MITSUBISHI ENDEAVOR 2004 Service Repair Manual

ENDEAVOR 2004

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57105/w960_57105-0.png

MITSUBISHI ENDEAVOR 2004 Service Repair Manual

Trending: Rear hub, Amplifier, Batter, recommended oil, parking brake, air filter, keyless

Page 1881 of 3870

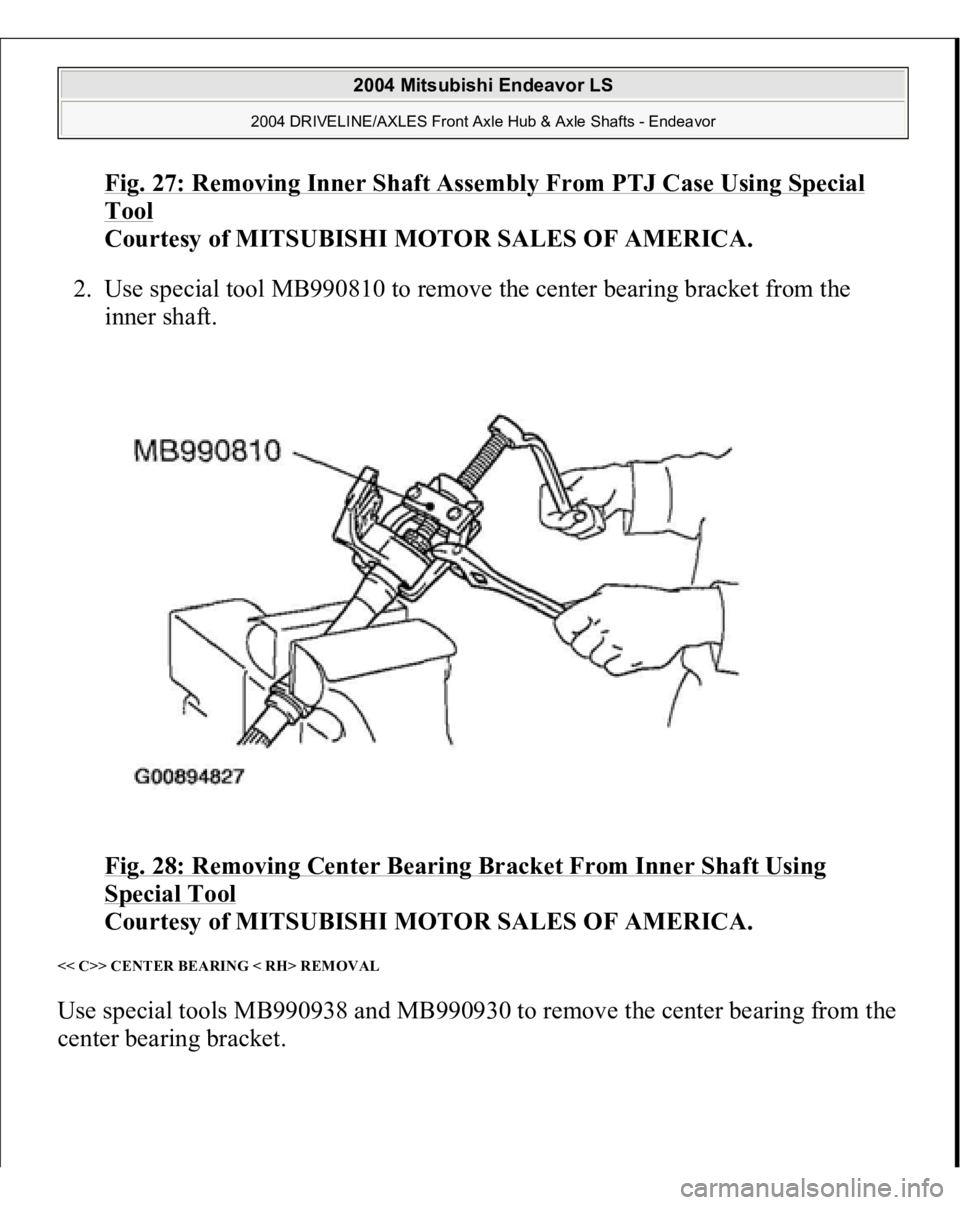

Fig. 27: Removing Inner Shaft Assembly From PTJ Case Using Special Tool

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

2. Use special tool MB990810 to remove the center bearing bracket from the

inner shaft.

