MITSUBISHI GALANT 1989 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 671 of 1273

MANUAL TRANSAXLE

- Transaxle Control22-7

ect- cable\

I Lever

(B)

09A0160

IIncorrect-I I

SERVICE POINTS OF INSTALLATIONM22JDAK

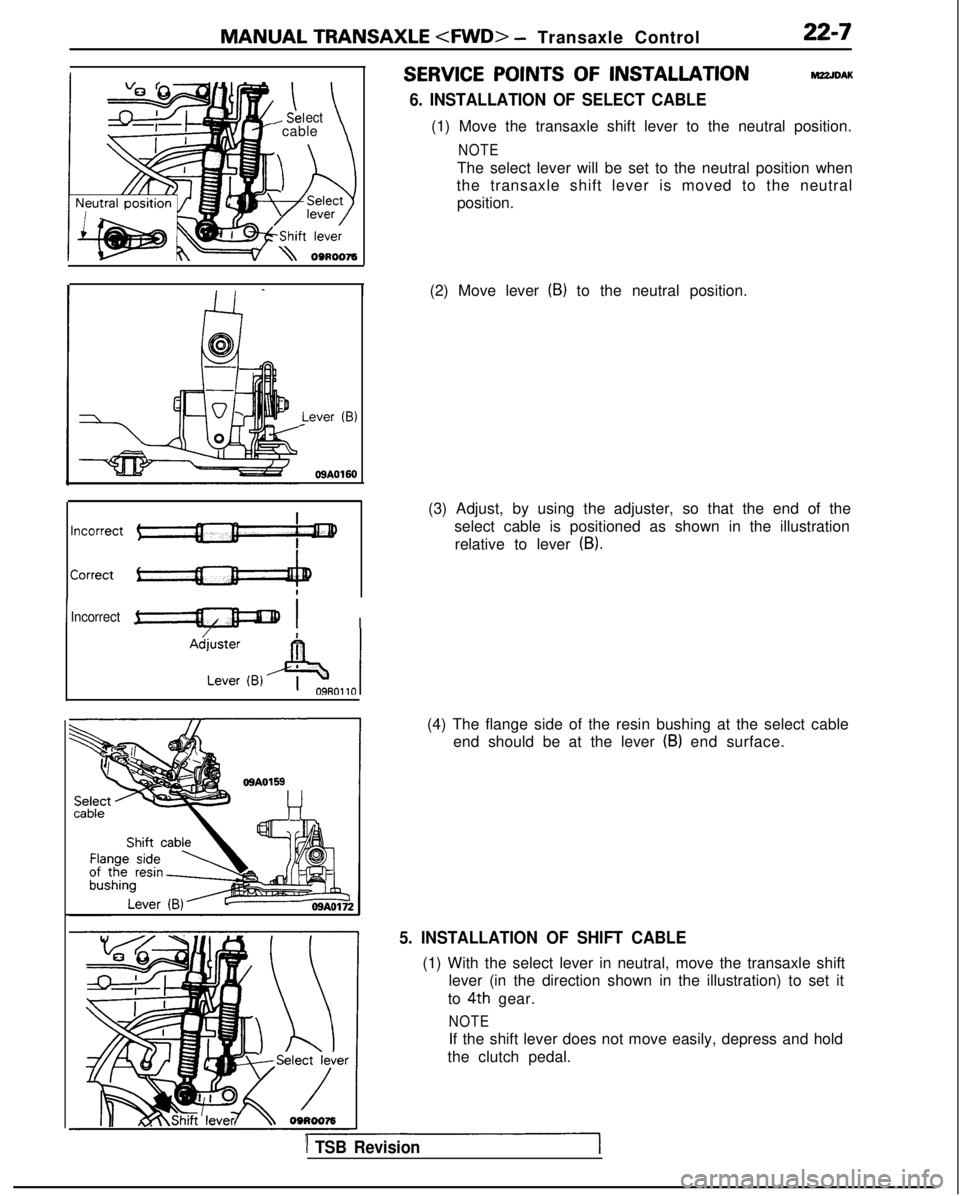

6. INSTALLATION OF SELECT CABLE

(1) Move the transaxle shift lever to the neutral position.

NOTE

The select lever will be set to the neutral position when

the transaxle shift lever is moved to the neutral position.

(2) Move lever

(B) to the neutral position.

(3) Adjust, by using the adjuster, so that the end of the select cable is positioned as shown in the illustrationrelative to lever

(B).

(4) The flange side of the resin bushing at the select cable end should be at the lever

(B) end surface.

5. INSTALLATION OF SHIFT CABLE

(1) With the select lever in neutral, move the transaxle shiftlever (in the direction shown in the illustration) to set it

to 4th

gear.

NOTE

If the shift lever does not move easily, depress and hold

the clutch pedal.

