MITSUBISHI GALANT 1989 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 171 of 1273

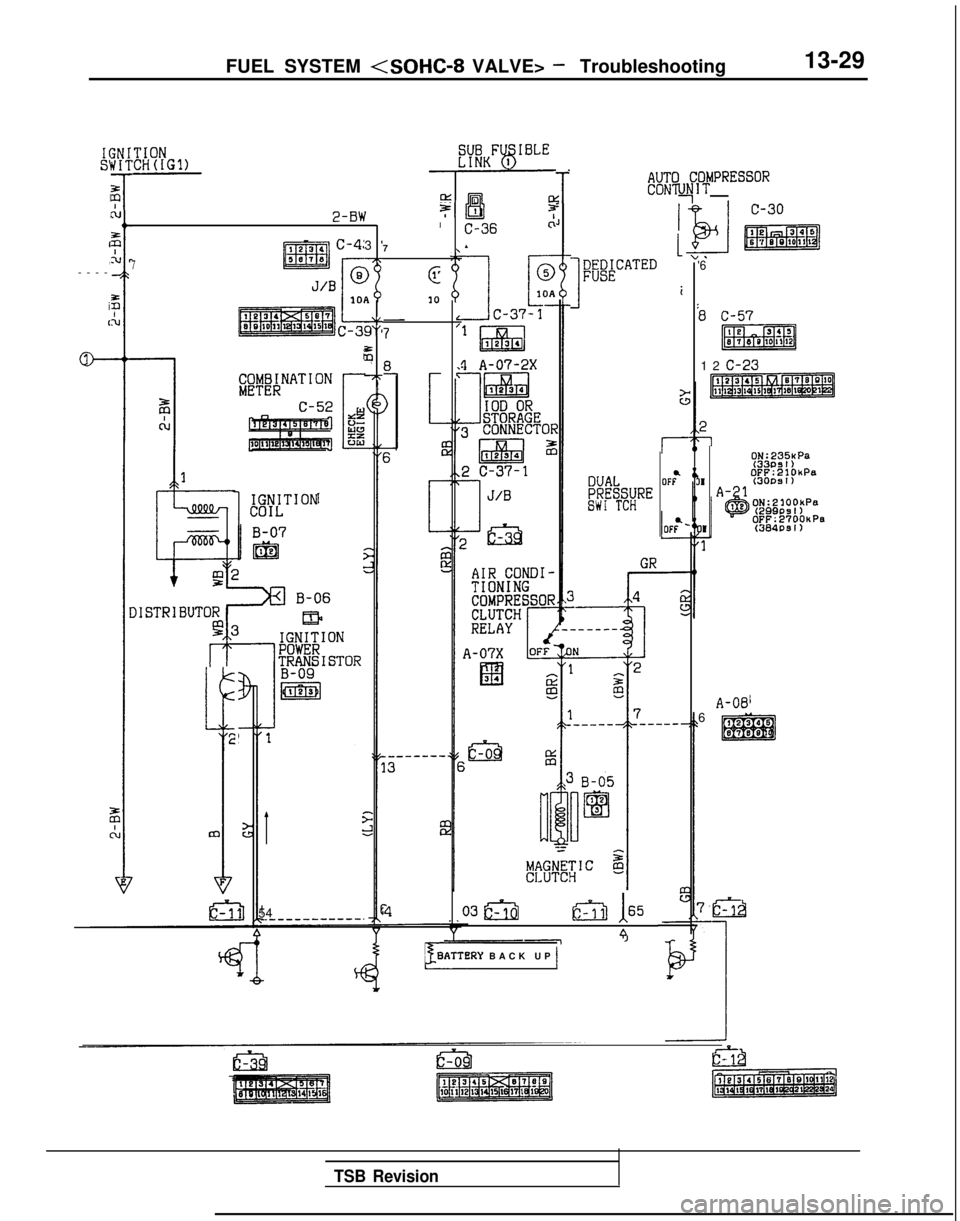

FUEL SYSTEM

13-29

;NIr(IT

zis-N2-BW?I

I

1234 c-4:3 a7

7mlss7.3 -77

J/BGi>

I

@

101RIO

2‘c-39'0

5

77

I,

r

,---

-

i

r

AUTO COMPRESSORCONTROLUYIT ITqIf3Cl36

5

c:

