sensor MITSUBISHI GALANT 1989 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 954 of 1273

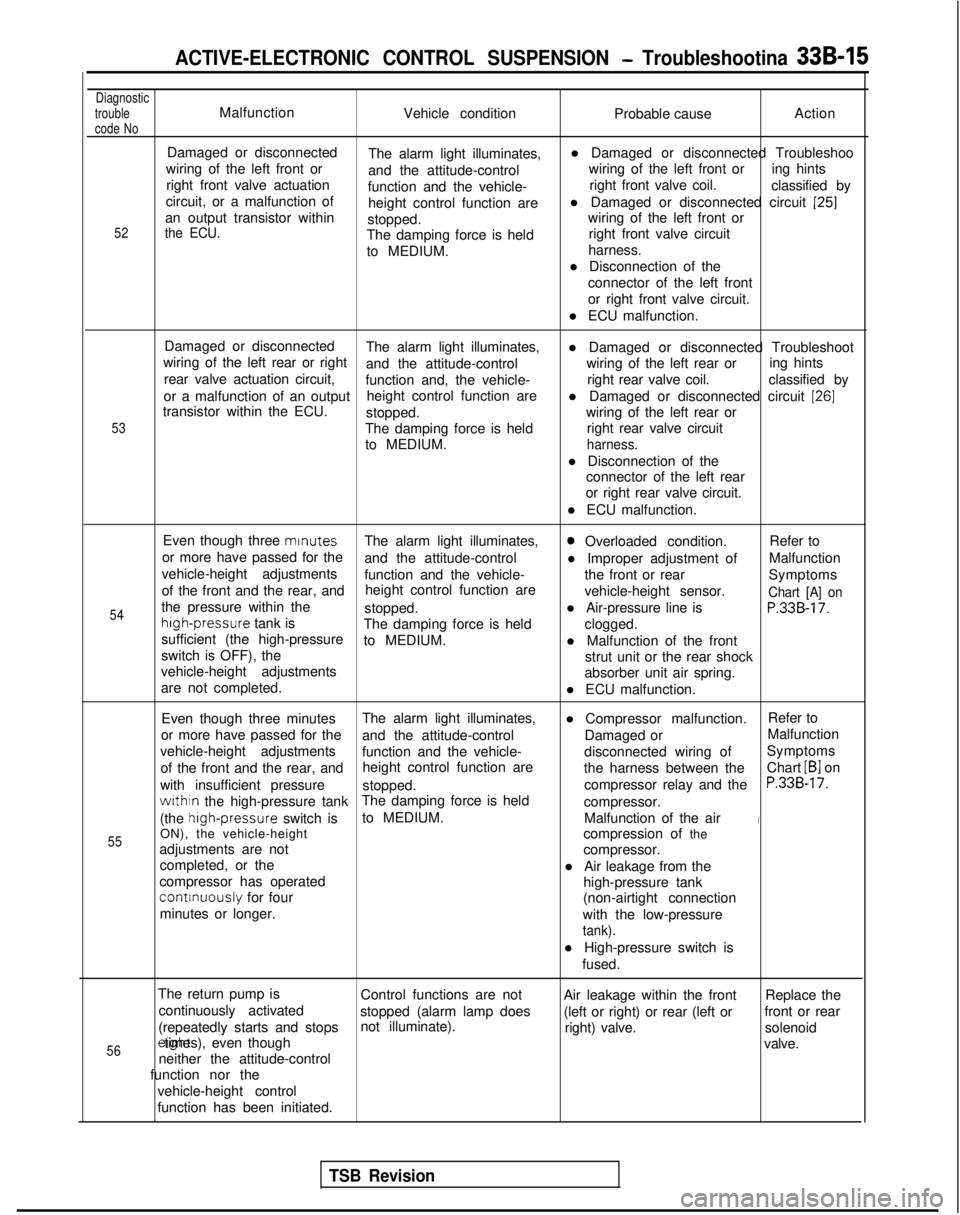

ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshootina 33B-15

Diagnostic

trouble

code NoMalfunction Vehicle condition Probable causeAction

52

Damaged or disconnected

The alarm light illuminates, l Damaged or disconnected Troubleshoo

wiring of the left front or and the attitude-control wiring of the left front or

ing hints

right front valve actuation function and the vehicle- right front valve coil.

classified by

circuit, or a malfunction of height control function arel Damaged or disconnected circuit

[25]an output transistor within

stopped. wiring of the left front orthe ECU.The damping force is held

right front valve circuit

to MEDIUM. harness.

l Disconnection of the connector of the left front

or right front valve circuit.

l ECU malfunction.

53

Damaged or disconnected The alarm light illuminates,

wiring of the left rear or right l Damaged or disconnected Troubleshoot

and the attitude-control wiring of the left rear or

rear valve actuation circuit, ing hints

function and, the vehicle- right rear valve coil.

classified by

or a malfunction of an output height control function are

transistor within the ECU. l Damaged or disconnected circuit

[26]

stopped.

wiring of the left rear or

The damping force is held right rear valve circuit

to MEDIUM.

harness.

l Disconnection of the connector of the left rear

or right rear valve circuit.

l ECU malfunction.