1 TSB Revision

Page 672 of 1273

22-8MANUAL TRANSAXLE

- Transaxle Control

09A0037

Incorrect Shift

lever

Correct

Incorrect09AO159

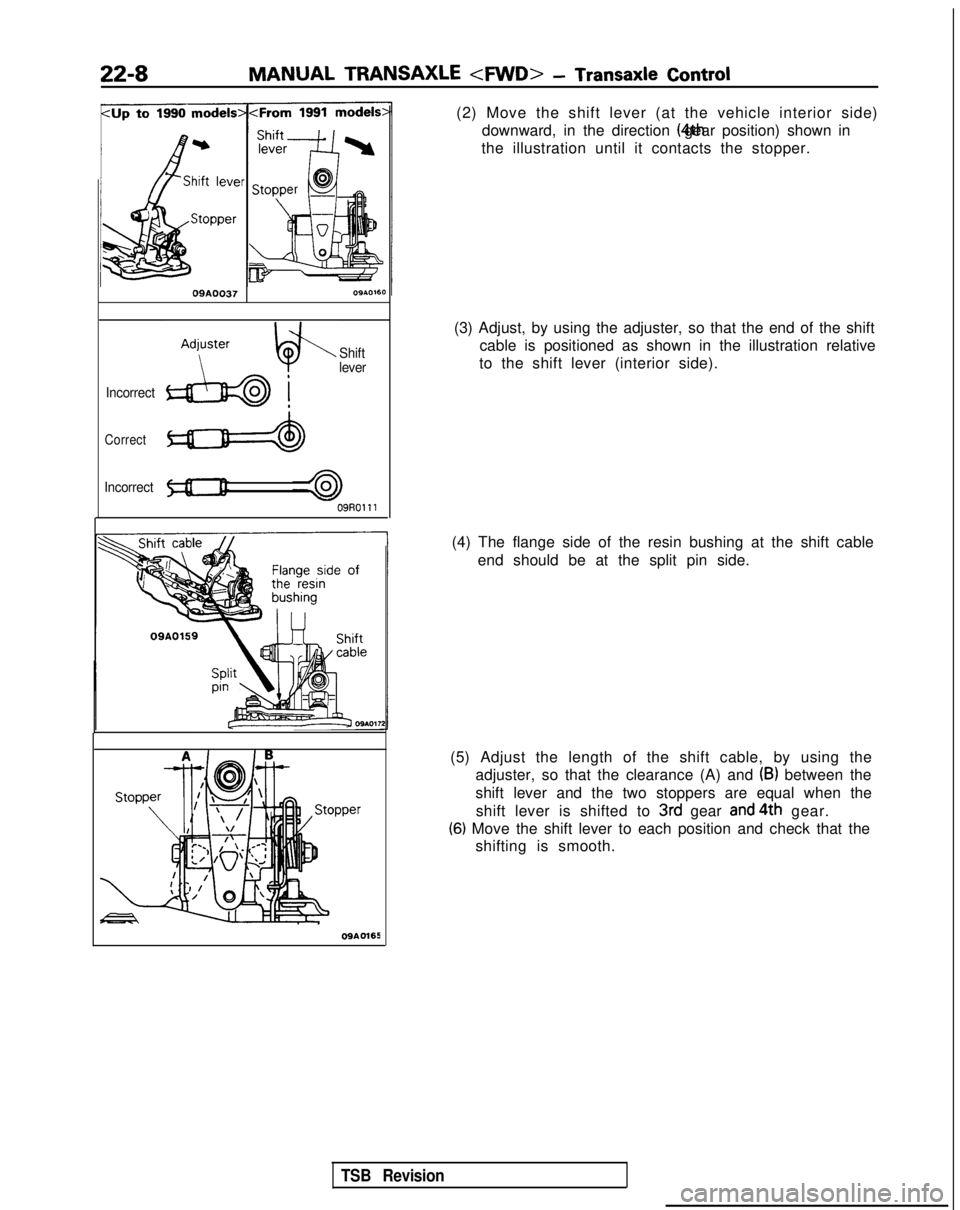

(2) Move the shift lever (at the vehicle interior side)

downward, in the direction (4th gear position) shown in

the illustration until it contacts the stopper.

(3) Adjust, by using the adjuster, so that the end of the shift cable is positioned as shown in the illustration relative

to the shift lever (interior side).

(4) The flange side of the resin bushing at the shift cable end should be at the split pin side.

(5) Adjust the length of the shift cable, by using the adjuster, so that the clearance (A) and

(B) between the

shift lever and the two stoppers are equal when the shift lever is shifted to 3rd

gear

and 4th

gear.

(6) Move the shift lever to each position and check that the

shifting is smooth.