Fig. 28: Removing Center Bearing Bracket From Inner Shaft Using

Special Tool

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

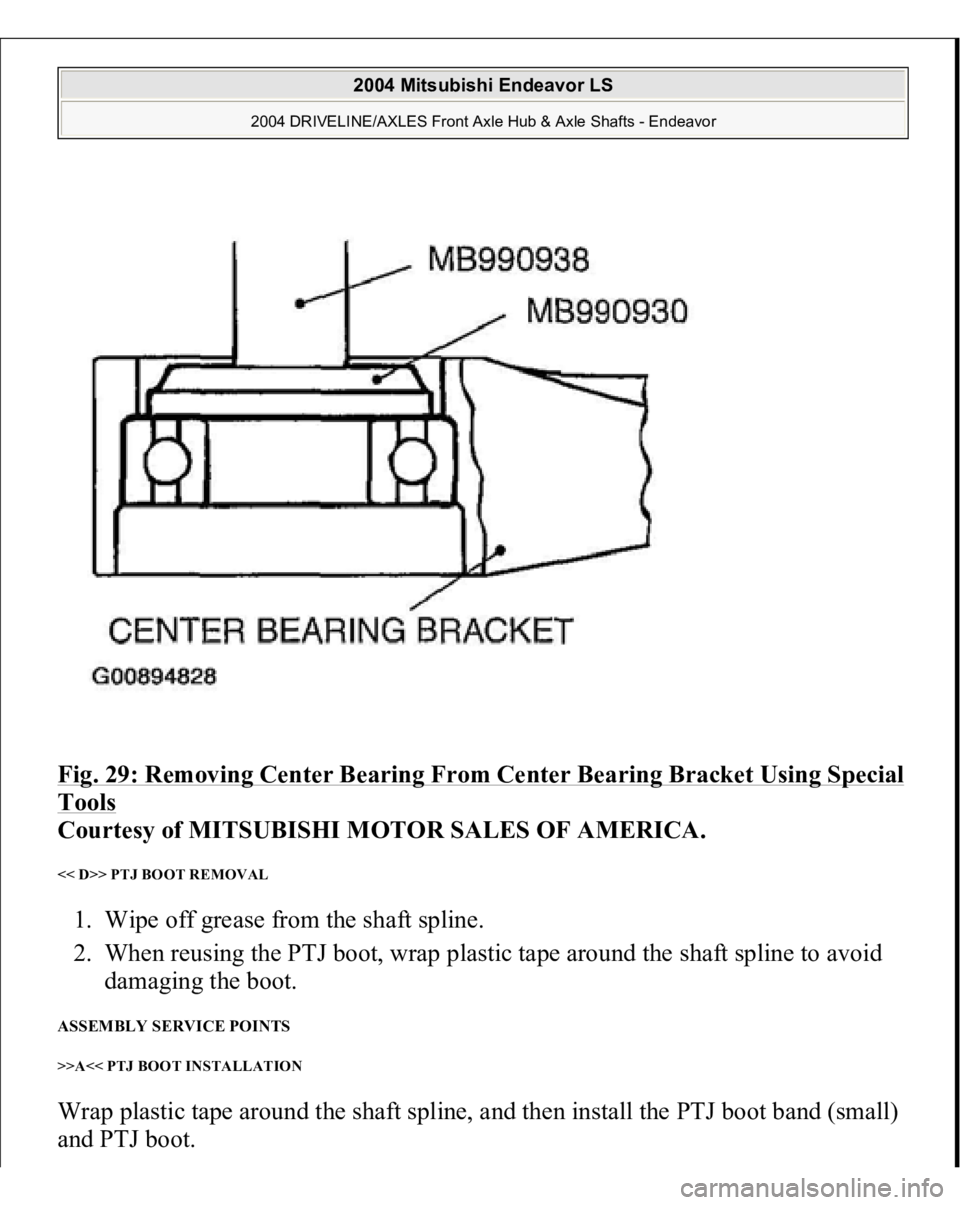

<< C>> CENTER BEARING < RH> REMOVAL Use special tools MB990938 and MB990930 to remove the center bearing from the

center bearin

g bracket.

2004 Mitsubishi Endeavor LS

2004 DRIVELINE/AXLES Front Axle Hub & Axle Shafts - Endeavor

Page 1882 of 3870

Fig. 29: Removin

g Center Bearin

g From Center Bearin

g Bracket Usin

g Special

Tools

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

<< D>> PTJ BOOT REMOVAL 1. Wipe off grease from the shaft spline.

2. When reusing the PTJ boot, wrap plastic tape around the shaft spline to avoid

damaging the boot. ASSEMBLY SERVICE POINTS >>A<< PTJ BOOT INSTALLATION Wrap plastic tape around the shaft spline, and then install the PTJ boot band (small)

and PTJ boot.

