MITSUBISHI GALANT 1989 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 151 of 1273

FUEL SYSTEM

13-9

r

I Connector

6FU1216

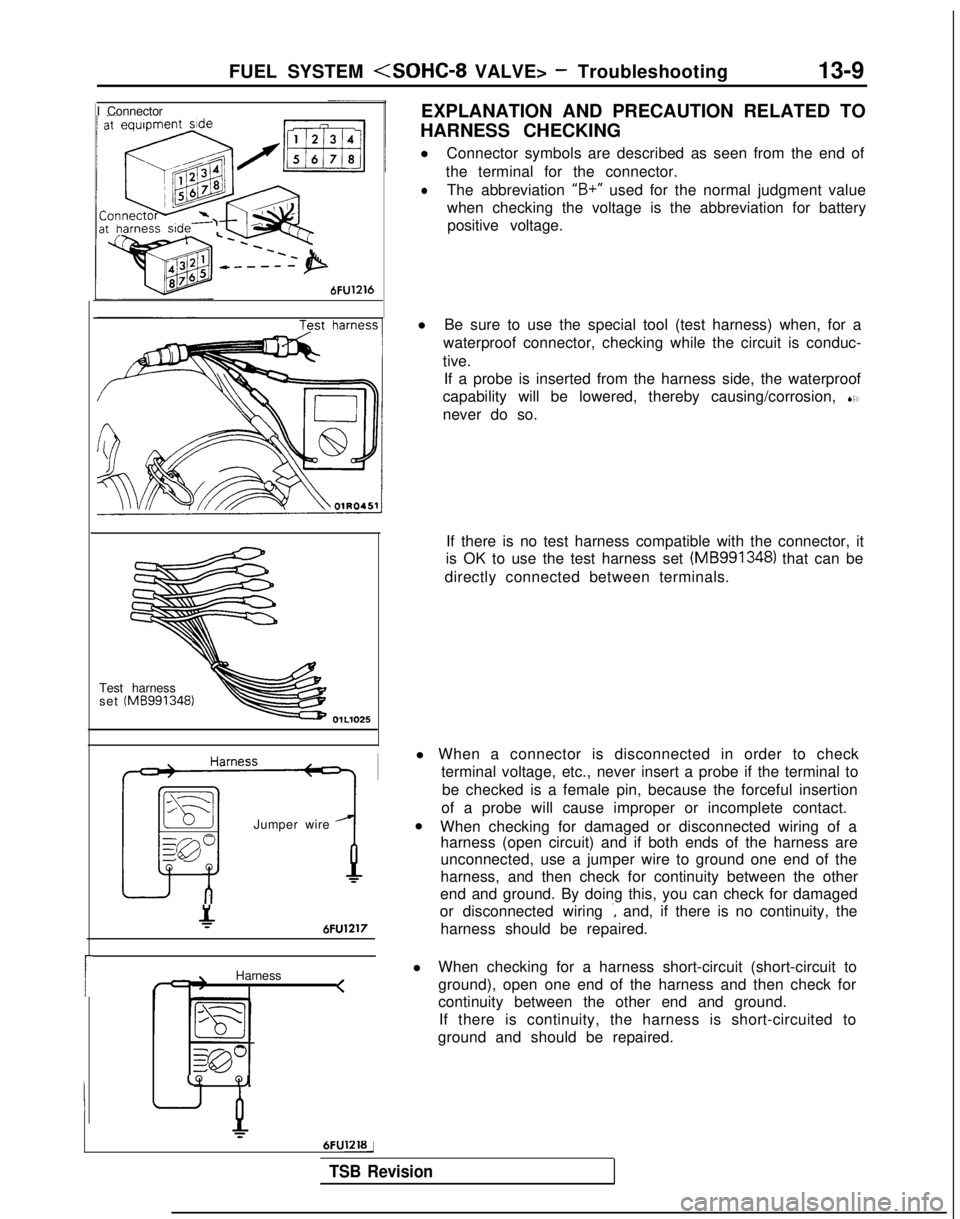

EXPLANATION AND PRECAUTION RELATED TO

HARNESS CHECKING

l Connector symbols are described as seen from the end of

the terminal for the connector.

lThe abbreviation “B+”

used for the normal judgment value

when checking the voltage is the abbreviation for battery positive voltage.

Test harness

set (MB991348)

Jumper wire

&6FU1217

Harness <

LQ

Q,

6FUlZlBj

l

Be sure to use the special tool (test harness) when, for a

waterproof connector, checking while the circuit is conduc-

tive. If a probe is inserted from the harness side, the waterproof

capability will be lowered, thereby causing/corrosion, SO

never do so.

If there is no test harness compatible with the connector, it

is OK to use the test harness set (MB991348)

that can be

directly connected between terminals.

l When a connector is disconnected in order to check terminal voltage, etc., never insert a probe if the terminal to

be checked is a female pin, because the forceful insertion

of a probe will cause improper or incomplete contact.

l When checking for damaged or disconnected wiring of a

harness (open circuit) and if both ends of the harness are

unconnected, use a jumper wire to ground one end of the

harness, and then check for continuity between the other

end and ground. By doing this, you can check for damaged

or disconnected wiring

., and, if there is no continuity, the

harness should be repaired.

l When checking for a harness short-circuit (short-circuit to

ground), open one end of the harness and then check for

continuity between the other end and ground.

If there is continuity, the harness is short-circuited to

ground and should be repaired.

TSB Revision

Page 152 of 1273

13-10

FUEL SYSTEM

at sensor side

1\~“‘,““W,O,’ ‘\*N 4-cnDQ5a,, \llllf,,

c 3 c-11 ‘.<-!

( .[&

;%* \ g ~ &.$$~&%,;

0%: E

.Oj-,,

giI lOWI -,n

/ ~ ( ~~‘-~~~

-.mo .u. m,.0 - rj*> ;;

