MITSUBISHI ENDEAVOR 2004 Service Repair Manual

ENDEAVOR 2004

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57105/w960_57105-0.png

MITSUBISHI ENDEAVOR 2004 Service Repair Manual

Trending: module location, Anchor, headrest, schedule, tcl, recommended oil, engine coolant

Page 1451 of 3870

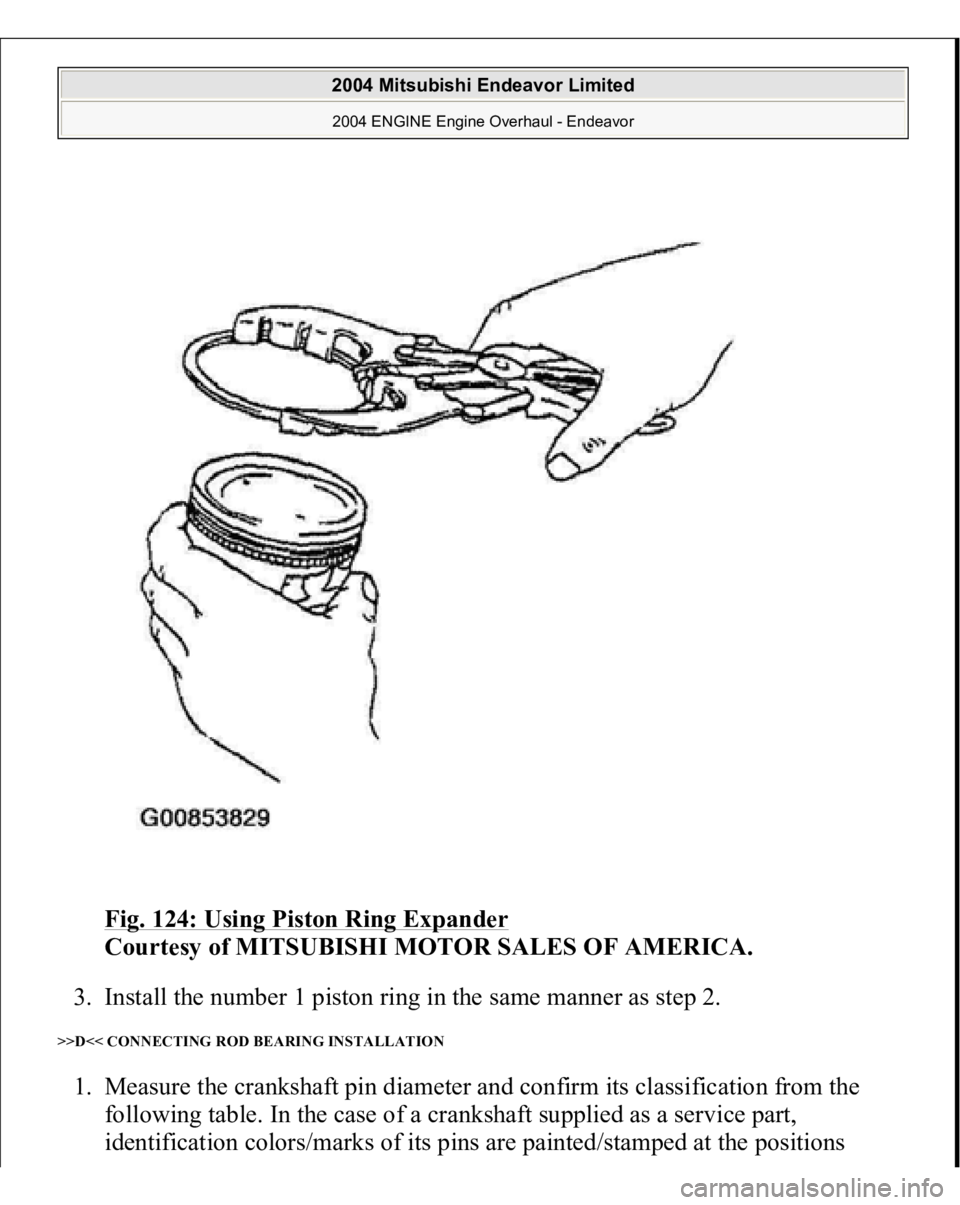

Fig. 124: Using Piston Ring Expander

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

3. Install the number 1 piston ring in the same manner as step 2.

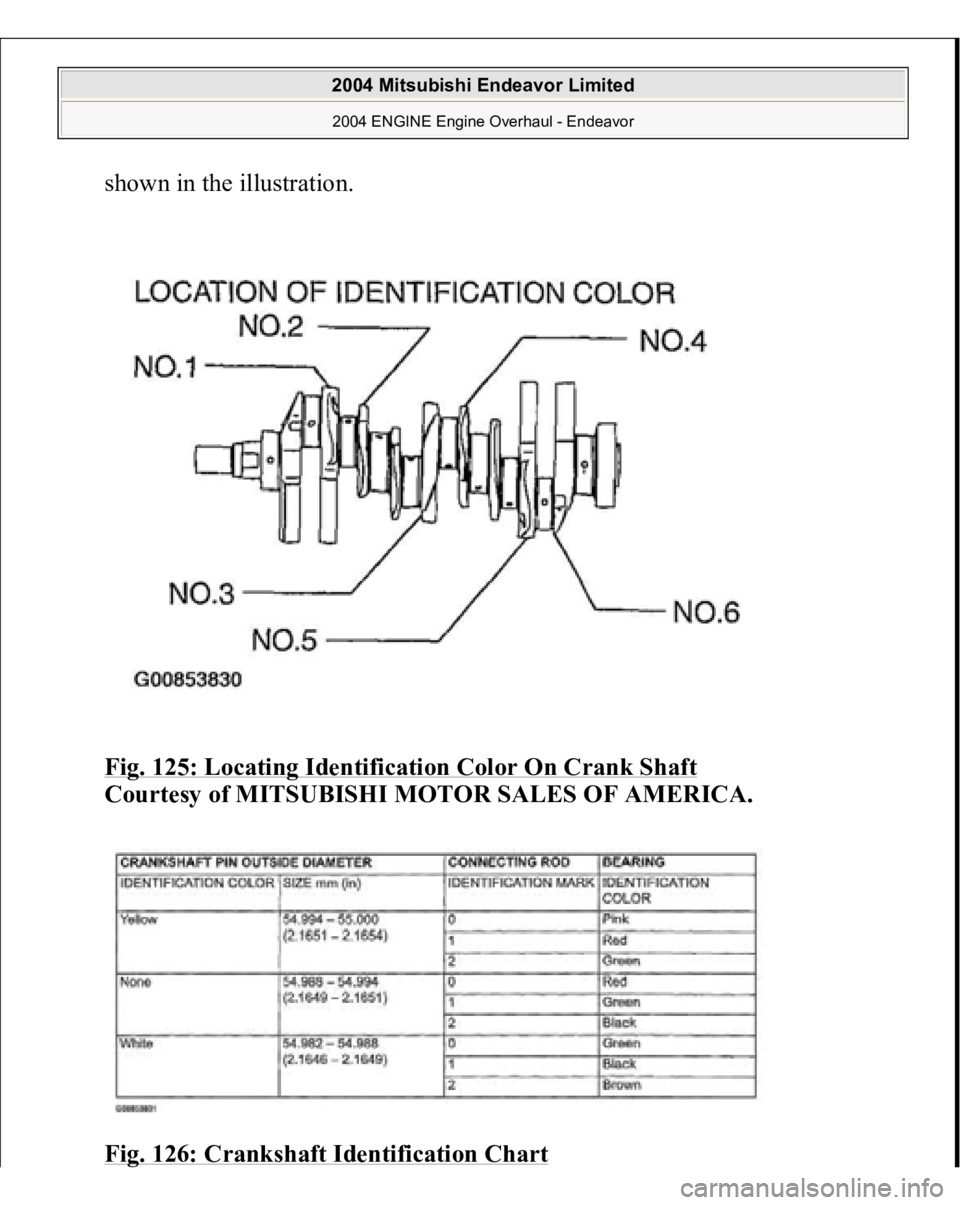

>>D<< CONNECTING ROD BEARING INSTALLATION 1. Measure the crankshaft pin diameter and confirm its classification from the

following table. In the case of a crankshaft supplied as a service part,

identification colors/marks of its

pins are

painte

d/stam

ped at the

positions

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1452 of 3870

shown in the illustration.

Fig. 125: Locating Identification Color On Crank Shaft

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

Fig. 126: Crankshaft Identification Chart

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1453 of 3870

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA

.