54

55

Even though three mrnutes

The alarm light illuminates,0 Overloaded condition. Refer to

or more have passed for the and the attitude-control l Improper adjustment ofMalfunction

vehicle-height adjustments function and the vehicle- the front or rear

of the front and the rear, and Symptoms

height control function are vehicle-height sensor.

Chart [A] onthe pressure within thestopped.l Air-pressure line isP.33B-17.high-pressure

tank is

The damping force is held

sufficient (the high-pressure clogged.

to MEDIUM. l Malfunction of the front

switch is OFF), the strut unit or the rear shock

vehicle-height adjustments absorber unit air spring.

are not completed. l ECU malfunction.

Even though three minutes The alarm light illuminates,

l Compressor malfunction.Refer to

or more have passed for the and the attitude-control Damaged orMalfunction

vehicle-height adjustments function and the vehicle- disconnected wiring ofSymptoms

of the front and the rear, and height control function are

the harness between theChart

LB1 on

with insufficient pressure stopped. compressor relay and the

P.33B-17.

withtn the high-pressure tankThe damping force is held

compressor.

(the high-pressure

switch isto MEDIUM.

Malfunction of the air

iON), the vehicle-height compression of the

adjustments are not compressor.

completed, or the l Air leakage from the

compressor has operated

continuously for four high-pressure tank

minutes or longer. (non-airtight connection

with the low-pressure

tank).

l High-pressure switch is fused.

The return pump is Control functions are not Air leakage within the frontReplace the

continuously activated stopped (alarm lamp does (left or right) or rear (left orfront or rear

(repeatedly starts and stops not illuminate).

right) valve.solenoid

56erght times), even though

valve.

neither the attitude-control

function nor the

vehicle-height control

function has been initiated.

TSB Revision

Page 956 of 1273

![MITSUBISHI GALANT 1989 Service Repair Manual ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting 33B-17

CHECKING ACCORDING TO CHARTS CLASSIFIED BY THE MALFUNCTION SYMPTOM

[A] DIAGNOSTIC TROUBLE CODE NO.54

No

Yes

b Excessive vehicle-height ad- MITSUBISHI GALANT 1989 Service Repair Manual ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting 33B-17

CHECKING ACCORDING TO CHARTS CLASSIFIED BY THE MALFUNCTION SYMPTOM

[A] DIAGNOSTIC TROUBLE CODE NO.54

No

Yes

b Excessive vehicle-height ad-](/img/19/57312/w960_57312-955.png)

ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting 33B-17

CHECKING ACCORDING TO CHARTS CLASSIFIED BY THE MALFUNCTION SYMPTOM

[A] DIAGNOSTIC TROUBLE CODE NO.54

No

Yes

b Excessive vehicle-height ad-justment

(overload) overload). time (due to -Unload the vehicle and turn* the ignition key to OFF; then

restart the engine and check

whether or not the system

functions normally.

Is the installation position of Nothe height sensor correct?

Yes Improper setting of the heightc sensor, or malfunction of the

height sensor. l Correct the installationcposition of the height sen-

sor, or adjust the vehicle

-height sensor rod.

l Check the height sensor. Refer to troubleshooting

hints [IO] and

[ll]classified by circuit.

Are the front strut and rear

NoMalfunction of the rolling

shock absorber unit air spr-* diaphragm.

Repair the rolling diaphragm,

or replace the shock absorber

ings in normal condition?Lunit.

(become folded)

Yes

Is the sound of operation

NoThe solenoid valves remain

heard from each solenoid closed, or there is air leakage

valve necessary for th

e

’ due to a malfunction of the

vehicle-height adjustment? valve seat.

Yes

Is the air pressure in the

vehicle-height adjustment

Nopressure line 950 kPa (135

psi) or higher?

I

Yes Damaged or disconnected

wiring of the high-pressure

switch, or incorrect vehicle

-height adjustment pressureline.

l Check the high-pressure switch circuit.

* Refer to troubleshooting hint [5] classified by circuit.

l Correct the clogging pro-

blem, or replace the air

tube.

Control unit malfunction.

[B] DIAGNOSTIC TROUBLE CODE NO.55

- No

Does the compressor func-

tion normally?

Yes Replace the control unit.c l Power is not supplied to

the compressor.Refer to troubleshooting

hint

[18] classified by cir-

cuit.

0 Improper compressor com- pression.

Is the air pressure in the

Novehicle-height adjustment

pressure line 760 kPa (108psi) or lower? High-pressure

switch

isRefer to troubleshooting hint

shorted____* [5] classified by circuit.

Yes Air leakage.