'61

I

!aACATEDi

b c-57

f?J%aq

12

C-23

1

IGNITIONCOIL

? A-07-2X i4

ON:235uPa

" A-21

l%M;“PaDUALOF:PRESSURESW1 TCH

2

rm

A-086

54

-.-----------.0355!j ,1165cd 4

pATTERY BACK UP )1

TSB Revision

Page 172 of 1273

13-30FUEL SYSTEM

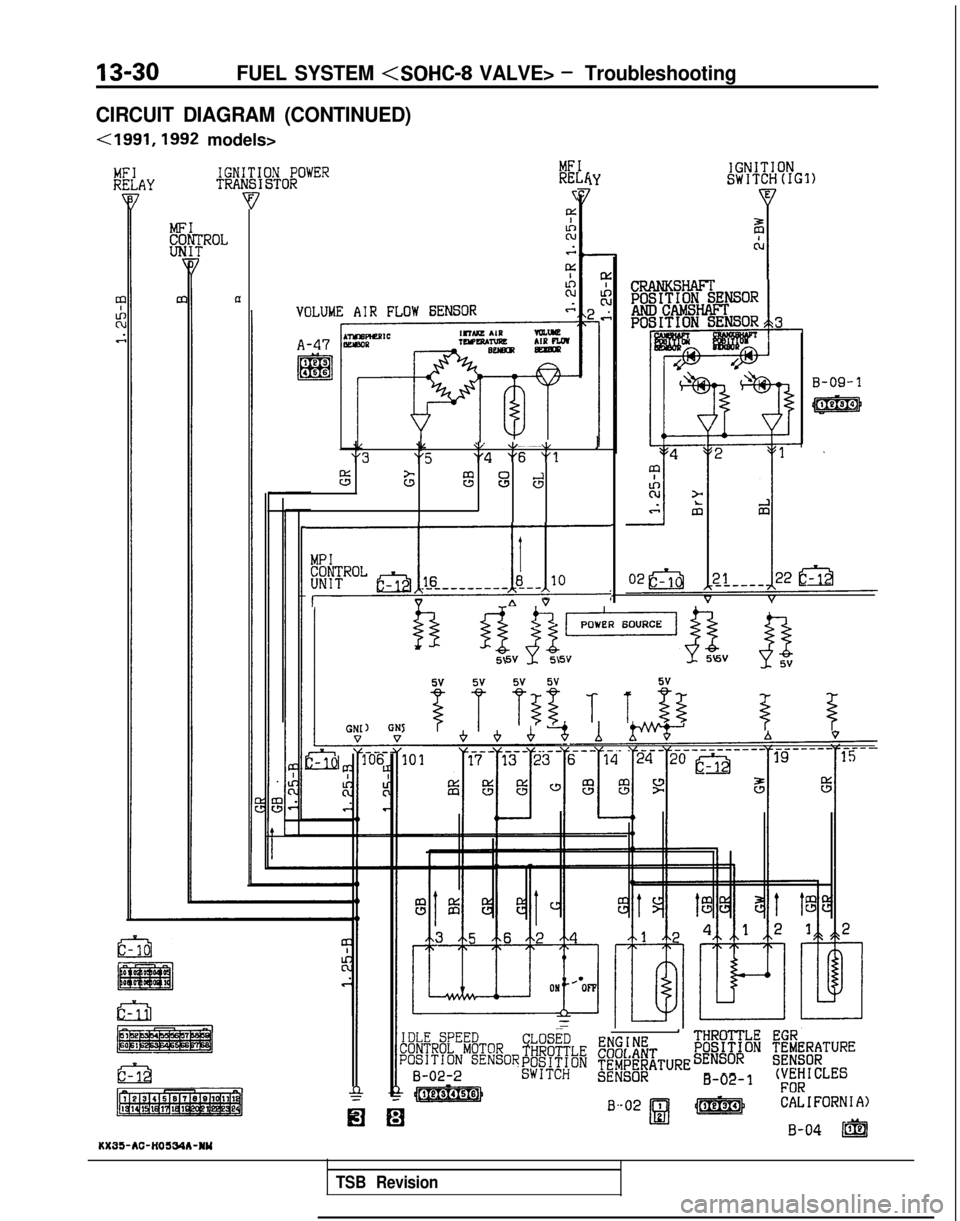

CIRCUIT DIAGRAM (CONTINUED)

<1991,1992 models>

IGNITIONSWITCH(IG1)IGNITION POWERTRANSISTOR

FROL

91

\lxI

z;.

F

R

VOLUME AIR FLOW SENSORs

LYAYE

z m

1

rl

\I\I/ ,,I"3"5"4 "6 "1

E

stz

8

d

j,

Y4Y (

gj ~~p=q~ @

5v5v5v

) f $ T$z T T $5$ $GNI

CLOSED'

THROTTLE :;:/,fT

THROTTLE EGRPOSITION ;;;;!;TURE

@~#ON ~&~~~~ATUREsENSoRB-02-1(VEHICLESFOR

B-02

1 4-1RI

CALIFORNIA)

B-04 /@KX35-AC-HOSWA-NY

TSB Revision

Page 173 of 1273

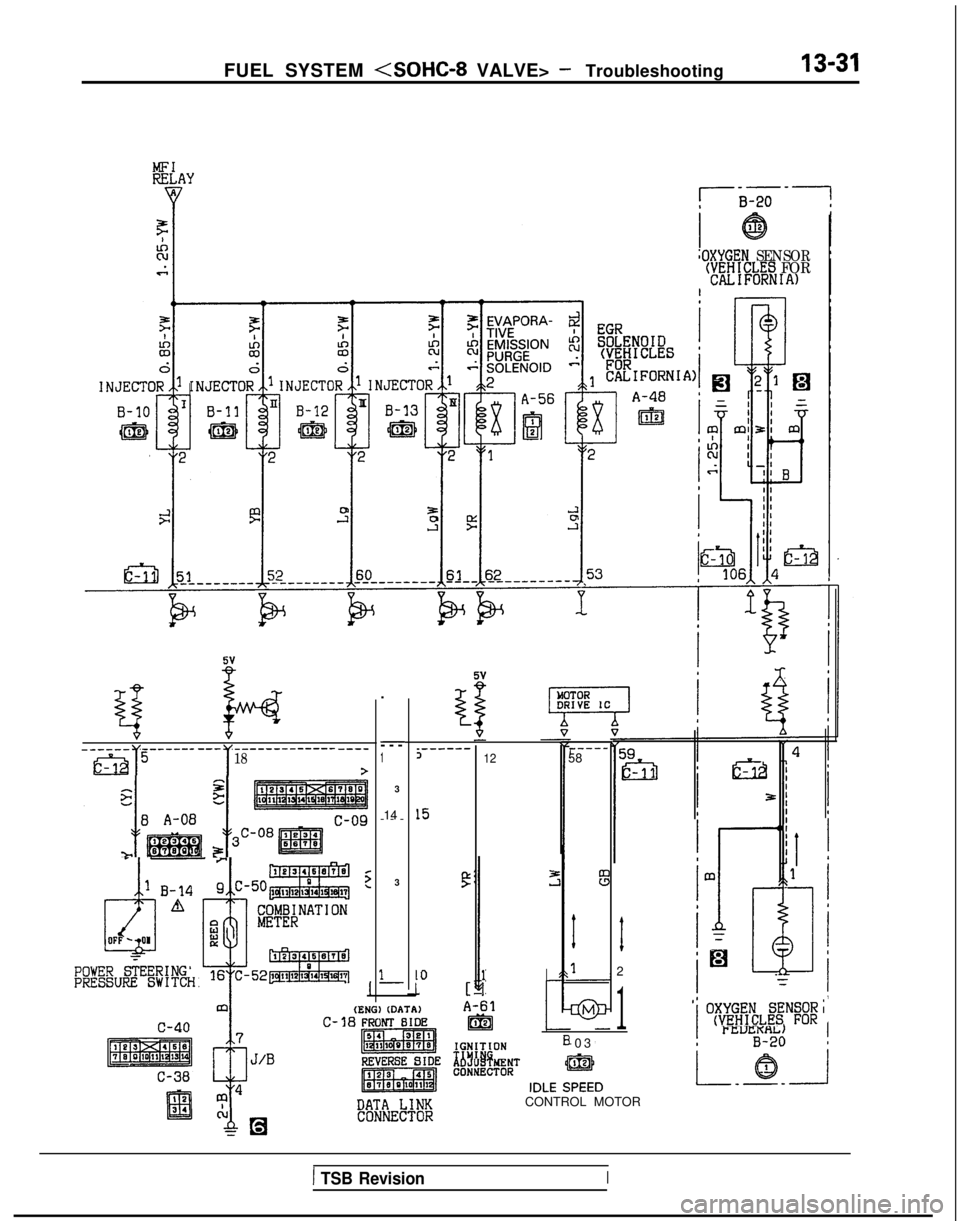

FUEL SYSTEM

MFIRELAY

IIOXYGEN SENSOR(VEHICLES FORCALIFORNIA)

g k______ -___----__ -------------

mlI

----518>

EF

!, -I

s A-08c-09

f@p&g~,,-yg@

POWER STEERINGPRESSURE SWITCH

.

