sensor MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 807 of 1273

AUTOMATIC TRANSAXLE - Transaxle Assembly

TRANSAXLE ASSEMBLY

REMOVAL AND INSTALLATION

23-101

mz3u-

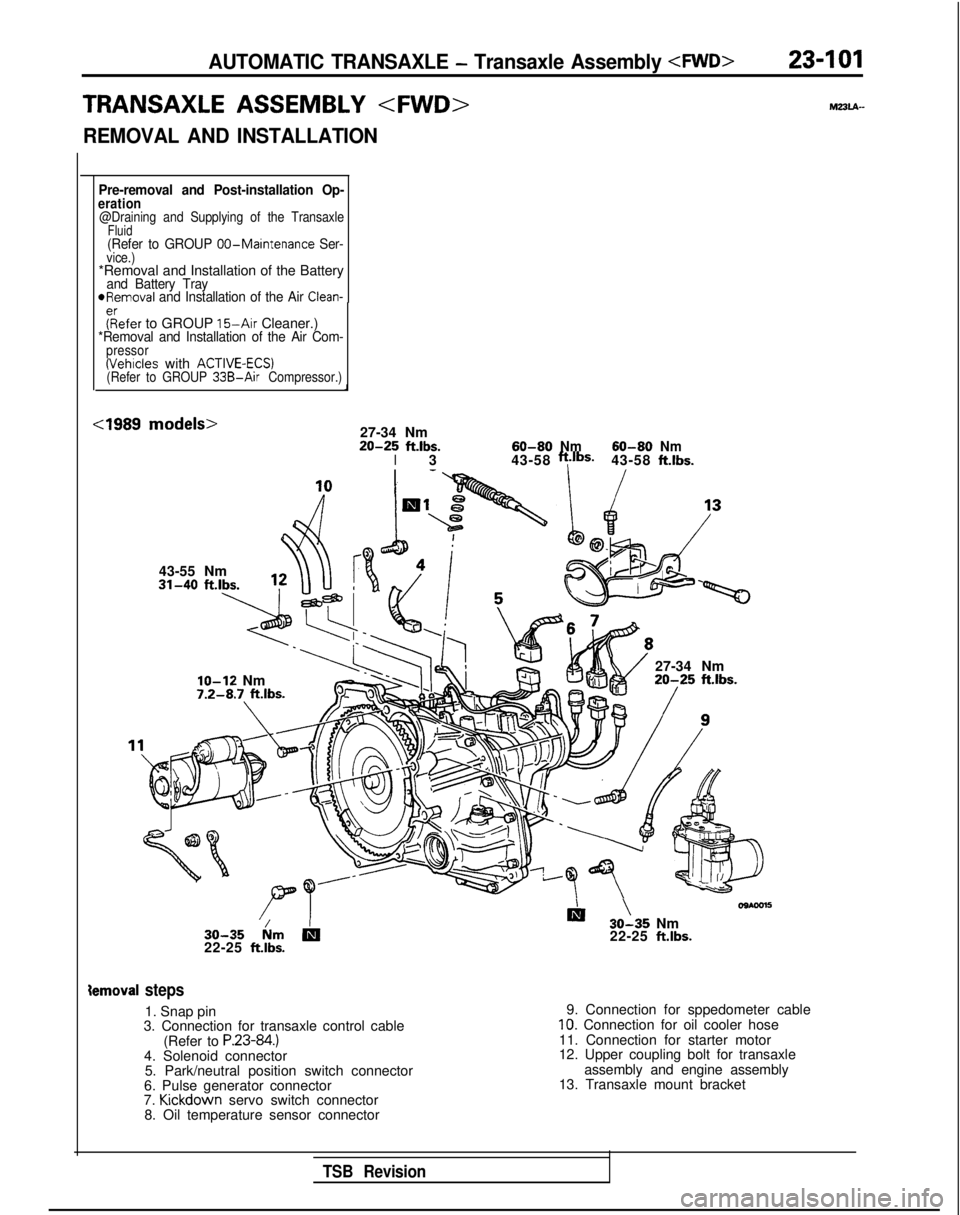

Pre-removal and Post-installation Op-eration@Draining and Supplying of the TransaxleFluid(Refer to GROUP 00-Maintenance Ser-vice.)*Removal and Installation of the Batteryand Battery TrayofRemoval and Installation of the Air Clean-

fRrefer to GROUP 15-Air

Cleaner.)*Removal and Installation of the Air Com-pressor(Vehicles with ACTIVE-ECS)(Refer to GROUP 33B-Air Compressor.)

cl989 models>27-34 Nm20-25ft.lbs.I360-80Nm43-58ft.lbS.60-80Nm43-58ft.lbs.

43-55 Nm

IO-12 Nm7.2-8.7 ft.lbs.

27-34 Nm20-25 ft.lbs.

30-35 km

b22-25 ft.lbs.

Iii ’30-35 Nm

22-25 ft.lbs.

