MITSUBISHI ENDEAVOR 2004 Service Repair Manual

ENDEAVOR 2004

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57105/w960_57105-0.png

MITSUBISHI ENDEAVOR 2004 Service Repair Manual

Trending: headrest, accessory belt, reset, relay, turn off alarm, Battery terminals, Oxygen sensor

Page 1471 of 3870

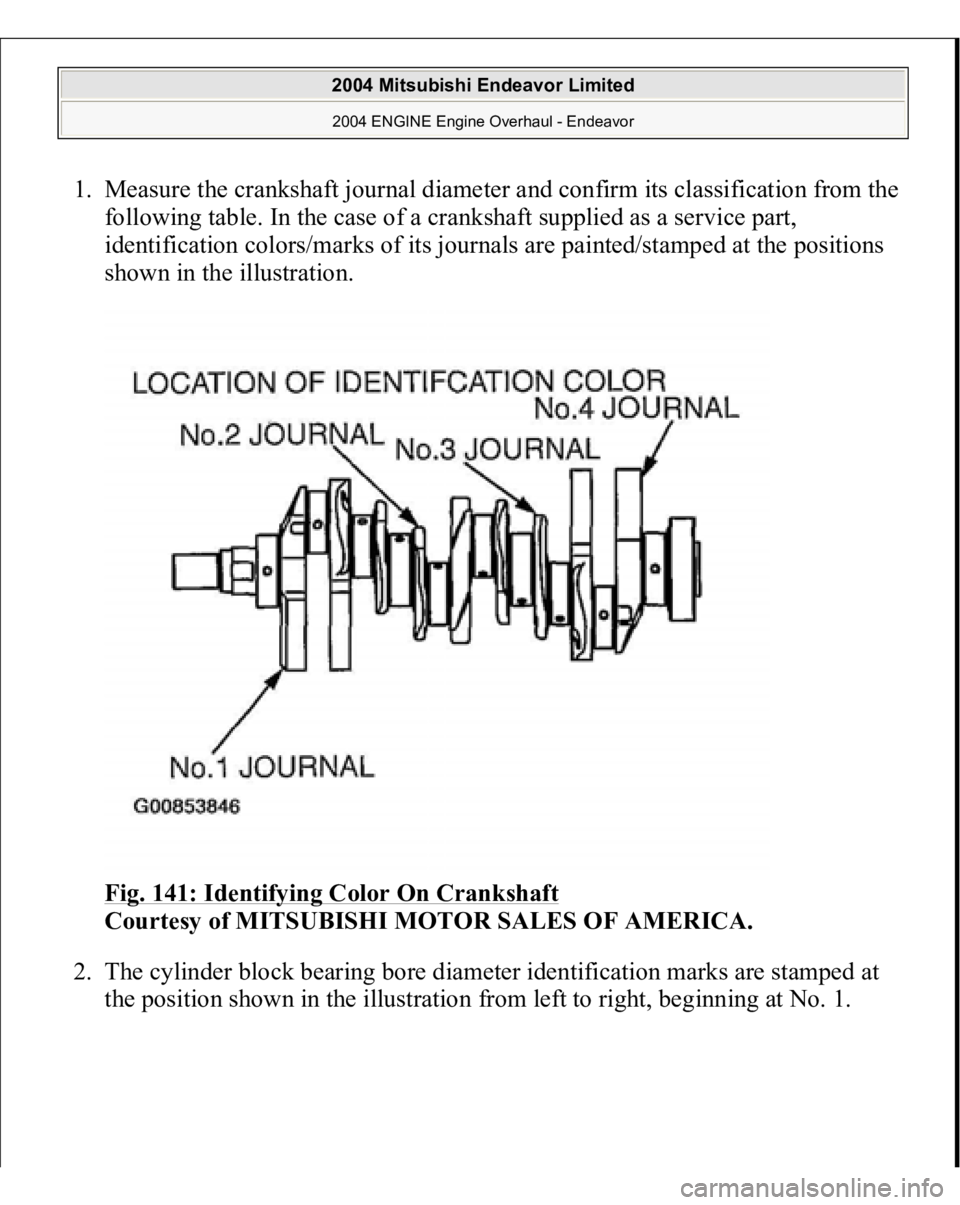

1. Measure the crankshaft journal diameter and confirm its classification from the

following table. In the case of a crankshaft supplied as a service part,

identification colors/marks of its journals are painted/stamped at the positions

shown in the illustration.