indicator lamp68AOO93

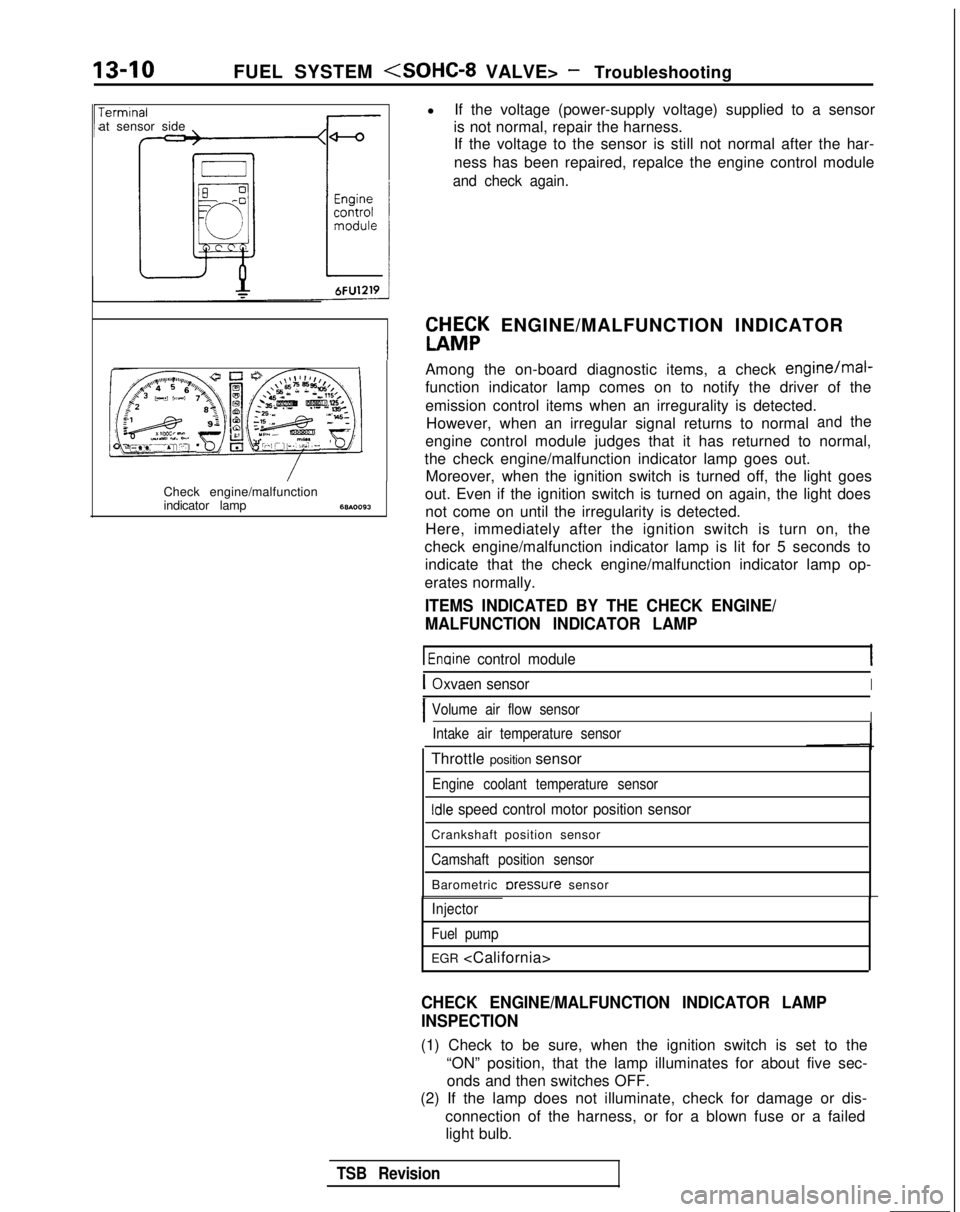

l

If the voltage (power-supply voltage) supplied to a sensor

is not normal, repair the harness. If the voltage to the sensor is still not normal after the har-

ness has been repaired, repalce the engine control module

and check again.

W&K ENGINE/MALFUNCTION INDICATOR

Among the on-board diagnostic items, a check

engine/mal-

function indicator lamp comes on to notify the driver of the

emission control items when an irregurality is detected. However, when an irregular signal returns to normal

andthe

engine control module judges that it has returned to normal,

the check engine/malfunction indicator lamp goes out. Moreover, when the ignition switch is turned off, the light goes

out. Even if the ignition switch is turned on again, the light does not come on until the irregularity is detected.

Here, immediately after the ignition switch is turn on, the

check engine/malfunction indicator lamp is lit for 5 seconds to indicate that the check engine/malfunction indicator lamp op-

erates normally.

ITEMS INDICATED BY THE CHECK ENGINE/

MALFUNCTION INDICATOR LAMP

1 Enaine control module

IOxvaen sensorI

IVolume air flow sensorIIntake air temperature sensor

Throttle position sensor

Engine coolant temperature sensor

Idle speed control motor position sensor

Crankshaft position sensor

Camshaft position sensor

Barometric rxessure sensor

Injector

Fuel pump

EGR

CHECK ENGINE/MALFUNCTION INDICATOR LAMP

INSPECTION

(1) Check to be sure, when the ignition switch is set to the “ON” position, that the lamp illuminates for about five sec-onds and then switches OFF.

(2) If the lamp does not illuminate, check for damage or dis-

connection of the harness, or for a blown fuse or a failedlight bulb.