TSB RevisionI

Page 957 of 1273

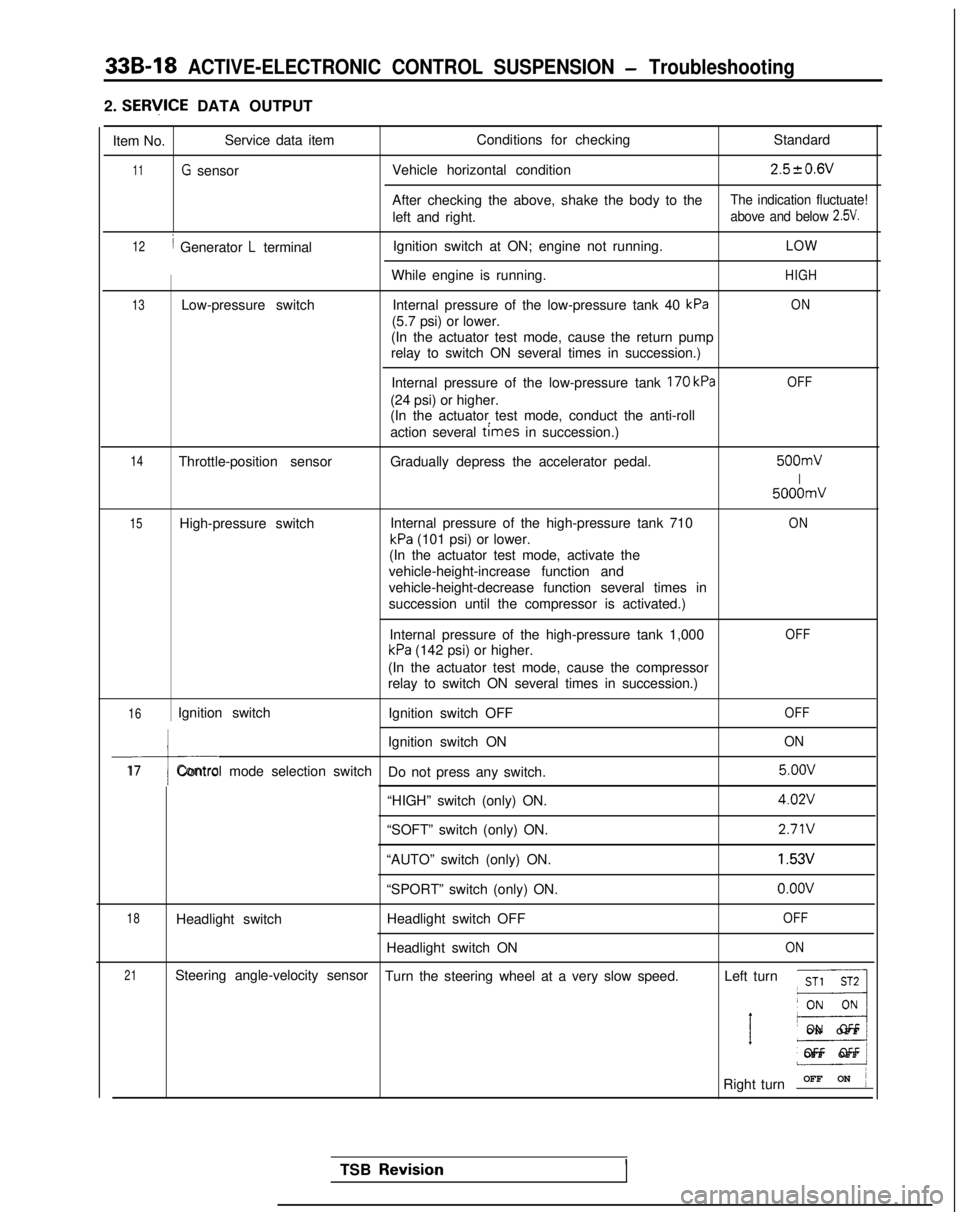

33B-18 ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting

2. SERlflCE DATA OUTPUT

Item No. Service data item

Conditions for checking

Standard

11G sensorVehicle horizontal condition2.520.6V

After checking the above, shake the body to theThe indication fluctuate!

left and right.above and below 2.5V.

12/ Generator L terminalIgnition switch at ON; engine not running.LOW

While engine is running.HIGH

13Low-pressure switch

Internal pressure of the low-pressure tank 40 kPaON

(5.7 psi) or lower.

(In the actuator test mode, cause the return pump

relay to switch ON several times in succession.)

Internal pressure of the low-pressure tank

170 kPa

(24 psi) or higher.

(In the actuator test mode, conduct the anti-roll

action several

times in succession.)

OFF

14Throttle-position sensor Gradually depress the accelerator pedal. 500mV

I

5000mV

15High-pressure switch

Internal pressure of the high-pressure tank 710ON

kPa (101 psi) or lower.

(In the actuator test mode, activate the

vehicle-height-increase function and

vehicle-height-decrease function several times in

succession until the compressor is activated.)

Internal pressure of the high-pressure tank 1,000

kPa (142 psi) or higher.

OFF

(In the actuator test mode, cause the compressor

relay to switch ON several times in succession.)

16Ignition switch Ignition switch OFFOFF

I

Ignition switch ONON

17Control mode selection switch

Do not press any switch. 5.oov

“HIGH” switch (only) ON.