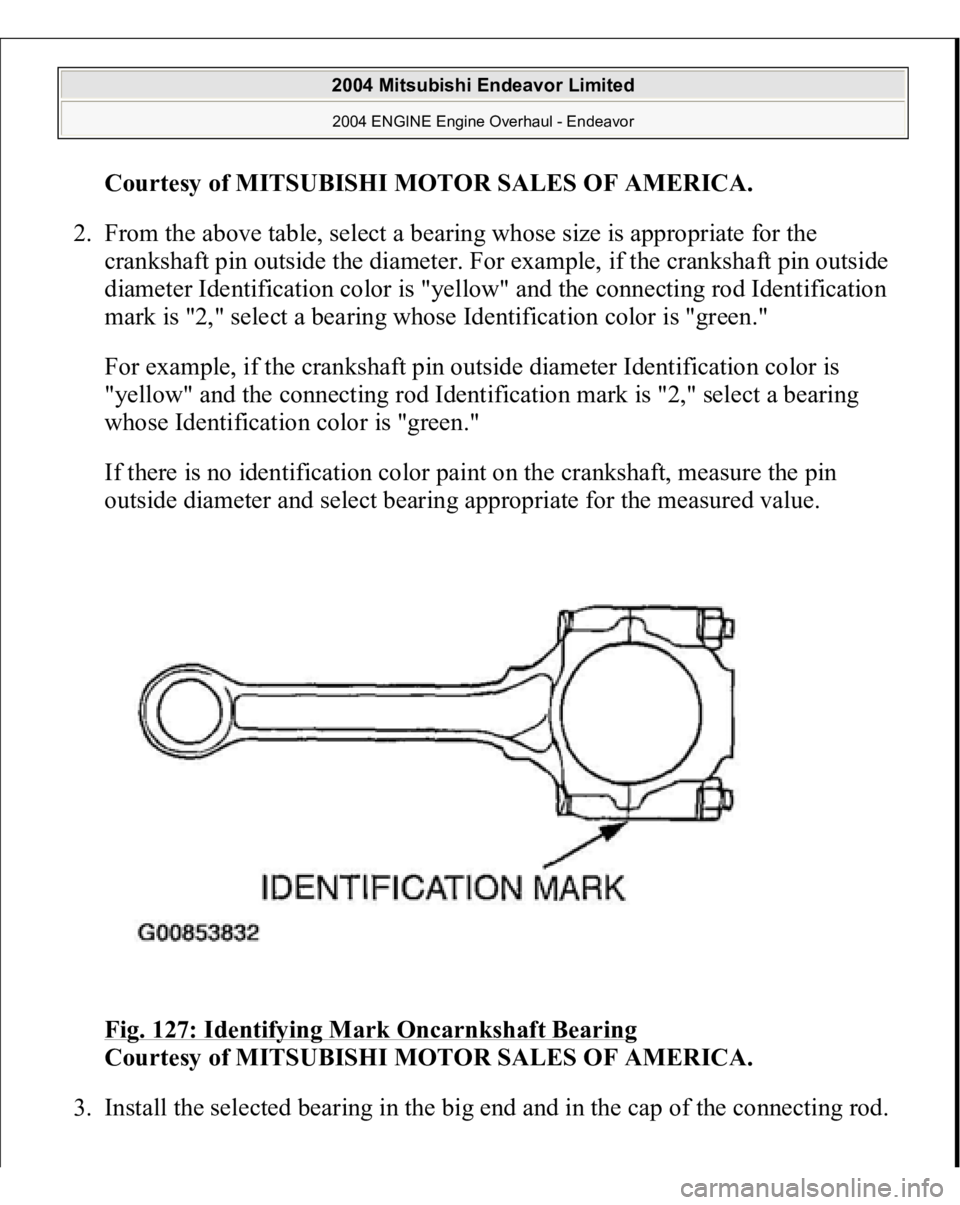

2. From the above table, select a bearing whose size is appropriate for the

crankshaft pin outside the diameter. For example, if the crankshaft pin outside

diameter Identification color is "yellow" and the connecting rod Identification

mark is "2," select a bearing whose Identification color is "green."

For example, if the crankshaft pin outside diameter Identification color is

"yellow" and the connecting rod Identification mark is "2," select a bearing

whose Identification color is "green."

If there is no identification color paint on the crankshaft, measure the pin

outside diameter and select bearing appropriate for the measured value.

