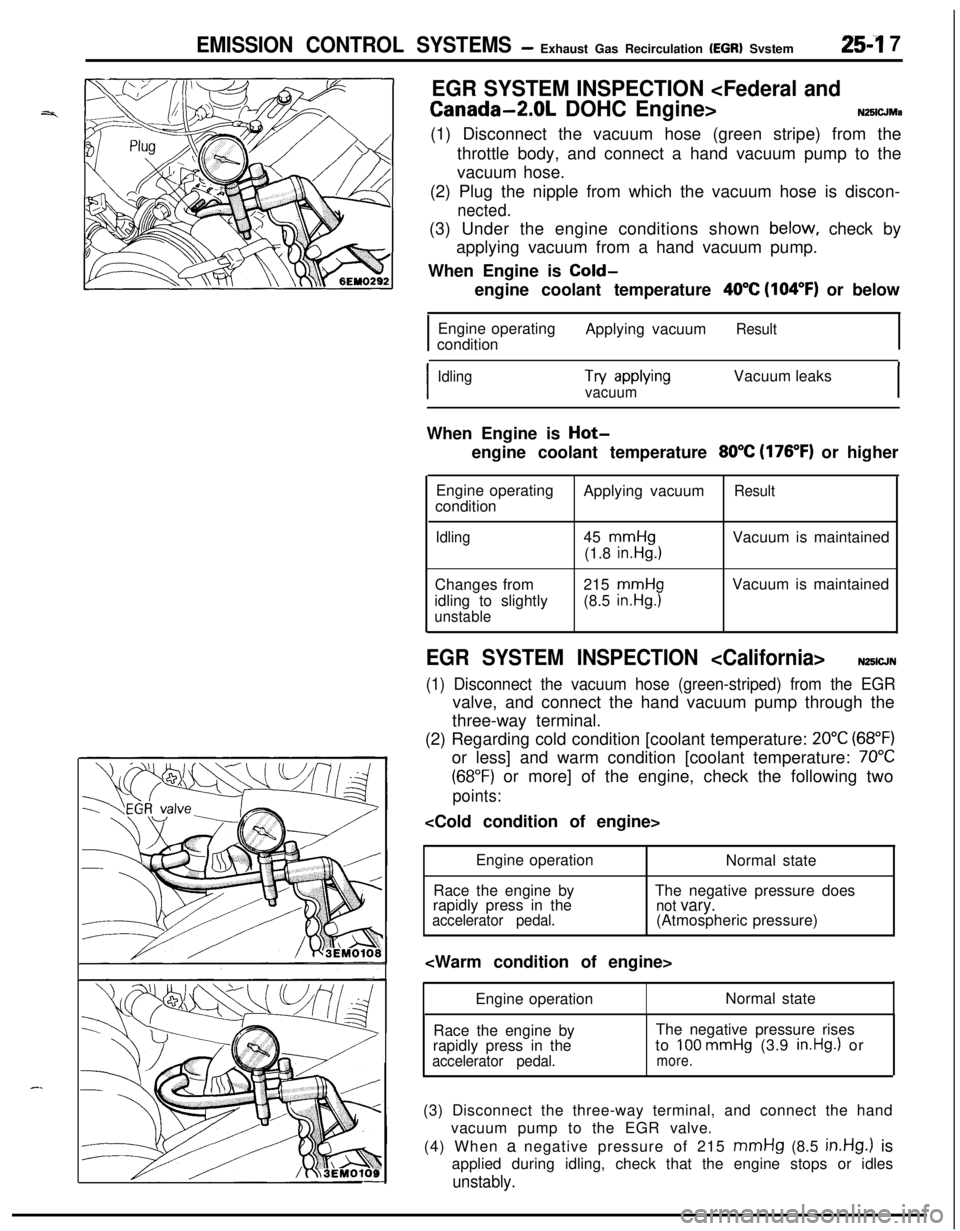

EMISSION CONTROL SYSTEMS- Exhaust Gas Recirculation (EGR) Svstem254 7

EGR SYSTEM INSPECTION

throttle body, and connect a hand vacuum pump to the

vacuum hose.

(2) Plug the nipple from which the vacuum hose is discon-

nected.(3) Under the engine conditions shown

below, check by

applying vacuum from a hand vacuum pump.

When Engine is

Cold-engine coolant temperature

40°C (104°F) or below

Engine operating

conditionApplying vacuum

Result

I

IdlingTry awMngVacuum leaksvacuumIWhen Engine is

Hot-engine coolant temperature

80°C (176°F) or higher

Engine operating

conditionApplying vacuum

Result

Idling45

mmHg(1.8

in.Hg.1Vacuum is maintained

Changes from

idling to slightly

unstable215

mmHg(8.5

in.Hg.1Vacuum is maintained

EGR SYSTEM INSPECTION

(1) Disconnect the vacuum hose (green-striped) from the EGRvalve, and connect the hand vacuum pump through the

three-way terminal.

(2) Regarding cold condition [coolant temperature:

20°C (68°F)or less] and warm condition [coolant temperature:

70°C

(68°F) or more] of the engine, check the following two

points:

Engine operation

Normal state

Race the engine byThe negative pressure does

rapidly press in the

not vary.accelerator pedal.(Atmospheric pressure)

Engine operationNormal state

Race the engine by

rapidly press in the

accelerator pedal.The negative pressure rises

to

100 mmHg (3.9 in.Hg.1 ormore.(3) Disconnect the three-way terminal, and connect the hand

vacuum pump to the EGR valve.

(4) When a negative pressure of 215

mmHg (8.5 in.Hg.) is

applied during idling, check that the engine stops or idles

unstably.