2004 Mitsubishi Endeavor LS

2004 DRIVELINE/AXLES Front Axle Hub & Axle Shafts - Endeavor

Page 1883 of 3870

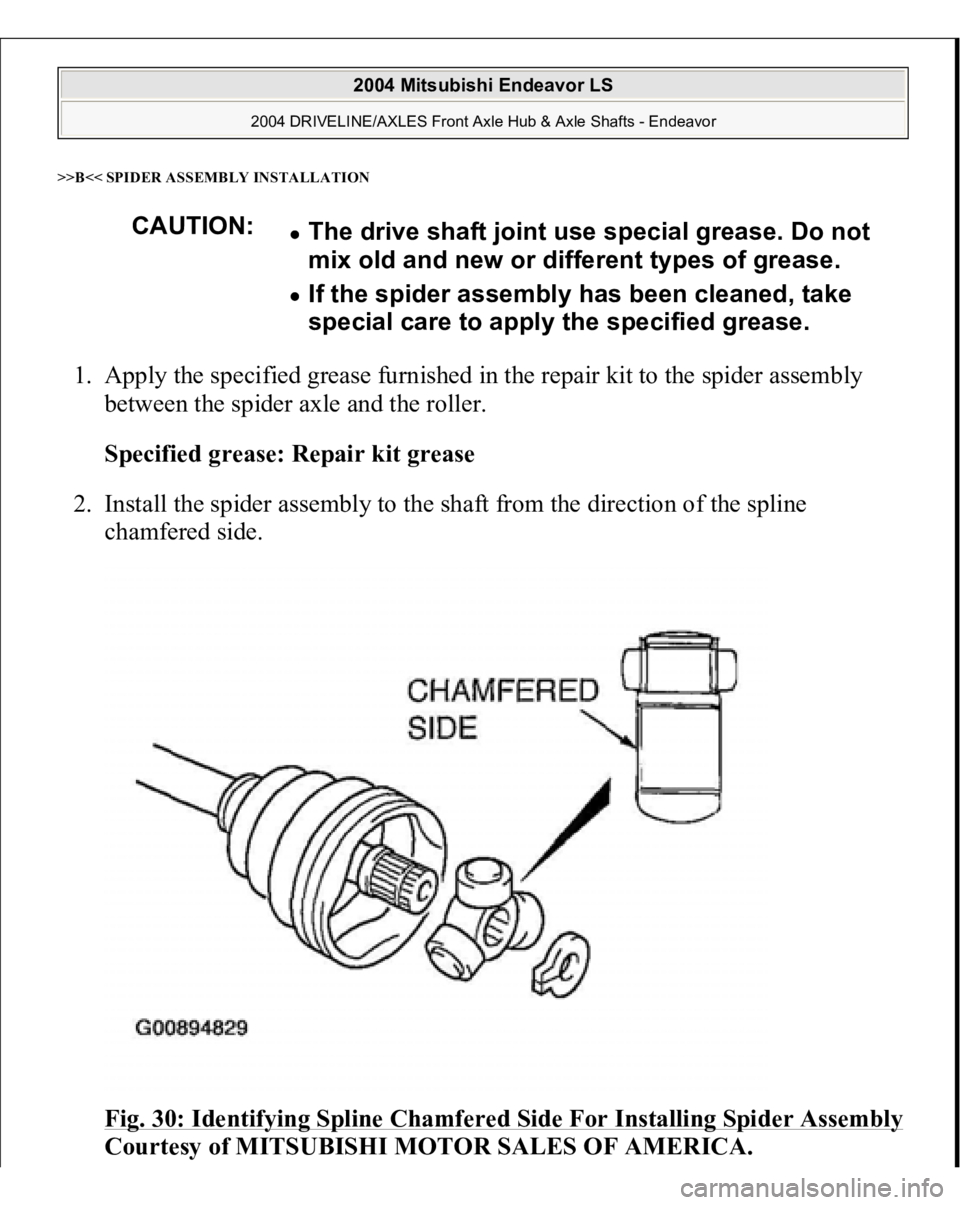

>>B<< SPIDER ASSEMBLY INSTALLATION1. Apply the specified grease furnished in the repair kit to the spider assembly

between the spider axle and the roller.

Specified grease: Repair kit grease

2. Install the spider assembly to the shaft from the direction of the spline

chamfered side.

Fig. 30: Identifying Spline Chamfered Side For Installing Spider Assembly

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

CAUTION:

The drive shaft joint use special grease. Do not

mix old and new or different types of grease. If the spider assembly has been cleaned, take

special care to apply the specified grease.