TSB Revision

Page 153 of 1273

FUEL SYSTEM

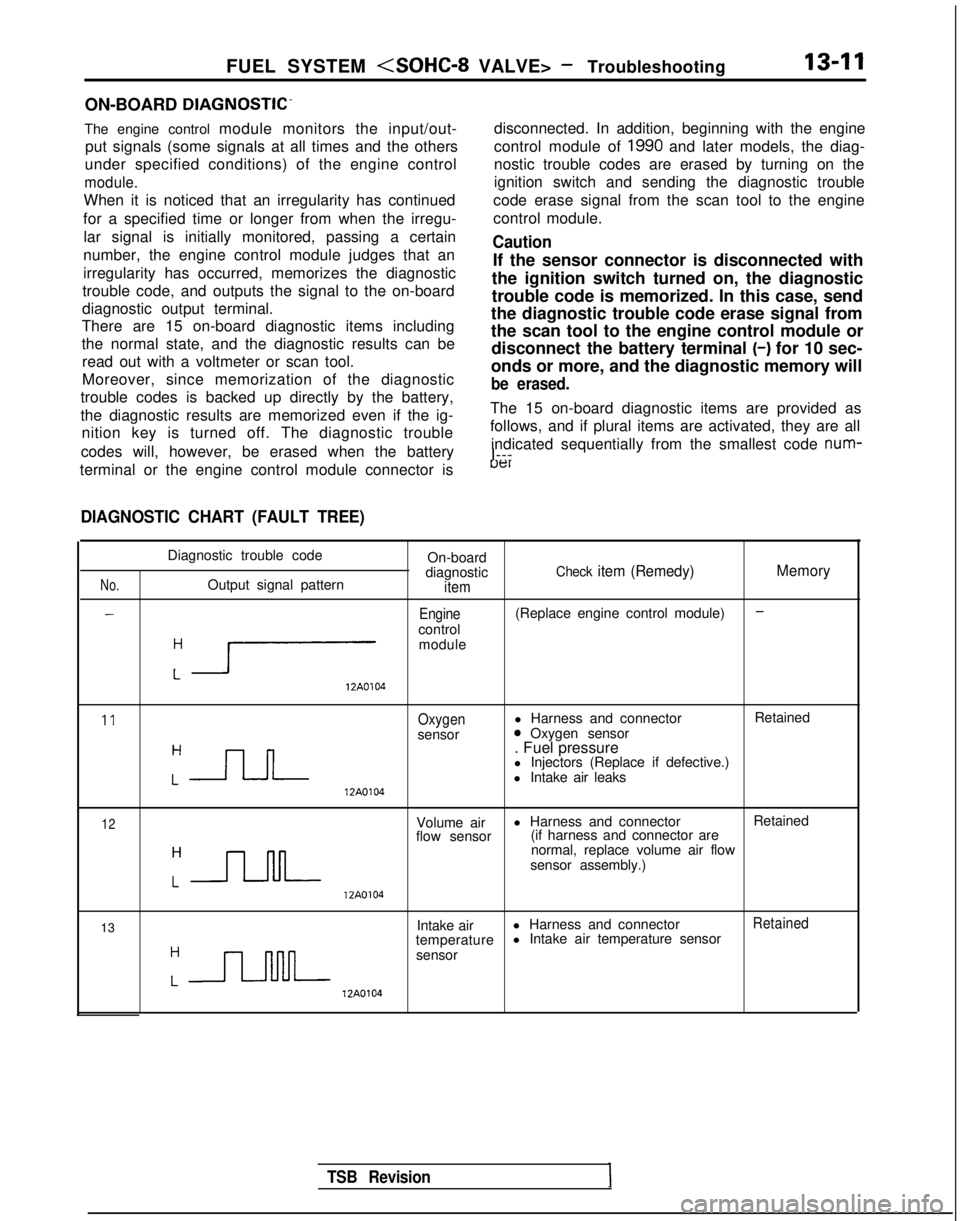

ON-BOARD DIAGNOSTIC-

The engine control module monitors the input/out-

put signals (some signals at all times and the others

under specified conditions) of the engine control

module.

When it is noticed that an irregularity has continued

for a specified time or longer from when the irregu- lar signal is initially monitored, passing a certain

number, the engine control module judges that an

irregularity has occurred, memorizes the diagnostic

trouble code, and outputs the signal to the on-board

diagnostic output terminal.

There are 15 on-board diagnostic items including

the normal state, and the diagnostic results can be

read out with a voltmeter or scan tool.

Moreover, since memorization of the diagnostic

trouble codes is backed up directly by the battery,

the diagnostic results are memorized even if the ig- nition key is turned off. The diagnostic trouble

codes will, however, be erased when the battery disconnected. In addition, beginning with the engine

control module of

1990 and later models, the diag-

nostic trouble codes are erased by turning on the

ignition switch and sending the diagnostic trouble

code erase signal from the scan tool to the engine

control module.

Caution

If the sensor connector is disconnected with

the ignition switch turned on, the diagnostic

trouble code is memorized. In this case, send

the diagnostic trouble code erase signal from

the scan tool to the engine control module or disconnect the battery terminal (-)

for 10 sec-

onds or more, and the diagnostic memory will

be erased.

The 15 on-board diagnostic items are provided as

follows, and if plural items are activated, they are all

indicated sequentially from the smallest code num-

I---

terminal or the engine control module connector is

uer

DIAGNOSTIC CHART (FAULT TREE)

No.

-

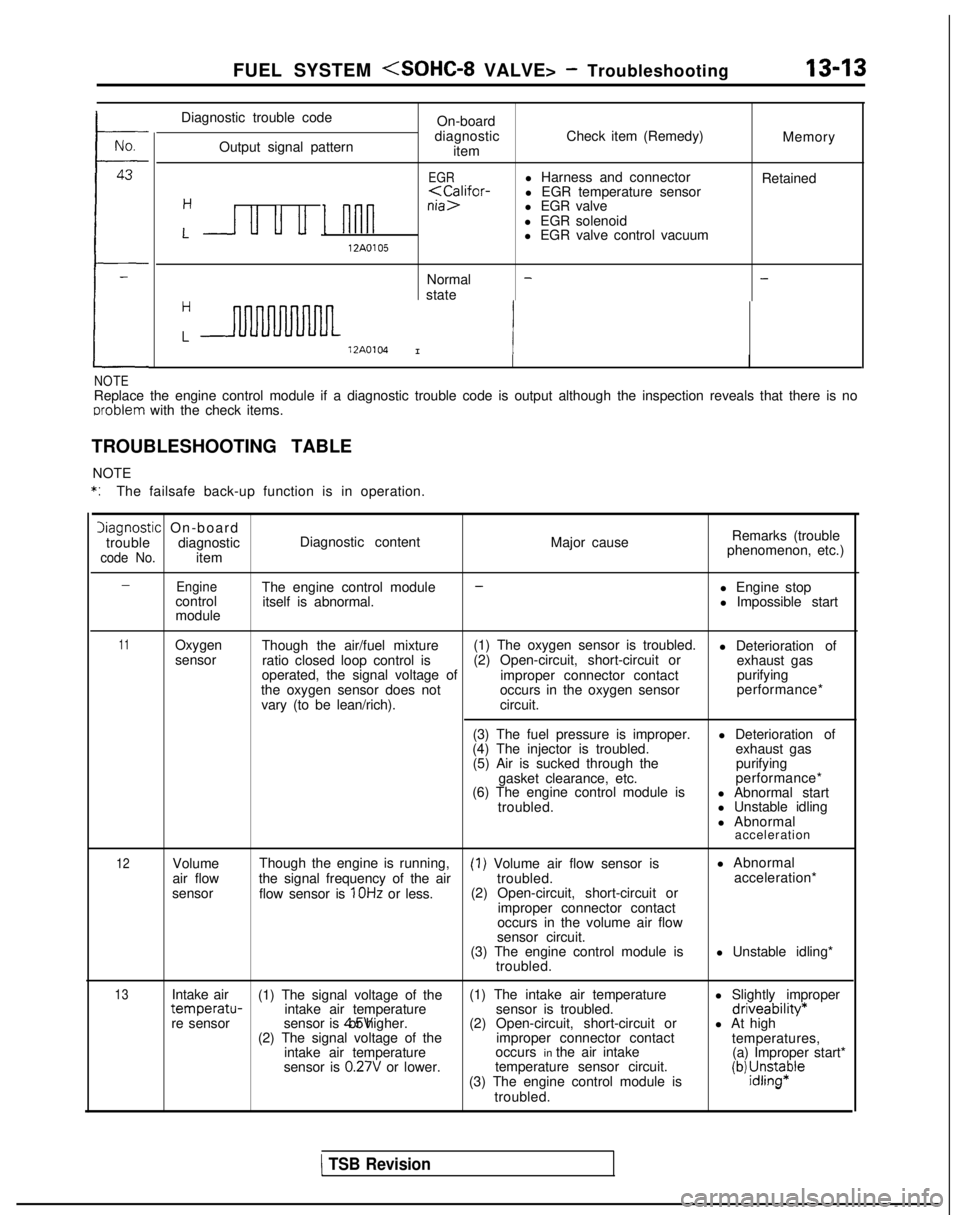

Diagnostic trouble code On-board

diagnostic

Check item (Remedy) MemoryOutput signal patternitem

-Engine(Replace engine control module)

control

:r

module 12A0104

11Oxygenl Harness and connector

Retained

sensor0 Oxygen sensor

:-JLJ--

. Fuel pressure

l Injectors (Replace if defective.)