ternoval steps

1. Snap pin

3. Connection for transaxle control cable

(Refer to

P.23-84.)4. Solenoid connector5. Park/neutral position switch connector

6. Pulse generator connector

7. Kickdown

servo switch connector

8. Oil temperature sensor connector 9. Connection for sppedometer cable

10. Connection for oil cooler hose

11. Connection for starter motor

12. Upper coupling bolt for transaxle assembly and engine assembly

13. Transaxle mount bracket

TSB Revision

Page 808 of 1273

23-102AUTOMATIC TRANSAXLE - Transaxle Assemblv

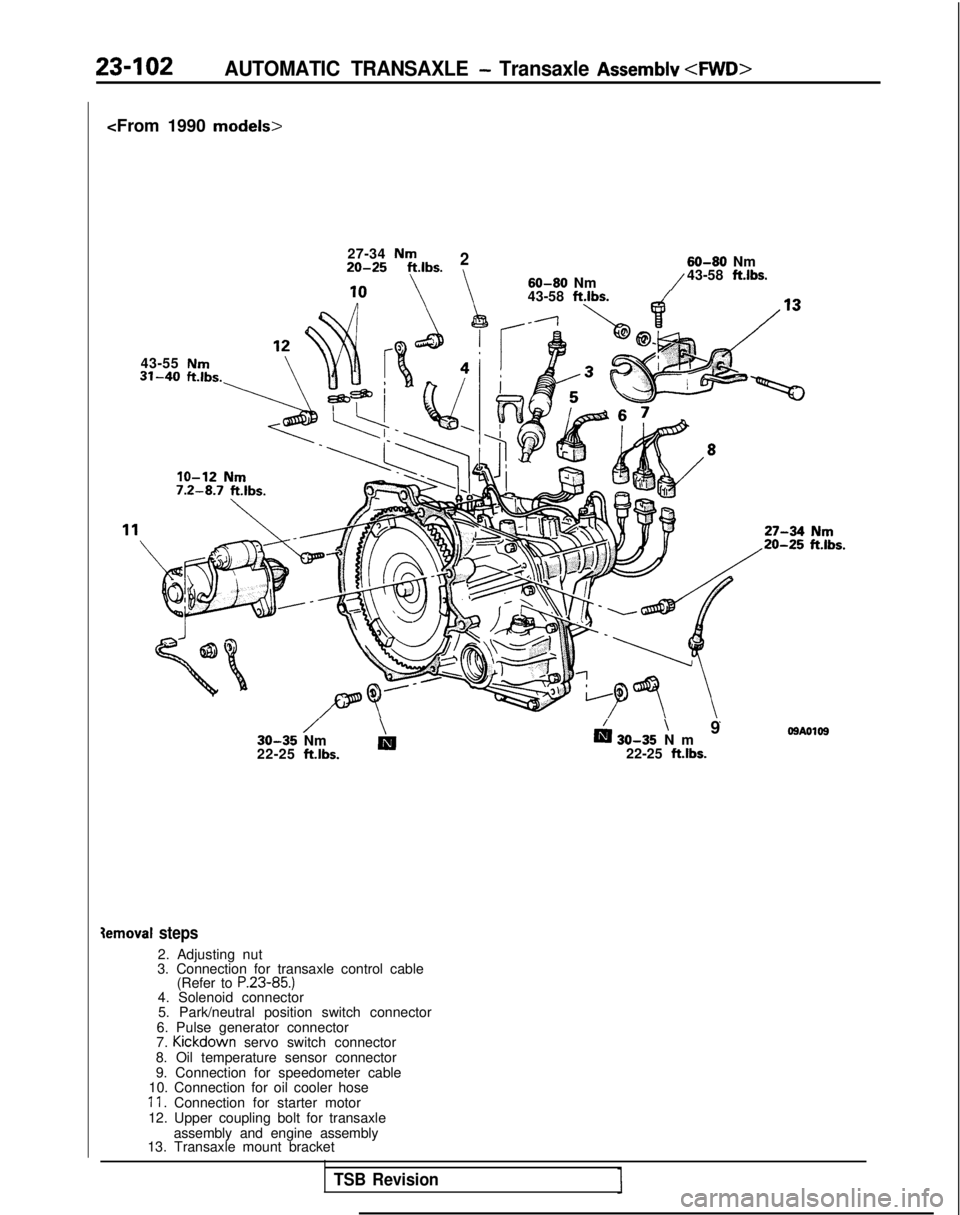

27-34 Nm220-25 ftlbs.

\

43-55 Nm

60-80 Nm

60-80 Nm

/43-58 ftlbs.

43-58

ftlbs.

/\ /\ 930-35 NmDm 30-35 N

m

22-25

ftlbs.22-25 ft.lbs.