TSB Revision

Page 673 of 1273

MANUAL TRANSAXLE

- Shift Lever Assembly

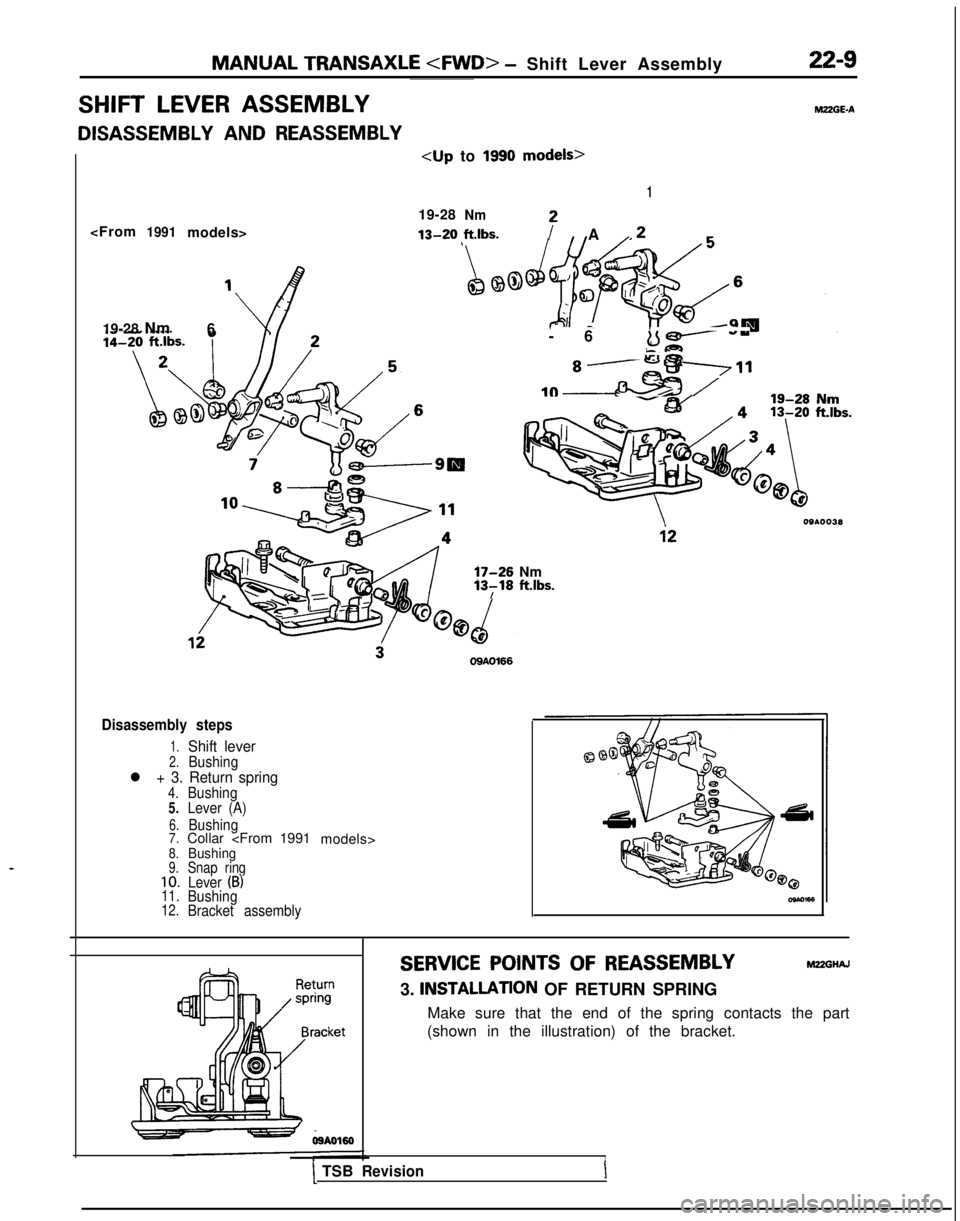

SHIFT LEVER ASSEMBLYMZZGE-A

DISASSEMBLY AND REASSEMBLY

1

19-28Nm

19-28 Nm6-

6

w*- “y

k!3

m8 /

17-28 Nm13T18 ft.lbs.

Disassembly steps

1.Shift lever2.Bushingl + 3. Return spring4.Bushing5.Lever (A)

6.Bushing7.Collar

- i9AOl60

SERVICE POINTS OF REASSEMBLYM22GHAJ

3. INSTALLATlON OF RETURN SPRING

Make sure that the end of the spring contacts the part

(shown in the illustration) of the bracket.