2004 Mitsubishi Endeavor LS

2004 DRIVELINE/AXLES Front Axle Hub & Axle Shafts - Endeavor

Page 1884 of 3870

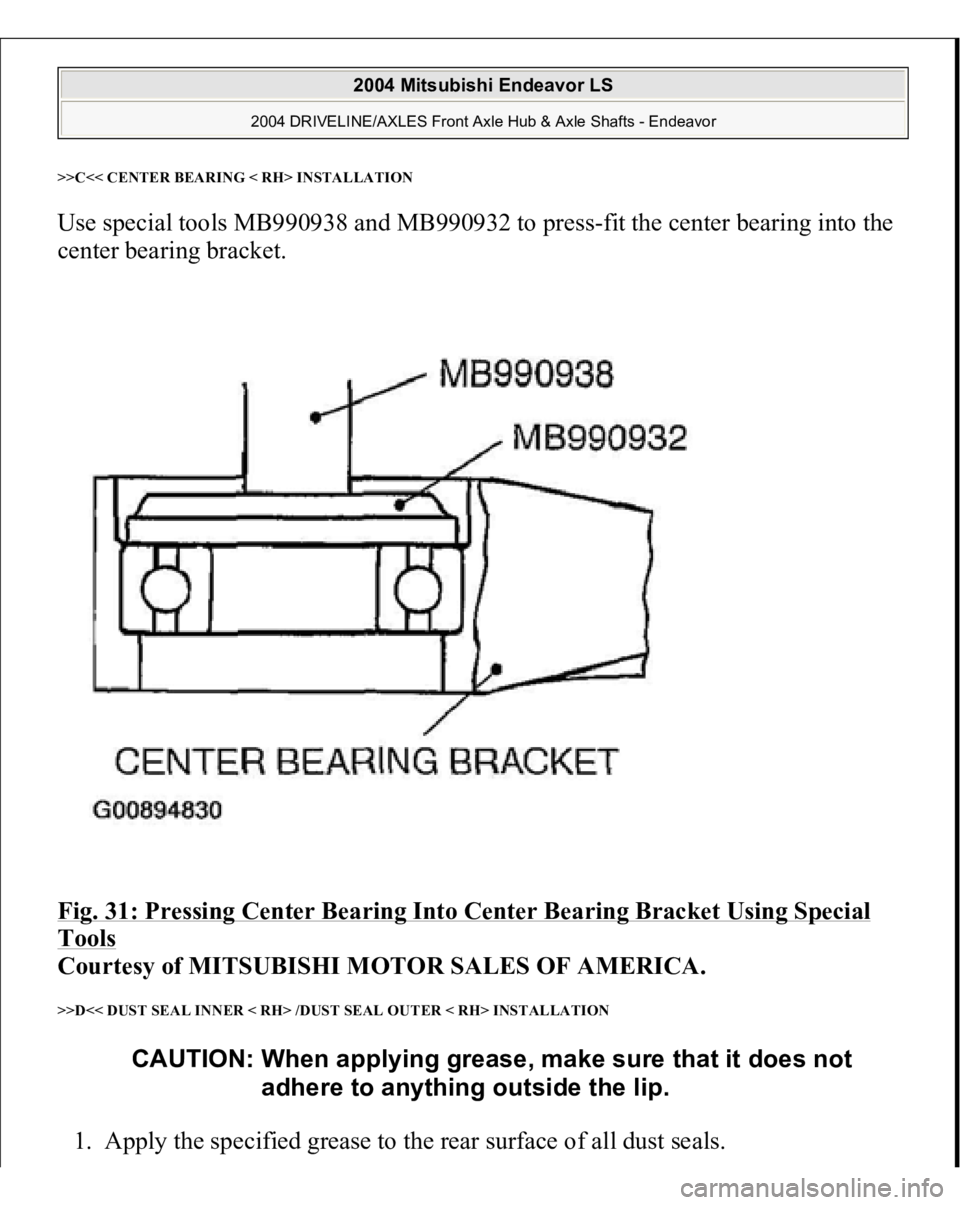

>>C<< CENTER BEARING < RH> INSTALLATIONUse special tools MB990938 and MB990932 to press-fit the center bearing into the

center bearing bracket.

Fig. 31: Pressing Center Bearing Into Center Bearing Bracket Using Special Tools

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

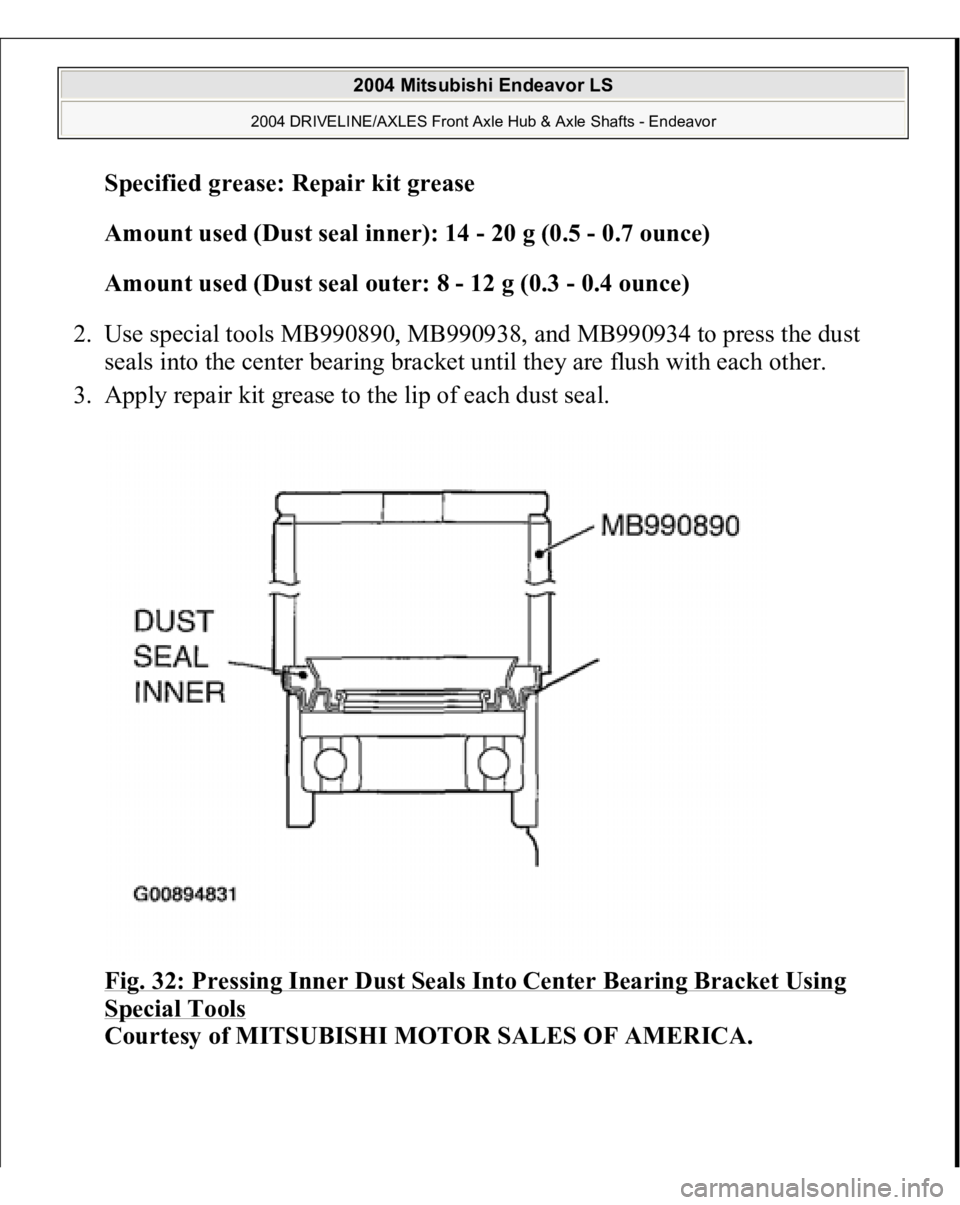

>>D<< DUST SEAL INNER < RH> /DUST SEAL OUTER < RH> INSTALLATION 1. A

pply the s

pecified

grease to the rear surface of all dust seals.

CAUTION: When applying grease, make sure that it does not

adhere to anything outside the lip.

2004 Mitsubishi Endeavor LS

2004 DRIVELINE/AXLES Front Axle Hub & Axle Shafts - Endeavor

Page 1885 of 3870

Specified grease: Repair kit grease

Amount used (Dust seal inner): 14 - 20 g (0.5 - 0.7 ounce)

Amount used (Dust seal outer: 8 - 12 g (0.3 - 0.4 ounce)

2. Use special tools MB990890, MB990938, and MB990934 to press the dust

seals into the center bearing bracket until they are flush with each other.