Iemoval steps

2. Adjusting nut

3. Connection for transaxle control cable (Refer to

P.23-85.)4. Solenoid connector

5. Park/neutral position switch connector

6. Pulse generator connector

7. Kickdown

servo switch connector

8. Oil temperature sensor connector

9. Connection for speedometer cable

10. Connection for oil cooler hose

11. Connection for starter motor

12. Upper coupling bolt for transaxle assembly and engine assembly

13. Transaxle mount bracket

TSB Revision

Page 811 of 1273

AUTOMATIC TRANSAXLE - Transaxle Assembly

TRANSAXLE ASSEMBLY

REMOVAL AND INSTALLATION

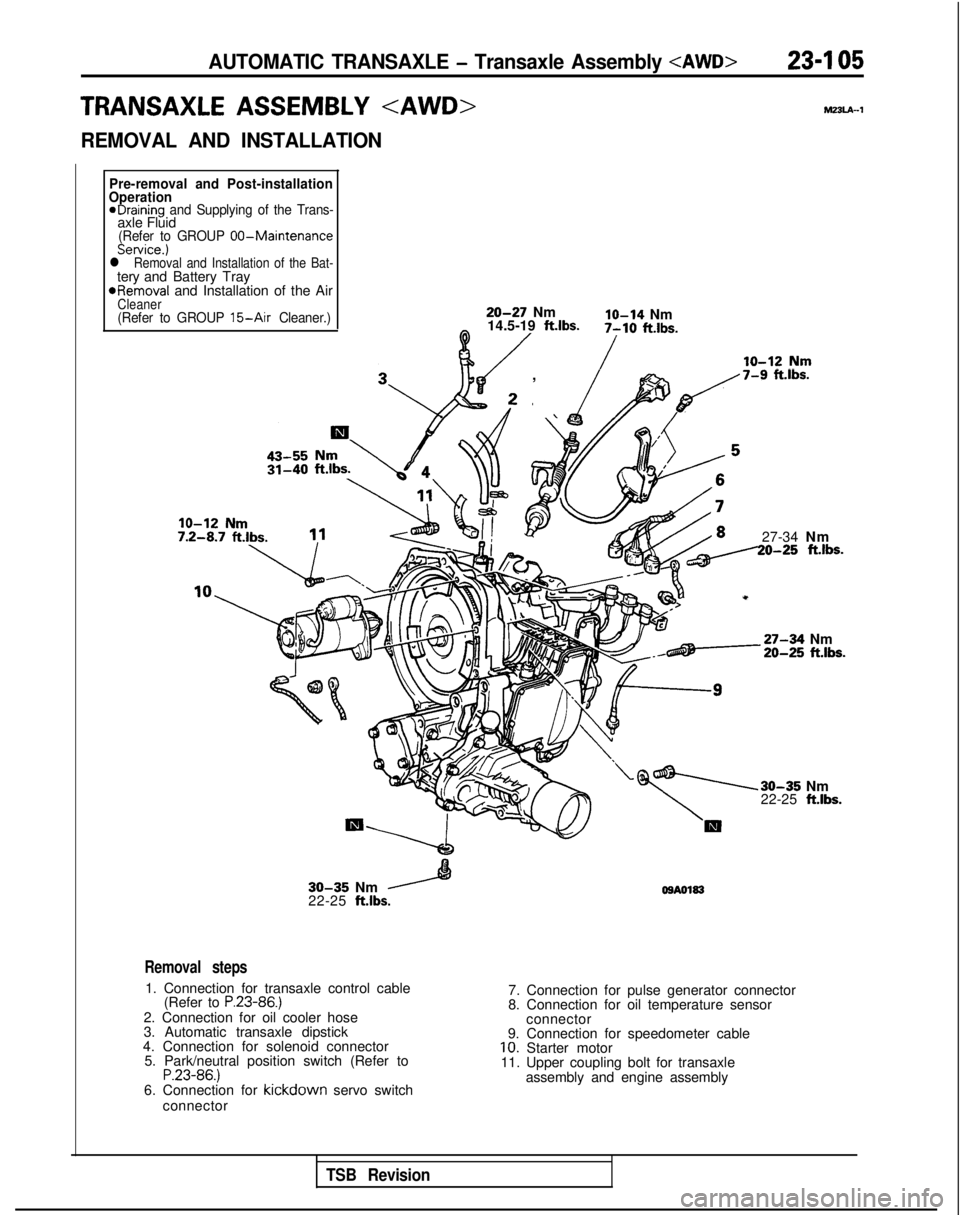

Pre-removal and Post-installation

Operation

eDraining and Supplying of the Trans-axle Fluid(Refer to GROUP 00-MaintenanceService.)l Removal and Installation of the Bat-tery and Battery Tray

*Removal

and Installation of the Air

Cleaner(Refer to GROUP 15-Air Cleaner.)20-27 Nmlo-14 Nm

14.5-19 ft.lbs.0 /7-10 ft.lbs.

/

, \ fp,/7-9 f%.lbs.

27-34 Nm20-25 ft.lbs.

-27-34 Nm20-25 ft.lbs.

30-35 Nm

22-25 ft.lbs.

30-35 Nm

22-25 ft.lbs. OSA0183

Removal steps

1. Connection for transaxle control cable

(Refer to P.23-86.)2. Connection for oil cooler hose

3. Automatic transaxle dipstick

4. Connection for solenoid connector 5. Park/neutral position switch (Refer to

P.23-86.)6. Connection for kickdown servo switch

connector 7. Connection for pulse generator connector

8. Connection for oil temperature sensor

connector

9. Connection for speedometer cable

10. Starter motor

11. Upper coupling bolt for transaxle

assembly and engine assembly

TSB Revision

Page 832 of 1273

26-2

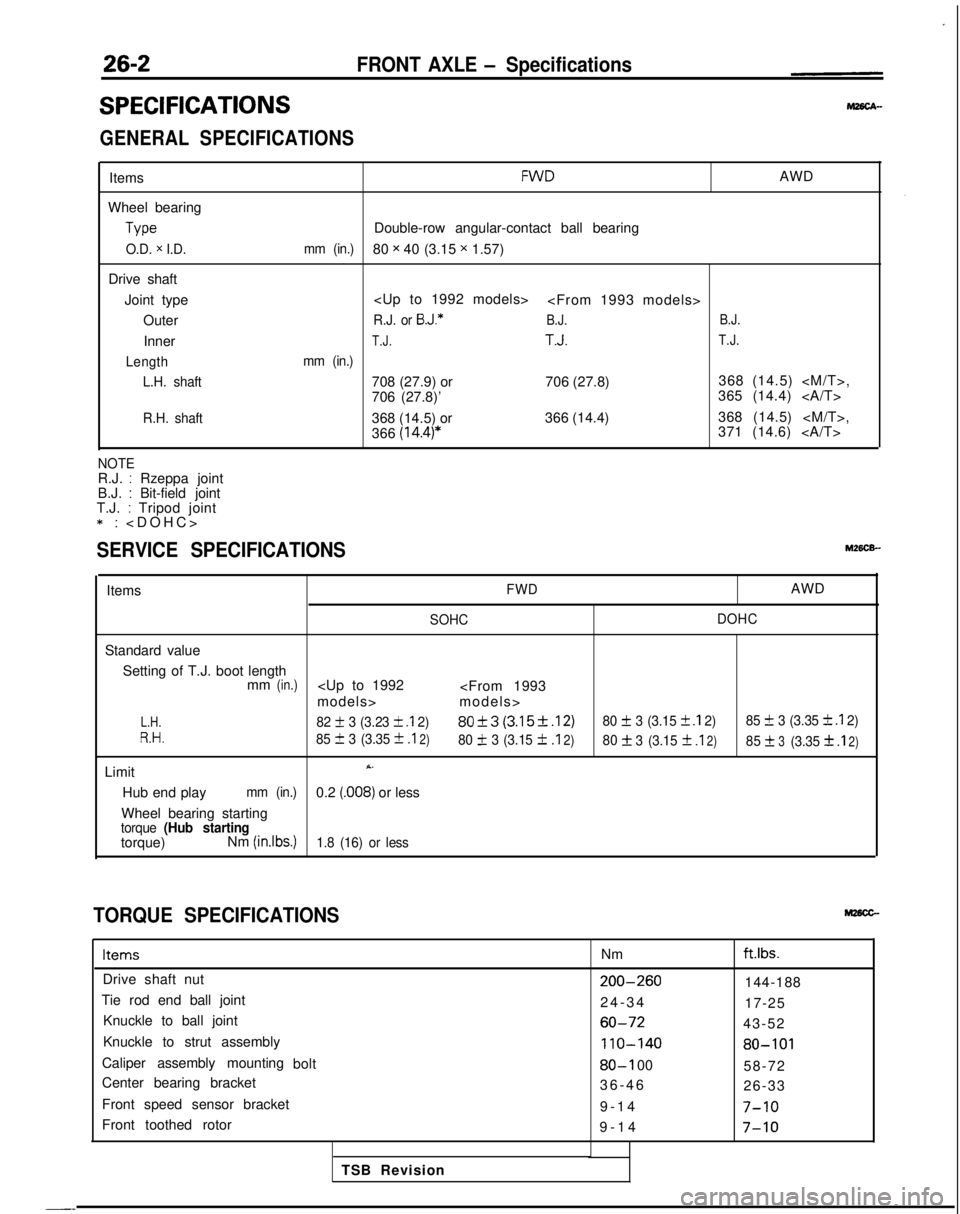

SPECIFICATIONS

FRONT AXLE - Specifications

GENERAL SPECIFICATIONS

Items

Wheel bearing Type

O.D. x I.D.

