MITSUBISHI ENDEAVOR 2004 Service Repair Manual

ENDEAVOR 2004

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57105/w960_57105-0.png

MITSUBISHI ENDEAVOR 2004 Service Repair Manual

Trending: differential, jump cable, stop start, checking oil, air condition, radio removal, Rear end

Page 3541 of 3870

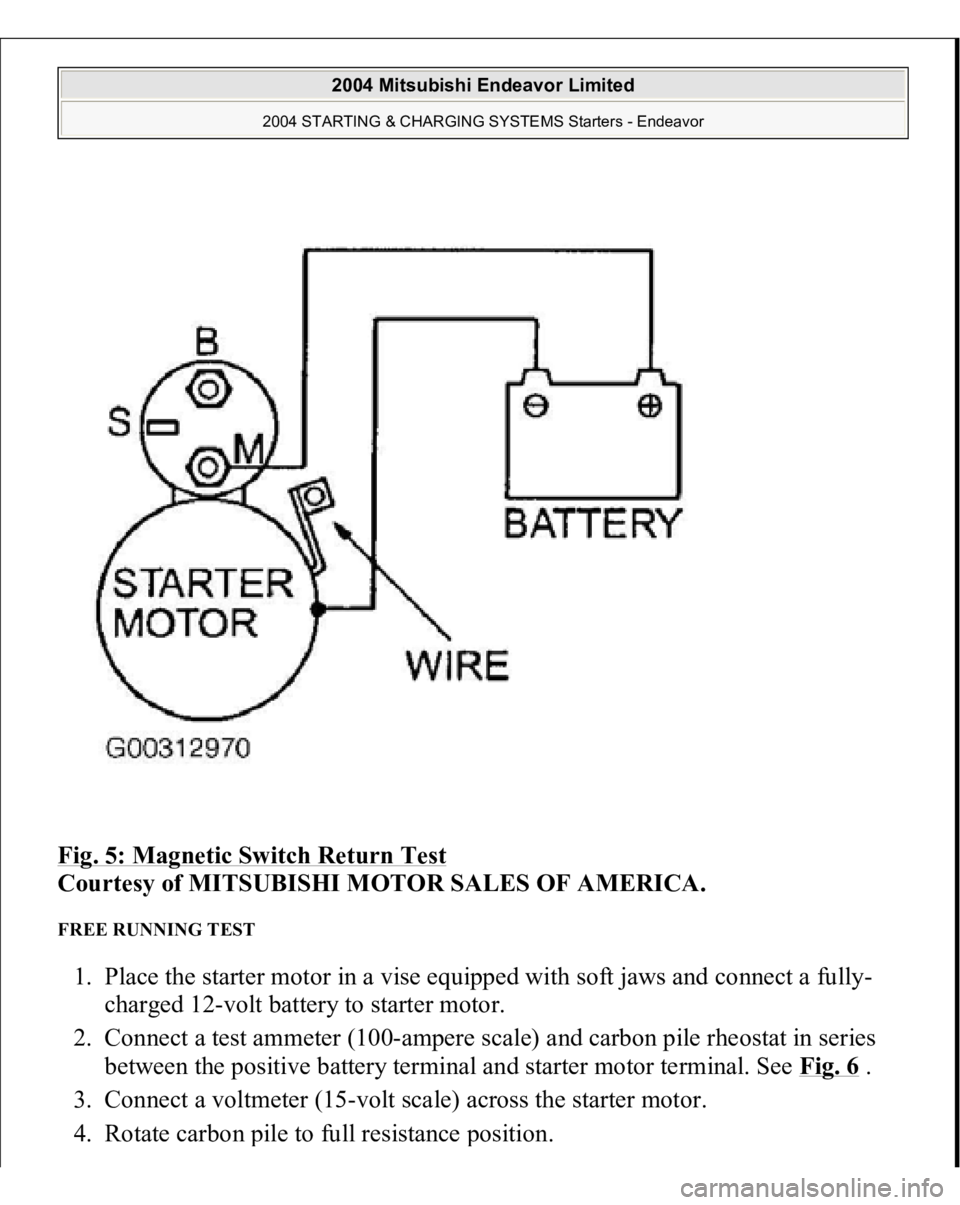

Fig. 5: Magnetic Switch Return Test

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

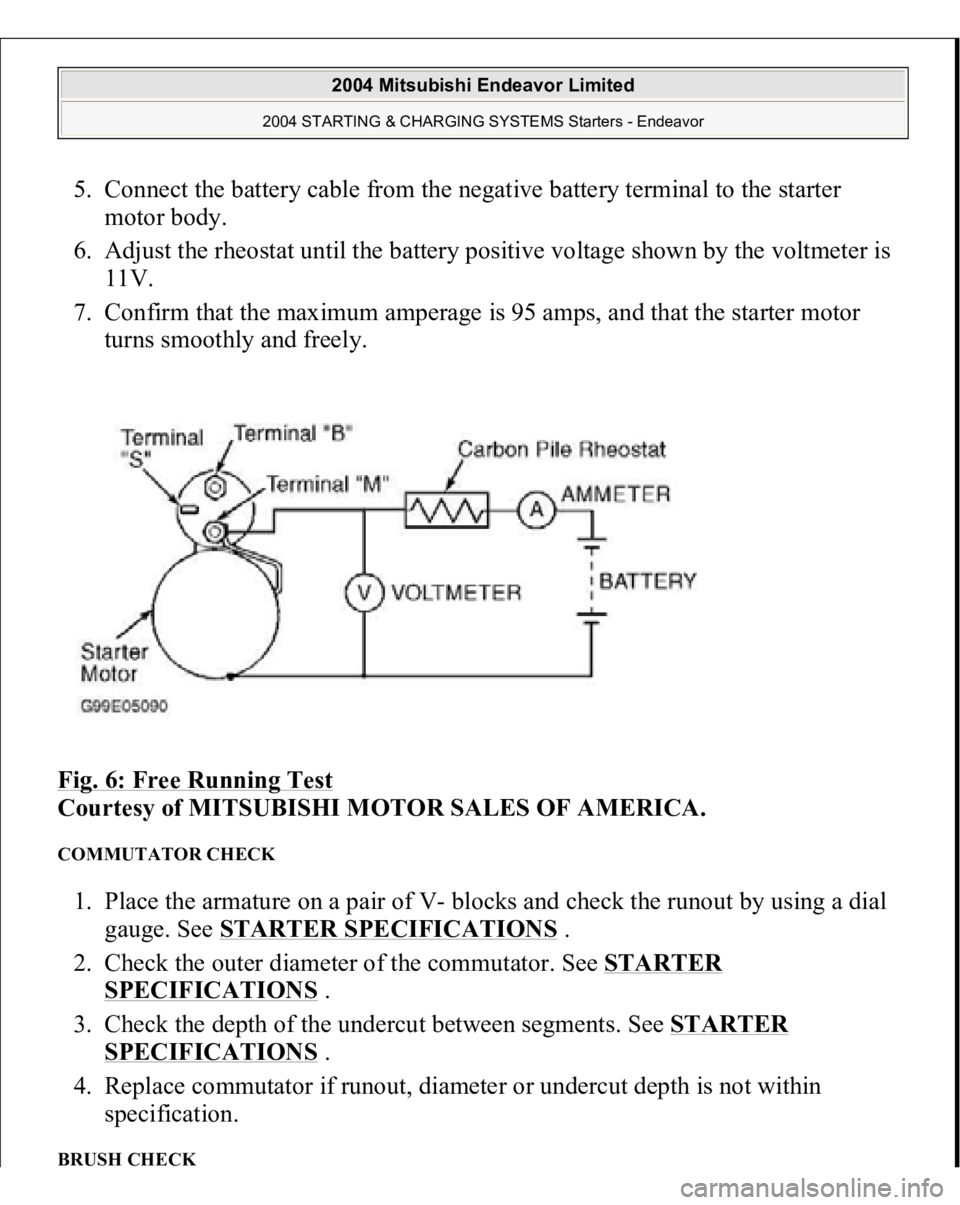

FREE RUNNING TEST 1. Place the starter motor in a vise equipped with soft jaws and connect a fully-

charged 12-volt battery to starter motor.

2. Connect a test ammeter (100-ampere scale) and carbon pile rheostat in series

between the positive battery terminal and starter motor terminal. See Fig. 6

.

3. Connect a voltmeter (15-volt scale) across the starter motor.

4. Rotate carbon

pile to full resistance

position.

2004 Mitsubishi Endeavor Limited

2004 STARTING & CHARGING SYSTEMS Starters - Endeavor

Page 3542 of 3870

5. Connect the battery cable from the negative battery terminal to the starter

motor body.

6. Adjust the rheostat until the battery positive voltage shown by the voltmeter is

11V.

7. Confirm that the maximum amperage is 95 amps, and that the starter motor

turns smoothly and freely.

Fig. 6: Free Running Test

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

COMMUTATOR CHECK 1. Place the armature on a pair of V- blocks and check the runout by using a dial

gauge. See STARTER SPECIFICATIONS

.

2. Check the outer diameter of the commutator. See STARTER

SPECIFICATIONS

.

3. Check the depth of the undercut between segments. See STARTER

SPECIFICATIONS

.

4. Replace commutator if runout, diameter or undercut depth is not within

specification.

BRUSH CHECK

2004 Mitsubishi Endeavor Limited

2004 STARTING & CHARGING SYSTEMS Starters - Endeavor

Page 3543 of 3870

1. Check the brush for roughness of the surface that contacts the commutator and

check the brush length. Replace the brush holder if this measurement exceeds

the limit. The minimum limit is .28" (7.0 mm)