---

-

1

3

14

--

-

3

1-

I

_------3

15

P

10

I [

12 t-----58

(ENG)

(DATA)

c-40-0

3

1

2

1

C-38

DATA LINKCONTROL MOTORCONNECTOR

' OXYGEN SENSOR'(VEHICLES FOR

1 TSB RevisionI

Page 174 of 1273

13-32

FUEL SYSTEM

FUEL TANK AND FUEL LINEMlBEAAA

Symptom Probable cause Remedy

Engtne malfunctions

Bent or kinked fuel pipe or hose Repair or replace3ue to insufficient fuel

SUPPlYClogged fuel pipe or hoseClean or replace

Clogged fuel filter or in-tank fuel filter Replace

Water in fuel filter Replace the fuel filter or clean the fuel tank

and fuel line

Dirty or rusted fuel tank interior Malfunctioning fuel pump

(Clogged filter in the pump) Clean or replace

Replace

Evaporative emission Mispiping of vapor line

Correct

control system malfunc-

tions (When fuel tank Disconnect vapor line piping joint Correct

filler tube cap is re- moved, pressure releas-

Folded, bent, cracked or clogged vapor line Replace

ng noise is heard) Faulty fuel tank filler tube cap

Malfunctioning fuel tank pressure control

valve Replace

Replace

LL

m ~~ : Paper clip-

F l!;“I /yFp- -

izd--_7-01

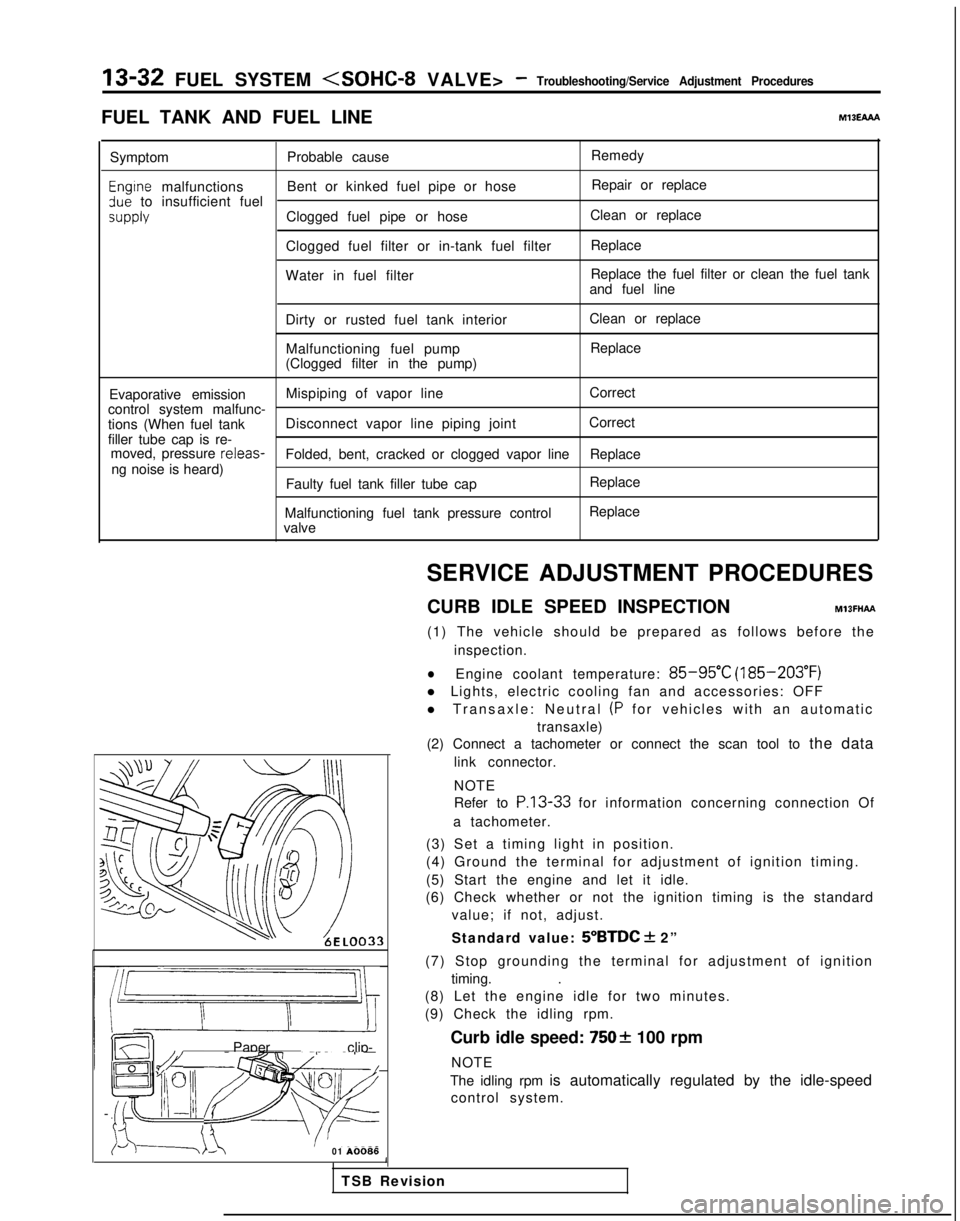

A0086SERVICE ADJUSTMENT PROCEDURES

CURB IDLE SPEED INSPECTION

MlBFHAFt

(1) The vehicle should be prepared as follows before the inspection.

lEngine coolant temperature: 85-95°C (185-203°F)

l Lights, electric cooling fan and accessories: OFF

l Transaxle: Neutral

(P for vehicles with an automatic

transaxle)

(2) Connect a tachometer or connect the scan tool to the data

link connector.