Fig. 141: Identifying Color On Crankshaft

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

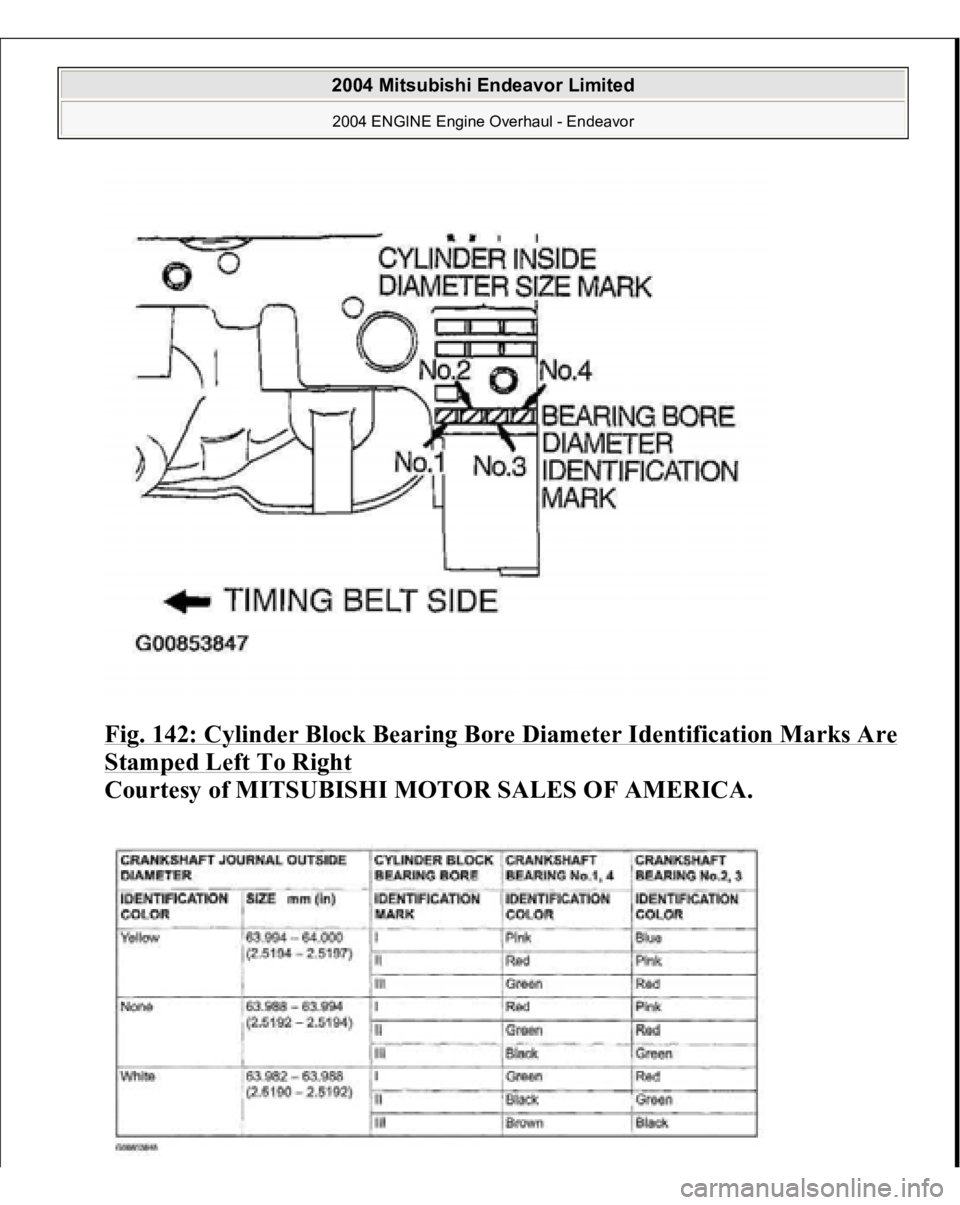

2. The cylinder block bearing bore diameter identification marks are stamped at

the

position shown in the illustration from left to ri

ght, be

ginnin

g at No. 1.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1472 of 3870

Fig. 142: Cylinder Block Bearing Bore Diameter Identification Marks Are Stamped Left To Right

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1473 of 3870

Fig. 143: Carnkshaft Identification Marking Char

t

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

3. From the above table, select a bearing whose size is appropriate for the

crankshaft journal outside diameter. If the crankshaft journal outside diameter

ID color is "yellow" and the cylinder block bearing bore ID mark is "III," for

example, select a bearing whose ID color is "green" < No.1, 4 > or "red" <

No.2, 3 >.

If there is no ID color paint on the crankshaft, measure the journal outside

diameter and select a bearing appropriate for the measured valve.