l Intake air leaks 12A0104

12Volume air

l Harness and connector

Retained

flow sensor (if harness and connector are

:-JJ-M-

normal, replace volume air flow

sensor assembly.) 12A0104

13 Intake air

l Harness and connector

Retained

temperature l Intake air temperature sensor

:n

sensor 12A0104

TSB Revision

Page 154 of 1273

13-12

FUEL SYSTEM

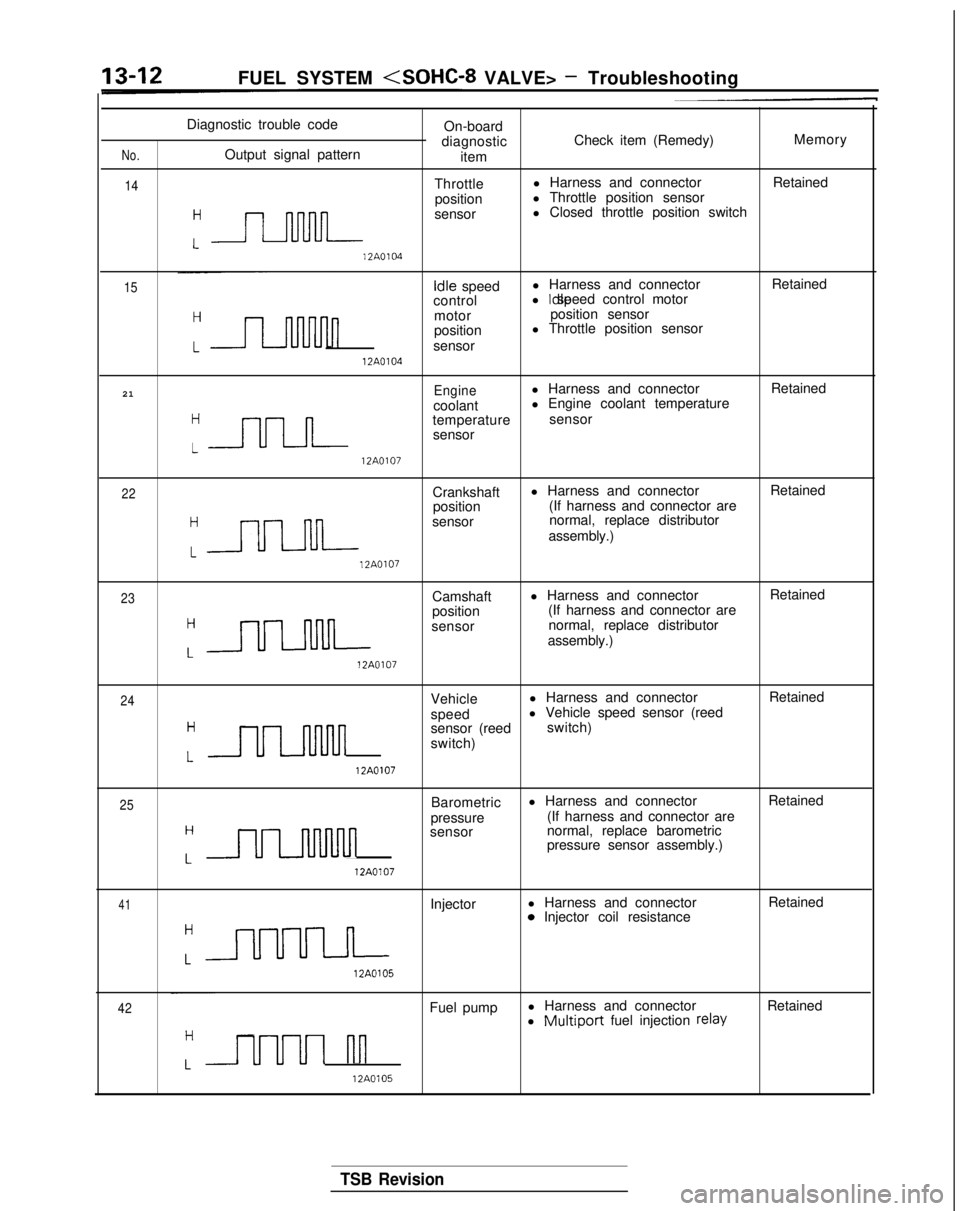

No.

14

Diagnostic trouble code

On-board

diagnostic Check item (Remedy)

Memory

Output signal pattern item

Throttle l Harness and connector

Retained

position l Throttle position sensor

:-

sensor l Closed throttle position switch 12A0104

15

Idle

speed l Harness and connector

Retained

control l Idle speed control motor

n

motor

position sensor

position l Throttle position sensor

sensor 12A0104

21

Enginel Harness and connector Retained

coolant l Engine coolant temperature

“=

temperature

sensor

sensor 12A0107

22Crankshaft

l Harness and connector

Retained

position (If harness and connector are

:-

sensor normal, replace distributor

assembly.) 12A0107

23Camshaft

l Harness and connector

Retained

position (If harness and connector are

:=

sensor normal, replace distributor

assembly.) 12A0107

24Vehicle

l Harness and connector

Retained

speed l Vehicle speed sensor (reed

H

uulnnn

sensor (reed

switch)

switch)

L 12A0107

25Barometric

l Harness and connector

Retained

pressure (If harness and connector are

H

ULnMnn

sensor

normal, replace barometric

pressure sensor assembly.)

L 12A0107

41Injector

l Harness and connector

Retained0 Injector coil resistance

:a 12A0105

42Fuel pump

l Harness and connector

Retained

l Multiport fuel injection relay

Luuul nn

12A0105

TSB Revision

Page 155 of 1273

FUEL SYSTEM

No.

43

4

-

Diagnostic trouble code

Output signal pattern On-board

diagnostic item Check item (Remedy)

Memory

EGRl Harness and connector

Retained

l EGR solenoid

L u u u I nnnl EGR valve control vacuum12A0105

Normal -state

-

H

L12A0104I 1

NOTEReplace the engine control module if a diagnostic trouble code is output\

although the inspection reveals that there is no

oroblem

with the check items.