I1 TSBRevisionI

Page 674 of 1273

22-10MANUAL TRANSAXLE

e

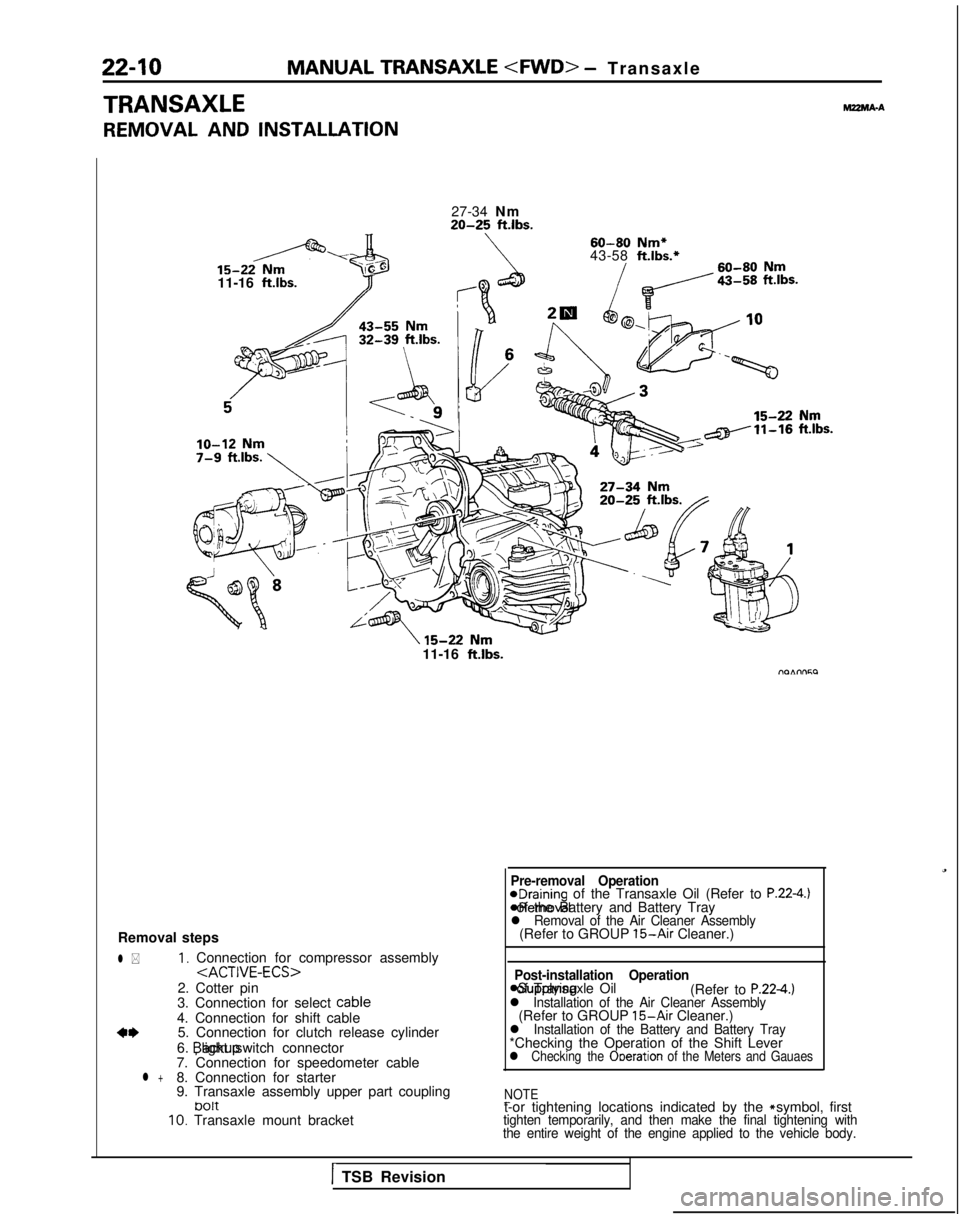

TRANSAXLE

REMOVAL AND INSTALLATION

MZMA-A

27-34 Nm20-25 ft.lbs.

60-80

Nm*

43-58 ft.lbs.*

11-16

ft.lbs.71

11-16 ftlbs.

Removal steps

l *1, Connection for compressor assembly

2. Cotter pin

3. Connection for select cable

4. Connection for shift cable

a*5. Connection for clutch release cylinder

6. backup light switch connector

7. Connection for speedometer cable

l +8. Connection for starter

9. Transaxle assembly upper part coupling

tJ01t10. Transaxle mount bracket

Pre-removal Operation@Draining of the Transaxle Oil (Refer to P.22-4.) *Removal of the Battery and Battery Tray

l Removal of the Air Cleaner Assembly(Refer to GROUP 15-Air Cleaner.)

Post-installation Operation

asupplying of Transaxle Oil

(Refer to P.224.)l Installation of the Air Cleaner Assembly(Refer to GROUP 15-Air Cleaner.)l Installation of the Battery and Battery Tray*Checking the Operation of the Shift Leverl Checking the Ooeration of the Meters and Gauaes

NOTE

-t-or tightening locations indicated by the * symbol, firsttighten temporarily, and then make the final tightening with

the entire weight of the engine applied to the vehicle body.

