MITSUBISHI GALANT 1989 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 1021 of 1273

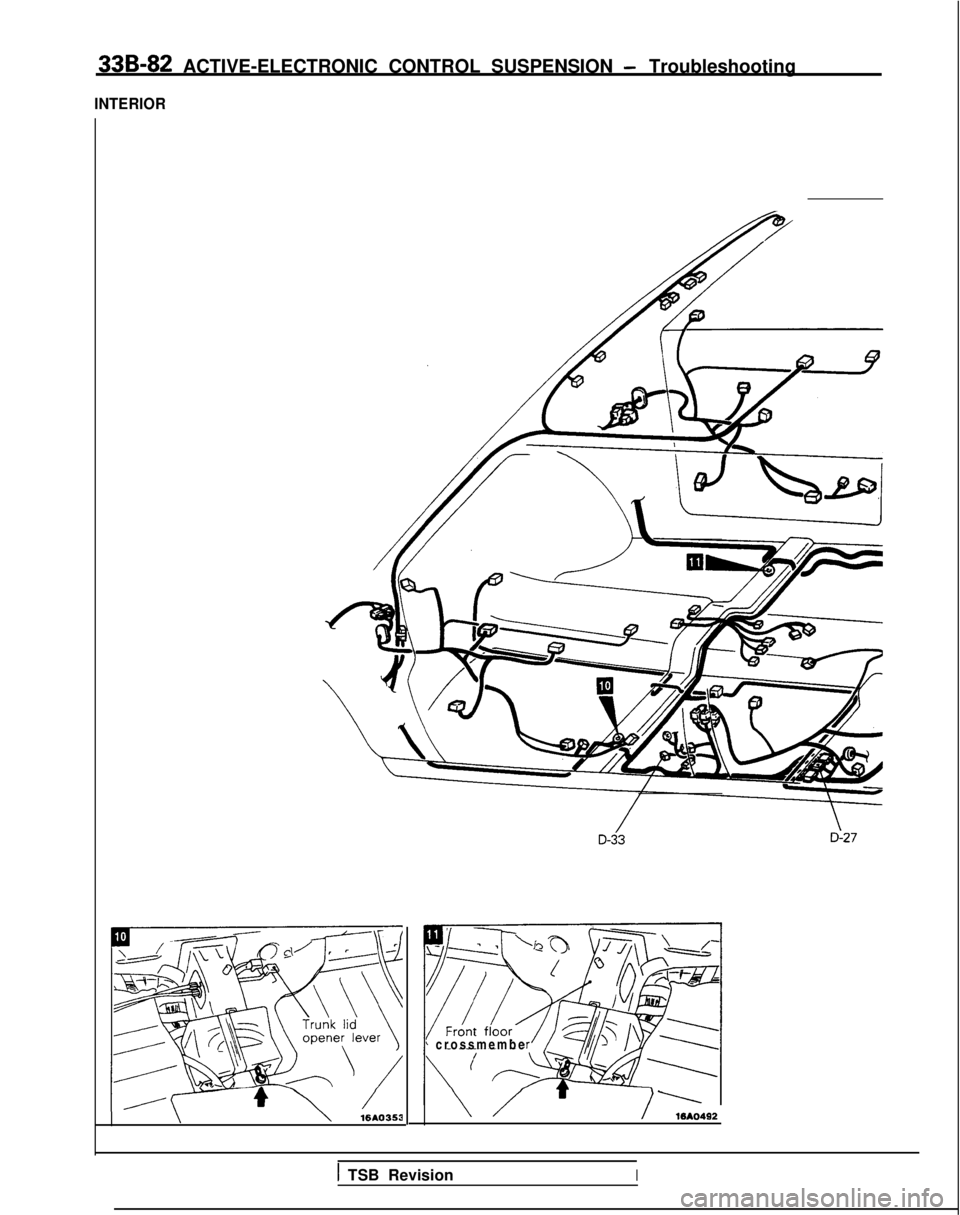

33B-82 ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting

INTERIOR

\\16AO353

’ crossmemb

e

\ //WA0492

1 TSB RevisionI

Page 1022 of 1273

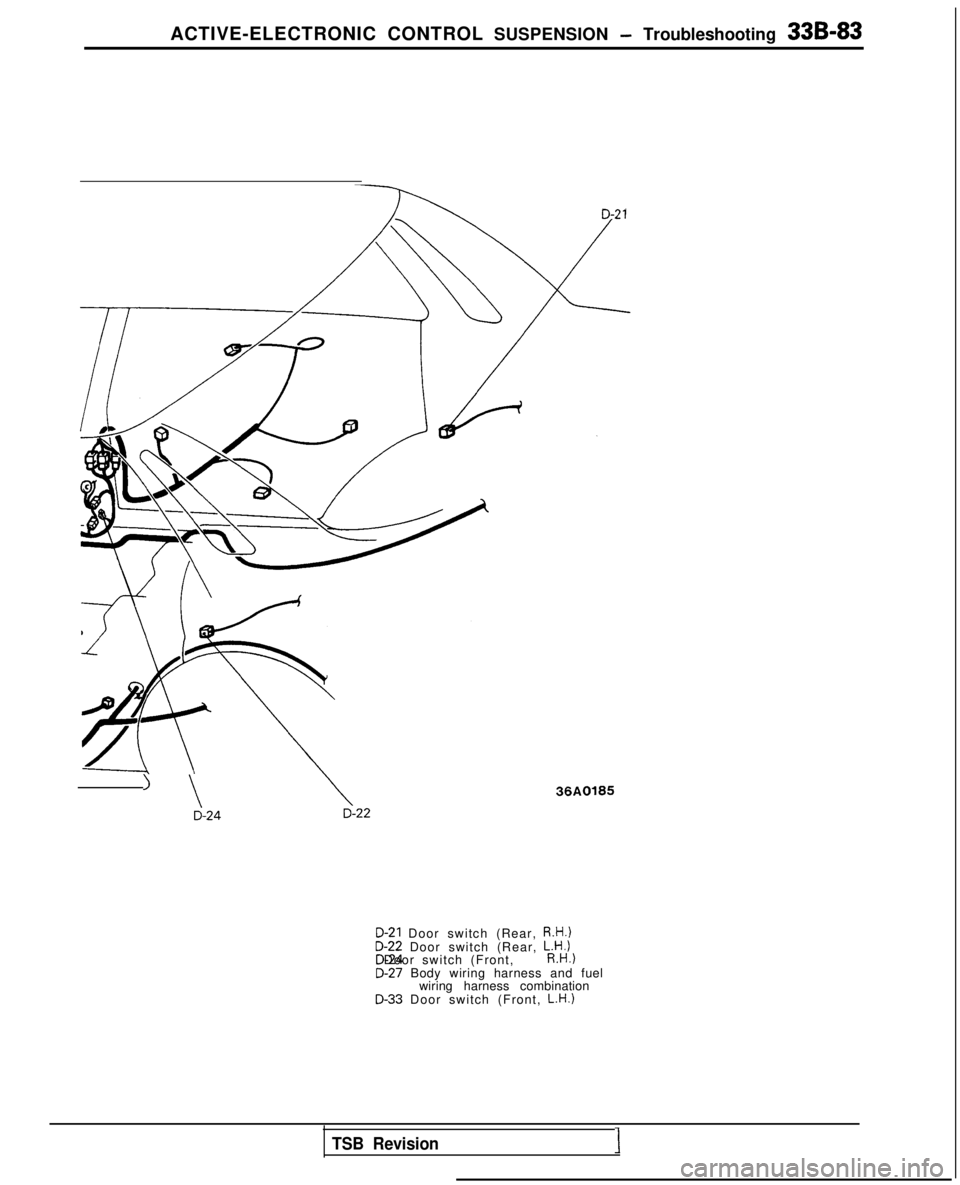

ACTIVE-ELECTRONIC CONTROL

SUSPENSION - Troubleshooting 33B-83

D-21

TSB RevisionI

>

\D-24 36A0185

D-21 Door switch (Rear, R.H.)D-22 Door switch (Rear,

L.H.l

D-24 Door switch (Front, R.H.)D-27 Body wiring harness and fuel

wiring harness combination

D-33 Door switch (Front, L.H.)