3. Apply repair kit grease to the lip of each dust seal.

Fig. 32: Pressing Inner Dust Seals Into Center Bearing Bracket Using Special Tools

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

2004 Mitsubishi Endeavor LS

2004 DRIVELINE/AXLES Front Axle Hub & Axle Shafts - Endeavor

Page 1886 of 3870

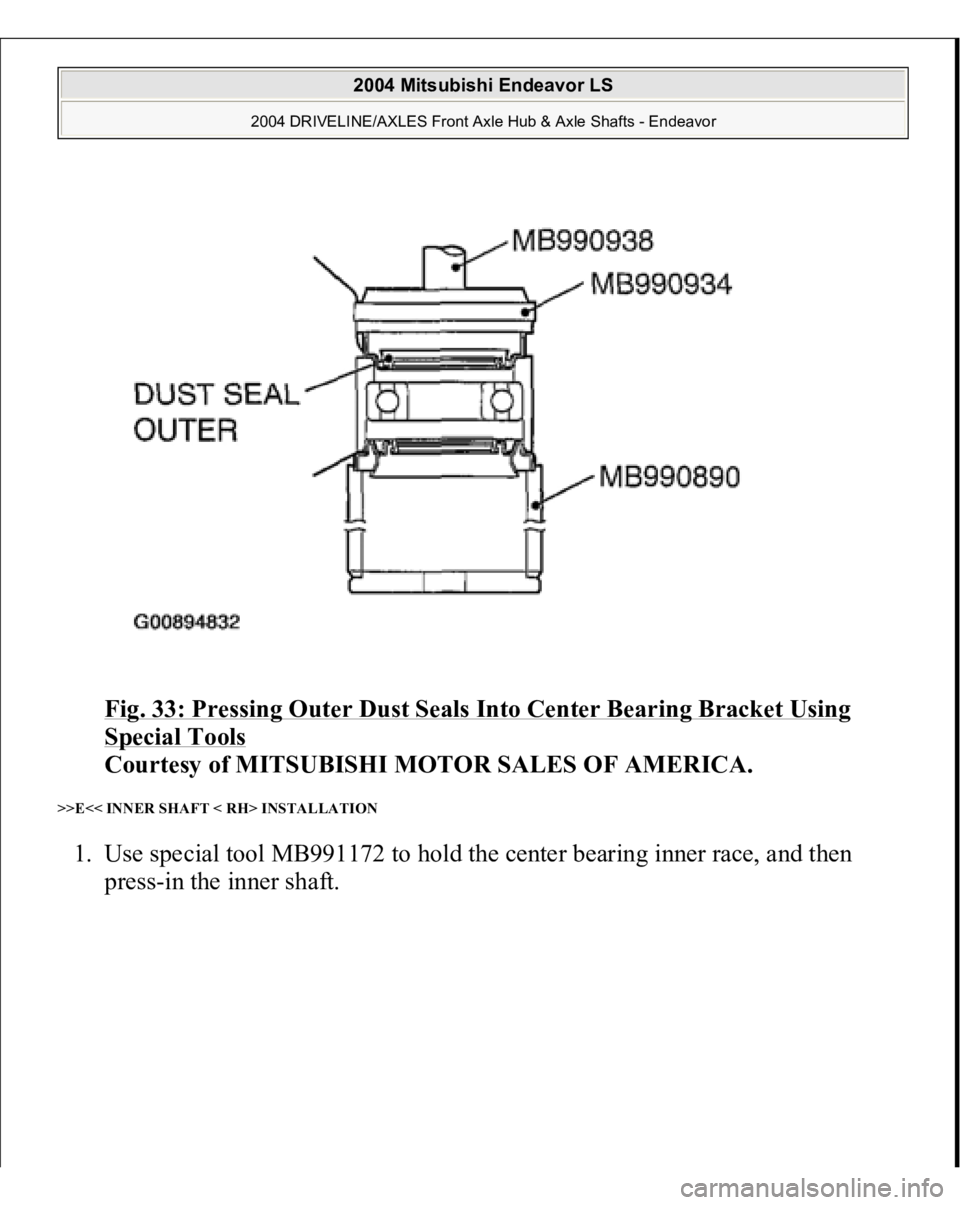

Fig. 33: Pressing Outer Dust Seals Into Center Bearing Bracket Using Special Tools