Drive shaft

Joint type Outer

Inner

Length L.H. shaft

R.H. shaft

FWDAWD

Double-row angular-contact ball bearing

mm (in.)80 x 40 (3.15 x 1.57)

R.J. or B.J.*B.J. B.J.

T.J.T.J.T.J.

mm (in.)

708 (27.9) or

706 (27.8)368 (14.5)

706 (27.8)’ 365 (14.4)

368 (14.5) or 366 (14.4)368 (14.5)

366

(14.4)*371 (14.6)

NOTER.J. : Rzeppa joint

B.J. : Bit-field joint

T.J. : Tripod joint *:

>

SERVICE SPECIFICATIONS

ItemsFWDAWD

SOHC

DOHC

Standard value

Setting of T.J. boot length mm

(in.)

L.H.82 + 3 (3.23 k .I 2)80f3 (3.15f.12)80 + 3 (3.15 f .I 2)

85 f 3 (3.35 k .I 2)

R.H.85 III 3 (3.35 +

.I2)80 IL 3 (3.15 f.I2)80f3

(3.15f .I2)85f3(3.3531

.I2)

LimitX.

Hub end playmm (in.)0.2 (.008) or less

Wheel bearing starting

torque (Hub startingtorque) Nm (inlbs.)1.8 (16) or less

TORQUE SPECIFICATIONS

ItemsNmftlbs.

Drive shaft nut200-260144-188

Tie rod end ball joint 24-3

4

17-25

Knuckle to ball joint

60-7243-52

Knuckle to strut assembly

110-14080-101

Caliper assembly mounting bolt80-I 0058-72

Center bearing bracket 36-4

6

26-33

Front speed sensor bracket 9-14

7-10

Front toothed rotor9-1

4

7-10

TSB Revision

-_

Page 836 of 1273

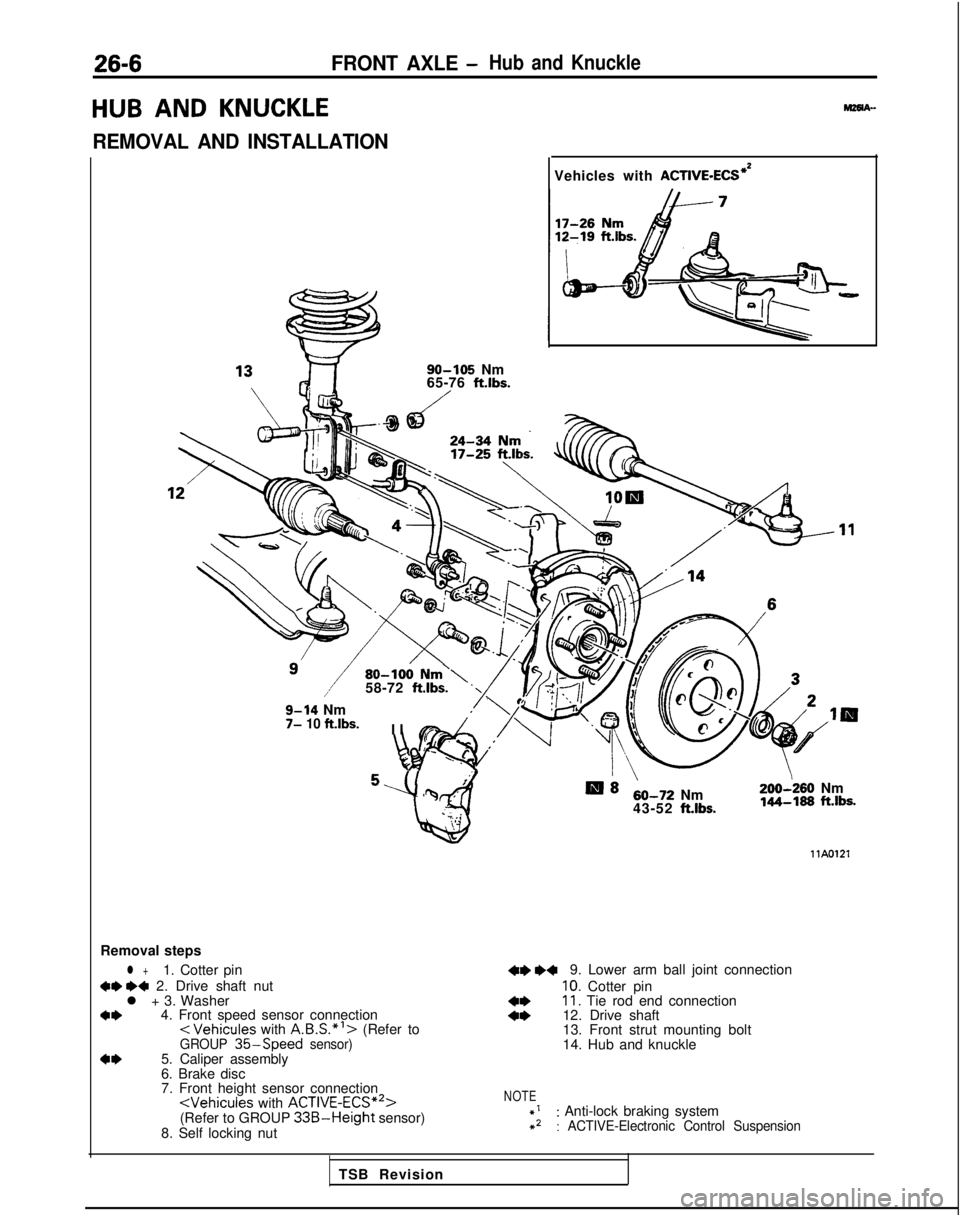

26-6FRONT AXLE -Hub and Knuckle

HUB AND

KNUCKLE

REMOVAL AND INSTALLATION

SO-105 Nm

65-76 ft.lbs.

Vehicles with ACTIVE-ECS*’

80-100 Nm’\58-72 ftlbs.