1TSB Revision

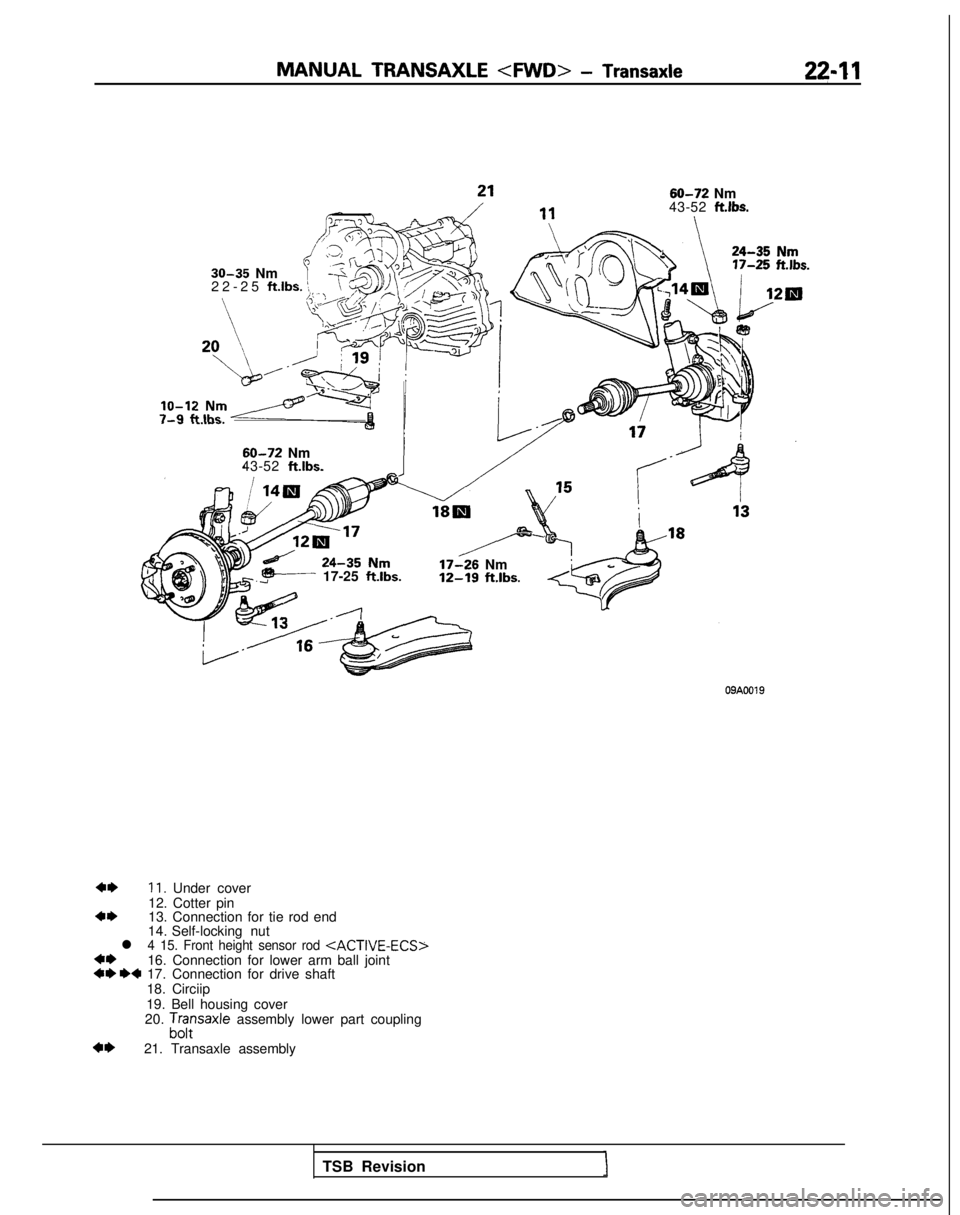

Page 675 of 1273

MANUAL TRANSAXLE

60-72 Nm

43-52 ftfbs.

i“1

30-35

Nm

22-25

ft.lbs. /(

7-4 filhs

60-72 Nm

43-52 ftlbs.

/-

.,- 17-25 ft.lbs.17-26 Nm12-19 ft.lbs.

09A0019

+I)Il. Under cover

12. Cotter pin

*I)13. Connection for tie rod end

14. Self-locking nut

l 4 15. Front height sensor rod

19. Bell housing cover

20.

/?a;saxle assembly lower part coupling

21. Transaxle assembly

TSB Revision

Page 676 of 1273

22-12MANUAL TRANSAXLE

- Transaxle

* ’TransaxlellK611I-I-1 TSB Revision

SERVICE POINTS OF REMOVALM22MBAK

1. DISCONNECTION OF COMPRESSOR ASSEMBLY

FROM TRANSAXLE ASSEMBLY

Remove the compressor assembly from the bracket, and

then secure at the body side without disconnecting the air hose coupling.

5. DISCONNECTION OF CLUTCH RELEASE CYLINDER

FROM TRANSAXLE ASSEMBLY

Remove the clutch release cylinder and clutch oil line

bracket installation bolt, and then secure at the body side

without disconnecting the oil line coupling.

11. REMOVAL OF UNDER COVER

Lift the vehicle before removing the under cover.

13. DISCONNECTION OF TIE ROD END FROM KNUCKLE

Using the special tool, disconnect the tie rod end from the

knuckle.

Caution

1. Be sure to tie the cord of the special tool to the

nearby part.

2. Loosen the nut but do not remove it.

16. DISCONNECTION OF LOWER ARM BALL JOINT

Using the special tool, disconnect the lower arm ball joint

from the knuckle.

Caution

1. Be sure to tie the cord of the special tool to the

nearby part.