4.02V

“SOFT” switch (only) ON.2.71V

“AUTO” switch (only) ON.1.53V

“SPORT” switch (only) ON.o.oov

18Headlight switch Headlight switch OFFOFF

Headlight switch ONON

21Steering angle-velocity sensor

Turn the steering wheel at a very slow speed. Left turnST1 ST2

__I

’ E3

ON OF

F

OFF OFF

Right turn OFF ON

j

TSB Revisio.nI

Page 958 of 1273

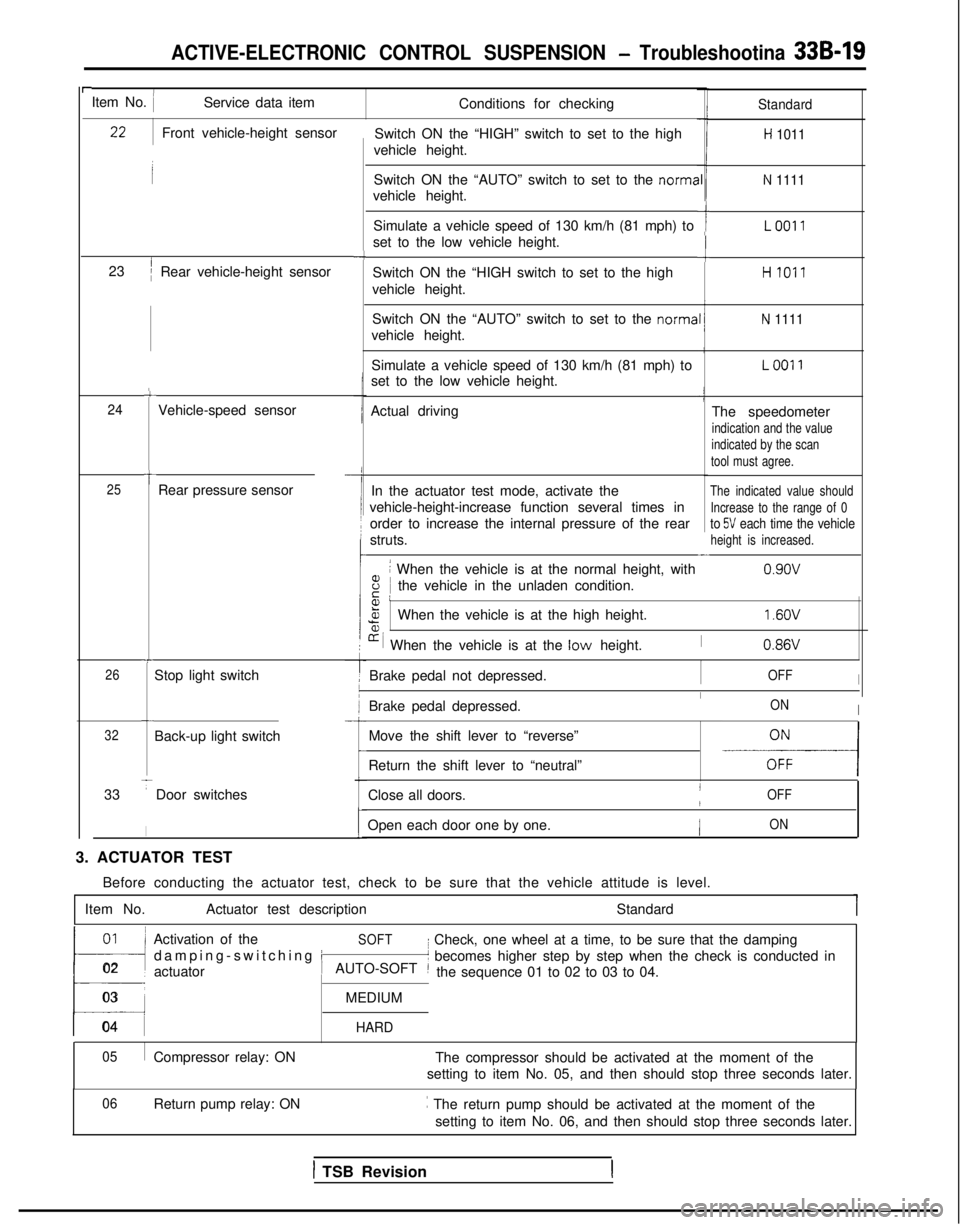

ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshootina 33B-19

rItem No. IService data itemConditions for checking

Switch ON the “HIGH” switch to set to the high

vehicle height.Standard

H 1011

Switch ON the “AUTO” switch to set to the norma

vehicle height.N 1111

Simulate a vehicle speed of 130 km/h (81 mph) to

set to the low vehicle height.ILO011

-cSwitch ON the “HIGH switch to set to the high

vehicle height.HI011

Switch ON the “AUTO” switch to set to the norma

vehicle height.

N 1111

Simulate a vehicle speed of 130 km/h (81 mph) to

set to the low vehicle height.LOO11

Actual driving The speedometer

indication and the value

indicated by the scan

tool must agree.

In the actuator test mode, activate theThe indicated value should

vehicle-height-increase function several times inIncrease to the range of 0

order to increase the internal pressure of the rearto 5V each time the vehicle

struts.height is increased.-

8

i When the vehicle is at the normal height, with

iE Ithe vehicle in the unladen condition. 0.9ov

Front vehicle-height sensor

23

’/Rear vehicle-height sensor

-4

c

24Vehicle-speed sensor

t25Rear pressure sensor

Fa,%When the vehicle is at the high height.

[r i When the vehicle is at the low height.

1.6OV

I0.86VT

26Stop light switch Brake pedal not depressed.IOFFI

Brake pedal depressed.IONIc

32Back-up light switch

33

TDoor switches

I

Move the shift lever to “reverse”

-E-----l

-

Return the shift lever to “neutral”

Close all doors.