9-14 Nm7- 10 ft.lbs.I

I

5rq :I

u

- 4. .i,'-

B860-72 Nm200-‘260 Nm

43-52

ft.lbs.IU-188 ft.lbs.

llA0121

Removal steps

l +1. Cotter pin

+e I)+ 2. Drive shaft nut

l + 3. Washer

a*4. Front speed sensor connection< Vehicules

with A.B.S.*‘> (Refer toGROUP 35-Speed sensor)a*5. Caliper assembly

6. Brake disc

7. Front height sensor connection

(Refer to GROUP 33B-Height sensor)

8. Self locking nut

+e ~~9. Lower arm ball joint connection

10. Cotter pin

::11. Tie rod end connection

12. Drive shaft

13. Front strut mounting bolt

14. Hub and knuckle

NOTE

::: Anti-lock braking system: ACTIVE-Electronic Control Suspension

TSB Revision

Page 837 of 1273

FRONT AXLE - Hub and Knuckle26-7

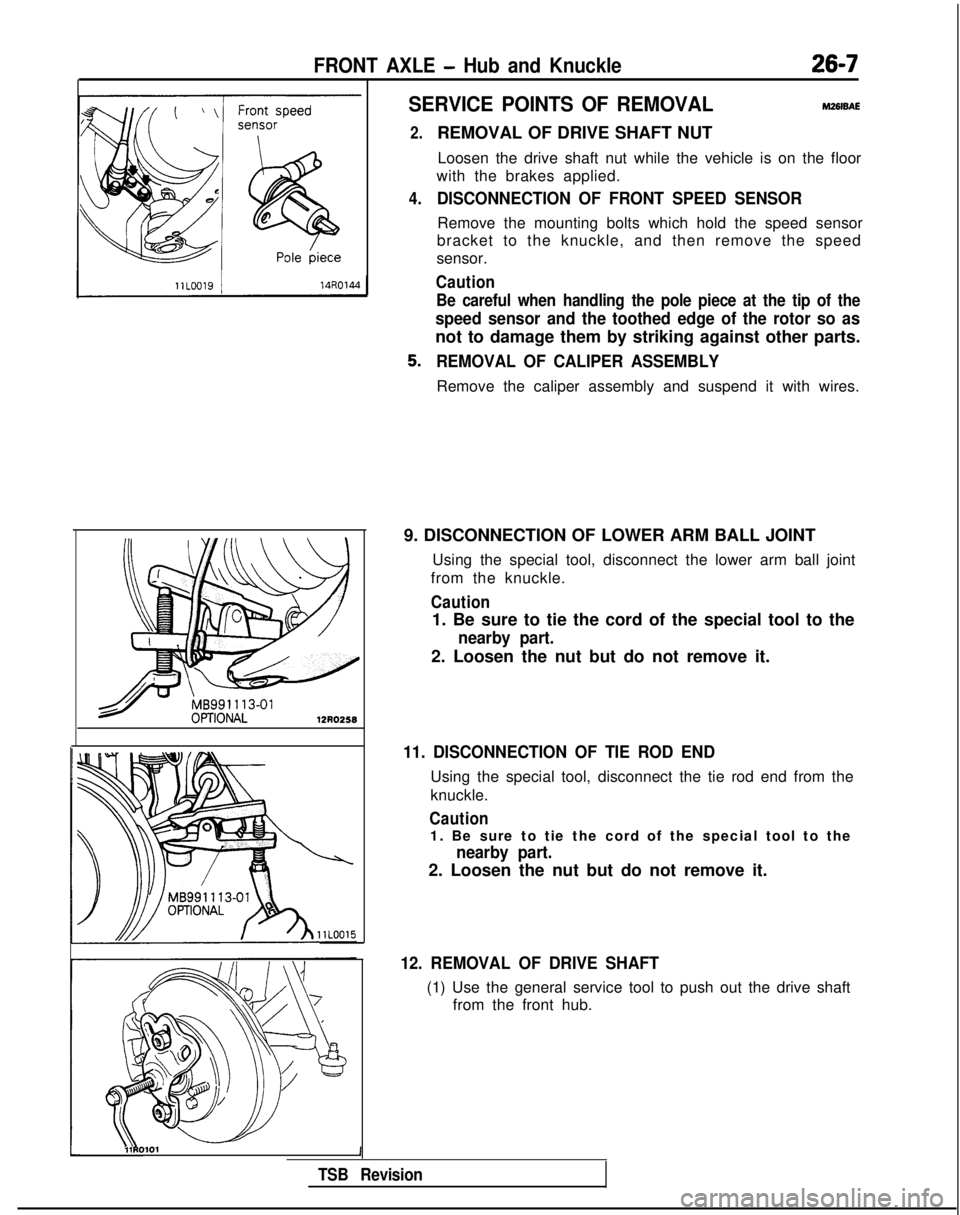

SERVICE POINTS OF REMOVALM261sAE

2.

4.

REMOVAL OF DRIVE SHAFT NUTLoosen the drive shaft nut while the vehicle is on the floor

with the brakes applied.

DISCONNECTION OF FRONT SPEED SENSOR

Remove the mounting bolts which hold the speed sensor

bracket to the knuckle, and then remove the speed

sensor.

Caution

Be careful when handling the pole piece at the tip of the

speed sensor and the toothed edge of the rotor so as

not to damage them by striking against other parts.

REMOVAL OF CALIPER ASSEMBLY

Remove the caliper assembly and suspend it with wires.

9. DISCONNECTION OF LOWER ARM BALL JOINT Using the special tool, disconnect the lower arm ball joint

from the knuckle.

Caution

1. Be sure to tie the cord of the special tool to the

nearby part.

2. Loosen the nut but do not remove it.

11. DISCONNECTION OF TIE ROD END

Using the special tool, disconnect the tie rod end from the

knuckle.

Caution

1. Be sure to tie the cord of the special tool to the

nearby part.

2. Loosen the nut but do not remove it.

12. REMOVAL OF DRIVE SHAFT

(1) Use the general service tool to push out the drive shaft from the front hub.