TROUBLESHOOTING TABLE NOTE

*:The failsafe back-up function is in operation.

Diagnostic On-board

trouble diagnostic Diagnostic content

code No.item Major cause

Remarks (trouble

phenomenon, etc.)

-EngineThe engine control module-l Engine stop

control itself is abnormal. l Impossible start

module

11Oxygen Though the air/fuel mixture (1) The oxygen sensor is troubled.

l Deterioration of

sensor ratio closed loop control is (2) Open-circuit, short-circuit or

exhaust gas

operated, the signal voltage of improper connector contactpurifying

the oxygen sensor does not occurs in the oxygen sensorperformance*

vary (to be lean/rich). circuit.

(3) The fuel pressure is improper. l Deterioration of

(4) The injector is troubled. exhaust gas

(5) Air is sucked through the purifying

gasket clearance, etc. performance*

(6) The engine control module is l Abnormal start

troubled. l Unstable idling

l Abnormal

acceleration

12Volume

air flow

sensor Though the engine is running,(I) Volume air flow sensor is

l Abnormal

the signal frequency of the air troubled.acceleration*

flow sensor is

1 OHz or less. (2) Open-circuit, short-circuit or

improper connector contact

occurs in the volume air flow

sensor circuit.

(3) The engine control module is l Unstable idling*

troubled.

13Intake air (1) The signal voltage of the (1) The intake air temperature

l Slightly impropertemperatu-intake air temperaturesensor is troubled.driveability*re sensorsensor is 4.5V or higher.

(2) Open-circuit, short-circuit or l At high

(2) The signal voltage of the improper connector contact

temperatures,

intake air temperature occurs in the air intake

(a) Improper start*

sensor is

0.27V or lower. temperature sensor circuit.

(3) The engine control module is(b) ;J;pe

troubled.

1 TSB Revision

Page 156 of 1273

13-14

FUEL SYSTEM

Iiagnostic On-boar

d

trouble diagnostic Diagnostic content Major causeRemarks (trouble

phenomenon, etc.)

code No. item

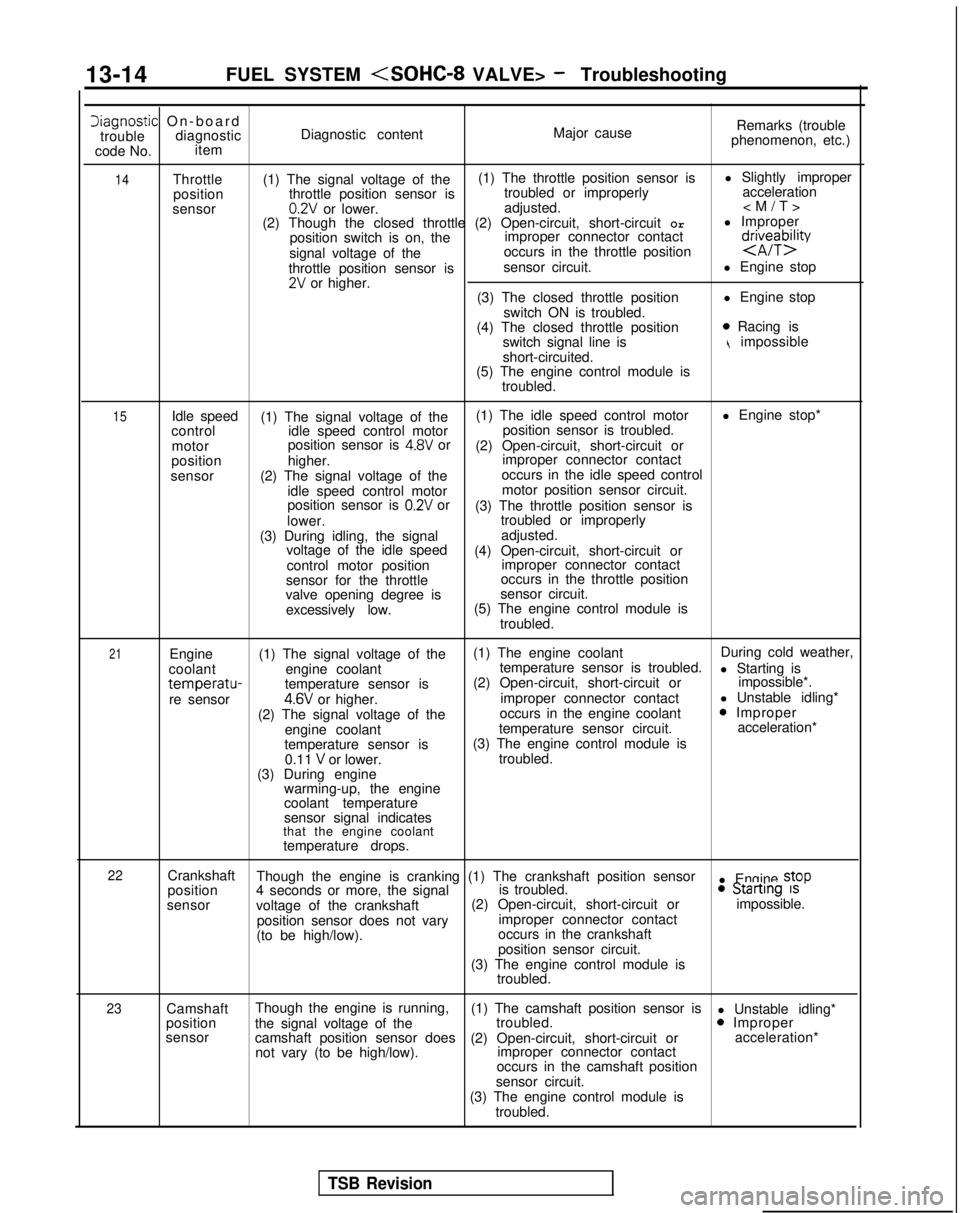

14Throttle

(1) The signal voltage of the (1) The throttle position sensor is

l Slightly improper

position throttle position sensor is troubled or improperly

acceleration

sensor

0.2V or lower. adjusted.

(2) Though the closed throttle (2) Open-circuit, short-circuit Orl Improper

position switch is on, the improper connector contact

signal voltage of the occurs in the throttle position

d$eybzty

throttle position sensor is

sensor circuit.

l Engine stop2V or higher.

(3) The closed throttle position l Engine stop

switch ON is troubled.

(4) The closed throttle position

0 Racing is

switch signal line ist impossible

short-circuited.

(5) The engine control module is

troubled.