IOFF/

Open each door one by one.ION

3. ACTUATOR TEST Before conducting the actuator test, check to be sure that the vehicle a\

ttitude is level.

Item No. Actuator test description Standard

01~

!l

Activation of theSOFT

damping-switching i

I Check, one wheel at a time, to be sure that the damping

02 actuator

t’ becomes higher step by step when the check is conducted in

AUTO-SOFT ~the sequence 01 to 02 to 03 to 04.

03MEDIUM

04 HARD

05

Compressor relay: ON The compressor should be activated at the moment of the

setting to item No. 05, and then should stop three seconds later.

Return pump relay: ON ~

The return pump should be activated at the moment of the

setting to item No. 06, and then should stop three seconds later.

06

1 TSB Revision

Page 960 of 1273

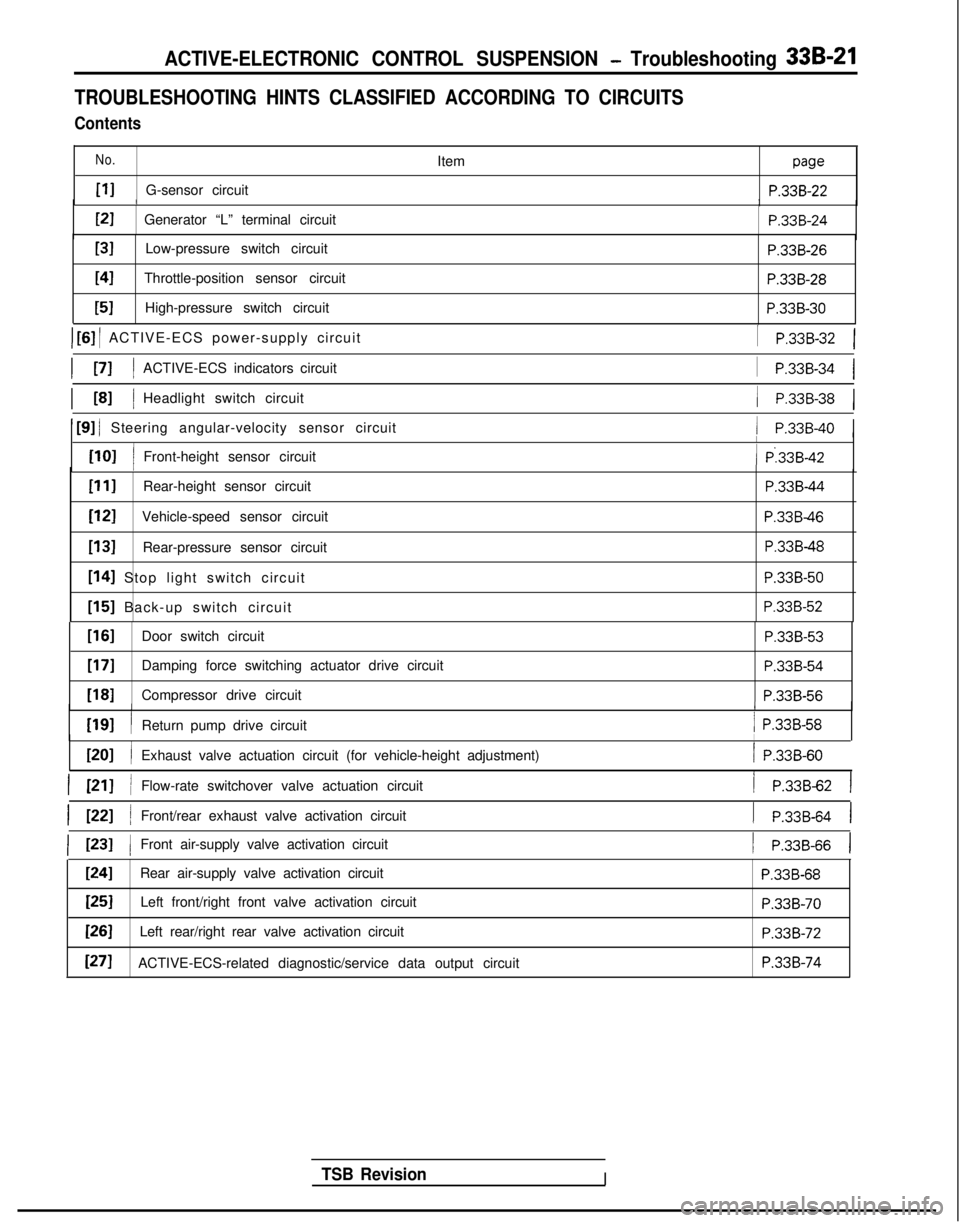

ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting 33B-21

TROUBLESHOOTING HINTS CLASSIFIED ACCORDING TO CIRCUITS

Contents

No.