2. Loosen the nut but do not remove it.

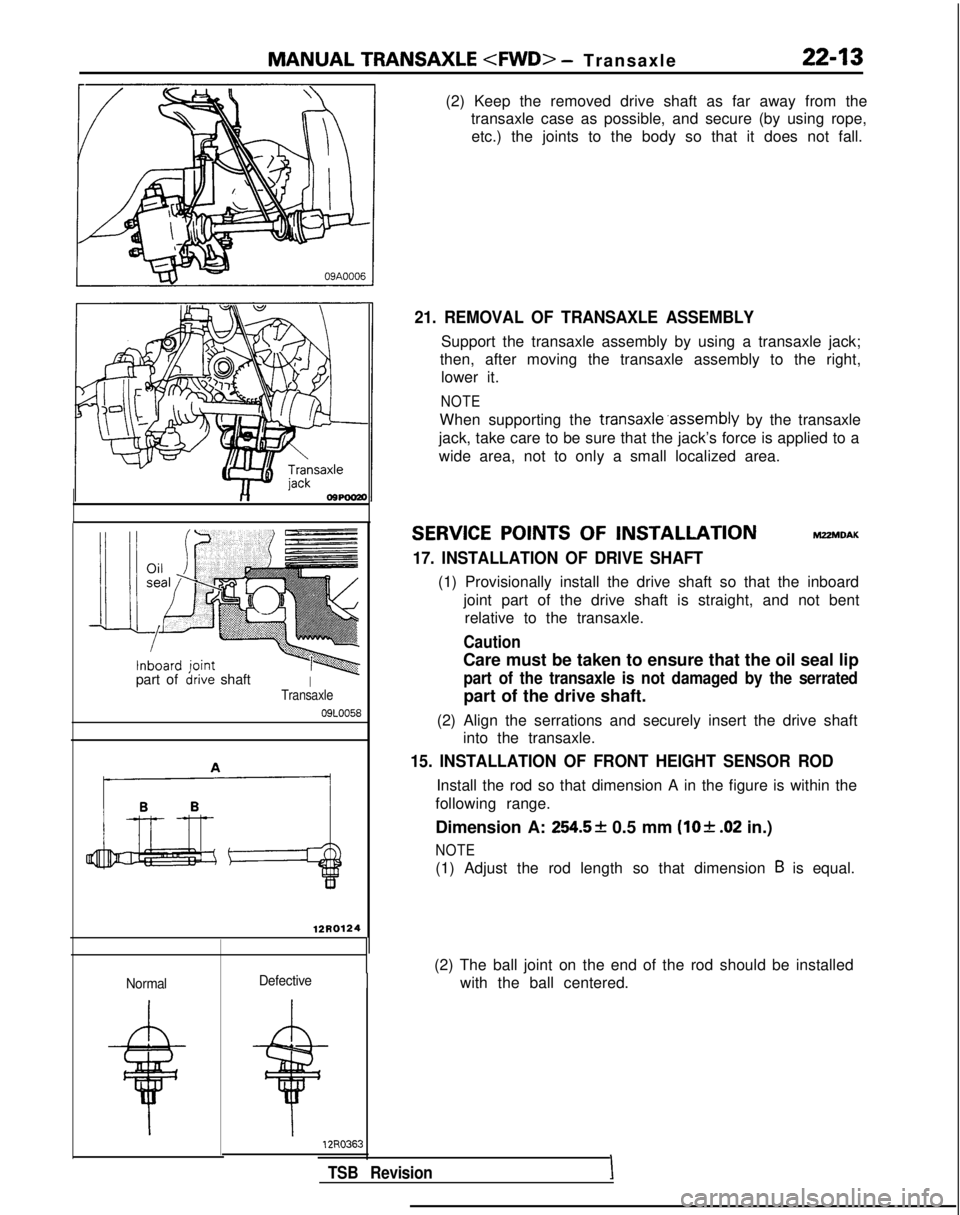

17. DISCONNECTION OF DRIVE SHAFT

(1) Insert a pry bar between the transaxle case and the drive shaft, and then pry the drive shaft from the

transaxle.

Caution

1. Do not pull on the drive shaft; doing so will

damage the inboard joint; be sure to use the pry

bar.

2. Do not insert the pry bar so deep as to damaged

the oil seal.

Page 677 of 1273

MANUAL TRANSAXLE

- Transaxl

e

22-13

part ofirive shaftITransaxle

09LOO58

12R0124

Normal

12R036:s

TSB Revision

(2) Keep the removed drive shaft as far away from the

transaxle case as possible, and secure (by using rope,

etc.) the joints to the body so that it does not fall.

21. REMOVAL OF TRANSAXLE ASSEMBLY

Support the transaxle assembly by using a transaxle jack;

then, after moving the transaxle assembly to the right, lower it.

NOTE

When supporting the transaxle’assembly by the transaxle

jack, take care to be sure that the jack’s force is applied to a

wide area, not to only a small localized area.

SERVICE POINTS OF INSTALLATION MZ?MDAK

17. INSTALLATION OF DRIVE SHAFT

(1) Provisionally install the drive shaft so that the inboard

joint part of the drive shaft is straight, and not bentrelative to the transaxle.

Caution

Care must be taken to ensure that the oil seal lip

part of the transaxle is not damaged by the serrated

part of the drive shaft.

(2) Align the serrations and securely insert the drive shaft into the transaxle.

15. INSTALLATION OF FRONT HEIGHT SENSOR ROD

Install the rod so that dimension A in the figure is within the

following range.

Dimension A:

254.5* 0.5 mm (lo& .02 in.)

NOTE

(1) Adjust the rod length so that dimension B is equal.

(2) The ball joint on the end of the rod should be installed with the ball centered.

Defective

I

Page 678 of 1273

22-WMANUAL TRANSAXLE

- Transaxle

rI8. INSTALLATION OF STARTER

Tighten with the lower starter installation the wiringharness clip bolt.