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

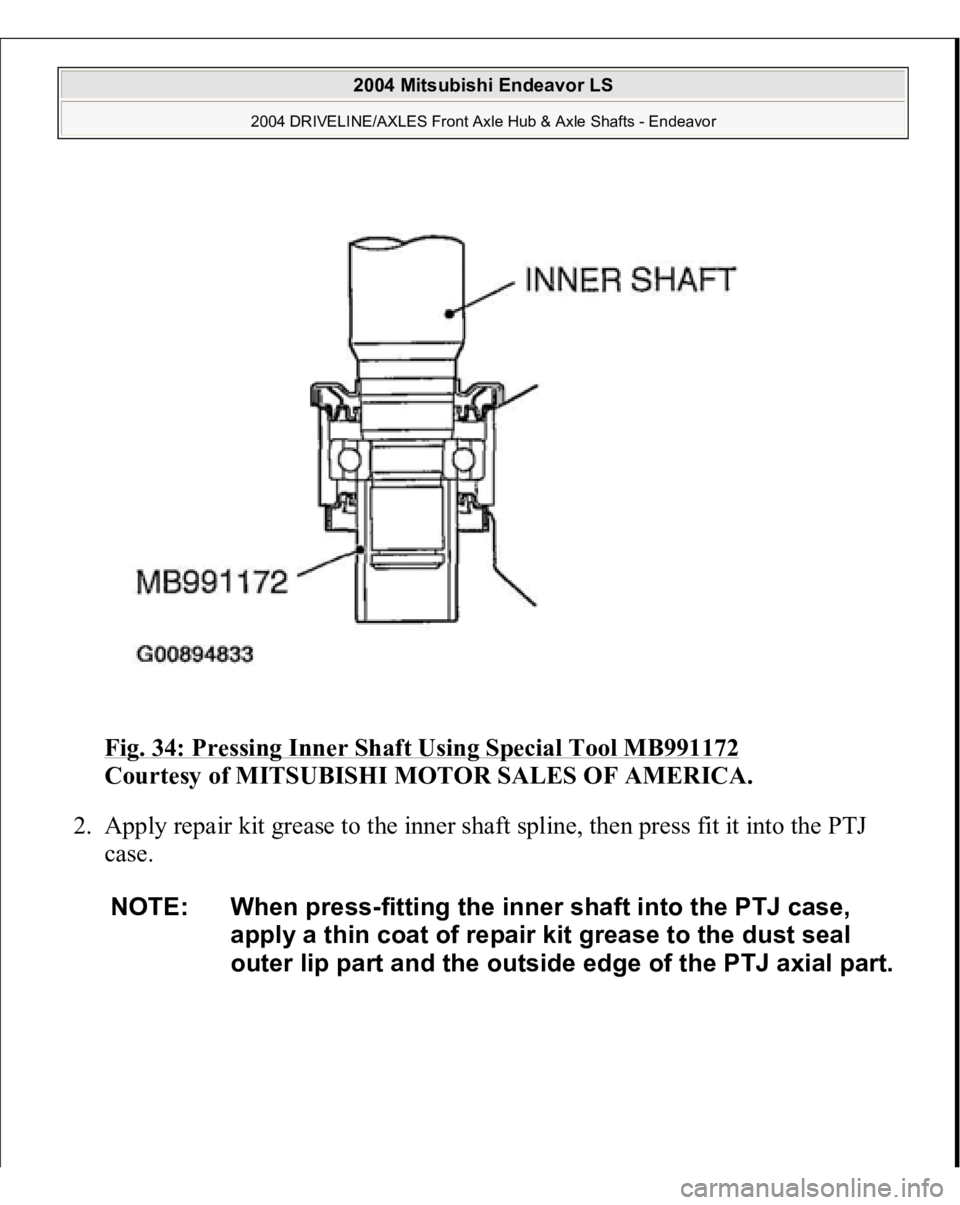

>>E<< INNER SHAFT < RH> INSTALLATION 1. Use special tool MB991172 to hold the center bearing inner race, and then

pres

s-in the inner shaft.

2004 Mitsubishi Endeavor LS

2004 DRIVELINE/AXLES Front Axle Hub & Axle Shafts - Endeavor

Page 1887 of 3870

Fig. 34: Pressing Inner Shaft Using Special Tool MB991172

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

2. Apply repair kit grease to the inner shaft spline, then press fit it into the PTJ

case.

NOTE: When press-fitting the inner shaft into the PTJ case,

apply a thin coat of repair kit grease to the dust seal

outer lip part and the outside edge of the PTJ axial part.