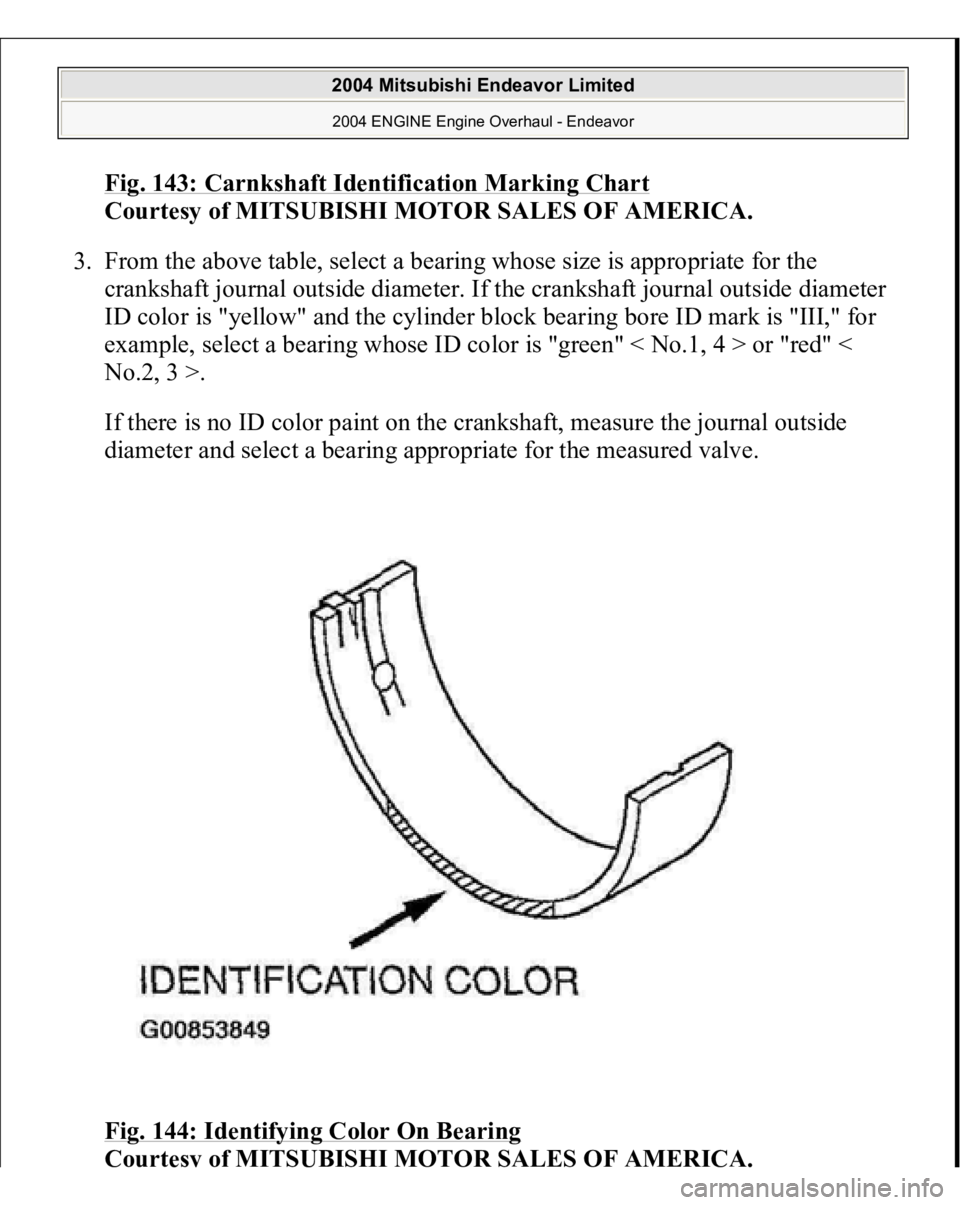

Fig. 144: Identifying Color On Bearing

Courtes

y of MITSUBISHI MOTOR SALES OF AMERICA

.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1474 of 3870

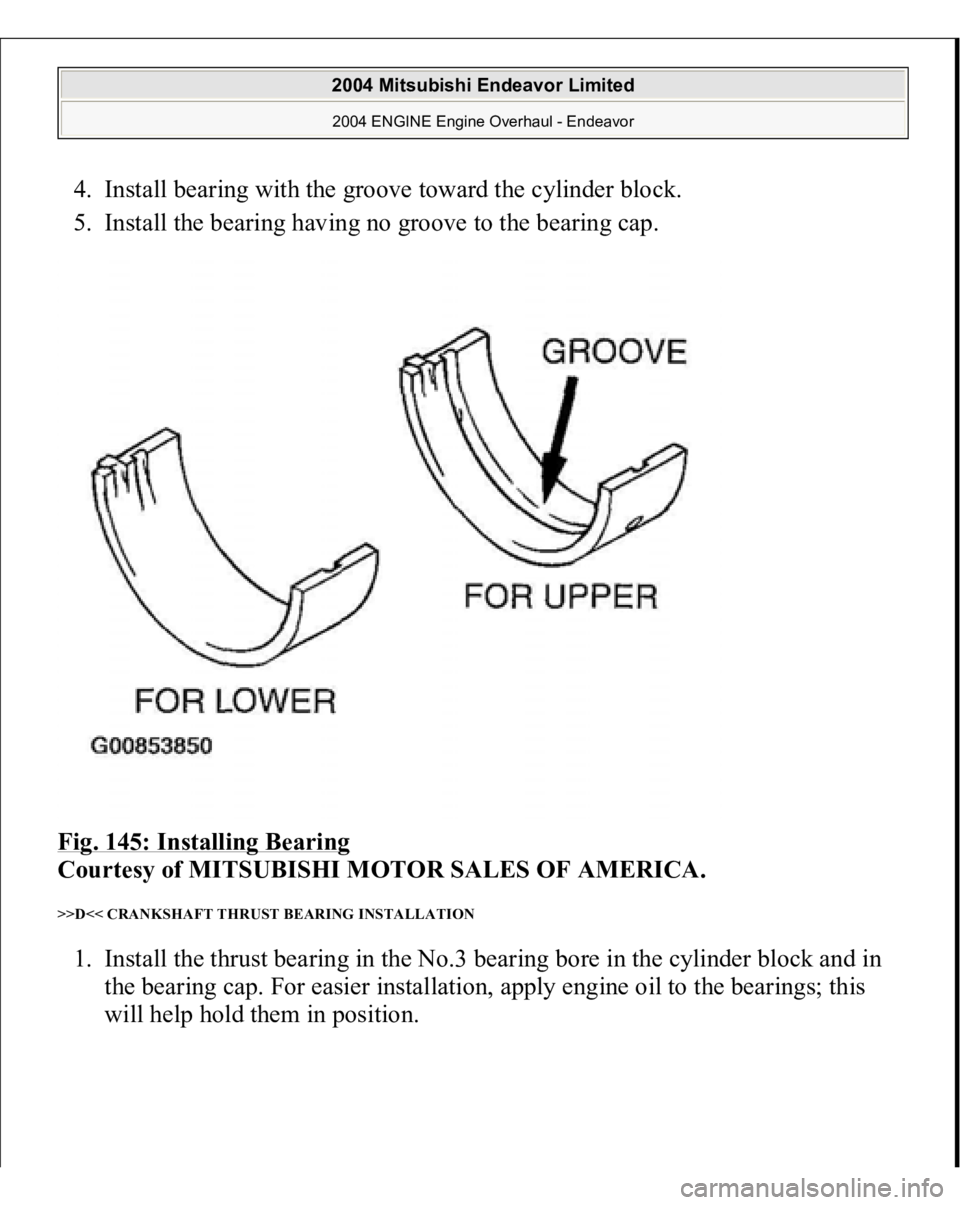

4. Install bearing with the groove toward the cylinder block.

5. Install the bearing having no groove to the bearing cap.

Fig. 145: Installing Bearing

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

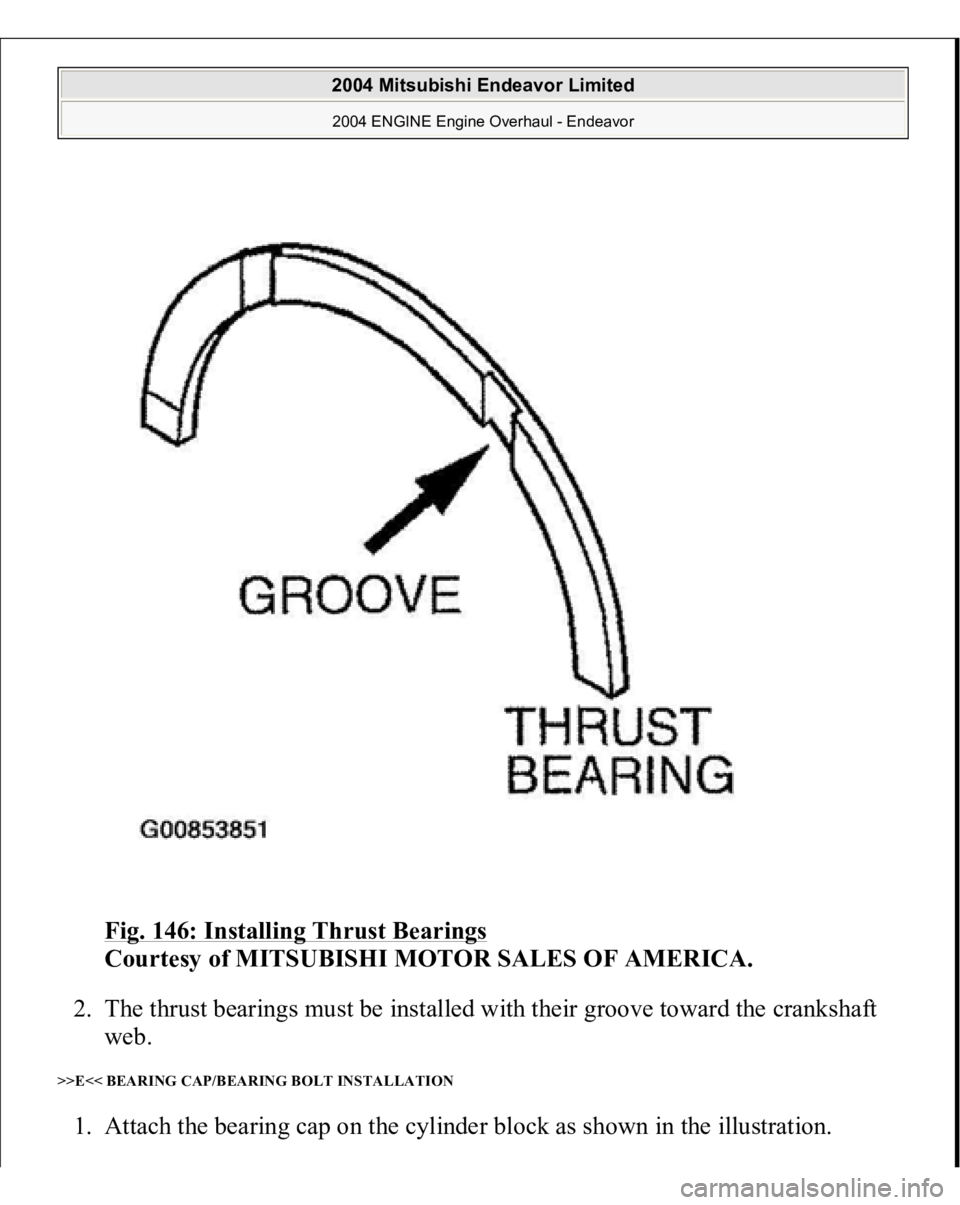

>>D<< CRANKSHAFT THRUST BEARING INSTALLATION 1. Install the thrust bearing in the No.3 bearing bore in the cylinder block and in

the bearing cap. For easier installation, apply engine oil to the bearings; this

will hel

p hold them in

position.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1475 of 3870

Fig. 146: Installing Thrust Bearings

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

2. The thrust bearings must be installed with their groove toward the crankshaft

web.