Fig. 127: Identifying Mark Oncarnkshaft Bearing

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

3. Install the selected bearin

g in the bi

g end and in the ca

p of the connectin

g rod.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1454 of 3870

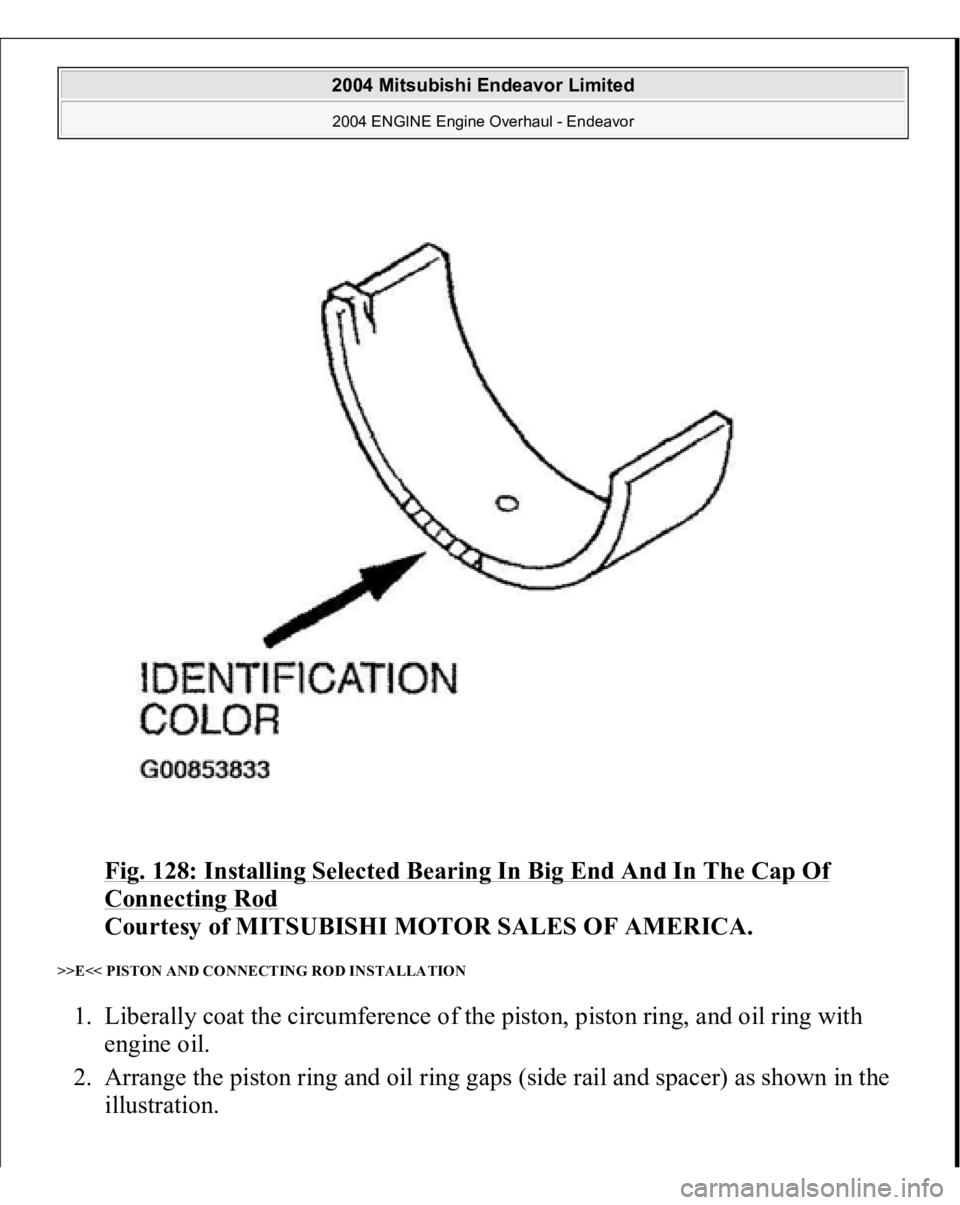

Fig. 128: Installing Selected Bearing In Big End And In The Cap Of Connecting Rod

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

>>E<< PISTON AND CONNECTING ROD INSTALLATION 1. Liberally coat the circumference of the piston, piston ring, and oil ring with

engine oil.