2004 Mitsubishi Endeavor LS

2004 DRIVELINE/AXLES Front Axle Hub & Axle Shafts - Endeavor

Page 1888 of 3870

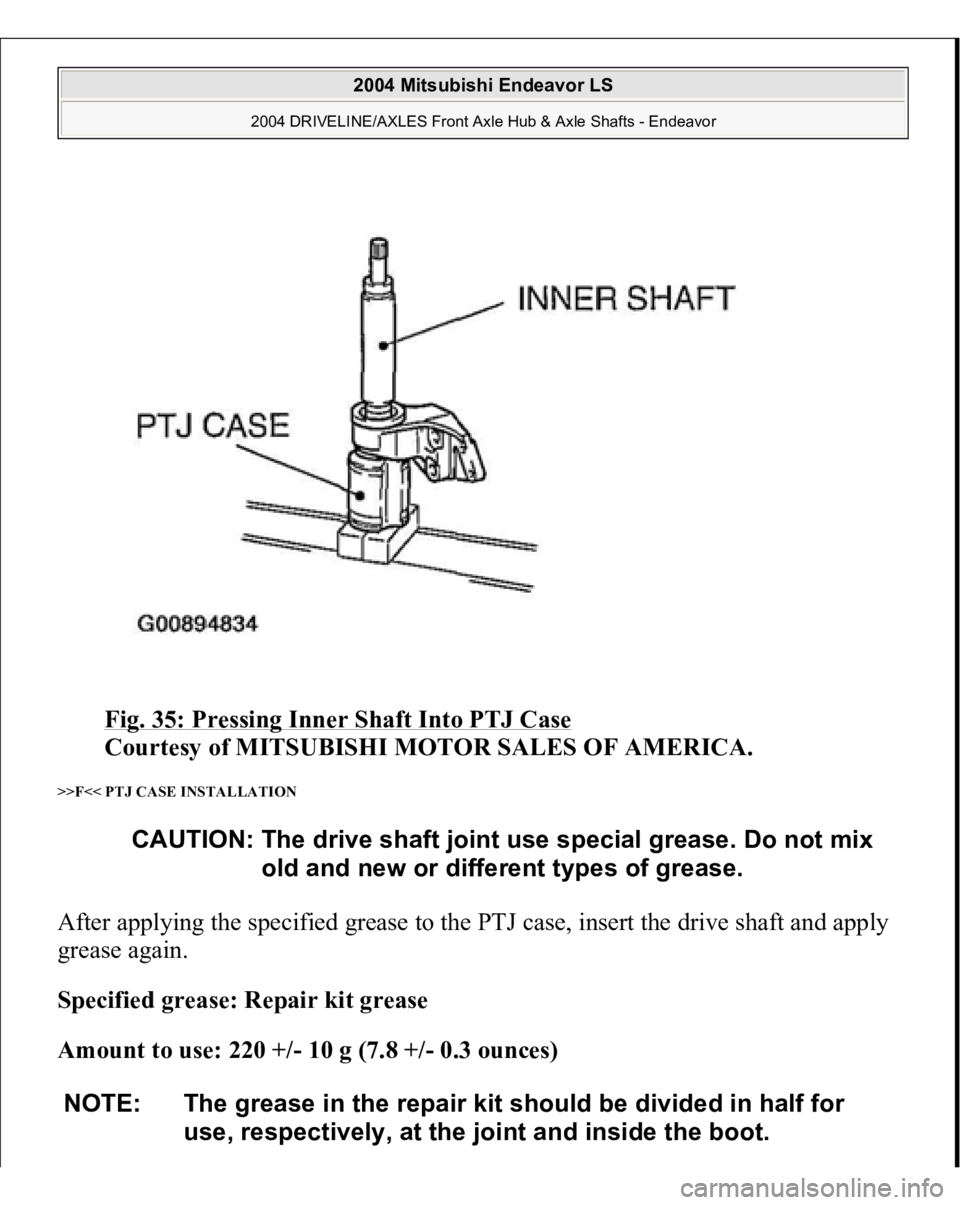

Fig. 35: Pressing Inner Shaft Into PTJ Case

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

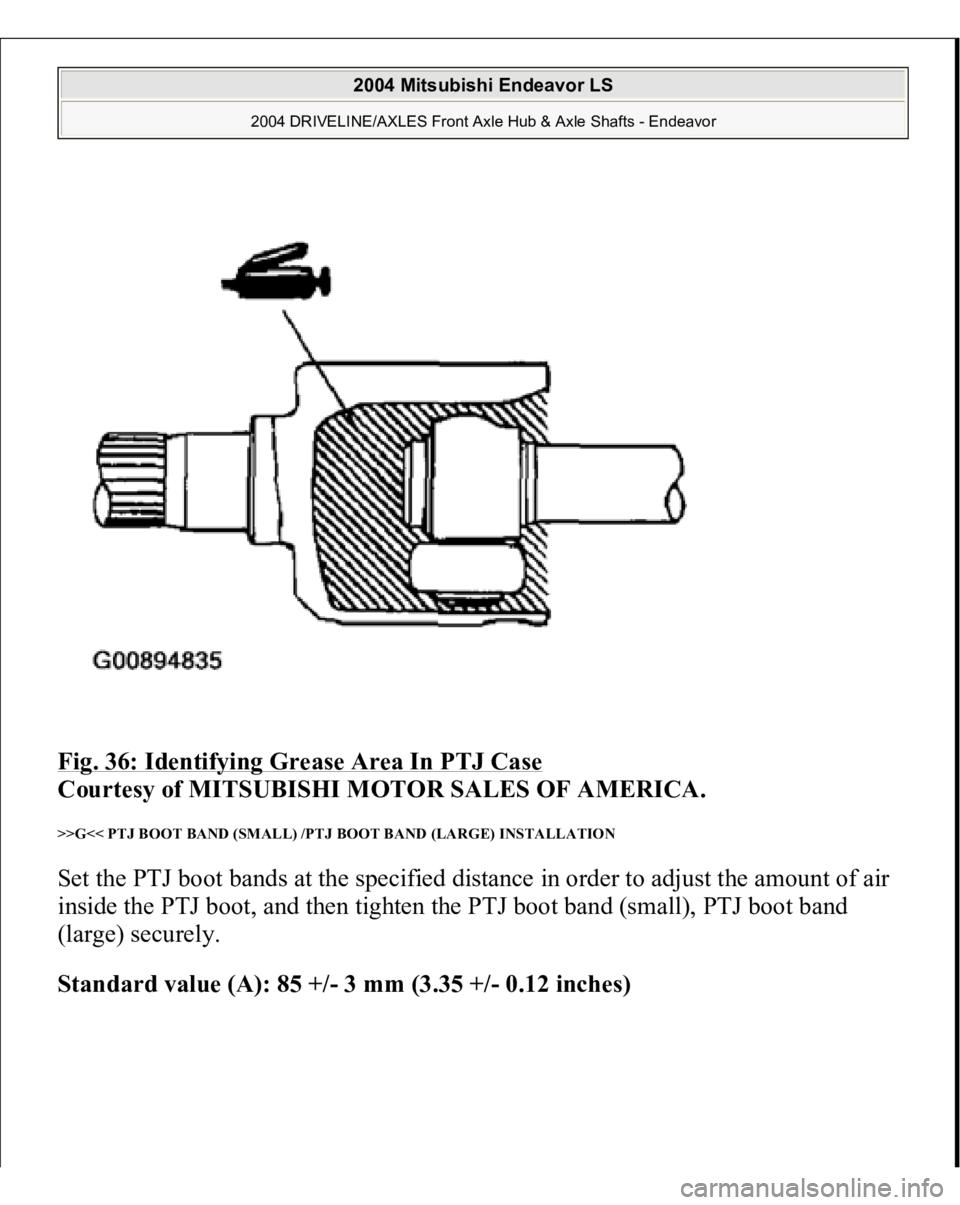

>>F<< PTJ CASE INSTALLATION After applying the specified grease to the PTJ case, insert the drive shaft and apply

grease again.