Page 1023 of 1273

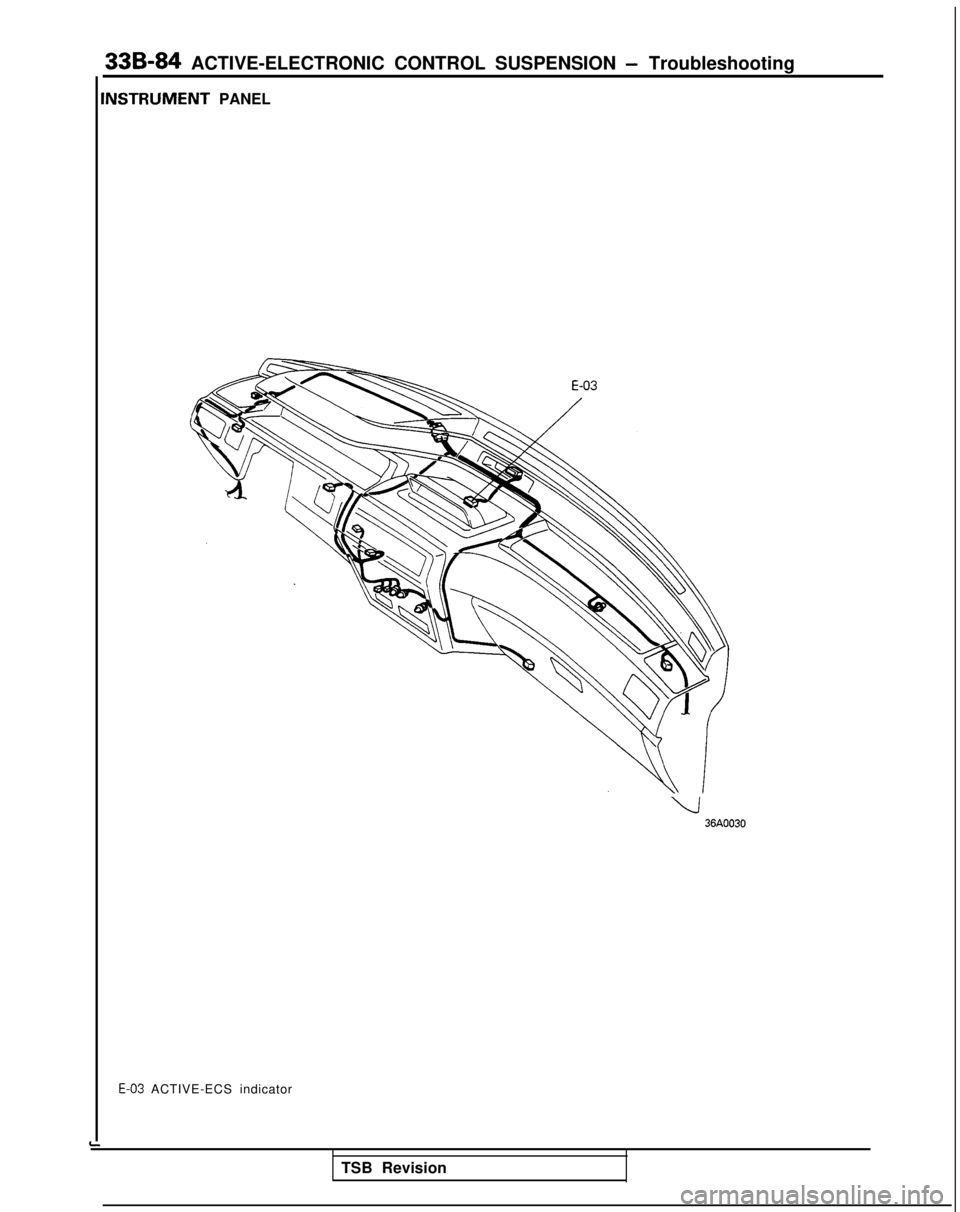

33B-84 ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting

IF

cUSTRUMENT

PANEL

Ll36AOO30

E-03 ACTIVE-ECS indicator

TSB Revision

Page 1024 of 1273

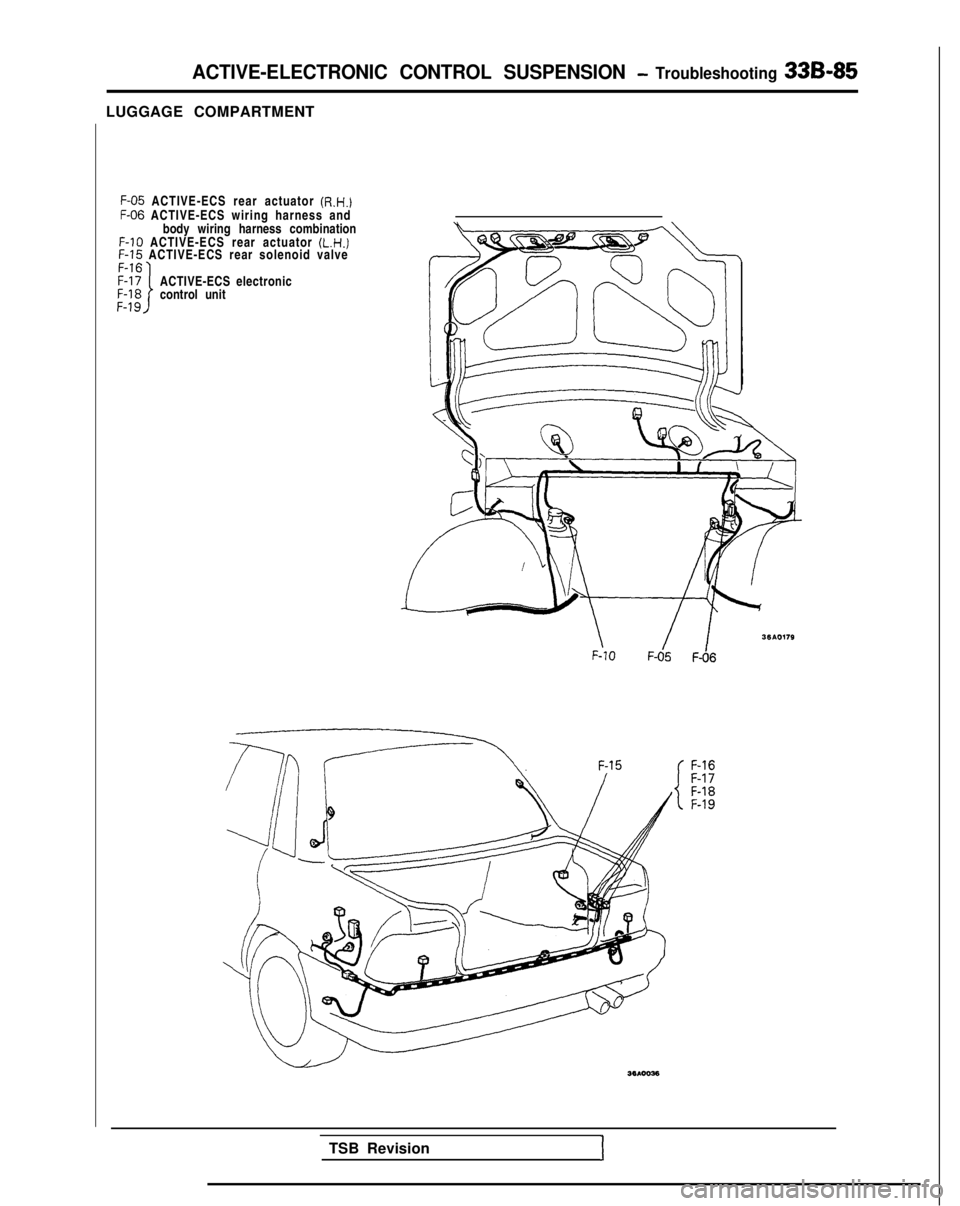

ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting 33B-85

LUGGAGE COMPARTMENTF-05

ACTIVE-ECS rear actuator (R.H.)

F-06

ACTIVE-ECS wiring harness and

body wiring harness combination F-10

ACTIVE-ECS rear actuator (L.H.)