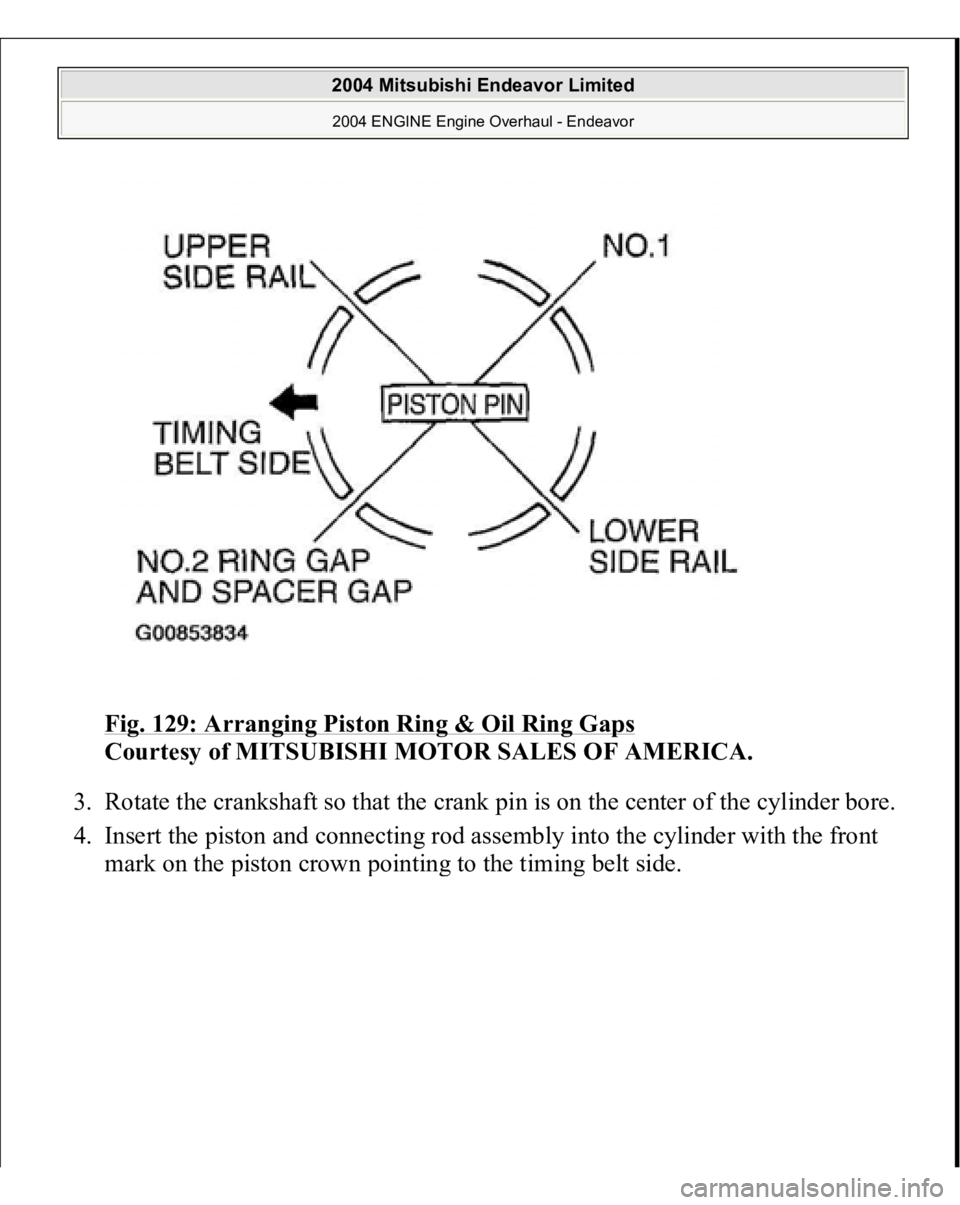

2. Arrange the piston ring and oil ring gaps (side rail and spacer) as shown in the

illustration.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1455 of 3870

Fig. 129: Arranging Piston Ring & Oil Ring Gaps

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

3. Rotate the crankshaft so that the crank pin is on the center of the cylinder bore.

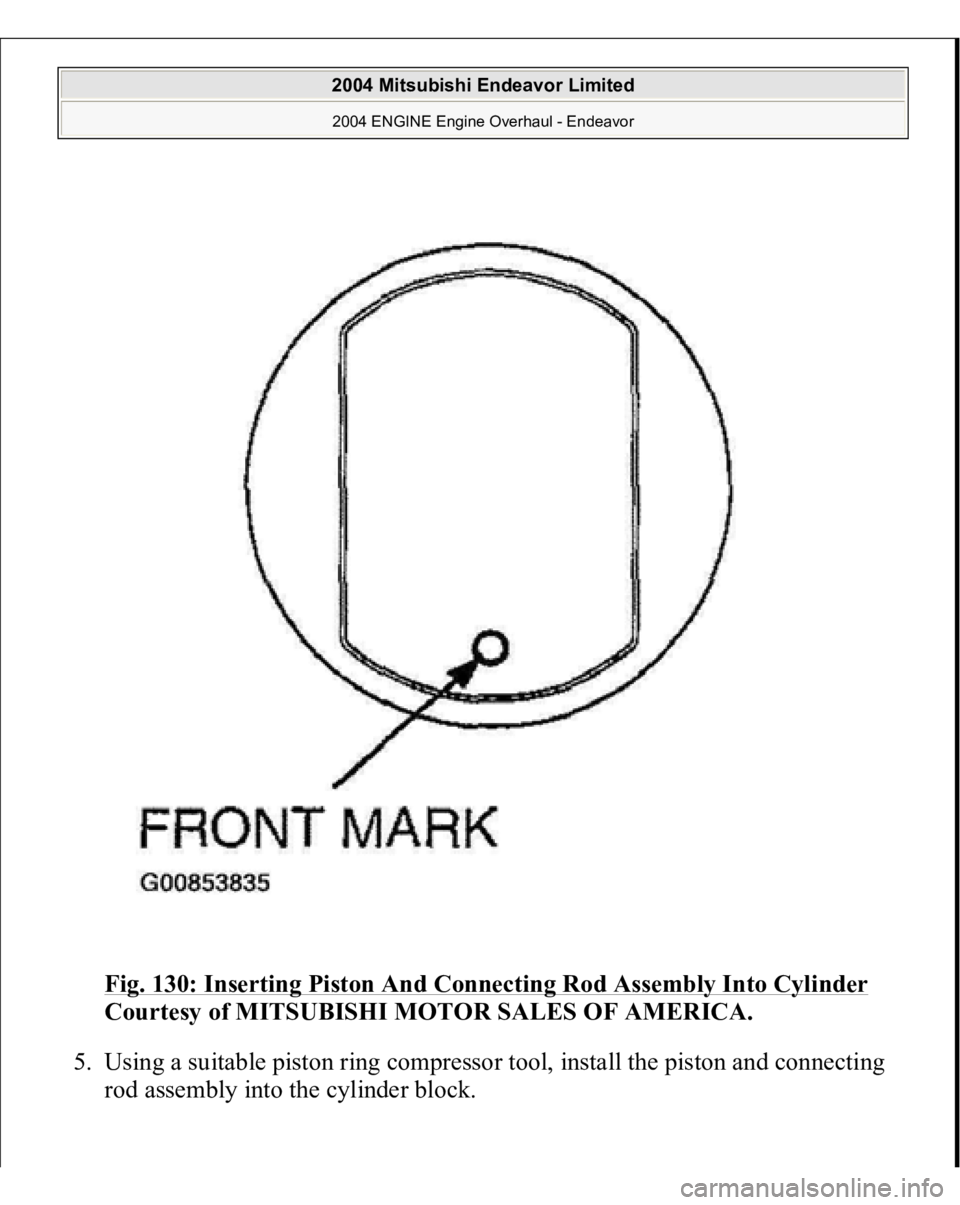

4. Insert the piston and connecting rod assembly into the cylinder with the front