15Idle speed (1) The signal voltage of the (1) The idle speed control motor

l Engine stop*

control idle speed control motor position sensor is troubled.

motor position sensor is

4.8V or

(2) Open-circuit, short-circuit or

position higher. improper connector contact

sensor (2) The signal voltage of the occurs in the idle speed control

idle speed control motor motor position sensor circuit.

position sensor is

0.2V or (3) The throttle position sensor is

lower. troubled or improperly

(3) During idling, the signal adjusted.

voltage of the idle speed (4) Open-circuit, short-circuit or

control motor position improper connector contact

sensor for the throttle occurs in the throttle position

valve opening degree is sensor circuit.

excessively low. (5) The engine control module is

troubled.

21Engine (1) The signal voltage of the (1) The engine coolant

During cold weather,

coolant engine coolant temperature sensor is troubled.

l Starting is

temperatu-temperature sensor is(2) Open-circuit, short-circuit or

impossible*.

re sensor4.6V or higher. improper connector contact

l Unstable idling*

(2) The signal voltage of the occurs in the engine coolant0 Improper

engine coolant temperature sensor circuit. acceleration*

temperature sensor is (3) The engine control module is

0.11

V or lower. troubled.

(3) During engine warming-up, the engine

coolant temperature

sensor signal indicates

that the engine coolant

temperature drops.

22Crankshaft Though the engine is cranking (1) The crankshaft position sensor

l Engine stop

position 4 seconds or more, the signal is troubled.0 Startrng 1s

sensor

voltage of the crankshaft (2) Open-circuit, short-circuit or

impossible.

position sensor does not vary improper connector contact

(to be high/low). occurs in the crankshaft

position sensor circuit.

(3) The engine control module is troubled.

23Camshaft Though the engine is running,

(1) The camshaft position sensor is

l Unstable idling*

position the signal voltage of the troubled.0 Improper

sensor camshaft position sensor does (2) Open-circuit, short-circuit or acceleration*

not vary (to be high/low). improper connector contact

occurs in the camshaft position

sensor circuit.

(3) The engine control module is troubled.

TSB Revision

Page 157 of 1273

FUEL SYSTEM

Diagnosti

trouble

code No.

24

25

41

42Set pump

43

iGR;aC;lifor-

COn-board

diagnostic

item

Vehicle

speed

sensor

(reed

switch) 3arometric

Iressuresensor

njector

Diagnostic content

Major cause

During acceleration of engine

revolution speed of 3,000 rpm

or more, the signal voltage of

the vehicle speed sensor doe: not vary (to be high/low). (1) The vehicle speed sensor is

troubled.

(2) Open-circuit, short-circuit or

improper connector contact

occurs in the vehicle speed

sensor circuit.

(1) The signal voltage of the barometric pressure

sensor is 4.5V or higher.

(2) The signal voltage of the barometric pressure

sensor is

0.2V or lower.

Injector is not continuously

driven for 4 seconds during

engine cranking or idle

operation.

The engine runs but power to

irive the motor is not supplied

:o the fuel pump.

luring engine running after Narming-up,

1) The

EGR amount is small.

(The signal voltage of the EGR temperature sensor

is excessively high.)

2) The signal voltage of the

EGR temperature sensor

is 0.1 V or less.

(3) The engine control module is troubled.

1) The barometric pressure sense

is troubled.

2) Open-circuit, short-circuit or

improper connector contact

occurs in the barometric pressure sensor circuit.

‘3) The engine control module is

troubled.

‘1) The injector is troubled.

12) Open-circuit, short-crrcuit

or

improper connector contact

occurs in the injector sensor

circuit.

13) The engine control module is

troubled.

:I) Open-circuit, short-circuit or improper connector contact

occurs in the fuel pump power

supply circuit.

(2) The

multiport fuel injection

relay is troubled.

(3) The engine control module is

troubled.

(1) The EGR valve is not opened.

(2) The negative pressure of the EGR valve control is excessively

(3)

?h”e EGR solenoid is troubled.

(4) The EGR temperature sensor is

troubled.

(5) Open-circuit, short-circuit or

improper connector contact

occurs in the EGR temperature

sensor circuit.

(6) The engine control module is troubled.

r 1l Unstable idling*

l Improper acceleration*

0 Improper start*

l Unstable idling

0 Improper acceleration

0 Improper start

l Impossible start

3 Engine stop4

4

,

B Deterioration of exhaust gaspurifying

performance

Remarks (trouble

phenomenon, etc.)

The engine

sometimes cuts off

when stopping afte

deceleration.

TSB RevisionI

Page 158 of 1273

13-16

FUEL SYSTEM

FAILSAFE/BACK-UP FUNCTIONS LIST

If trouble with any major sensor is detected by the on-board diagnostic,\

the vehicle will be kept in the safe

driving conditions according to the preset control logic.

Trouble item Control content for trouble

Volume air flow Fuel injection timing and ignition timing are determined according to th\

e throttle position

sensor sensor

(TPS) and engine revolution speed signal (crankshaft position sensor signal)\

.

Intake air temperature The control is executed with the suction air temperature regarded as

25°C (77°F).

sensor

Throttle position The fuel injection rate is not increased for acceleration according to t\

he throttle position

sensor

(TPS)sensor signal.

Idle speed control After the idle speed control motor plunger is driven and contracted, the\

idle revolution speed

motor position sensor is not controlled.

Engine coolant The control is executed with the engine coolant temperature regarded as \

8OO.C (176°F).temperature sensor (Even if the sensor signal becomes normal again, the control is continued

until the ignltlon

switch is turned off.)

Camshaft position Simultaneous injection of fuel is executed for all cylinders. (In this \

case, the

No.1 cylinder top

sensor dead center is not detected at all after the ignition key is turned on.)\

Barometric pressure The control is executed with the pressure regarded as 760 mmHg

(30

in.Hg).

sensor

Oxygen sensor Closed loop control of the air/fuel mixture ratio is not executed.