PIG-sensor circuitItem

paw

P.33B-22/IPI

Generator “L” terminal circuit

P.33B-24

[31Low-pressure switch circuitP.33B-26

I41Throttle-position sensor circuitP.33B-28

[51High-pressure switch circuit P.338-30

) [6] / ACTIVE-ECS power-supply circuit

I PI IACTIVE-ECS indicators circuit

1 P.33B-32 1

1

P.33B-34 1

/ P.33B-38 1I L81 IHeadlight switch circuit

1 [9] / Steering angular-velocity sensor circuit/ P.33B-40 1

[lOI /

I

Front-height sensor circuit( P:33B-42I

PIIRear-height sensor circuit

[I21Vehicle-speed sensor circuit

[13]Rear-pressure sensor circuit

[I41 Stop light switch circuit

[I51 Back-up switch circuit

P.33B-44

P.33B46

P.33B-48 P.338-50

P.33B-52

TSB RevisionI

[If31Door switch circuitP.33B-53

[17]Damping force switching actuator drive circuit

P.338-54

1181Compressor drive circuitP.33B-561

WI

I

I

Return pump drive circuit/ P.33B-58

ml /

I

Exhaust valve actuation circuit (for vehicle-height adjustment)/ P.33B-60

I PII /Flow-rate switchover valve actuation circuit/ P.33B-62 1

I WI /Front/rear exhaust valve activation circuit1 P.33B-64 I

( 1231 1Front air-supply valve activation circuit1 P.33B-66 1

1241Rear air-supply valve activation circuitP.33B-68

[25]Left front/right front valve activation circuitP.33B-70

[=ILeft rear/right rear valve activation circuitP.33B-72

[271ACTIVE-ECS-related diagnostic/service data output circuitP.33B-74

Page 961 of 1273

![MITSUBISHI GALANT 1989 Service Repair Manual 33B-22 ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting

[l] G-SENSOR CIRCUIT

112A0462

A-23

G-sensor output characteristic

Output voltage (VIRight- Left

IDirection of acceleration

-48.6" -30"

0� MITSUBISHI GALANT 1989 Service Repair Manual 33B-22 ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting

[l] G-SENSOR CIRCUIT

112A0462

A-23

G-sensor output characteristic

Output voltage (VIRight- Left

IDirection of acceleration

-48.6" -30"

0�](/img/19/57312/w960_57312-960.png)

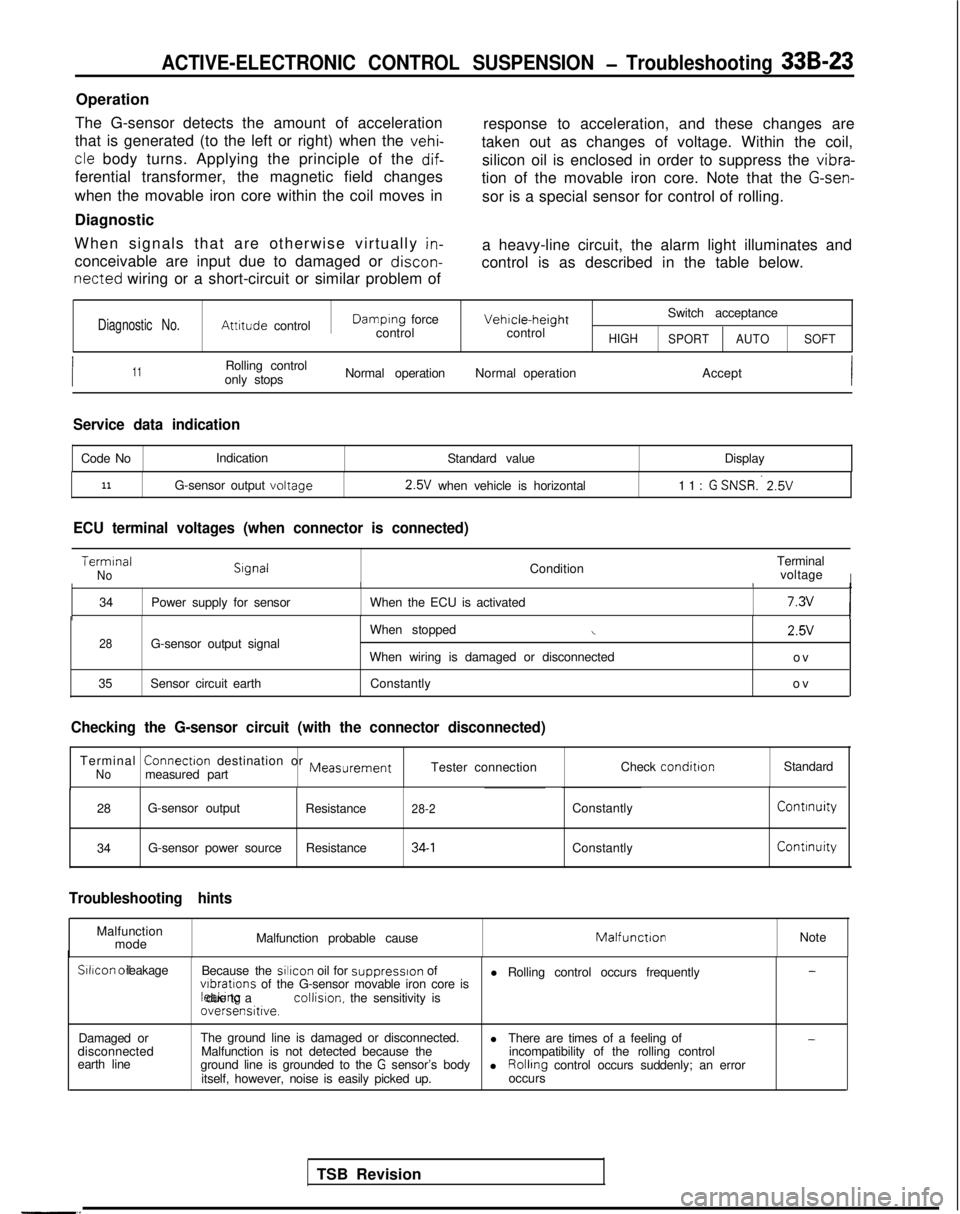

33B-22 ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting

[l] G-SENSOR CIRCUIT

112A0462

A-23

G-sensor output characteristic

Output voltage (VIRight- Left

IDirection of acceleration

-48.6" -30"