mark on the

piston crown

pointin

g to the timin

g belt side.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1456 of 3870

Fig. 130: Inserting Piston And Connecting Rod Assembly Into Cylinder

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

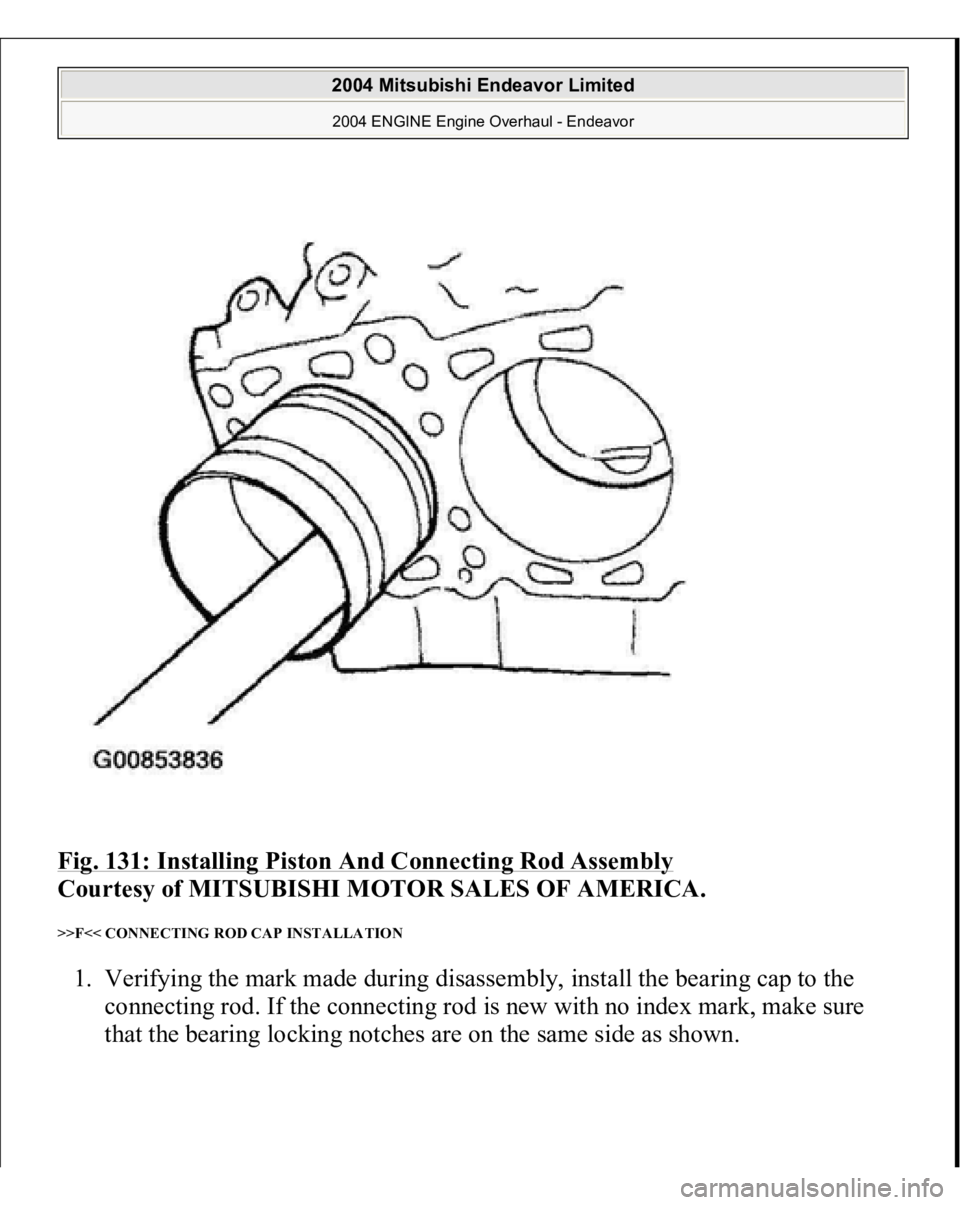

5. Using a suitable piston ring compressor tool, install the piston and connecting

rod assembly into the cylinder block.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1457 of 3870