F-15

ACTIVE-ECS rear solenoid valve

ACTIVE-ECS electronic

control unit

\ F-101 IF-05

F-06

F-16

F-17

F-18

F-19

TSB Revision

1

Page 1025 of 1273

33B-86 ACTIVE-ELECTRONIC CONTROL SUSPENSION - ~~u,:~%i?:~~~~

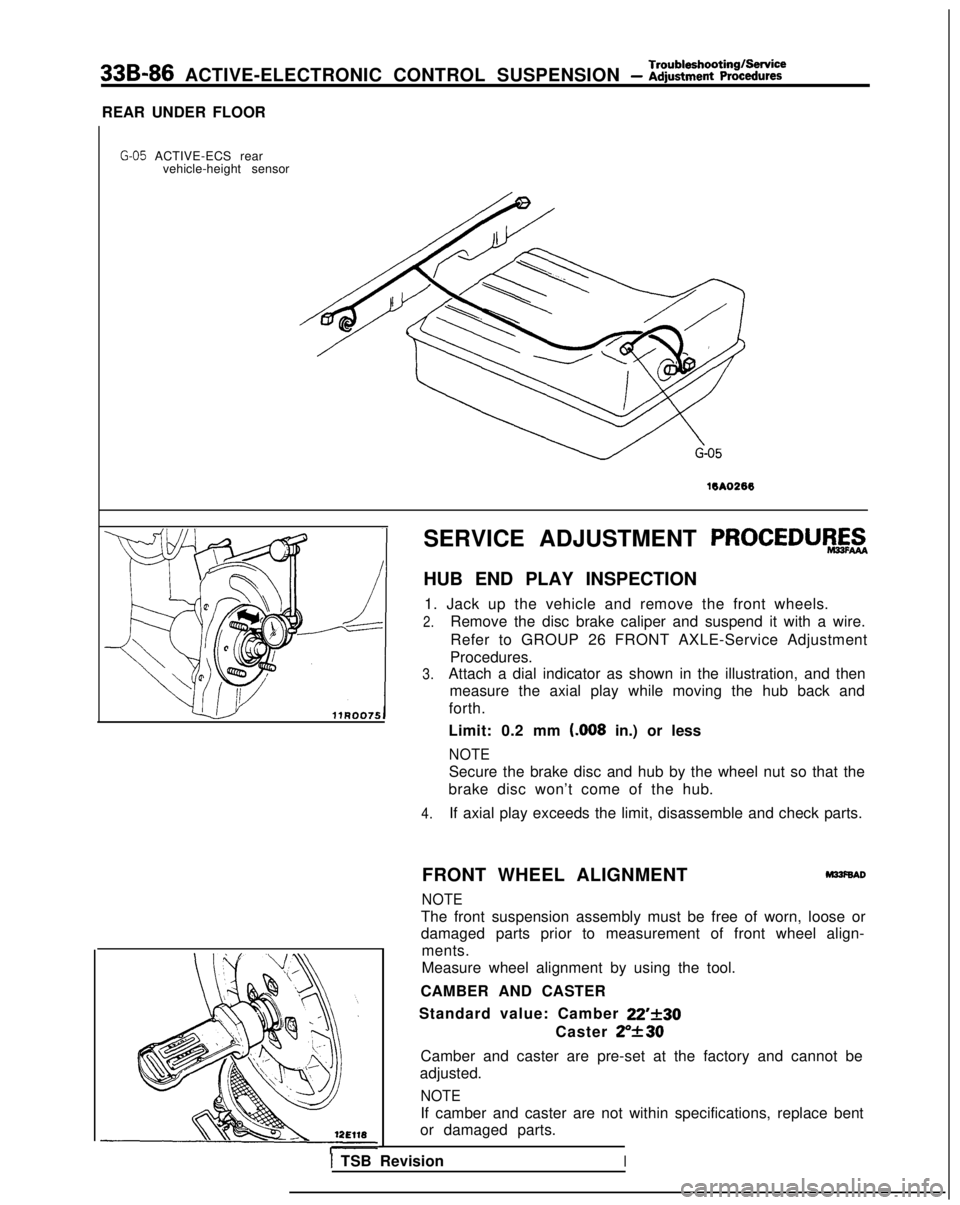

REAR UNDER FLOOR

G-05 ACTIVE-ECS rear vehicle-height sensor

16A0266

SERVICE ADJUSTMENT PROCEDURAZ

HUB END PLAY INSPECTION

1. Jack up the vehicle and remove the front wheels.

2.Remove the disc brake caliper and suspend it with a wire.

Refer to GROUP 26 FRONT AXLE-Service Adjustment

Procedures.

3.Attach a dial indicator as shown in the illustration, and then measure the axial play while moving the hub back and

forth.

Limit: 0.2 mm t.008

in.) or less

NOTE

Secure the brake disc and hub by the wheel nut so that the