i

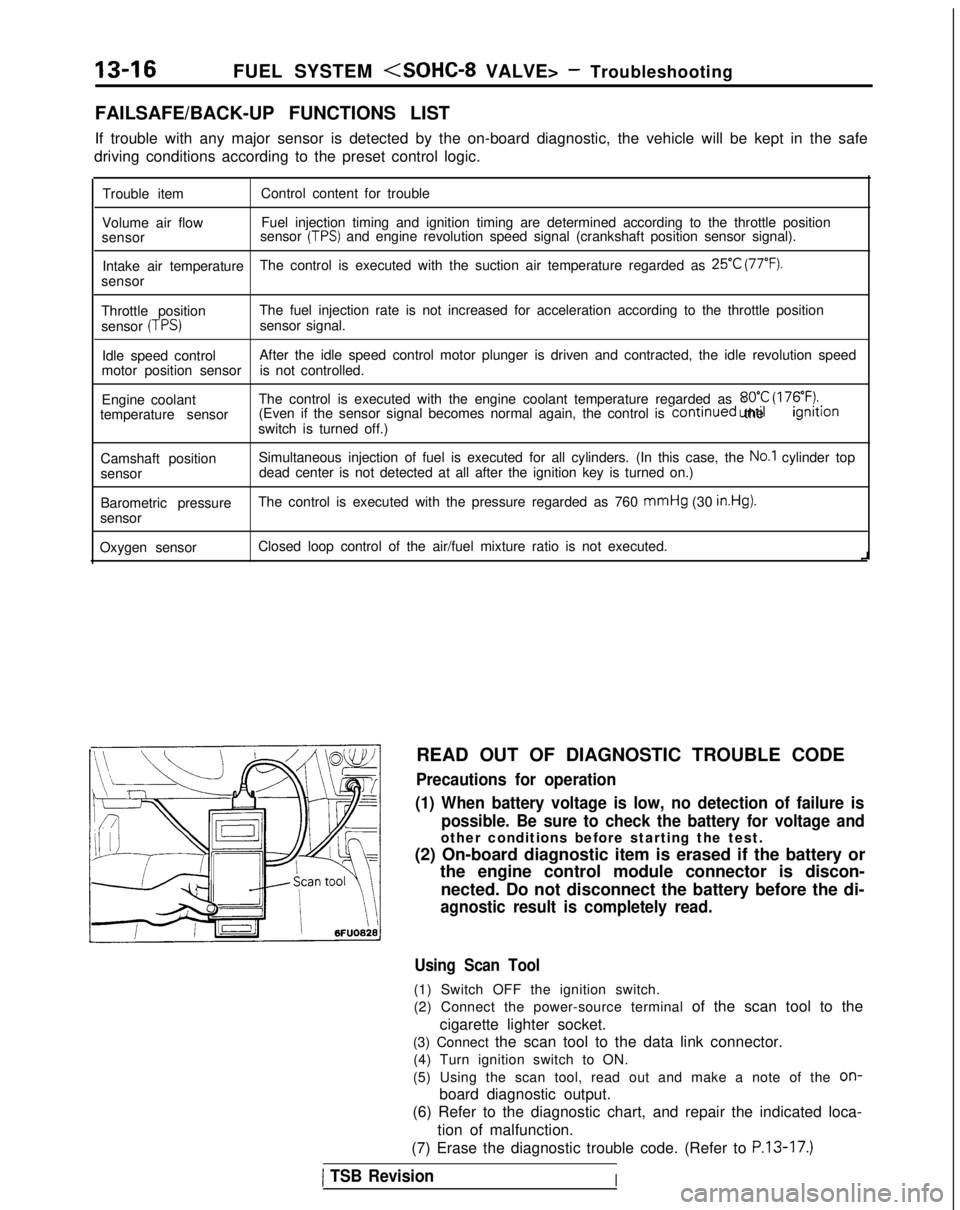

READ OUT OF DIAGNOSTIC TROUBLE CODE

Precautions for operation

(1) When battery voltage is low, no detection of failure is possible. Be sure to check the battery for voltage and

other conditions before starting the test.

(2) On-board diagnostic item is erased if the battery or the engine control module connector is discon-

nected. Do not disconnect the battery before the di-

agnostic result is completely read.

Using Scan Tool

(1) Switch OFF the ignition switch.

(2) Connect the power-source terminal of the scan tool to the

cigarette lighter socket.

(3) Connect the scan tool to the data link connector. (4) Turn ignition switch to ON.

(5) Using the scan tool, read out and make a note of the

on-

board diagnostic output.

(6) Refer to the diagnostic chart, and repair the indicated loca-

tion of malfunction.

(7) Erase the diagnostic trouble code. (Refer to

P.13-17.)