l\\11RO101 1

TSB Revision

Page 839 of 1273

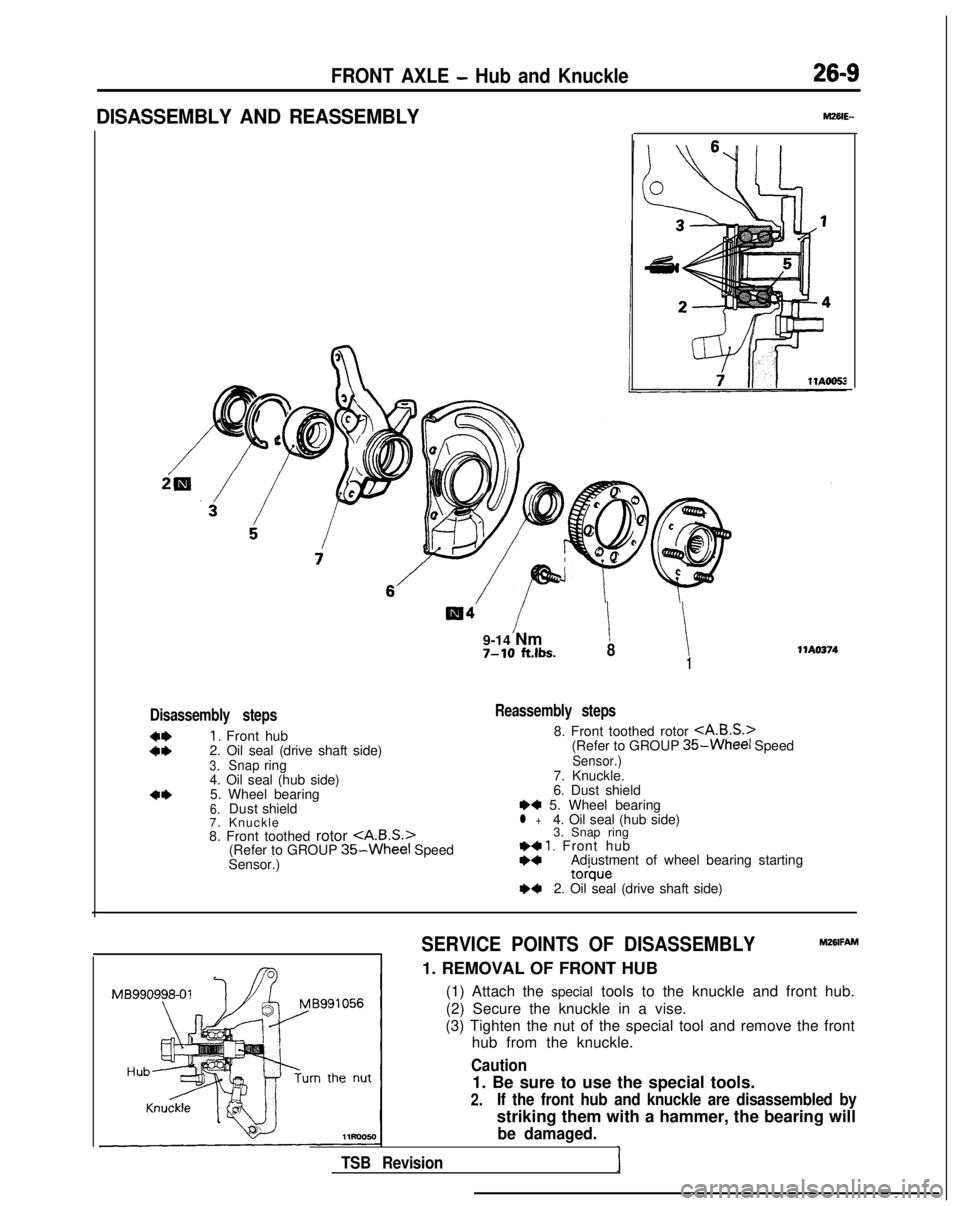

FRONT AXLE - Hub and Knuckle26-9

DISASSEMBLY AND REASSEMBLY

9-14 Nm7-10 ft.lbs.i !81

Disassembly steps

::

I. Front hub

2. Oil seal (drive shaft side)

3.Snapring

4. Oil seal (hub side)

4*5. Wheel bearing6.Dust shield

7. Knuckl

e

8. Front toothed rotor

(Refer to GROUP

35-Wheel Speed

Sensor.)

WA0374

Reassembly steps

8. Front toothed rotor

(Refer to GROUP 35-Wheel SpeedSensor.)7. Knuckle.

6. Dust shield

I)+ 5. Wheel bearingl +4. Oil seal (hub side) 3. Snap ring

I)+ 1. Front hubI)*Adiustment of wheel bearing starting torque

I)+2. Oil seal (drive shaft side)

SERVICE POINTS OF DISASSEMBLY

Mz6lFAM

1. REMOVAL OF FRONT HUB (1) Attach the special tools to the knuckle and front hub.

(2) Secure the knuckle in a vise.

(3) Tighten the nut of the special tool and remove the front hub from the knuckle.

Caution

1. Be sure to use the special tools.

2.If the front hub and knuckle are disassembled by

striking them with a hammer, the bearing will

be damaged.