2. In the case contacting surface has been corrected or the brush has been

replaced, correct the contacting surface winding sandpaper around the

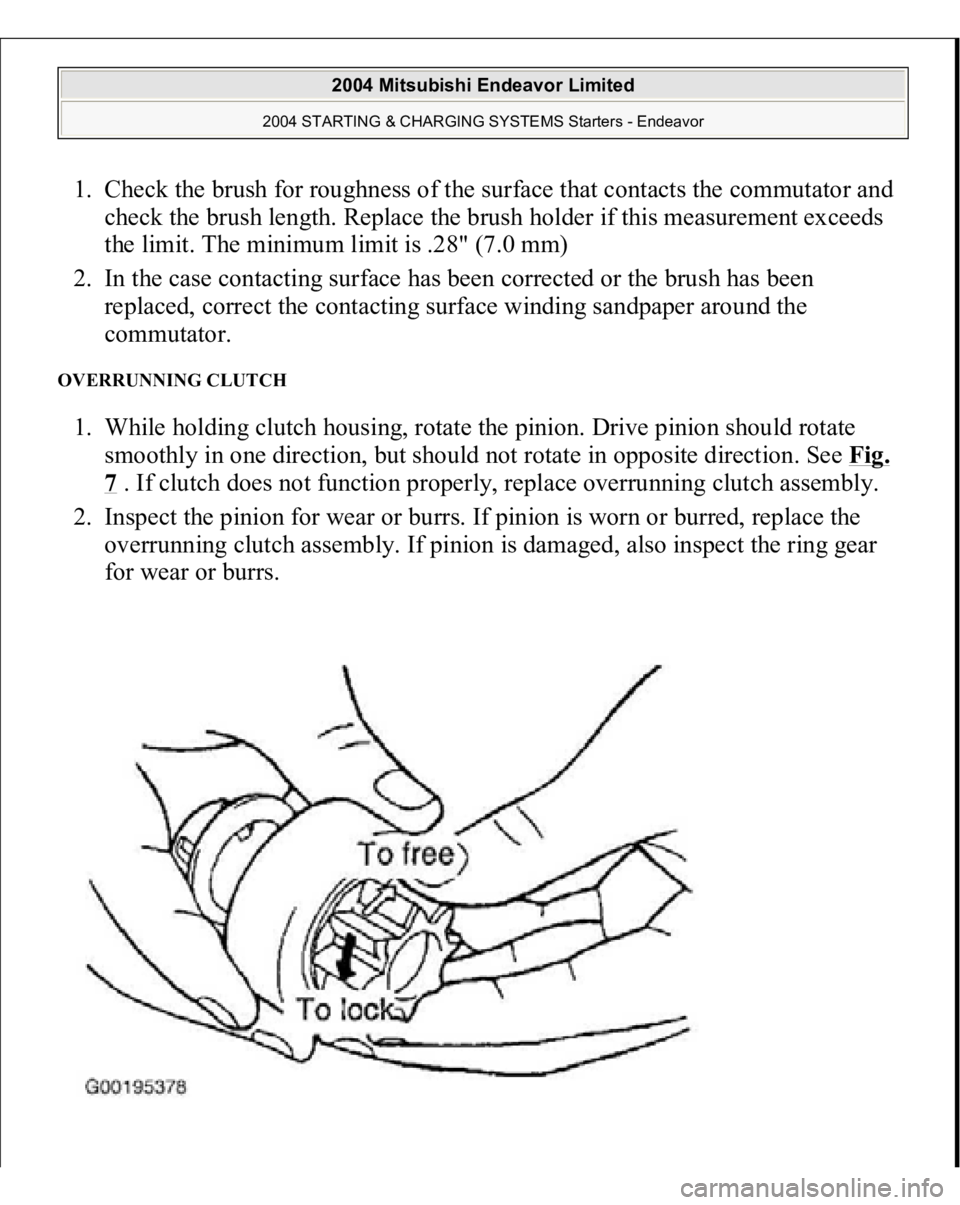

commutator. OVERRUNNING CLUTCH 1. While holding clutch housing, rotate the pinion. Drive pinion should rotate

smoothly in one direction, but should not rotate in opposite direction. See Fig.

7 . If clutch does not function properly, replace overrunning clutch assembly.

2. Inspect the pinion for wear or burrs. If pinion is worn or burred, replace the

overrunning clutch assembly. If pinion is damaged, also inspect the ring gear

for wear or burrs.

2004 Mitsubishi Endeavor Limited

2004 STARTING & CHARGING SYSTEMS Starters - Endeavor

Page 3544 of 3870

Fig. 7: Checking Overrunning Clutc

h

Courtesy of KIA MOTORS AMERICA, INC.

FRONT & REAR BRACKET BUSHING CHECK Inspect the bushing for wear or burrs. If the bushing is worn or burred, replace the