0’ 3P48.6"

LH --RH

Accelera-tion (G)Angle (D)[(A) surfacestandard]

G sensor

C-06

-1

F-l 8

[jiiEB%]

.8_-----

14

ECU

M

713_----

M

0

m

7835

1

standard

surface (A)- 12A0494

TSB RevisionI

Page 962 of 1273

ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting 33B-23

Operation

The G-sensor detects the amount of acceleration

that is generated (to the left or right) when the

vehi-

response to acceleration, and these changes are

cle body turns. Applying the principle of the dif-

taken out as changes of voltage. Within the coil,

ferential transformer, the magnetic field changes silicon oil is enclosed in order to suppress the vibra-

tion of the movable iron core. Note that the

G-sen-

when the movable iron core within the coil moves in

Diagnostic sor is a special sensor for control of rolling.

When signals that are otherwise virtually

in-

conceivable are input due to damaged or discon-

a heavy-line circuit, the alarm light illuminates and

control is as described in the table below.

netted wiring or a short-circuit or similar problem of

Diagnostic No.Attitude controlDamplng force

controlVehicle-heightcontrol Switch acceptanceHIGH

SPORT AUTO SOFT

I11Rolling control

only stops Normal operation

Normal operation Accept

Service data indication

Code NoIndication

Standard value Display

11G-sensor output voltage 2.5V

when vehicle is horizontal 11: G SNSR:

2.5V

ECU terminal voltages (when connector is connected)

Terminal

NoCondition

Terminal

voltageIII

34 Power supply for sensor When the ECU is activated7.3vI

28G-sensor output signal

35 Sensor circuit earth When stoppedi

When wiring is damaged or disconnected

Constantly 2.5V

ov

ov

TSB Revision

-.

Checking the G-sensor circuit (with the connector disconnected)

Terminal ConnectIon

destination or MeasurementNomeasured part Tester connection

Check conditionStandard

28 G-sensor output

Resistance

28-2ConstantlyContinuity

34G-sensor power source

Resistance34-1ConstantlyContinuity

Troubleshooting hints

Malfunction

mode Malfunction probable causeMatfunctIonNoteSilicon

oil leakage

Because the sillcon

oil for

suppresslon of

l Rolling control occurs frequently-

vlbratlons of the G-sensor movable iron core is leaktng due to a collision.

the sensitivity is

oversensitive.

Damaged or

disconnected

earth line The ground line is damaged or disconnected.

l-Malfunction is not detected because the There are times of a feeling of

ground line is grounded to the G sensor’s body incompatibility of the rolling control

l

itself, however, noise is easily picked up. Rolling

control occurs suddenly; an error

occurs

Page 967 of 1273

![MITSUBISHI GALANT 1989 Service Repair Manual 33B-28 ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting

[4] THROll-LE-POSITION SENSOR CIRCUIT

(1989 models)

(From 1990 models) A-54

+@7jg

(From 1990 models)

Throttle-position sensor output chara MITSUBISHI GALANT 1989 Service Repair Manual 33B-28 ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting

[4] THROll-LE-POSITION SENSOR CIRCUIT

(1989 models)

(From 1990 models) A-54

+@7jg

(From 1990 models)

Throttle-position sensor output chara](/img/19/57312/w960_57312-966.png)