NOTE

Refer to

P.13-33 for information concerning connection Of

a tachometer.

(3) Set a timing light in position.

(4) Ground the terminal for adjustment of ignition timing.

(5) Start the engine and let it idle.

(6) Check whether or not the ignition timing is the standard

value; if not, adjust.

Standard value:

5”BTDC + 2”

(7) Stop grounding the terminal for adjustment of ignition timing. .

(8) Let the engine idle for two minutes.

(9) Check the idling rpm.

Curb idle speed:

7502 100 rpm

NOTE

The idling rpm is automatically regulated by the idle-speed control system.

1

TSB Revision

Page 175 of 1273

FUEL SYSTEM

For a female

pin

For a male pin

(insert at side (Insert at lock tab side.,

opposite from lock tab.)

OlLO246

(10)lf not within the standard value range, refer to the CHECK

CHART CLASSIFIED BY PROBLEM SYMPTOMS and check the

MFI component.

BASIC IDLE SPEED ADJUSTMENT

MlBFHBA

(1) The vehicle should be prepared as follows before the inspection and adjustment.

l Engine coolant temperature:

85-95°C (185-205°F)

l Lights, electric cooling fan and accessories: OFF

l Transaxle: Neutral

(P for vehicles with an automatic

transaxle)

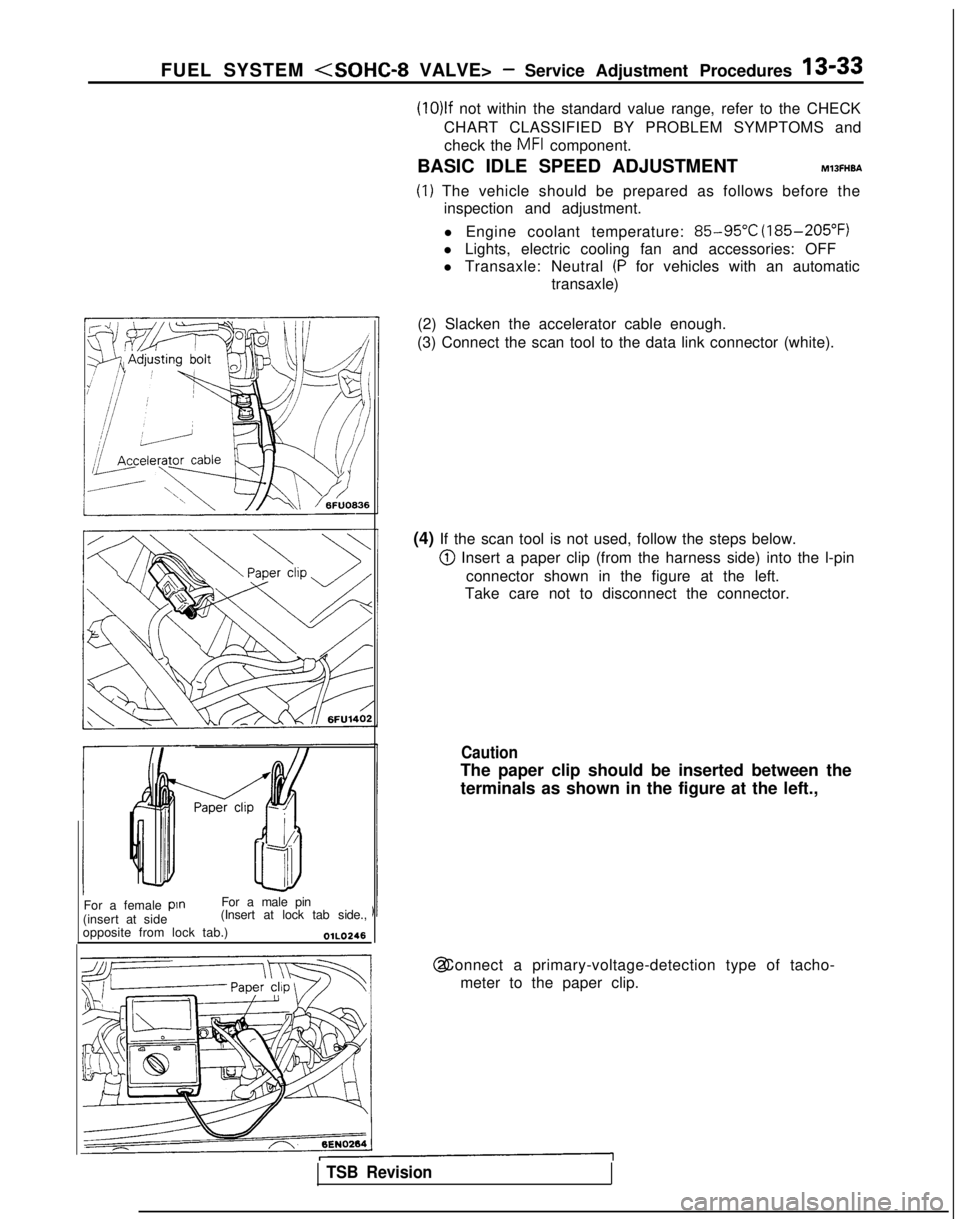

(2) Slacken the accelerator cable enough.

(3) Connect the scan tool to the data link connector (white).

(4) If the scan tool is not used, follow the steps below.

@I Insert a paper clip (from the harness side) into the l-pin connector shown in the figure at the left.

Take care not to disconnect the connector.

Caution

The paper clip should be inserted between the

terminals as shown in the figure at the left., @ Connect a primary-voltage-detection type of tacho-

meter to the paper clip.

TSB Revision

Page 176 of 1273

13-34 FUEL SYSTEM

(5) Switch ON the ignition switch (but do not start the engine)and leave as if for 15 seconds or longer.

NOTE

When the ignition switch is switched ON, the idle speed

control plunger extends to the fast-idle opening degree,

and, after 15 seconds have passed, contracts to the initialposition and stops there.

Initial position: the suitable idling position at which the idle speed control motor position sensor output

voltage is

0.9V.