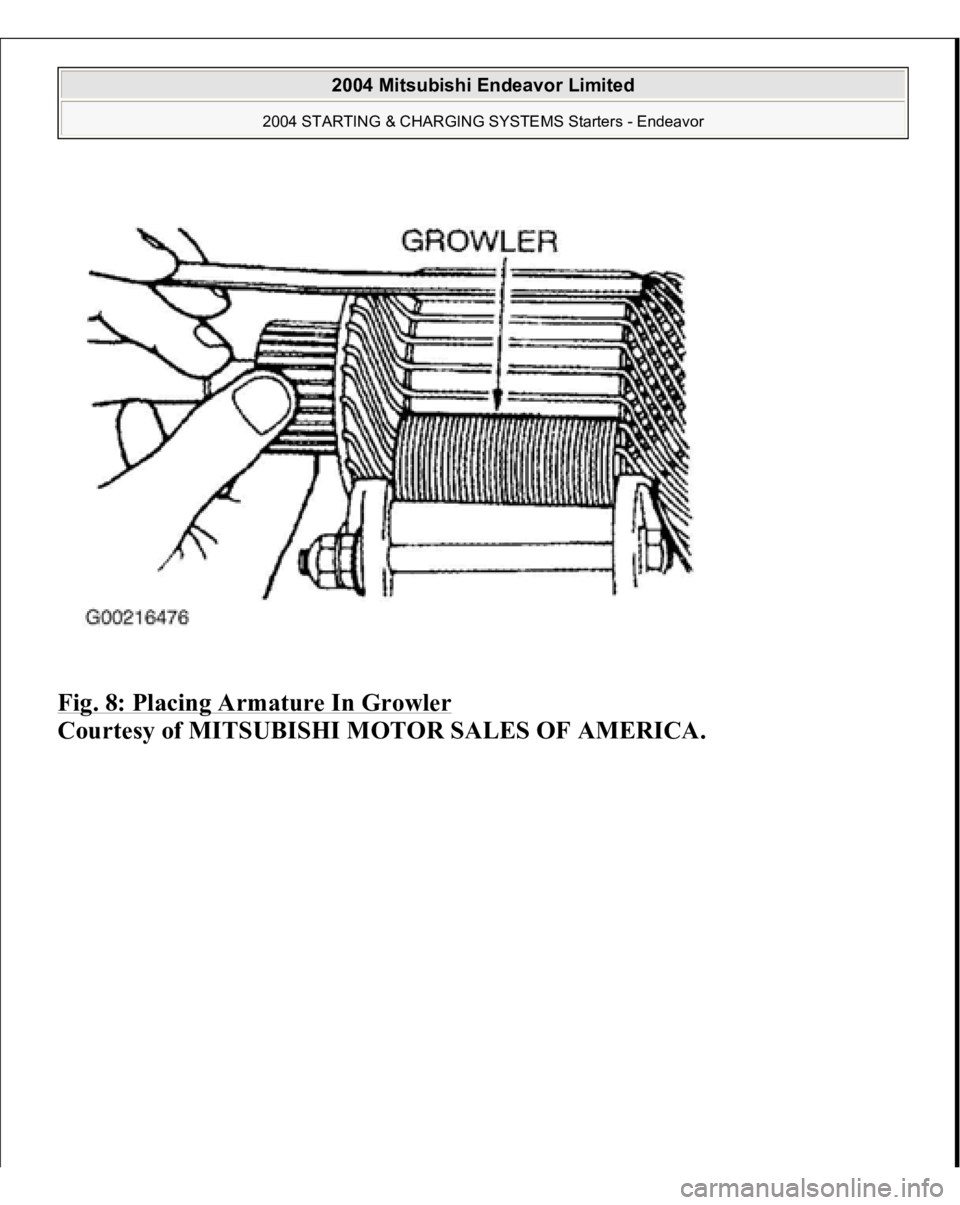

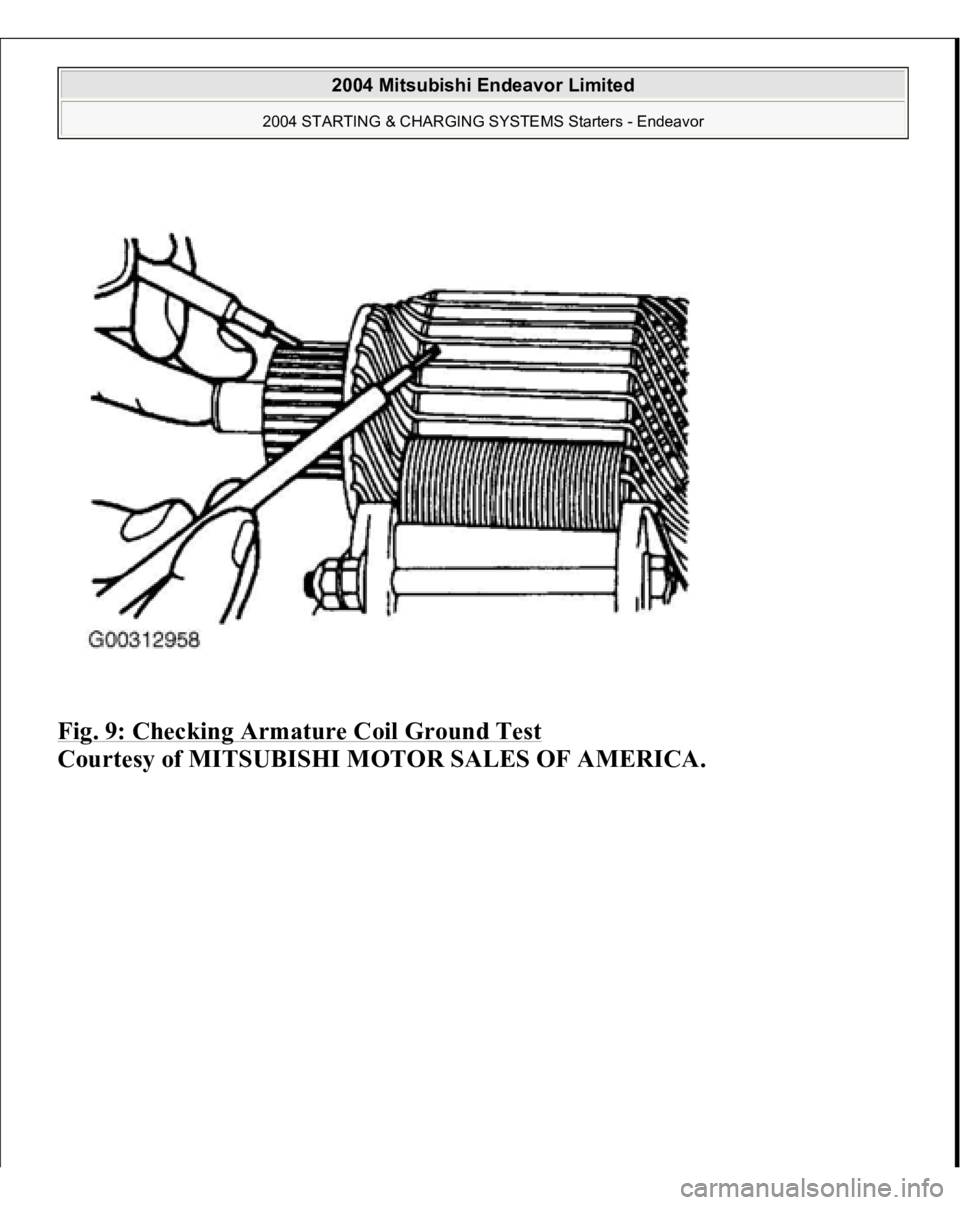

front bracket assembly or rear bracket assembly. ARMATURE CHECK 1. Check that the armature coil is not grounded.

2. Place armature in a growler. See Fig. 8

.

3. Hold a thin steel blade parallel and just above while rotating the armature

slowly in the growler. A shorted armature will cause a blade to vibrate and

attract to the core. Replace the shorted armature.

4. Check the insulation between the armature coil cores and the commutator

segments. They are normal if there is no continuity. See Fig. 9

.