TSB RevisionI

Page 843 of 1273

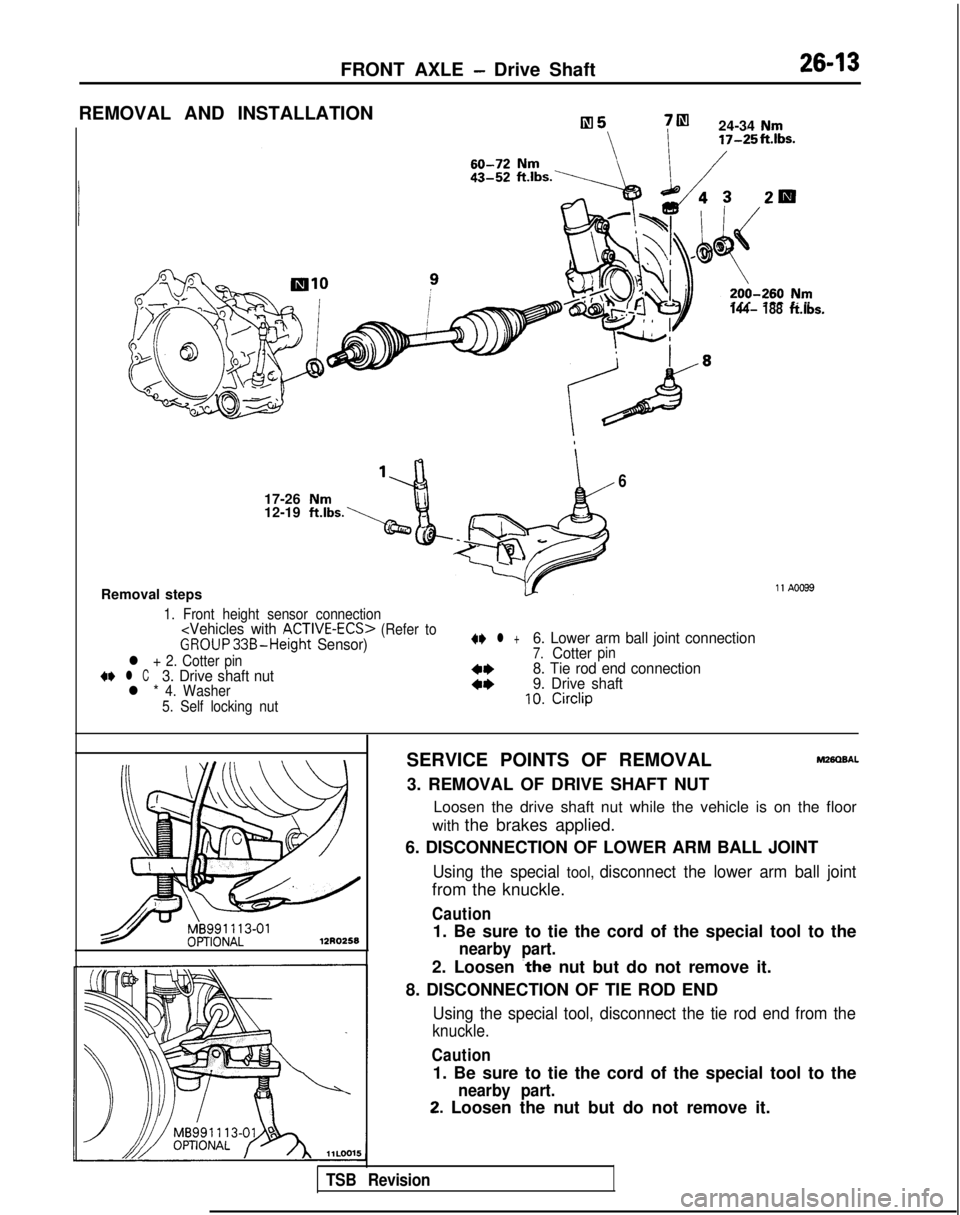

FRONT AXLE - Drive Shaft2643

REMOVAL AND INSTALLATION

7m

24-34 Nm 17-25ft.Ibs.

144- 188ft.lbs.

6

17-26 Nm12-19 ft.lbs.

Removal steps11 A0099

1. Front height sensor connection

(Refer toGROUP33B-Height Sensor)

l + 2. Cotter pin+e l C3. Drive shaft nutl * 4. Washer

5. Self locking nut

4I) l +6. Lower arm ball joint connection7.Cotterpin

4+8. Tie rod end connection

4*9. Drive shaft10.Circlip

12R0258

SERVICE POINTS OF REMOVALM280BAL

3. REMOVAL OF DRIVE SHAFT NUT

Loosen the drive shaft nut while the vehicle is on the floor

with the brakes applied.

6. DISCONNECTION OF LOWER ARM BALL JOINT

Using the special tool, disconnect the lower arm ball joint

from the knuckle.

Caution

1. Be sure to tie the cord of the special tool to the

nearby part.

2. Loosen ~the nut but do not remove it.

8. DISCONNECTION OF TIE ROD END

Using the special tool, disconnect the tie rod end from the

knuckle.

Caution

1. Be sure to tie the cord of the special tool to the

nearby part.

2. Loosen the nut but do not remove it.

TSB Revision

Page 862 of 1273

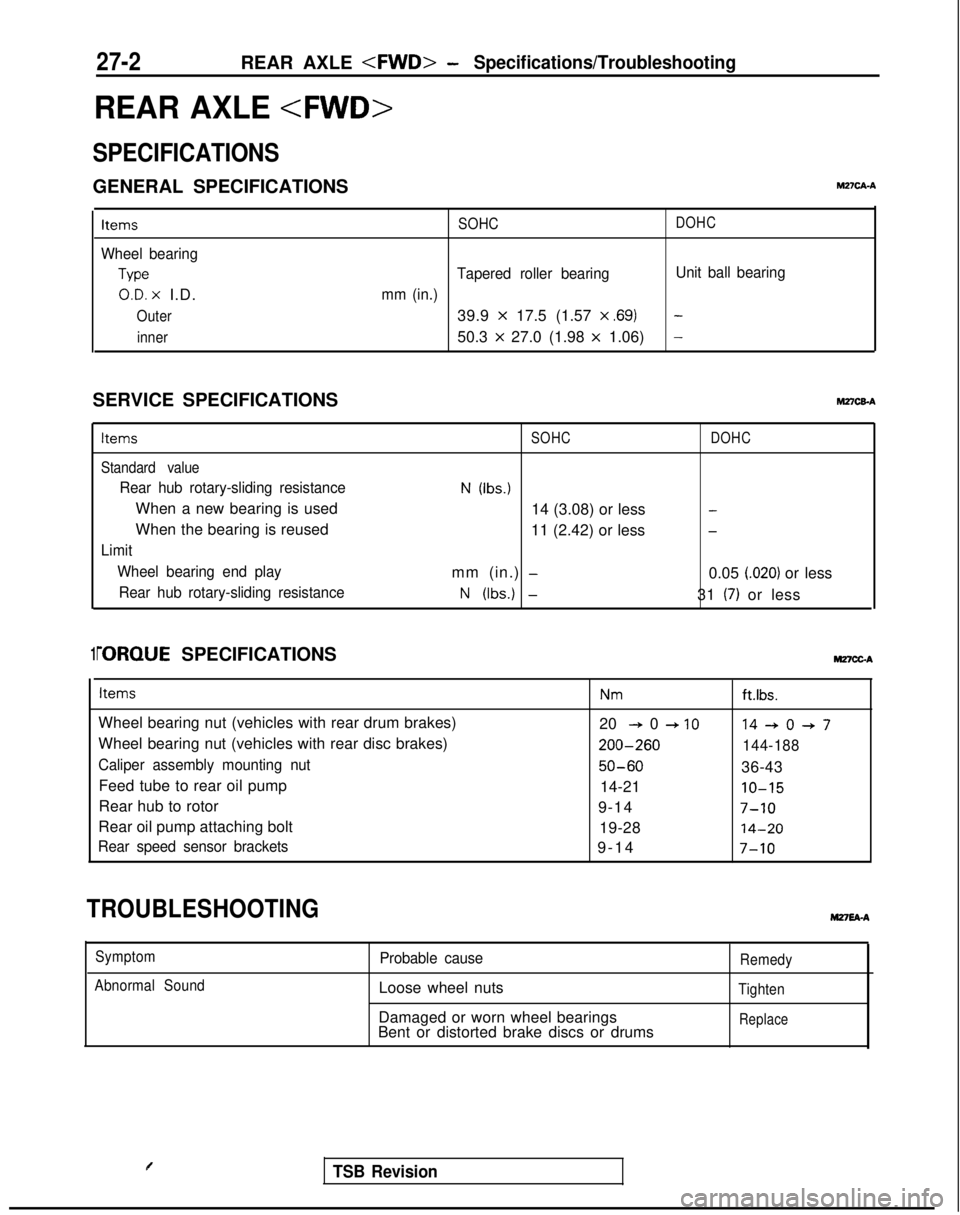

27-2REAR AXLE

REAR AXLE

SPECIFICATIONS

GENERAL SPECIFICATIONSM2?CA-A

Items

Wheel bearing

Type

O.D. x I.D.