brake disc won’t come of the hub.

4.If axial play exceeds the limit, disassemble and check parts.

FRONT WHEEL ALIGNMENT

M33f6AD

NOTE

The front suspension assembly must be free of worn, loose or

damaged parts prior to measurement of front wheel align- ments.

Measure wheel alignment by using the tool.

CAMBER AND CASTER

Standard value: Camber

22’f30

Caster ZY30

Camber and caster are pre-set at the factory and cannot be

adjusted.

NOTE

If camber and caster are not within specifications, replace bent

or damaged parts.

I TSB RevisionI

Page 1026 of 1273

ACTIVE-ELECTRONIC CONTROL SUSPENSIONService Adjustment- Procedures33B-87

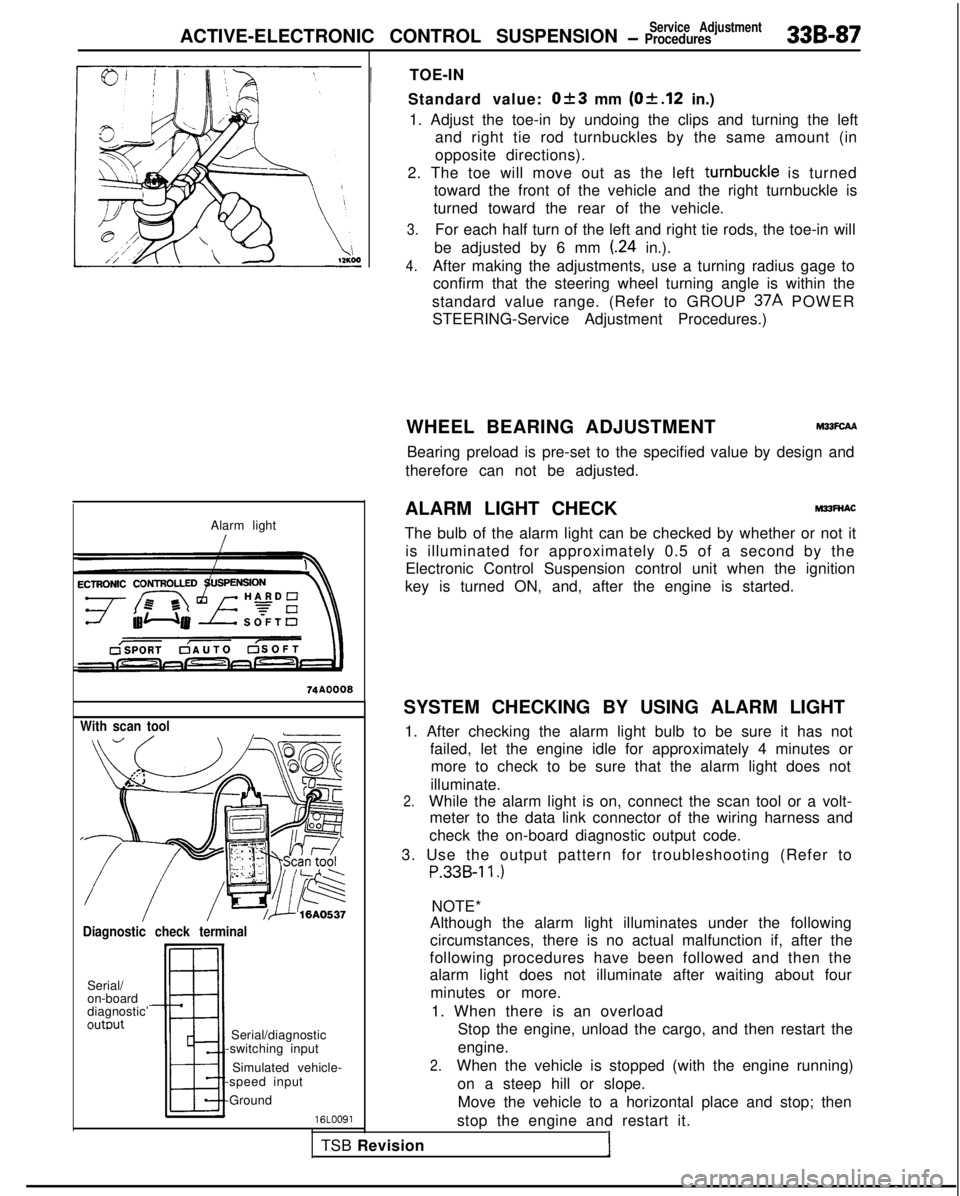

Alarm light

With scan tool

Diagnostic check terminal

Serial/

on-board

diagnostic’