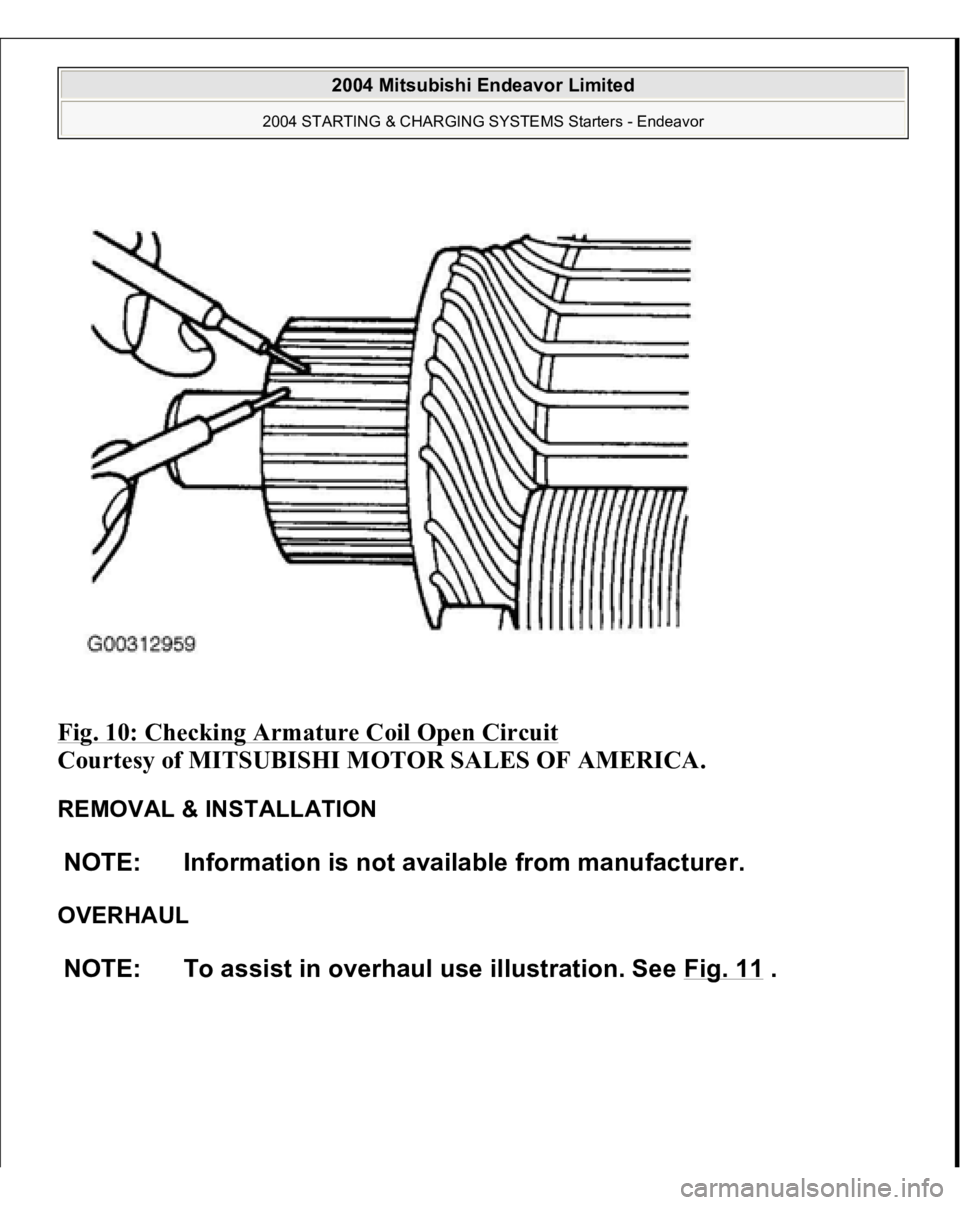

5. Check for continuity between the segments. The condition is normal if there is

continuit

y. See Fig. 10

.

2004 Mitsubishi Endeavor Limited

2004 STARTING & CHARGING SYSTEMS Starters - Endeavor

Page 3545 of 3870

Fig. 8: Placing Armature In Growler

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

2004 Mitsubishi Endeavor Limited

2004 STARTING & CHARGING SYSTEMS Starters - Endeavor