Specified grease: Repair kit grease

Amount to use: 220 +/- 10 g (7.8 +/- 0.3 ounces)

CAUTION: The drive shaft joint use special grease. Do not mix

old and new or different types of grease.

NOTE: The grease in the repair kit should be divided in half for

use, respectively, at the joint and inside the boot.

2004 Mitsubishi Endeavor LS

2004 DRIVELINE/AXLES Front Axle Hub & Axle Shafts - Endeavor

Page 1889 of 3870

Fig. 36: Identifying Grease Area In PTJ Case

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

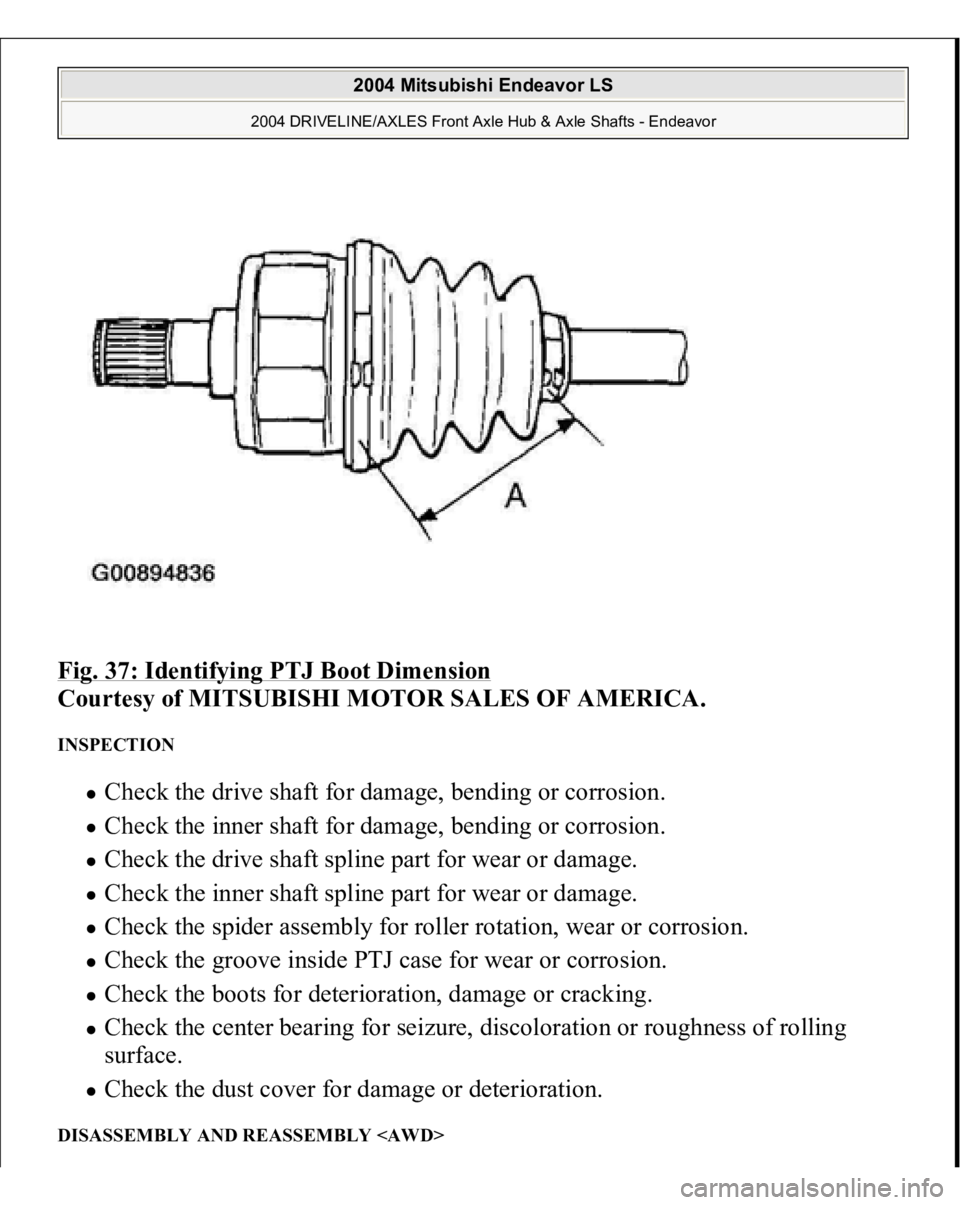

>>G<< PTJ BOOT BAND (SMALL) /PTJ BOOT BAND (LARGE) INSTALLATION Set the PTJ boot bands at the specified distance in order to adjust the amount of air

inside the PTJ boot, and then tighten the PTJ boot band (small), PTJ boot band

(large) securely.

Standard value (A): 85 +/- 3 mm (3.35 +/- 0.12 inches)

2004 Mitsubishi Endeavor LS

2004 DRIVELINE/AXLES Front Axle Hub & Axle Shafts - Endeavor

Page 1890 of 3870

Fig. 37: Identifying PTJ Boot Dimension

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

INSPECTION

Check the drive shaft for damage, bending or corrosion. Check the inner shaft for damage, bending or corrosion. Check the drive shaft spline part for wear or damage. Check the inner shaft spline part for wear or damage. Check the spider assembly for roller rotation, wear or corrosion. Check the groove inside PTJ case for wear or corrosion. Check the boots for deterioration, damage or cracking. Check the center bearing for seizure, discoloration or roughness of rolling

surface. Check the dust cover for damage or deterioration.

DISASSEMBLY AND REASSEMBLY

2004 Mitsubishi Endeavor LS

2004 DRIVELINE/AXLES Front Axle Hub & Axle Shafts - Endeavor

Trending: Sensor, fuel pressure, change key battery, clock, fluid, fuse box, park assist