outwt

TSB RevisionI

Serial/diagnostic

-switching input

Simulated vehicle-

-speed input

-Ground

16LOO91

!

TOE-IN

Standard value:

Ok3 mm (Of.12 in.)

1. Adjust the toe-in by undoing the clips and turning the left and right tie rod turnbuckles by the same amount (in

opposite directions).

2. The toe will move out as the left turnbuckle

is turned

toward the front of the vehicle and the right turnbuckle is

turned toward the rear of the vehicle.

3.For each half turn of the left and right tie rods, the toe-in will

be adjusted by 6 mm

(.24 in.).

4.After making the adjustments, use a turning radius gage to confirm that the steering wheel turning angle is within the

standard value range. (Refer to GROUP 37A

POWER

STEERING-Service Adjustment Procedures.)

WHEEL BEARING ADJUSTMENT

M33FcAA

Bearing preload is pre-set to the specified value by design and

therefore can not be adjusted.

ALARM LIGHT CHECK

MPFNAC

The bulb of the alarm light can be checked by whether or not it is illuminated for approximately 0.5 of a second by the

Electronic Control Suspension control unit when the ignition

key is turned ON, and, after the engine is started.

SYSTEM CHECKING BY USING ALARM LIGHT 1. After checking the alarm light bulb to be sure it has not failed, let the engine idle for approximately 4 minutes ormore to check to be sure that the alarm light does not

illuminate.

2.While the alarm light is on, connect the scan tool or a volt- meter to the data link connector of the wiring harness and

check the on-board diagnostic output code.

3. Use the output pattern for troubleshooting (Refer to

P.33B-11.)

NOTE*

Although the alarm light illuminates under the following

circumstances, there is no actual malfunction if, after the

following procedures have been followed and then the

alarm light does not illuminate after waiting about four

minutes or more.

1. When there is an overload Stop the engine, unload the cargo, and then restart the

engine.

2.When the vehicle is stopped (with the engine running)

on a steep hill or slope.Move the vehicle to a horizontal place and stop; then

stop the engine and restart it.

Page 1027 of 1273

338-88 ACTIVE-ELECTRONIC CONTROL SUSPENSION - ~~~%.,~Rment

With voltmeter

!//ii’12A0476

L

edge surface17AOOW(Right

Front) (Left

Rear)

12A0224 J3. When vehicle-height adjustments are made frequently

After stopping the engine, open the hood and allowthe compressor to cool; then restart the engine.

4. When the vehicle is driven on winding roads in the

mountains continuously for 18 minutes or longer.

To protect the return pump from damage, stop the

engine and then restart it.

*: Applicable to 1989 models only.

CHECKING BY ON-BOARD DIAGNOSTIC

1.Regardless of whether or not the alarm light is illuminated,

check the diagnostic output codes at the diagnostic termi-

nal.

2. If a malfunction code is output to the diagnostic terminal, perform the troubleshooting procedures according to the

output code.

NOTE

Diagnostic trouble codes are entered into the memory, even if

the ignition is at the OFF position, so that it is possible to check

for the existence of malfunctions that occurred previously.