Page 3546 of 3870

Fig. 9: Checking Armature Coil Ground Test

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

2004 Mitsubishi Endeavor Limited

2004 STARTING & CHARGING SYSTEMS Starters - Endeavor

Page 3547 of 3870

Fig. 10: Checking Armature Coil Open Circuit

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

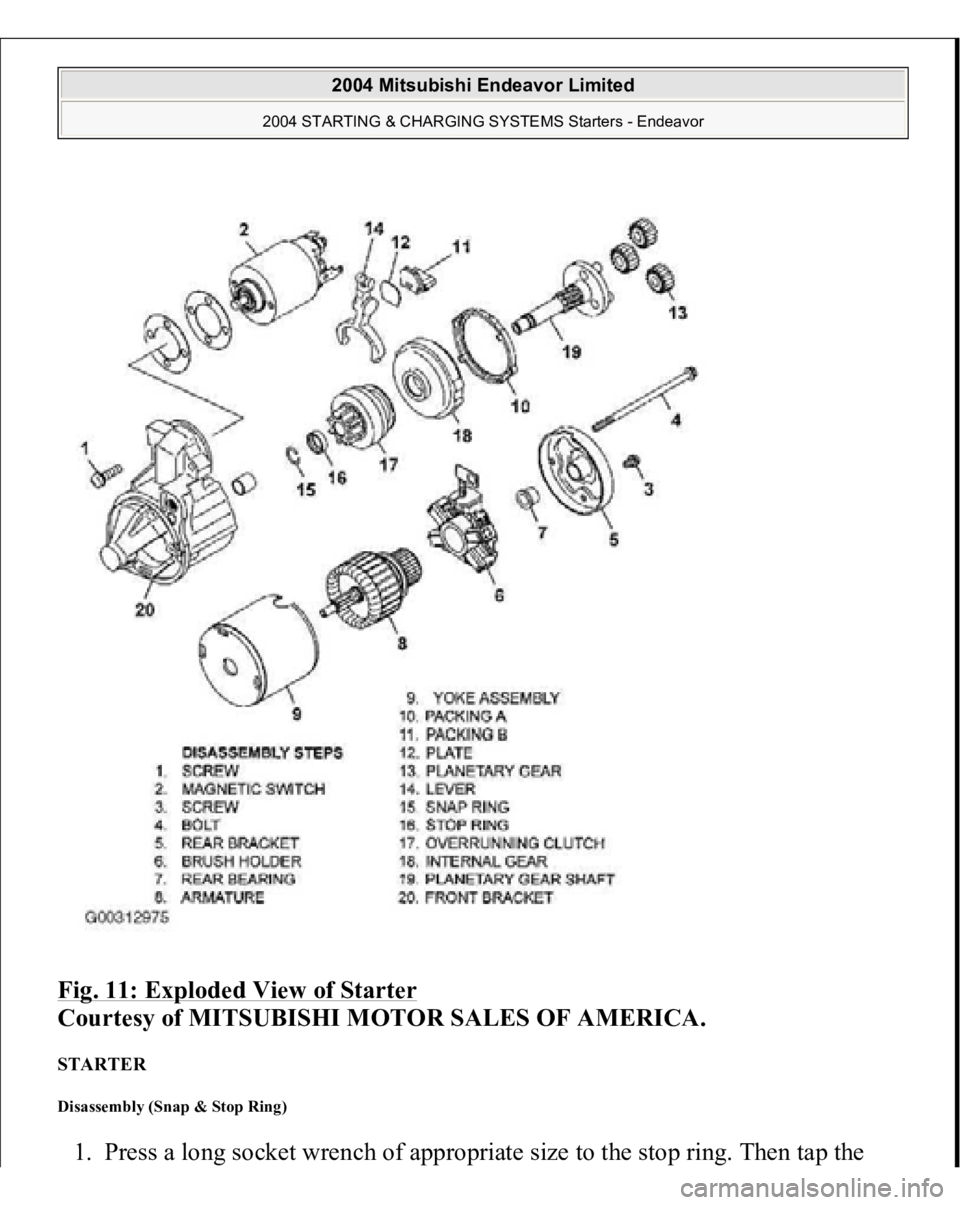

REMOVAL & INSTALLATION

OVERHAUL NOTE: Information is not available from manufacturer.