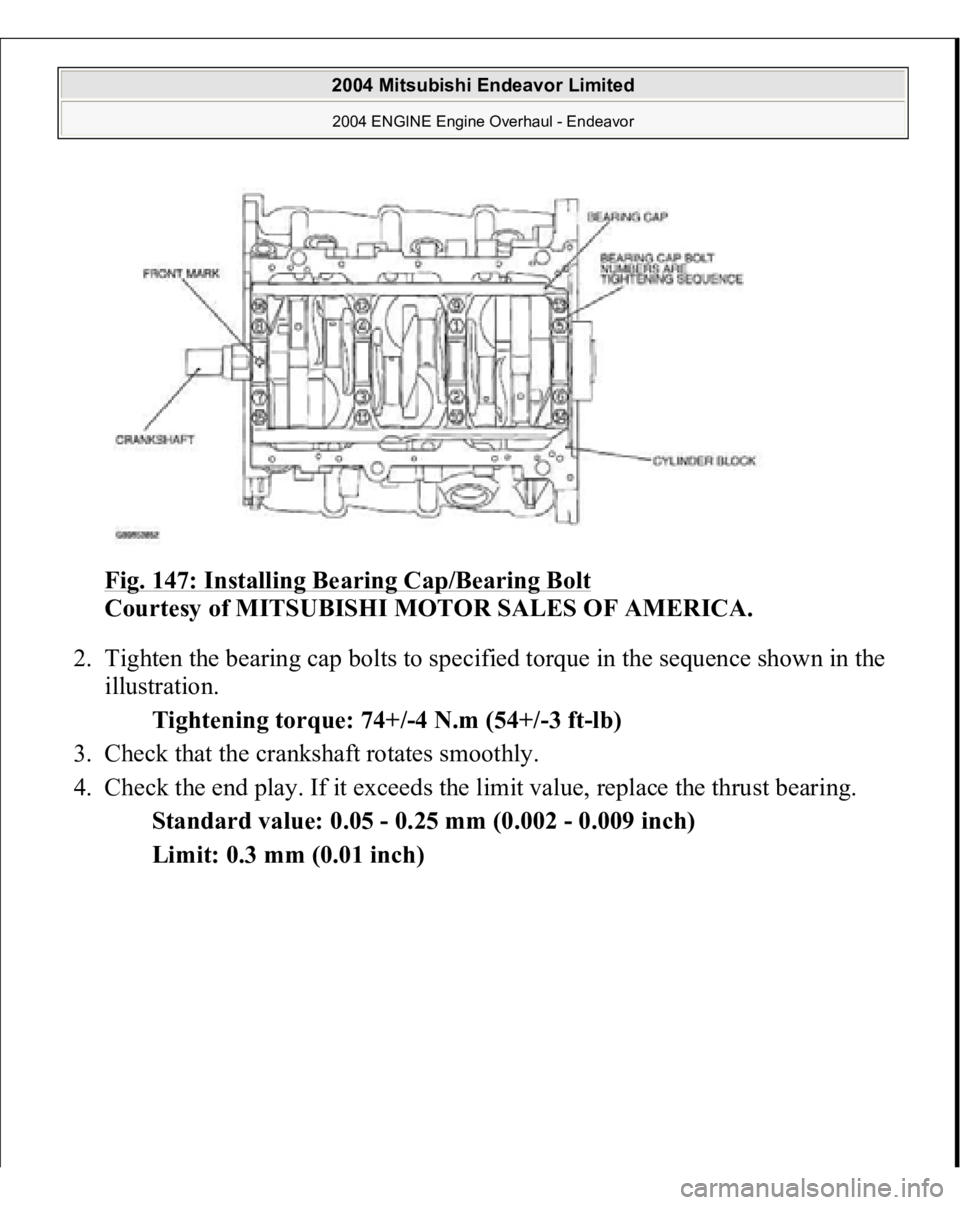

>>E<< BEARING CAP/BEARING BOLT INSTALLATION 1. Attach the bearing cap on the cylinder block as shown in the illustration.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1476 of 3870

Fig. 147: Installing Bearing Cap/Bearing Bolt

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

2. Tighten the bearing cap bolts to specified torque in the sequence shown in the

illustration.

Tightening torque: 74+/-4 N.m (54+/-3 ft-lb)

3. Check that the crankshaft rotates smoothly.

4. Check the end play. If it exceeds the limit value, replace the thrust bearing.

Standard value: 0.05 - 0.25 mm (0.002 - 0.009 inch)

Limit: 0.3 mm (0.01 inch)