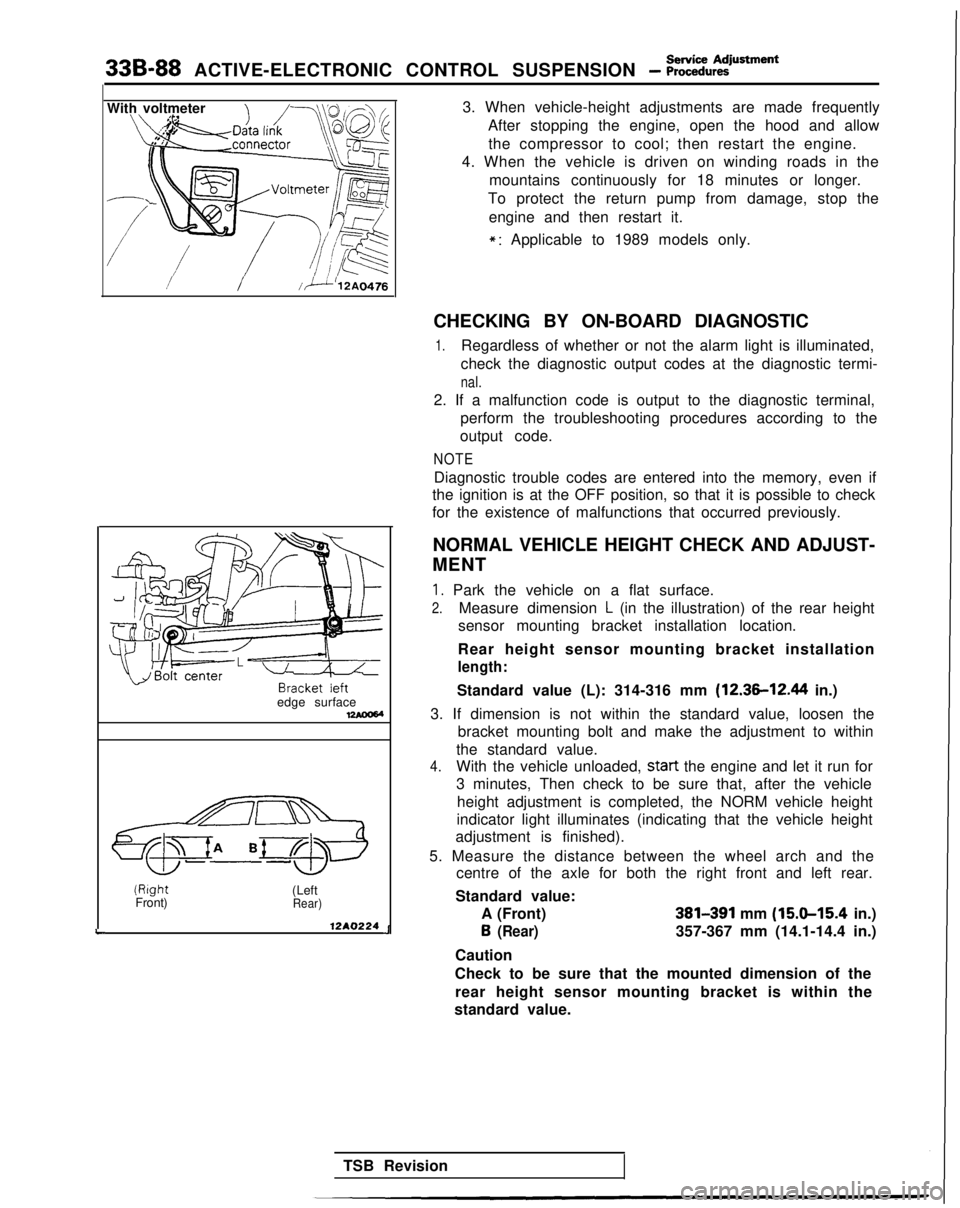

NORMAL VEHICLE HEIGHT CHECK AND ADJUST-

MENT

1. Park the vehicle on a flat surface.

2.Measure dimension L (in the illustration) of the rear height

sensor mounting bracket installation location.

Rear height sensor mounting bracket installation

length:

Standard value (L): 314-316 mm (12.36-12.44 in.)

3. If dimension is not within the standard value, loosen the bracket mounting bolt and make the adjustment to within

the standard value.

4.With the vehicle unloaded, start

the engine and let it run for

3 minutes, Then check to be sure that, after the vehicle

height adjustment is completed, the NORM vehicle height

indicator light illuminates (indicating that the vehicle height

adjustment is finished).

5. Measure the distance between the wheel arch and the centre of the axle for both the right front and left rear.

Standard value: A (Front)

381391 mm (15.9-15.4 in.) 6

(Rear)357-367 mm (14.1-14.4 in.)

Caution

Check to be sure that the mounted dimension of the rear height sensor mounting bracket is within the

standard value.

TSB Revision

Page 1028 of 1273

ACTIVE-ELECTRONIC CONTROL SUSPENSION - ~~:i%,~:iustment 33B-89

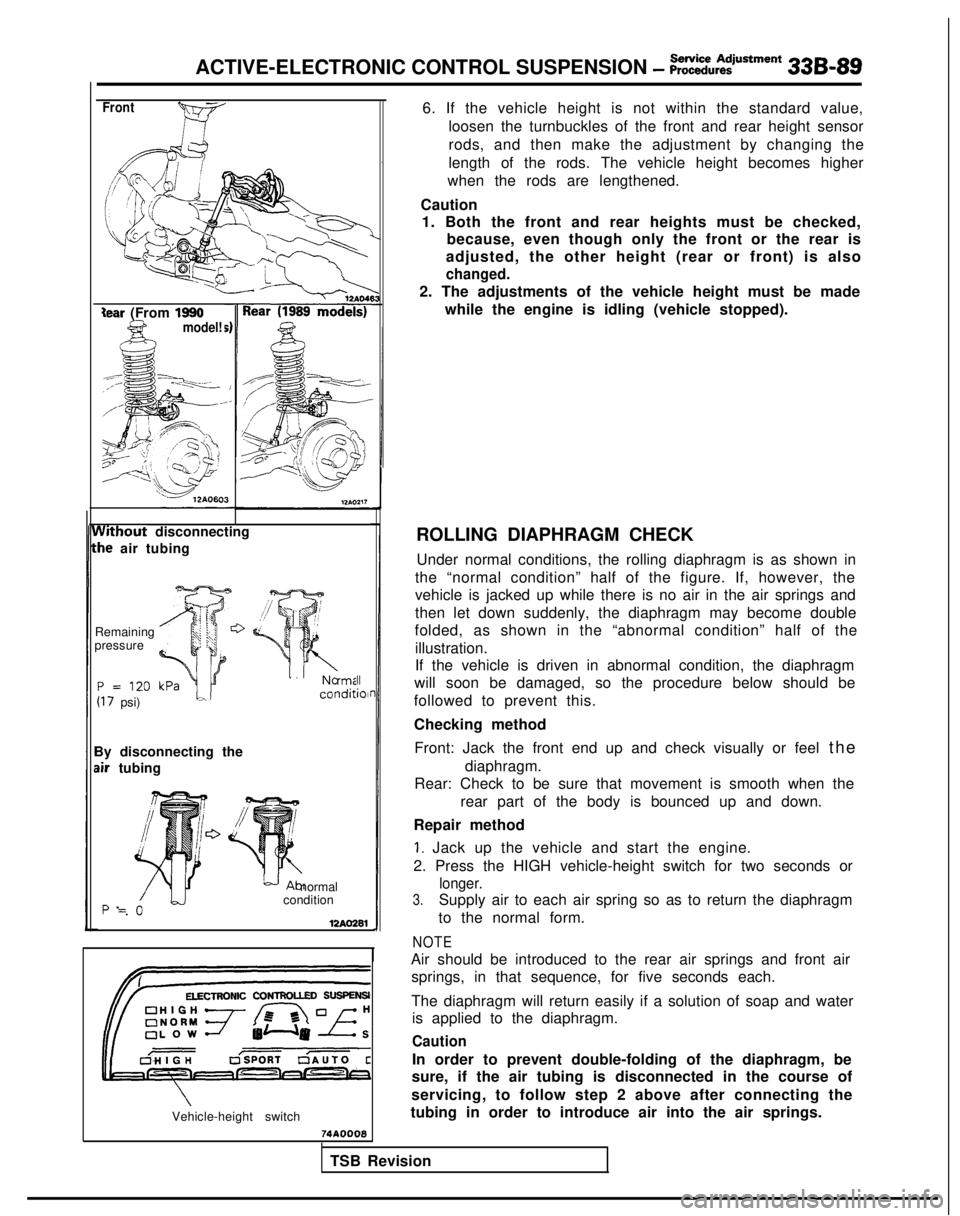

Without

disconnecting

:he air tubing

Remaining

pressure

P =

120 kPa

(17 psi)

By disconnecting the

fir tubing

normal

condition

P ‘=.0

Front

tear (From 1990

model!

rmzIIconditlui

12AO281

Vehicle-height switch 6. If the vehicle height is not within the standard value,

loosen the turnbuckles of the front and rear height sensor

rods, and then make the adjustment by changing the

length of the rods. The vehicle height becomes higher

when the rods are lengthened.