NOTE: To assist in overhaul use illustration. See Fig. 11

.

2004 Mitsubishi Endeavor Limited

2004 STARTING & CHARGING SYSTEMS Starters - Endeavor

Page 3548 of 3870

Fig. 11: Exploded View of Starter

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

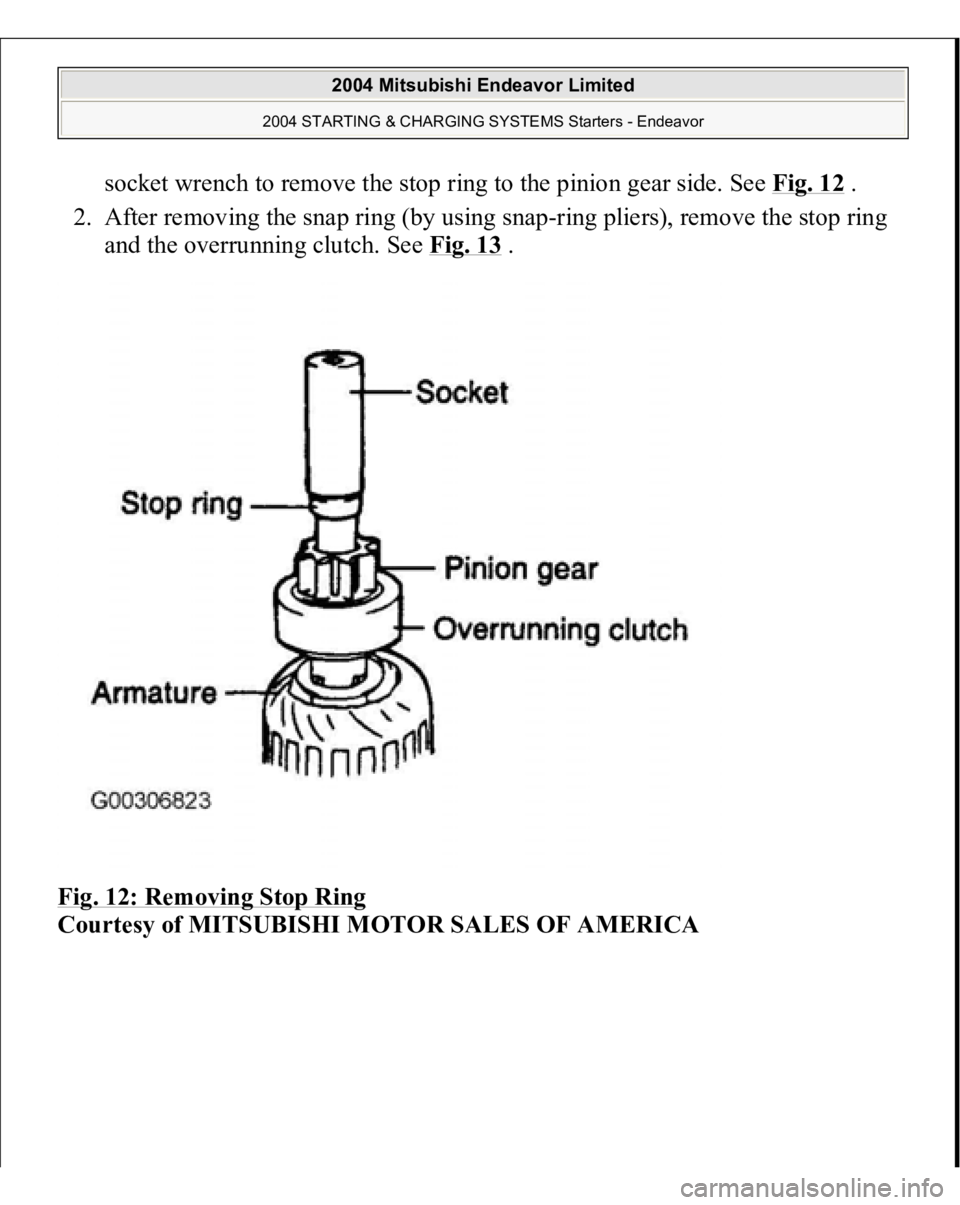

STARTER Disassembly (Snap & Stop Ring) 1. Press a lon

g socket wrench of a

ppropriate size to

the sto

p rin

g. Then ta

p the

2004 Mitsubishi Endeavor Limited

2004 STARTING & CHARGING SYSTEMS Starters - Endeavor

Page 3549 of 3870

socket wrench to remove the stop ring to the pinion gear side. See Fig. 12

.