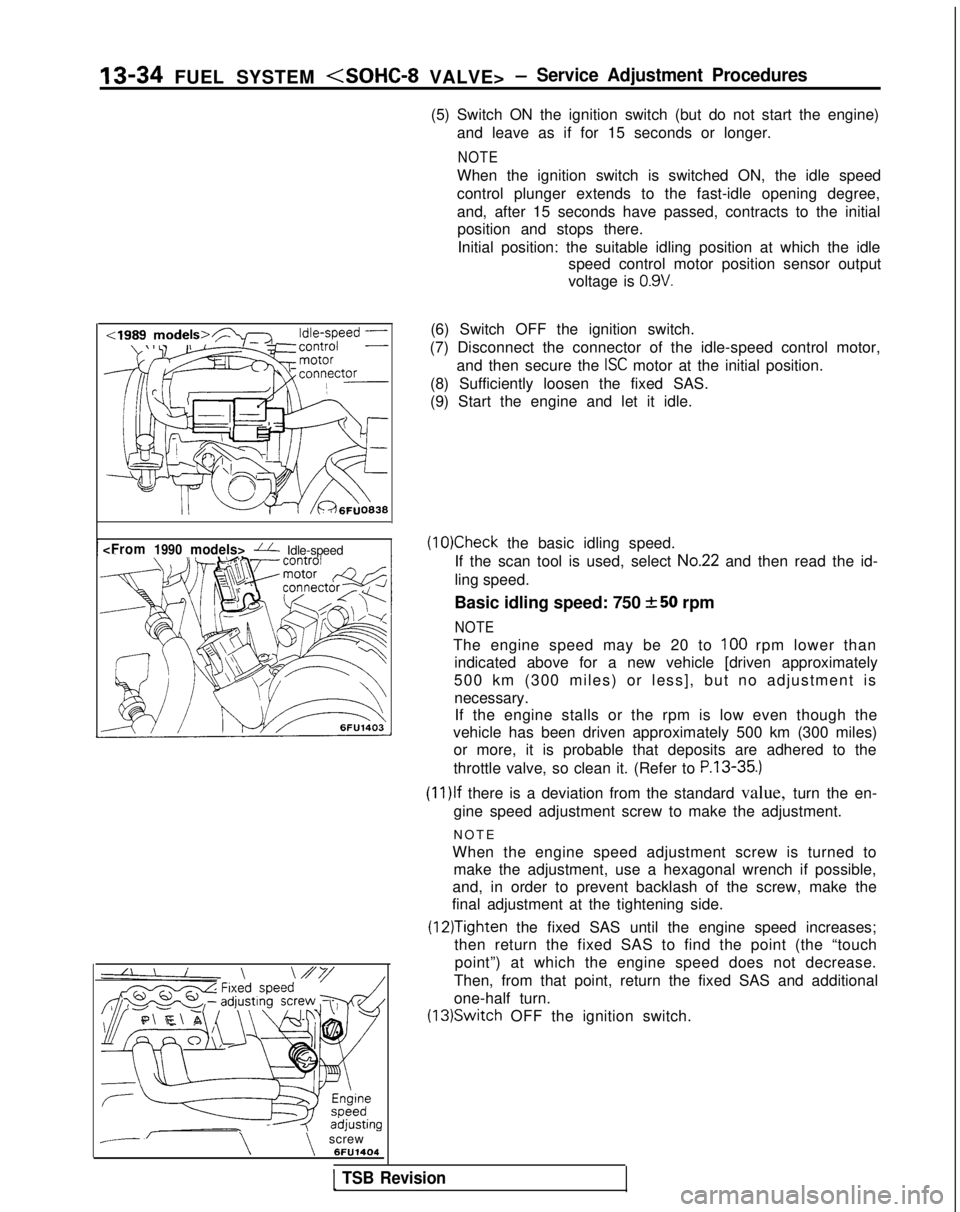

--\\screw 6FU1404(6) Switch OFF the ignition switch.

(7) Disconnect the connector of the idle-speed control motor, and then secure the

ISC motor at the initial position.

(8) Sufficiently loosen the fixed SAS.

(9) Start the engine and let it idle.

(10)Check the basic idling speed.

If the scan tool is used, select

No.22 and then read the id-

ling speed.

Basic idling speed: 750

+-50 rpm

NOTE

The engine speed may be 20 to 100 rpm lower than

indicated above for a new vehicle [driven approximately

500 km (300 miles) or less], but no adjustment is necessary.If the engine stalls or the rpm is low even though the

vehicle has been driven approximately 500 km (300 miles) or more, it is probable that deposits are adhered to the

throttle valve, so clean it. (Refer to

P.13-35.)

(1l)lf there is a deviation from the standard value, turn the en-

gine speed adjustment screw to make the adjustment.

NOT

E

When the engine speed adjustment screw is turned to make the adjustment, use a hexagonal wrench if possible,

and, in order to prevent backlash of the screw, make the

final adjustment at the tightening side.

(12)Tighten the fixed SAS until the engine speed increases;

then return the fixed SAS to find the point (the “touch

point”) at which the engine speed does not decrease.

Then, from that point, return the fixed SAS and additional

one-half turn. (13)Switch

OFF the ignition switch.

1 TSB Revision

Page 177 of 1273

FUEL SYSTEM

(14)Adjust the play of the accelerator cable. (Refer to P.13-

329.)

(15)Connect the idle-speed control motor’s connector.

(16)Adjust the throttle-position sensor.

(17)Start the engine again and let it run at idle speed for about

ten minutes; check to be sure that the idling condition is

normal.

THROTTLE BODY (THROTTLE VALVE AREA)

CLEANING

MllFlCK

(1)Start the engine and warm it up until the temperature of the

engine coolant reaches

80°C (176°F) or higher; then stop

the engine.

(2) Disconnect the air intake hose at the throttle body side.

(3) Spray cleaning liquid (from the intake port of the throttle body) onto the valve, and then leave as is for about fiveminutes.

(4) Start the engine and race it a few times; then let it run at idle speed for about one minute.

NOTE

If the engine idling speed is unstable (or the engine stalls),

let the engine run with the throttle valve slightly open.

(5) If deposits are not removed from the throttle valve, repeat steps (3) and (4).

(6) Connect the air intake hose.

(7) Using the scan tool, erase the diagnostic trouble code, or disconnect the battery’s ground cable for ten seconds orlonger and then reconnect it.

(8) Adjust the basic idle speed (engine speed adjusting screw). (Refer to

P.13-33.)

(9) Adjust the throttle position sensor.