09POOl3

1 TSB Revision

Page 679 of 1273

MANUAL TRANSAXLE

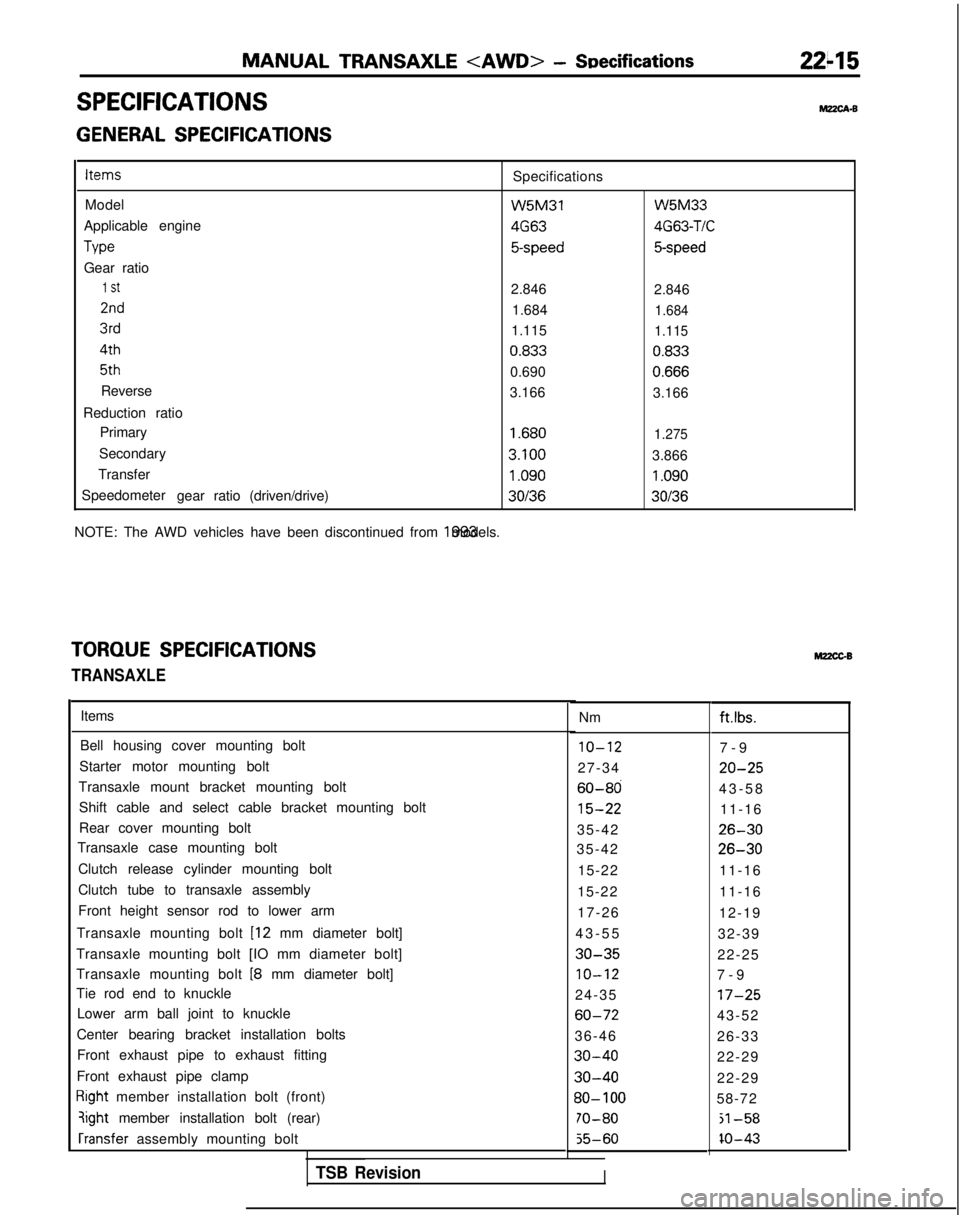

SPECIFICATIONSM?zcA-B

GENERAL SPECIFICATIONSItems

Specifications

Model W5M31

Applicable engine 4G63

Tvw

5-speed

Gear ratio

1 St2.846

2nd1.684

3rd1.115 4th

0.833

5th

0.690

Reverse 3.166

Reduction ratio Primary

1.680

Secondary 3.100

Transfer

1.090

Speedometer gearratio(driven/drive)30136

NOTE: The AWD vehicles have been discontinued from 1993 models. W5M33

4G63-TIC

5-speed

2.846

1.684

1.115

0.833 0.666

3.166

1.275

3.866

1.090

30136

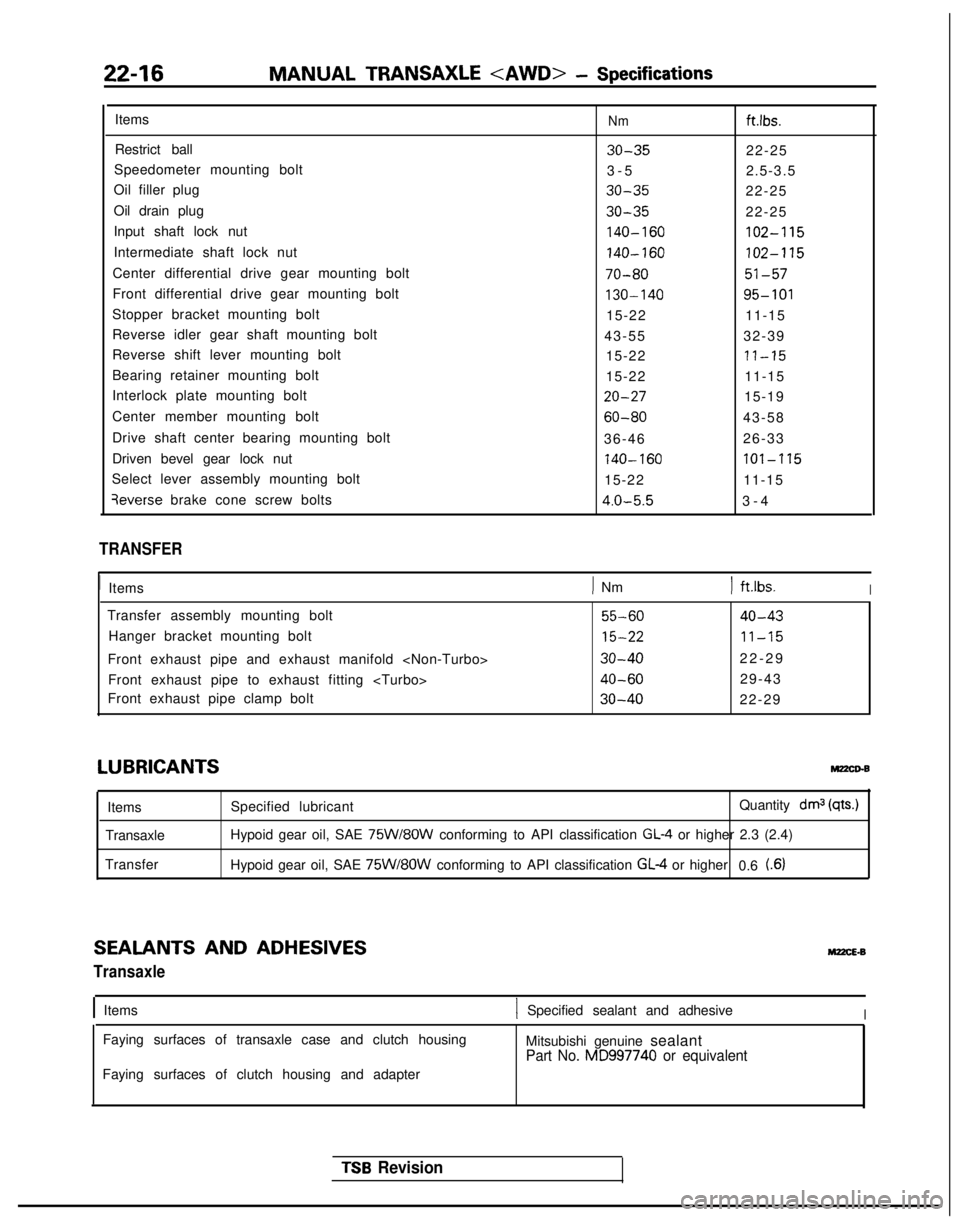

TORQUE SPECIFICATIONS

TRANSAXLE

Items

Bell housing cover mounting bolt

10-127-

9

Starter motor mounting bolt 27-34

20-25

Transaxle mount bracket mounting bolt60-8043-5

8

Shift cable and select cable bracket mounting bolt

15-2211-16

Rear cover mounting bolt 35-42

26-30

Transaxle case mounting bolt 35-4226-30

Clutch release cylinder mounting bolt 15-2211-16

Clutch tube to transaxle assembly 15-2211-16

Front height sensor rod to lower arm 17-2612-19

Transaxle mounting bolt

[I2 mm diameter bolt] 43-5

5

32-39

Transaxle mounting bolt [IO mm diameter bolt]

30-3522-25

Transaxle mounting bolt

18 mm diameter bolt]IO-127-

9

Tie rod end to knuckle 24-35

17-25

Lower arm ball joint to knuckle60-7243-52

Center bearing bracket installation bolts 36-4626-33

Front exhaust pipe to exhaust fitting

30-4022-29

Front exhaust pipe clamp

30-4022-29

Right member installation bolt (front)30- 10058-72

qight member installation bolt (rear)70-80jl-58 rransfer

assembly mounting bolt

55-60IO-43

Nm M22CGBft.lbs.