Fig. 131: Installing Piston And Connecting Rod Assembly

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

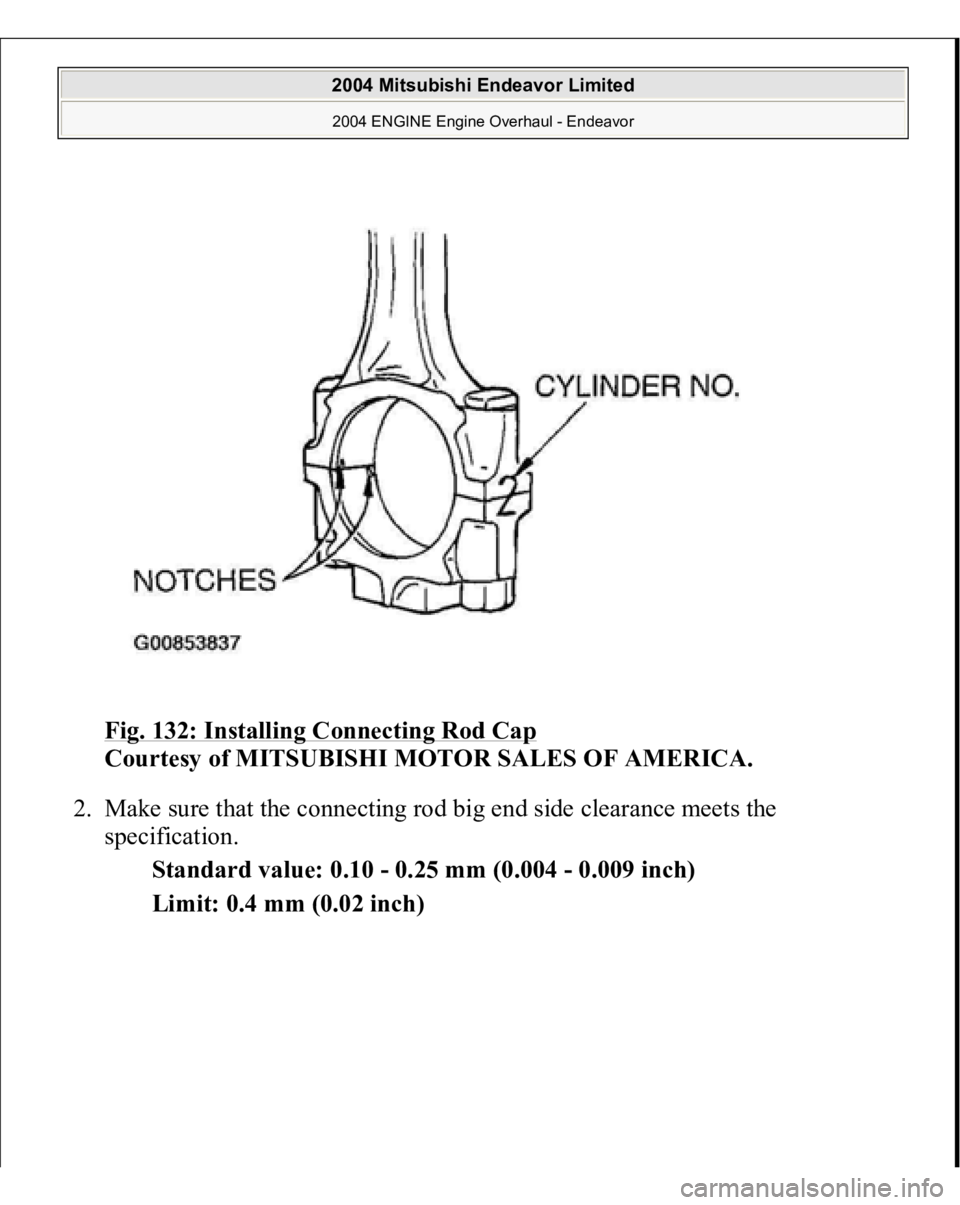

>>F<< CONNECTING ROD CAP INSTALLATION 1. Verifying the mark made during disassembly, install the bearing cap to the

connecting rod. If the connecting rod is new with no index mark, make sure

that the bearin

g lockin

g notches are on the same side as shown.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1458 of 3870

Fig. 132: Installing Connecting Rod Cap

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

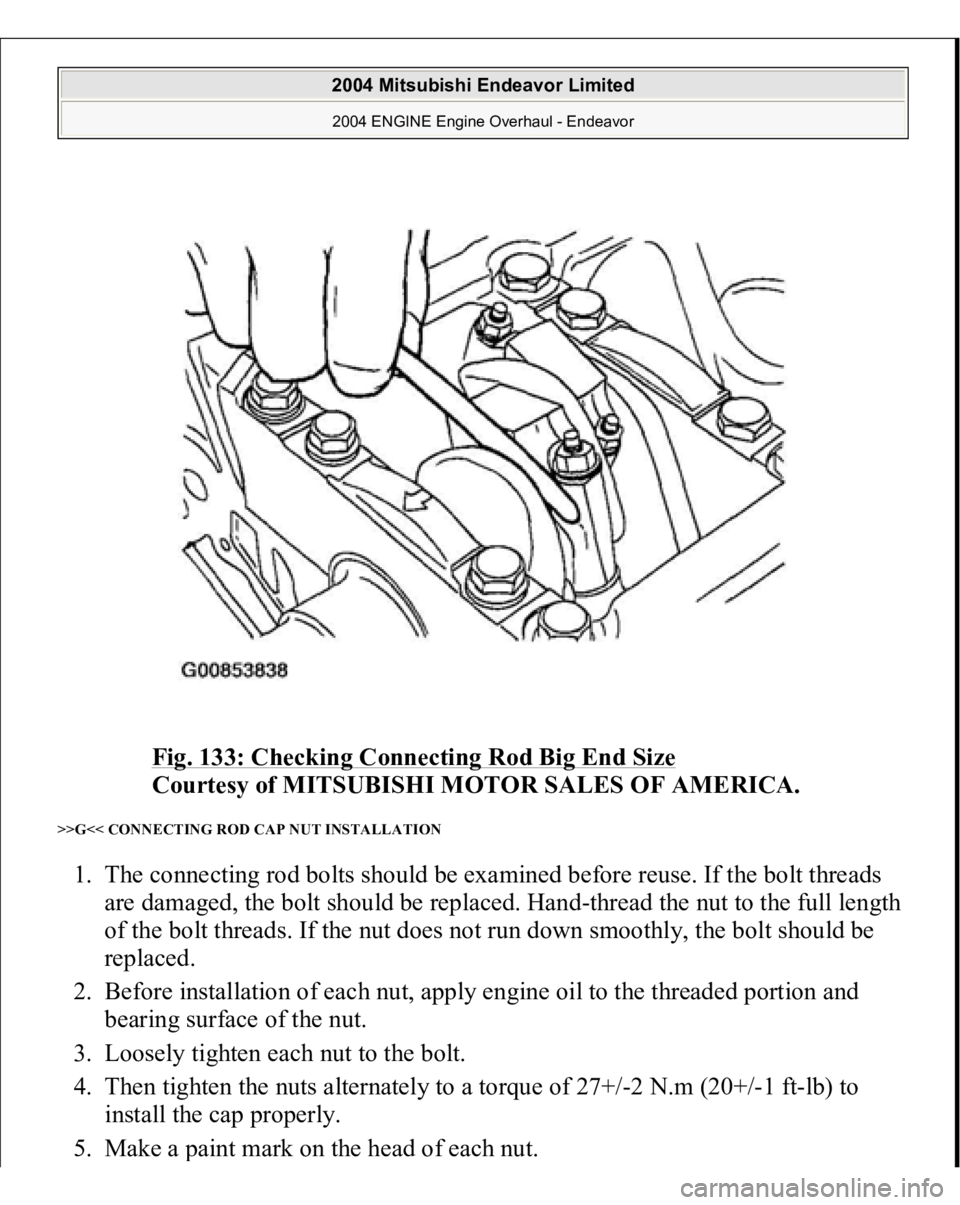

2. Make sure that the connecting rod big end side clearance meets the

specification.