Caution 1. Both the front and rear heights must be checked, because, even though only the front or the rear is

adjusted, the other height (rear or front) is also

changed.

2. The adjustments of the vehicle height must be made

while the engine is idling (vehicle stopped).

ROLLING DIAPHRAGM CHECK Under normal conditions, the rolling diaphragm is as shown in

the “normal condition” half of the figure. If, however, the

vehicle is jacked up while there is no air in the air springs and

then let down suddenly, the diaphragm may become double

folded, as shown in the “abnormal condition” half of the

illustration.

If the vehicle is driven in abnormal condition, the diaphragm

will soon be damaged, so the procedure below should be

followed to prevent this.

Checking method

Front: Jack the front end up and check visually or feel th

e

diaphragm.

Rear: Check to be sure that movement is smooth when the

rear part of the body is bounced up and down.

Repair method

1. Jack up the vehicle and start the engine.

2. Press the HIGH vehicle-height switch for two seconds or

longer.

3.Supply air to each air spring so as to return the diaphragm

to the normal form.

NOTE

Air should be introduced to the rear air springs and front air springs, in that sequence, for five seconds each.

The diaphragm will return easily if a solution of soap and water is applied to the diaphragm.

Caution

In order to prevent double-folding of the diaphragm, be

sure, if the air tubing is disconnected in the course of

servicing, to follow step 2 above after connecting the

tubing in order to introduce air into the air springs.

74AOOQ8

TSB Revision

Page 1029 of 1273

33B-90 ACTIVE-ELECTRONIC CONTROL SUSPENSION - i?:~i~:i@~~=“~

With vehicle speed simulatorClip attachment

posltion

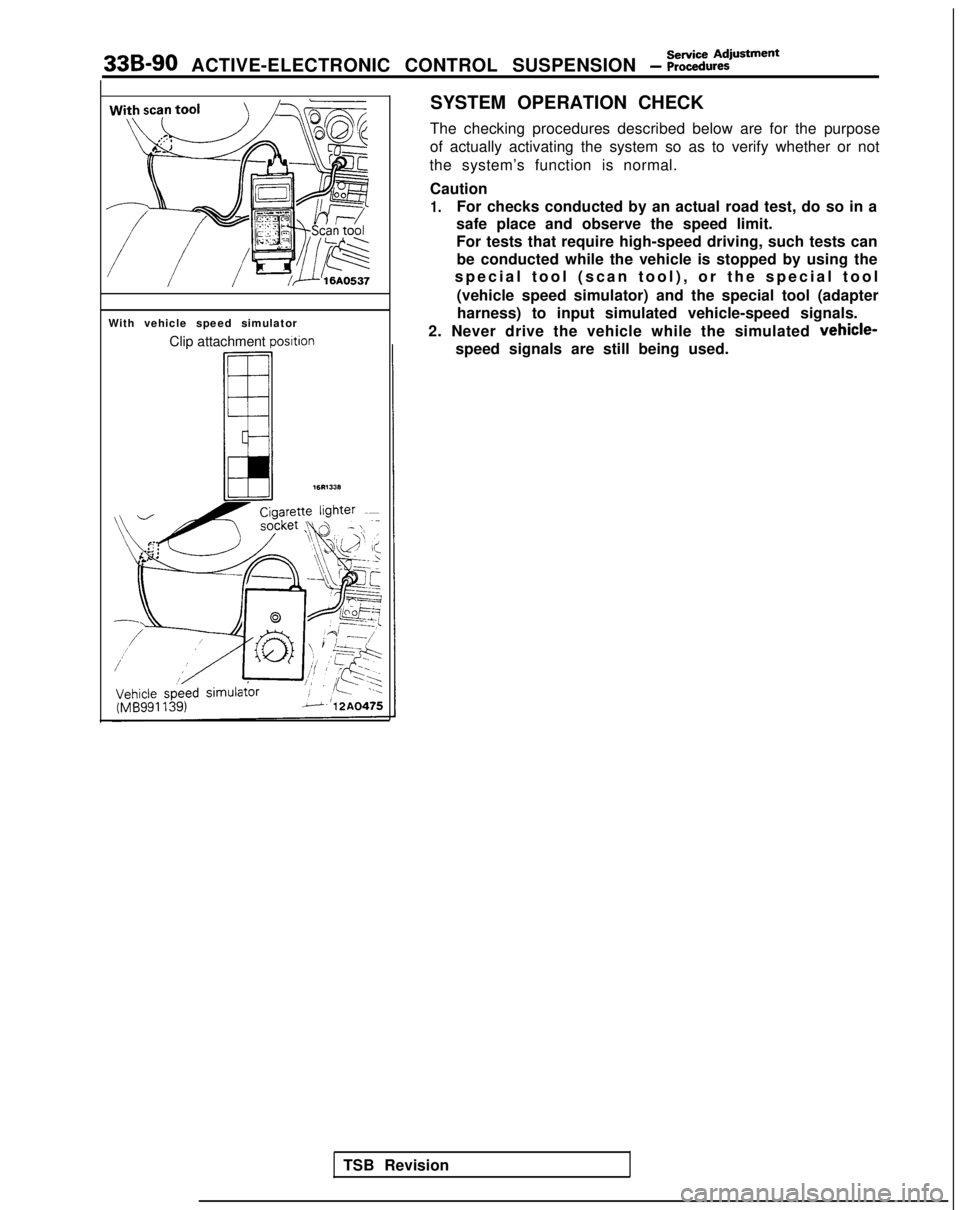

SYSTEM OPERATION CHECK

The checking procedures described below are for the purpose

of actually activating the system so as to verify whether or not

the system’s function is normal.