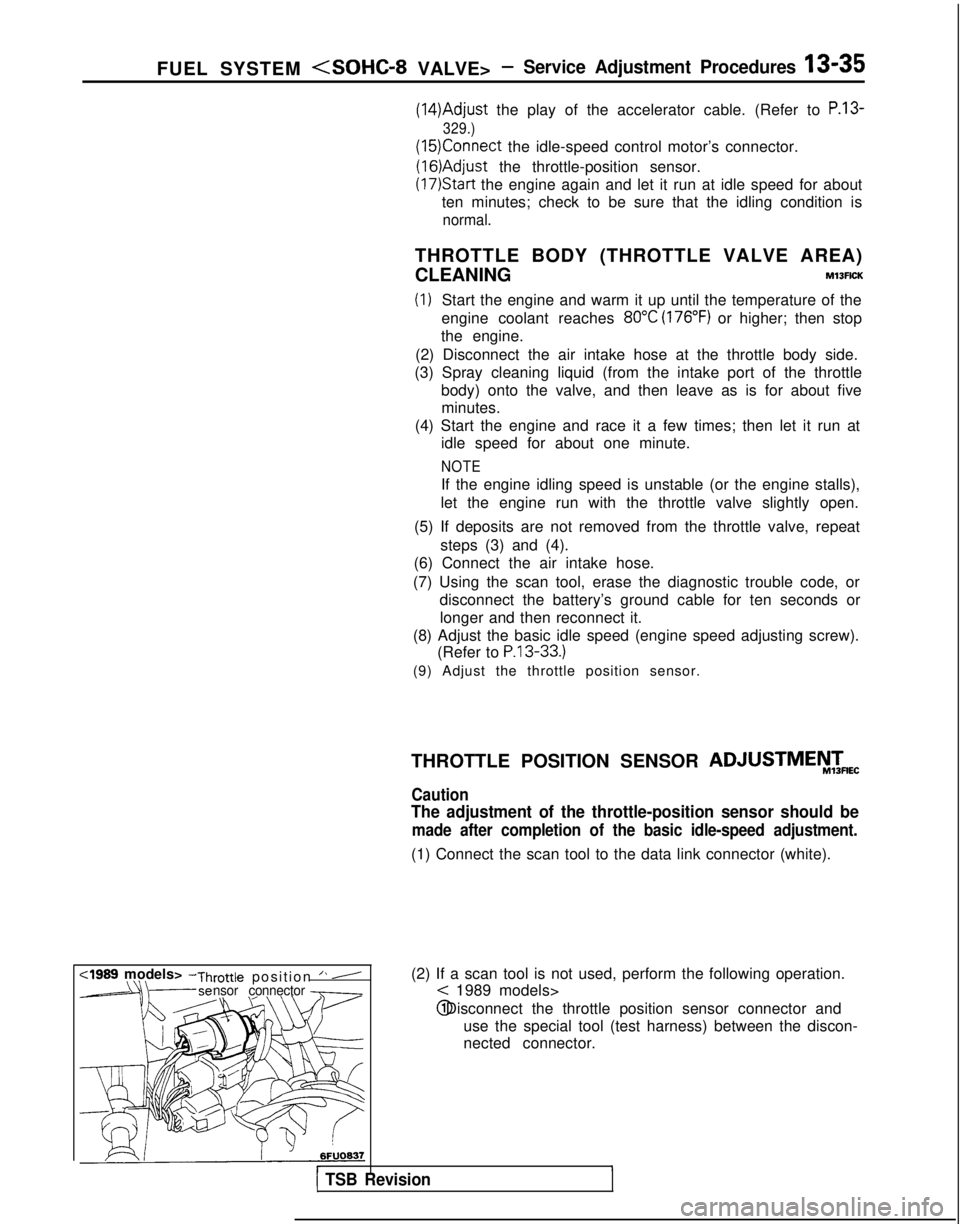

(2) If a scan tool is not used, perform the following operation.

< 1989 models> @ Disconnect the throttle position sensor connector and

use the special tool (test harness) between the discon-

nected connector.

r1 TSB Revision

THROTTLE POSITION SENSOR ADJUSTMEiW&

Caution

The adjustment of the throttle-position sensor should be

made after completion of the basic idle-speed adjustment.

(1) Connect the scan tool to the data link connector (white).