Outer

inner SOHC

DOHC

Tapered roller bearing

Unit ball bearing

mm (in.)

39.9 x 17.5 (1.57 x ,691-

50.3 x 27.0 (1.98 x 1.06)-

SERVICE SPECIFICATIONShl27CEA

Items

Standard value

Rear hub rotary-sliding resistance

When a new bearing is used

When the bearing is reused

Limit Wheel bearing end playRear hub rotary-sliding resistance

SOHC

N (Ibs.)

14 (3.08) or less

11 (2.42) or less

mm (in.)

-

N (Ibs.) -

DOHC

-

-

0.05 i.020) or less

31

(7) or less

1i-ORQUE SPECIFICATIONS MnCGA

Items

Wheel bearing nut (vehicles with rear drum brakes)

Wheel bearing nut (vehicles with rear disc brakes)

Caliper assembly mounting nut

Feed tube to rear oil pump

Rear hub to rotor

Rear oil pump attaching bolt

Rear speed sensor brackets

Nmft.lbs.

20 + 0 + IO14+0+7 200-260

144-188

50-6036-43

14-21

IO-15

9-147-10

19-2814-20

9-1

4

7-10

TROUBLESHOOTINGM27EA-A

Symptom

Abnormal SoundProbable cause

Loose wheel nuts

Damaged or worn wheel bearings

Bent or distorted brake discs or drums

Remedy

Tighten

Replace

TSB Revision

Page 868 of 1273

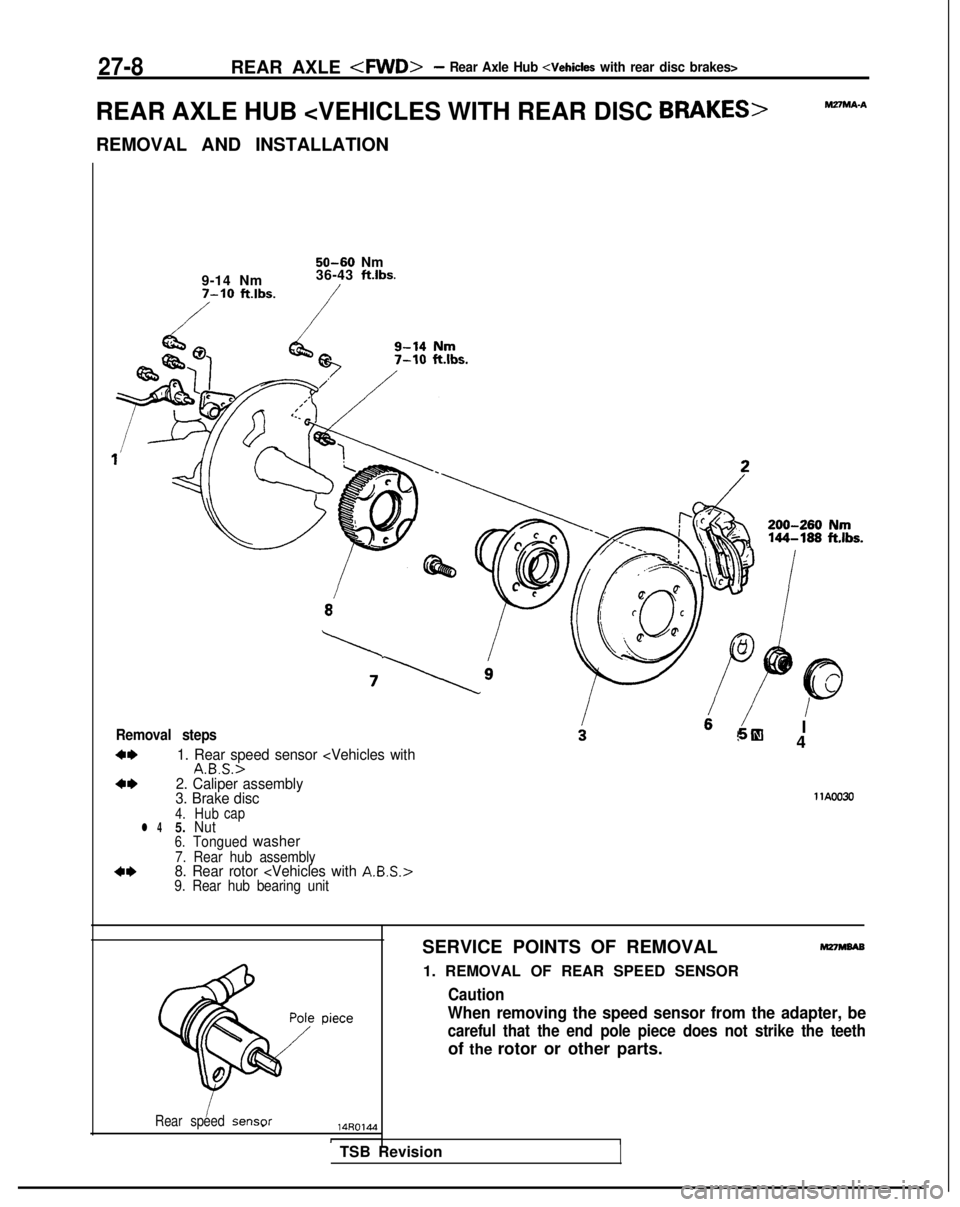

27-8REAR AXLE -4WD>- Rear Axle Hub

REAR AXLE HUB

REMOVAL AND INSTALLATION

M27MA-A

9-14 Nm7-10 ft.lbs.

50-60 Nm

36-43 ftlbs.

Removal steps

+*1. Rear speed sensor

3. Brake disc

I!jiEl 4

llA0030

4. Hub capl 45.

Nut6.Tonguedwasher

7. Rear hub assembly+*8. Rear rotor

Rear speedsensor14ROlMI

SERVICE POINTS OF REMOVAL

1. REMOVAL OF REAR SPEED SENSOR

Caution

M27wBAB

When removing the speed sensor from the adapter, be

careful that the end pole piece does not strike the teeth

of the rotor or other parts.

TSB Revision