Caution

1.For checks conducted by an actual road test, do so in a

safe place and observe the speed limit.

For tests that require high-speed driving, such tests can

be conducted while the vehicle is stopped by using the

special tool (scan tool), or the special too

l

(vehicle speed simulator) and the special tool (adapter harness) to input simulated vehicle-speed signals.

2. Never drive the vehicle while the simulated

vehicle-

speed signals are still being used.

TSB Revision

Page 1030 of 1273

ACTIVE-ELECTRONIC CONTROL SUSPENSION - %ii%:justment 33B-91

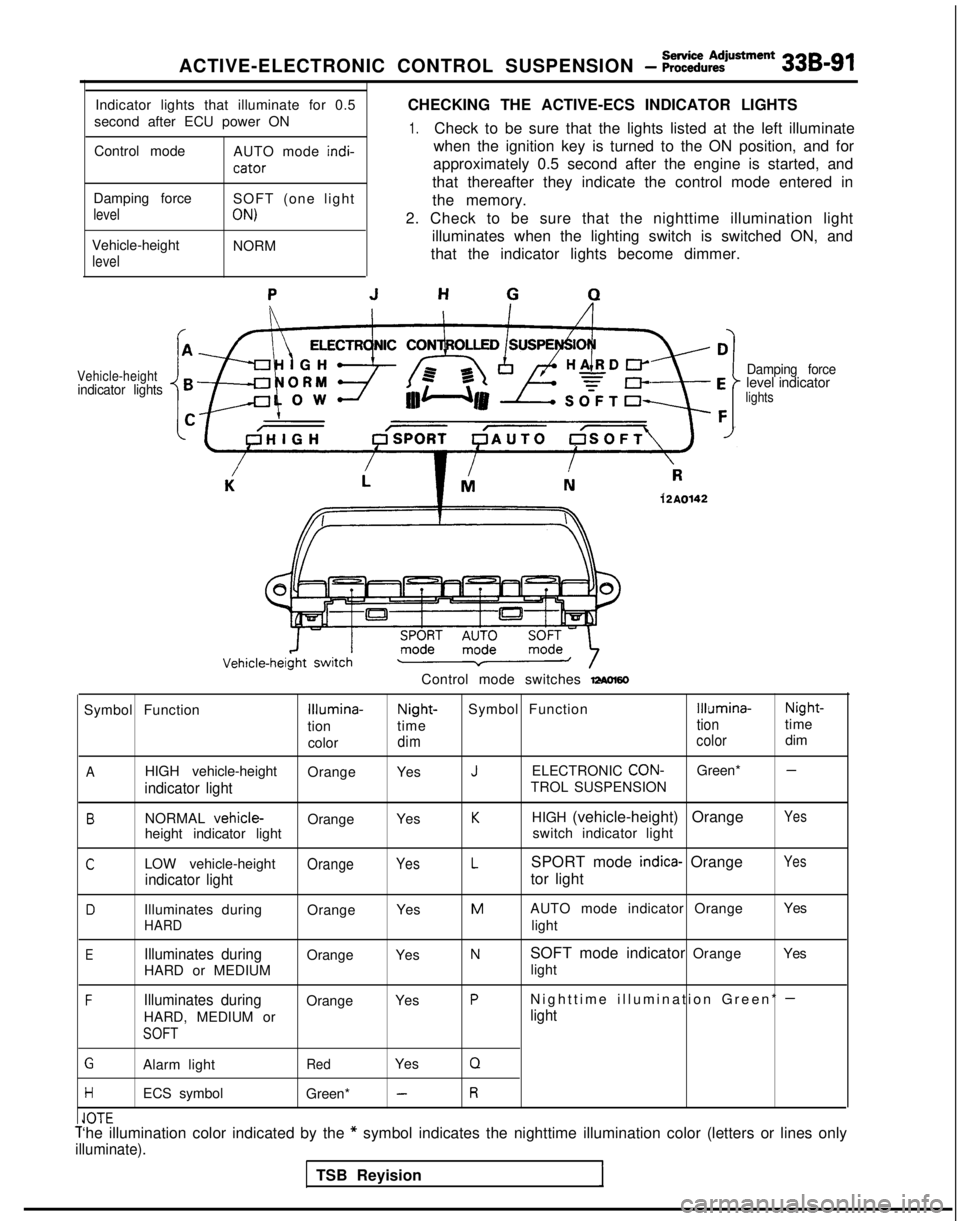

Indicator lights that illuminate for 0.5

second after ECU power ON

Control mode AUTO mode indi-

cator

CHECKING THE ACTIVE-ECS INDICATOR LIGHTS

1.Check to be sure that the lights listed at the left illuminate

when the ignition key is turned to the ON position, and for

approximately 0.5 second after the engine is started, and

that thereafter they indicate the control mode entered in

Damping force

level

Vehicle-height

level

SOFT (one light

ON)

NORM the memory.

2. Check to be sure that the nighttime illumination light illuminates when the lighting switch is switched ON, and

that the indicator lights become dimmer.

Vehicle-heightindicator lights Damping forcelevel indicatorlights

12A0142

Control mode switches -60

Symbol FunctionIllumina-Night-

Symbol FunctionIllumina- Night-

tion time

tiontime

color

dim colordim

AHIGH vehicle-height

OrangeYesJELECTRONIC CON-Green* -

indicator lightTROL SUSPENSION

BNORMAL vehicle-OrangeYesKHIGH (vehicle-height) OrangeYes

height indicator light switch indicator light

CLOW vehicle-heightOrangeYesLSPORT mode indica- OrangeYes

indicator lighttor light

DIlluminates during

OrangeYesMAUTO mode indicator Orange Yes

HARDlight

EIlluminates duringOrange

YesNSOFT mode indicator Orange Yes

HARD or MEDIUM light

FIlluminates duringOrange

YesPNighttime illumination Green* -

HARD, MEDIUM orlight

SOFT

GAlarm lightRedYesQ

HECS symbol

Green* -R

IA-r-Cl”lCT‘he illumination color indicated by the * symbol indicates the nighttime illumination color (letters or lines on\

ly

illuminate).

TSB Reyision