,

Page 178 of 1273

13-36 FUEL SYSTEM

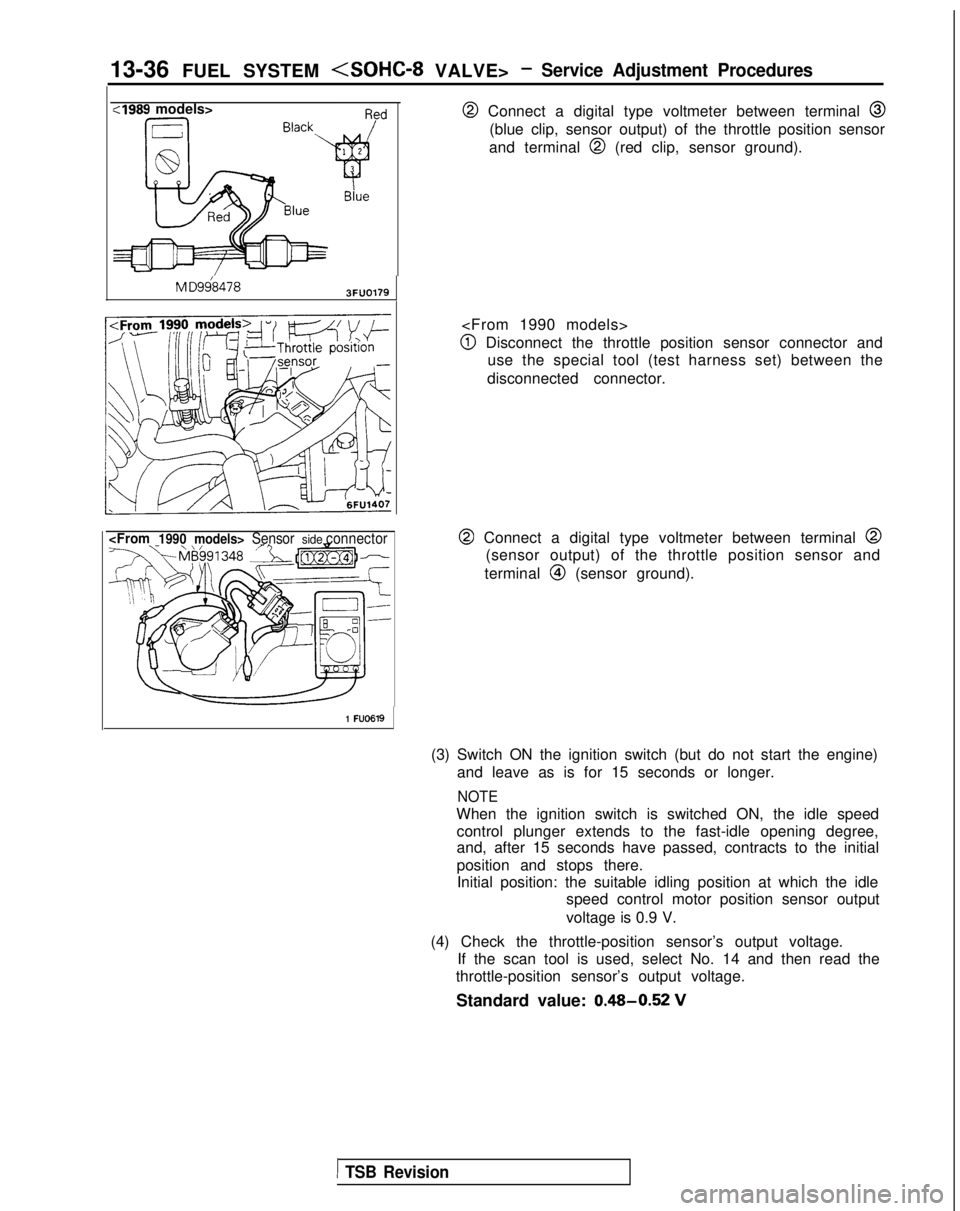

:I989 models>

M

D9684783FUO179

@ Connect a digital type voltmeter between terminal @

(blue clip, sensor output) of the throttle position sensor

and terminal

@I (red clip, sensor ground).

@I Disconnect the throttle position sensor connector and use the special tool (test harness set) between the

disconnected connector.

@ Connect a digital type voltmeter between terminal @

(sensor output) of the throttle position sensor and

terminal

@I (sensor ground).

1 FU0619

(3) Switch ON the ignition switch (but do not start the engine) and leave as is for 15 seconds or longer.

NOTE

When the ignition switch is switched ON, the idle speedcontrol plunger extends to the fast-idle opening degree,

and, after 15 seconds have passed, contracts to the initial

position and stops there.Initial position: the suitable idling position at which the idle speed control motor position sensor output

voltage is 0.9 V.

(4) Check the throttle-position sensor’s output voltage. If the scan tool is used, select No. 14 and then read the

throttle-position sensor’s output voltage.

Standard value: 0.48-0.52

V

1 TSB Revision

Page 179 of 1273

FUEL SYSTEM (SOHC-8 VALVE> -Service Adjustment Procedures 13-37

MO-L

6FU1405

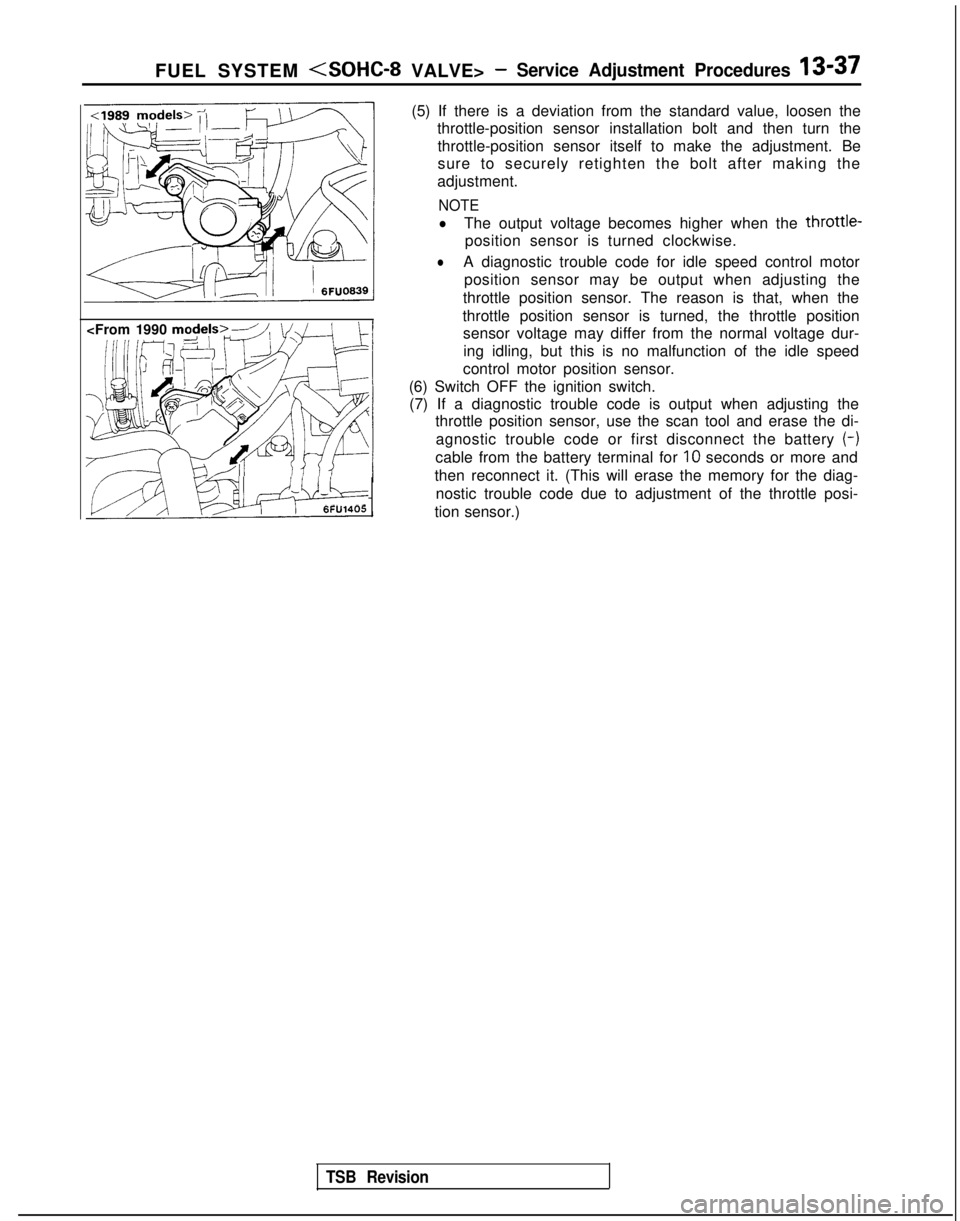

(5) If there is a deviation from the standard value, loosen the

throttle-position sensor installation bolt and then turn the

throttle-position sensor itself to make the adjustment. Be

sure to securely retighten the bolt after making the

adjustment.