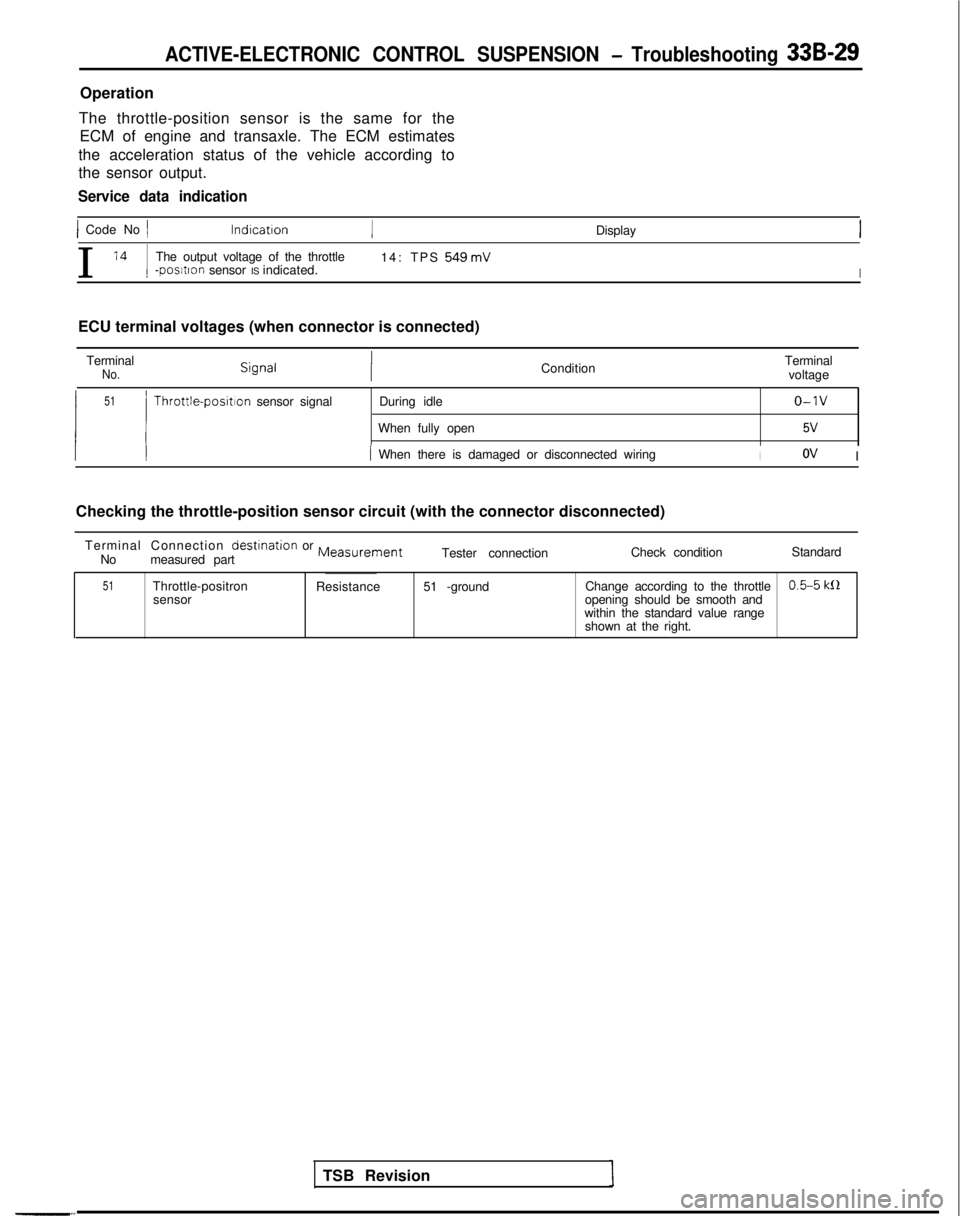

33B-28 ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting

[4] THROll-LE-POSITION SENSOR CIRCUIT

(1989 models)

(From 1990 models) A-54

+@7jg

(From 1990 models)

Throttle-position sensor output characteristic

5

24

%13932a501

0’ ’’I III III1020304050

60 70

8082

FullyThrottle openingFUIIYclose

d

(degrees)open

7FUO75

ECM

A-54

(1989 models)

Throttle-position

sensor

NOTE* mark is applicable for 1990, 1991, 1992, 1993 models. 12A0432

TSB Revision

Page 968 of 1273

ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting 33B-29

Operation

The throttle-position sensor is the same for the ECM of engine and transaxle. The ECM estimates

the acceleration status of the vehicle according to

the sensor output.

Service data indication

) Code No 1 lndrcatron

Display

I

l4 1

The output voltage of the throttle 14: TPS 549mV-postron sensor IS indicated.I

ECU terminal voltages (when connector is connected)

Terminal

No.Condition Terminal

voltage

51

1 !

Throttle-posrtlon sensor signal During idleo-1v

When fully open5v

/ When there is damaged or disconnected wiringIov I

Checking the throttle-position sensor circuit (with the connector disco\

nnected) Terminal Connection

destrnation or MeasurementNo measured part Tester connection

Check condition

Standard

51Throttle-positron

sensor Resistance

51 -ground Change according to the throttle0.5-5 k0opening should be smooth and

within the standard value range shown at the right.

TSB Revision

Page 979 of 1273

![MITSUBISHI GALANT 1989 Service Repair Manual 33B-40 ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting

[9] STEERING ANGULAR-VELOCITY SENSOR CIRCUIT

\ k=3 -2

Steering angular-veloclty sensor- m0439

Photo-Interruptor B/12A0208

F-19ECU

heel

an MITSUBISHI GALANT 1989 Service Repair Manual 33B-40 ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting

[9] STEERING ANGULAR-VELOCITY SENSOR CIRCUIT

\ k=3 -2

Steering angular-veloclty sensor- m0439

Photo-Interruptor B/12A0208

F-19ECU

heel

an](/img/19/57312/w960_57312-978.png)

33B-40 ACTIVE-ELECTRONIC CONTROL SUSPENSION - Troubleshooting

[9] STEERING ANGULAR-VELOCITY SENSOR CIRCUIT

\ k=3 -2

Steering angular-veloclty sensor- m0439

Photo-Interruptor B/12A0208

F-19ECU

heel

anoular- 1

F-06

pT$q

pFlz$EJ c-07

A

d2 7

I!

t

ii --

ii -I

7 aC-68

12 3

P4r _ v n

w jTT~jR-$+j 1

Steering angular-velocity sensor

-1

12AO411

TSB Revision