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1477 of 3870

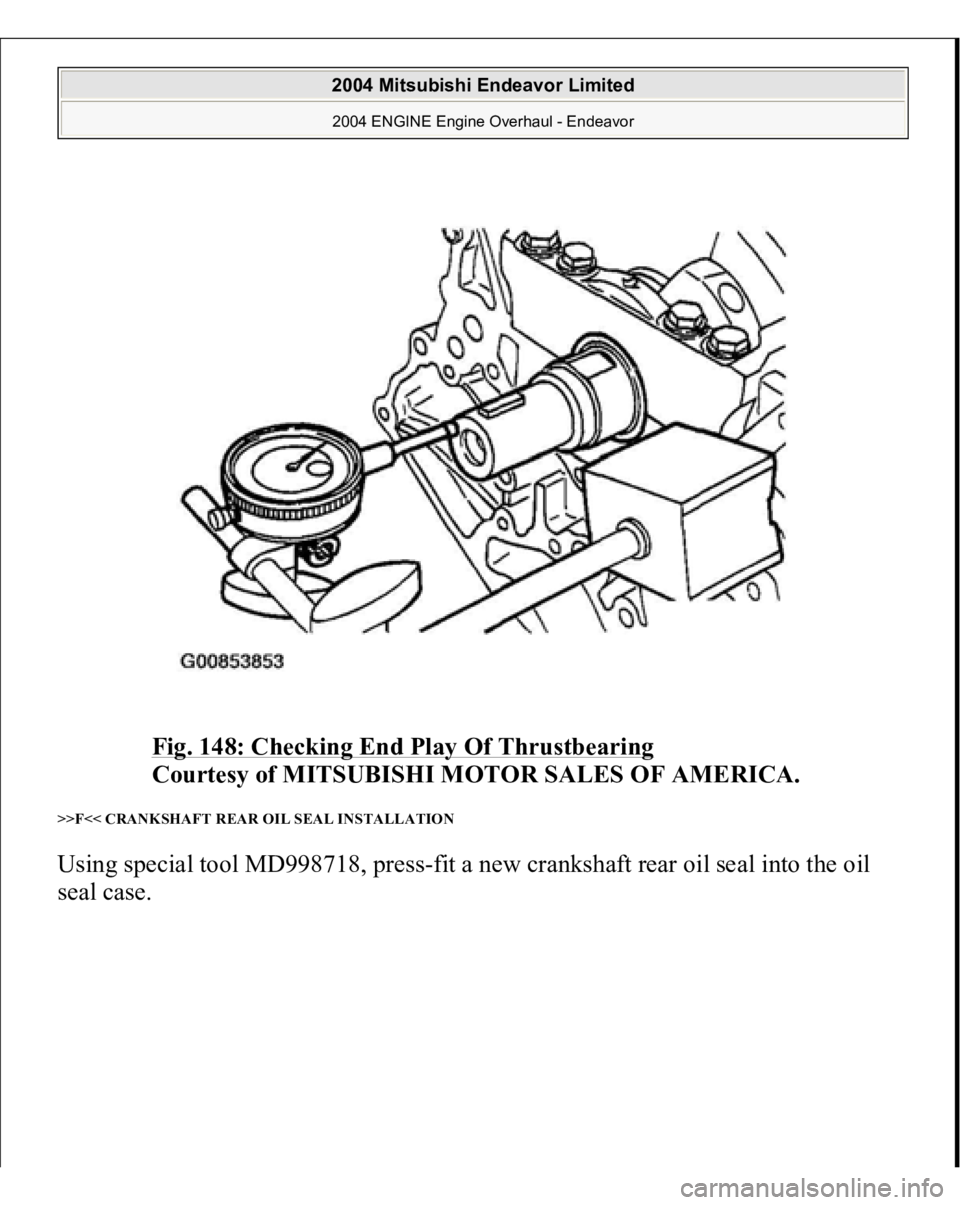

Fig. 148: Checking End Play Of Thrustbearing

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

>>F<< CRANKSHAFT REAR OIL SEAL INSTALLATION Using special tool MD998718, press-fit a new crankshaft rear oil seal into the oil