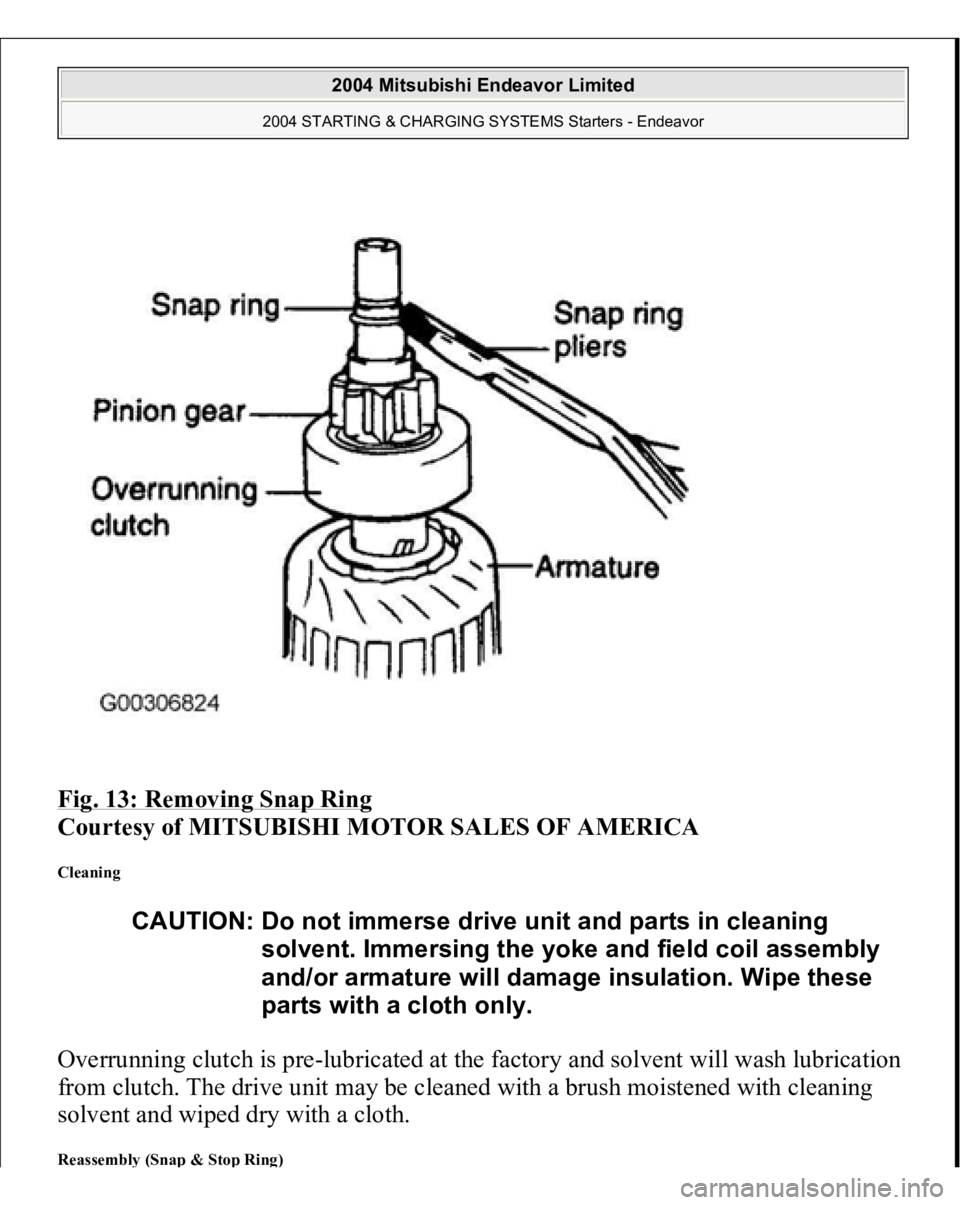

2. After removing the snap ring (by using snap-ring pliers), remove the stop ring

and the overrunning clutch. See Fig. 13

.

Fig. 12: Removing Stop Ring

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA

2004 Mitsubishi Endeavor Limited

2004 STARTING & CHARGING SYSTEMS Starters - Endeavor

Page 3550 of 3870

Fig. 13: Removing Snap Ring

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA

Cleaning Overrunning clutch is pre-lubricated at the factory and solvent will wash lubrication

from clutch. The drive unit may be cleaned with a brush moistened with cleaning

solvent and wiped dry with a cloth. Reassembl

y (Sna

p & Sto

p Rin

g)

CAUTION: Do not immerse drive unit and parts in cleaning

solvent. Immersing the yoke and field coil assembly

and/or armature will damage insulation. Wipe these

parts with a cloth only.

2004 Mitsubishi Endeavor Limited

2004 STARTING & CHARGING SYSTEMS Starters - Endeavor

Trending: lock, ad blue, 2 ohm, service reset, Throttle body, air condition compressor, coolant level