TSB RevisionI

Page 680 of 1273

22-16MANUAL TRANSAXLE

ItemsNmftlbs.

Restrict ball30-3522-25

Speedometer mounting bolt 3-

5

2.5-3.5

Oil filler plug

30-3522-25

Oil drain plug

30-3522-25

Input shaft lock nut

140-160102-115

Intermediate shaft lock nut140-160102-115

Center differential drive gear mounting bolt70-8051-57

Front differential drive gear mounting bolt130-14095-101

Stopper bracket mounting bolt 15-2211-15

Reverse idler gear shaft mounting bolt 43-5532-39

Reverse shift lever mounting bolt 15-22

71-15

Bearing retainer mounting bolt15-2211-15

Interlock plate mounting bolt

20-2715-19

Center member mounting bolt

60-8043-58

Drive shaft center bearing mounting bolt 36-4626-33

Driven bevel gear lock nut

740-160lOl-‘1’15

Select lever assembly mounting bolt 15-2211-15qeverse

brake cone screw bolts

4.0-5.53-

4

TRANSFER

1

Items

) Nm) ft.lbs.I

Transfer assembly mounting bolt55-6040-43

Hanger bracket mounting bolt15-2211-15

Front exhaust pipe and exhaust manifold

9

Front exhaust pipe to exhaust fitting

40-6029-43

Front exhaust pipe clamp bolt

30-4022-29

LUBRICANTSMz2co-B

Items

Transaxle

Transfer Specified lubricant

Quantity drnj

(qts.)

Hypoid gear oil, SAE 75W/8OW conforming to API classification GL-4 or higher 2.3 (2.4)

Hypoid gear oil, SAE

75W/8OW conforming to API classification GL-4 or higher 0.6 t.6)

SEALANTS AND ADHESIVES

Transaxle

M22cE.B

IItems1 Specified sealant and adhesiveI

Faying surfaces of transaxle case and clutch housing

Mitsubishi genuine sealant

Part No. MD997740 or equivalent

Faying surfaces of clutch housing and adapter

TSB Revision