seal case.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1478 of 3870

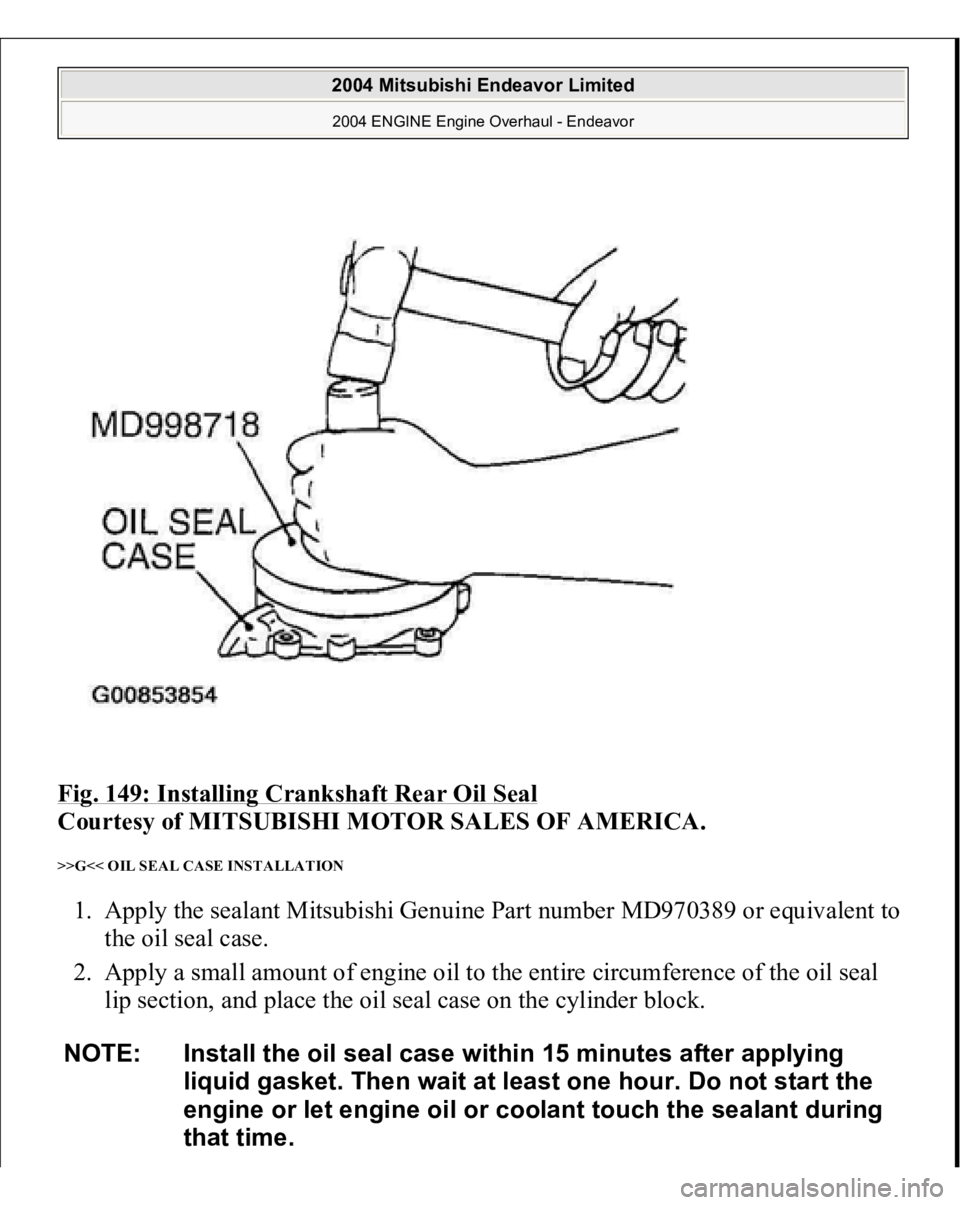

Fig. 149: Installing Crankshaft Rear Oil Seal

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

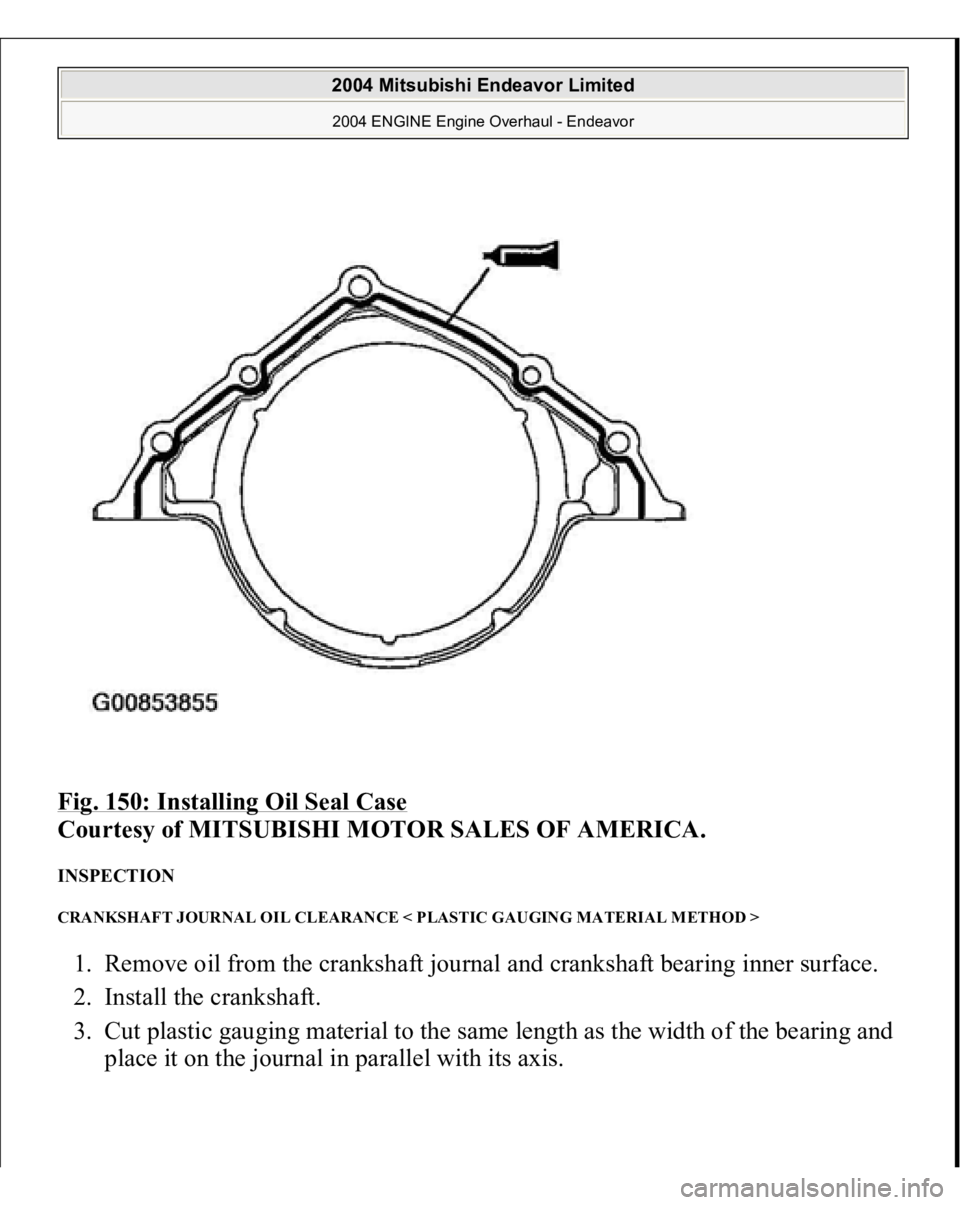

>>G<< OIL SEAL CASE INSTALLATION 1. Apply the sealant Mitsubishi Genuine Part number MD970389 or equivalent to

the oil seal case.