1 TSB RevisionI

Page 159 of 1273

FUEL SYSTEM

\ I\-\\\\\\6FUO807

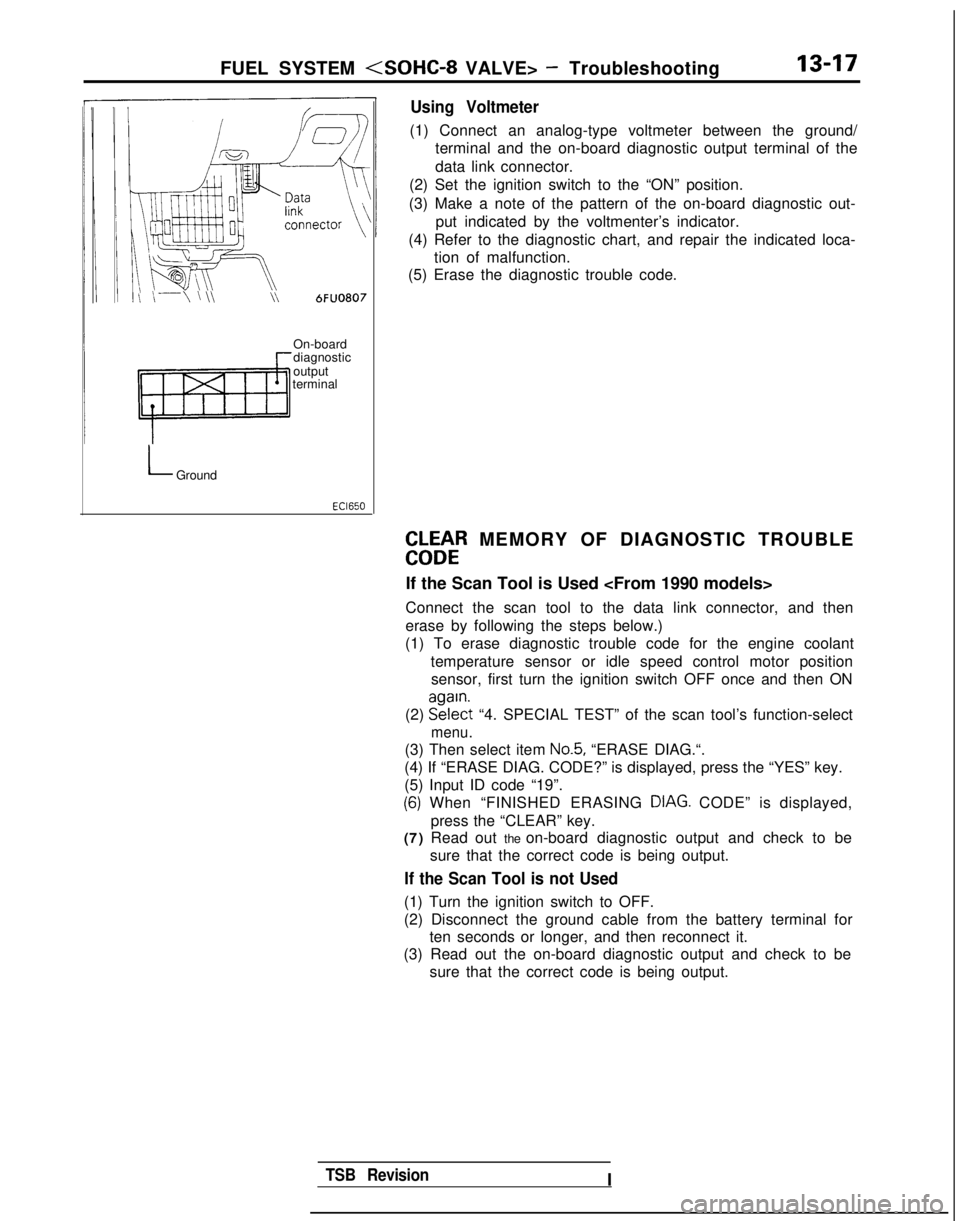

Using Voltmeter

(1) Connect an analog-type voltmeter between the ground/

terminal and the on-board diagnostic output terminal of the

data link connector.

(2) Set the ignition switch to the “ON” position.

(3) Make a note of the pattern of the on-board diagnostic out- put indicated by the voltmenter’s indicator.

(4) Refer to the diagnostic chart, and repair the indicated loca- tion of malfunction.

(5) Erase the diagnostic trouble code.

On-board

diagnostic

output

terminal

LGround

EbLbtR MEMORY OF DIAGNOSTIC TROUBLE

If the Scan Tool is Used

Connect the scan tool to the data link connector, and then

erase by following the steps below.)

(1) To erase diagnostic trouble code for the engine coolant

temperature sensor or idle speed control motor positionsensor, first turn the ignition switch OFF once and then ON

(2) EE?$t

“4. SPECIAL TEST” of the scan tool’s function-select

menu.

(3) Then select item No.5, “ERASE DIAG.“.

(4) If “ERASE DIAG. CODE?” is displayed, press the “YES” k\

ey.

(5) Input ID code “19”.

(6) When “FINISHED ERASING DIAG. CODE” is displayed,> Ipress the “CLEAR” key.

(7) Read out the on-board diagnostic output and check to be

sure that the correct code is being output.

If the Scan Tool is not Used

(1) Turn the ignition switch to OFF.

(2) Disconnect the ground cable from the battery terminal forten seconds or longer, and then reconnect it.

(3) Read out the on-board diagnostic output and check to be

sure that the correct code is being output.

TSB RevisionI

Page 160 of 1273

13-18

FUEL SYSTEM

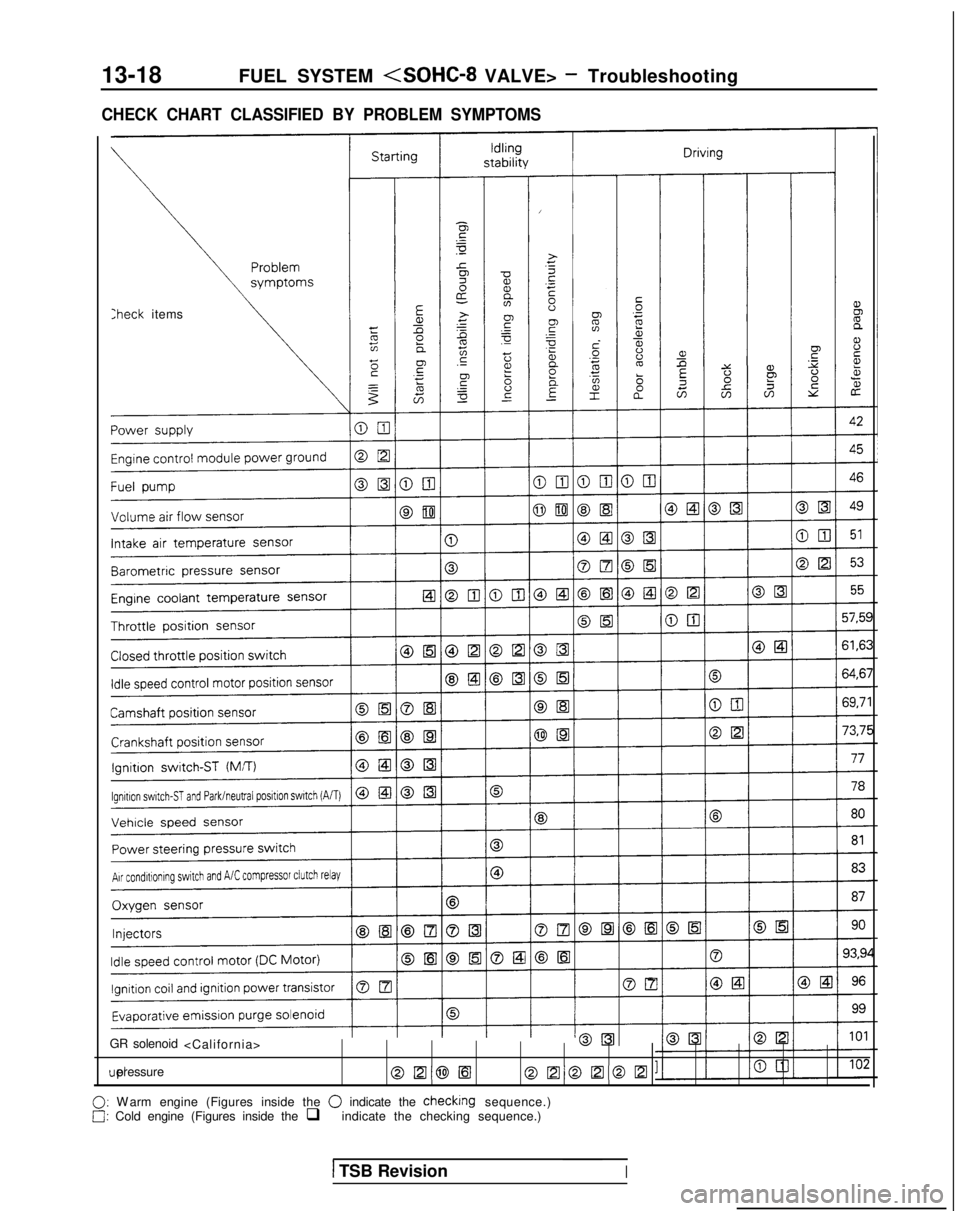

CHECK CHART CLASSIFIED BY PROBLEM SYMPTOMS

:heck items

GR solenoid

@El@lEloEloElom

0: W

arm engine (Figures inside the

0 indicate the checking sequence.)0: Cold engine (Figures inside the

q indicate the checking sequence.)

1 TSB RevisionI