NOTE

lThe output voltage becomes higher when the throttle-

position sensor is turned clockwise.

lA diagnostic trouble code for idle speed control motor position sensor may be output when adjusting the

throttle position sensor. The reason is that, when the

throttle position sensor is turned, the throttle position sensor voltage may differ from the normal voltage dur-

ing idling, but this is no malfunction of the idle speed

control motor position sensor.

(6) Switch OFF the ignition switch. (7) If a diagnostic trouble code is output when adjusting the throttle position sensor, use the scan tool and erase the di-

agnostic trouble code or first disconnect the battery (-)

cable from the battery terminal for IO

seconds or more and

then reconnect it. (This will erase the memory for the diag- nostic trouble code due to adjustment of the throttle posi-

tion sensor.)

TSB Revision

Page 180 of 1273

13-38

FUEL SYSTEM

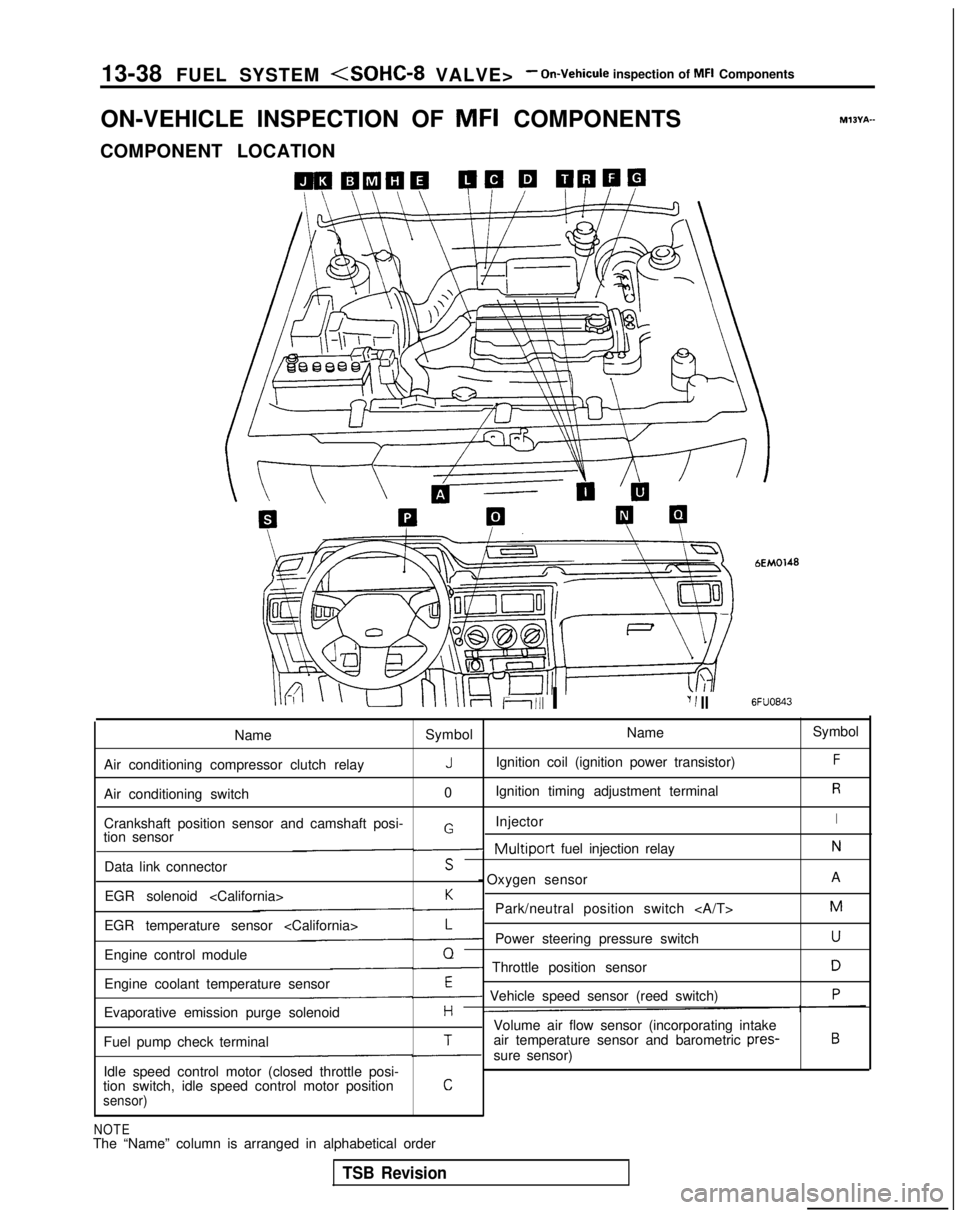

ON-VEHICLE INSPECTION OF MFI

COMPONENTS

COMPONENT LOCATION

Ii111 I‘I 1 II

bEM0148

6FUO843

M?BYA-

Name Symbol Name

Symbol

Air conditioning compressor clutch relay

JIgnition coil (ignition power transistor)F

Air conditioning switch 0Ignition timing adjustment terminalR

Crankshaft position sensor and camshaft posi- InjectorIGtion sensor-Multiport fuel injection relayN

Data link connectorS - Oxygen sensor

A

EGR solenoid

K-Park/neutral position switch M

EGR temperature sensor

L-Power steering pressure switchU

Engine control moduleQ- Throttle position sensorD

Engine coolant temperature sensorE- Vehicle speed sensor (reed switch)P

Evaporative emission purge solenoidHVolume air flow sensor (incorporating intake

Fuel pump check terminalTair temperature sensor and barometric pres-B

-sure sensor)

Idle speed control motor (closed throttle posi-

tion switch, idle speed control motor position

Csensor)

NOTEThe “Name” column is arranged in alphabetical order

TSB Revision