Standard value: 0.10 - 0.25 mm (0.004 - 0.009 inch)

Limit: 0.4 mm (0.02 inch)

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1459 of 3870

Fig. 133: Checking Connecting Rod Big End Size

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

>>G<< CONNECTING ROD CAP NUT INSTALLATION 1. The connecting rod bolts should be examined before reuse. If the bolt threads

are damaged, the bolt should be replaced. Hand-thread the nut to the full length

of the bolt threads. If the nut does not run down smoothly, the bolt should be

replaced.

2. Before installation of each nut, apply engine oil to the threaded portion and

bearing surface of the nut.

3. Loosely tighten each nut to the bolt.

4. Then tighten the nuts alternately to a torque of 27+/-2 N.m (20+/-1 ft-lb) to

install the cap properly.

5. Make a

paint mark on the head of each nut.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1460 of 3870

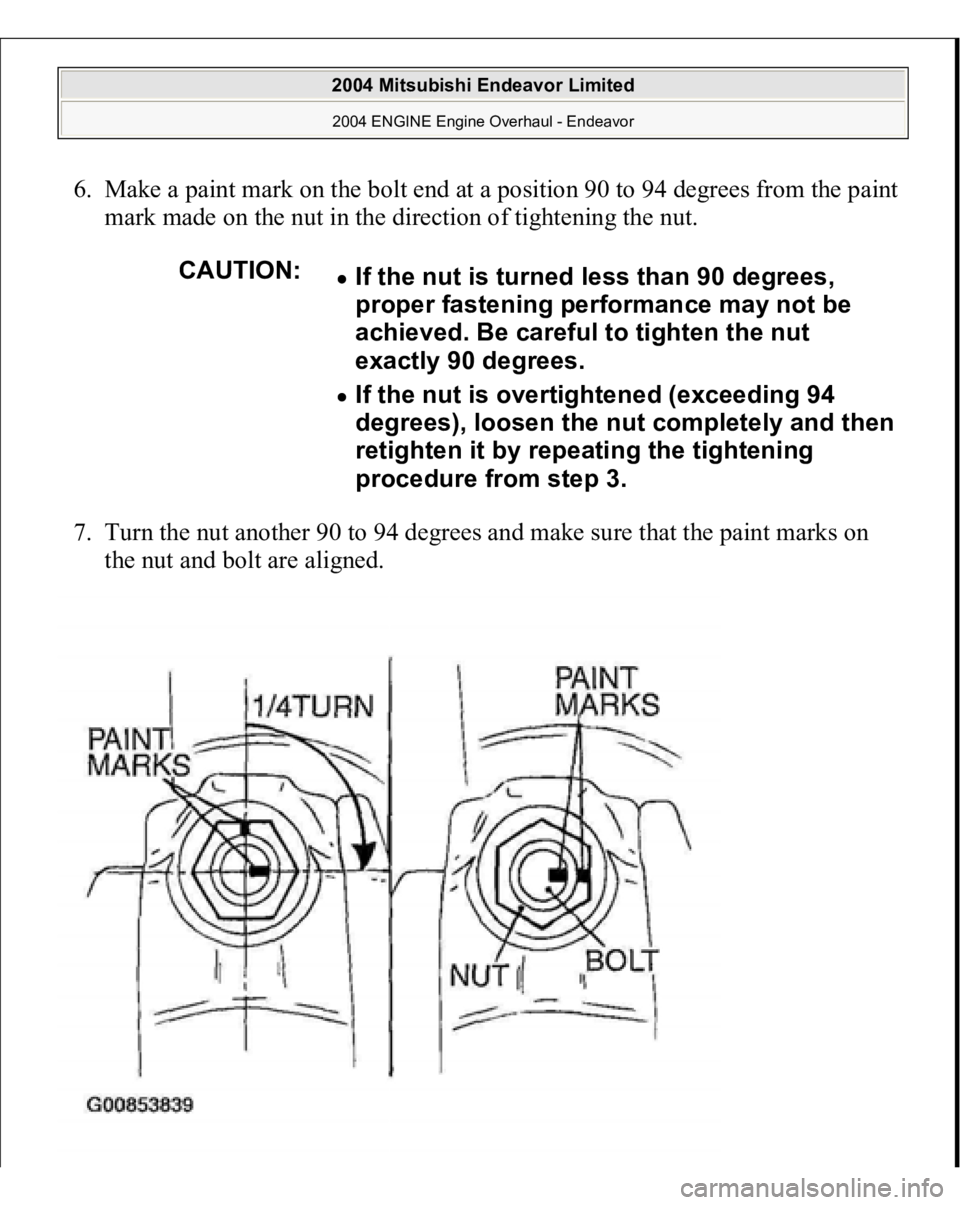

6. Make a paint mark on the bolt end at a position 90 to 94 degrees from the paint

mark made on the nut in the direction of tightening the nut.

7. Turn the nut another 90 to 94 degrees and make sure that the paint marks on

the nut and bolt are aligned.

CAUTION:

If the nut is turned less than 90 degrees,

proper fastening performance may not be

achieved. Be careful to tighten the nut

exactly 90 degrees. If the nut is overtightened (exceeding 94

degrees), loosen the nut completely and then

retighten it by repeating the tightening

procedure from step 3.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Trending: Egr valve, maintenance schedule, module location, transmission control, rear entertainment, windshield wipers, heating