2. Apply a small amount of engine oil to the entire circumference of the oil seal

lip section, and place the oil seal case on the cylinder block. NOTE: Install the oil seal case within 15 minutes after applying

liquid gasket. Then wait at least one hour. Do not start the

engine or let engine oil or coolant touch the sealant during

that time.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1479 of 3870

Fig. 150: Installing Oil Seal Case

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

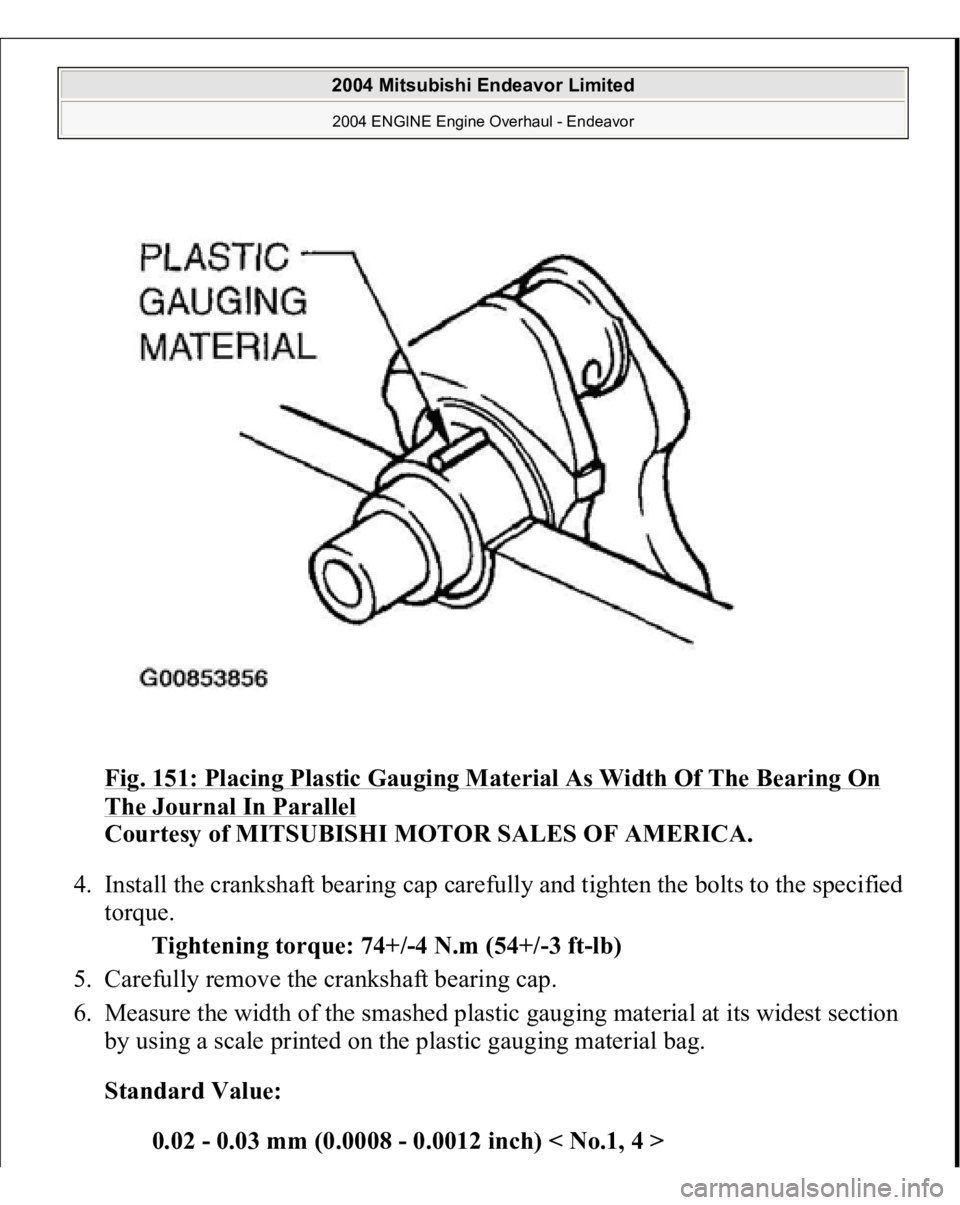

INSPECTION CRANKSHAFT JOURNAL OIL CLEARANCE < PLASTIC GAUGING MATERIAL METHOD > 1. Remove oil from the crankshaft journal and crankshaft bearing inner surface.

2. Install the crankshaft.

3. Cut plastic gauging material to the same length as the width of the bearing and

place it on the

journal in

parallel with its axis.

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Page 1480 of 3870

Fig. 151: Placing Plastic Gauging Material As Width Of The Bearing On The Journal In Parallel

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

4. Install the crankshaft bearing cap carefully and tighten the bolts to the specified

torque.

Tightening torque: 74+/-4 N.m (54+/-3 ft-lb)

5. Carefully remove the crankshaft bearing cap.

6. Measure the width of the smashed plastic gauging material at its widest section

by using a scale printed on the plastic gauging material bag.

Standard Value:

0.02 - 0.03 mm (0.0008 - 0.0012 inch) < No.1, 4 >

2004 Mitsubishi Endeavor Limited 2004 ENGINE Engine Overhaul - Endeavor

Trending: wheel bolts, fuel, drain bolt, control module, oil, automatic transmission, adding oil